High-Q-value lithium titanate-based microwave dielectric ceramic material and preparation method thereof

A technology of microwave dielectric ceramics and lithium titanate, which is applied in the field of ceramic materials, can solve problems such as not meeting production requirements, and achieve the effects of improving sintering characteristics, simple preparation process and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

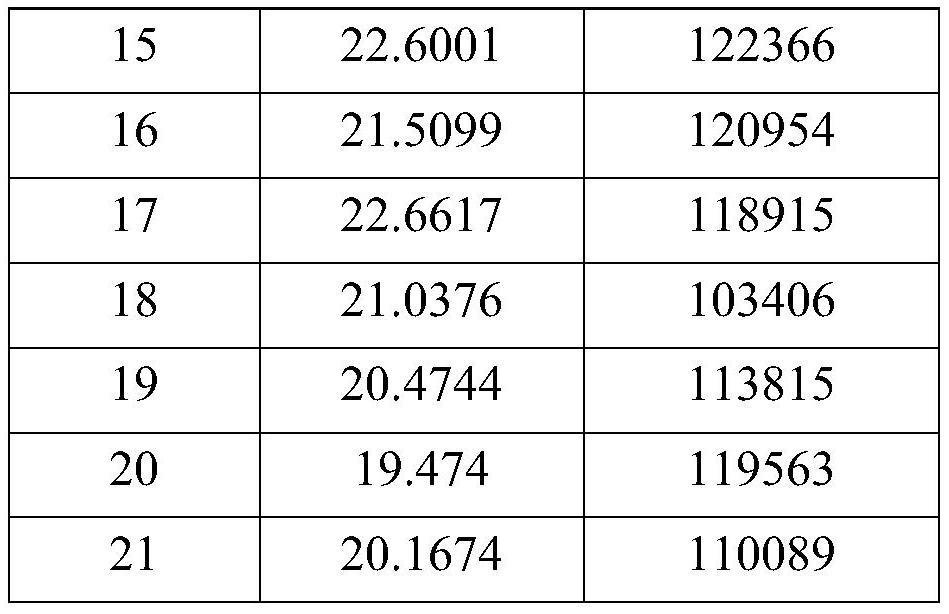

Image

Examples

Embodiment 1

[0030] (1) Will li 2 CO 3 TiO 2 Mass moon ratio is Li 2 CO 3 TiO 2 = 1: 1 For ingredients, put the powder into the polyester ball grinding tank, the mass ratio of the raw material and deionized water and zirconia balls is 1:30:15, and the ball mill is 400 in the planetary ball mill. / Twist;

[0031] (2) Put the raw material after ball milling of step (1) into a drying tank, drying at 120 ° C for 4 hours, and then 40 mesh sieve;

[0032] (3) Put the powder after the step (2) is placed in a medium temperature furnace, pre-fever at 900 ° C, heat insulation for 4 hours, synthesis Li 2 TIO 3 , Then cross 40 sieves;

[0033] (4) Sex (3) The amount of mass percentage of the powder is 8% as the binder, which is 80 mesh sieve;

[0034] (5) Powder the powder pressurizing machine of step (4) is pressed under 2 MPa pressure;

[0035] (6) Sintering the green body of step (5) at 1140 ° C, 8 hours, resulting in a lithium titanate microwave medium ceramic material of the present embodiment;

[0...

Embodiment 2

[0038] (1) Will li 2 CO 3 TiO 2 Mass moon ratio is Li 2 CO 3 TiO 2 = 1: 1 For ingredients, put the powder into the polyester ball grinding tank, the mass ratio of the raw material and deionized water and zirconia balls is 1:30:15, and the ball mill is 400 in the planetary ball mill. / Twist;

[0039] (2) Put the raw material after ball milling of step (1) into a drying tank, drying at 120 ° C for 4 hours, and then 40 mesh sieve;

[0040] (3) Put the powder after the step (2) is placed in a medium temperature furnace, pre-fever at 850 ° C, heat insulation for 4 hours, synthesis Li 2 TIO 3 , Then cross 40 sieves;

[0041] (4) MGF with a mass percentage content of 1% by weight of the powder after sieving step (3) 2 Mixing, the mixed powder is placed in a polyester ball grinding tank, and the mass ratio of the feedstock and deionized water and zirconia balls is 1:30:15, and the ball mill is 400 / 400 / Split;

[0042] (5) Put the raw material after ball milling of step (4) into the dryi...

Embodiment 3

[0048] According to the method of Example 2, a titanate-based microwave medium ceramic material was prepared and the microwave dielectric properties of the resulting article were tested, wherein the pre-stench time in step (3) was 950 ° C, which was 8 hours; step (4) added MGF with a mass percentage of 1.5 wt% 2 The sintering temperature in step (8) was 1120 ° C, and the remaining process conditions were the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com