Hydrophobic modified organic/inorganic composite flocculant and preparation method and application thereof

A composite flocculant and hydrophobic modification technology, which is applied in the field of environmental pollution control, can solve the problems of limited application range, inability to remove hydrophilic and hydrophobic small molecular pollutants and macromolecular pollutants at the same time, and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1. Under the condition of 0℃, add the toluene solution of acryloyl chloride (the concentration of acryloyl chloride is 42.5g / L) to the mixed solution composed of n-propylamine, triethylamine and toluene (acryloyl chloride, n-propylamine, triethylamine, The ratio of the amount of toluene is 1:1:5:20) and magnetically stirred, the dropping rate is 5mL / min, and the stirring speed is 200r / min. After the dropwise addition, react at 4°C for 5 hours. After the reaction, the precipitate is separated by filtration under normal pressure, and the filtrate is collected to obtain an acryloyl n-propylamine solution;

[0055] 2. Dissolve thioglycolic acid in toluene (the ratio of the amount of thioglycolic acid to acryloyl chloride (step 1) is 1:5 to obtain the thioglycolic acid solution (the concentration of thioglycolic acid is 45g / L), and place it on the round bottom In the flask, magnetic stirring is used to dissolve completely (stirring speed is 200r / min). The temperature is raised ...

Embodiment 2

[0063] 1. Under 5℃, add the toluene solution of acryloyl chloride (the concentration of acryloyl chloride is 85g / L) to the mixed solution of n-propylamine, triethylamine and toluene (acryloyl chloride, n-propylamine, triethylamine, toluene). The ratio of the amount of the substance is 1:5:1:10) and magnetically stirred, the dropping rate is 8mL / min, and the stirring speed is 250r / min. After the dripping is completed, the reaction is carried out at 60°C for 40 hours. After the reaction is completed, the precipitate is separated by filtration under normal pressure, and the filtrate is collected to obtain the acryloyl n-propylamine solution;

[0064] 2. Dissolve thioglycolic acid in toluene (the ratio of thioglycolic acid to acryloyl chloride is 1:50 to obtain a thioglycolic acid solution (the concentration of thioglycolic acid is 20g / L), and place it in a round bottom flask. Stir and dissolve completely (the stirring speed is 250r / min). The temperature is increased to 90°C, and nit...

Embodiment 3

[0071] 1. Under 3℃, add the toluene solution of acryloyl chloride (the concentration of acryloyl chloride is 59.5g / L) to the mixed solution composed of isopropylamine, triethylamine and toluene (acryloyl chloride, isopropylamine, triethylamine, The ratio of the amount of toluene is 1:2.5:3:14) and magnetically stirred, the dropping rate is 10 mL / min, and the stirring speed is 300 r / min. After the dropwise addition, the reaction was carried out at 30°C for 15 hours. After the reaction, the precipitate was separated by filtration under normal pressure, and the filtrate was collected to obtain the acrylamide solution;

[0072] 2. Dissolve thioglycolic acid in toluene (the ratio of the amount of thioglycolic acid to acryloyl chloride is 1:25 to obtain the thioglycolic acid solution (the concentration of thioglycolic acid is 32g / L), and place it in a round-bottomed flask. Stir and dissolve completely (the stirring speed is 300r / min). The temperature is increased to 40°C, and nitrogen ...

PUM

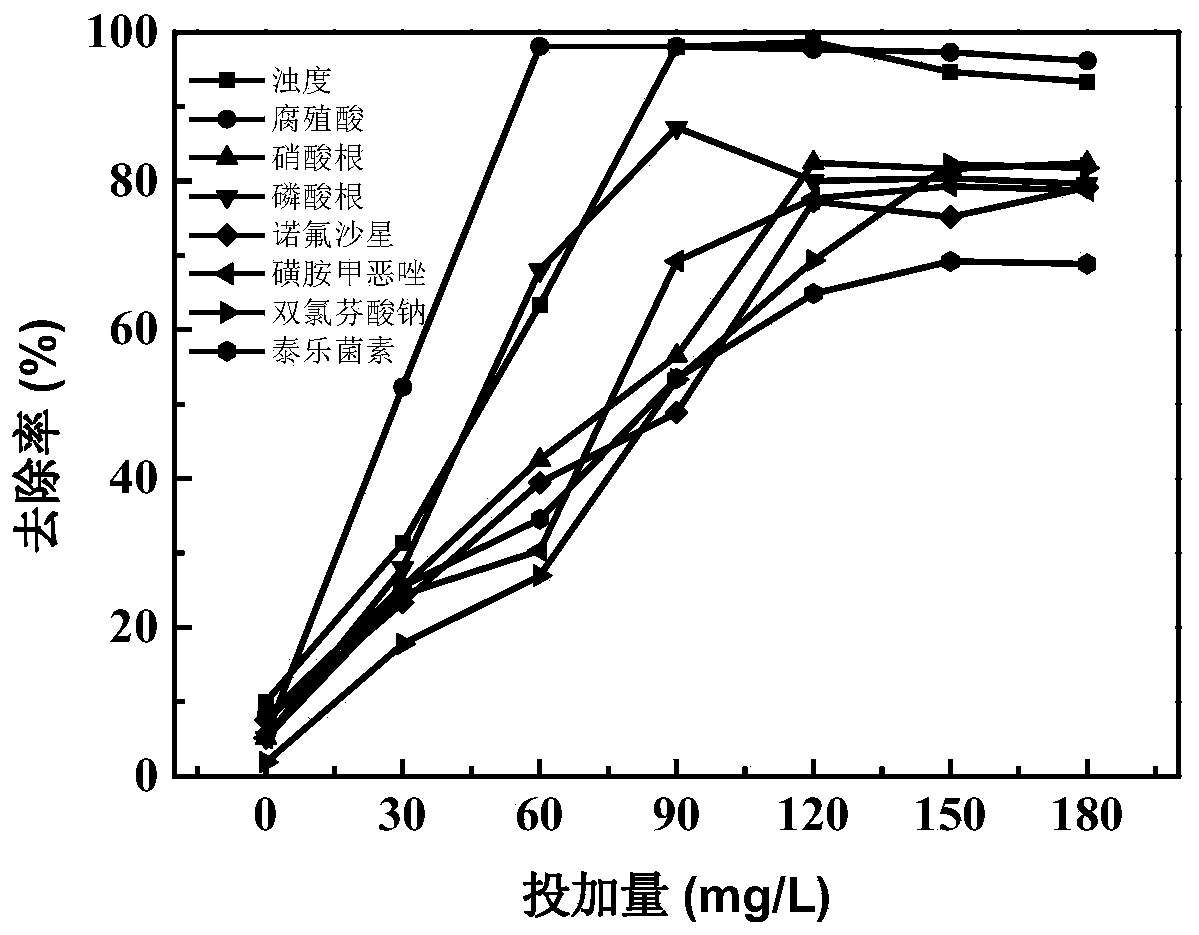

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com