Method for preparing wide-working-temperature-zone thermostabilization composite dielectric ceramic

A composite medium and thermally stable technology, which is applied in the field of electronic information materials and components, can solve the problems of not meeting thermal stability standards, narrow working temperature range, and inability to meet the requirements of high reliability, and achieve nano-powder activity High, excellent dielectric properties, good sintering properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

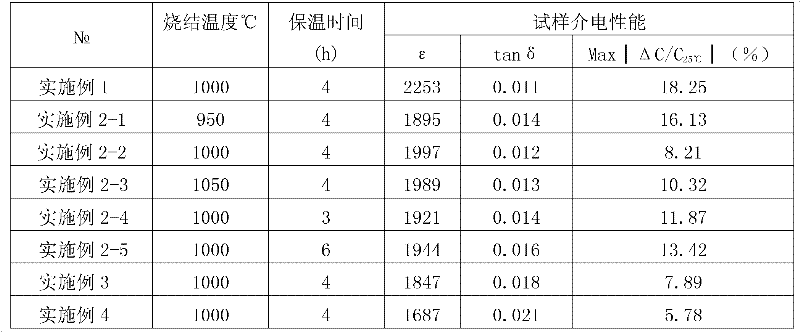

Examples

Embodiment 1

[0021] (1) According to 0.05 (Na 0.5 Bi 0.5 )TiO 3 -0.95BaTiO 3 (x=0.05) stoichiometric ratio, at first dispose bismuth sodium titanate solution, with 0.0025mol dissolving bismuth nitrate pentahydrate in 50ml glacial acetic acid, heat magnetic stirring, make it dissolve, obtain bismuth nitrate solution; Dissolve 0.0025mol anhydrous acetic acid Sodium was dissolved in 50ml of glacial acetic acid, heated and magnetically stirred to dissolve to obtain a sodium acetate solution; 0.005mol tetrabutyl titanate was dissolved in 50ml of absolute ethanol, and magnetically stirred at room temperature for 1 hour to obtain a tetrabutyl titanate solution; Then the bismuth nitrate solution and the sodium acetate solution were respectively added dropwise into the tetrabutyl titanate solution, and magnetically stirred at 70° C. for 2 hours to obtain a clear sodium bismuth titanate sol.

[0022] (2) According to the stoichiometric ratio in step (1), configure barium titanate solution again, ...

Embodiment 2-1

[0028] (1) According to 0.1 (Na 0.5 Bi 0.5 )TiO 3 -0.9BaTiO 3 (x=0.1) stoichiometric ratio, at first dispose bismuth sodium titanate solution, with 0.005mol dissolving bismuth nitrate pentahydrate in 50ml glacial acetic acid, heat magnetic stirring, make it dissolve, obtain bismuth nitrate solution; Dissolve 0.005mol anhydrous acetic acid Sodium was dissolved in 50ml of glacial acetic acid, heated and magnetically stirred to dissolve to obtain a sodium acetate solution; 0.01mol tetrabutyl titanate was dissolved in 50ml of absolute ethanol, and magnetically stirred at room temperature for 1 hour to obtain a tetrabutyl titanate solution; Then the bismuth nitrate solution and the sodium acetate solution were respectively added dropwise into the tetrabutyl titanate solution, and magnetically stirred at 70° C. for 2 hours to obtain a clear sodium bismuth titanate sol.

[0029] (2) According to the stoichiometric ratio in step (1), configure barium titanate solution again, dissol...

Embodiment 2-2

[0035] Step (6) is "sintering at 950°C and keeping it warm for 4 hours to obtain (Na 0.5 Bi 0.5 )TiO 3 -BaTiO 3 Composite dielectric ceramics. ", other processes are the same as embodiment 2-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com