Preparation method of aluminum-scandium alloy sputtering target material

A sputtering target, sputtering target technology, applied in sputtering coating, metal material coating process, ion implantation coating, etc. , affecting the film-forming performance and other issues, to achieve uniform particle size and microstructure, uniform chemical composition, and eliminate shrinkage porosity and shrinkage cavities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing an aluminum scandium alloy sputtering target, comprising the following steps:

[0031] The aluminum source and the scandium source are mixed, and the obtained aluminum-scandium alloy ingredients are subjected to vacuum melting to obtain a molten aluminum-scandium alloy liquid;

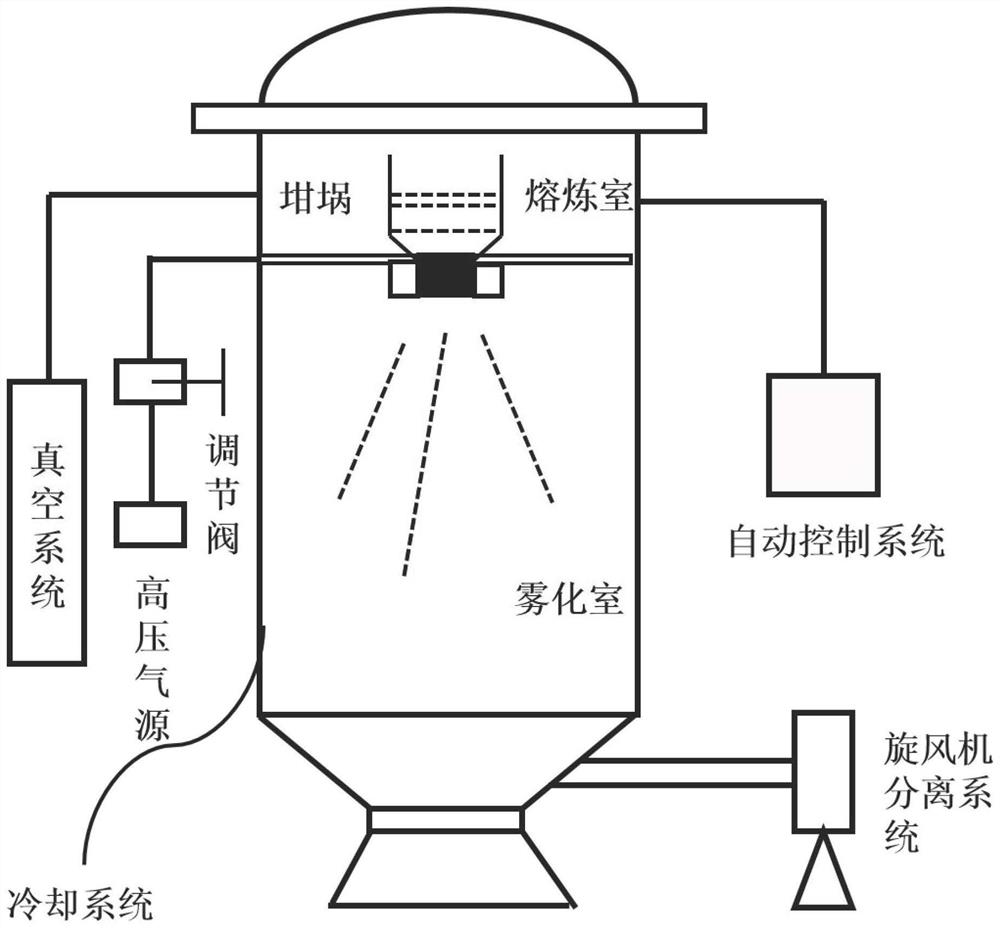

[0032] Vacuum atomizing the aluminum-scandium molten alloy liquid by using an inert gas flow to obtain aluminum-scandium alloy powder;

[0033] The aluminum-scandium alloy powder is sequentially subjected to outer sheathing and hot isostatic pressing to obtain an aluminum-scandium alloy sputtering target blank;

[0034] The aluminum-scandium alloy sputtering target blank is subjected to binding machining to obtain an aluminum-scandium alloy sputtering target material.

[0035] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0036] In the ...

Embodiment 1

[0067] according to figure 1 The process flow chart shown in the preparation of aluminum scandium alloy sputtering target:

[0068] (1) Aluminum (purity is 99.999%) is mechanically descaled, and a sulfuric acid solution with a concentration of 95wt% is used for degreasing treatment, washed with water to remove residual sulfuric acid solution and metal ions, and then placed in a vacuum drying oven at 25°C drying; the spongy scandium (purity is 99.99%) is dried in a vacuum oven at 25°C; the treated spongy scandium and aluminum are evenly mixed according to the ratio of 10at%:90at% to obtain aluminum scandium alloy ingredients;

[0069] (2) Vacuum the high-frequency induction melting furnace to a vacuum degree of 3×10 -3 Pa, the aluminum-scandium alloy batching is placed in the Al with graphite outer lining in the high-frequency induction melting furnace 2 o 3In the crucible, fill the melting furnace with high-purity argon (5N) as a protective gas, vacuum melt at 1150 °C for 2...

Embodiment 2

[0076] Prepare the Al-Sc alloy sputtering target according to the method of Example 1, the difference from Example 1 is:

[0077] In step (1), spongy scandium: aluminum=15at%: 85at%;

[0078] In step (2), the degree of vacuum is 4×10 -3 Pa, the vacuum melting temperature is 1200°C, and the superheating temperature is 150°C;

[0079] In step (3), the jet pressure is 1.7MP, and the spherical powder yield is 93%;

[0080] In step (4), the heating temperature is 1100° C., and the pressing pressure is 90 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com