High-oriented high-strength array drawn carbon nanotube film and preparation method thereof

A carbon nanotube film and oriented carbon nanotube technology, applied in the field of nanomaterials, can solve the problems of airflow disturbance, limited shrinkage of the film, etc., and achieve the effects of not easy bifurcation, reduced gap between tube bundles, and improved orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

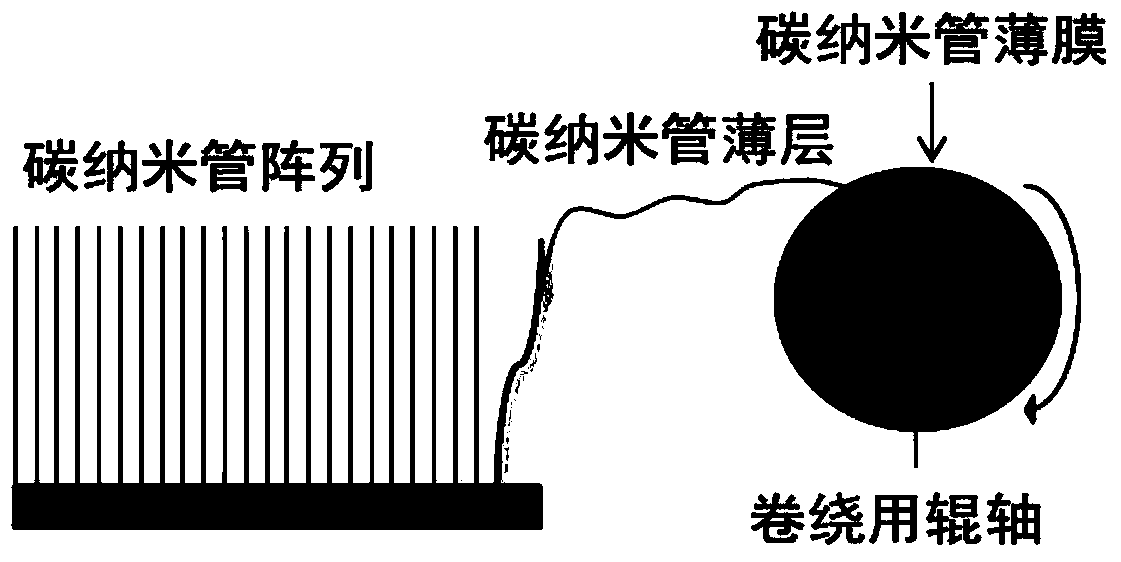

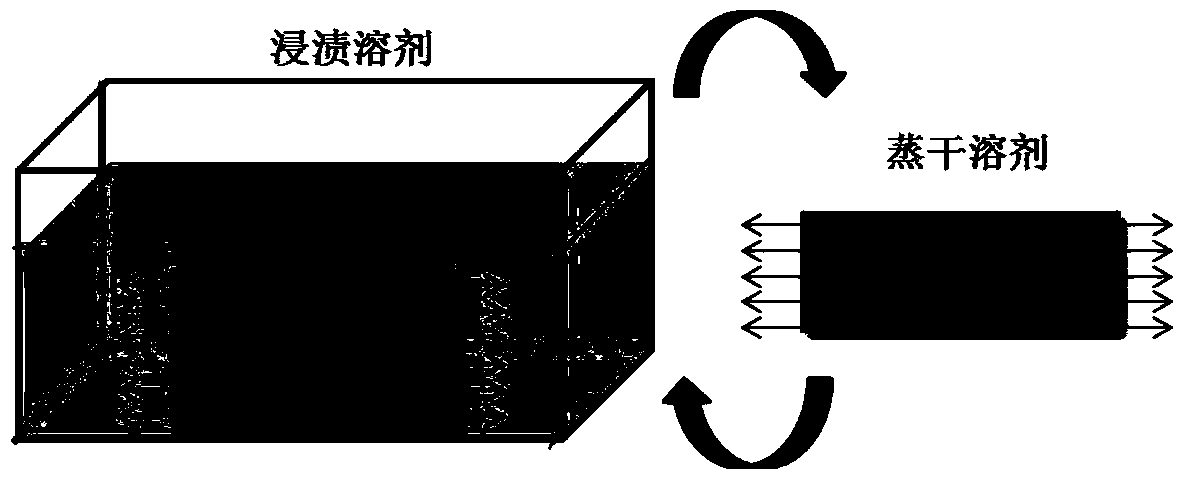

[0026] The present invention provides a highly oriented and high-strength array-stretched carbon nanotube film and a preparation method thereof. The preparation method specifically includes the following steps:

[0027] In the first step, spinnable carbon nanotube arrays are prepared.

[0028] The spinnable carbon nanotube array can be prepared by chemical vapor deposition. The carbon nanotubes are arranged in parallel to the substrate plane in the array. The length and wall number of the carbon nanotubes are determined by the growth conditions. Generally speaking, carbon nanotubes The tube length is 100 μm to 500 μm, and single-wall, few-wall (2 to 6 walls) and multi-wall (more than 6 walls) carbon nanotubes can be used.

[0029] The preparation of the spinnable carbon nanotube array by the chemical vapor deposition method comprises the following steps:

[0030] Electron beam evaporation technology is used to coat a layer of 0.4nm to 50nm aluminum layer, iron layer, cobalt l...

Embodiment 1

[0041] Adopt the method provided by the invention to prepare the carbon nanotube thin film of high orientation and high strength, concrete steps are as follows:

[0042] The first step is the growth of carbon nanotube arrays;

[0043] An aluminum layer with a thickness of 30nm and an iron layer with a thickness of 1nm were successively plated on a silicon substrate as a catalyst layer by electron beam evaporation technology. Then place the catalyst-coated silicon chip substrate in the quartz tube of the tube furnace, and at 750 ° C, under the protection of an inert gas (containing argon with a volume ratio of 6% nitrogen) to the tube at a speed of 1.5 L / min The carbon source ethylene was injected into the type furnace, and the carbon nanotubes were grown on the silicon substrate by chemical vapor deposition, and the spinnable carbon nanotube arrays with a height of 200 μm could be obtained after growing for 15 minutes.

[0044] The second step, the preparation of carbon nanot...

Embodiment 2

[0051] Adopt the method provided by the invention to prepare the carbon nanotube thin film of high orientation and high strength, concrete steps are as follows:

[0052] The first step is the growth of carbon nanotube arrays;

[0053] An aluminum layer with a thickness of 30nm and an iron layer with a thickness of 1nm were successively plated on a silicon substrate as a catalyst layer by electron beam evaporation technology. Then place the silicon chip substrate coated with the catalyst layer in the quartz tube of the tube furnace. The carbon source ethylene was injected into the type furnace, and the carbon nanotubes were grown on the silicon substrate by chemical vapor deposition, and the spinnable carbon nanotube arrays with a height of 200 μm could be obtained after growing for 15 minutes.

[0054] The second step, the preparation of carbon nanotube film;

[0055] Use a blade to pull out a thin layer of single-layer carbon nanotubes about 3 cm wide from the spinnable car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com