Preparation method of bismuth ferrite-lead titanate-bismuth magnesium niobate ternary system high-temperature piezoelectric ceramic

A bismuth magnesium niobate ternary, high-temperature piezoelectric technology, which is applied in the field of piezoelectric ceramic materials, can solve the problems of high Curie temperature and high-voltage voltage coefficient, and is beneficial to environmental protection and human health, reducing consumption, Effect of improving piezoelectricity and ferroelectricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

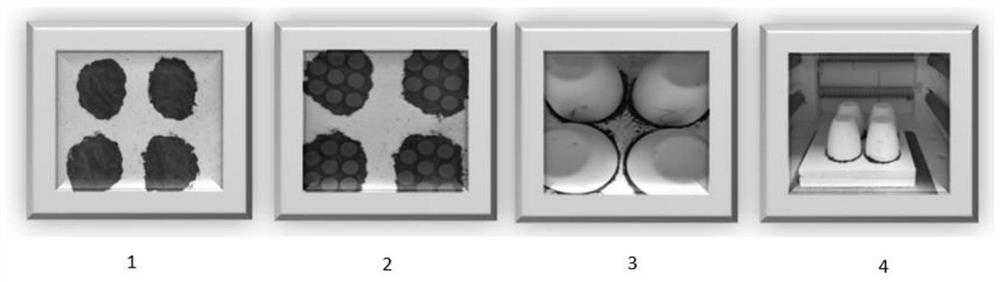

Image

Examples

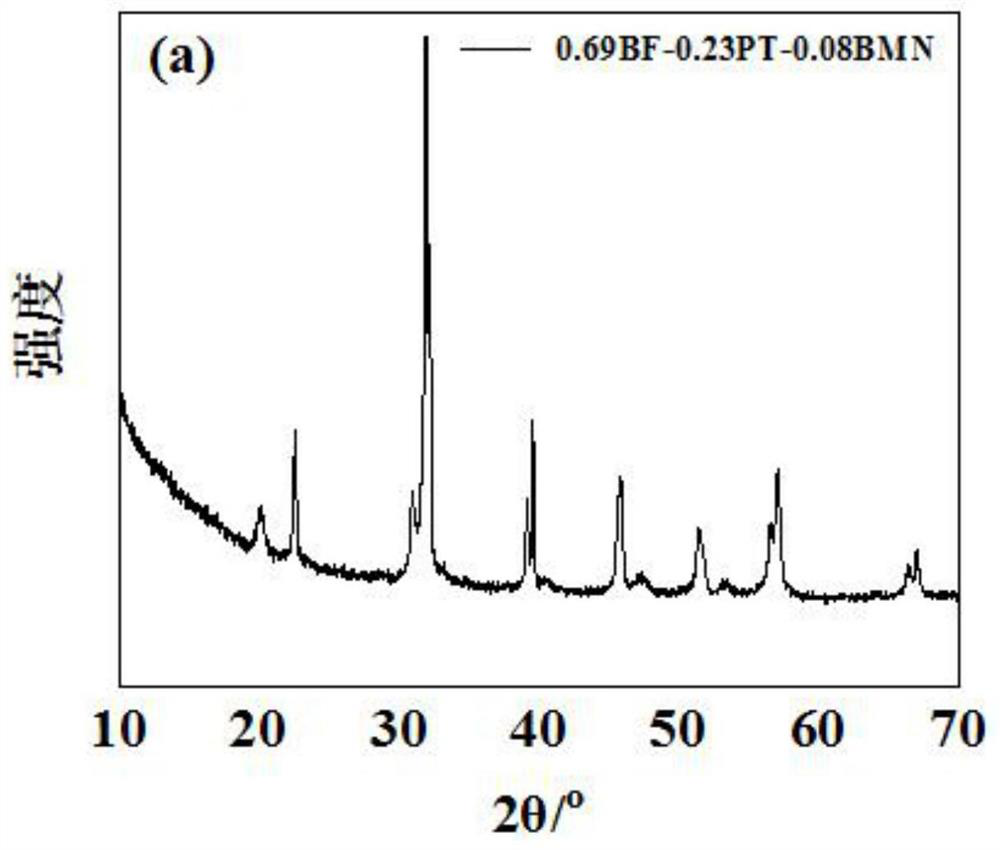

Embodiment 1

[0064] A bismuth ferrite-lead titanate-bismuth magnesium niobate ternary system high-temperature piezoelectric ceramic, the components of which are selected as: 0.69BiFeO 3 -0.08Bi(Mg 2 / 3 Nb 1 / 3 )O 3 -0.23PbTiO 3 , the preparation steps include:

[0065] Step S1: Weigh raw materials: according to the chemical formula 0.69BiFeO 3 -0.23PbTiO 3 -0.08Bi(Mg 2 / 3 Nb 1 / 3 )O 3 , secondary component 0.01Bi 2 o 3 +0.01MnO+0.01PbO were weighed separately: 39g main component + 1g auxiliary component;

[0066] Step S2: Primary ball milling: Put the raw materials weighed in step S1 into the ball milling tank, add absolute ethanol as the ball milling medium, the ball milling body is zirconia pellets, the weight of the zirconia pellets is 125g, and perform the first ball milling with a ball mill Ball milling, the ball milling time is 12h;

[0067] Step S3: Drying: Take out the slurry after the first ball milling in step S2 and put it into an oven for rapid drying. The temperature o...

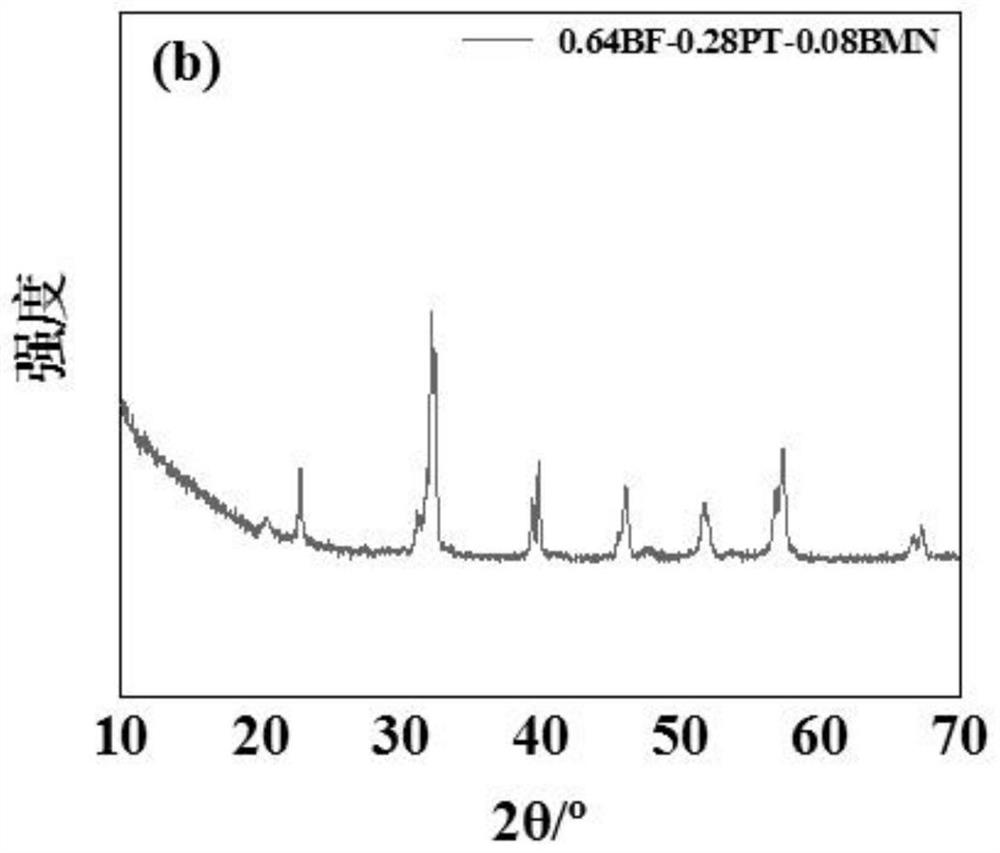

Embodiment 2

[0080] A bismuth ferrite-lead titanate-bismuth magnesium niobate ternary system high-temperature piezoelectric ceramic, the components of which are selected as: 0.64BiFeO 3 -0.08Bi(Mg 2 / 3 Nb 1 / 3 )O 3 -0.28PbTiO 3 , the preparation steps include:

[0081] Step S1: Weigh raw materials: according to the chemical formula 0.69BiFeO 3 -0.23PbTiO 3 -0.08Bi(Mg 2 / 3 Nb 1 / 3 )O 3 , secondary component 0.01Bi 2 o 3 +0.01MnO+0.01PbO were weighed separately: 39g main component + 1g auxiliary component;

[0082] Step S2: Primary ball milling: Put the raw materials weighed in step S1 into the ball milling tank, add absolute ethanol as the ball milling medium, the spheroidal ink body is zirconia balls, the weight of zirconia balls is 125g, and use the ball mill for the first time Ball milling, the ball milling time is 12h;

[0083] Step S3: Drying: Take out the slurry after the first ball milling in step S2 and put it into an oven for rapid drying. The temperature of the oven is 87°...

Embodiment 3

[0096] A bismuth ferrite-lead titanate-bismuth magnesium niobate ternary system high-temperature piezoelectric ceramic, the components of which are selected as: 0.62BiFeO 3 -0.08Bi(Mg 2 / 3 Nb 1 / 3 )O 3 -0.3PbTiO 3 , the preparation steps include:

[0097] Step S1: Weigh raw materials: according to the chemical formula 0.69BiFeO 3 -0.23PbTiO 3 -0.08Bi(Mg 2 / 3 Nb 1 / 3 )O 3 , secondary component 0.01Bi 2 o 3 +0.01MnO+0.01PbO were weighed separately: 39g main component + 1g auxiliary component;

[0098] Step S2: Primary ball milling: Put the raw materials weighed in step S1 into the ball milling tank, add absolute ethanol as the ball milling medium, the spheroidal ink body is zirconia balls, the weight of zirconia balls is 125g, and use the ball mill for the first time Ball milling, the ball milling time is 12h;

[0099] Step S3: Drying: Take out the slurry after the first ball milling in step S2 and put it into an oven for rapid drying. The temperature of the oven is 87°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com