Low temperature co-fired ceramic (LTCC)-based metamaterial harmonic oscillator and manufacturing method thereof

A harmonic oscillator and metamaterial technology, applied in the field of filters, can solve the problems of high loss and difficulty in mastering, and achieve the effects of reducing loss, reducing sintering temperature, and preventing delamination and warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

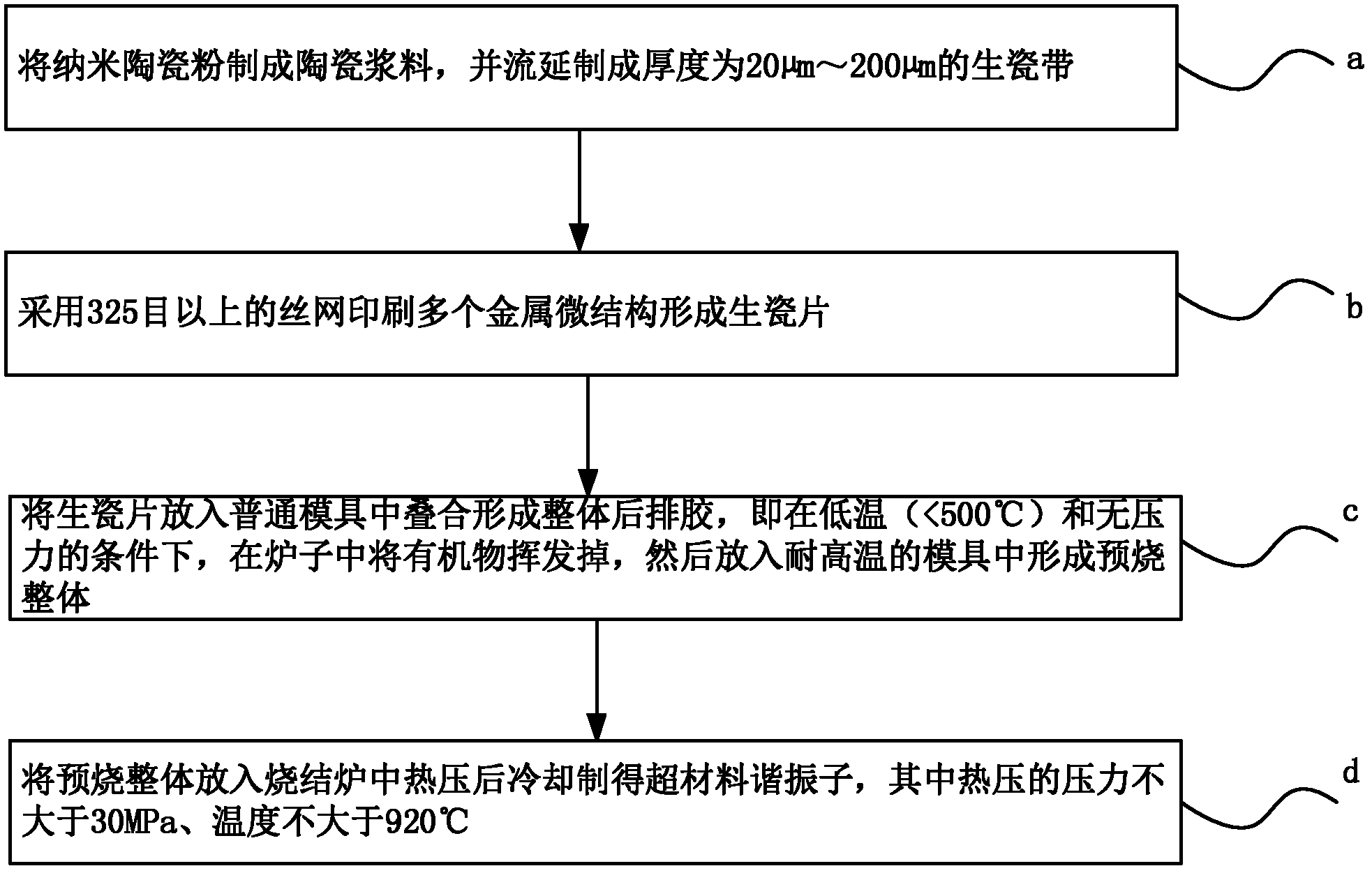

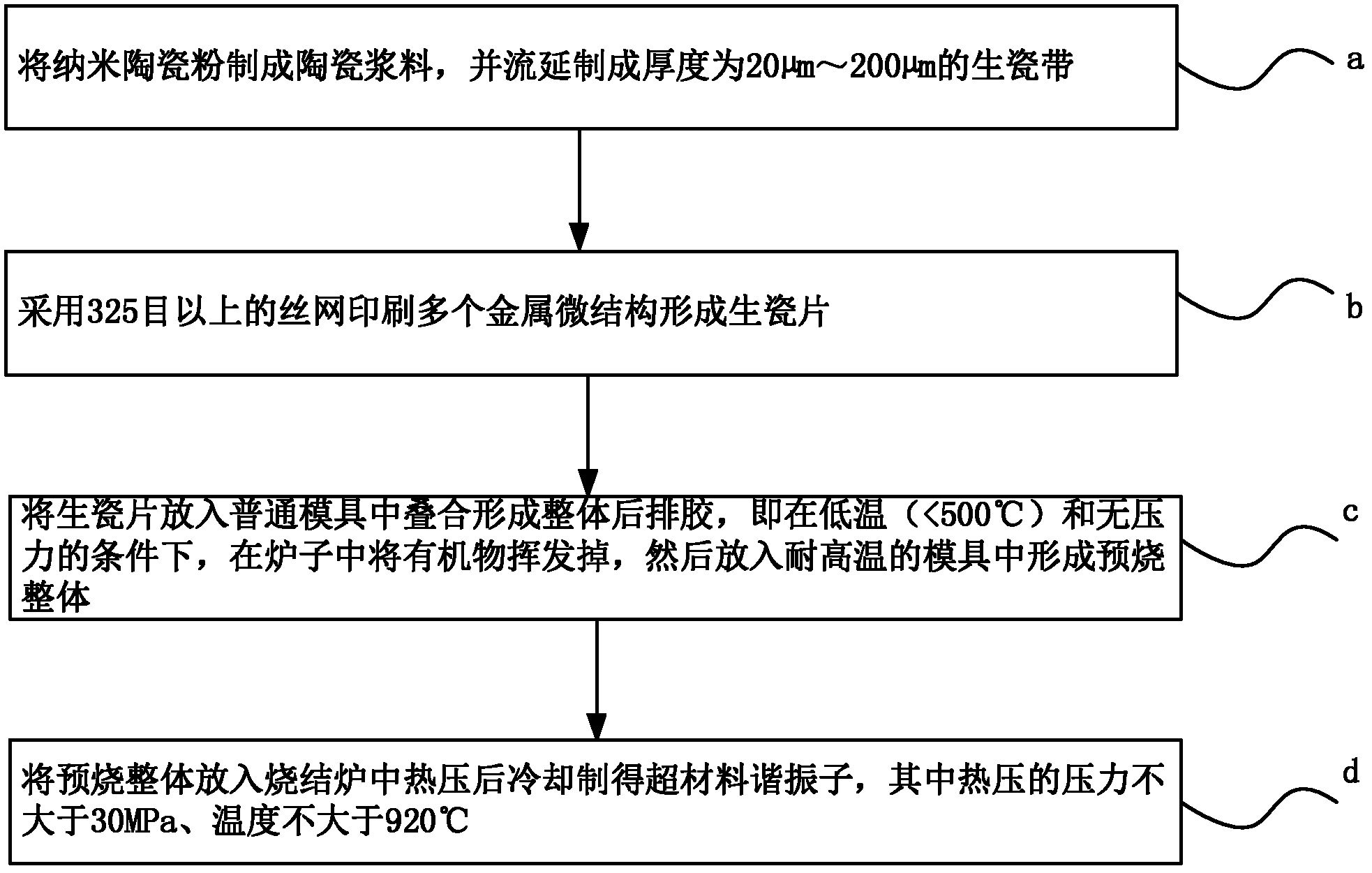

[0019] A kind of preparation method of the metamaterial harmonic oscillator based on LTCC, described preparation method comprises the following steps: as figure 1 shown

[0020] a. Making nano-ceramic powder into ceramic slurry, and casting it into a green ceramic belt with a thickness of 20 μm to 200 μm;

[0021] Wherein the nano-ceramic powder can be prepared by the sol-gel method, and can also be prepared by other methods;

[0022] b. Use a screen printing of more than 325 mesh to form a green ceramic sheet with multiple metal microstructures;

[0023] c. Put the green ceramic sheets into the ordinary mold and stack them to form a whole, and then discharge the glue, that is, under the condition of low temperature (<500°C) and no pressure, the organic matter is volatilized in the furnace, and then put into a high temperature resistant mold Form a pre-fired whole;

[0024] d. Put the pre-fired whole into a sintering furnace and heat press it to make a metamaterial resonato...

Embodiment 1

[0028] ZnNb made by sol-gel method 2 o 6 Nano-ceramic powder, and make ceramic slurry from nano-ceramic powder;

[0029] Cast the ceramic slurry into a green ceramic belt with a thickness of 20 μm, and use a 350-mesh screen to print a number of metal microstructures with a specific shape such as an I-shape to form a green ceramic sheet. The metal used is silver paste or the content of palladium is low. silver palladium paste;

[0030] Put the green ceramic sheets into the ordinary mold and stack them to form the whole adhesive discharge, that is, under the condition of low temperature (<500 ℃) and no pressure, the organic matter is volatilized in the furnace, and then put into the high temperature resistant mold to form the pre-set. Burn the whole;

[0031] The pre-fired whole is put into a sintering furnace and hot-pressed for 0.5-2 hours, and then cooled to obtain a metamaterial resonator, wherein the hot-pressing pressure is 28MPa and the temperature is 900°C.

Embodiment 2

[0033] Preparation of BaTi by sol-gel method 4 o 9 Nano-ceramic powder, and make ceramic slurry from nano-ceramic powder;

[0034] Cast the ceramic slurry into a green ceramic belt with a thickness of 100 μm, and use a 400-mesh screen to print multiple metal microstructures with specific shapes such as I-shaped to form a green ceramic sheet. The metal used is silver paste or palladium content is low silver palladium paste;

[0035] Put the green ceramic sheets into the ordinary mold and stack them to form the whole adhesive discharge, that is, under the condition of low temperature (<500 ℃) and no pressure, the organic matter is volatilized in the furnace, and then put into the high temperature resistant mold to form the pre-set. Burn the whole;

[0036] The pre-fired whole is put into a sintering furnace and hot-pressed for 0.5-2 hours, and then cooled to obtain a metamaterial resonator, wherein the hot-pressing pressure is 28MPa and the temperature is 920°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com