Method for producing mixed oxides comprising lithium

A technology of mixed oxides and lithium compounds, applied in chemical instruments and methods, nickel compounds, cobalt compounds, etc., can solve the problems of high production capacity, low production capacity, unsuitable scale, etc., and achieve good sintering properties, high production capacity, and scale-up effect of scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

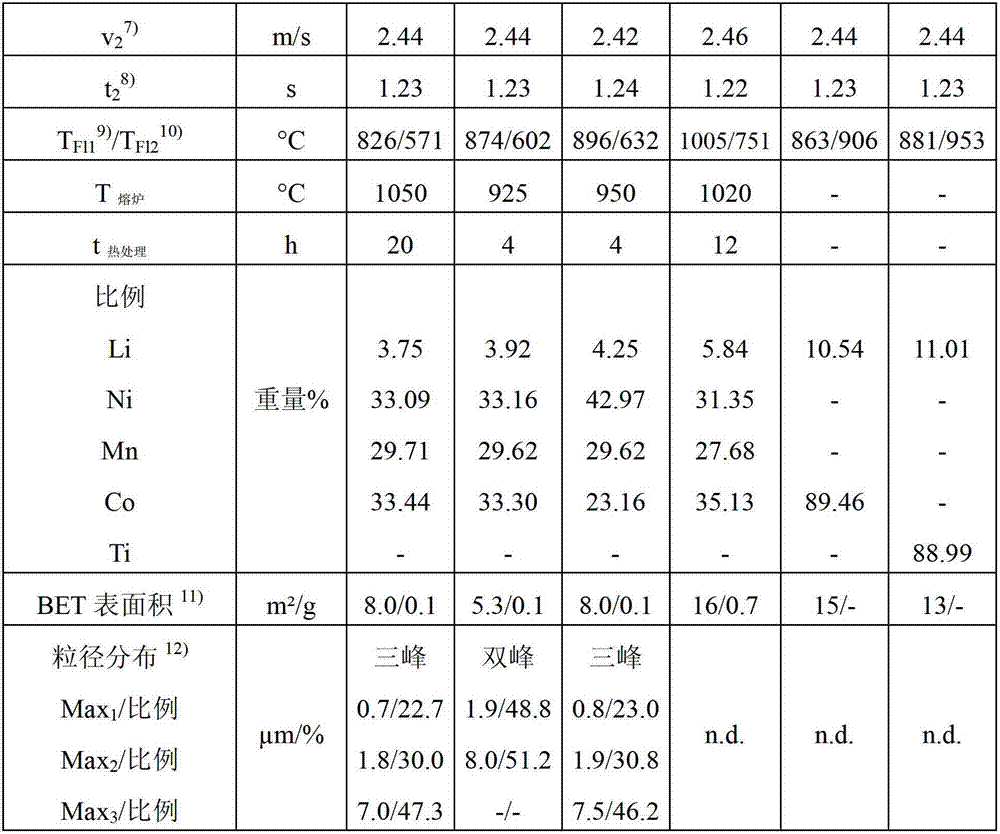

[0030] analyze:

[0031] d from the cumulative distribution curve of the volume-average particle size distribution 50 . This is determined in a conventional manner by means of laser light scattering. For the purposes of the present invention, a Cilas 1064 instrument from Cilas was used for this purpose. d 50 is the value at which 50% of the mixed oxide particles A are in the indicated particle size range. d 90 is the value at which 90% of the mixed oxide particles A are in the indicated particle size range. d 99is the value at which 99% of the mixed oxide particles A are in the indicated particle size range.

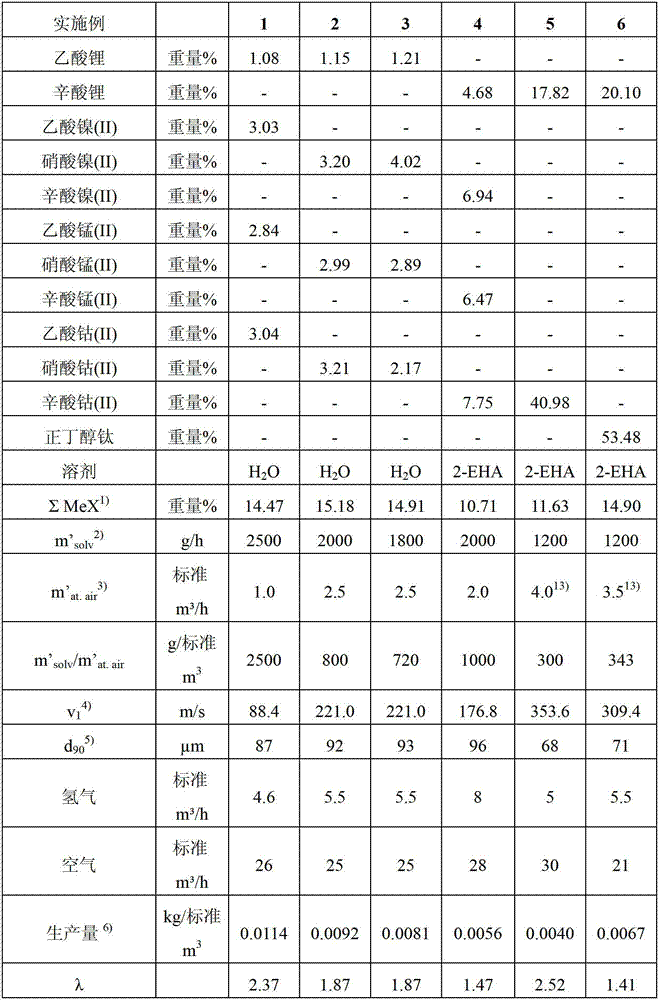

[0032] Solutions used: For Examples 1-6, solutions comprising the salts described in Table 1 were prepared in each case with water or 2-ethylhexanoic acid (2-EHA) as solvent.

[0033] An aerosol is produced from said solution by means of atomizing gas and a nozzle and atomized into the reaction space. Here, hydrogen and air H 2 / O 2 The flame burns and the ae...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com