Potassium-sodium niobate-based leadless piezoelectric material and preparation thereof

A potassium-sodium niobate-based, lead-free piezoelectric technology is applied in the field of functional ceramic preparation, which can solve the problems of inability to obtain compactness, reduce the temperature stability of piezoelectric properties of potassium-sodium niobate-based ceramics, and achieve enhanced overall electrical properties. , The effect of increasing the upper limit of sintering temperature and reducing polarization leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

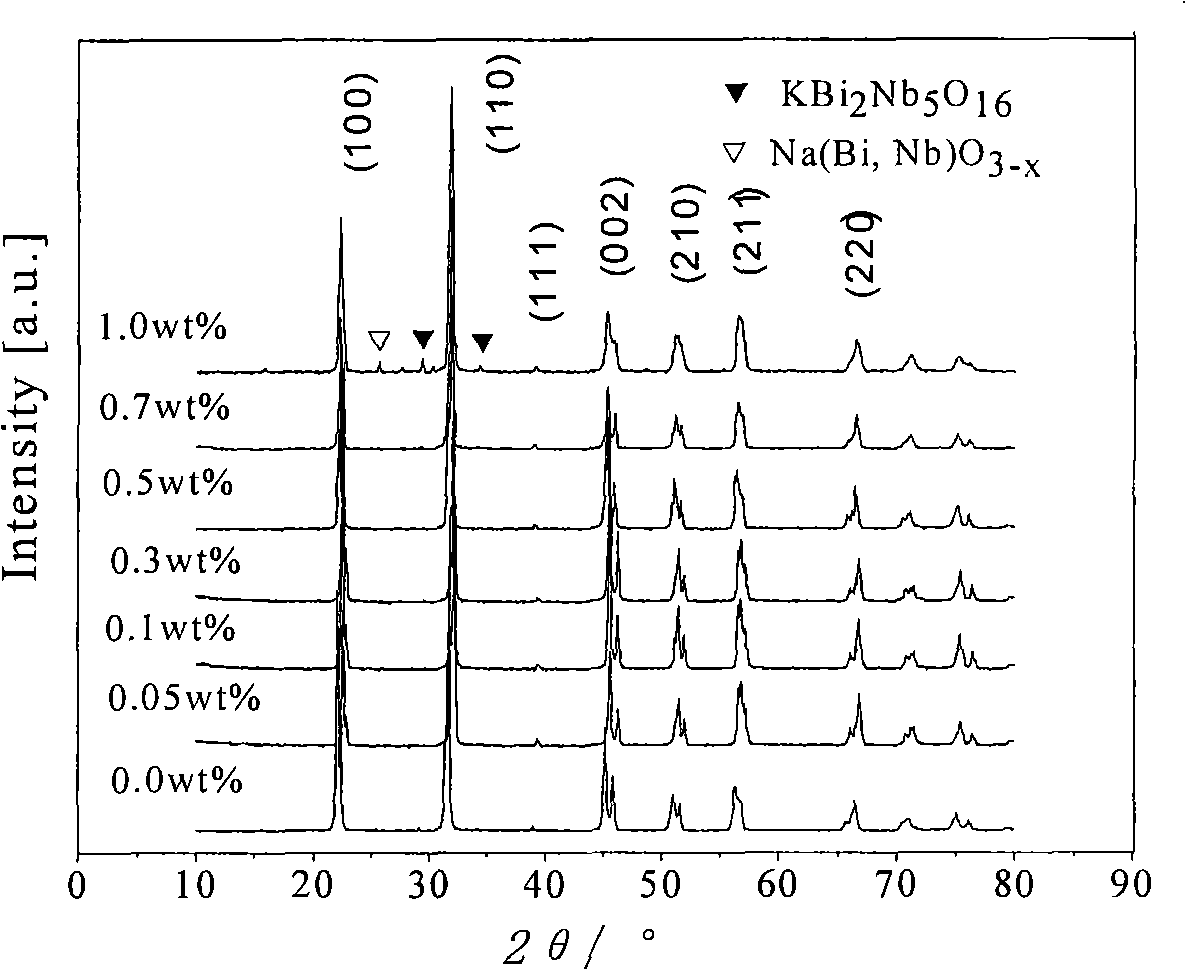

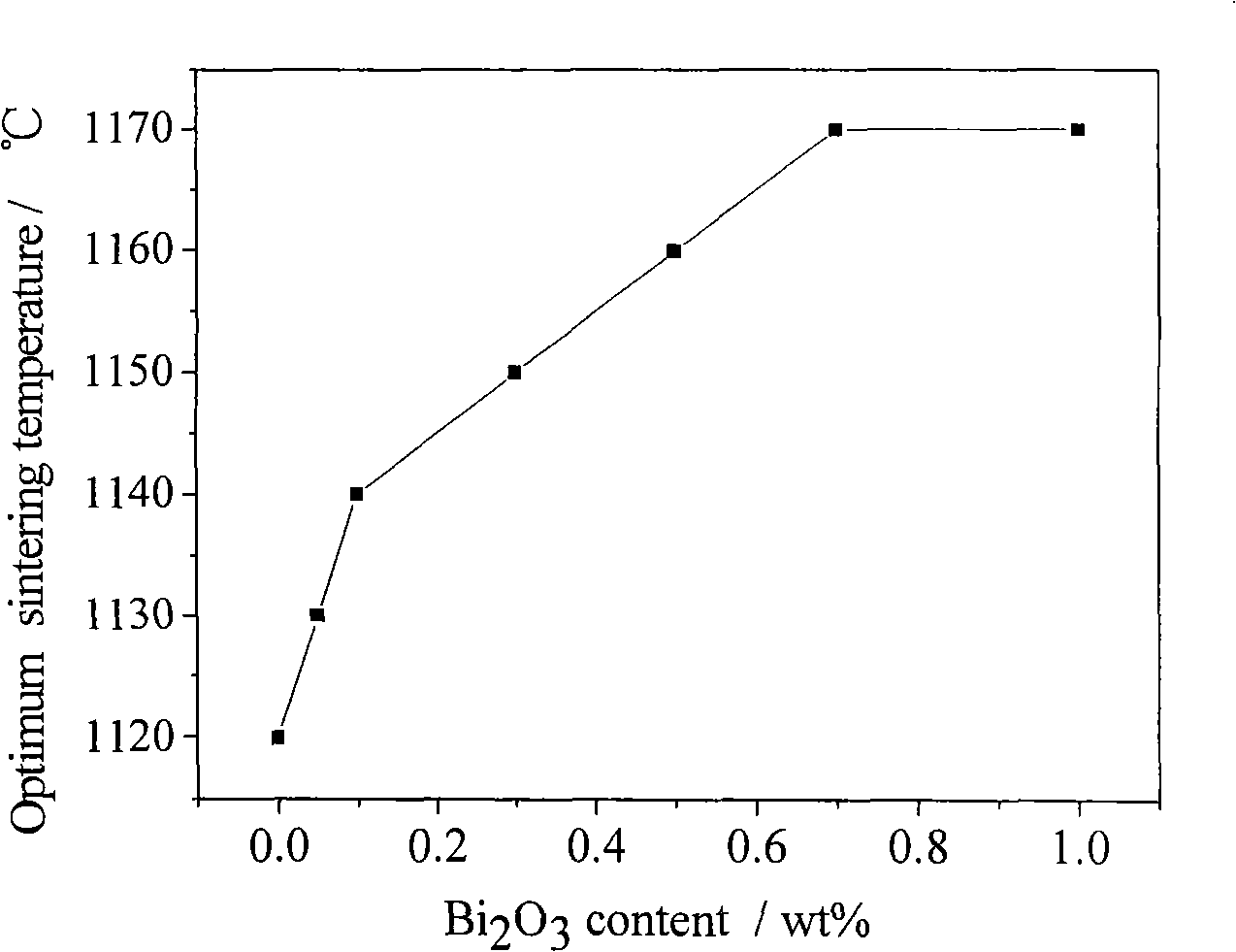

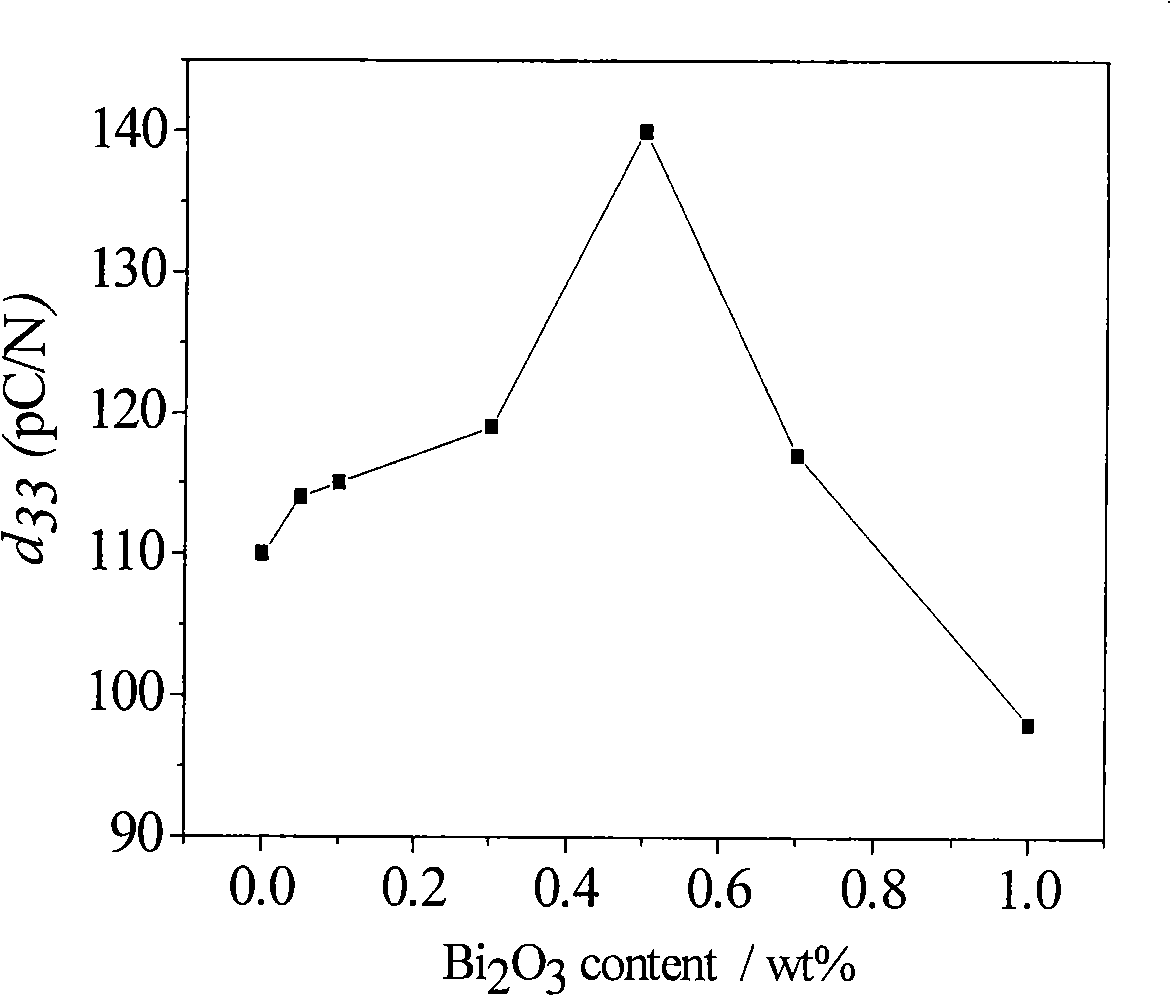

[0025] The raw material of present embodiment comprises anhydrous potassium carbonate, anhydrous sodium carbonate, niobium pentoxide and bismuth trioxide, and its stoichiometric ratio is (K 0.5 Na 0.5 )NbO 3 .

[0026] The preparation process of this embodiment is:

[0027] (1) Analytical pure anhydrous potassium carbonate, anhydrous sodium carbonate, and niobium pentoxide were dried at 150°C for 5 hours, and the stoichiometric ratio was (Na 0.5 K 0.5 )NbO 3 ingredients.

[0028] (2) The raw material is ZrO in ethanol 2The ball is a medium planetary ball mill for 24 hours, dried and ground to obtain a dry powder. Keep the obtained powder in the air at 900°C for 5 hours. The calcined powder is manually ground and calcined again in the air at 900°C for 5 hours. After grinding and sieving, the potassium sodium niobate powder with perovskite phase is obtained.

[0029] (3) Put the pre-burned potassium sodium niobate powder in ethanol for another 12 hours and mix it by plan...

Embodiment 2

[0036] The raw material of present embodiment comprises anhydrous potassium carbonate, anhydrous sodium carbonate, niobium pentoxide and bismuth trioxide, and its stoichiometric ratio is (K 0.5 Na 0.5 )NbO 3 -0.1wt% Bi 2 o 3 .

[0037] The preparation process of this embodiment is:

[0038] (1) Analytical pure anhydrous potassium carbonate, anhydrous sodium carbonate, and niobium pentoxide were dried at 150°C for 5 hours, and the stoichiometric ratio was (Na 0.5 K 0.5 )NbO 3 ingredients.

[0039] (2) The raw material is ZrO in ethanol 2 The ball is a medium planetary ball mill for 24 hours, dried and ground to obtain a dry powder. Keep the obtained powder in the air at 850°C for 4 hours. The calcined powder is manually ground and calcined again in the air at 950°C for 4 hours. After grinding and sieving, the potassium sodium niobate powder with perovskite phase is obtained.

[0040] (3) the potassium sodium niobate powder and bismuth trioxide will be calcined accordi...

Embodiment 3

[0047] The raw material of present embodiment comprises anhydrous potassium carbonate, anhydrous sodium carbonate, niobium pentoxide and bismuth trioxide, and its stoichiometric ratio is (K 0.5 Na 0.5 )NbO 3 -0.3wt% Bi 2 o 3 .

[0048] The preparation process of this embodiment is:

[0049] (1) Analytical pure anhydrous potassium carbonate, anhydrous sodium carbonate, and niobium pentoxide were dried at 150°C for 5 hours, and the stoichiometric ratio was (Na 0.5 K 0.5 )NbO 3 ingredients.

[0050] (2) The raw material is ZrO in ethanol 2 The ball is a medium planetary ball mill for 24 hours, dried and ground to obtain a dry powder. Keep the obtained powder in the air at 900°C for 5 hours. The calcined powder is manually ground and calcined again in the air at 900°C for 5 hours. After grinding and sieving, the potassium sodium niobate powder with perovskite phase is obtained.

[0051] (3) the potassium sodium niobate powder and bismuth trioxide will be calcined accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com