Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

206results about How to "High degree of densification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

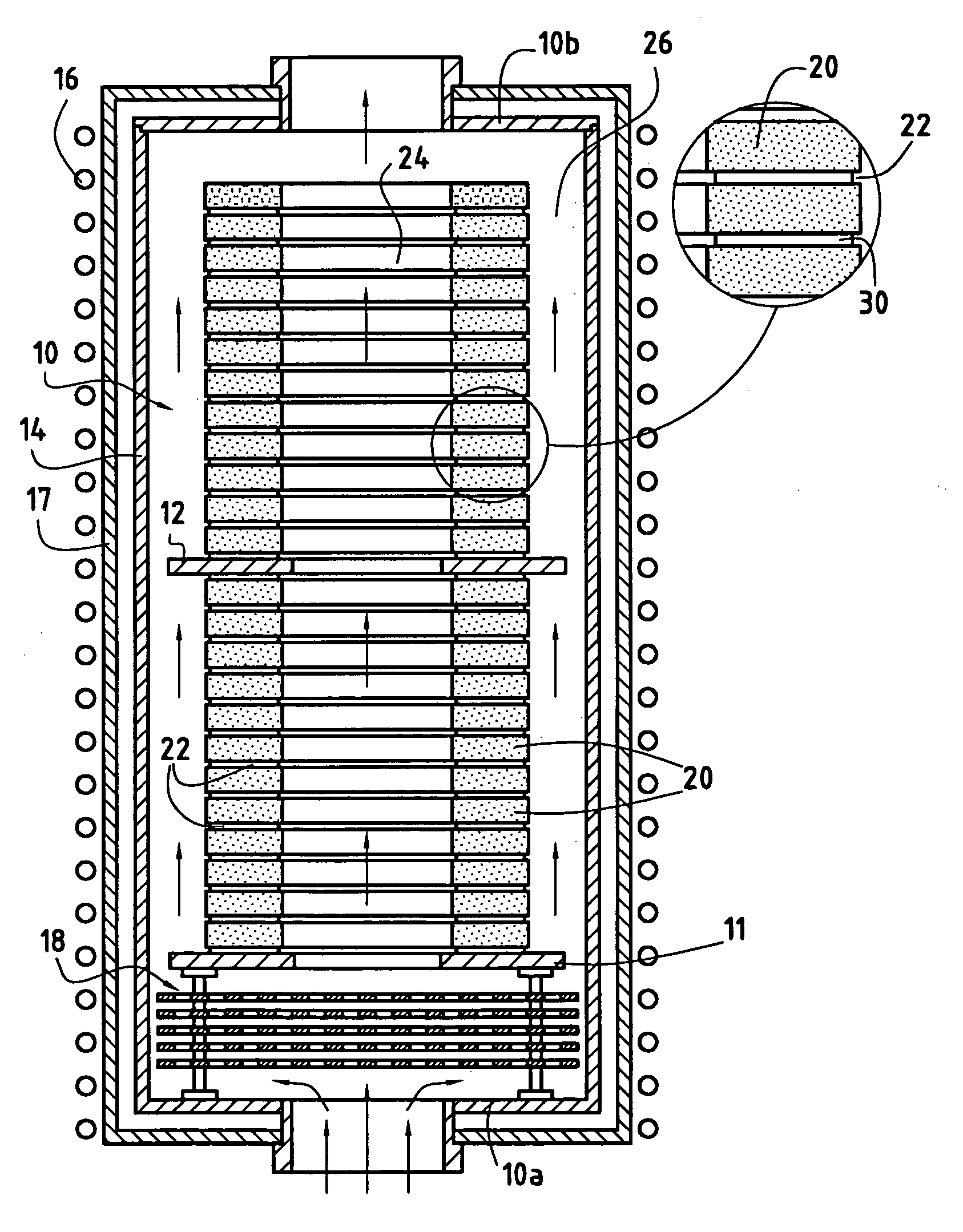

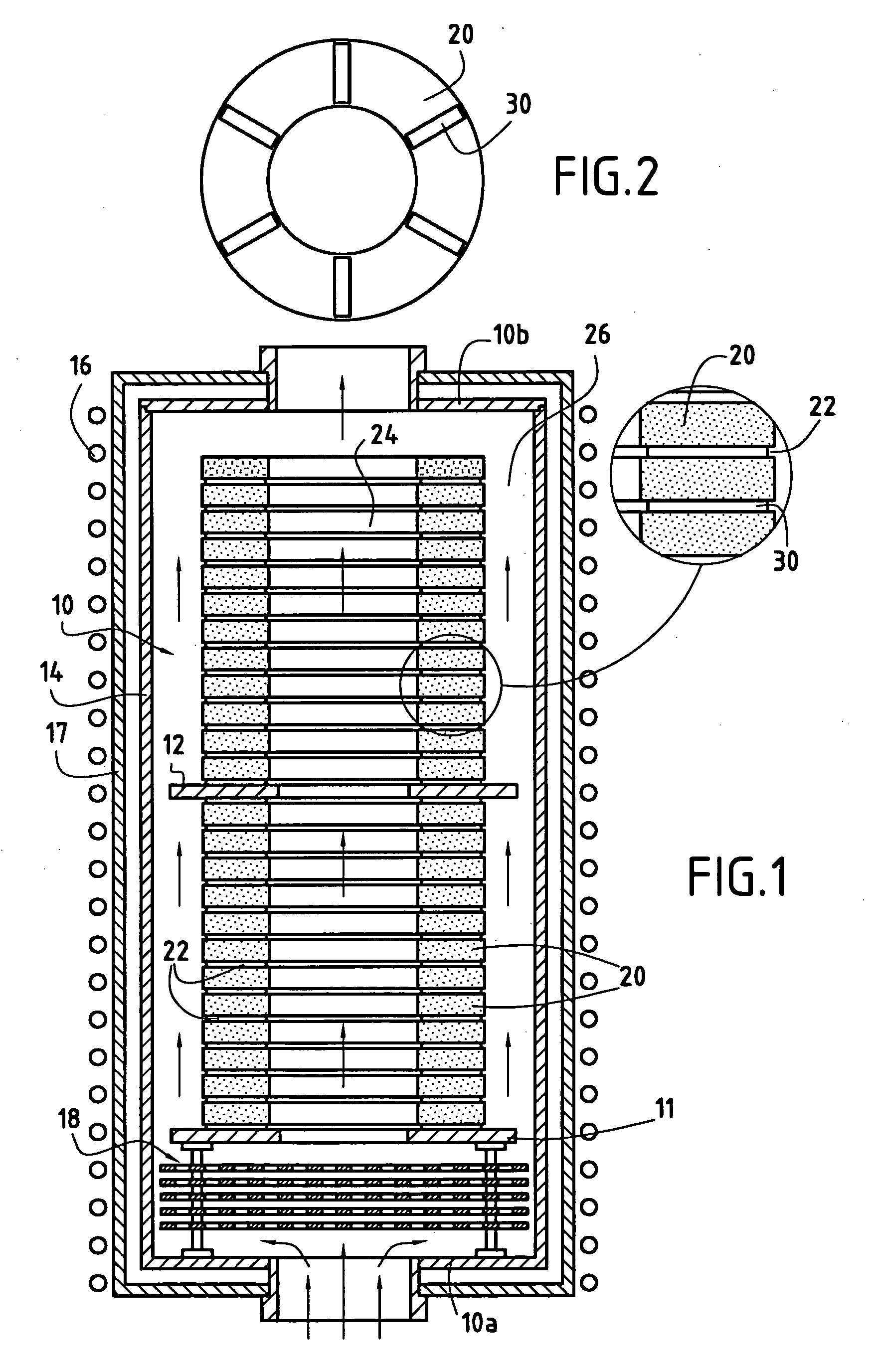

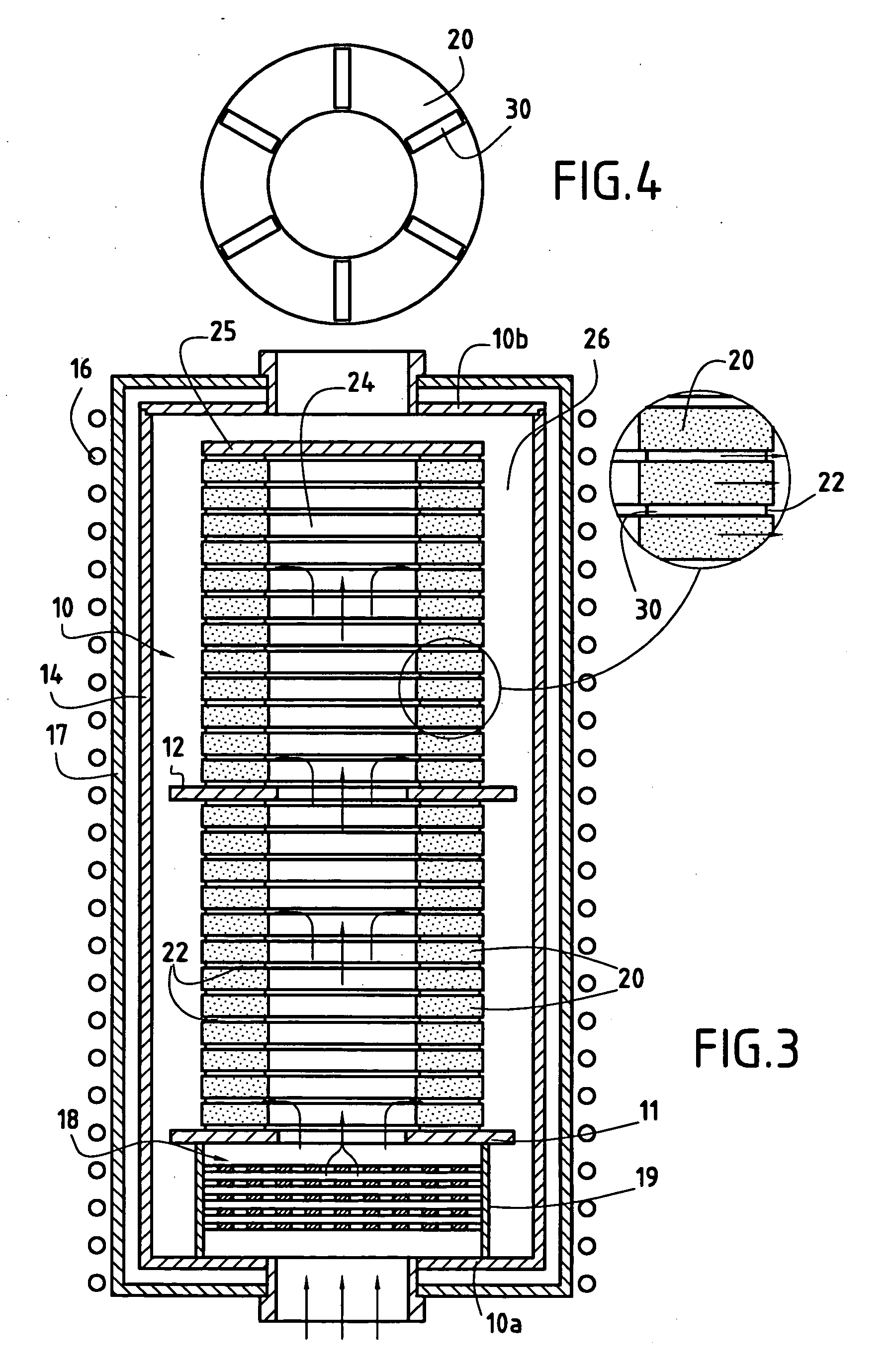

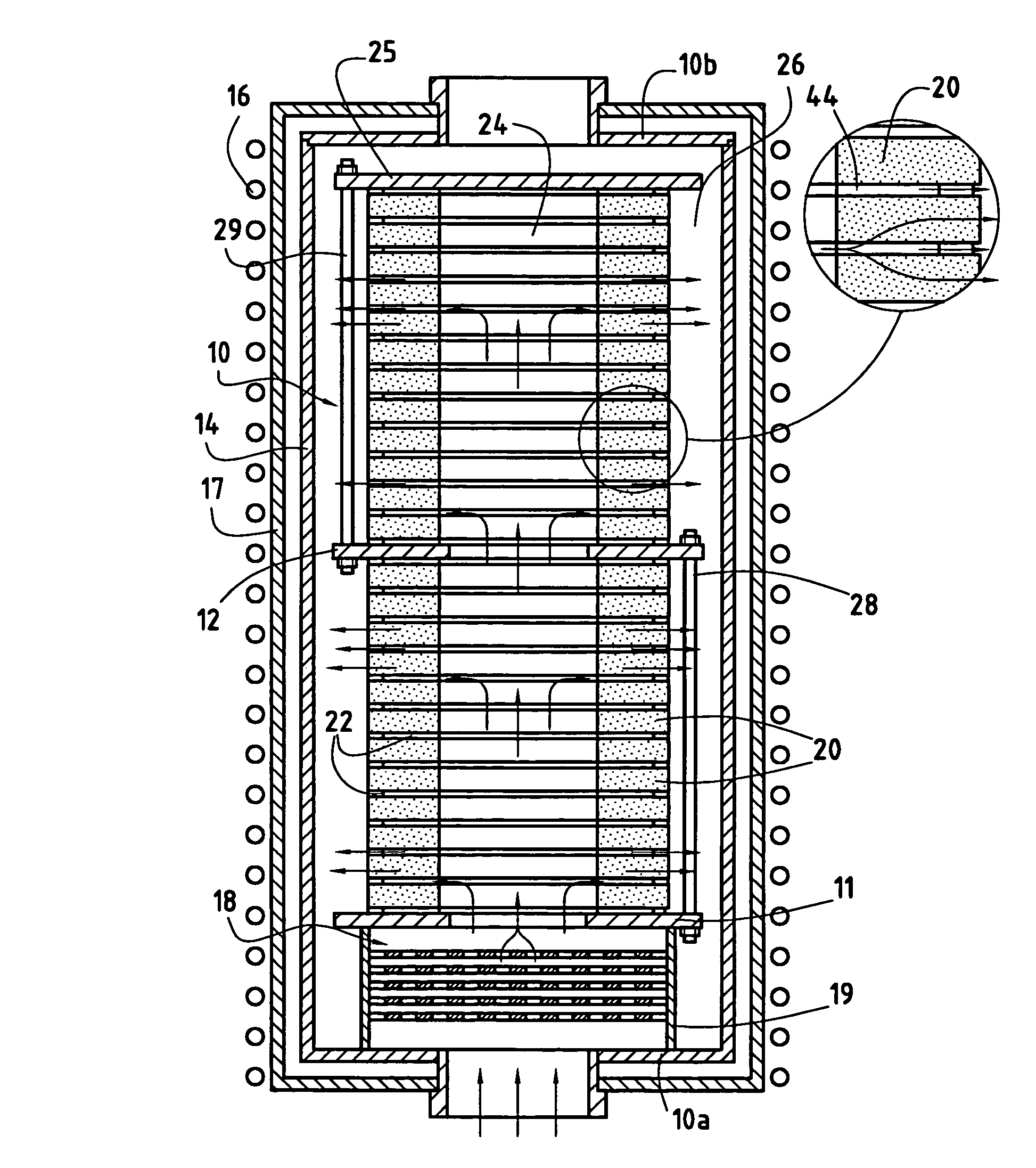

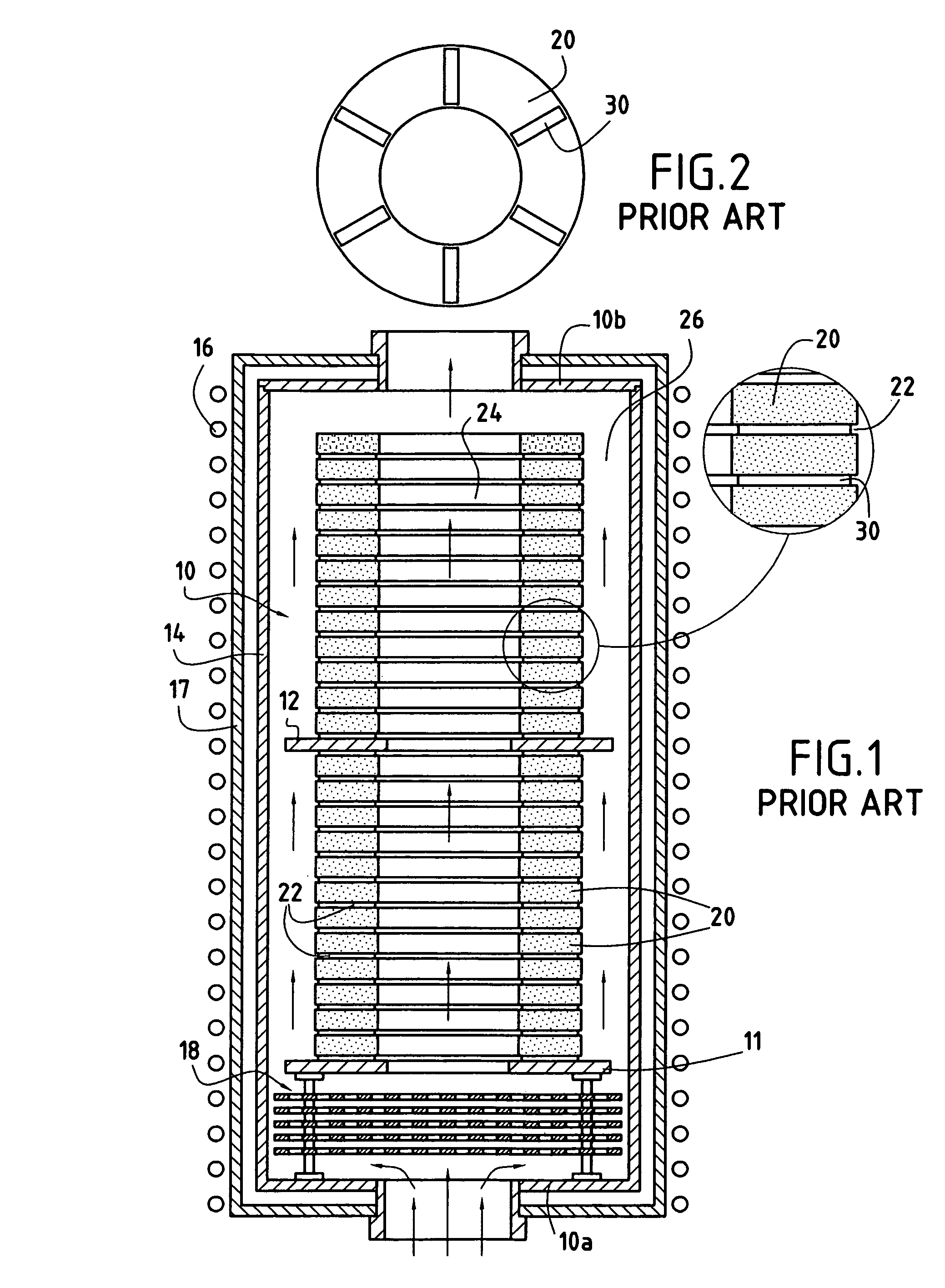

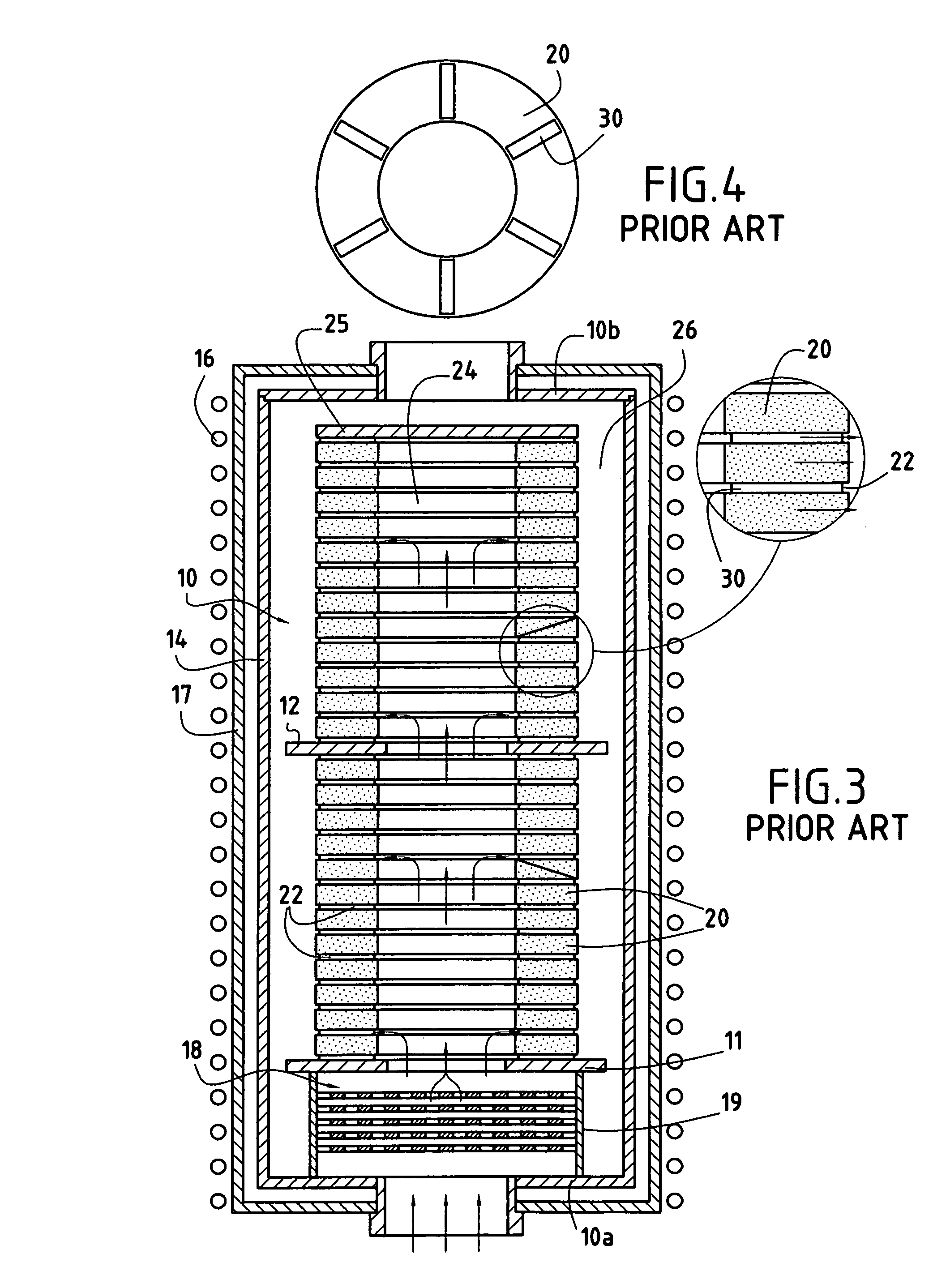

Chemical vapour infiltration method for densifying porous substrates having a central passage

InactiveUS20040071877A1High degree of densificationSolid state diffusion coatingAircraft braking arrangementsPorous substrateGas phase

Annular substrates (20) are stacked in an enclosure where they define an inside volume (24) and an outer volume (26) outside the stack. A gas containing at least one precursor of a matrix material to be deposited within the pores of the substrates is channeled inside the enclosure to a first one (24) of the two volumes, and a residual gas is extracted from the enclosure from the other one (26) of the volumes. One or more leakage passages (22) allow the volumes to communicate with each other, other than through the substrates. The total section of the leakage passages has a value lying between a minimum value for ensuring that a maximum gas pressure in the first volume is not exceeded until the end of densification, and a maximum value such that a pressure difference is indeed established between the two volumes from the beginning of densification.

Owner:SAFRAN CERAMICS SA

Chemical vapor infiltration method for densifying porous substrates having a central passage

InactiveUS7182980B2High degree of densificationAvoid disadvantagesSolid state diffusion coatingAircraft braking arrangementsPorous substrateGas phase

Annular substrates (20) are stacked in an enclosure where they define an inside volume (24) and an outer volume (26) outside the stack. A gas containing at least one precursor of a matrix material to be deposited within the pores of the substrates is channeled inside the enclosure to a first one (24) of the two volumes, and a residual gas is extracted from the enclosure from the other one (26) of the volumes. One or more leakage passages (22) allow the volumes to communicate with each other, other than through the substrates. The total section of the leakage passages has a value lying between a minimum value for ensuring that a maximum gas pressure in the first volume is not exceeded until the end of densification, and a maximum value such that a pressure difference is indeed established between the two volumes from the beginning of densification.

Owner:SAFRAN CERAMICS SA

High-strength high-conductivity oxidation-resisting low-silver copper-base alloy and preparation thereof

A copper base alloy, which possesses high-strength, high conductivity, oxidation resistance and contains silver of low content, is characterized in that said high-strength high-conductivity oxidation-resistance low-silver copper base alloy is composed of low-silver copper base alloy powder, diamond powder of 0.2-1.0% and graphitized nanometer carbon fibre and is prepared through a powder metallurgy technological process, wherein said low-silver copper base alloy powder contains Ag of 0.08 -0.12%, Y, La and Ce of 0.05 -0.5% or one of misch metal or mixture of several misch metal. Said alloy in accordance with the present invention possesses higher intensity and hardness, stronger anti-crackle forming and stomatic expandability, and exhibits definite puddle welding resistance and better electroconductive performances at the same time.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Composite shielding material and preparation method thereof

InactiveCN103276254AImprove neutron shielding performanceNeutron Shielding Performance GuaranteeShieldingGamma rayNeutron

The invention discloses a composite shielding material and a preparation method thereof and aims at solving the problems that when a B4C / Al composite material is used as a shielding material and the content of B4C exceeds a certain percentage, bad mechanical performance, plastically and workability of the material bring great difficulty for preparation of the material to greatly affect the application of the material although the higher the content of the B4C is, the greater and better the shielding effect on thermal neutrons are. The composite shielding material comprises materials prepared from the following raw materials in percentage by weight: 0.01%-5% of B, 0.1%-30% of W-containing substance, 3%-50% of B4C, 40%-90% of aluminum or aluminum alloy and 0-8% of other substances. The composite shielding material has excellent neutron / gamma radiation shielding performance, good mechanical performance and processing performance and high degree of densification and is especially suitable for the field of neutron / gamma ray shielding.

Owner:SICHUAN INST OF MATERIALS & TECH

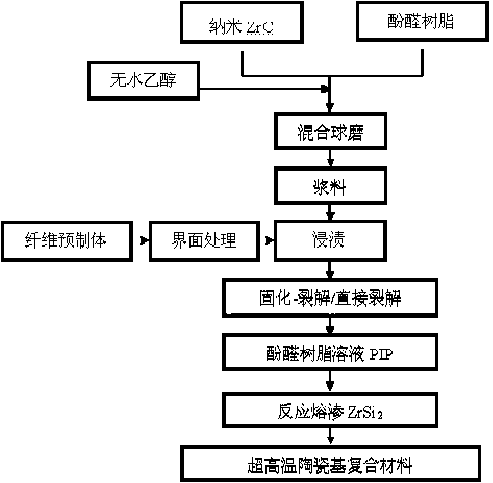

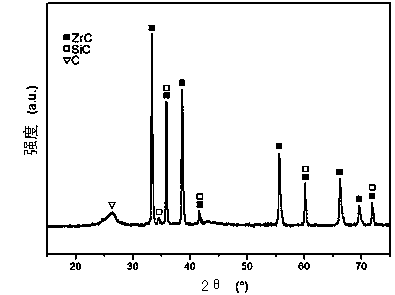

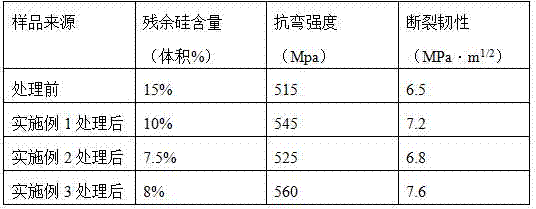

Preparation method for fiber-reinforced superhigh temperature ceramic matrix composite

The invention relates to a preparation method for a fiber-reinforced superhigh temperature ceramic matrix composite. The preparation method comprises the following steps: 1) adopting a slurry infiltration fibrous preform containing nano zirconium carbide and phenolic resin, and obtaining a fibrous tackified preform containing ZrC through curing-splitting or direct splitting; 2) using organic polymer as an organic carbon source precursor to infiltrate the fibrous tackified preform containing the ZrC, and splitting so as to obtain a ZrC-C composite porous intermediate; 3) using zirconium disilicide as a silicon source and a zirconium source to perform infiltration on the porous intermediate at the temperature of 1800-1950 DEG C so as to obtain the fiber-reinforced superhigh temperature ceramic matrix composite.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for enhancing density of SiC/SiC ceramic matrix composite

The invention relates to a method for enhancing density of a SiC / SiC ceramic matrix composite. The method comprises the following steps: (1) a SiC / SiC ceramic matrix composite with a certain densification degree is immersed in slurry, in which an organic precursor and SiC powder are uniformly dispersed, and impregnation is carried out in an environment of 5-10 KPa vacuum degree for 20-50 min; (2) a material which has undergone vacuum impregnation is dried and the dried material undergoes cross-linking and curing; (3) the cross-linked and cured material undergoes pyrolysis treatment; and (4) the material which has undergone pyrolysis treatment further undergoes densification process in the atmosphere of a gaseous precursor containing Si and C elements by a chemical vapor infiltration technology while infiltration temperature is 850-1100 DEG C, pressure intensity is 10-20 KPa and infiltration time is 4-30 h. The method provided by the invention has advantages of simple operation, short densification time, good repeatability and high densification efficiency and has obvious advantages in the aspect of filling material voids. The method is a method with operability and development prospect.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

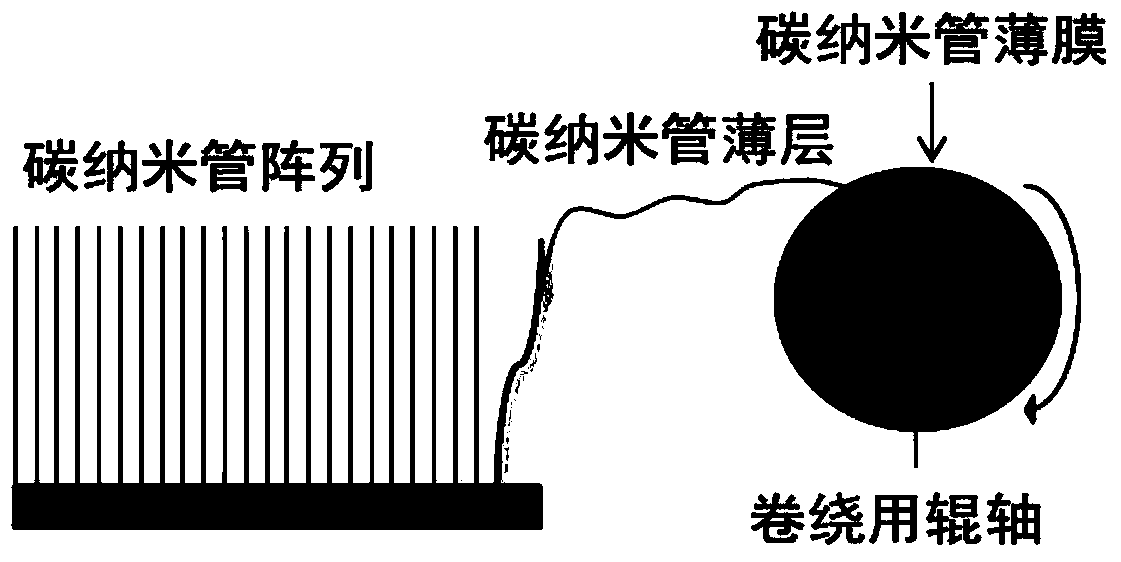

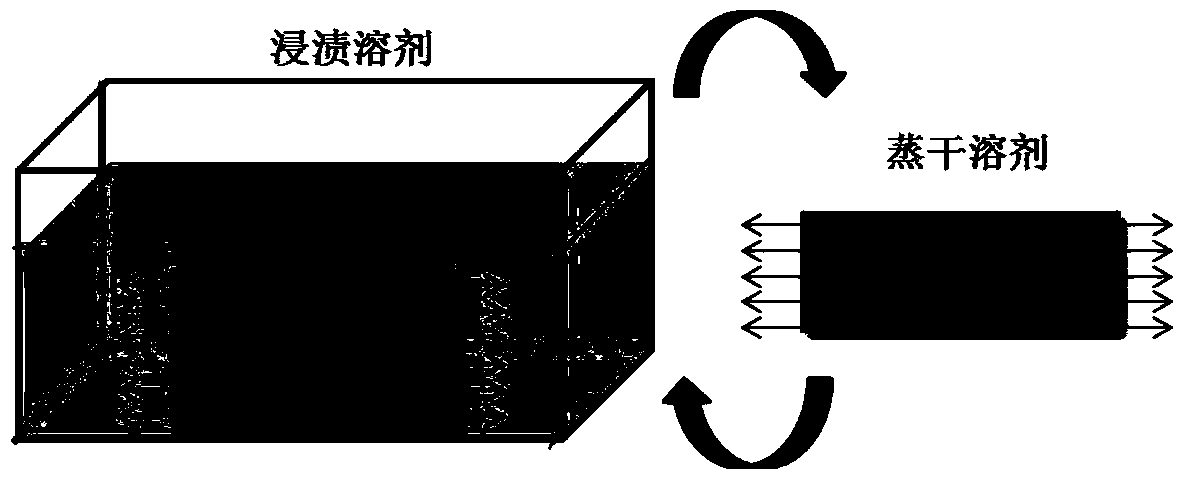

High-oriented high-strength array drawn carbon nanotube film and preparation method thereof

ActiveCN104176722ANot easy to forkHigh degree of densificationMaterial nanotechnologyDistillationCarbon nanotube

The invention discloses a high-oriented high-strength array drawn carbon nanotube film and a preparation method thereof. The preparation method comprises the following steps: firstly, preparing a spinnable carbon nanotube array; then, winding the spinnable carbon nanotube array by using an array film-drawing method so as to obtain a dry-spun oriented carbon nanotube film, and improving the densification and orientation of the dry-spun oriented carbon nanotube film by using a method of solvent impregnating-drying by distillation; and finally, carrying out compaction treatment on the carbon nanotube film so as to obtain a high-oriented high-strength array drawn carbon nanotube film. The preparation method provided by the invention is simple in operation and strong in controllability; and the prepared high-oriented high-strength array drawn carbon nanotube film has a unique internal aggregation structure and excellent mechanical properties, and has great development potential and application value in the fields of structural materials, electronic devices, solar cells, and the like.

Owner:BEIHANG UNIV +1

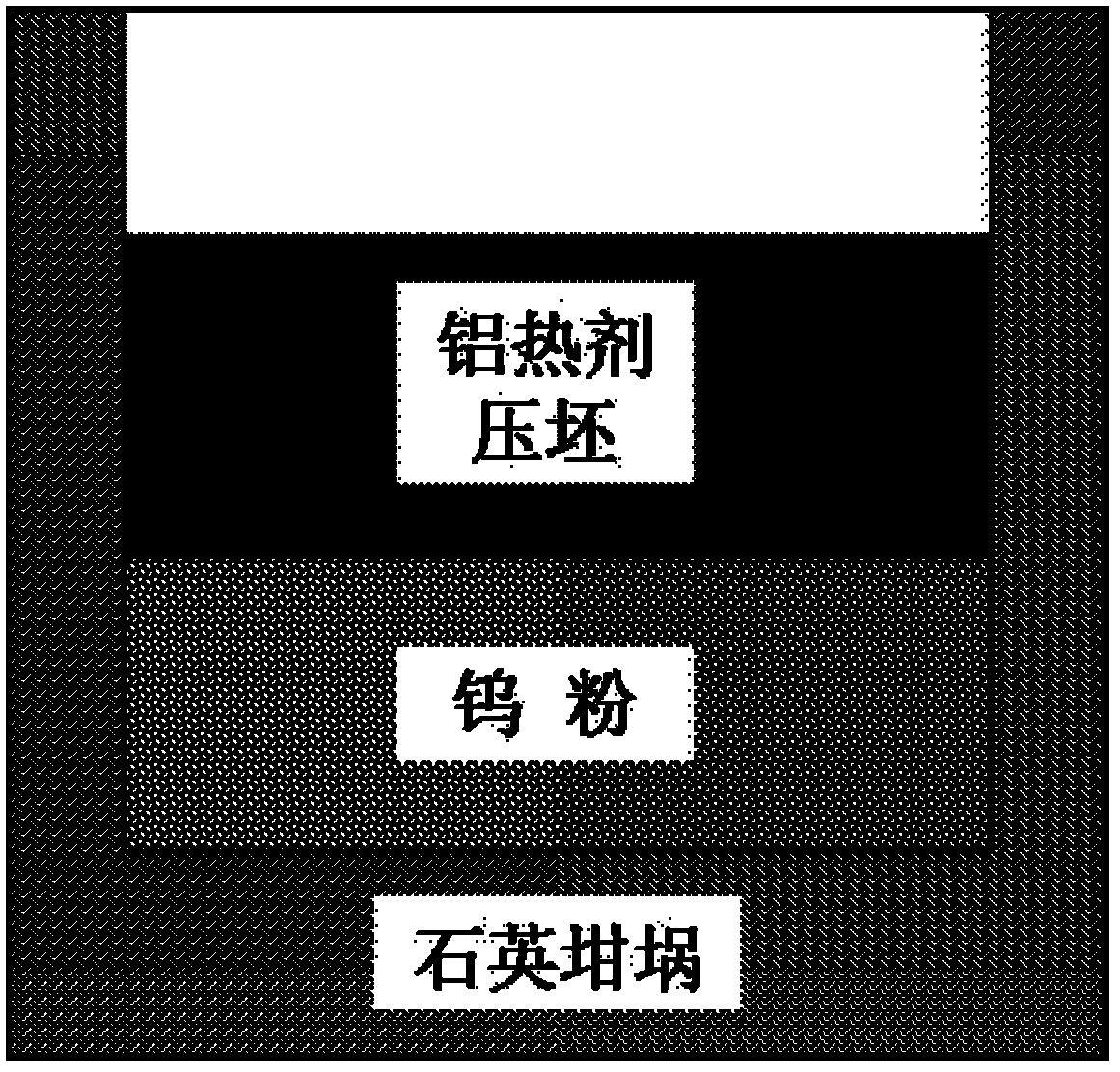

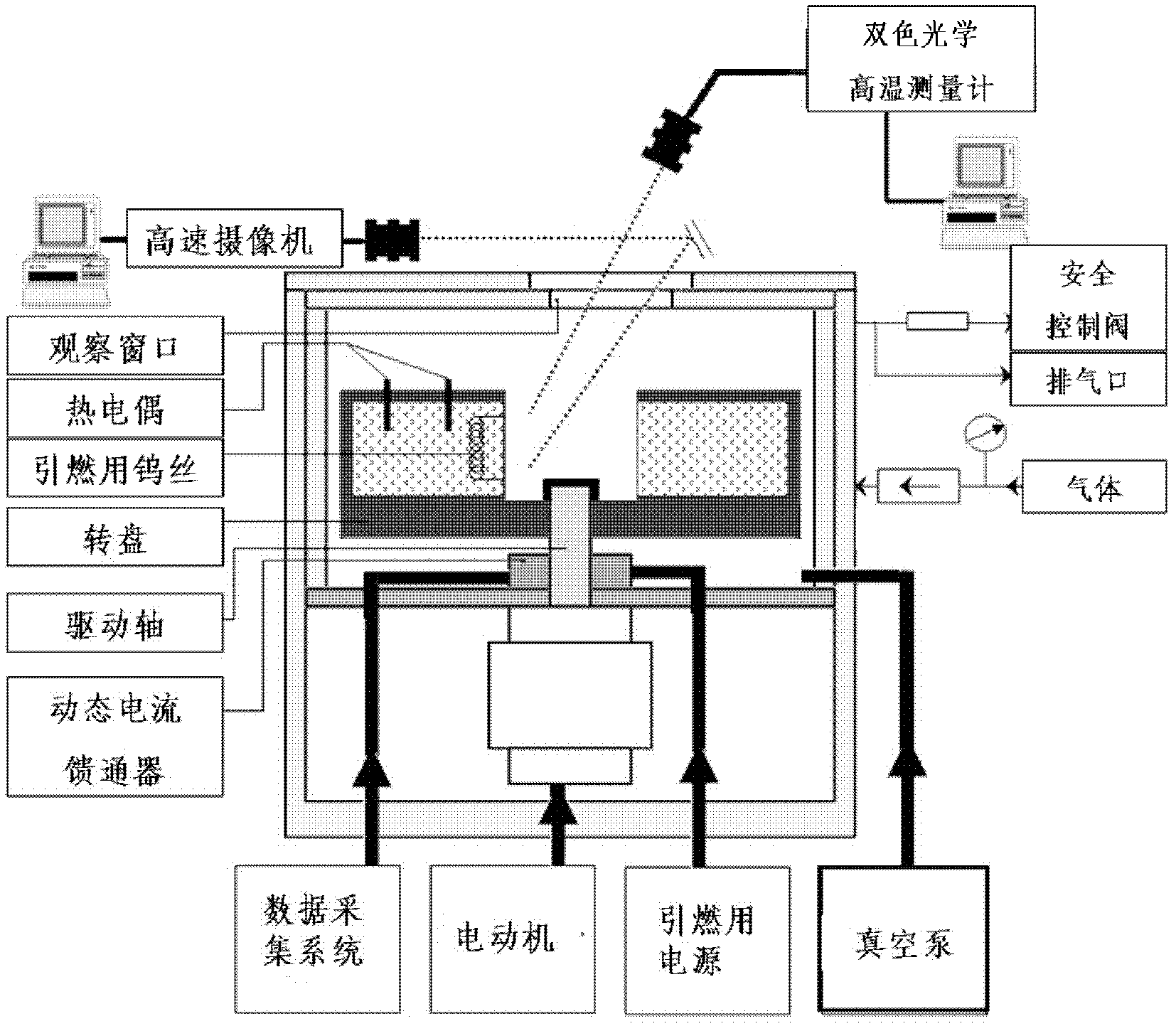

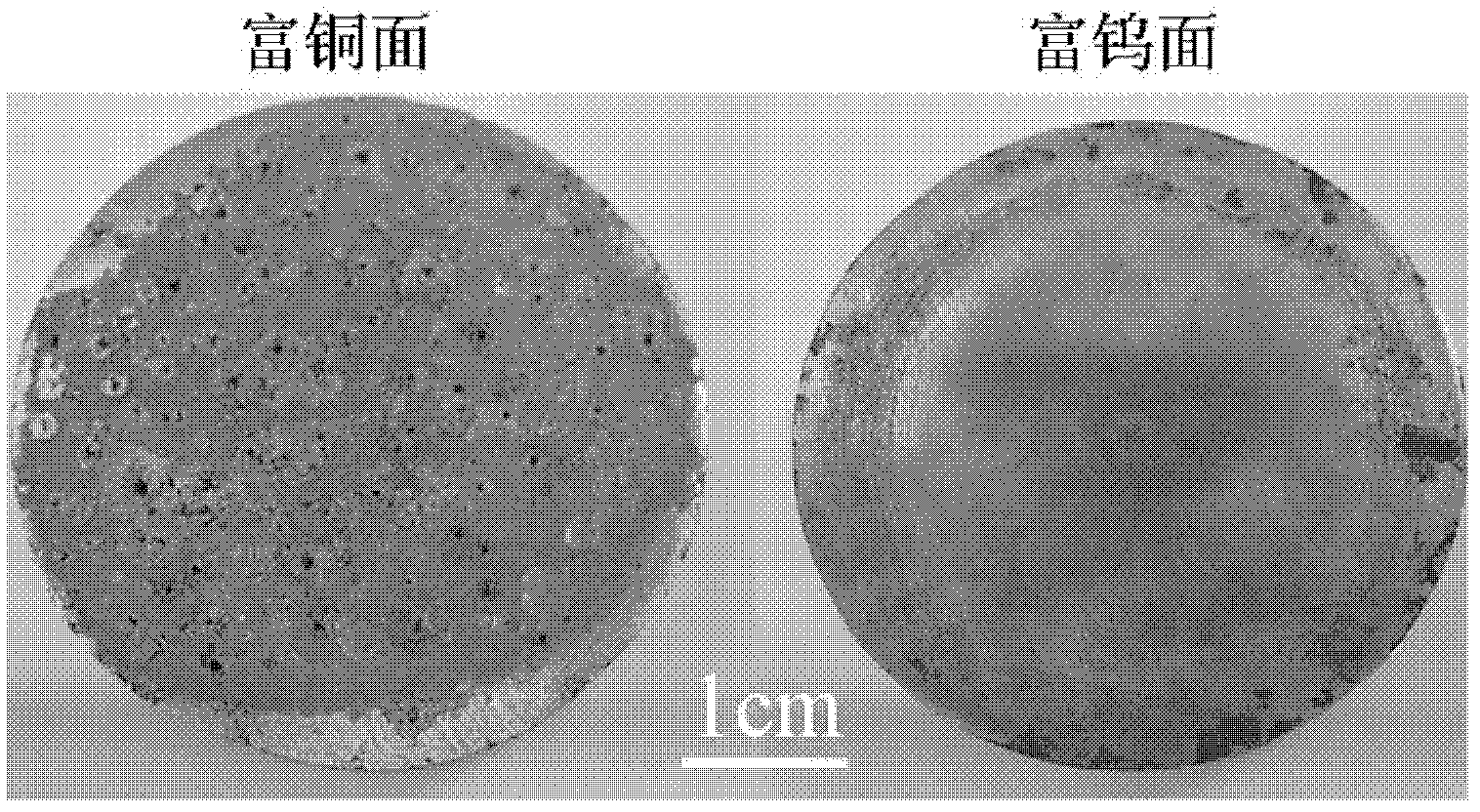

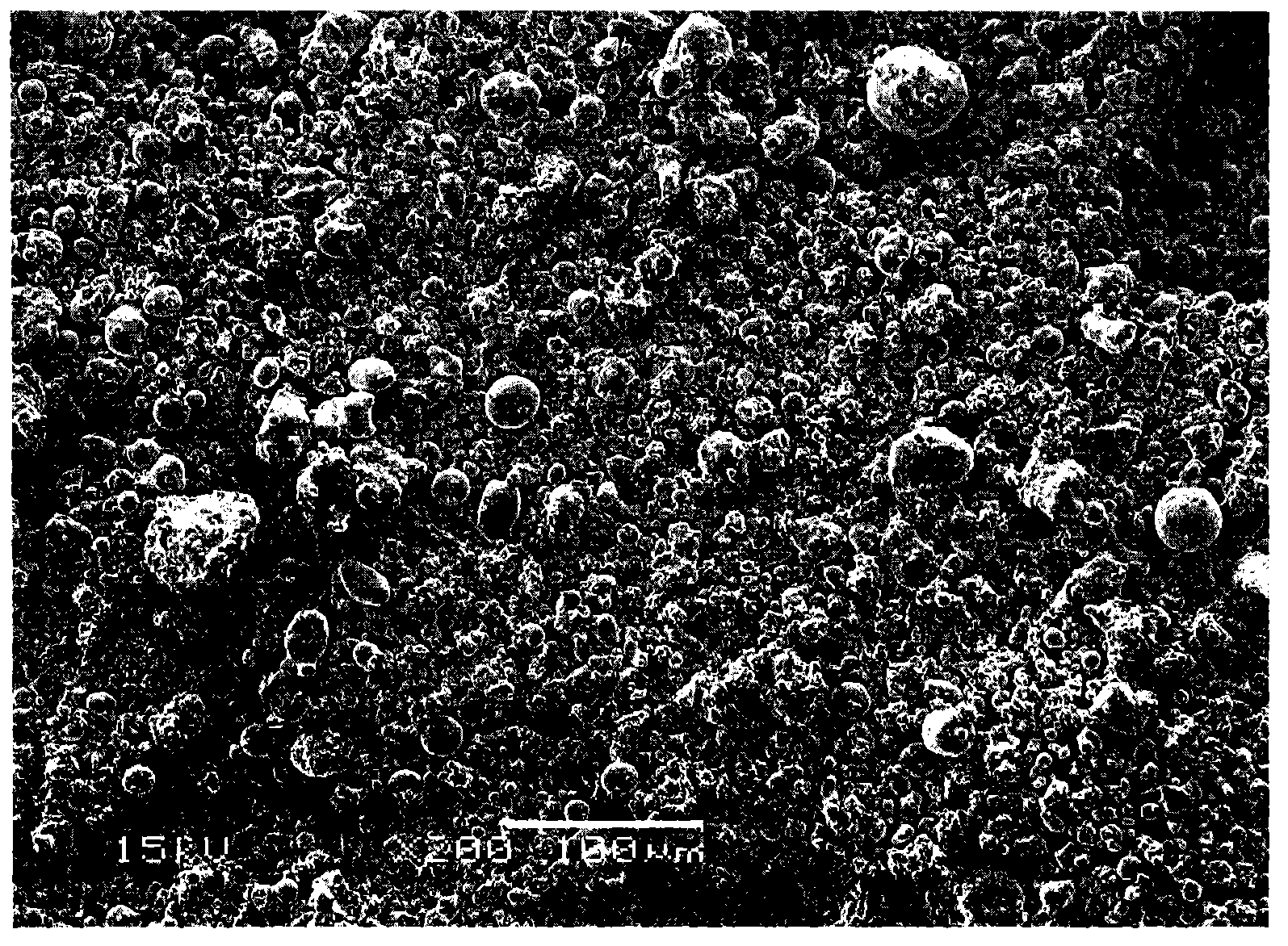

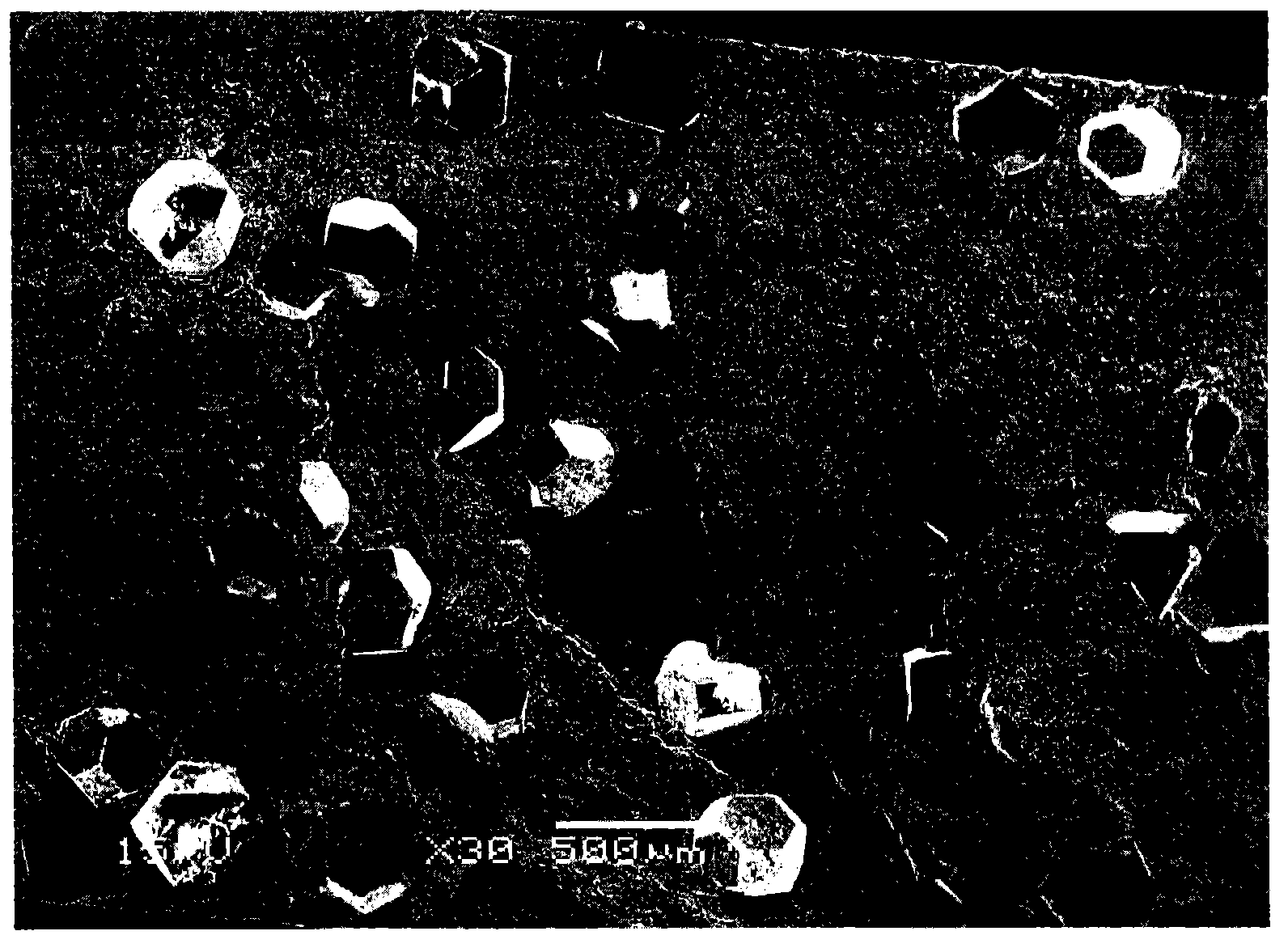

Tungsten/copper gradient material and preparation method thereof

The invention discloses a tungsten / copper gradient material and a preparation method thereof. The tungsten content and copper content in the tungsten / copper gradient material are in continuous gradient distribution, the tungsten content is gradually increased from one side to the other side, and the copper content is gradually reduced; and the gradient material has high densifying degree, uniformmicrostructure, continuous ingredient gradient distribution and good overall performance. The preparation method comprises the following steps of: loosely loading W powder to the bottom of a quartz crucible; mixing Al powder and Cu2O powder, compacting, then placing the mixed powder of the Al powder and the Cu2O powder on the W powder in the quartz crucible, placing the quartz crucible in a supergravity infiltration device, vacuumizing, and electrifying a tungsten wire to initiate a reaction under the supergravity condition so as to obtain the tungsten / copper gradient material; and the preparation method disclosed by the invention has a simple process, low cost and high efficiency.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Rare earth prealloyed powder and preparation method thereof

The invention relates to rare earth prealloyed powder which is obtained by water atomization. The powder comprises the following components in percentage by weight: 36-45wt% of Cu, 5-8wt% of Sn, 5-8wt% of Ni, 0.5-1.5wt% of Ce, 8-12wt% of Co and 26-43wt% of Fe. According to the rare earth prealloyed powder provided by the invention, the sintering temperature is 740-800 DEG C, the bending strength is grater than 1000MPa, the utilization ratio of diamond reaches over 50%, the service life of the product is improved by over 30%, and the sharpness of the product is improved by over 20%. The rare earth prealloyed powder provided by the invention is wide in application range, and can be widely applied to granite cutting saw webs of various specifications.

Owner:JIANGSU FENGTAI TOOLS

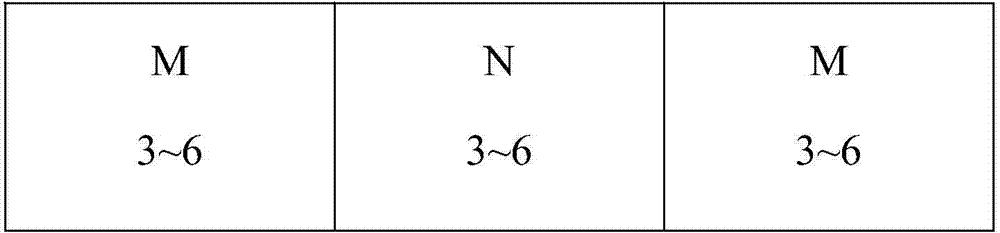

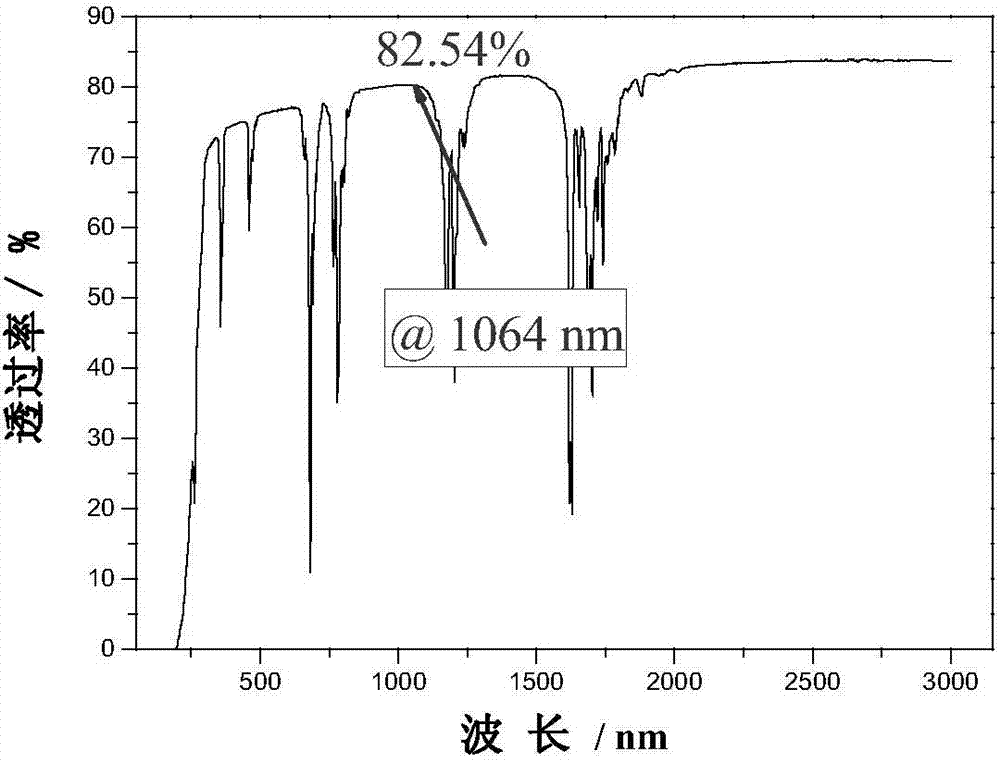

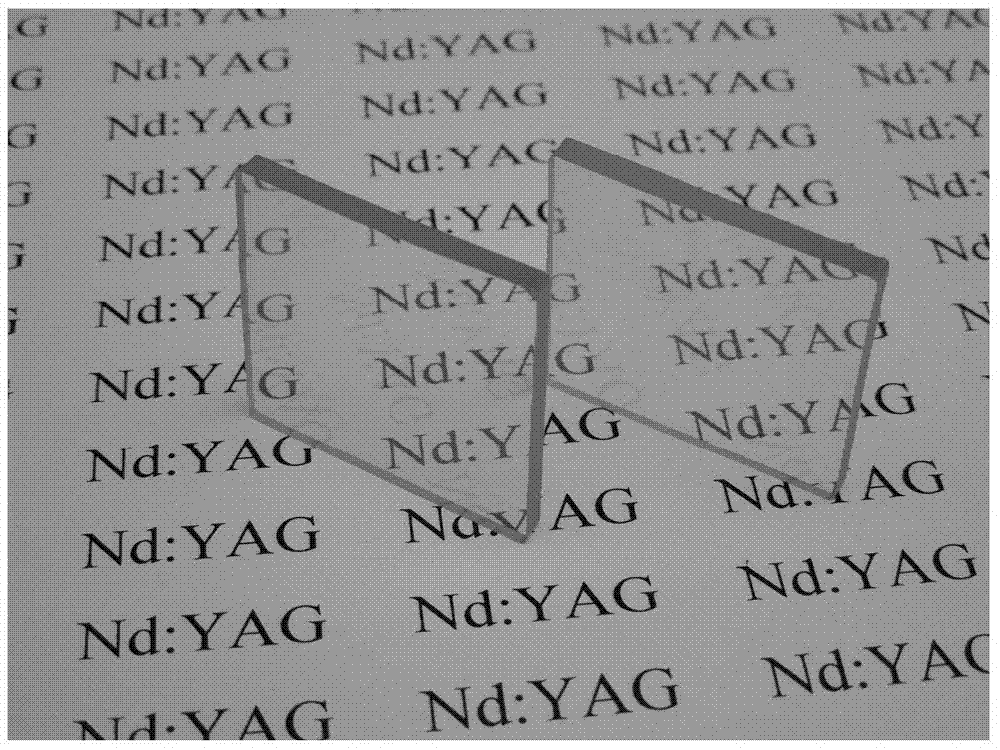

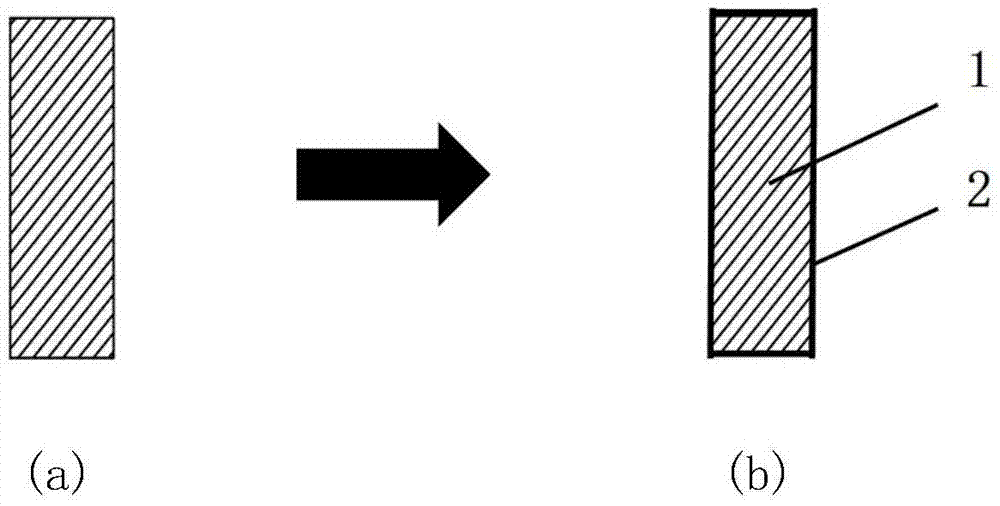

Preparation method of multilayer composite structured transparent ceramic

ActiveCN104725052AComplex structureHigh purityCeramic layered productsHigh transmittanceTape casting

The invention relates to a preparation method of multilayer composite structured transparent ceramic, which is characterized in that the prepared multilayer ceramic meets a structure shown in the following formula: YAG / Re: YAG / YAG; a middle layer is Re:YAG multilayer consisting of a (Y1-xRex)3Al5O12 component flake, and two end layers are respectively a YAG multilayer consisting of a Y3Al5O12 flake. The method comprises the following steps: preparing a size for flow casting; then, carrying out tape casting, and sintering the obtained object so as to obtain a multiple YAG / Re: YAG / YAG composite structured ceramic biscuit; and finally, calcinating the biscuit in the air, and then sintering the obtained product in a vacuum environment, so that the multilayer composite structured transparent ceramic is obtained. The multilayer composite structured transparent ceramic prepared according to the invention has the characteristics of high purity, complicated structure, good optical quality, high transmittance, small ion diffusion scope, and the like, and is extremely applicable to the preparation of large-sized and complex-structured YAG-based transparent ceramic materials.

Owner:XUZHOU ALL TO PHOTOELECTRIC TECH CO LTD

Method for synthesizing tantalum-containing SiC ceramic precursor

InactiveCN101186504AWide variety of sourcesControllable and adjustable contentFiberSynthesis methods

The invention discloses a synthesis method of an SiC-containing ceramics precursor, which comprises the steps that: 1. low molecular weight polymer with main chain containing silicon is sent into a three-mouth flask, and is added with 0.5wt% - 20wt% of tantalum organic compounds or chloride; 2. under the protection of Ar or N2 or compound of the Ar or N2, the temperature of the three-mouth flask is raised to 350 to 500 DEG C, and the temperature of a cracking column is controlled within 450 DEG C to 550 DEG C; then thermal decomposition rearrangement reaction is carried out for 0.5 to 25 hours, and then cooling is done; 3. the obtained rough product is dissolved by xylene and filtered; the filtrate solution is distilled by reducing temperature to between 250 to 390 DEG C, then the obtained material is cooled. The invention has the advantages of wide raw material source, reaction process being easy to be controlled, simple equipment, high purity of product, good formability, and good performance of super-high temperature and absorbing property; in addition, the ceramics fiber produced in the method has good oxidation resistance performance and is easy to realize large-scale industrial production.

Owner:NAT UNIV OF DEFENSE TECH

Mold-releasing type complexing agent with effects of resisting high temperature, insulating heat and demolding

ActiveCN103537613AIncrease contact interfaceReduce porosityFoundry mouldsFoundry coresThermal fatiguePhysical chemistry

The invention provides a mold-releasing type complexing agent with effects of resisting a high temperature of more than 1450 DEG C, insulating heat and demolding and a preparation method thereof. The mold-releasing type complexing agent comprises the following raw materials in percentage by weight: 20-60% of nano colloidal silicon dioxide solution; 5-30% of composite oxide ultramicro (0.1-1.0 microns) powder including Na, Mg, Ca, Fe, Li, Al, Si, B, Zr and other elements; 0.2-2% of water-based dispersing agent;0.02-0.5% of water-based thickening agent and the balance of water; and the sum of the weight of the components is 100%. According to the mold-releasing type complexing agent with effects of resisting high temperature, insulating heat and demolding, the nano colloidal silicon dioxide solution is cooperated with the ultramicro (0.1-1.0 microns) multielement composite oxide powder, so that the excellent performances of high temperature resistance, heat insulation, demolding, environment protection and the like are achieved, the thermal fatigue resistance of the mold surface is effectively improved, and the service life of the mold is prolonged. The mold-releasing type complexing agent with effects of resisting high temperature, insulating heat and demolding is particularly applicable to using at the part of a mold directly contacting molten steel in fired mold casting and other high temperature forming technologies of metal.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

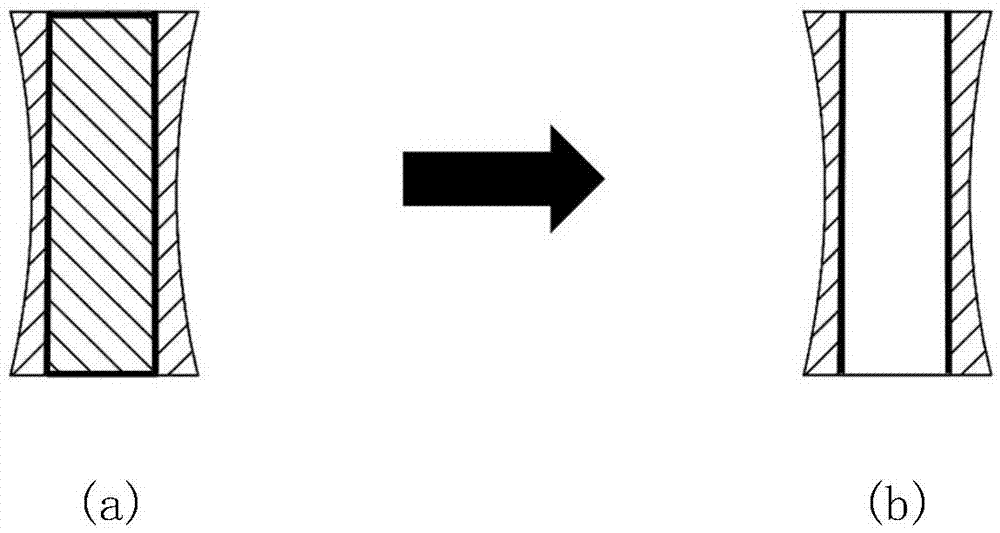

High-density Ti2AlNb powder alloy near-net forming technology

The invention provides a high-density Ti2AlNb powder alloy near-net forming technology.The technology comprises the following steps that 1, a Ti2AlNb alloy bar is smelted by taking components of Ti2AlNb-based alloy as ingredients; 2, the alloy bar processed through finish turning is put into plasma rotation electrode powder preparing equipment, and the Ti2AlNb alloy bar is prepared into Ti2AlNb spherical powder under the inert gas shielding condition; 3, the prepared Ti2AlNb spherical powder is located into a stainless steel or low-carbon steel sheath; 4, the sheath which contains the Ti2AlNb spherical powder and is compacted through vibration is degassed; 5, hot isostatic pressing forming is performed on the degassed sheath.The Ti2AlNb powder alloy prepared through the method has the isotropic character and is high in density degree, uniform in tissue and component, excellent in mechanical property and capable of achieving Ti2AlNb alloy parts with the large size and complex shapes.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Low-temp sintered aluminium nitride-base composition and its preparing process

A low-temp sintered AIN-base composition is prepared from AIN (50-80 wt%), lead borosilicate glass (15-50), and LiF (rest) through hot pressing and sinter, including heating and pressurizing by threestages, and holding temp at 950 or 1000 deg.C under 18-25 MPa for 2-8 hr. Its advantages include low sinter temp and density, high heat conductivity (11 W / m.k) and low cost.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of low-cost boron carbide/aluminum composite board

ActiveCN104308161ALow impurity contentImprove distribution uniformityNuclear energy generationReactors manufactureBoron carbideUltimate tensile strength

The invention discloses a preparation method of a low-cost boron carbide / aluminum composite board and the preparation method can be used for simplifying a preparation process of a B4C / Al neutron absorption board and lowering the cost. The preparation method comprises the following steps: preparing a mixture, molding a powder compact and rolling. Compared with a traditional B4C / Al composite preparation technology, the preparation method has the advantages that long-time sintering is not needed, a pressed green compact is directly subjected to hot rolling after being subjected to vacuum heating, and the pressed green compact forms a compact green compact body by virtue of control of a hot rolling process, so that a composite board is obtained. the process flow is effectively shortened and the production cost and the energy consumption are reduced on the premise of ensuring the board quality, and the preparation method has the advantages of short production period and low energy consumption. The composite board prepared by the preparation method is high in quality, low in impurity content, good in B4C distribution uniformity and excellent in strength and tenacity matching, can meet the demand of the neutron shielding field, and is suitable for serving as a neutron absorption material in a reactor spent fuel water pond and a transport container and used for controlling the critical safety of a spent fuel storage environment.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

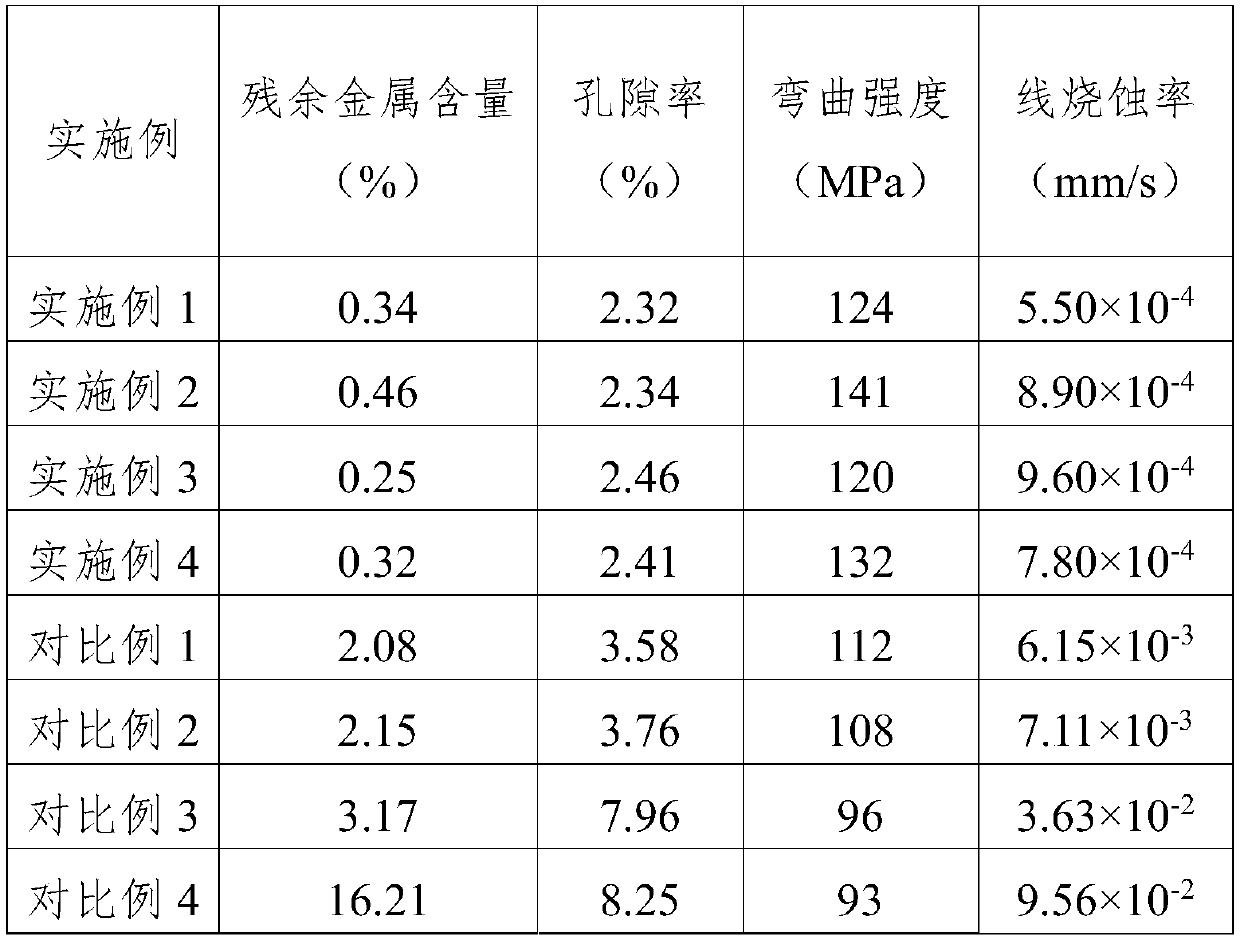

Carbon fiber reinforced carbon-silicon carbide-zirconium carbide composite material and preparation method thereof

ActiveCN111099911ALow cost of preparationImprove anti-ablation performanceCarbide siliconZirconium carbide

The invention relates to a carbon fiber reinforced carbon-silicon carbide-zirconium carbide composite material and a preparation method thereof. The method comprises the following steps: (1) depositing a pyrolytic carbon matrix on the surface of carbon fibers contained in a carbon fiber preform to obtain a modified carbon fiber preform; (2) preparing a mixed resin solution of silicon powder, zirconium powder, graphite powder and phenolic resin in a mass ratio of (1-3): (4-6): 5: 100; (3) impregnating the modified carbon fiber preform with the mixed resin solution, and then sequentially carrying out curing and carbonization reactions on the impregnated modified carbon fiber preform, wherein the carbonization reaction is carried out in an inert atmosphere, the temperature of the carbonization reaction is 1650-1750 DEG C, and the time is 0.5-2 hours; and (4) repeating the step (3) at least once to obtain the composite material. According to the invention, silicon carbide and zirconium carbide can be uniformly distributed in the composite material, the content of free metals is reduced, and the oxidation resistance and ablation resistance of the material are improved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

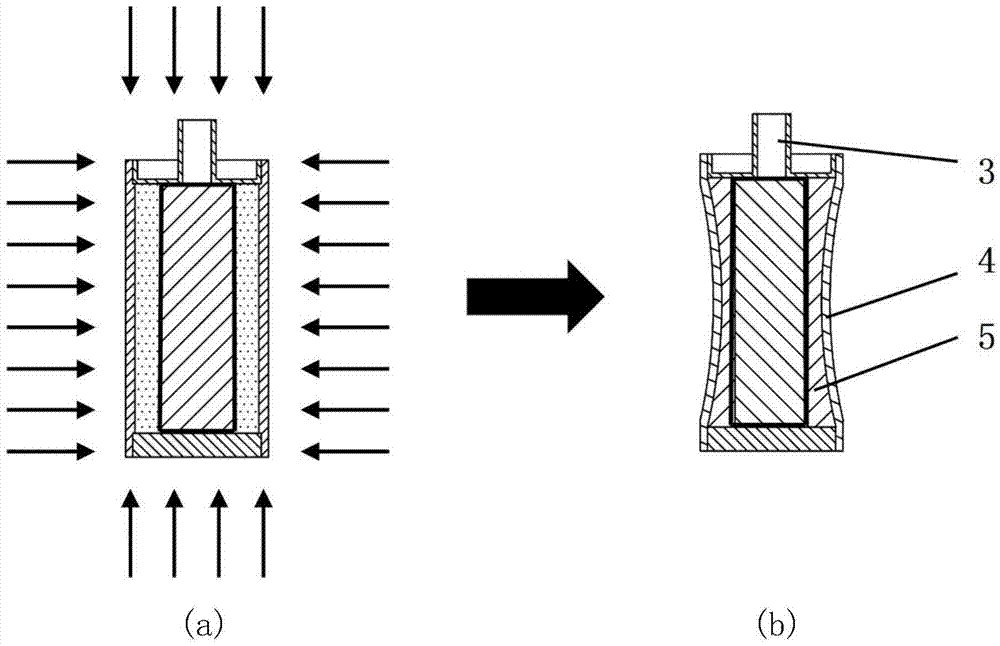

Hot isostatic pressing forming method used for improving part surface quality

ActiveCN105436505AImprove creep deformation efficiencyHigh degree of densificationCeramic coatingHigh pressure

The invention discloses a hot isostatic pressing forming method used for improving the part surface quality. The hot isostatic pressing forming method comprises the following steps that three-dimensional models of a wrapping sleeve and a shape control die core are designed according to the shape and size of a formed part; the stainless steel wrapping sleeve and the carbon steel shape control die core are manufactured according to the manufactured three-dimensional models; a ceramic coating is sprayed on the surface of the shape control die core through a physical vapor deposition (PVD) method; the shape control die core is fixed in the wrapping sleeve, and the wrapping sleeve is filled with powder and shaken to be compacted; the wrapping sleeve is subjected to air exhausting and heating treatment, sealing welding is conducted when the vacuum degree in the wrapping sleeve reaches a certain degree; the wrapping sleeve is subjected to hot isostatic pressing treatment through a technique that the temperature is increased at first and then the pressure is increased so as to make the powder be tightened and compacted under the action of the high temperature and the high pressure; and the wrapping sleeve and the shape control die core are removed to obtain the final part. According to the hot isostatic pressing forming method, the carbon steel die core with the coating serves as the shape control die core, and element diffusion between carbon steel cores and the powder can be effectively prevented; element segregation of the alloy surface due to diffusion is avoided, and the alloy surface quality is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

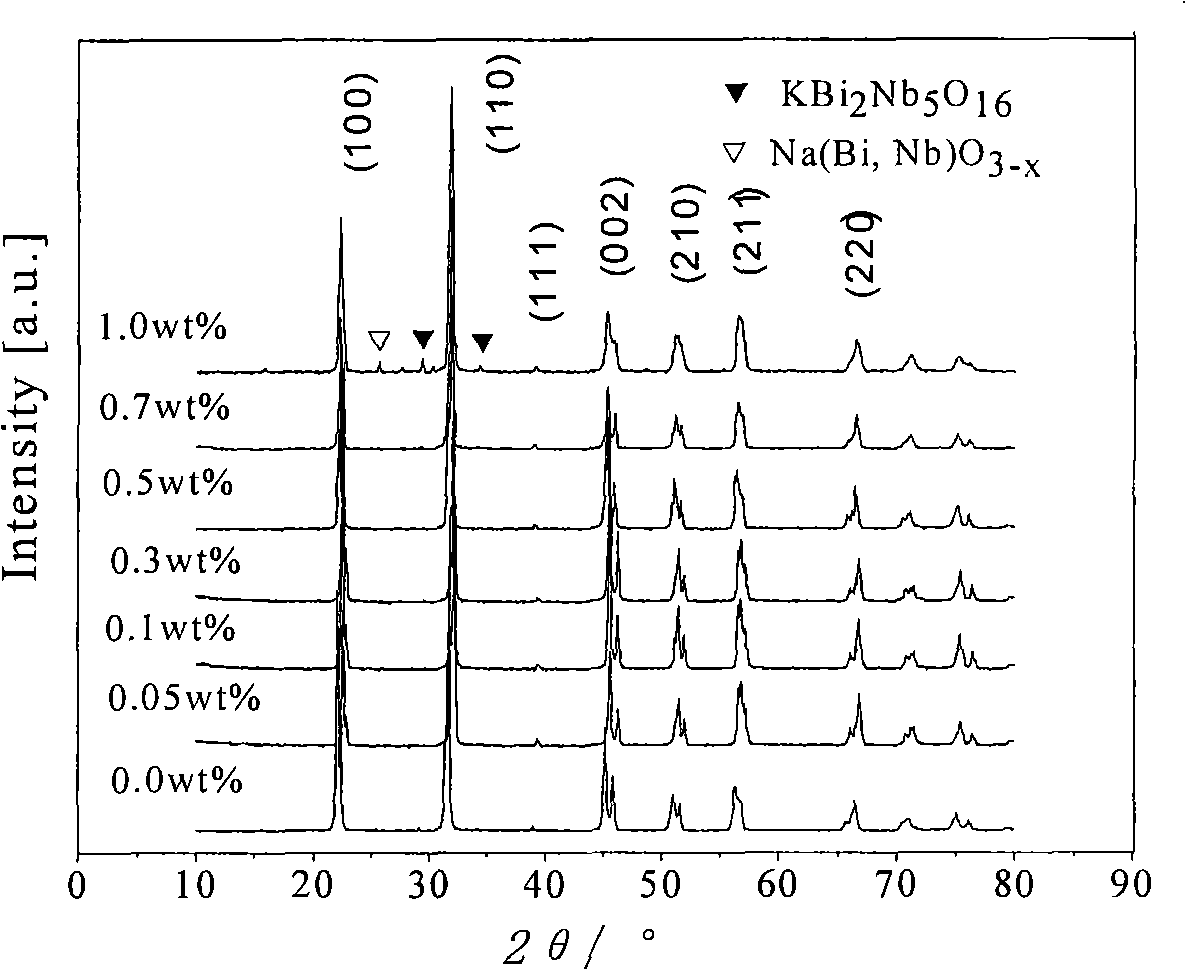

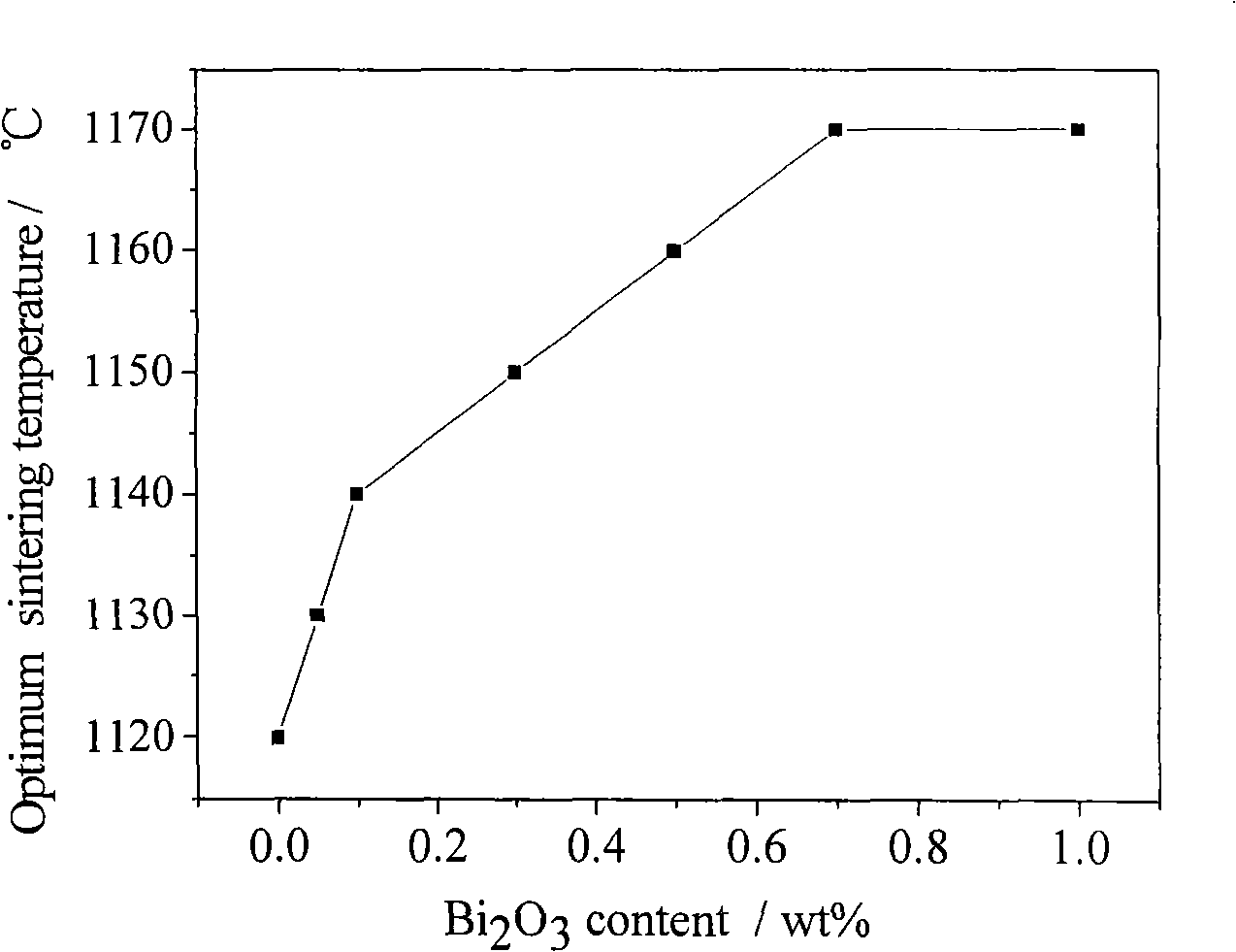

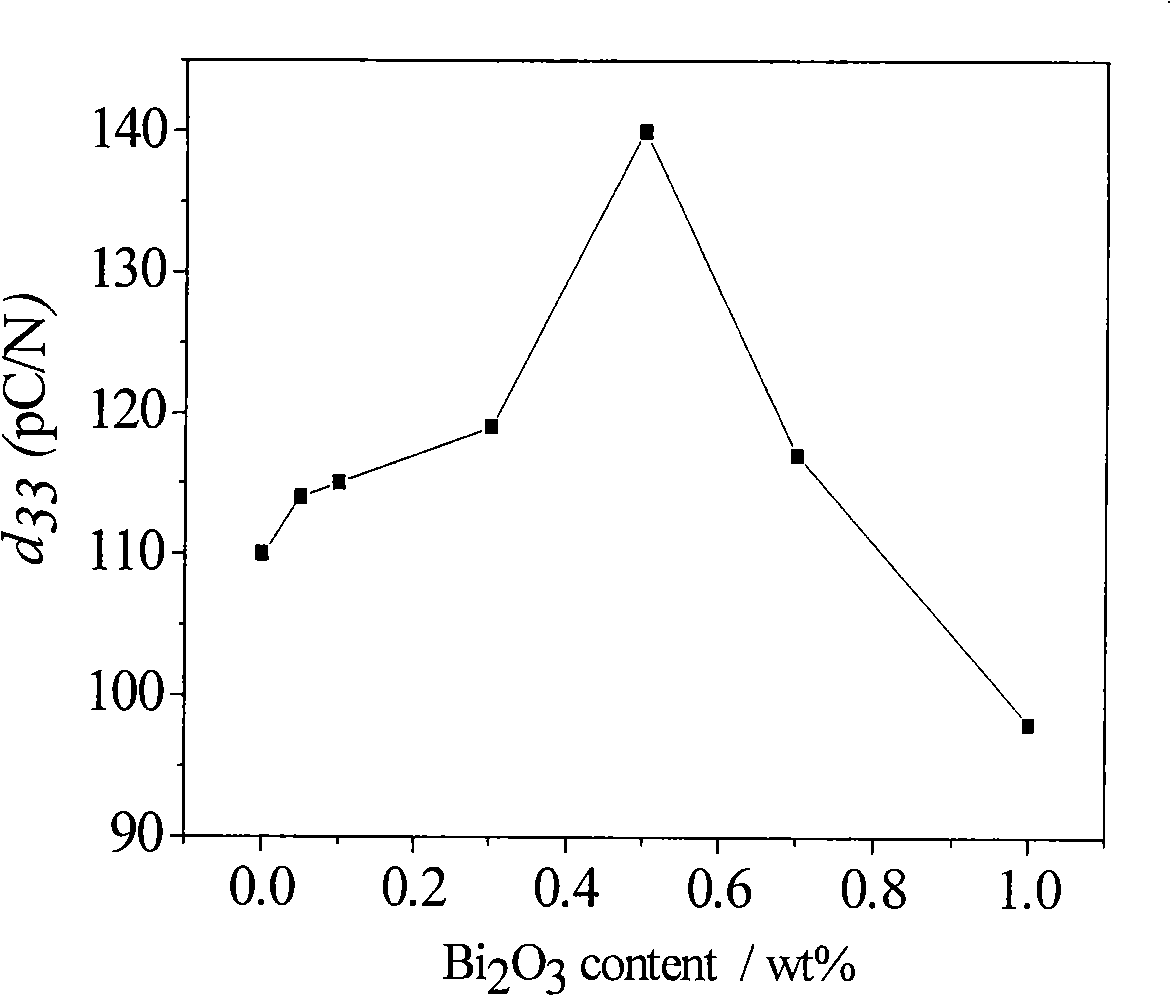

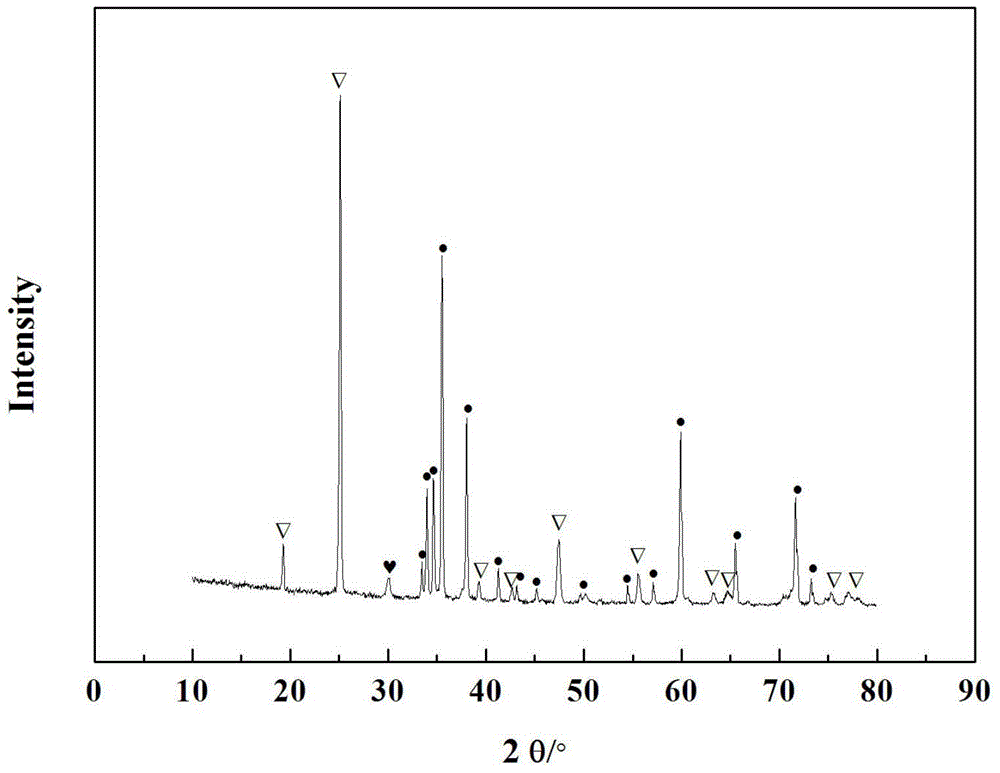

Potassium-sodium niobate-based leadless piezoelectric material and preparation thereof

InactiveCN101302106AImprove sintering propertiesHigh degree of densificationSilver electrodeDrain current

The invention discloses a piezoelectric material for lead-free piezoelectric ceramic with potassium-sodium niobate and a preparing method, which strengthens the ferroelectric performance of potassium-sodium niobate ceramic and further improves the piezoelectric performance. The material of the invention comprises anhydrous potassium carbonate, natrium carbonicum calcinatum, niobium pentaoxide and dibismuth trioxide, the stoichiometric proportion of the lead-free piezoelectric ceramic is (K0.5 Na0.5) Nb3 + x weight percent Bi 2O3, wherein the x is more than or equal to 0 and less than or equal to 1, the piezoelectric material for lead-free piezoelectric ceramic with potassium-sodium niobate is obtained through mixture making, drying and burnishing, granulation, molding, sintering and after polarization by a silver electrode; therefore, the densification of the ceramic is improved, polarized drain current of the ceramic is reduced, and the polarization process is carried out more easily; moreover, the piezoelectric material adopts the material from a conventional process and industry, has the characteristics of good process stability and no pollution.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Production process of ultrathin aluminum nitride ceramic substrate

ActiveCN112876260AHigh degree of densificationDoes not significantly increase production costsAl powderSlurry

The invention relates to the technical field of aluminum nitride ceramics, and provides a production process of an ultrathin aluminum nitride ceramic substrate. The process comprises the following steps: (1) uniformly mixing aluminum nitride powder, a composite sintering aid, a UV monomer, a reactive diluent, a photoinitiator, a dispersant and a silane coupling agent to obtain ceramic slurry; (2) subjecting the ceramic slurry to tape casting on a tape casting machine, initiating a polymerization reaction through ultraviolet radiation, subjecting the slurry to in-situ curing molding to obtain a ceramic green body, and then cutting the ceramic green body into required shapes and sizes through a mold to obtain ceramic green sheets; (3) laminating the ceramic green sheets, and putting the laminated ceramic green sheets into a glue discharging furnace for glue discharging; and (4) carrying out hot pressed sintering on the ceramic blank sheet after glue discharging under the protection of nitrogen atmosphere, cooling to room temperature after the sintering, and then carrying out powder removal and polishing processes to obtain the ultrathin aluminum nitride ceramic substrate. The prepared aluminum nitride ceramic substrate is ultrathin, good in thermal conductivity and high in bending strength.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

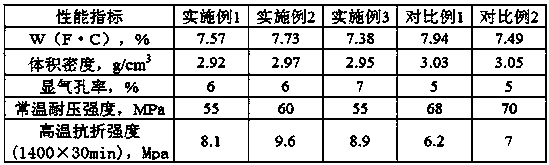

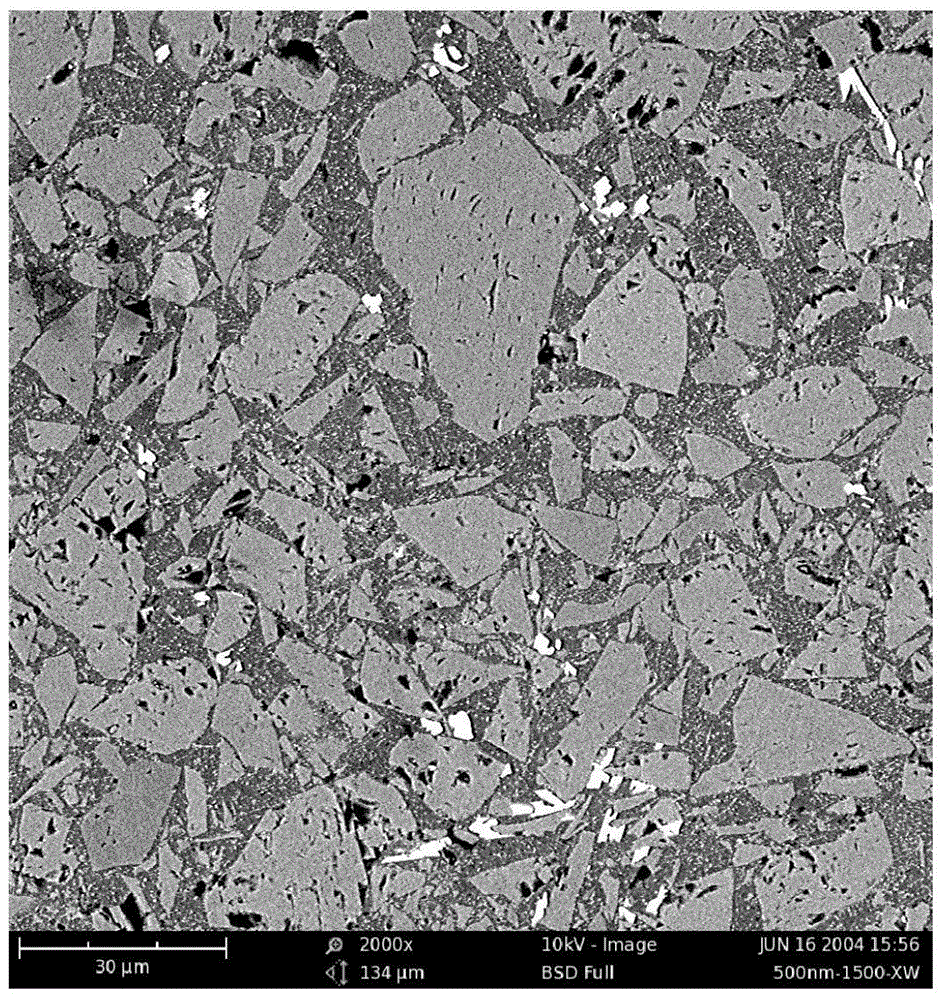

Al2O3-SiC-C refractory brick for torpedo ladle produced by utilizing waste Al2O3-C and preparation method of Al2O3-SiC-C refractory brick

InactiveCN107555970AExtended service lifeHigh degree of densificationMelt-holding vesselsBrickMaterials science

The invention belongs to the field of refractory matters for ferrous metallurgy and in particular relates to an Al2O3-SiC-C refractory brick for a torpedo ladle produced by utilizing a waste Al2O3-C material and a preparation method of the Al2O3-SiC-C refractory brick. The Al2O3-SiC-C refractory brick comprises the following raw materials in percentage by weight: 10-40% of special grade bauxite clinker particles with the particle size of 3-5mm, 10-30% of special grade bauxite clinker particles with the particle size of 1-3mm, 5-20% of alundum particles with the particle size of 0.088-1mm, 5-20% of corundum fine powder with the particle size of less than 0.088mm, 2-8% of silicon carbon particulates with the particle size of 0.088-1mm, 2-8% of silicon carbon fine powder with the particle size of less than 0.088mm, 10-25% of waste Al2O3-C material fine powder with the particle size of less than 0.088mm, 5-15% of alumina micro powder with the particle size of less than 0.088mm, 3-10% of binding clay fine powder with the particle size of less than 0.088mm, 1-10% of crystalline flake graphite powder with the particle size of less than 0.088mm, 0.5-5% of asphalt powder with the particle size of less than 0.088mm, and 4-8% of additional phenolic resin.

Owner:UNIV OF SCI & TECH LIAONING

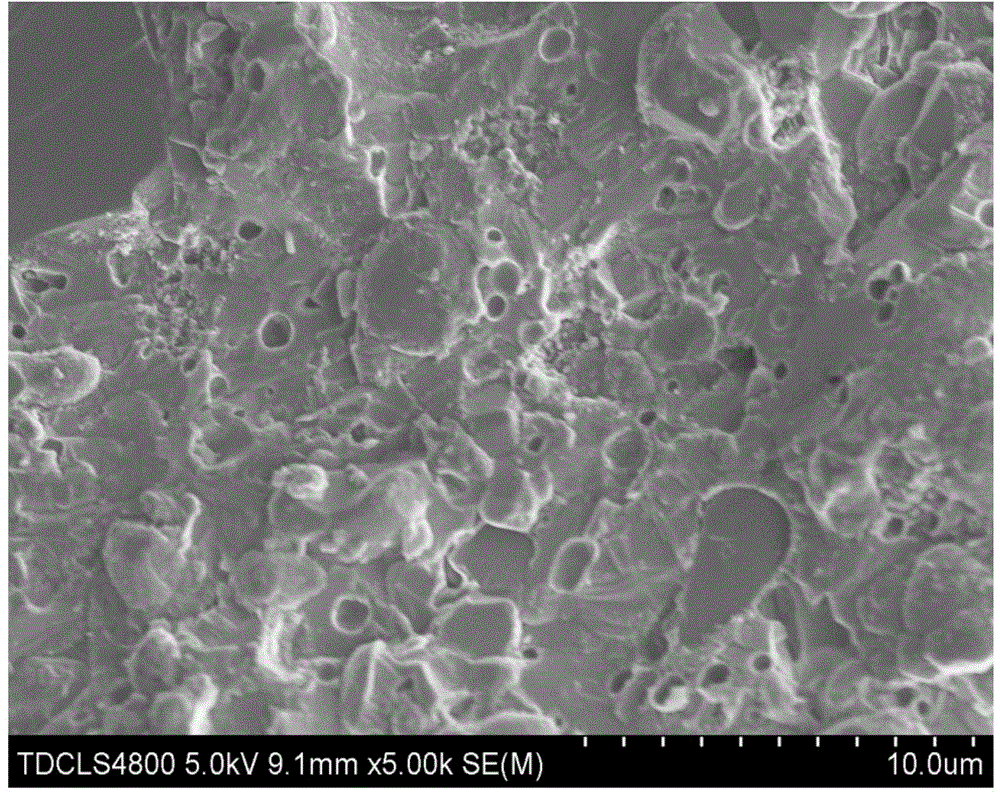

Injection molding reactive sintering B4C/SiC composite ceramic material and preparation method thereof

The invention relates to an injection molding reactive sintering B4C / SiC composite ceramic material and a preparation method thereof. The composite ceramic material is prepared from the following raw materials in percentage by weight by virtue of material mixing, milling, injection, degreasing and sintering: 45-60% of boron carbide, 15-30% of silicon carbide, 1-5% of charcoal powder, 1-3% of a surfactant, 0-2% of a dispersant, 6-15% of a lubricant, and 4-12% of a binding agent, wherein the sum of the used amounts of all the components is 100%. For the reactive sintering B4C / SiC composite ceramic material prepared by the method provided by the invention, the apparent porosity is lower than 0.30%, the bending strength is 300MPa or above, the hardness is more than 3.04GPa, and the fracture toughness is more than 4.27MPa.m<1 / 2>.

Owner:SHANDONG UNIV

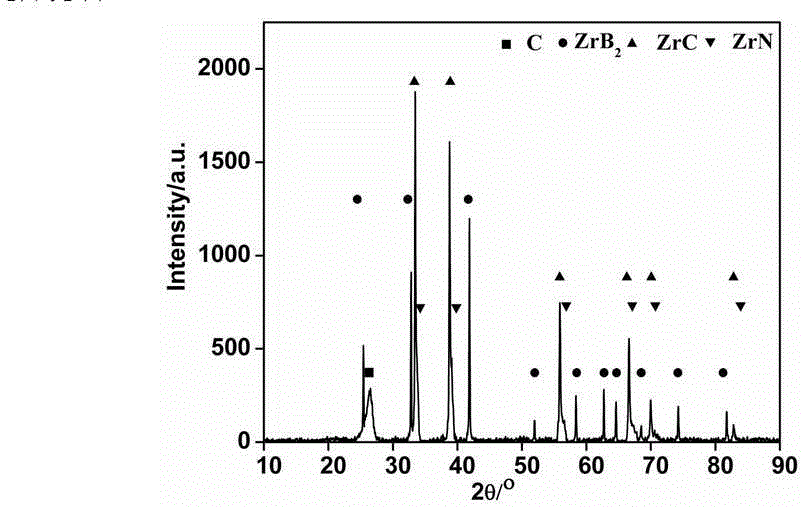

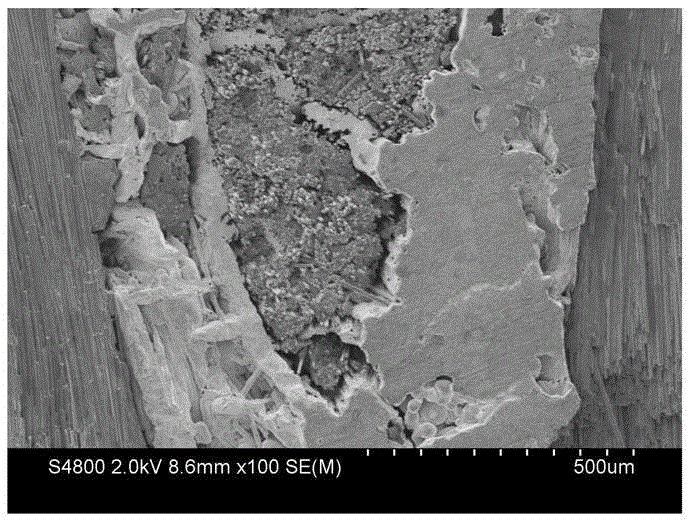

Carbon fiber-enhanced ZrB2-ZrN composite ceramic-based composite material and preparation method thereof

The invention discloses a carbon fiber-enhanced ZrB2-ZrN composite-ceramic-based composite material and a preparation method thereof. In the composite material, carbon fibers are employed as an enhancement body and ZrB2-ZrN composite ceramic is employed as a base body. The preparation method includes the following steps: with propylene as a precursor, depositing a carbon coating layer on surface of the carbon fiber enhancement body through a chemical vapor deposition process to obtain the carbon fiber enhancement body of which the surface is deposited by the carbon coating layer; compacting the carbon fiber enhancement body of which the surface is deposited by the carbon coating layer to obtain a porous C / BN prefabricate; and performing fusion infiltration to the porous C / BN prefabricate with zirconium metal or zirconium alloy to obtain the carbon fiber-enhanced ZrB2-ZrN composite-ceramic-based composite material. The preparation method is simple, is low in cost and is short in period. The composite material is high in compactness degree, is high in ceramic phase volume percentage and is homogeneous in distribution.

Owner:NAT UNIV OF DEFENSE TECH

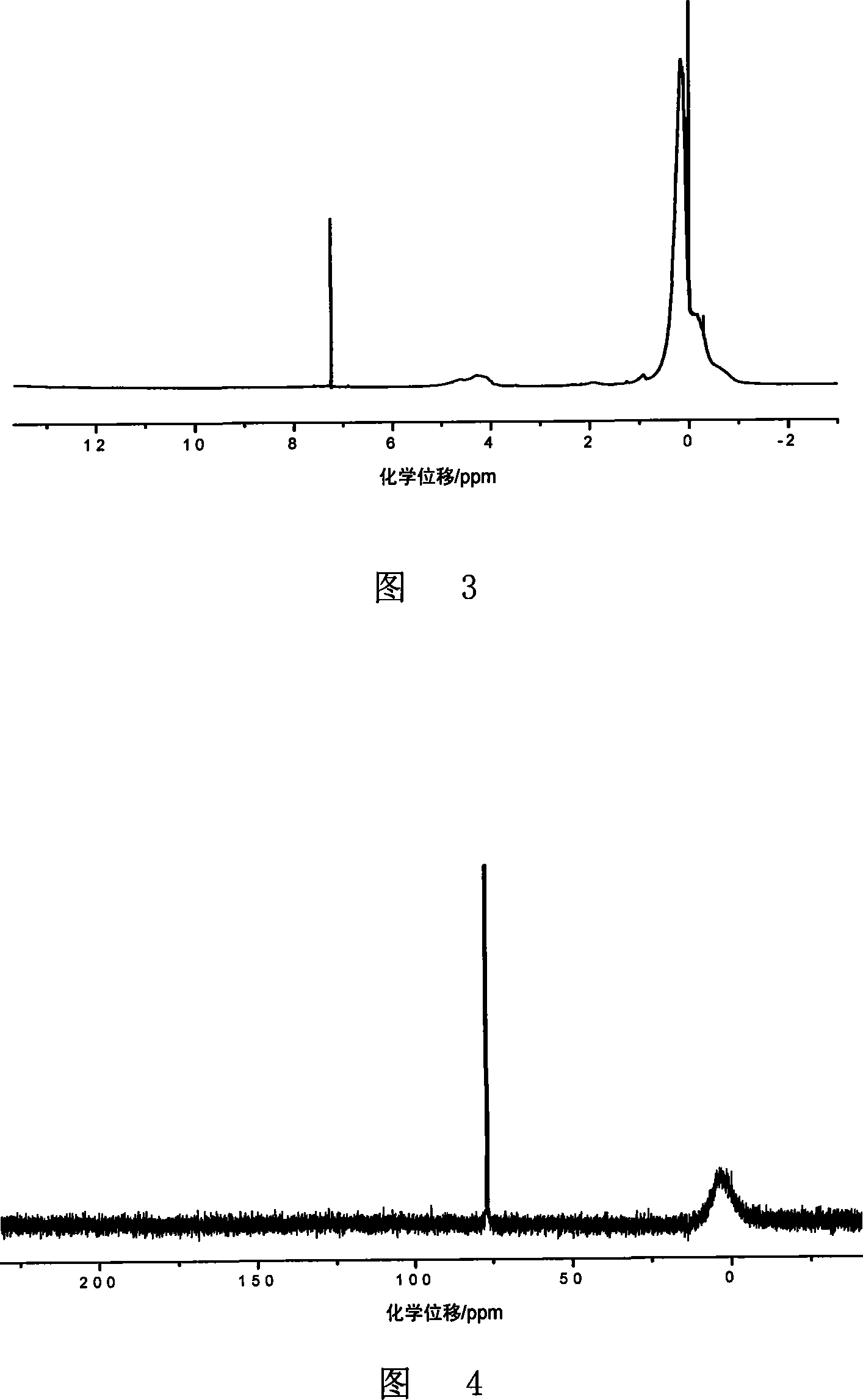

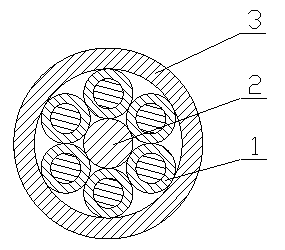

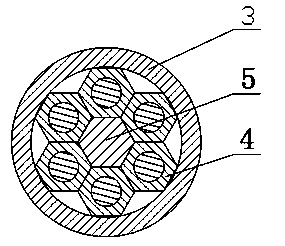

Method for preparing C-mixed multi-core MgB2 super-conduction wires through solution coating method

ActiveCN103956221AAvoid reunionHigh activitySuperconductors/hyperconductorsSuperconductor devicesManufacturing technologyElectrical conductor

The invention discloses a method for preparing C-mixed multi-core MgB2 super-conduction wires through a solution coating method and belongs to the technical field of super-conduction wire manufacturing. A MgB2 super-conduction core wire, a metal Nb-Ti composite blocking layer, a center copper-niobium reinforcing core and an outer-coating Cu-Ni alloy layer are included. First, a solution coating technology is used for preparing a C-mixed tubing precursor powder body, then the tubing precursor powder body is placed into a Nb-Ti composite tube cleaned by acid pickling in a filling mode manually, rolling is carried out, single-core wires are formed by machining, then secondary assembling is carried out according to a seven-core conductor structure, outer-coating materials are a Cu-Ni alloy tube, a center is reinforced through a copper-niobium composite rod, a secondary composite body is subjected to a machining process with rotary swaging drawing and hole pattern rolling combined, multi-core wires are prepared, and finally after heat treatment, the high-mechanical-strength high-critical-current-density C-mixed multi-core MgB2 super-conduction wires are obtained. The wires can be used in fields such as power transmission and distribution, super-strong magnets, energy storage, power generators, transformers and medical treatment.

Owner:BAOSHENG SCI & TECH INNOVATION

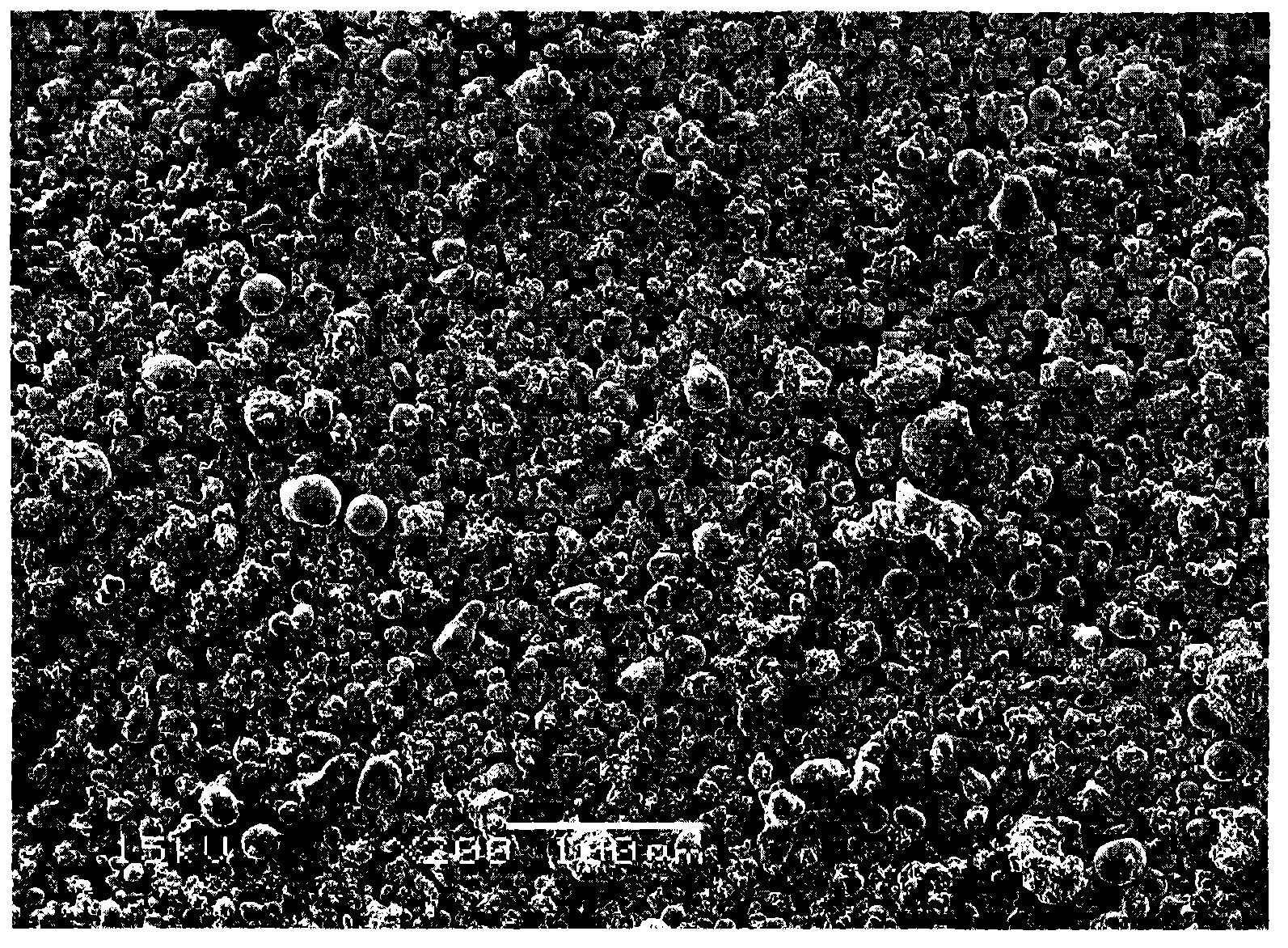

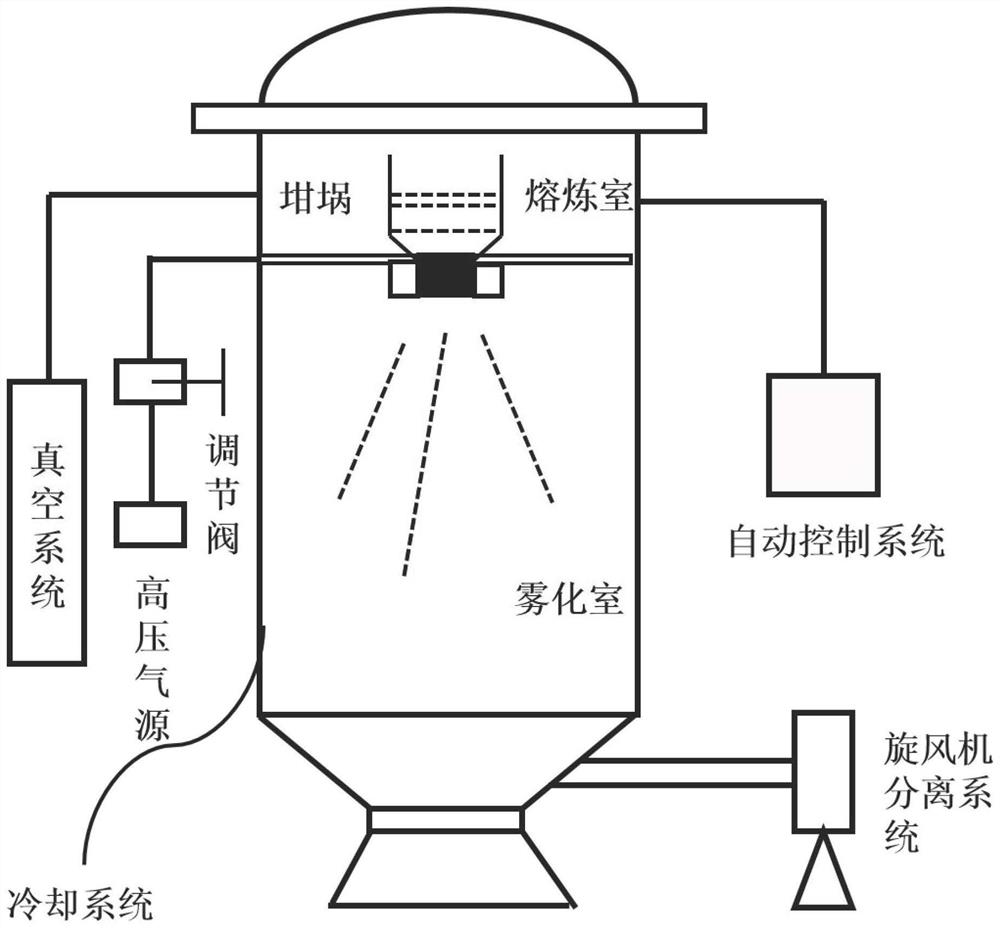

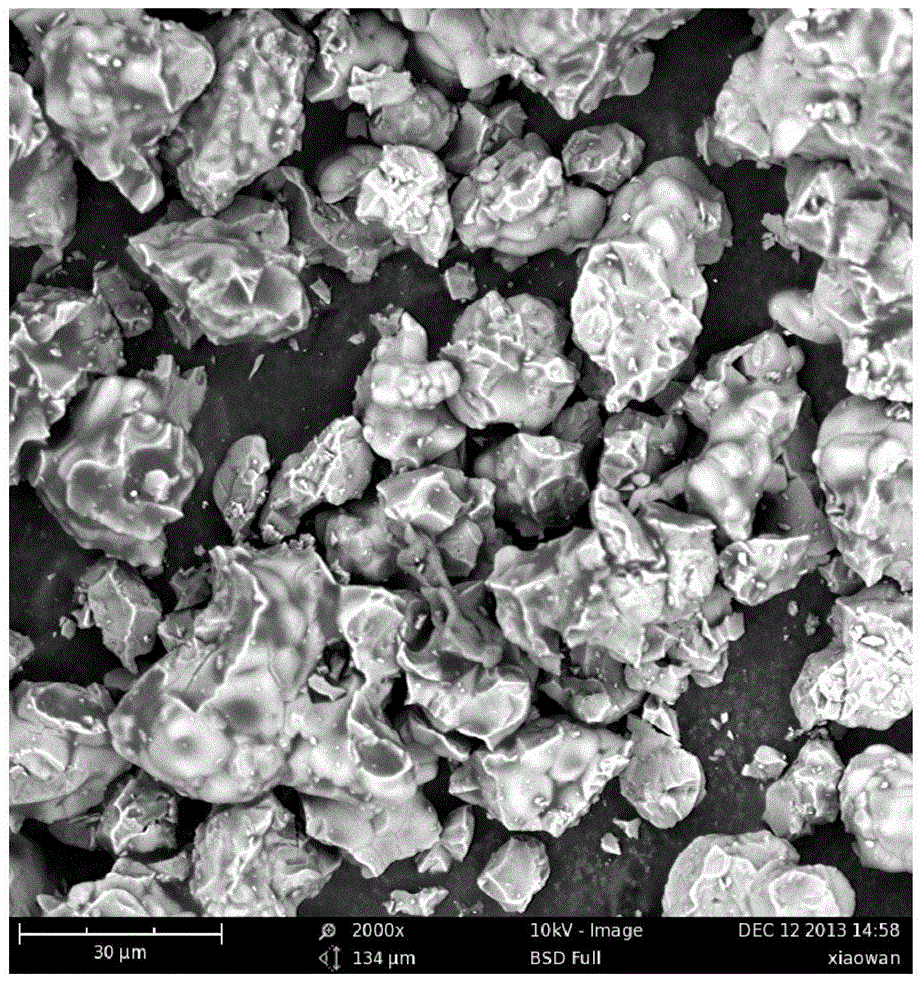

Preparation method of aluminum-scandium alloy sputtering target material

InactiveCN111636054AReduce oxygen contentHigh degree of densificationVacuum evaporation coatingSputtering coatingGrain structureHot isostatic pressing

The invention provides a preparation method of an aluminum-scandium alloy sputtering target material, and relates to the technical field of target material preparation. The preparation method of the aluminum-scandium alloy sputtering target material comprises the following steps that an aluminum source and a scandium source are mixed, and vacuum melting is conducted on an obtained aluminum-scandium alloy ingredient to obtain a molten aluminum-scandium alloy liquid; vacuum gas atomization is conducted on the molten aluminum-scandium alloy liquid by using an inert gas flow to obtain aluminum-scandium alloy powder; outer sheathing and hot isostatic pressing molding are sequentially conducted on the aluminum-scandium alloy powder to obtain an aluminum-scandium alloy sputtering target blank; and the aluminum-scandium alloy sputtering target blank is bound and machined to obtain an aluminum-scandium alloy sputtering target material. According to the method, the vacuum gas atomization is conducted by using the inert gas flow, contact between the molten aluminum-scandium alloy liquid and oxygen is isolated, the prepared aluminum-scandium alloy powder is high in sphericity degree, low in oxygen content, and uniform in grain structure, particle size and microstructure, and the aluminum-scandium alloy sputtering target material obtained by utilizing hot isostatic pressing molding is highin density, uniform in chemical component, and free of the defects such as segregation.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

Surface treatment method of C/TiB2 composite

The invention belongs to the field of surface treatment of carbon fiber reinforced ceramic-based composites and particularly discloses a surface treatment method of a C / TiB2 composite. The C / TiB2 composite is embedded in B4C powder and treated at the temperature of 950-1,100 DEG C under the vacuum condition; Ti powder, NH4Cl and Al2O3 powder are mixed uniformly, and mixed powder is obtained; the obtained mixed powder is used for embedding the treated C / TiB2 composite, and the C / TiB2 composite is subjected to a reaction at the temperature of 1,200-1,300 DEG C under the vacuum condition for 3-5 h and then naturally cooled. According to the method, a B4C layer is firstly deposited on the surface of the composite, Ti powder and residual silicon react to produce TiSi2, besides, the Ti powder can react with B4C on the surface to produce TiB2, and the performance of the composite is further stabilized.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Prepn process of sand blasting ceramic nozzle

The preparation process of sand blasting ceramic nozzle includes adding (W, Ti)C solid solution into B4C substrate and small amount of Si sintering assistant and hot pressed sintering with in-situ chemical reaction between B4C and (W, Ti)C to produce B4C / TiB / W2B5. The B4C base sand-blasting ceramic nozzle produced through the said process has high compactness, strength and toughness high than those of B4C ceramic one, sintering temperature reduce to below 1900 deg.c, short sintering time and high erosion and wear resistance.

Owner:SHANDONG UNIV

Preparation method of zero-expansion LAS/SiC composite material

InactiveCN104892000ASimple processReduce manufacturing costThermal expansionUltimate tensile strength

Disclosed is a preparation method of a zero-expansion LAS / SiC composite material. The method comprises: firstly, preparing LAS powder via a powder sintering method; then adopting SiC powder with a matching diameter as a conditioning agent of the zero-expansion LAS / SiC composite material; calculating the ratio of LAS powder and SiC powder for macro-control of the thermal expansion coefficient of the composite material; and finally adopting a hot pressed sintering method and post-process treatment to prepare the zero-expansion LAS / SiC composite material. The composite material obtained in the invention is high in densification degree. A matrix is softened at a high temperature, so that densification is beneficial to perform. Further, the externally-applied pressure quickens the densification process, so that pores, which cannot be discharged in the absence of pressure, can be forced to be eliminated under the action of stress. Organization is homogenized; the pore ratio is reduced; and the strength of the composite material is improved.

Owner:XI AN JIAOTONG UNIV

Ablation-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite as well as preparation method and application thereof

The invention discloses an ablation-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite as well as a preparation method and an application thereof. The preparation method of the ablation-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite comprises the following steps: S1, preparing Si-B-C-N-Zr powder; S2, performing surface modification treatment on fiber to obtain modifiedfiber; S3, mixing the modified fiber with the Si-B-C-N-Zr powder to obtain composite powder; S4, performing hot pressing and sintering on the composite powder to prepare the ablation-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite. The prepared ablative-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite has good microstructure and higher fracture toughness, mechanical property and ablative resistance, used raw materials are widely sourced and low in price, the preparation process is simple and mature, the preparation period is short, all the steps can be realized with existing technologies and equipment, and the composite is suitable for industrial production.

Owner:HARBIN INST OF TECH

Construction method for densifying surface layer of middle/low-strength concrete

InactiveCN101886474AStrengthen early maintenanceImprove compactnessBuilding material handlingSurface layerUltimate tensile strength

The invention discloses a construction method for densifying the surface layer of middle / low-strength concrete, which relates to the technical field of concrete construction. The middle / low-strength concrete is poured by a concrete temperature and humidity preservation maintenance template which is disclosed in a patent with the patent number of 2009200384330. The mixing proportion of the middle / low-strength concrete is optimized, the using amount of a gelatinization material and the using amount of water are controlled, the ratio of the water to the gelatinization material is also controlled, and the early-stage maintenance of the concrete is enhanced, so the ratio of the water to the gelatinization material of the concrete of the surface layer can be maximally reduced, the compactness and durability of the concrete can be improved, the surface layer densifying degree of the middle / low-strength concrete can be improved, the generation of temperature shrinkage cracks of the concrete can be prevented and the full development of the strength of the concrete is ensured.

Owner:JIANGSU WATER CONSERVANCY SCI RES INST

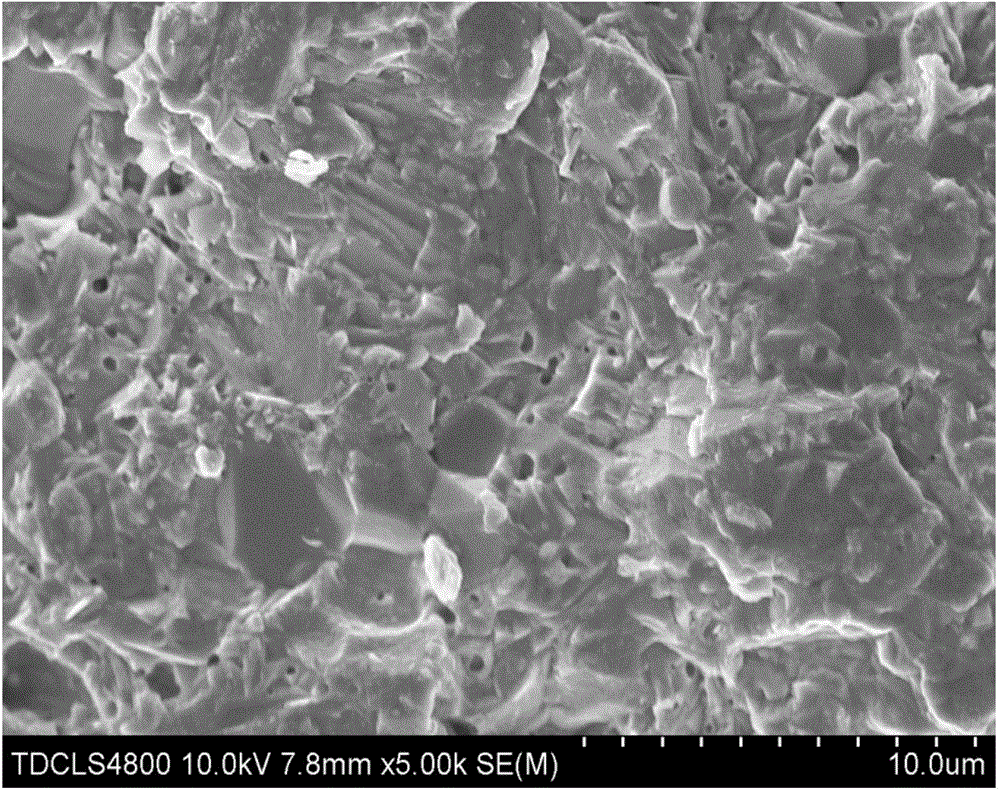

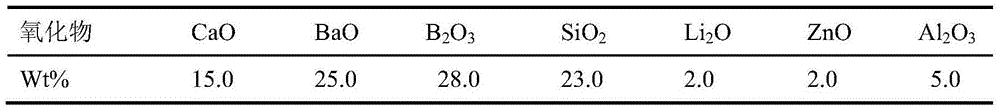

Multi-component borosilicate glass and aluminum nitride low-temperature co-fired ceramic material and preparation method thereof

InactiveCN103553558ALower sintering temperatureHigh degree of densificationCo-fired ceramicThermal conductivity

The invention relates to a multi-component borosilicate glass and aluminum nitride low-temperature co-fired ceramic material and a preparation method thereof. The material comprises a low-melting point multi-component glass phase and an aluminum nitride ceramic phase, wherein the mass fraction of the low-melting point glass phase in the composite material is 50-70 wt%. The sintering temperature of the low-temperature co-fired composite material prepared by the preparation method is low, the sintering can be realized at the temperature of 750-850 DEG C, and the sintering temperature is far lower than an upper limit (950 DEG C) of the sintering temperature of the existing LTCC (low-temperature co-fired ceramic) material; the thermal conductivity of the composite material is relatively high, and the obtained material has the advantages of high density and low porosity. In addition, the process flow for preparing the material is simple, and the cost is low.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com