Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Improve sintering properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

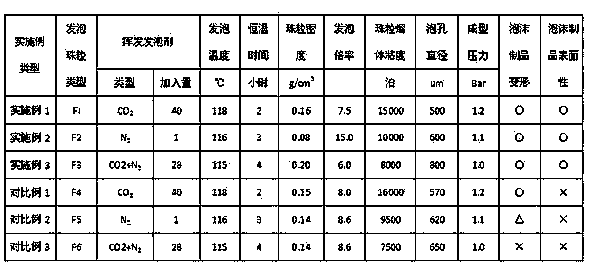

Foaming thermoplastic polyurethane bead and preparation method thereof

ActiveCN103642200AExtended melt processing temperature rangeImprove athletic abilityChemistryMelt viscosity

The invention discloses a foaming thermoplastic polyurethane bead. The foaming bead comprises 100 parts of thermoplastic polyurethane particles, 1-10 parts of cell size stabilizer, and 1-35 parts of melt viscosity modifier. The bead is prepared through the following steps: steeping the thermoplastic polyurethane particles containing a cell size stabilizer and a melt viscosity modifier in an aqueous suspension and foaming by volatilizing foaming agent. The melt viscosity of the foaming thermoplastic polyurethane bead is 8000-15000 poise below 180 DEG C, the size of the prepared foaming thermoplastic polyurethane bead is stable, the diameter of the cell is uniform, the surface is bright, the yield of the product is high, the foaming thermoplastic polyurethane bead has good sintering property even under lower vapor pressure, and the molding foam product deforms slightly and has low shrinking percentage compared with the size of the die, good dimensional stability and attractive appearance.

Owner:MIRACLL CHEM

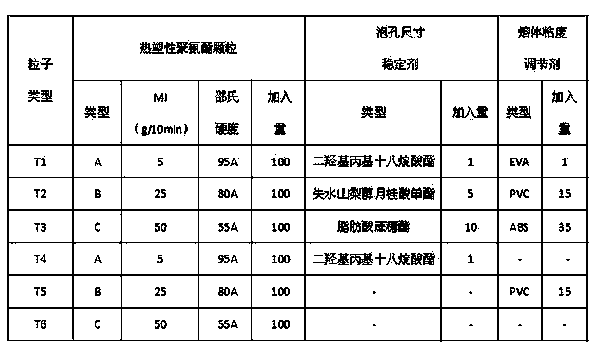

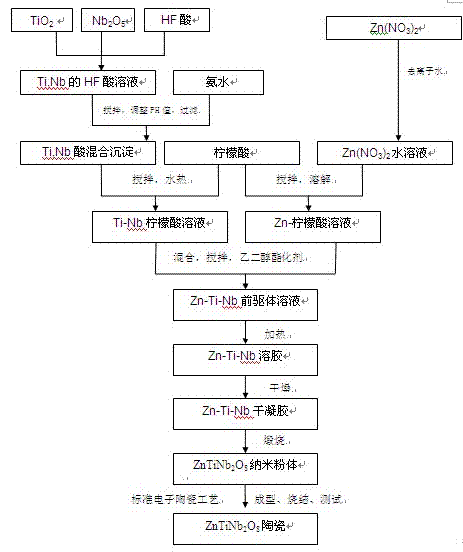

Method for finely synthesizing ternary ZnO-Nb2O5-TiO2 microwave dielectric ceramics by wet chemical process

InactiveCN102775141ASynthesis temperature is lowImprove sintering propertiesSpecific surface energyMicrowave dielectric properties

The invention belongs to the technical field of preparation and application of electronic ceramics, and particularly relates to a method for finely synthesizing ternary ZnO-Nb2O5-TiO2 microwave dielectric ceramics by a wet chemical process. The technical scheme is as follows: the method comprises the following steps: 1) preparing a Zn ion citric acid water solution; 2) preparing a Ti and Nb ion citric acid water solution; and 3) synthesizing a ternary ZnO-Nb2O5-TiO2 microwave dielectric ceramic precursor, and preparing the ceramics. The invention has the advantages of low synthesis temperature, uniform ceramic particles, favorable dispersity, pure phase, nano particle size of powder, high specific surface energy, high activity and the like, can implement low-temperature sintering, and maintains favorable microwave dielectric properties, thereby satisfying the application requirements for LTCC (low temperature co-fired ceramic).

Owner:UNIV OF JINAN

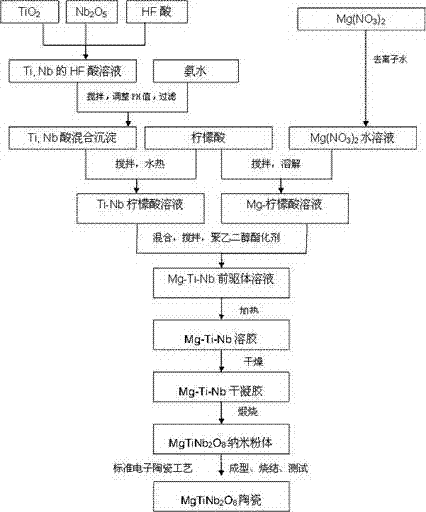

Method for preparing magnesium niobate microwave ceramic powder on the basis of sol-gel technique

The invention discloses a method for preparing magnesium niobate microwave ceramic powder on the basis of sol-gel technique. The method comprises the following steps: (1) preparing the citric acid solution of niobium (Nb); (2) preparing the citric acid solution of magnesium (Mg); and (3) obtaining a Mg-Nb precursor solution, xerogel and nano-powder. The invention can overcome the disadvantages of high temperature and large particle size in the existing synthesis of magnesium niobate microwave ceramic powder on the basis of solid-phase method by preparing the magnesium niobate microwave ceramic powder with the average particle diameter being 40nm to 80nm under the condition that the calcination temperature is 550 to 850 DEG C.

Owner:TIANJIN UNIV

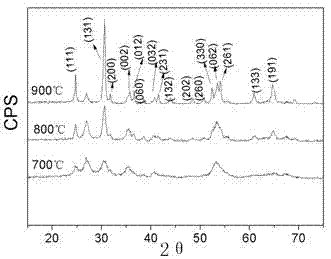

Low temperature sintering piezoelectric ceramic material and preparation method thereof

InactiveCN102850050ALower sintering temperatureReduce manufacturing costDopantElectromechanical coupling coefficient

The invention discloses a low temperature sintering piezoelectric ceramic material, wherein composition of the material is represented by a chemical general formula Pb(0.995-a-b-3c / 2)BaaSrbFec(Zn1 / 3Nb2 / 3)xZryTi(1-x-y)O3+u%Li2CO3+v%M2O3+w%ZnO, M is a trivalent metal element, a molar ratio of Ba to Sr to Fe to (Zn1 / 3Nb2 / 3) to Zr is a:b:c:x:y, a is more than or equal to 0 and is less than or equal to 0.05, b is more than or equal to 0 and is less than or equal to 0.03, c is more than or equal to 0 and is less than or equal to 0.01, x is more than or equal to 0.25 and is less than or equal to 0.35, y is more than or equal to 0.30 and is less than or equal to 0.40, the Pb(0.995-a-b-3c / 2)BaaSrbFec(Zn1 / 3Nb2 / 3)xZryTi(1-x-y)O3 is adopted as matrix ceramic powder, u% represents a weight percentage of Li2CO3 in the matrix ceramic powder, v% represents a weight percentage of M2O3 in the matrix ceramic powder, w% represents a weight percentage of ZnO in the matrix ceramic powder, u is more than 0 and is less than or equal to 1, v is more than 0 and is less than or equal to 2, and w is more than 0 and is less than or equal to 0.2. According to the present invention, an oxide dopant is added and combined, such that a sintering temperature of the ceramic can be reduced to a temperature of 900 DEG C from a temperature of 1200 DEG C, a high piezoelectric constant (d33 is more than or equal to 450 pC / N ), a high electromechanical coupling coefficient (KP is more than or equal to 0.60), a high Curie point (Tc is more than 350 DEG C) and a moderate dielectric constant (epsilonr is 2000-3500) can be obtained, and application requirements on the ceramic material by the laminated piezoelectric driver are met.

Owner:HUAZHONG UNIV OF SCI & TECH

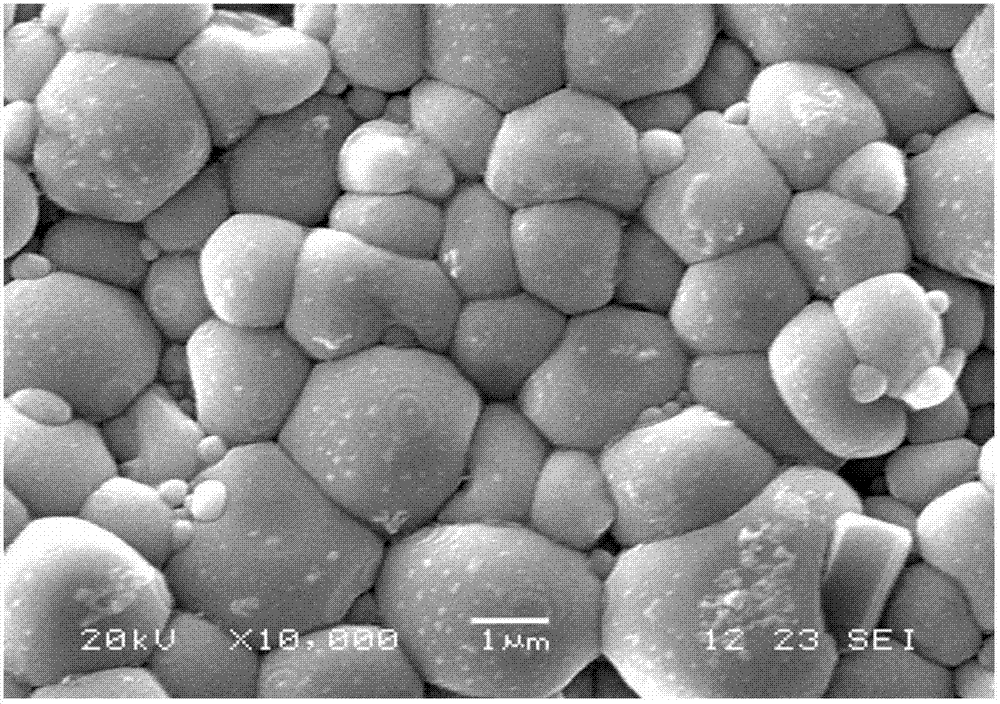

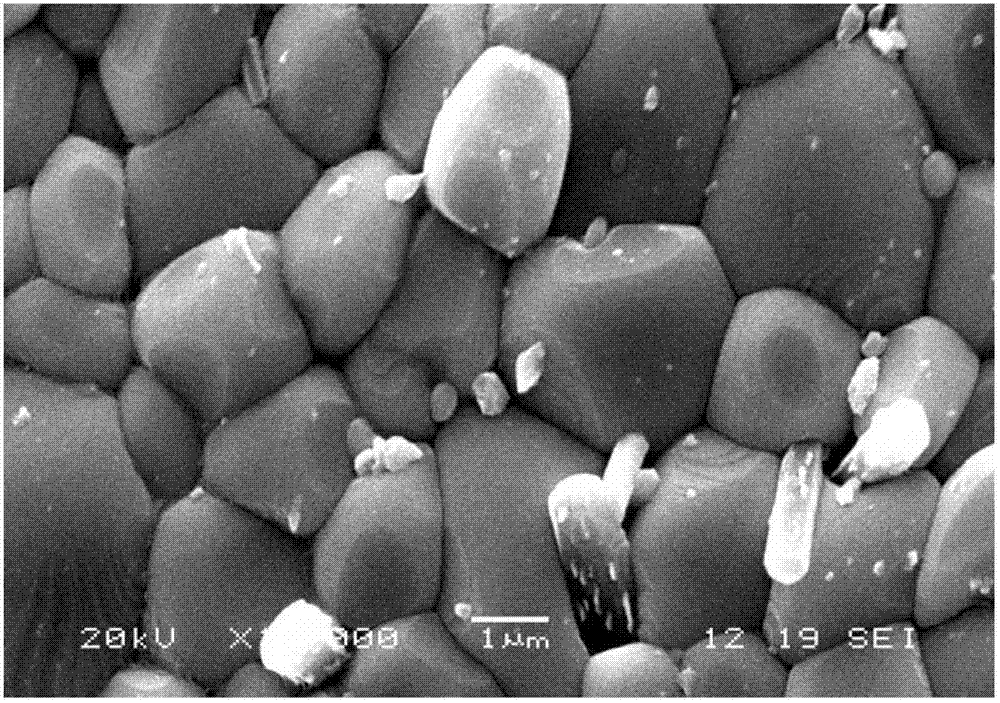

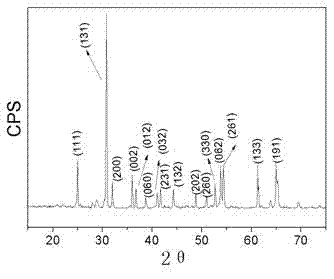

New method for finely preparing ixiolite structure MgTiNb2O8 microwave dielectric ceramic by using chemical process

Owner:UNIV OF JINAN

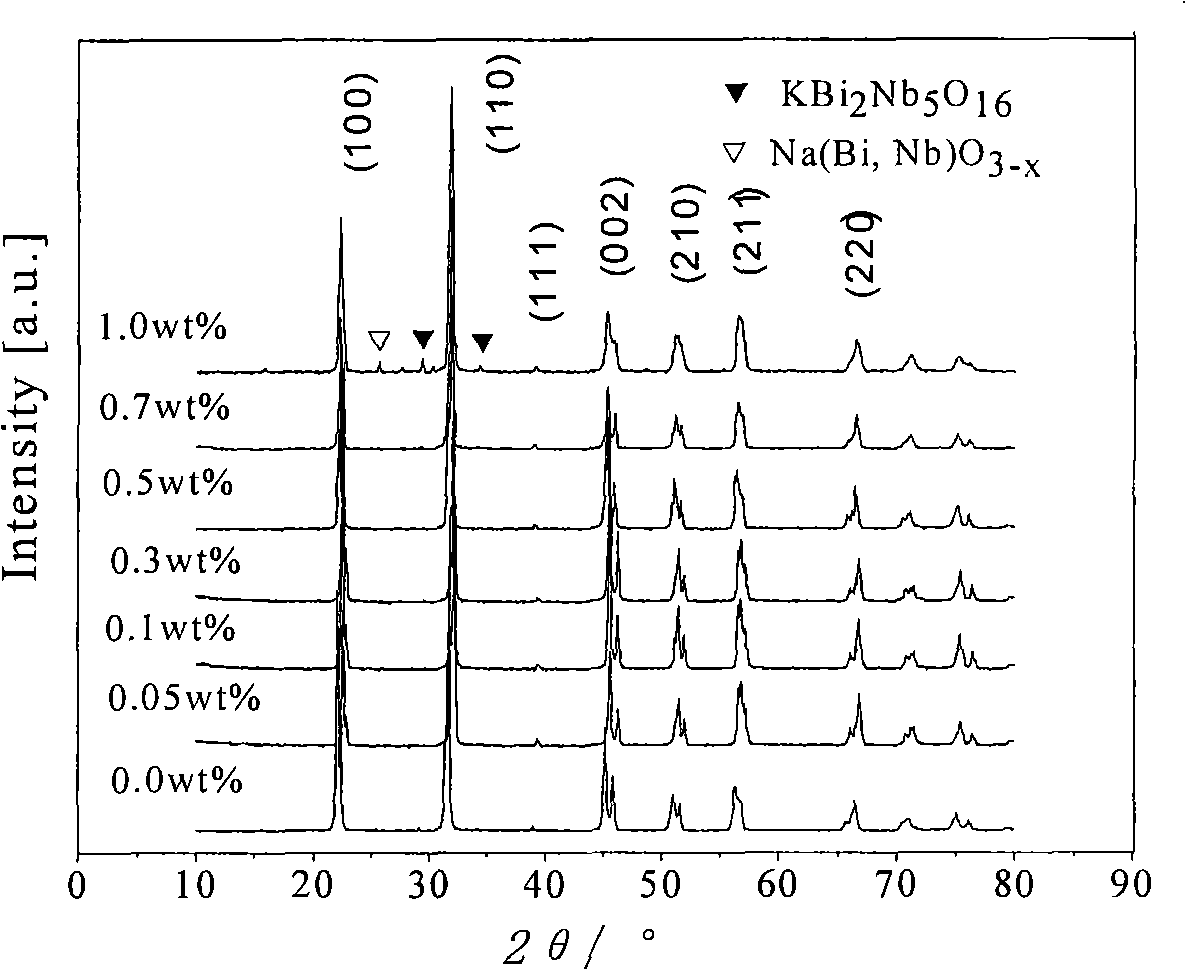

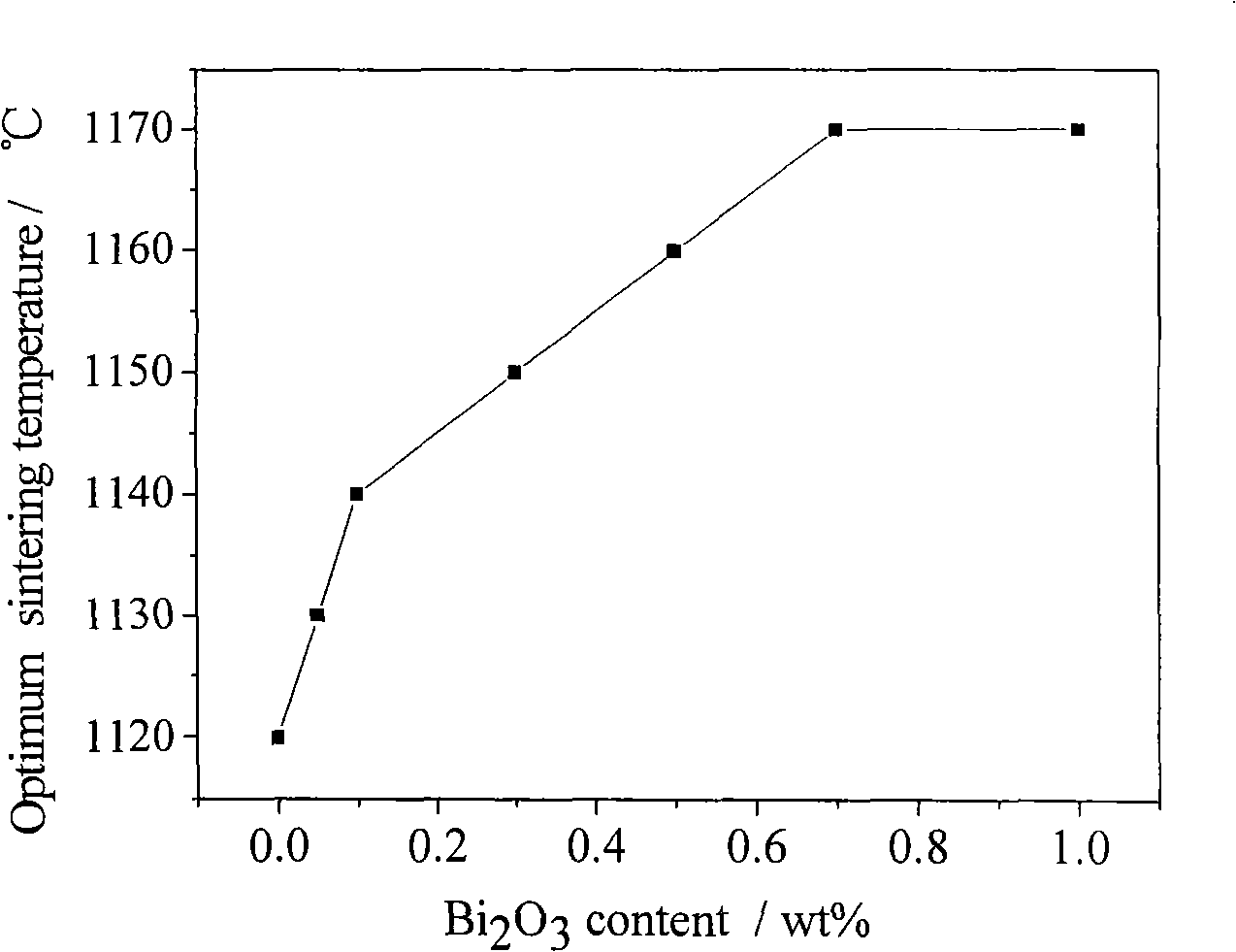

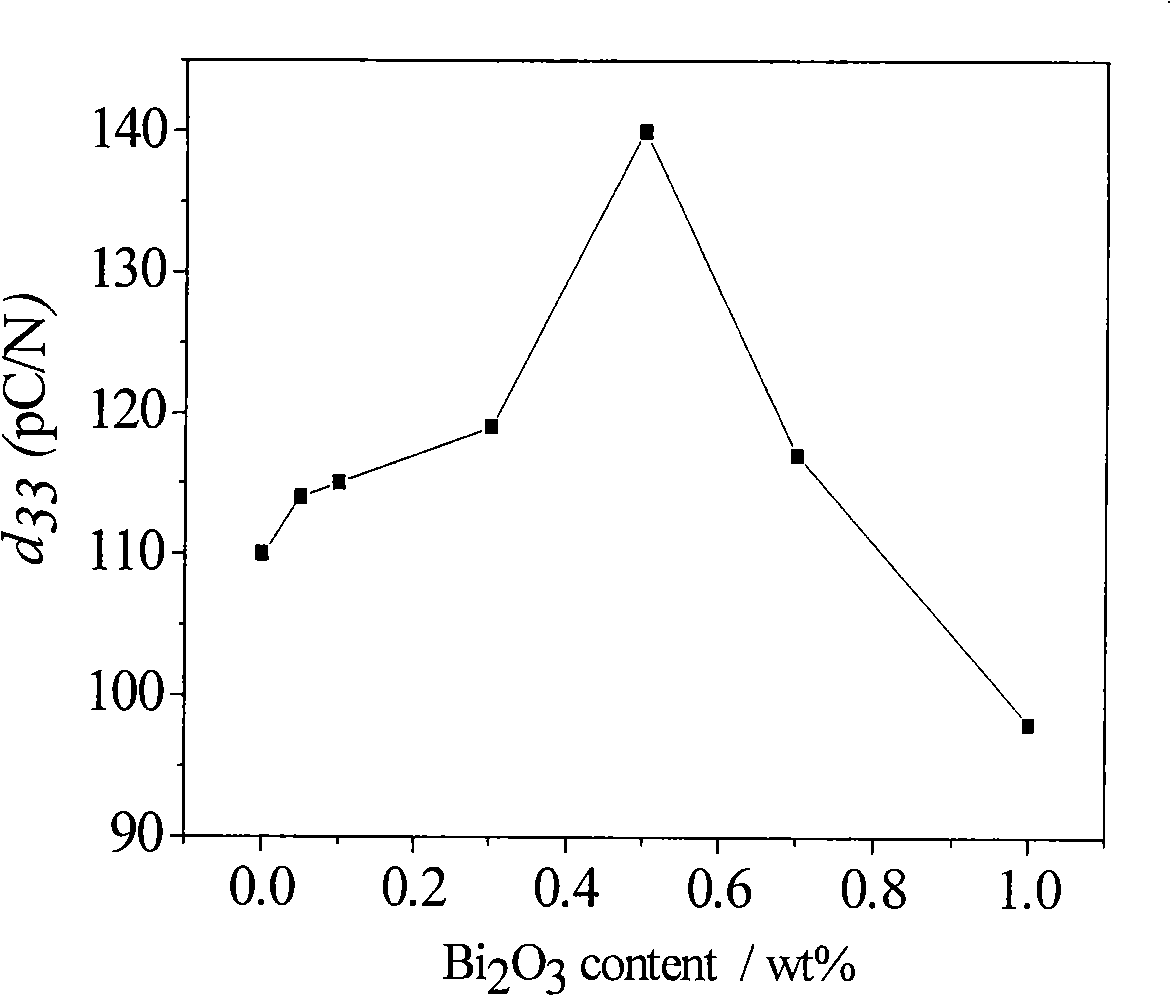

Potassium-sodium niobate-based leadless piezoelectric material and preparation thereof

InactiveCN101302106AImprove sintering propertiesHigh degree of densificationSilver electrodeDrain current

The invention discloses a piezoelectric material for lead-free piezoelectric ceramic with potassium-sodium niobate and a preparing method, which strengthens the ferroelectric performance of potassium-sodium niobate ceramic and further improves the piezoelectric performance. The material of the invention comprises anhydrous potassium carbonate, natrium carbonicum calcinatum, niobium pentaoxide and dibismuth trioxide, the stoichiometric proportion of the lead-free piezoelectric ceramic is (K0.5 Na0.5) Nb3 + x weight percent Bi 2O3, wherein the x is more than or equal to 0 and less than or equal to 1, the piezoelectric material for lead-free piezoelectric ceramic with potassium-sodium niobate is obtained through mixture making, drying and burnishing, granulation, molding, sintering and after polarization by a silver electrode; therefore, the densification of the ceramic is improved, polarized drain current of the ceramic is reduced, and the polarization process is carried out more easily; moreover, the piezoelectric material adopts the material from a conventional process and industry, has the characteristics of good process stability and no pollution.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Mid-temperature solid oxide fuel battery complex cathode material and method of preparing battery cathode

InactiveCN101179128AImprove conductivityGood thermal stabilityCell electrodesFinal product manufactureComposite cathodeCathode material

A preparation process of intermediate temperature solid oxide fuel cell composite cathode material and cell cathode, relates to a preparation method of solid oxide fuel cell composite cathode material and cell cathode. The invention solves the problems that it has already been unsuitable for the cathode materials for high temperature fuel cell to work at middle temperature now and also the problems of the high production cost of adding noble metal Pt or Pd into electrode materials and also the oxides of sliver doped oxide composite electrode are all with perovskite structures. The general formula of composition of cell composite cathode material is La2-XSrXNiO4-Ag. The preparations of cell cathode are: first, prepare La2-XSrXNiO4, then prepare La2-XSrXNiO4 and electrolyte cathode assemblies, then drop AgNO3 for sintering and will obtain intermediate temperature solid oxide fuel cell composite cathode. The La2-XSrXNiO4 of intermediate temperature solid oxide fuel cell composite cathode materials in the invention is the K2NiF4 type oxides and the cell composite cathode material has holey microstructure, thereby improving the diffusion effect of gas and bringing down the production cost remarkably.

Owner:HEILONGJIANG UNIV

Method for preparing magnesium tantalate microwave ceramic powder by sol-gel technique

The invention discloses a method for preparing magnesium tantalate microwave ceramic powder by a sol-gel technique, which comprises the following steps of: (1) preparing citric acid aqueous solution of tantalum, wherein the mol ratio of citric acid to tantalum ions is 2:1-6:1; (2) preparing citric acid aqueous solution of magnesium, wherein the mol ratio of the citric acid to magnesium nitrate is 5:1-10:1, and the pH value is 3 to 5; and (3) preparing solution of Mg-Ta precursor, xerogel and nano powder. The method overcomes the defects that the current solid phase method for synthesizing the magnesium tantalate microwave ceramic powder has high synthesis temperature, large particle size, impure phase and the like; and the method prepares high-purity magnesium tantalate microwave ceramic powder with the average particle size of 40 to 80 nanometers.

Owner:TIANJIN UNIV

Process for producing silver tantalate niobate nano-powder

The invention discloses a method for preparing the sol-gel of Ag(Nb, Ta)O3 (silver tanto-niobate) nano-powder on the basis of the presence of potassium carbonate as a co-solvent. The method comprises the following steps: (1) preparing the citric acid solution of niobium; (2) preparing the citric acid solution of tantalum; (3) preparing the citric acid solution of silver; and (4) preparing the silver tanto-niobate (Ag(Nb, Ta)O3) sol and obtaining the nano-powder. The invention overcomes the defects of the preparing process caused by the existing presence of highly corrosive hydrofluoric acid and the Ag(Nb, Ta)O3 (silver tanto-niobate) ceramic nano-powder with the average particle diameter being 20 to 50 nm can be prepared.

Owner:TIANJIN UNIV

Li series microwave dielectric ceramic material as well as preparation method and use thereof

InactiveCN109534806AImprove dielectric constantImprove temperature characteristicsLow-k dielectricCeramic

The invention provides a Li series microwave dielectric ceramic material as well as a preparation method and use thereof. The Li series microwave dielectric ceramic material is prepared from main materials of Li2CO3, SiO2 and MgO, and substituted material NiO. The Li series microwave dielectric ceramic material has the excellent features of low dielectric constant, high quality factor, high relative density and low densification temperature. The preparation method of the Li series microwave dielectric ceramic material improves the sintering features, the micromorphology and the electric performance of Li2MgSiO4 microwave dielectric ceramic at the low sintering temperature of 1120 to 1160 DEG C; under the condition of adding a small quantity of sintering auxiliary agents, the sintering temperature lower than 961 DEG C can be realized.

Owner:工业和信息化部电子第五研究所华东分所

Method for Manufacturing Conductive Metal Thin Film Using Carboxylic Acid

ActiveUS20120219703A1Improve conductivityImprove sintering propertiesMaterial nanotechnologyPigmenting treatmentOxideHeat treated

The present invention relates to a method for manufacturing a conductive metal thin film, including: preparing a conductive metal coating solution by adding carboxylic acid to a dispersion including a conductive metal particle having a core / shell structure; coating the conductive metal coating solution on a top portion of a substrate, heat-treating it, and removing an metal oxide layer of the surface of the conductive metal particle having the core / shell structure; and forming a thin film of the conductive metal particle from which the metal oxide layer is removed.

Owner:HANWHA CHEMICAL CORPORATION +1

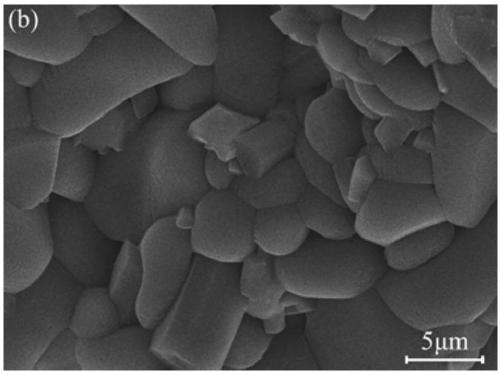

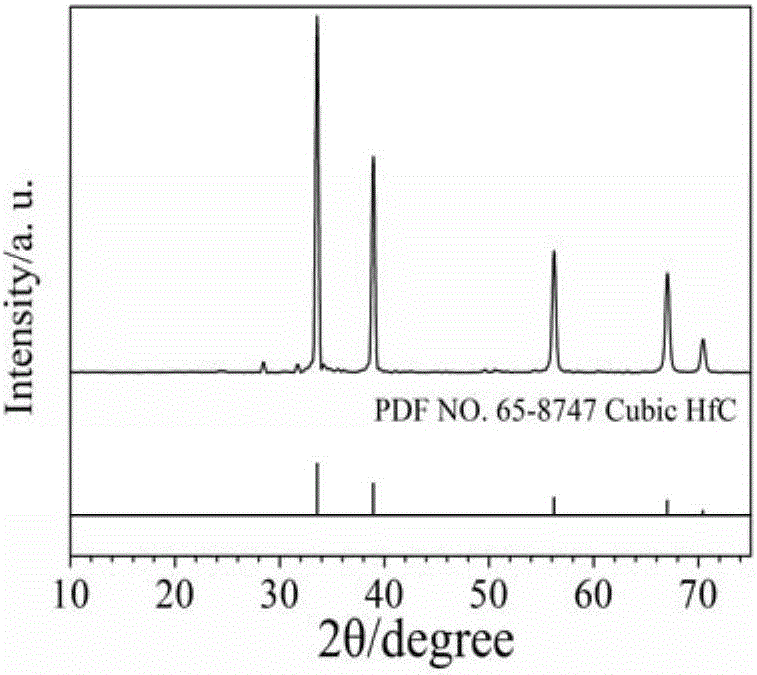

Method for preparing superhigh temperature carbonized hafnium ceramic nano-powder

ActiveCN106588018AGood dispersionSolve the problem of difficult sinteringMaterial nanotechnologyDispersityRoom temperature

The invention relates to a method for preparing superhigh temperature carbonized hafnium ceramic nano-powder. Anhydrous saccharose is evenly dispersed in deionized water, a mixed template is added, stirring is carried out, an even and transparent precursor solution is obtained, and the solution is poured into a hydrothermal still; the hydrothermal still is placed in an electric heating air blowing drying box for reacting after being sealed, then the product is cooled to room temperature, and filtering, separation, washing and drying are carried out; finally, the product is mixed with hafnium powder, a vacuum carburizing reaction is carried out, and HfC nano particles are prepared. Compared with the prior art, the prepared carbonized hafnium ceramic nano-powder is good in crystallinity and dispersity and controllable in morphology.

Owner:SHANGHAI JIAO TONG UNIV

Composite soft magnetic sintered material having high density and high magnetic permeability and method for preparation thereof

InactiveUS7371271B2Improve sintering propertiesHigh densityLayered productsInorganic material magnetismFerrite layerSilicon dioxide

An object of the present invention is to provide a composite soft magnetic sintered material that has high density, high mechanical strength and high relative magnetic permeability at high frequencies and, in order to achieve this object, the present invention provides a method of producing the composite soft magnetic sintered material, which comprises mixing a composite soft magnetic powder, that consists of iron powder, Fe—Si based soft magnetic iron alloy powder, Fe—Al based soft magnetic iron alloy powder, Fe—Si—Al based soft magnetic iron alloy powder, Fe—Cr based soft magnetic iron alloy powder or nickel-based soft magnetic alloy powder (hereinafter these powders are referred to as soft magnetic metal powder) of which particles arc coated with a ferrite layer which has a spinel structure, with 0.05 to 1.0% by weight of silicon dioxide powder having a mean powder particle size of 100 nm or less and sintering the mixed powder after compression molding, or processing two or more kinds of the composite soft magnetic powders, of which particles are coated with ferrite layer having a spinel structure of a different compositions, by compression molding and sintering.

Owner:DIAMET CORP

Preparation method of zinc cobalt sodium silicate nano powder

The invention discloses a preparation method of zinc cobalt sodium silicate microwave dielectric ceramic nano powder. The method comprises the following steps: (1) firstly preparing a zinc nitrate solution and a cobalt nitrate solution and then mixing the two solutions, wherein the raw material components and molar percentage content are shown in the following formula: CoxZn2-xSiO4, and x is larger than 0 and less than or equal to 1; (2) preparing a tetraethyl orthosilicate solution; (3) dropwise adding the mixed solution in the step (1) to the tetraethyl orthosilicate solution, wherein the pH value is 2-4, adding deionized water and then magnetically stirring so as to obtain CoxZn2-xSiO4 sol; (4) drying the CoxZn2-xSiO4 sol to form jelly-shaped gel, and then drying the gel to form dried gel; and (5) thermally treating the dried gel at the temperature of 650-950 DEG C so as to obtain the CoxZn2-xSiO4 nano powder. The CoxZn2-xSiO4 nano powder prepared by using the method has an averageparticle size of 90nm and has the advantages of high purity, simple process, cheap raw material, high activity and good sintering property; and the sintering temperature of the nano power is lowered by 100-300 DEG C as compared with that of a solid phase method, and a material support is provided for preparation of high-property CoxZn2-xSiO4 microwave dielectric ceramic.

Owner:TIANJIN UNIV

Method for producing a porous titanium material article

Method for producing a porous titanium material for example a support. Starting from a titanium powder this powder is sintered under vacuum conditions in an inert / reducing atmosphere. Titanium hydride is added as powder and decomposes during sintering. The hydride ions provide a very reducing atmosphere preventing any titanium oxide or carbide / nitride composition to be formed at elevated temperature.

Owner:STICHTING ENERGIEONDERZOEK CENT NEDERLAND

Method for preparing wide-working-temperature-zone thermostabilization composite dielectric ceramic

The invention discloses a method for preparing wide-working-temperature-zone thermostabilization composite dielectric ceramic. The method comprises the following steps of: (1) according to the formula of x(Na0.5Bi0.5)TiO3-(1-X)BaTiO3, preparing bismuth nitrate solution and sodium acetate solution, wherein x is more than 0.01 and less than 0.5; preparing tetrabutyl titanate solution, and dropwise adding the bismuth nitrate solution and the sodium acetate solution into tetrabutyl titanate solution to obtain sodium bismuth titanate sol; (2) preparing barium titanate solution; (3) preparing (Na0.5Bi0.5)TiO3-BaTiO3 composite sol; (4) preparing xerogel; (5) preparing (Na0.5Bi0.5)TiO3-BaTiO3 composite nano powder; and (6) pelleting and performing compression moulding, sintering at the temperature of between 950 and 1,050 DEG C to obtain the composite dielectric ceramic. The nano powder prepared by a sol-gel method has a fine particle size, and the average grain diameter of the powder is 100nm; and the powder has high activity and sintering property, and the wide-working-temperature-zone thermostabilization composite dielectric ceramic with high dielectrical property can be prepared at low sintering temperature.

Owner:TIANJIN UNIV

Preparation for magnesium niobate microwave ceramic powder through sol-gel technology

The invention discloses a method for preparing magnesium niobate microwave ceramic powder through a sol-gel technology. The method comprises the following steps: (1), preparing a citric acid aqueous solution for niobium; (2), preparing a citric acid aqueous solution for magnesium; (3), obtaining a Mg-Nb precursor solution, xerogel and nano-powder. According to the invention, the defects that the magnesium niobate microwave ceramic powder synthesized through a solid phase method at present is high in temperature and large in particle size are overcome, and the magnesium niobate microwave ceramic powder, of which the average particle size is 40-80 nm, is prepared under the condition that the calcination temperature is 550-850 DEG C.

Owner:JINAN WEIBO NEW MATERIAL

Leadless piezoelectric ceramics with bismuth ion replacing modified potassium sodium niobate base and method for preparing same

InactiveCN101311139AImprove sintering propertiesHigh degree of densificationPiezoelectric/electrostrictive/magnetostrictive devicesNiobium compoundsTrioxideSodium carbonate anhydrous

The invention relates to a modified potassium-sodium niobate based leadless piezoelectric ceramics substituted by bismuth ion and a preparation method thereof; the raw materials includes anhydrous potassium carbonate, anhydrous sodium carbonate, niobium pentaoxide and dibismuth trioxide; the stoichiometric ratio thereof is ((K0.5Na0.5)1-3xBix)NbO3(x is more than or equal to 0.0 and less than or equal to 0.05), wherein, x is more than or equal to 0.0 and less than or equal to 0.5; the bismuth ion is added to replace the ion at A position in (K0.5Na0.5)NbO3 ceramics, thus improving sintering characteristics and ferroelectric properties of potassium-sodium niobate ceramics and further enhancing piezoelectric properties thereof. During preparation, according to the principle of electrical valence equilibrium, the bismuth ion is added and K ion and Na ion are reduced at the same time, thus generating the vacancy at the A position and avoiding the formation of residual matter; therefore, the piezoelectric properties d33 and kp can reach 164pC / N and 47% respectively; moreover, the invention is characterized by broad source of the raw materials, good stability of the technique and no environment pollution.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

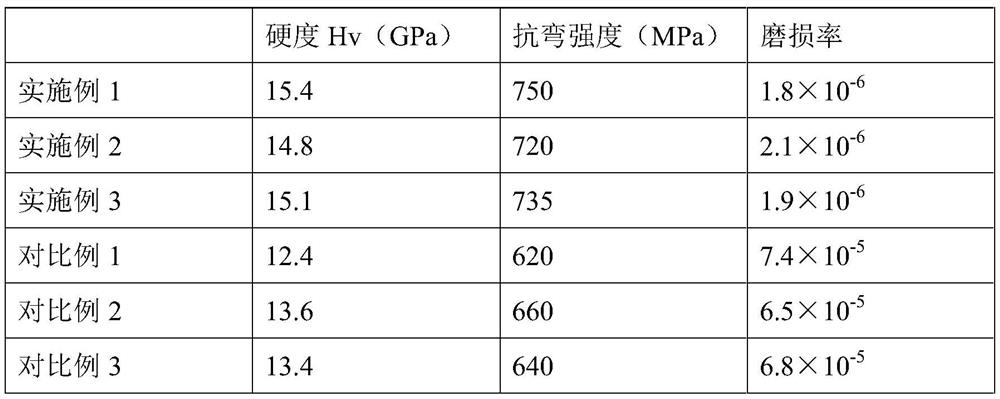

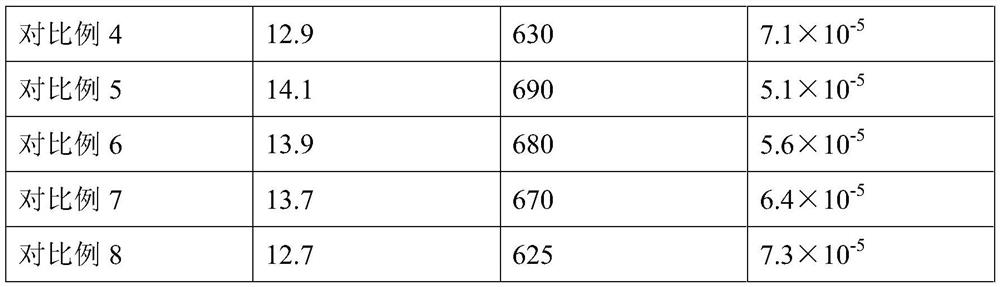

Wear-resistant domestic ceramic and preparation method thereof

ActiveCN112174697AImprove the toughness of the glaze layerImprove resistance performanceClaywaresCeramic glazeTitanium carbide

The invention discloses a wear-resistant domestic ceramic and a preparation method thereof. The wear-resistant domestic ceramic comprises a domestic ceramic body and a glaze layer, wherein the glaze layer is prepared from the following raw materials in parts by weight: 30-40 parts of zircon sand, 10-15 parts of baddeleyite, 5-10 parts of nepheline syenite, 3-6 parts of titanium carbide powder, 3-5parts of titanium dioxide, 4-6 parts of lutetium oxide, 2-4 parts of tungsten powder, 2-4 parts of polyvinyl alcohol with mass fraction being 5 wt%, 2-4 parts of glycerin, and 20-30 parts of water. According to the wear-resistant domestic ceramic disclosed by the invention, through synergistic cooperation of the components, the obtained wear-resistant domestic ceramic is flat and smooth in glazesurface and good in texture, and has excellent hardness, bending strength and wear resistance.

Owner:潮州市欧博瓷业有限公司

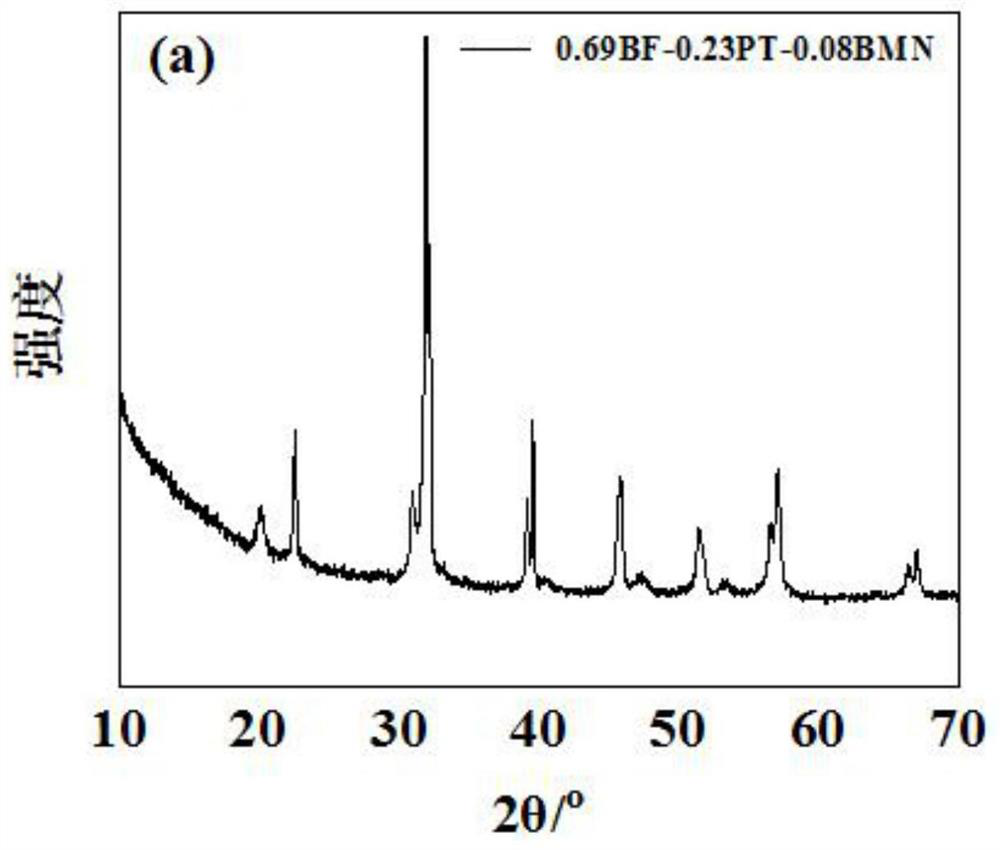

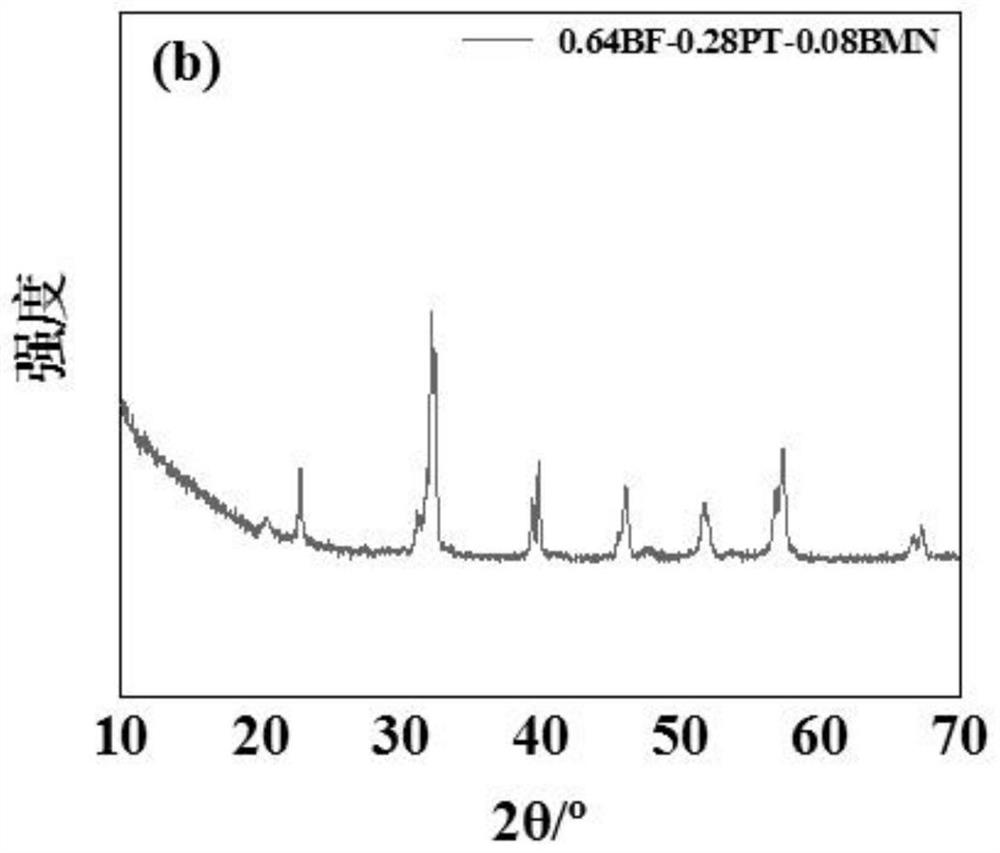

Preparation method of bismuth ferrite-lead titanate-bismuth magnesium niobate ternary system high-temperature piezoelectric ceramic

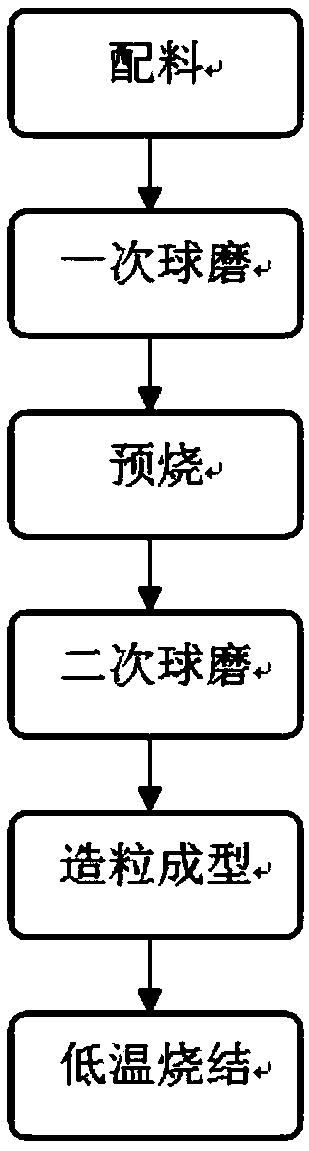

PendingCN113307619ALower sintering temperaturePromote densificationPhysical chemistryPiezoelectric coefficient

The invention belongs to the field of piezoelectric ceramic materials, and particularly relates to a preparation method of bismuth ferrite-lead titanate-bismuth magnesium niobate ternary system high-temperature piezoelectric ceramic. The chemical formula is (1-x-y) BiFeO3-xPbTiO3-yBi (Mg2 / 3Nb1 / 3) O3, x and y are molar weights, and x is more than or equal to 0.20 and less than or equal to 0.40; 0.01 < = y < = 0.10; the auxiliary component is mBi2O3 + nPbO + zMnO, m, n and z are the mass percent of the total formula, and m is larger than or equal to 0 and smaller than or equal to 0.10; 0 < = n < = 0.10; 0 < = z < = 0.10. The preparation method comprises the following steps: S1, weighing the raw materials; s2, carrying out primary ball milling; step S3: drying; s4, performing solid-phase synthesis; step S5, carrying out secondary ball milling; step S6, granulating and forming; step S7, glue discharging; step S8; and step S9. The sintering temperature of a system can be reduced, ceramic densification is promoted, cracking and pulverization are avoided, the ceramic has the good sintering characteristic, the c / a ratio of the system is reduced, the material is easy to polarize, the ceramic obtains the large piezoelectric coefficient under the condition that the high Curie temperature is guaranteed, the insulativity and temperature stability of the material are improved, and the service life of the material is prolonged. And practical application of devices at high temperature is facilitated.

Owner:XIAN INT UNIV

A wear-resistant daily-use ceramic and its preparation method

The invention discloses a wear-resistant ceramic for daily use and a preparation method thereof. The wear-resistant daily-use ceramics include a daily-use ceramic body and a glaze layer, and the glaze layer is made of the following raw materials in parts by weight: 30-40 parts of zircon sand, 10-15 parts of baddeleyite, and 5-10 parts of syenite, 3-6 parts of titanium carbide powder, 3-5 parts of titanium dioxide, 4-6 parts of lutetium oxide, 2-4 parts of tungsten powder, 2-4 parts of polyvinyl alcohol with a mass fraction of 5wt% 2-4 parts of glycerin, 20-30 parts of water. The wear-resistant daily-use ceramics of the present invention are obtained through synergistic cooperation of components, and the obtained wear-resistant daily-use ceramics have a smooth glazed surface, good texture, excellent hardness and bending strength, and excellent wear resistance.

Owner:潮州市欧博瓷业有限公司

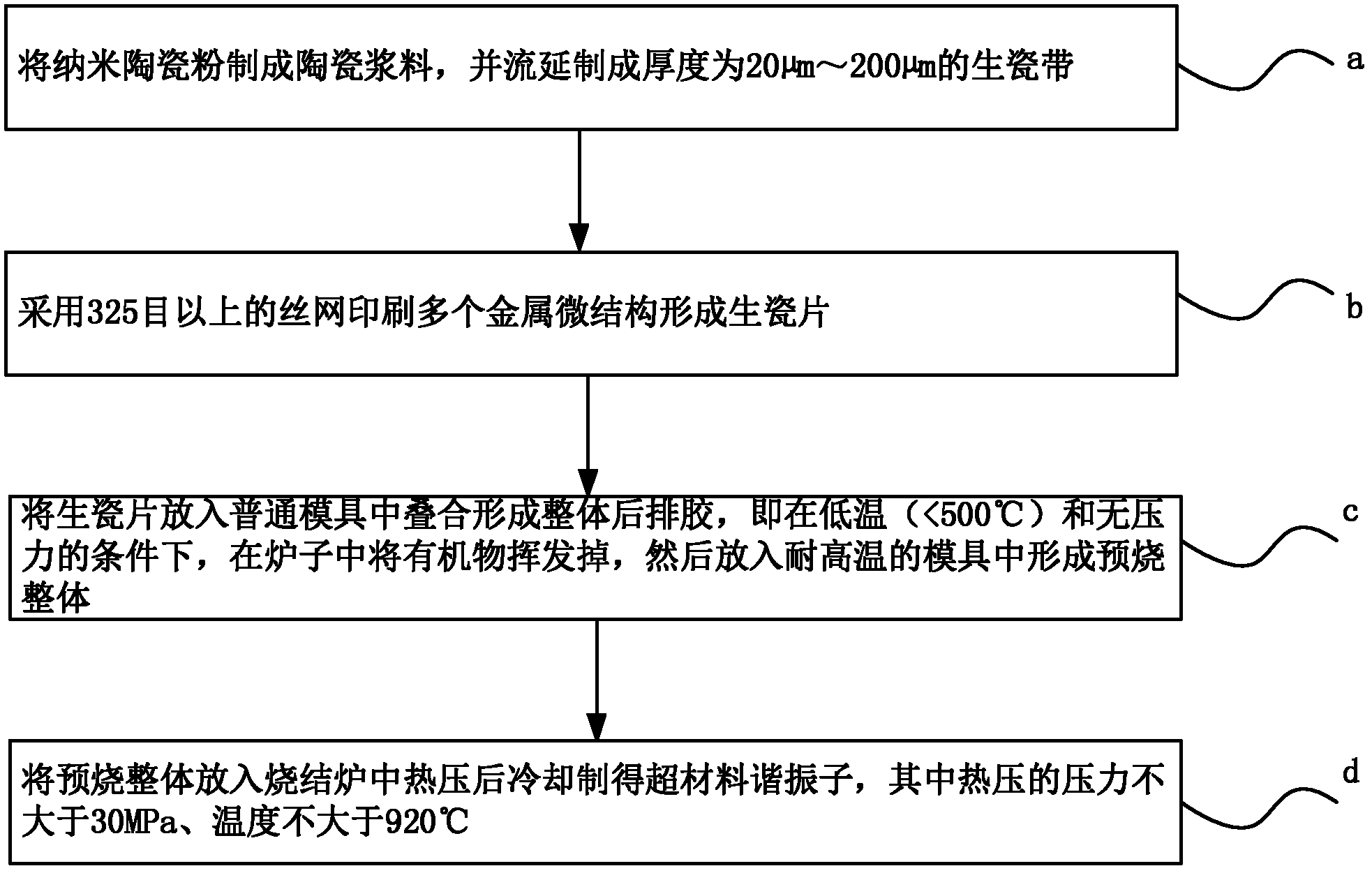

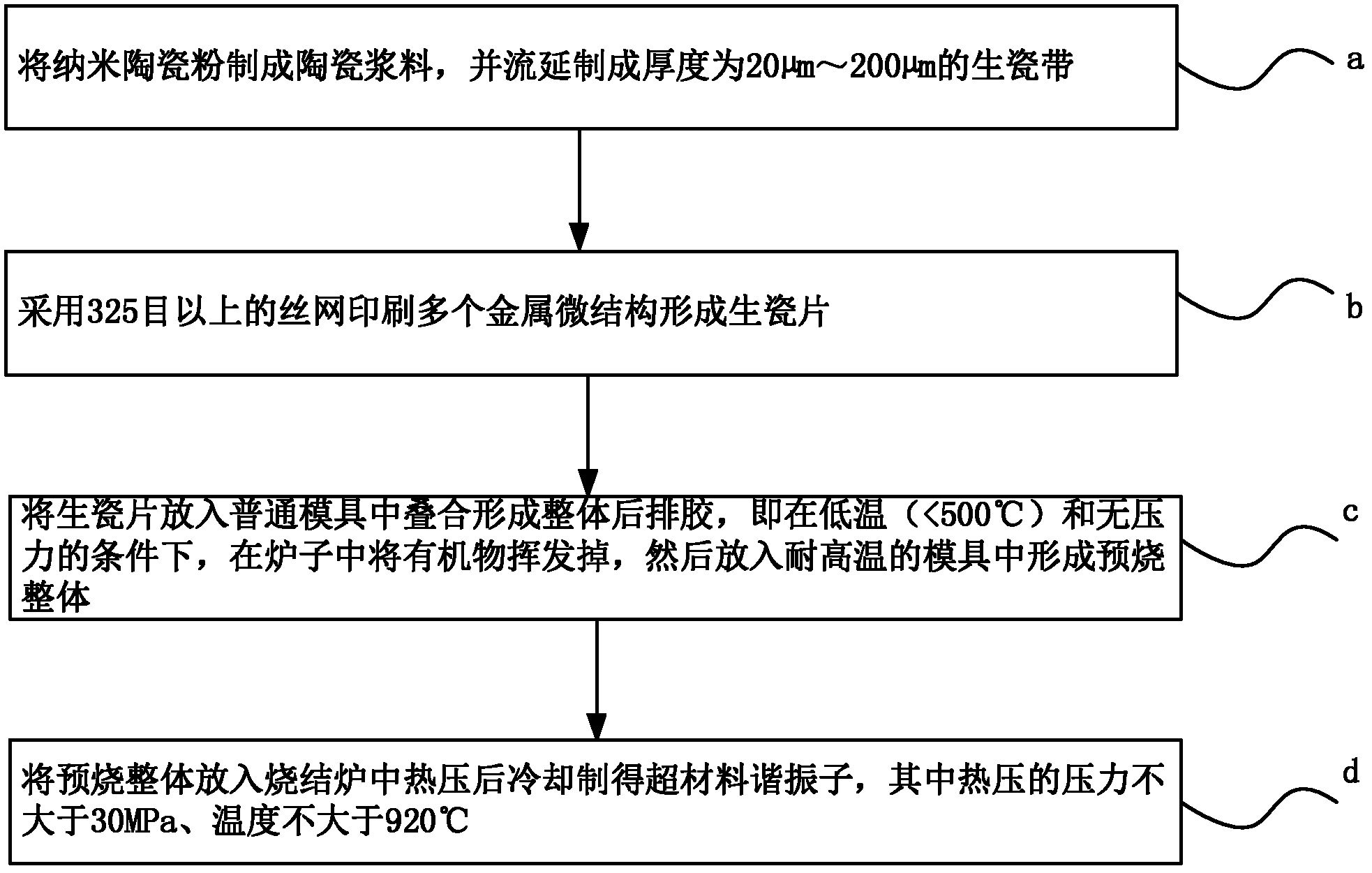

Low temperature co-fired ceramic (LTCC)-based metamaterial harmonic oscillator and manufacturing method thereof

The invention provides a low temperature co-fired ceramic (LTCC)-based metamaterial harmonic oscillator and a manufacturing method thereof. The manufacturing method comprises the following steps of: preparing ceramic slurry from nano ceramic powder, and casting to prepare a green tape; manufacturing a metal microstructure on the green tape to form green ceramic chips through screen printing; superposing the green ceramic chips, putting the green ceramic chips into a mold after tape ranking to form a presintering whole; and performing hot-pressing and cooling the presintering whole to obtain the metamaterial harmonic oscillator. Because the nano-powder has high sintering property, the sintering temperature of the nano ceramic powder can be reduced in the process of preparing the metamaterial harmonic oscillator from the nano ceramic powder; and therefore, a sintering aid is not added into the nano ceramic powder or a small amount of sintering aids can be added into the nano ceramic powder so as to realize low-temperature co-firing, and the loss of the metamaterial harmonic oscillator is reduced; by the hot-pressing technology, the phenomena of layering and warping in the sintering process are avoided, and the sintering temperature is lower than the traditional pressureless sintering temperature under the pressure conditions, and the sintering temperature is reduced further.

Owner:KUANG CHI INST OF ADVANCED TECH

High-Q-value lithium titanate-based microwave dielectric ceramic material and preparation method thereof

The invention belongs to the technical field of ceramic materials, and discloses a high-Q-value lithium titanate-based microwave dielectric ceramic material and a preparation method thereof. The preparation method comprises the following steps: subjecting Li2CO3 and TiO2 to burdening, ball milling, drying and sieving according to a stoichiometric formula Li2TiO3 and then performing presintering at a temperature of 800-1000 DEG C; adding an M doping agent, carrying out ball milling, drying, sieving and granulating successively, and conducting pressing to obtain a green body; and sintering the green body at a temperature of 1100-1180 DEG C. The chemical formula of the obtained high-Q-value lithium titanate-based microwave dielectric ceramic material is Li<2>TiO<3+x>M, wherein M is Li2CO3, MgO, LiF, MgF2 or MgO + LiF, and x is equal to 0.6 wt.%-3.6 wt.%. According to the invention, different types of dopants are introduced into Li2TiO3, so the sintering characteristic of microwave dielectric ceramic is improved, and the defect that the Qf value of pure Li2TiO3is low is overcome; the produced material has a high quality factor and a moderate dielectric constant; a preparation process is simple; and microwave dielectric devices manufactured, researched and developed on the basis of the material have wide application prospects.

Owner:TIANJIN UNIV

Preparing method of superfine/nano tantalum tungsten composite powder and superfine/nano tantalum tungsten composite powder prepared through same

ActiveCN105855561ASmall grain sizeImprove performanceMaterial nanotechnologyTransportation and packagingCrystalliteSurface-active agents

The invention provides a preparing method of a superfine / nano tantalum tungsten composite powder. Adopting a fluorotantalic acid solution and tungstate as raw materials, the preparing method of the superfine / nano tantalum tungsten composite powder comprises the steps of firstly adding calculated amount of tungstate powder into the fluorotantalic acid solution, and then adding a surface active agent to prepare a sol solution; then adding an alkaline precipitant until pH is equal to 9 to 12, and precipitating to obtain a tantalum tungsten precursor composite powder; then carrying out hydrogen reduction, alkali metal reduction and magnesium reduction and deoxygenization to obtain the superfine / nano tantalum tungsten composite powder. The invention furthermore provides the superfine / nano tantalum tungsten composite powder prepared through the preparing method, wherein the grain size ranges from 10nm to 200nm, and the mass percent of tungsten ranges from 2.5 percent to 70 percent. According to the superfine / nano tantalum tungsten composite powder provided by the invention, the tantalum and tungsten components are distributed uniformly, and the sintering activity is high.

Owner:JIUJIANG TANBRE

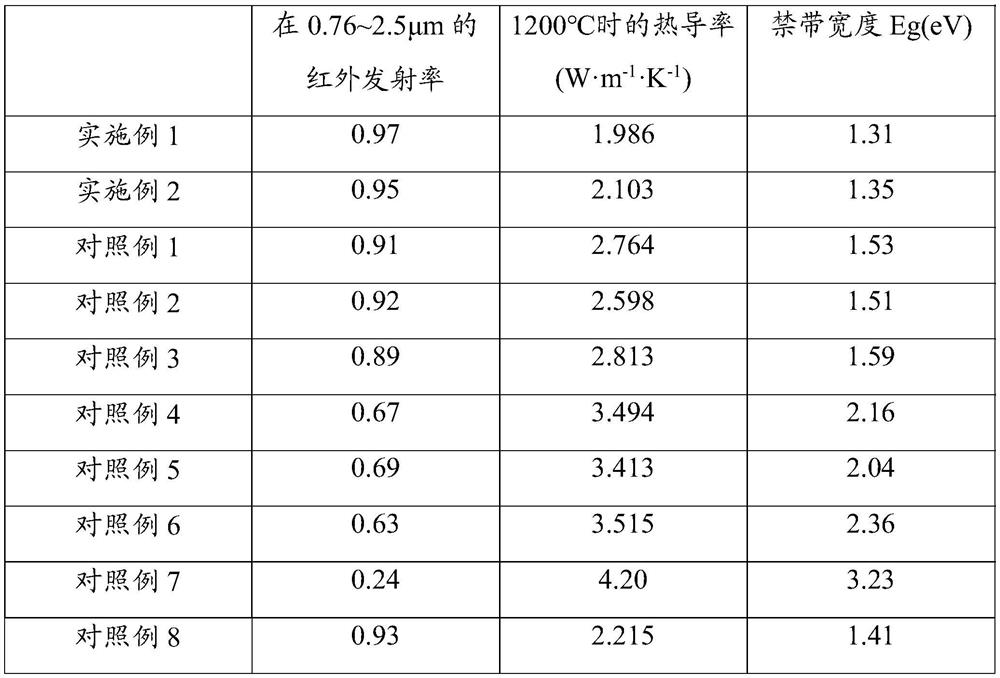

Preparation method of Sr, Ni and Cr co-doped LaAlO3 ceramic material and product thereof

ActiveCN111825442AImprove compactnessImprove Radiation PerformanceUltrasonic dispersionCHROMIC NITRATE

The invention discloses a preparation method of a Sr, Ni and Cr co-doped LaAlO3 ceramic material and a product thereof. According to the stoichiometric ratio of the chemical formula of LaaSrbNicAldCreO3, the chemical formula of LaaSrbNicAldCreO3 is as shown in the specification, wherein a=0.7-0.9; b = 0.05-0.15, c = 0.05-0.15, d = 0.7-0.9, e=0.1-0. 3, weighing strontium nitrate, nickel nitrate, chromium nitrate, lanthanum nitrate and aluminum nitrate; soluble in water, then adding a certain amount of urea, performing ultrasonic dispersion and microwave heating, drying and roasting, grinding and compression molding, calcining for a period of time to obtain the product, the product is good in compactness and excellent in radiation performance, the infrared emissivity of the product at 0.76-2.5 microns is 0.95-0.97, the thermal conductivity of the product at the temperature of 1200 DEG C is 1.986-2.103 W.m <-1 >. K <-1 >, and the forbidden band width of the product is 1.31-1.35 eV.

Owner:长沙麓桥科技有限公司

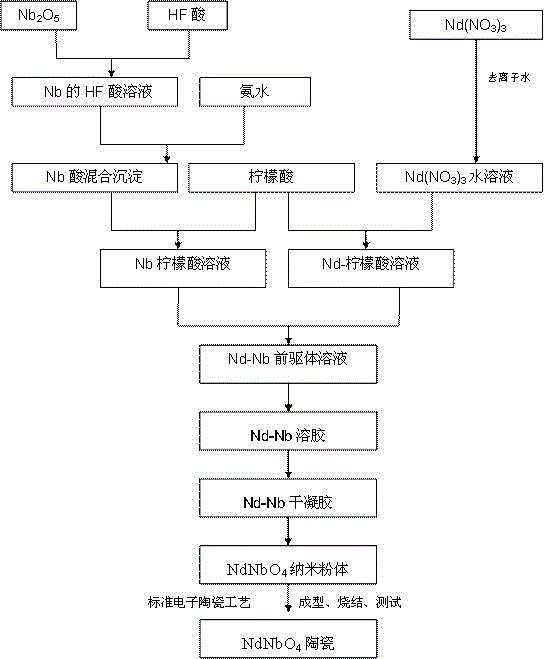

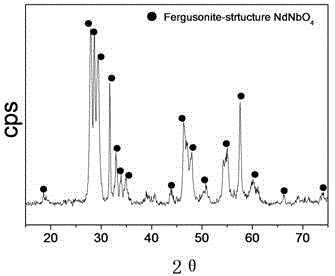

Method for preparing NdNbO4 microwave dielectric ceramic of fergusonite structure by use of wet chemical process

The invention belongs to the technical field of preparation and application of ceramics, and particularly relates to a method for preparing NdNbO4 microwave dielectric ceramic by utilizing a wet chemical process. The technical scheme is as follows: the method for preparing the NdNbO4 microwave dielectric ceramic by utilizing the wet chemical process comprises the following steps: (1) preparing a citric acid water solution of Nd ions; (2) preparing a citric acid water solution of Nb ions; (3) synthesizing a NdNbO4 microwave dielectric ceramic nanometer precursor and preparing the ceramic. The method has the remarkable advantages that the synthetic temperature is low, ceramic particles are uniform, the dispersity is good, the phase is pure, and the powder body has a nanometer particle size (which is about 50 nanometers), also has high specific surface energy and has relatively high activity, and the like. In comparison with a conventional solid phase method, the method disclosed by the invention can be used for reducing the sintering temperature by 100 to 200 DEG C, realizing intermediate and low-temperature sintering and also retaining good microwave dielectric performance of the ceramic, and is expected to meet the LTCC application requirements.

Owner:UNIV OF JINAN

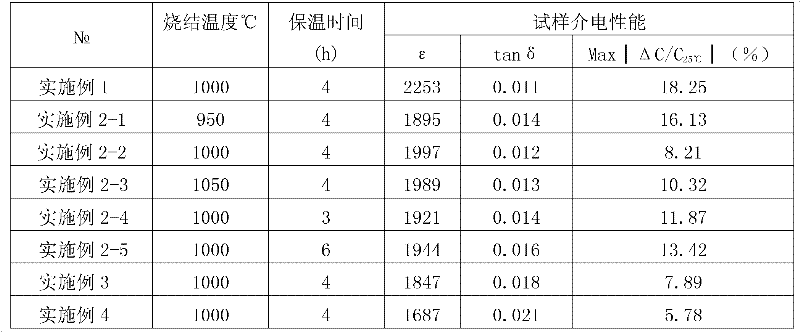

High-conductivity glass powder and preparation method thereof, and barium titanate-based glass ceramic based high-conductivity glass powder, and preparation method thereof

The invention discloses high-conductivity glass powder and a preparation method thereof, and a barium titanate-based glass ceramic based the high-conductivity glass powder, and a preparation method thereof. According to the present invention, 0.85BaTiO3-0.15Bi(Mg2 / 3Nb1 / 3)O3(BTBMN) ceramic powder is prepared by using a solid phase method, a low-melting-point high-conductivity glass B2O3-Na2B4O7-Na2SiO3(BNN) is prepared at a temperature of 900-1000 DEG C by using a melting method, high temperature taking and quenching is performed to obtain a glass, and a BTBMN-xBNN(BG)glass ceramic is preparedby using a solid phase method, wherein x represents the mass fraction of the BNN glass, and x is more than or equal to 1% and is less than or equal to 12%; the dense BG glass ceramic is obtained by sintering at a temperature of 850-1225 DEG C by adjusting the glass addition amount; the glass ceramic has an electric field strength of 240 kV / cm, a release energy density of 1.26 J / cm<3> and an energystorage efficiency of 81%, can meet a temperature change rate |[delta]C / C25 DEG C| of less than or equal to 15% within a temperature range of -61-275 DEG C, has good dielectric constant temperature stability, and can meet the temperature stability requirements of general capacitor operation; the glass ceramic material preparation process is simple, the technology is mature, and the method is suitable for industrial production; and the obtained glass ceramic has high puncture strength and good temperature stability.

Owner:SHAANXI UNIV OF SCI & TECH

Mn-doped ZrTi2O8/ZnNb2O8 multiphase microwave dielectric ceramic and preparation method thereof

InactiveCN107867847AImprove sintering propertiesExcellent microwave dielectric propertiesMicrowave dielectric propertiesDielectric ceramics

The application discloses a Mn-doped ZrTi2O8 / ZnNb2O8 composite microwave dielectric ceramic and a preparation method thereof, wherein the mass proportion of ZrTi2O8 is 65wt%, the mass proportion of Mn is 1.2wt%, and the balance is ZnNb2O8. The preparation method of Mn-doped ZrTi2O8 / ZnNb2O8 composite microwave dielectric ceramics includes: 1. Synthesizing ZrTi2O8 / ZnNb2O8 base material by solid phase method; 2. Adding MnCO3 to ZrTi2O8 / ZnNb2O8 base material; 3. Adding MnCO3 base material Put it into a polyurethane ball mill tank for ball milling; 4. Dry and sieve; 5. Granulate; 6. Dry press molding; Keep warm at 1250°C for 5 hours; 8. Cool to room temperature. The invention effectively improves the sintering characteristics of the dielectric ceramics through Mn doping modification, can be sintered densely in the air at 1250 DEG C, and has good microwave dielectric properties.

Owner:徐平芳

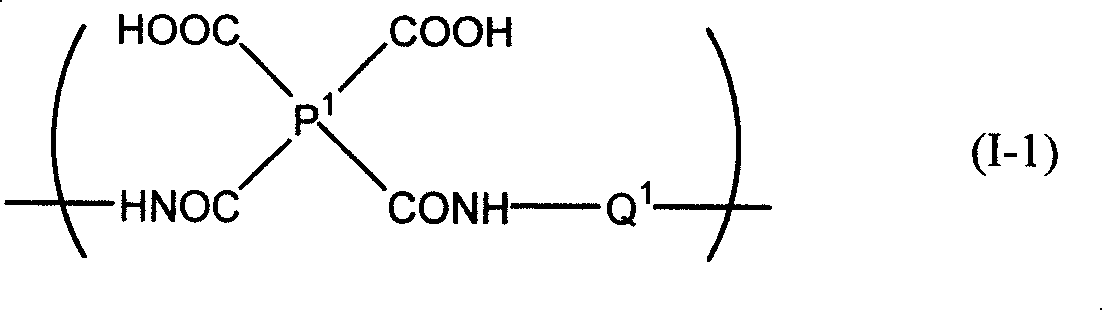

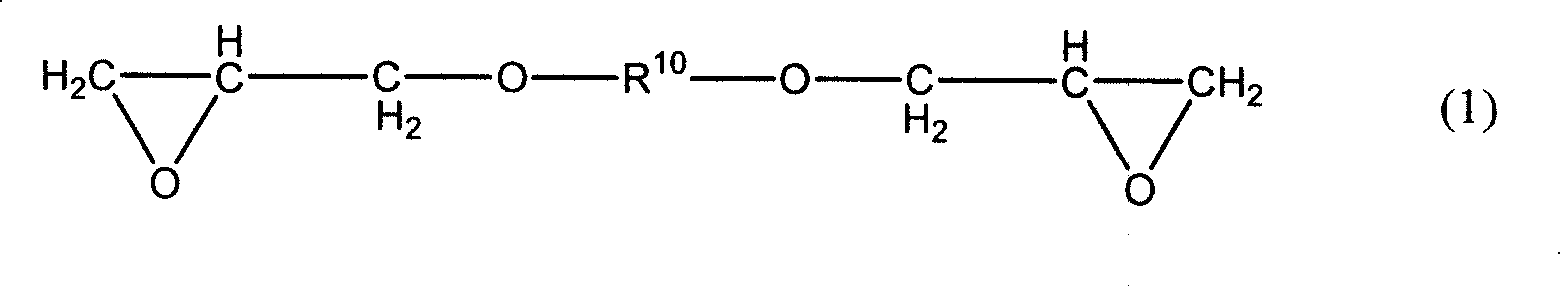

Liquid crystal orientation agent

ActiveCN100397159CImprove sintering propertiesEasy to useLiquid crystal compositionsStatic indicating devicesCrystallographyImide

The invention is to provide a liquid crystal aligning agent for a liquid crystal display device to obtain a liquid crystal alignment layer having excellent burning characteristics even when not only an ITO but a reflective electrode is used, and to provide a liquid crystal display device having a liquid crystal alignment layer obtained from the agent. The liquid crystal aligning agent comprises 100 parts by weight of a polymer having an amic acid repeating unit and an imide repeating unit, with the proportion of the amic acid repeating unit by 40 to 60% by weight in the entire repeating units, and at least 5 parts by weight of a compound having at least two epoxy groups in the molecule.

Owner:JSR CORPORATIOON

Tin oxide target material doped with silver as well as preparation method and application thereof

ActiveCN110257786AImprove sintering propertiesHigh densityTransportation and packagingMetal-working apparatusOptical propertyVolumetric Mass Density

The invention provides a tin oxide target material doped with silver as well as a preparation method and application thereof and belongs to the technical field of preparation of target material. The tin oxide target material is prepared from Ag powder and SnO2 powder, wherein the mass ratio of Ag powder to SnO2 powder is (1:50)-(1:100). Ag is doped in the tin oxide target material to improve the sintering performance of SnO2 based target material and increase the density of the target material, and the density of the target material affects the sputtering rate, and the electrical and optical property of a film. The higher the density of the target material is, the higher the performance of the film is, and the film can better bear the thermal stress during the sputtering process. In addition, the resistance to oxidation of the target material can be improved to prolong the service life of the film.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com