Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

140results about How to "Facilitate rearrangement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

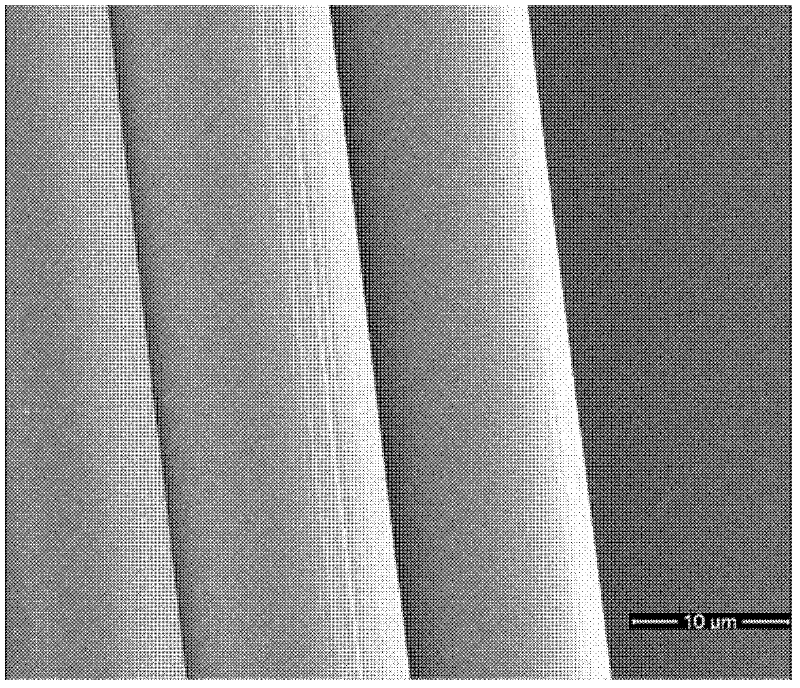

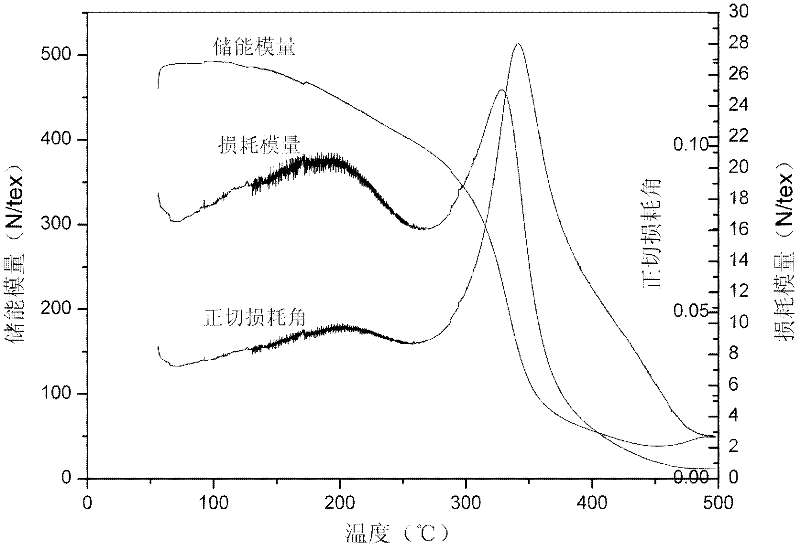

High-strength high modulus polyimide fiber and preparation method thereof

ActiveCN102345177AImprove performanceReasonable molecular structureArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention relates to high-strength high modulus polyimide fiber and a preparation method thereof, which belongs to the high performance organic fiber technical field. The fiber comprises the polyimide fiber which is prepared by biphenyltetracarboxylic dianhydride (BPDA), para-phenylene diamine (pPDA) and 2-(4-aminophenyl)-5-aminobenzimidazoles (BIA), wherein the mol ratio of pPDA to BIA is 1:10-3:1, other di-amine and di-anhydride monomers are added in the synthesis process, a gradient temperature reaction method and a one step continuous preparation method are used in the preparation process, so that the difficulties for synthesizing and processing due to the content increase of 2-(4-aminophenyl)-5-aminobenzimidazoles are solved, the problems of poor homogeneity and stability of thefiber performance can be solved, and the high-strength high modulus polyimide fiber can be obtained, the strength can reach 4.5GPa, the modulus can reach 201GPa, and the raw material source is wide, the spinning process can be continuously performed, the method has low cost and high efficiency which is capable of realizing the industrial production.

Owner:JIANGSU XIANNUO NEW MATERIAL TECH

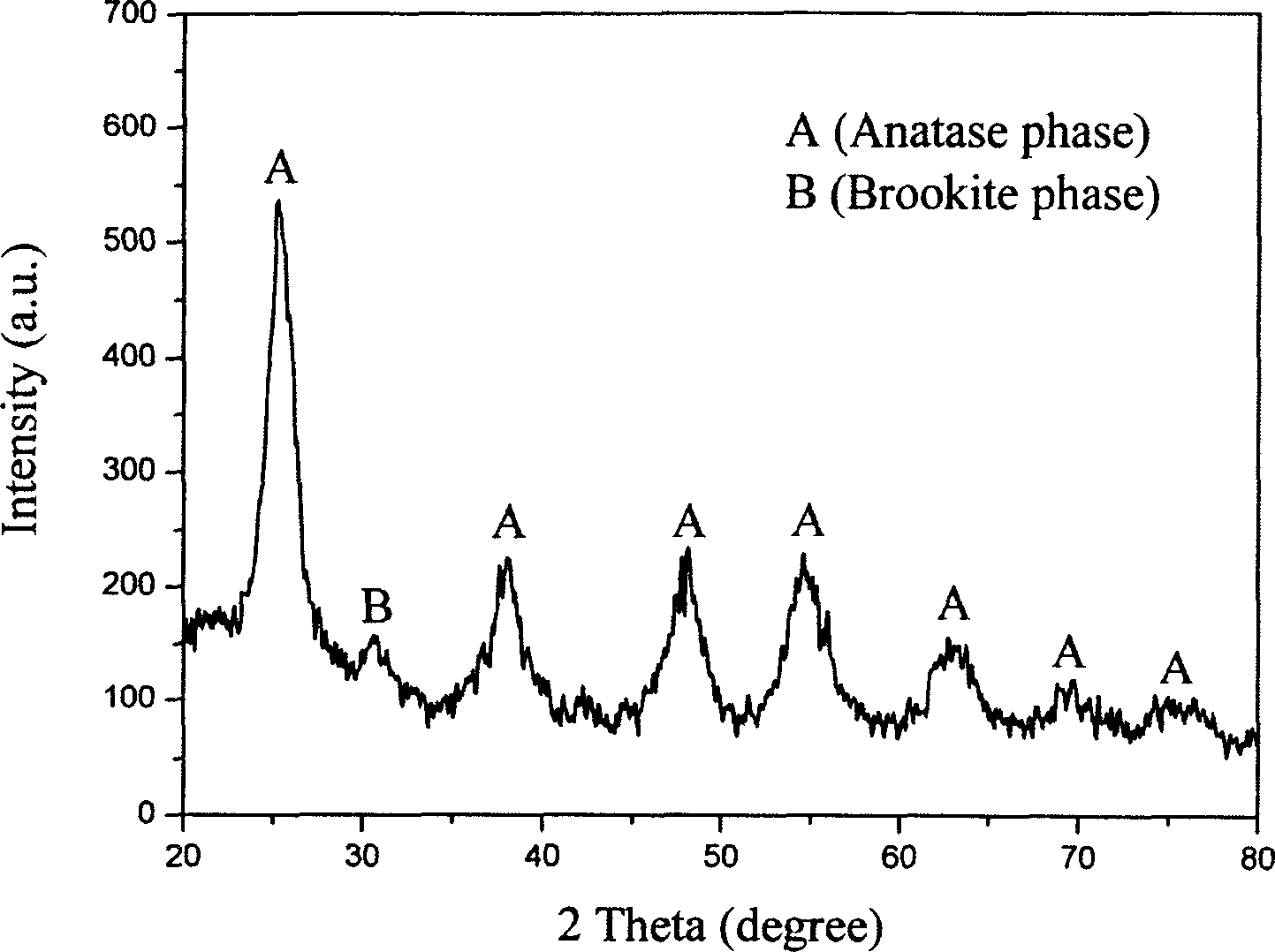

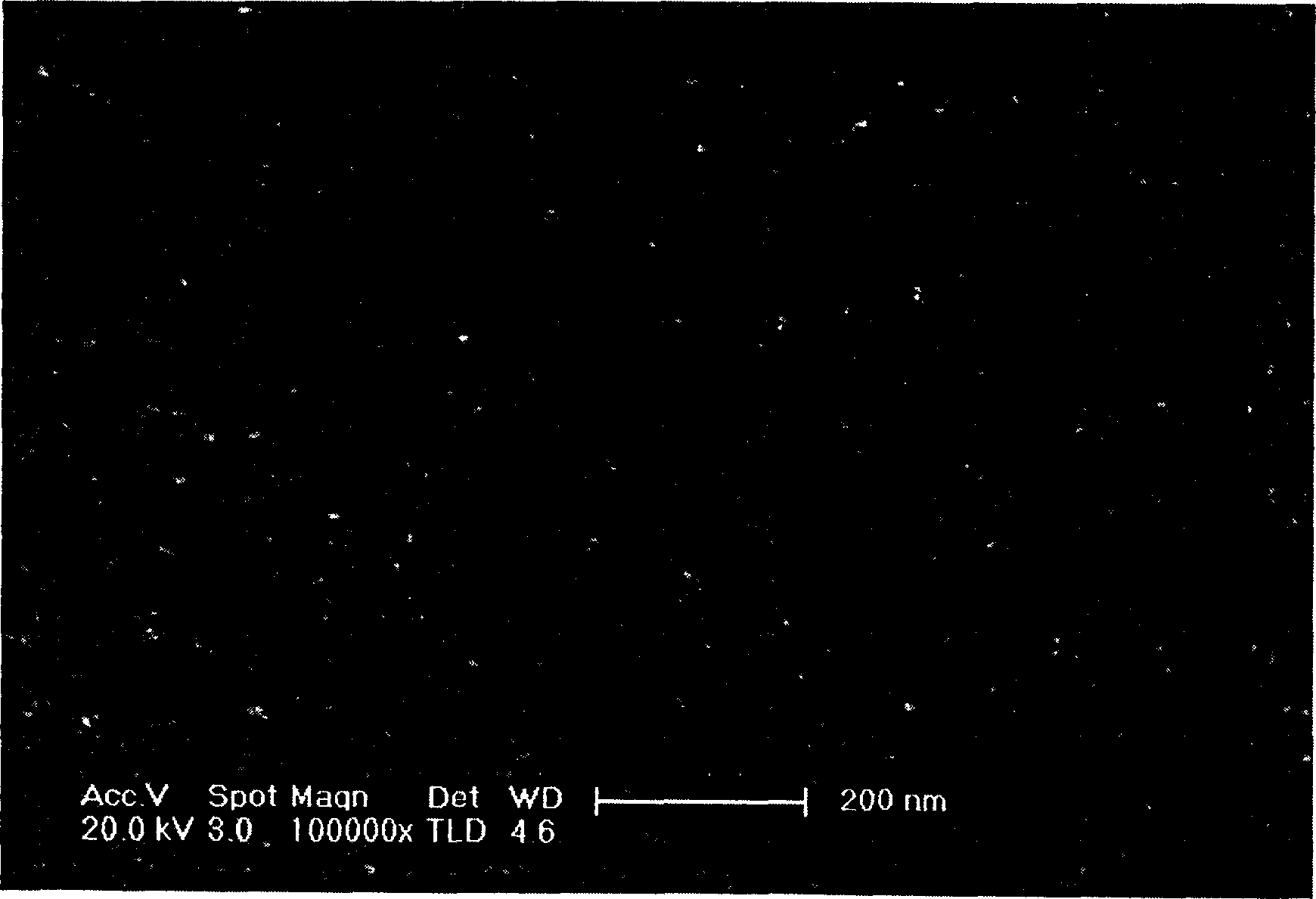

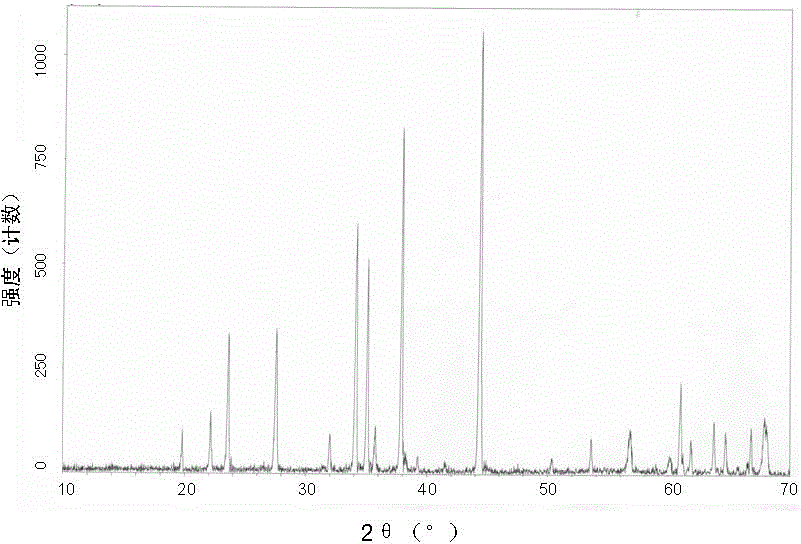

Process for preparing anatase type TiO2 sol

InactiveCN1699181AReduce energy consumptionImprove bindingPhysical/chemical process catalystsTitanium dioxideAlcoholDecomposition

The invention discloses a process for preparing anatase type TiO2 sol which comprises preparing alcoholic solution of titanium compounds from titanium compounds and alcohols by the mol ratio of 1:1.42-12, agitating and dropping the alcoholic solution of titanium compounds into the water solution of acid with pH=1.0-4.0 for hydrolytic decomposition, the mol ratio of titanium compounds and water in the aqueous solution of acids being 1:76-151, inversing flow for 6-48 hours at 65-85 deg. C, evaporating the obtained sol at 50-55 deg. C to remove the alcohols, thus obtaining octahedrite type titanium dioxide collosol.

Owner:SOUTHEAST UNIV

High-strength high-conductivity oxidation-resisting low-silver copper-base alloy and preparation thereof

A copper base alloy, which possesses high-strength, high conductivity, oxidation resistance and contains silver of low content, is characterized in that said high-strength high-conductivity oxidation-resistance low-silver copper base alloy is composed of low-silver copper base alloy powder, diamond powder of 0.2-1.0% and graphitized nanometer carbon fibre and is prepared through a powder metallurgy technological process, wherein said low-silver copper base alloy powder contains Ag of 0.08 -0.12%, Y, La and Ce of 0.05 -0.5% or one of misch metal or mixture of several misch metal. Said alloy in accordance with the present invention possesses higher intensity and hardness, stronger anti-crackle forming and stomatic expandability, and exhibits definite puddle welding resistance and better electroconductive performances at the same time.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

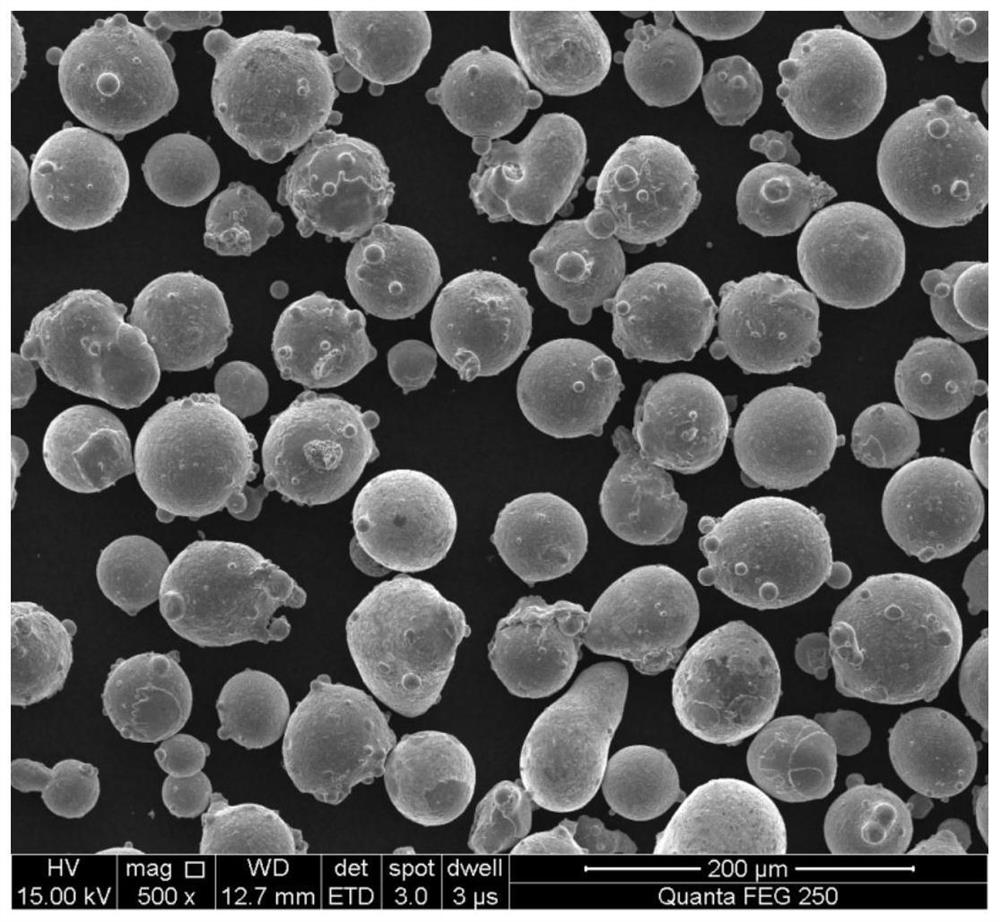

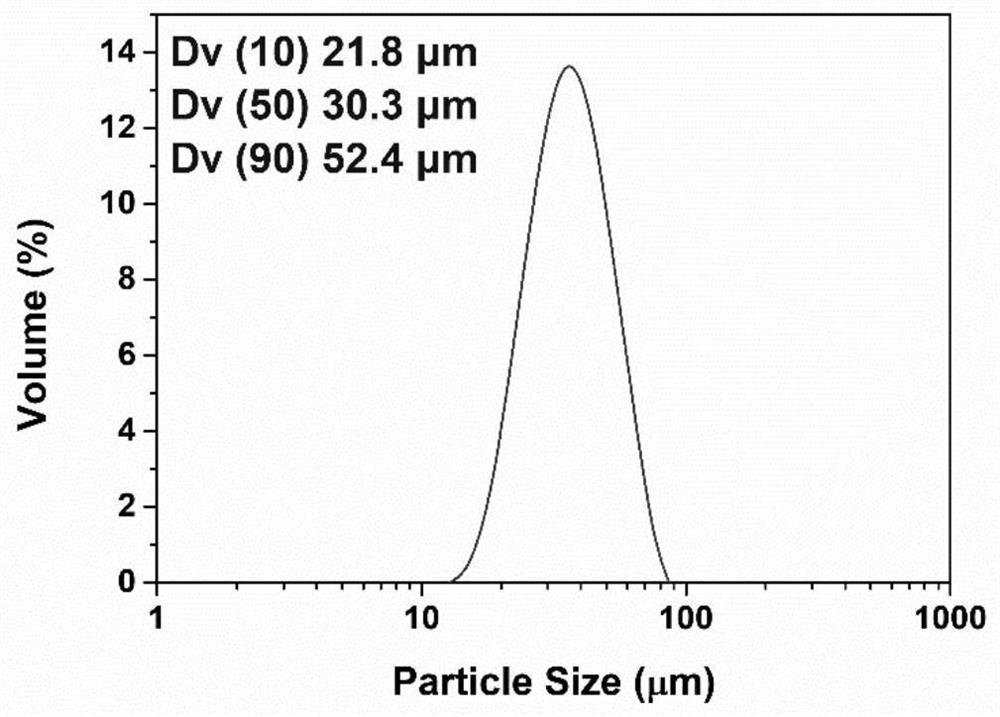

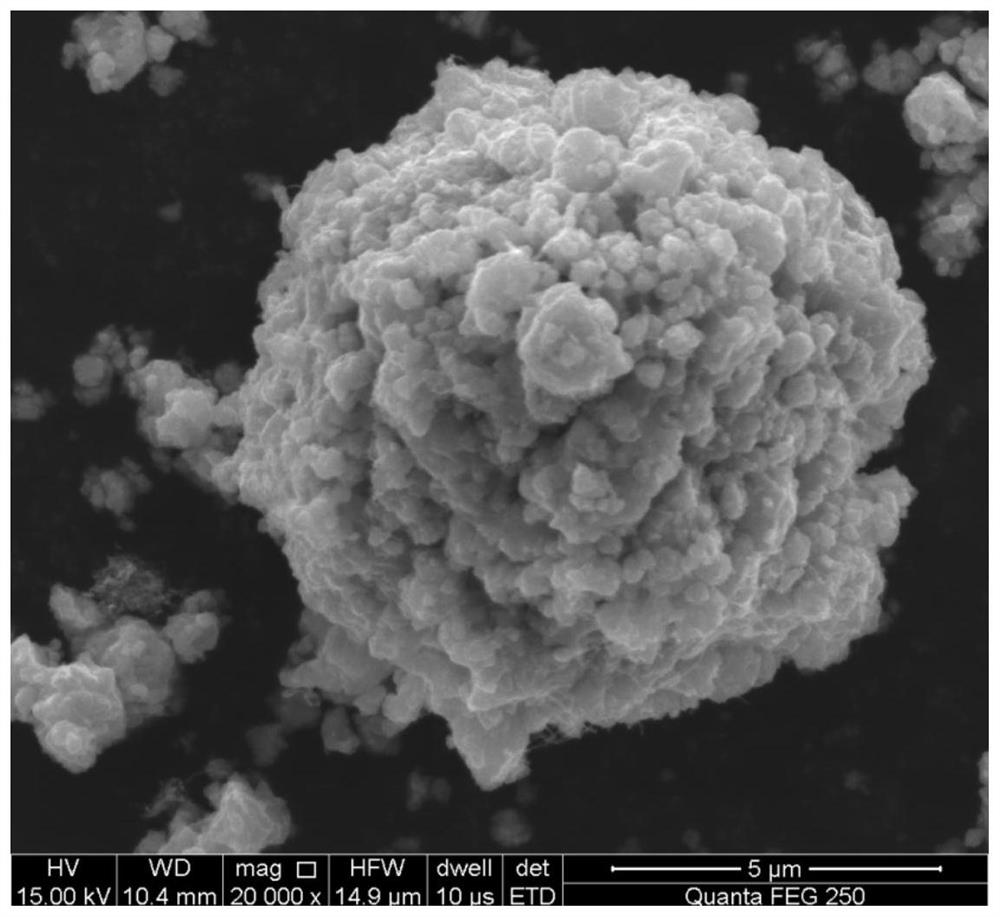

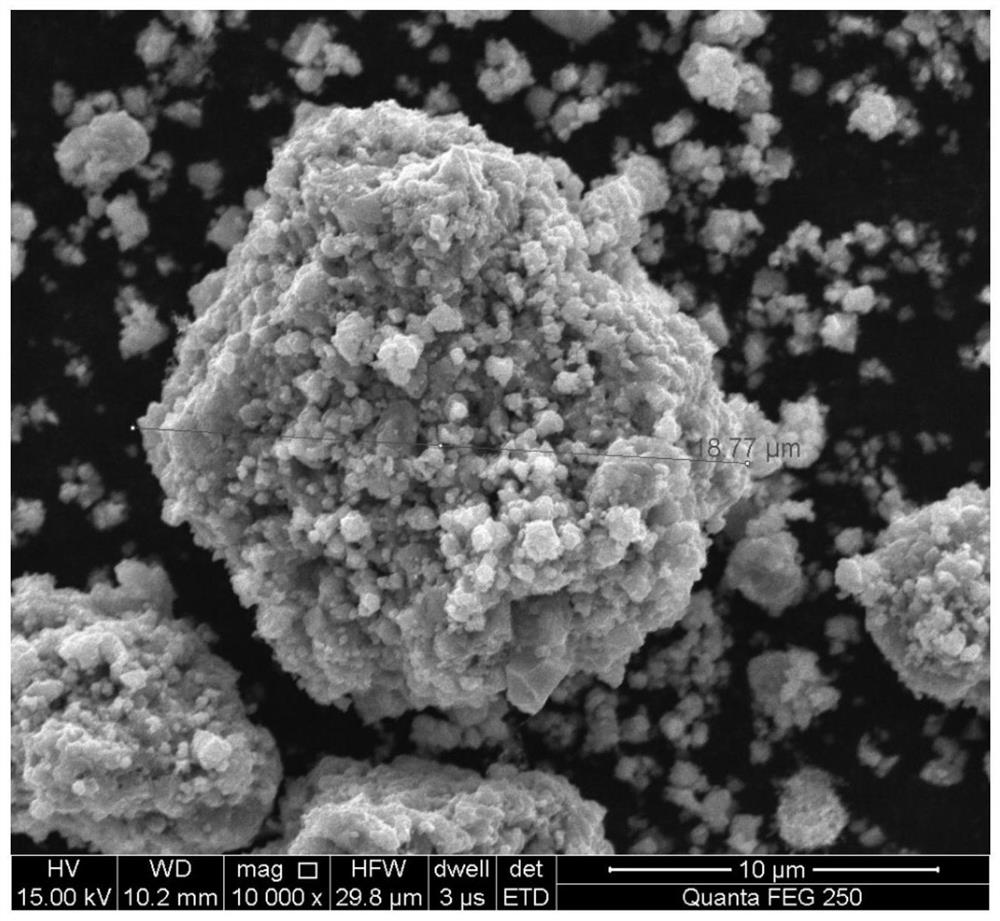

Nano ceramic metal composite powder for 3D printing and application

ActiveCN111940723AHigh sphericityGood liquidityAdditive manufacturing apparatusTransportation and packagingCeramic particleCeramic metal

The invention provides nano ceramic metal composite powder for 3D printing and application. A metal material is used as a matrix, and ceramic particles are used as a reinforcing phase. One or more ceramic particles of micron-sized TiC, TiB2, WC, SiC, CrC, Al2O3, Y2O3 and TiO2 are used as raw materials, the mass percent of the added ceramic particles is 0.5-10.0%, through a specific ball milling process, plasma spheroidization, airflow classification and screening, the metal composite powder with high sphericity, good fluidity, narrow particle size range and uniformly distributed nano-ceramicsis obtained, and the high requirement of a 3D printing technology for powder is met; and a nano-ceramic reinforced metal composite material is prepared through the 3D printing technology. According tothe prepared metal composite material, nano ceramic phases are uniformly distributed, and the metal composite material has excellent mechanical properties. Micron-sized ceramic particles are adopted,uniform dispersion is achieved through nanocrystallization, and the cost is low; and parts in any complex shape can be integrally formed and prepared, and the material utilization rate is increased.

Owner:CENT SOUTH UNIV

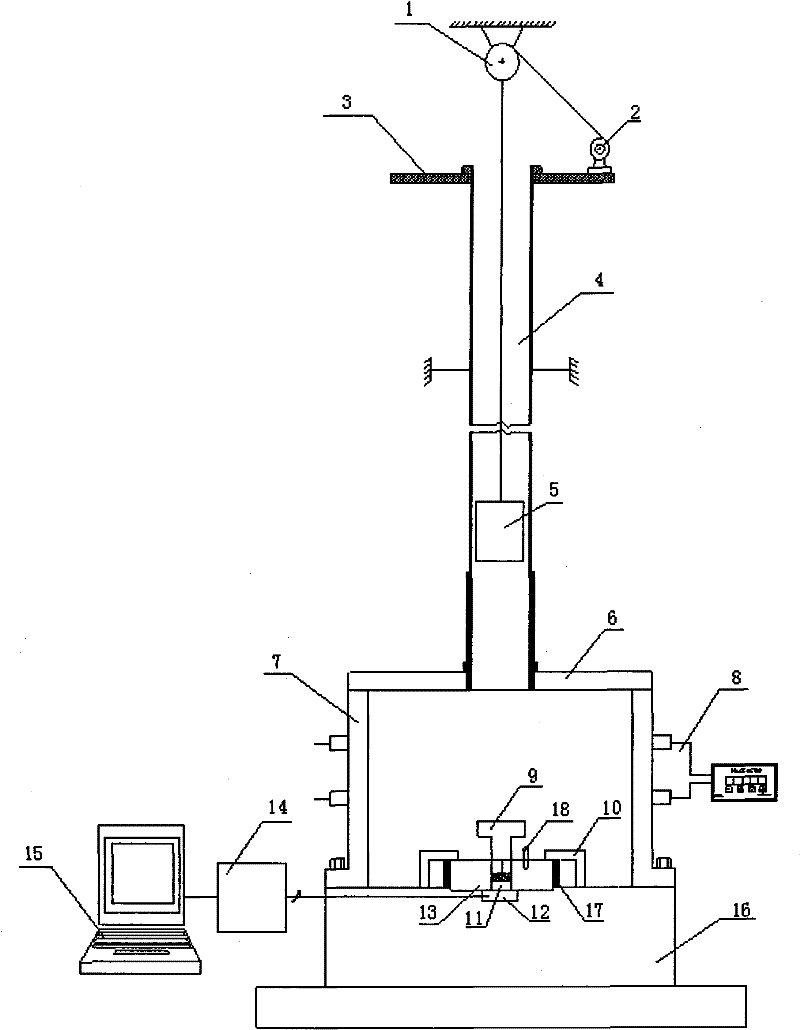

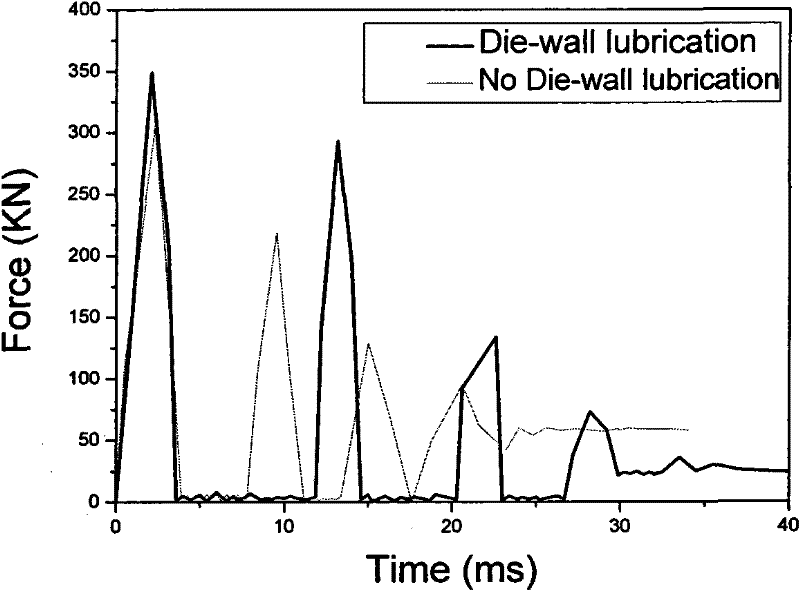

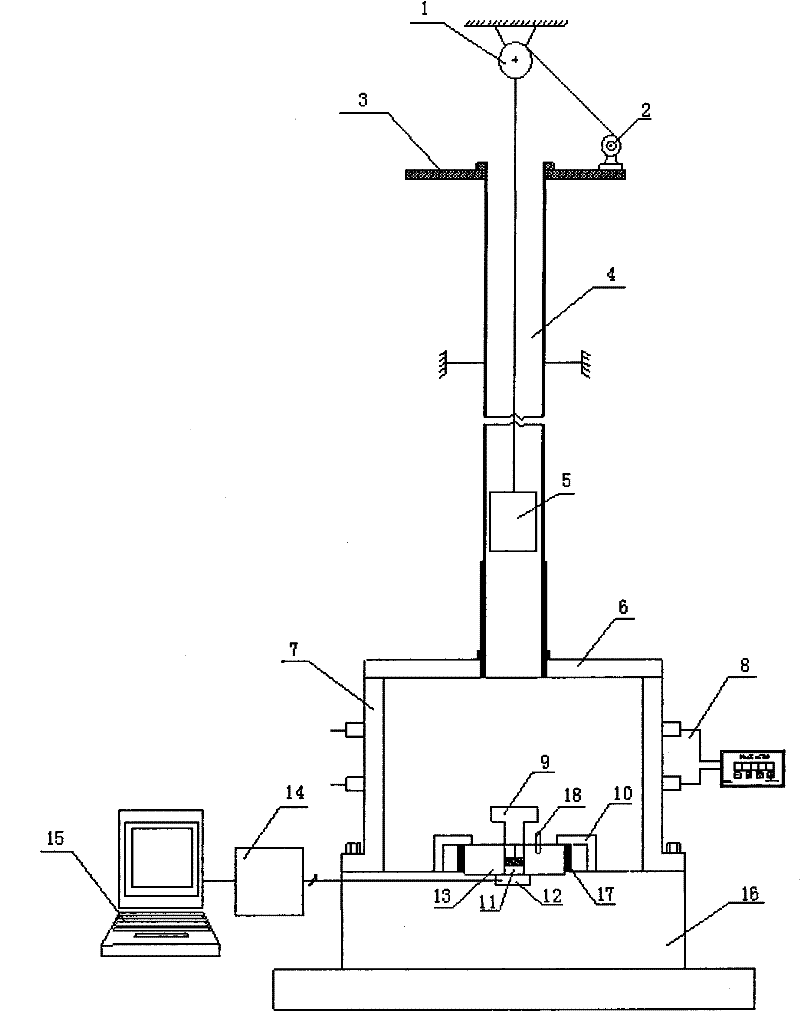

High speed pressing and forming method of warm powder and device thereof

InactiveCN101745638AIncrease the speed of warm pressingPromote particle rearrangementShock waveIntegrated technology

The invention discloses a high speed pressing and forming method of warm powder and a device thereof. The method is an integrated technology of warm-pressing as well as high speed pressing and forming, takes the gravitational potential energy of a drop hammer as pressing energy, a punch hammer falls down to impact on an upper punch to transfer the energy to the powder so as to rapidly and densely form the powder. The punch hammer rope of the device for carrying out the method is connected with a motor by a pulley installed above a guide cylinder and is kept to freely and vertically move in the guide cylinder; a speedometer is symmetrically installed on the two sides of a side die plate; a heating ring is directly sleeved on a die; a pressure sensor is contacted with the lower die punch and is connected with a data acquisition card; and the data acquisition card is connected with a computer by a USB interface. The pressing graph of a shock wave is displayed on the computer, and the maximum value of an impact force and the time impacting on the powder can be directly read from the graphs; and the invention has simple structure, convenient use, reliability and practicability as well as relative low price, is particularly suitable for colleges and universities as well as research and development institutions.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing multi-scale ceramic phase reinforced metal composite material by 3D printing

ActiveCN111957967ANarrow particle size rangeEvenly distributedAdditive manufacturing apparatusTransportation and packagingMicron scaleMetallic materials

The invention provides a method for preparing a multi-scale ceramic phase reinforced metal composite material by 3D printing, which takes a metal material as a base body and takes ceramic particles asa reinforcement phase. The method comprises the following steps: adopting one or more ceramic particles of micro TiC, TiB2, WC, SiC, CrC and Al2O3 as raw materials, adding the ceramic particles and certain proportion of metal powder in batches, wherein mass percentage of the added ceramic particles is 0-10.0%; and performing a special ball-milling process, plasma spheroidizing, gas-flow grading and screening to obtain multi-scale uniform-ceramic-phase metal composite powder which is good in spheroidizing degree, is good in mobility and is narrow in particle size range, thereby obtaining multi-scale ceramic phase reinforced the metal composite material prepared by 3D printing. The prepared metal composite material is uniform in ceramic phase distribution, has different scales, and is excellent in mechanical property. Micro-scale ceramic particles are adopted, so that cost is low; and parts with any complex shapes can be prepared through integral forming, so that a material utilizationrate is increased.

Owner:CENT SOUTH UNIV

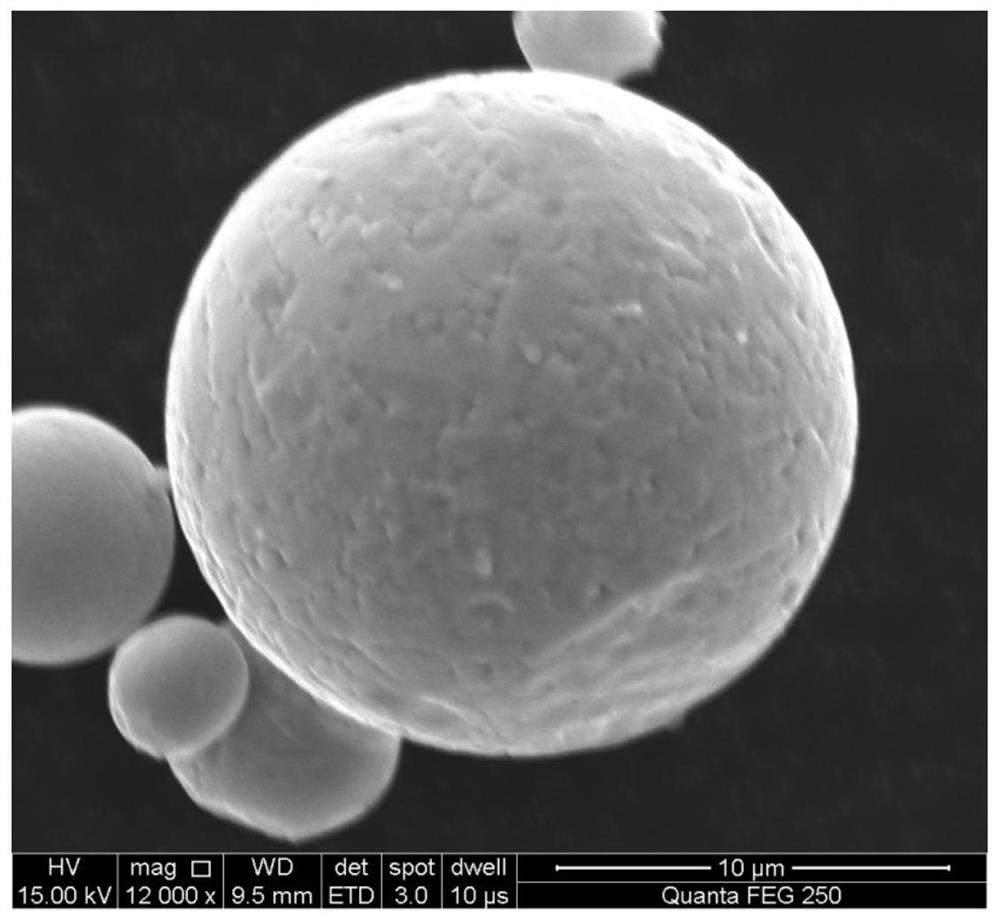

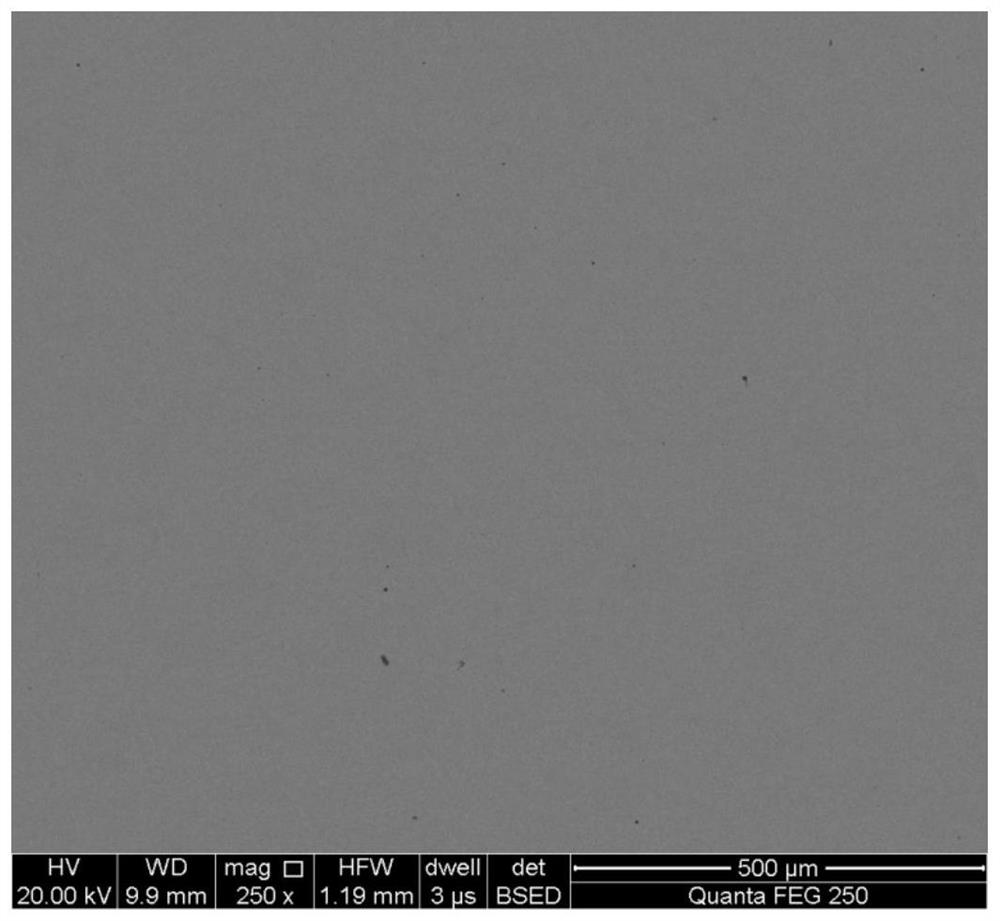

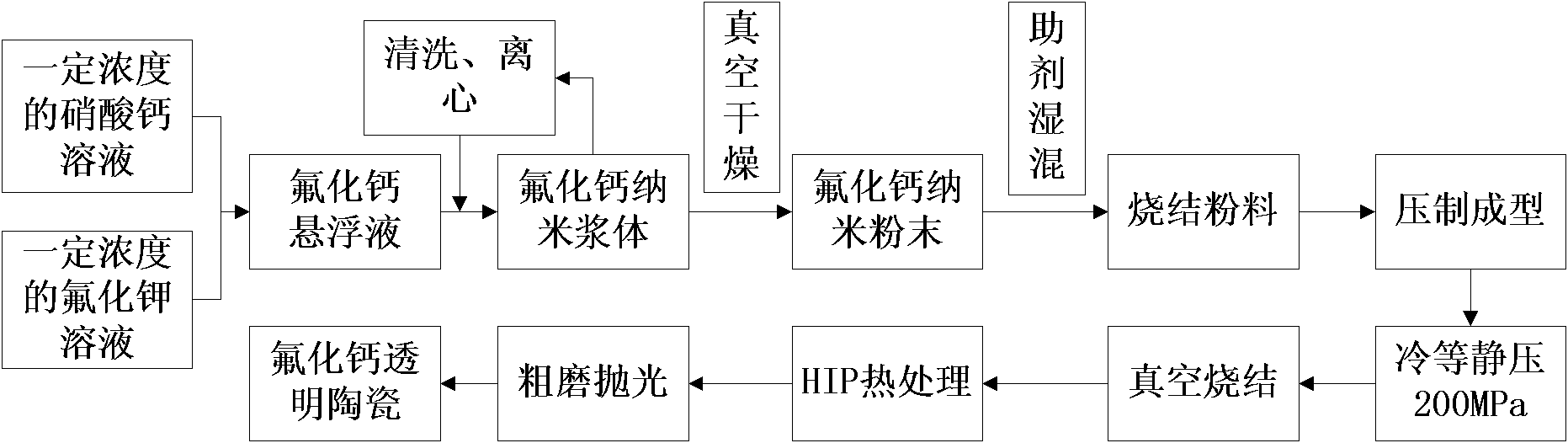

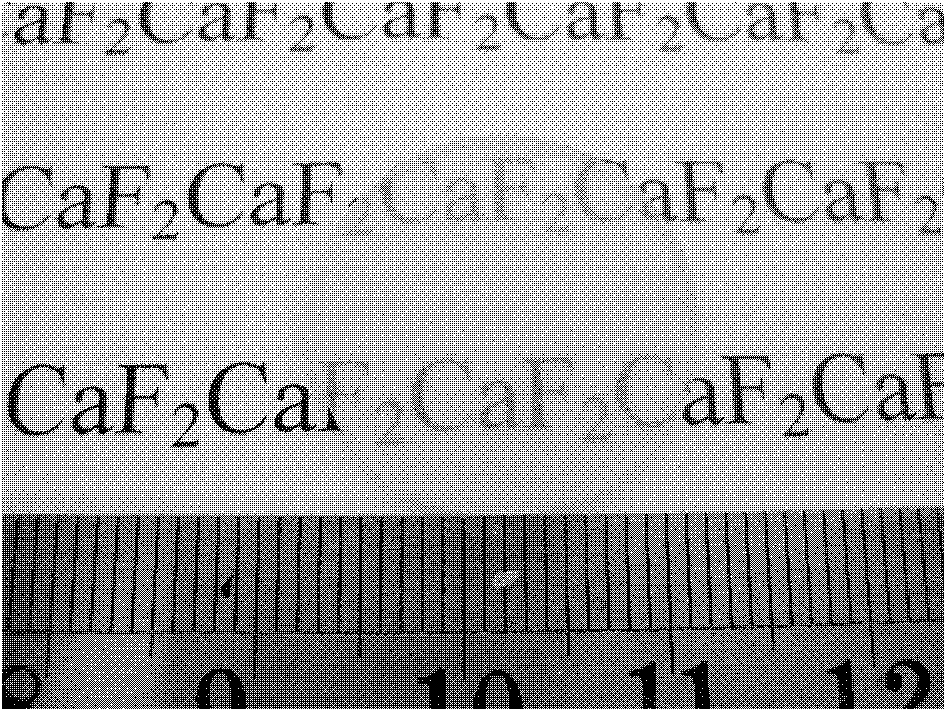

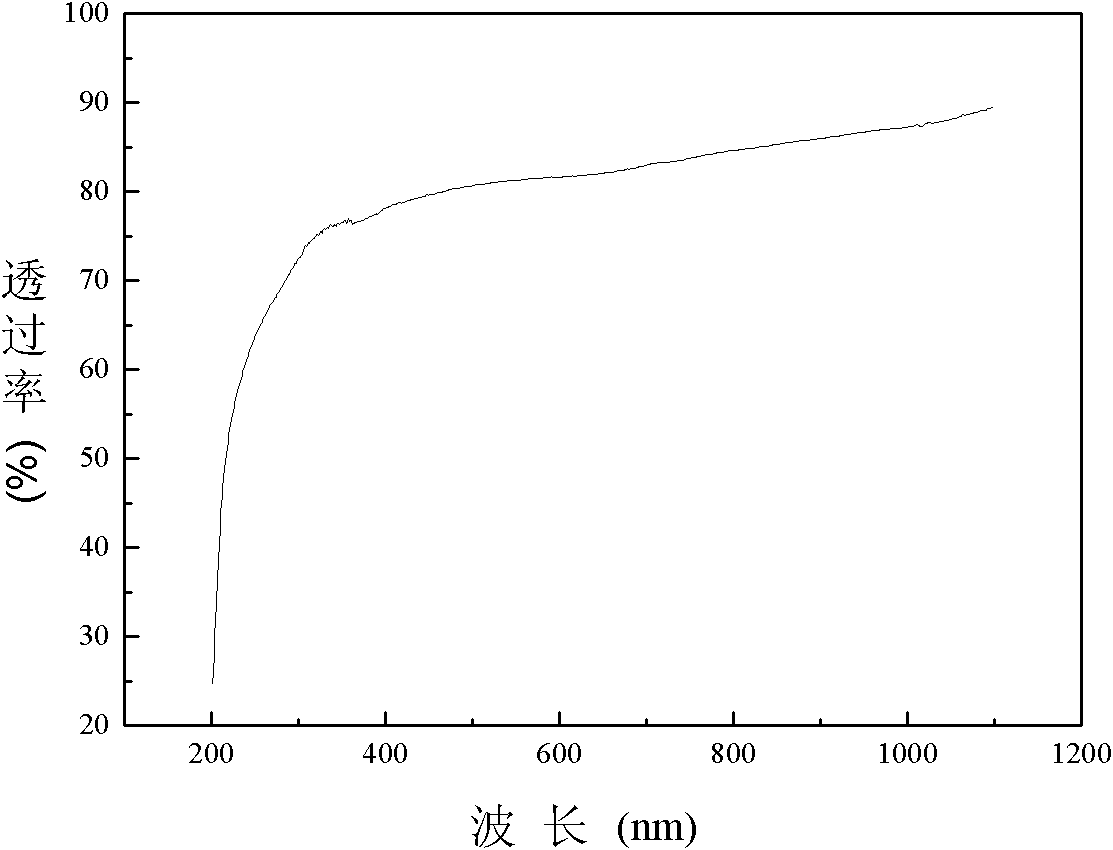

Method for preparing transparent calcium fluoride ceramic

The invention relates to a method for preparing transparent calcium fluoride ceramic, comprising the steps of nano raw powder synthesizing, vacuum sintering, heat treatment and product finishing, wherein the adopted sintering powder is nano powder which is synthesized by adopting a chemical reaction precipitation method and has the grain size of 20-70nm; the adopted sintering auxiliary is lithiumfluoride (0.5-5mol%) and sodium fluoride (0.5-3mol%); the processes are adopted, of the prepared transparent calcium fluoride ceramic prepared by vacuum sintering and heat aftertreatment has the density of not lower than 99.5% and the transmittance in visual and near infrared bands of lower than 75%, thus the ceramic is an ideal transparent material. The invention has the advantages that the raw material yield is high, the operation is simple and the ceramic transmittance is high.

Owner:WUHAN UNIV OF TECH

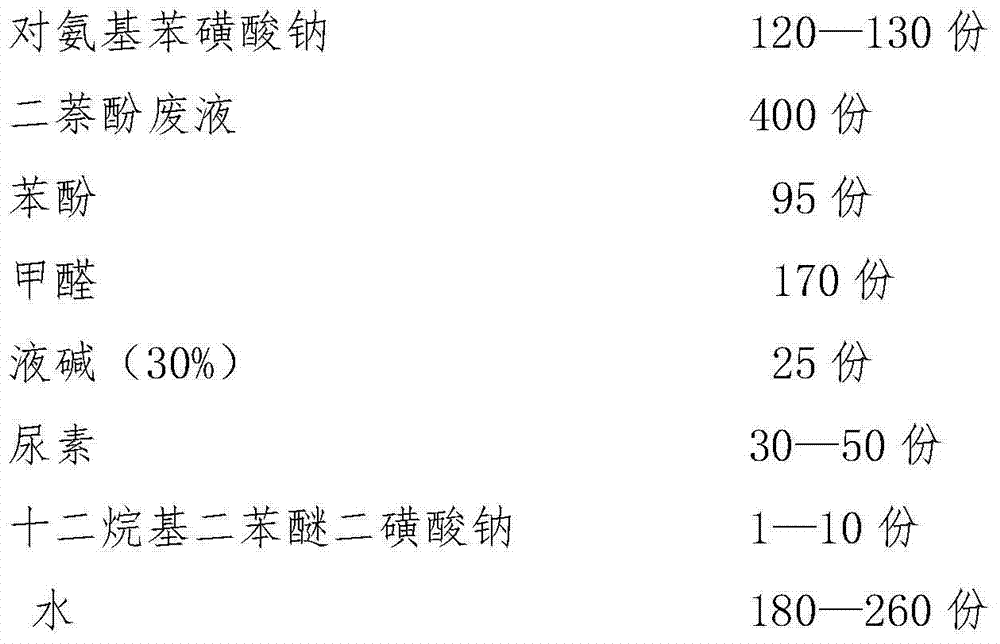

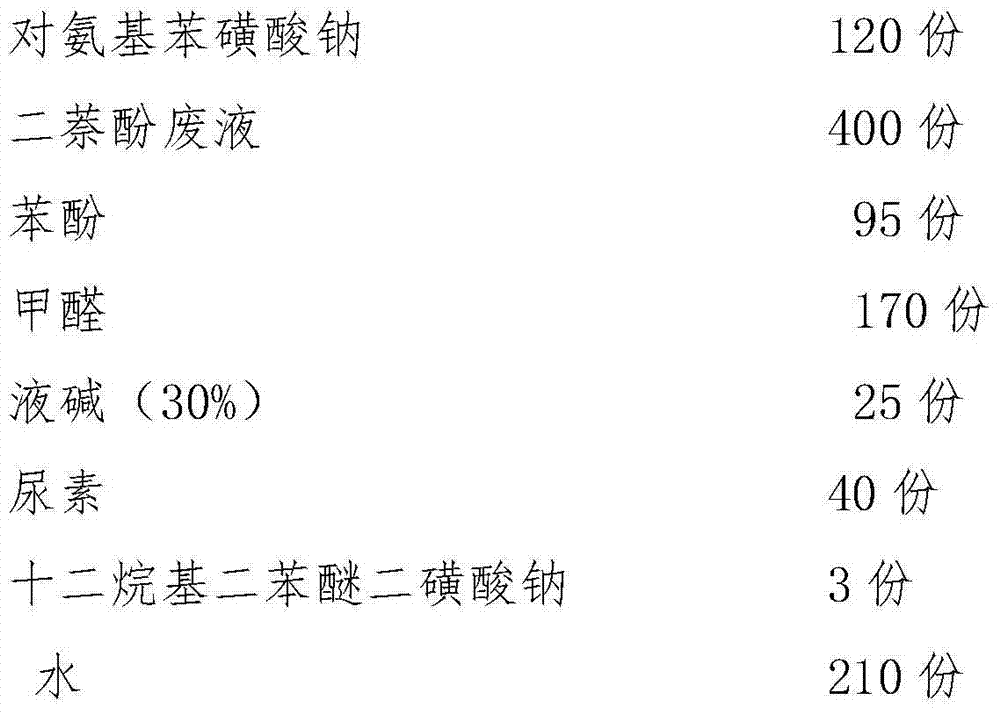

Modified sulfamate efficient water reducer and preparation method thereof

The invention provides a modified sulfamate efficient water reducer and a preparation method thereof, particularly relates to a dinaphthol waste modified sulfamate efficient water reducer and relates to the technical field of waste treatment. The reducer comprises raw materials of, by weight, 120 parts to 130 parts of sodium sulfanilate, 400 parts of dinaphthol waste, 95 parts of phenol, 170 parts of formaldehyde, 25 parts of liquid caustic soda (30%), 30 parts to 50 parts of urea, 1 part to 10 parts of dodecyl diphenyl ether sodium disulfonate and 180 parts to 260 parts of water. By means of the water reducer and the preparation method thereof, dinaphthol waste recycling is achieved, waste water are not needed to be subjected to concentration or any other treatment of physical chemical treatment and the like, energy consumption is saved, and pollution and damage of the waste to the environment and humans are prevented.

Owner:萧县沃德化工科技有限公司

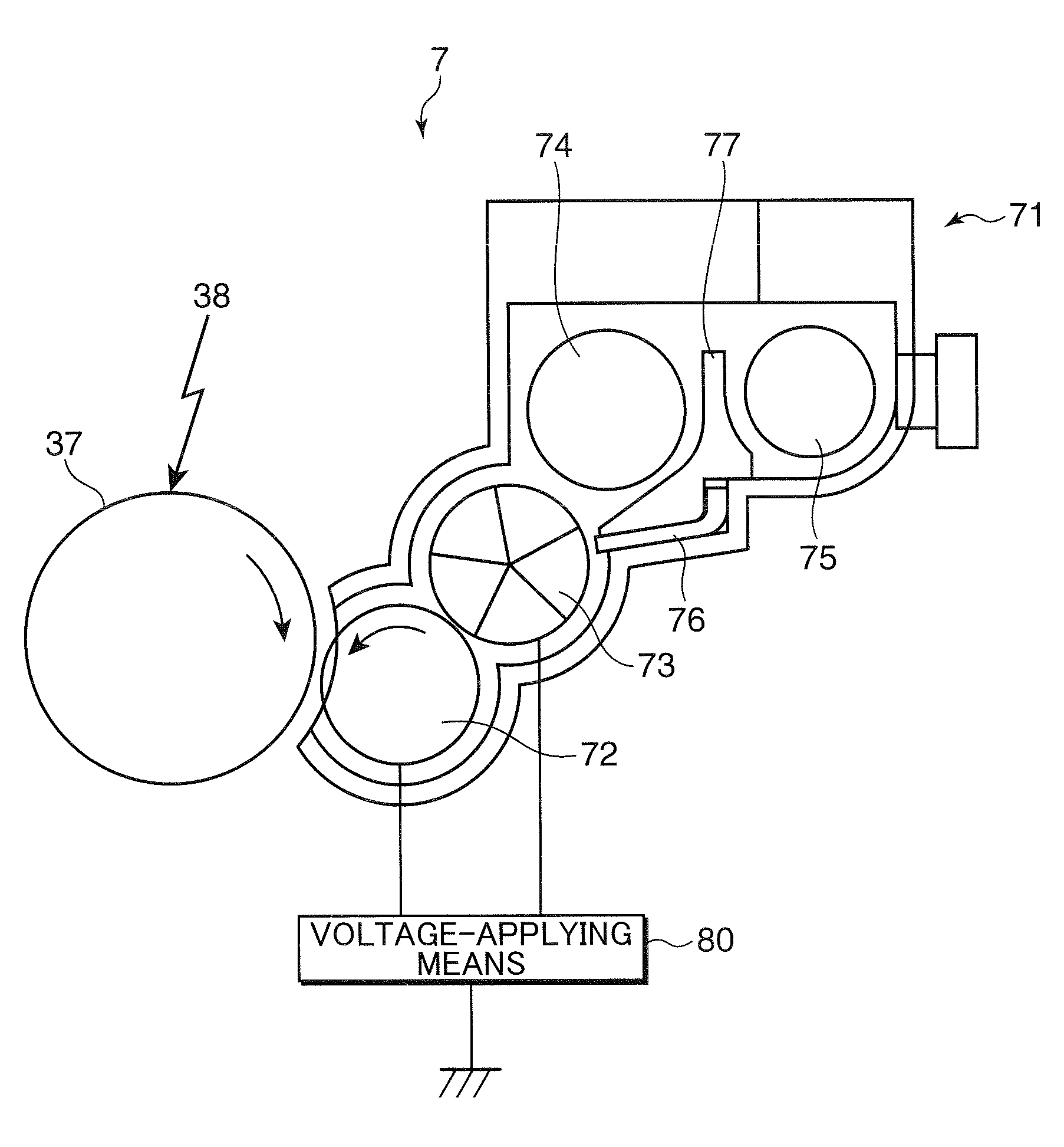

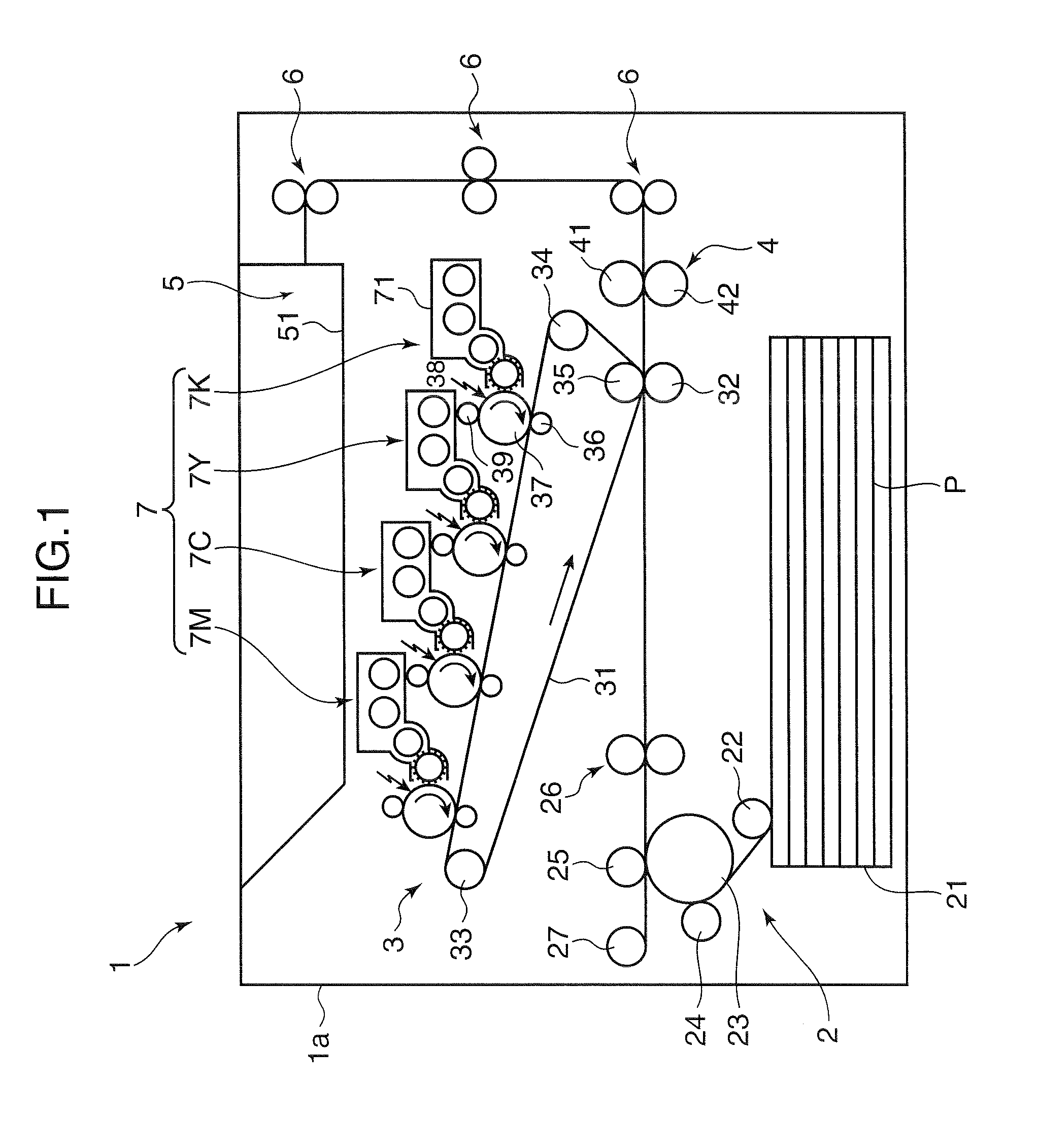

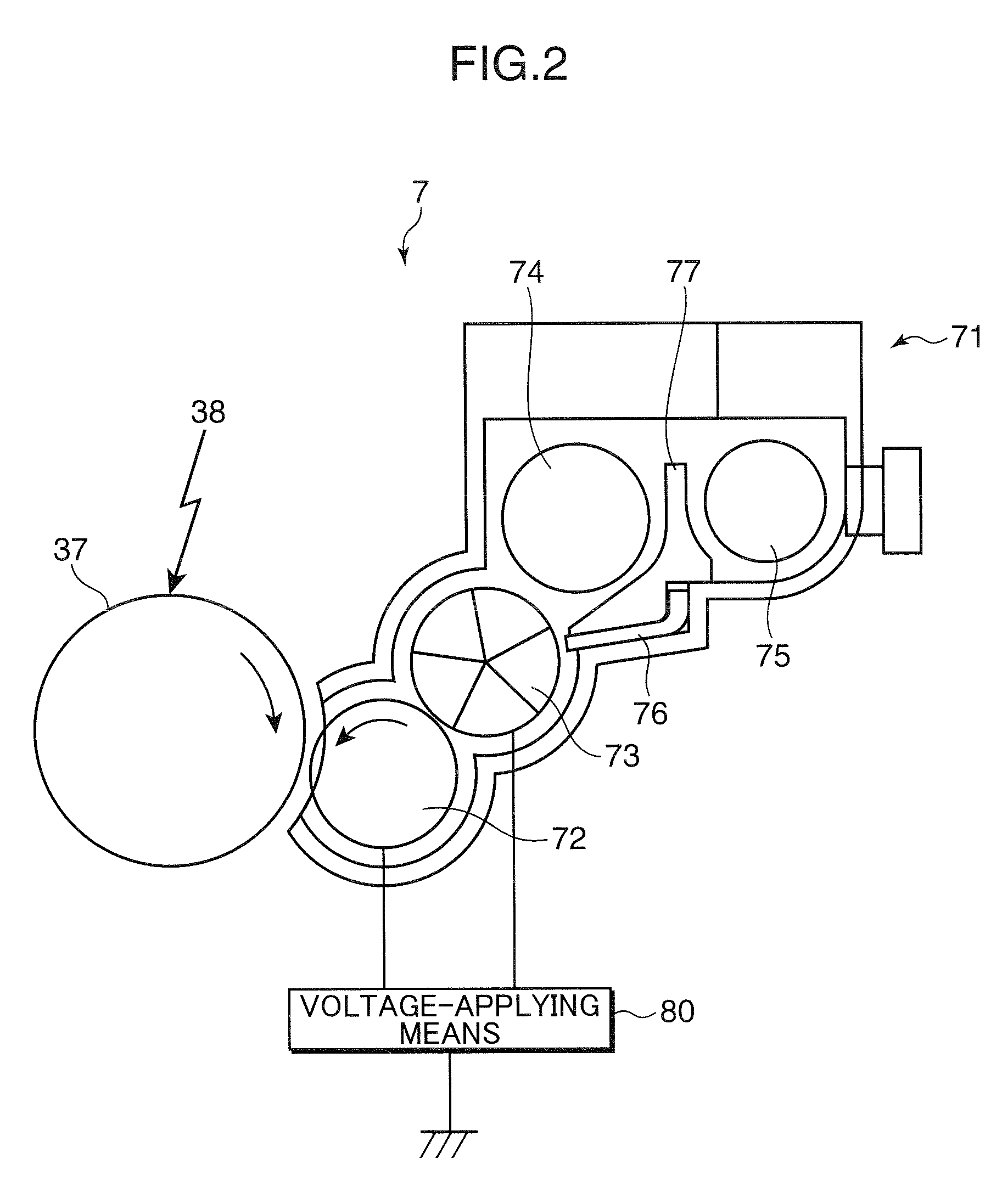

Developing unit and image forming apparatus

ActiveUS20080226320A1Suppress image unevennessLow densityElectrographic process apparatusLatent imageImage formation

A developing unit has a voltage-applicator (80) to apply a developing bias voltage to a developing roller (72). The voltage-applicator (80) applies the developing bias voltage for a first duration to apply an AC voltage having a rectangular waveform, and a second duration to stop applying the AC voltage. The AC voltage has a duty ratio of 50% or more in a direction for causing toner to develop an electrostatic latent image. The number of cycles of the AC voltage in the first duration is two or more, and the AC voltage has a voltage in a direction for pulling the toner back to the developing roller, just before transition to the second duration. The developing unit suppresses occurrence of image unevenness due to a fluctuation in developing gap. Thus, an image forming apparatus equipped with the developing unit forms a high-quality image while suppressing image unevenness.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

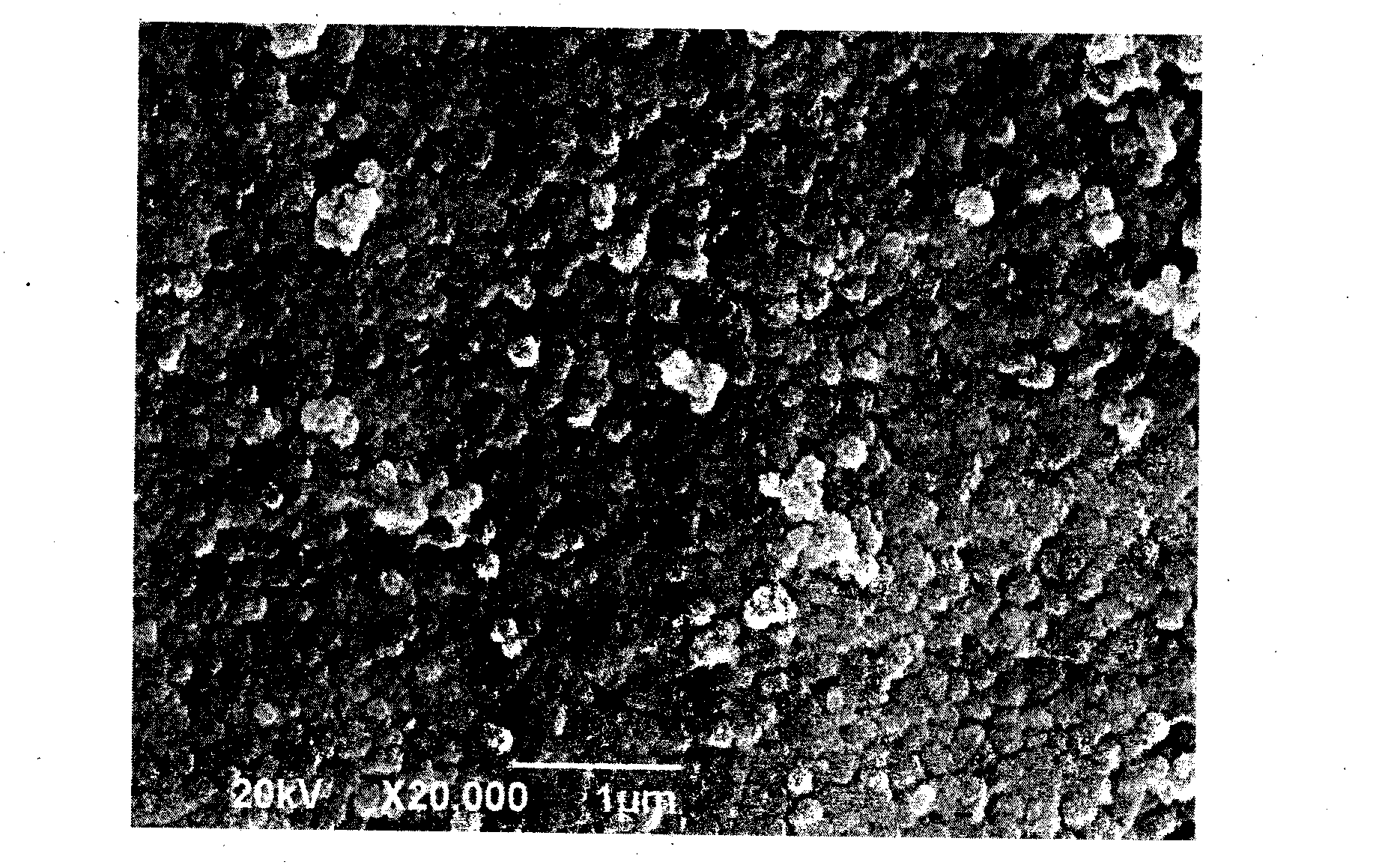

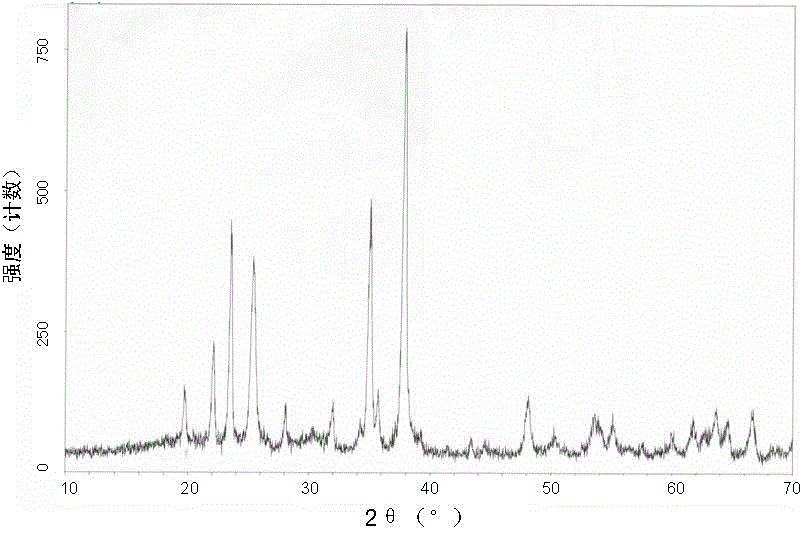

Method for improving ceramic sintering performance by adding a small amount of polylactic acid in artificial bone prepared by laser

InactiveCN103467104APromote rearrangement and densificationImprove sintering performanceProsthesisBone tissue engineeringDisadvantage

A method for improving ceramic sintering performance by adding a small amount of polylactic acid in an artificial bone prepared by laser belongs to the field of bone tissue engineering. When a selective laser sintering (SLS) technology is used for preparing a porous biphasic calcium phosphate ceramic (BCP) artificial bone, a sintering part has the disadvantages of low density and insufficient mechanical properties, and the invention aiming at the disadvantages provides the method for improving BCP sintering performance by adding 0.1-1% by mass percentage of poly-L-lactic acid (PLLA). The advantages of the method are that: a transient liquid phase introduced by use of low temperature fusion of the PLLA can promote the rearrangement and densification of BCP particles so as to improve BCP sintering performance; the PLLA can be fully oxidized until complete disappearance under reasonable process parameters, PLLA residual in the artificial bone can be avoided, and finally the high-performance porous artificial bone completely made from BCP is prepared. The invention relates to the method for improving calcium phosphate bioceramic laser sintering performance by adding a small amount of a polymer material, and the method has the characteristics of simple operation process, good product performance and wide application range.

Owner:CENT SOUTH UNIV

High-compactness boron carbide composite ceramic material preparation method

The invention relates to a high-compactness boron carbide composite ceramic material preparation method, which comprises: 1) preparing uniformly-mixed raw material powder, wherein the raw material powder comprises boron carbide powder, transition metal boride powder, transition metal oxide powder, carbon and / or a carbon precursor substance; and 2) preparing the biscuit of a boron carbide composite ceramic material from the raw material powder prepared in the step 1), and sintering the biscuit at a temperature of 2000-2150 DEG C in a vacuum or inert atmosphere to obtain the boron carbide composite ceramic material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

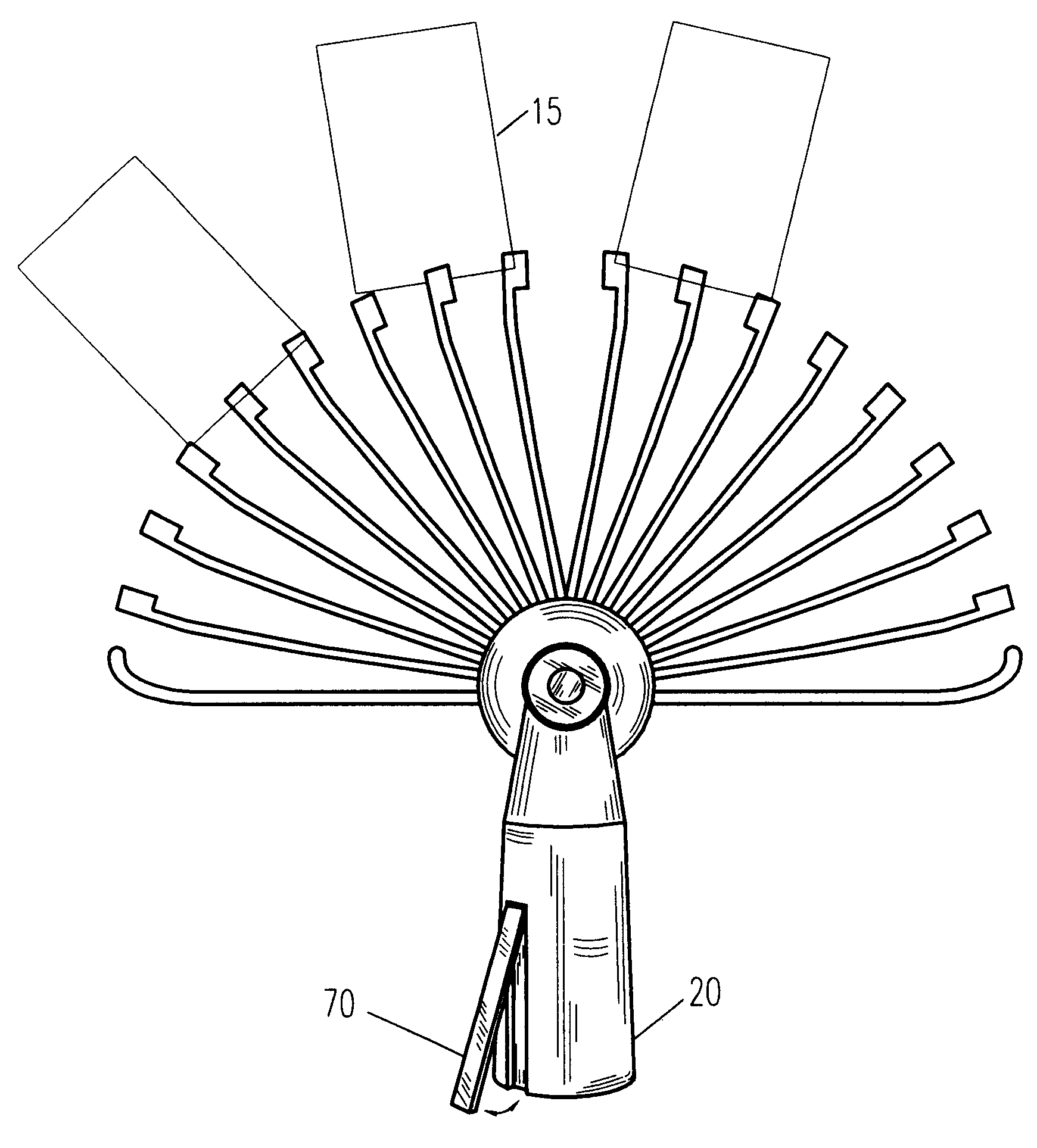

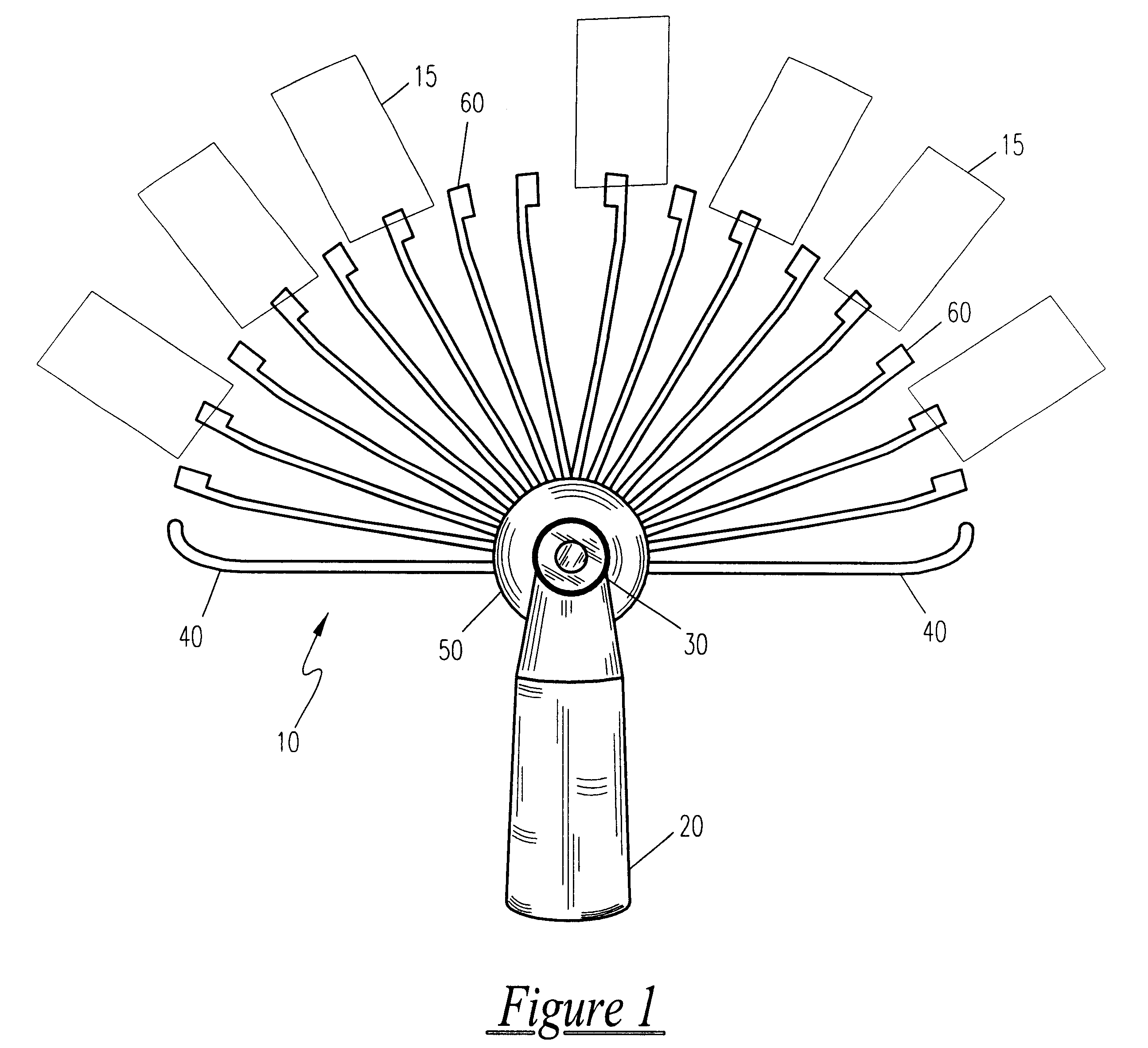

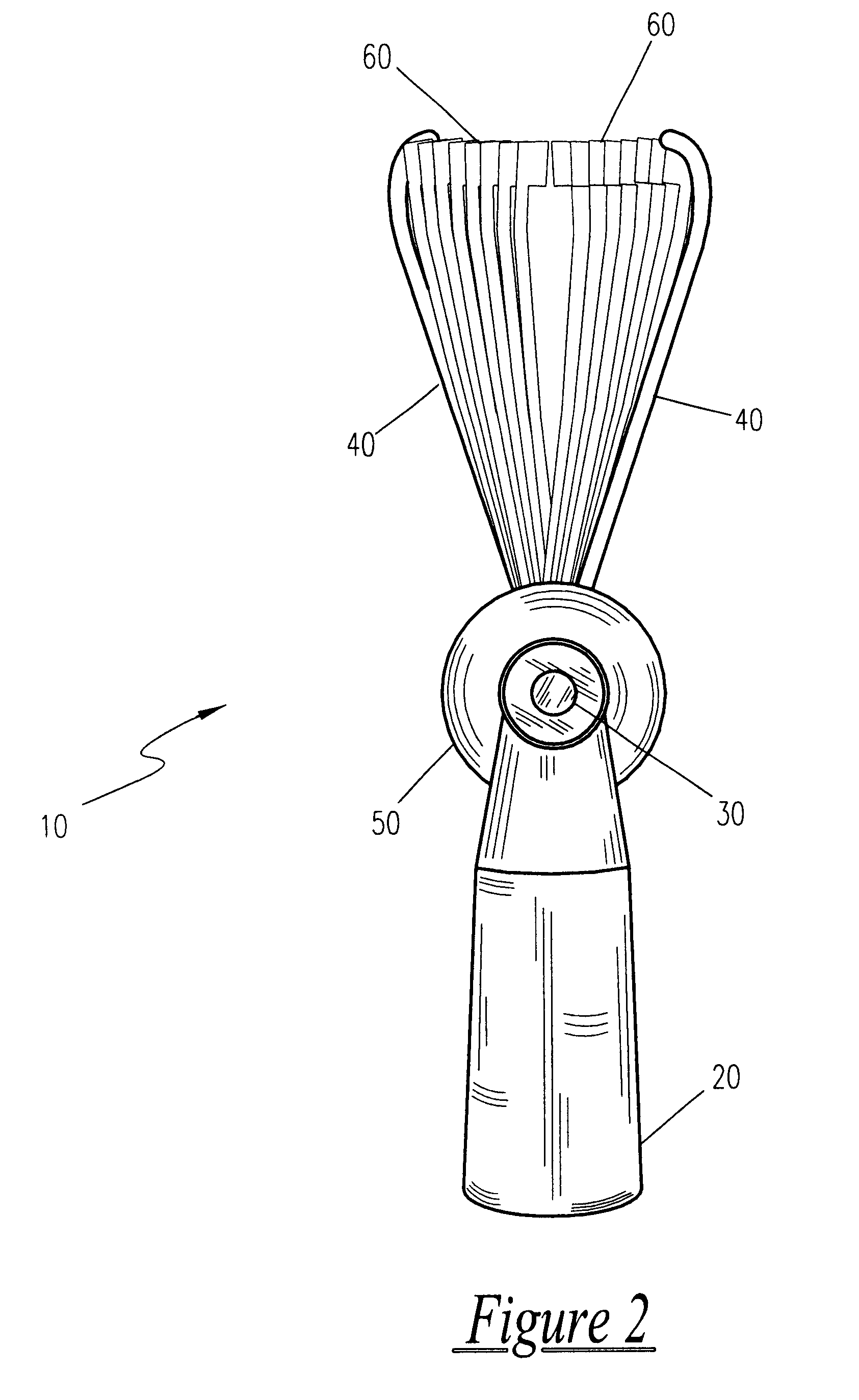

Collapsible, game card holding means

InactiveUS6349940B1Reduce the amount requiredFacilitate rearrangementCard gamesPlaying cardEngineering

A collapsible, game card holding means is provided having a handle that allows the user to organize and hold a hand of playing cards and greatly reduces the amount of effort required to maintain the hand. Pivotally attached to the top of the handle portion are a plurality of flexible fingers. The flexible fingers can be laterally separated and retracted in a fan-like configuration, even while the playing cards are positioned and held in place at the end of the flexible fingers by a playing card securement means. A stand extends from the base of the present invention to permit the present invention to remain in the vertical position without being held. In an alternate embodiment, fan facie covers the front of the present invention, providing a visible barrier to viewing of the playing cards in the card securement means.

Owner:NIMRY BETTY FLORENE

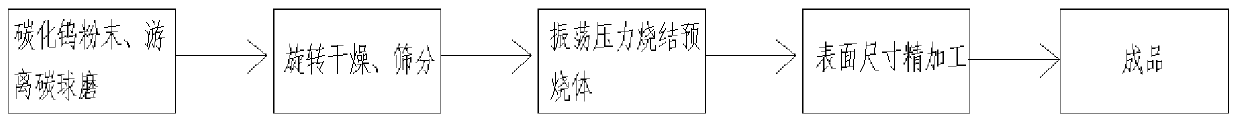

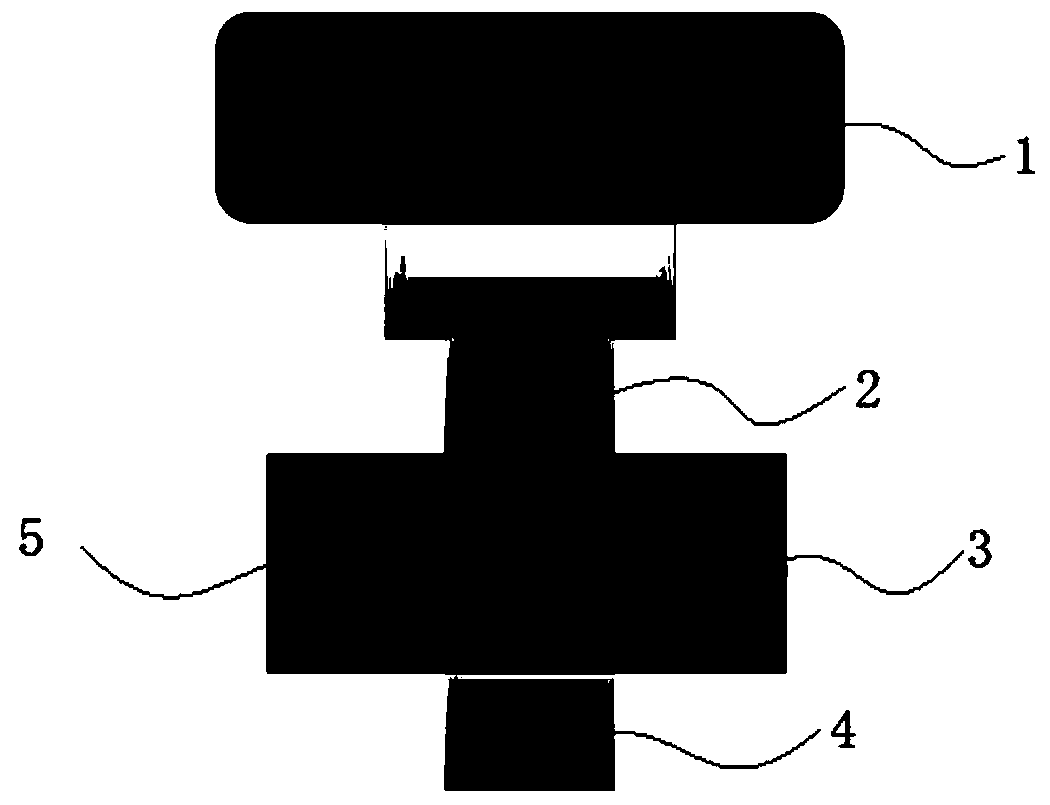

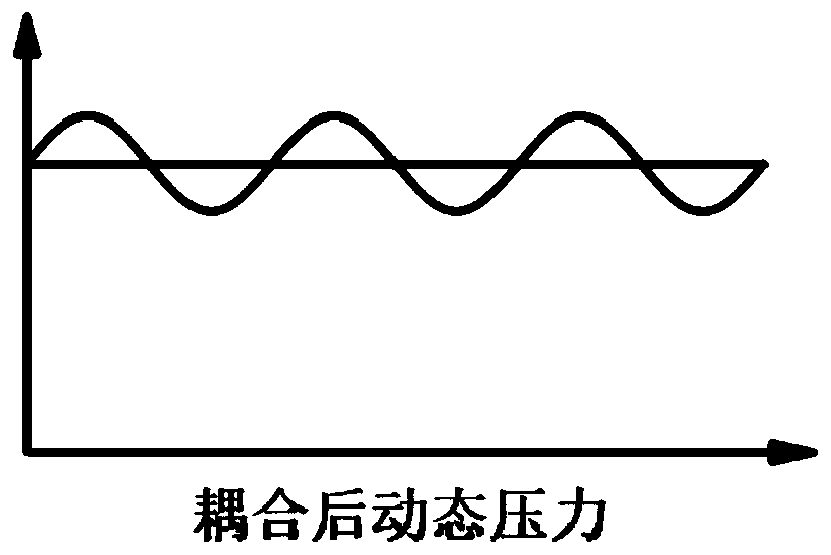

Large-size high-density non-binding-phase tungsten carbide target material and preparing method thereof

ActiveCN110171975AGuaranteed purityQuality improvementVacuum evaporation coatingSputtering coatingHigh pressureMaterials science

The invention provides a preparing method of a large-size high-density non-binding-phase tungsten carbide target material. The method includes the following steps of S1, preparing materials; S2, conducting ball-milling and screening treatment; S3, conducting sintering treatment; S4, conducting after-treatment. The raw materials include tungsten carbide powder and free carbon. The dynamic vibrationpressure is exerted in the sintering treatment process. By introducing the free carbon into the pure tungsten carbide powder, traditional medical binding phases are abandoned, the purity of the target material is ensured, and the quality of a magnetron sputtering coating can be easily improved. The dynamic vibration pressure is introduced in the sintering process, particle rearrangement is promoted in the early sintering stage of the tungsten carbide powder, the removal of residual pores is promoted in the later sintering stage, and the grain is refined when the sintering density is improved;by means of the high-pressure vibration assisted sintering, the sintering temperature is lowered by 50-200 DEG C on the basis of a traditional hot pressing process, the tungsten carbide target material with high density and fine grain is prepared, and the film coating quality is improved.

Owner:株洲万融新材科技有限公司 +1

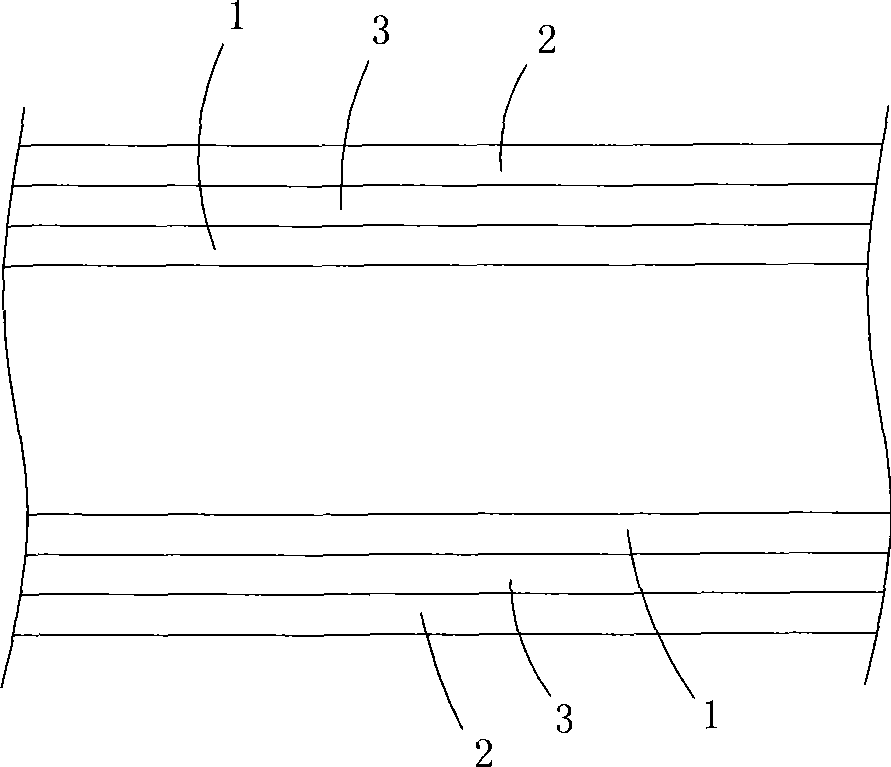

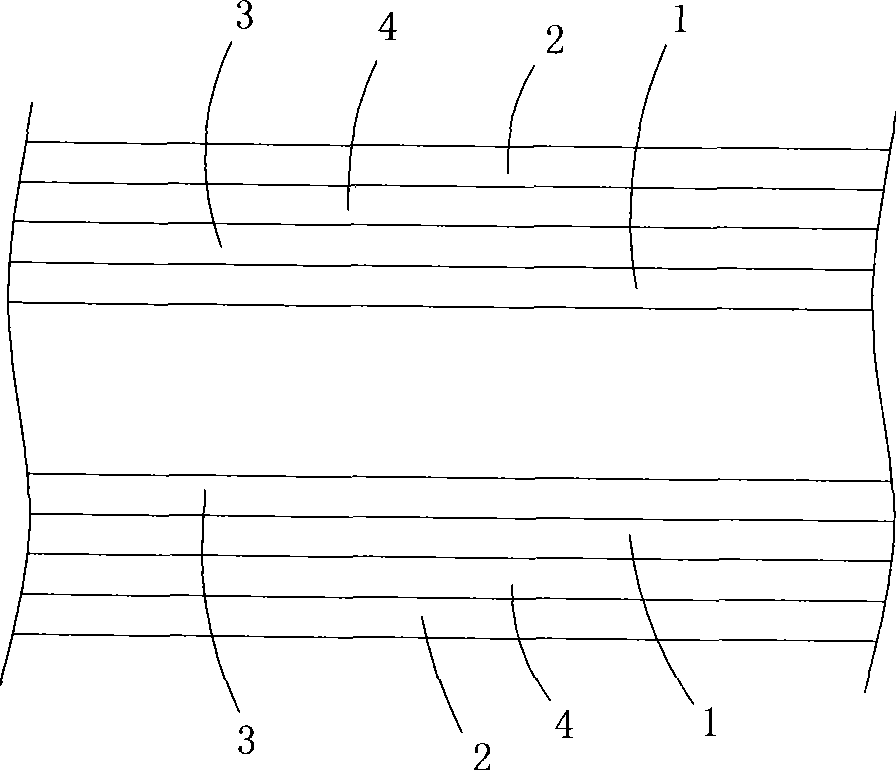

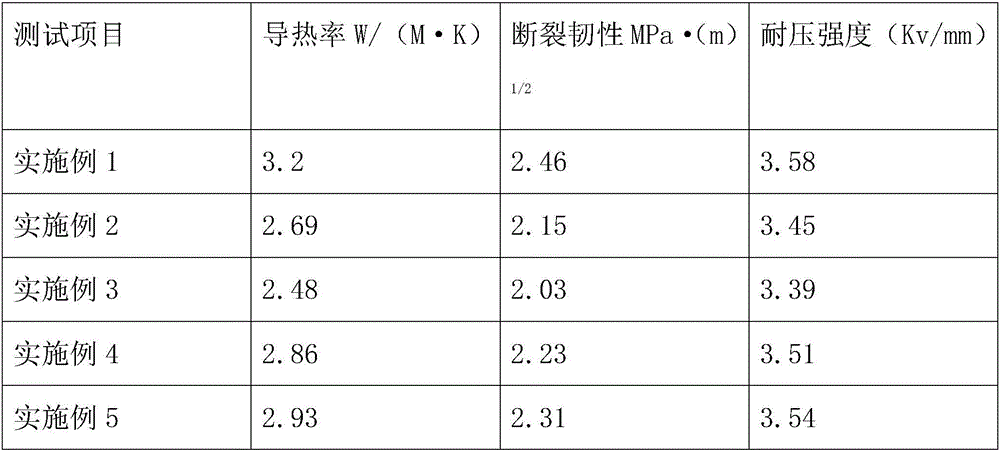

Production process of ultrathin aluminum nitride ceramic substrate

ActiveCN112876260AHigh degree of densificationDoes not significantly increase production costsAl powderSlurry

The invention relates to the technical field of aluminum nitride ceramics, and provides a production process of an ultrathin aluminum nitride ceramic substrate. The process comprises the following steps: (1) uniformly mixing aluminum nitride powder, a composite sintering aid, a UV monomer, a reactive diluent, a photoinitiator, a dispersant and a silane coupling agent to obtain ceramic slurry; (2) subjecting the ceramic slurry to tape casting on a tape casting machine, initiating a polymerization reaction through ultraviolet radiation, subjecting the slurry to in-situ curing molding to obtain a ceramic green body, and then cutting the ceramic green body into required shapes and sizes through a mold to obtain ceramic green sheets; (3) laminating the ceramic green sheets, and putting the laminated ceramic green sheets into a glue discharging furnace for glue discharging; and (4) carrying out hot pressed sintering on the ceramic blank sheet after glue discharging under the protection of nitrogen atmosphere, cooling to room temperature after the sintering, and then carrying out powder removal and polishing processes to obtain the ultrathin aluminum nitride ceramic substrate. The prepared aluminum nitride ceramic substrate is ultrathin, good in thermal conductivity and high in bending strength.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

Easy-to-tear polypropylene packing bag and manufacturing method thereof

InactiveCN101376439AMechanical properties unchangedPhysical properties unchangedBagsSacksReduction treatmentStretch ratio

The invention discloses an easy-to-tear type polypropylene packing bag and a manufacturing method thereof. The packing bag comprises a heat-seal layer which is made of polypropylene film through one-way orientation stretching. The manufacturing method comprises the following steps: firstly, polypropylene film which meets sanitary requirements is taken as the material, and one-way orientation stretching is performed to the polypropylene film after the polypropylene film is heated to 100 to 600 DEG C, and the stretch ratio is 1.1 to 5; secondly, temperature reduction treatment performed to the film which is processed through orientation stretching, concretely the temperature of the film which is processed through orientation stretching is quenched to the environment temperature; thirdly, corona treatment is performed to the film which is stretched, to ensure the surface tension of the film to be larger than 38 dynes, thereby a shaped easy-to-tear type polypropylene packing film is obtained, and is rolled; fourthly, the film is superposed on a required additional layer to obtain the wall layer of the packing bag, namely, a composite layer structure; and fifthly, the wall layer is folded and a plurality sides are sealed to form a bag shape with an opening to obtain a finished packing bag. When the packing bag is torn along the stretching direction of the heat-seal layer, the opening is in a straight-line shape.

Owner:ZHEJIANG GOLDSTONE PACKING

Warm processing powdered iron, and preparation method

A warm-pressing iron powder is prepared from reductive iron powder, polar graphite powder, lubricant PEG, adhesive PVP, Ni powder, Cu powder and Mo powder through high-temp reduction of the scales of low-carbon steel to obtain sponge iron, crushing, ball grinding, further reduction, crushing, grinding, sieving to obtain reductive iron powder, adding Ni powder, Cu powder and Mo powder, removing stress by tempering in vacuum or protecting atmosphere, adding PVP, mixing, adding polar graphite powder and PEG, mixing, drying at 50 deg.C, and sieving.

Owner:合肥波林新材料股份有限公司

High temperature-resistant resistor ceramic composite material and preparation method thereof

InactiveCN106587990AHigh thermal conductivityImprove heat resistanceZirconium hydrideCeramic composite

The invention discloses a high temperature-resistant resistor ceramic composite material. The high temperature-resistant resistor ceramic composite material is prepared from barium titanate, zirconium dioxide, eucryptite, magnesium oxide, zirconium boride, hafnium diboride, lead zirconate, strontium carbonate, molybdenum disulfide, titania, yttrium oxide, calcium carbonate, thallium carbide, hafnium carbide, zirconium carbide, silicon nitride, zirconium oxide, polyvinyl alcohol, copper oxide, niobium pentoxide, tungsten trioxide, lead tetraoxide, alumina, silica and assistants. The invention also provides a preparation method of the high temperature-resistant resistor ceramic composite material. The high temperature-resistant resistor ceramic composite material has excellent high temperature resistance.

Owner:ANHUI RUIXIN AUTOMATION INSTR

Method for preparing nano-phase reinforced nickel-based superalloy by adopting micron ceramic particles

ActiveCN112011702AFine grainGood mechanical propertiesMaterial nanotechnologyAdditive manufacturing apparatusMicron scaleNanoceramic

The invention provides a method for preparing a nano-phase reinforced nickel-based superalloy by adopting micron ceramic particles. In the nano-phase reinforced nickel-based superalloy, a nickel-basedsuperalloy is taken as a matrix, and one or more of TiC, TiB2, WC and Al2O3 are taken as a reinforcing phase. The particle size of a ceramic particle raw material as the reinforcing phase is 1-5 [mu]m; the adding amount of the ceramic particle raw material is 1 to 5 percent by weight; nickel-based superalloy composite powder with uniformly distributed nano-ceramics is prepared through a specificball milling process; the nano-ceramic phase reinforced nickel-based superalloy is prepared through a 3D printing technology; and the prepared material is uniform in nano-ceramic phase distribution and has excellent mechanical properties. Micron-sized ceramic particles are adopted, so that the cost is low; and parts in any complex shape can be integrally formed and prepared, so that the material utilization rate is increased.

Owner:CENT SOUTH UNIV

Production process of composite metal oxide

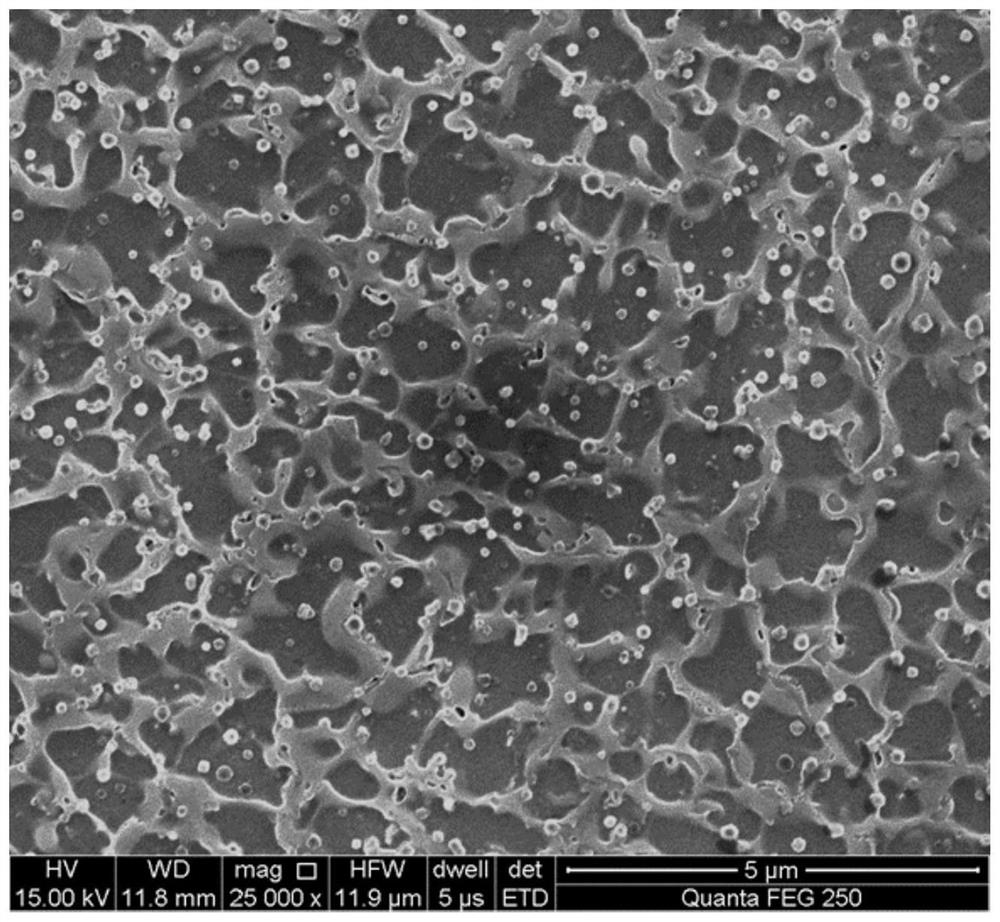

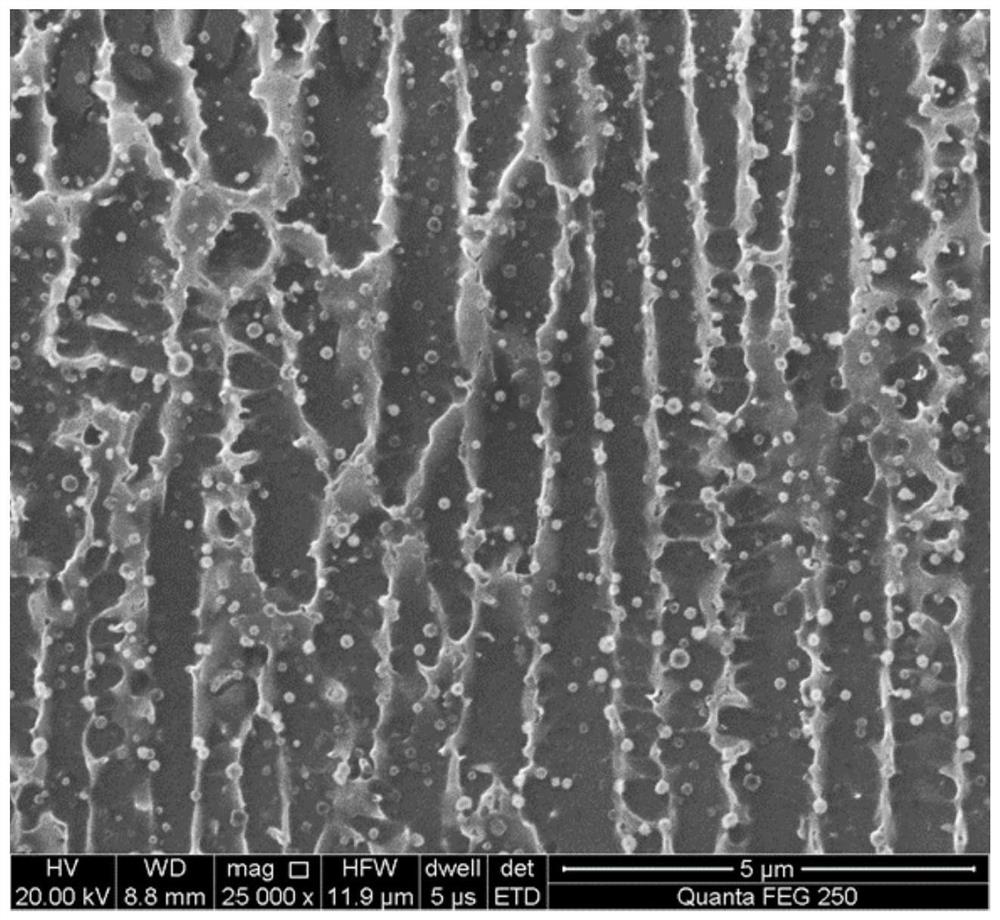

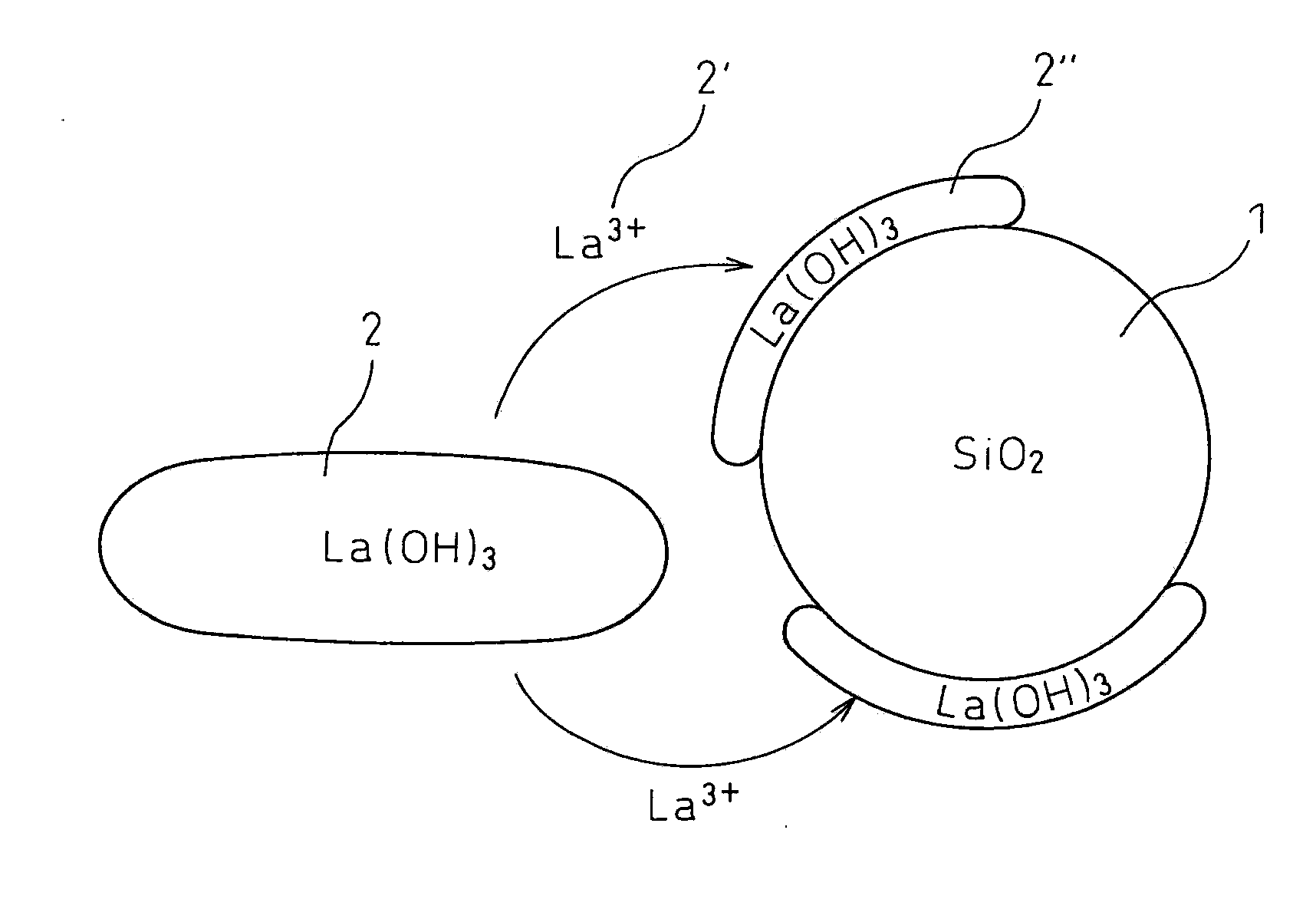

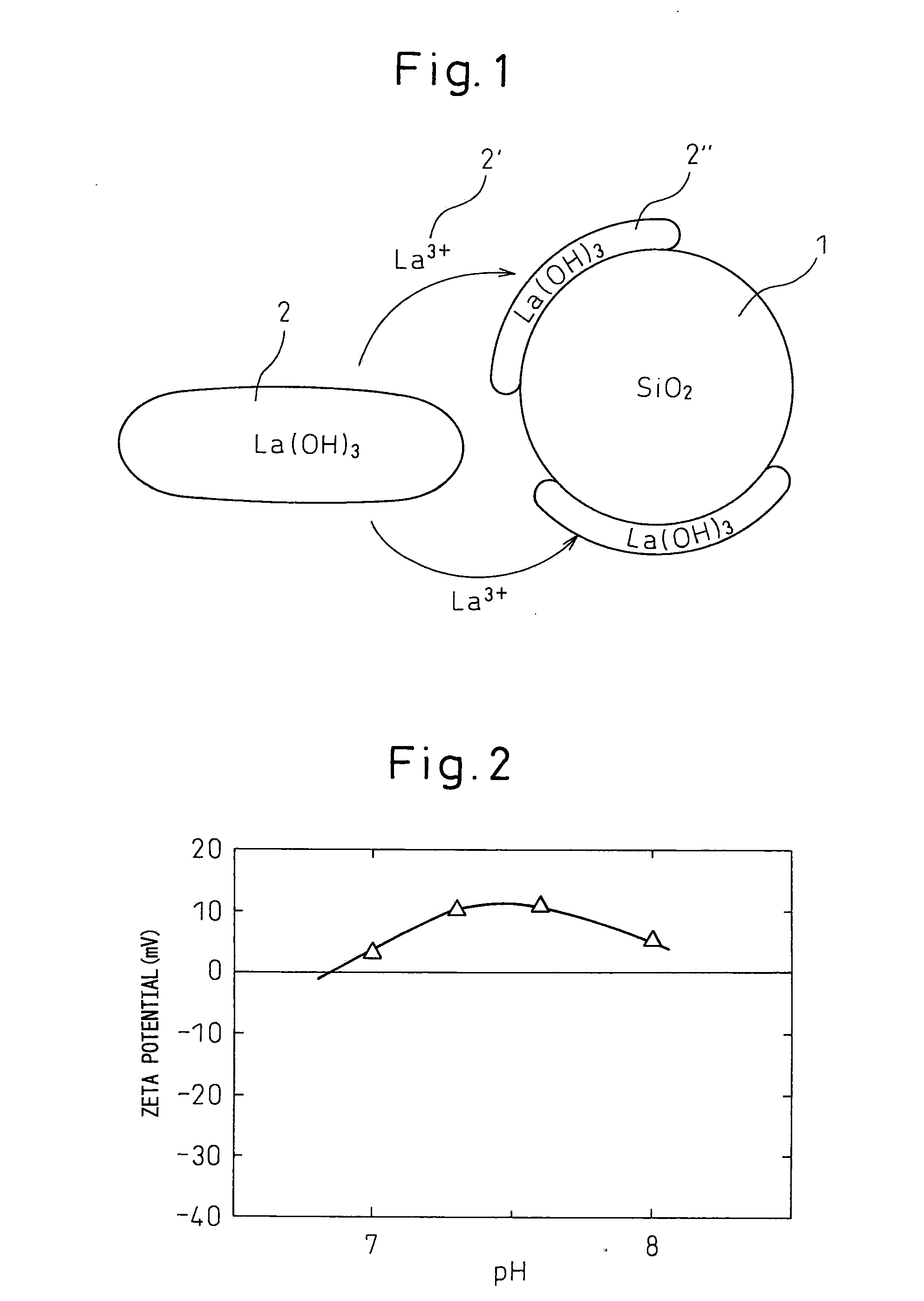

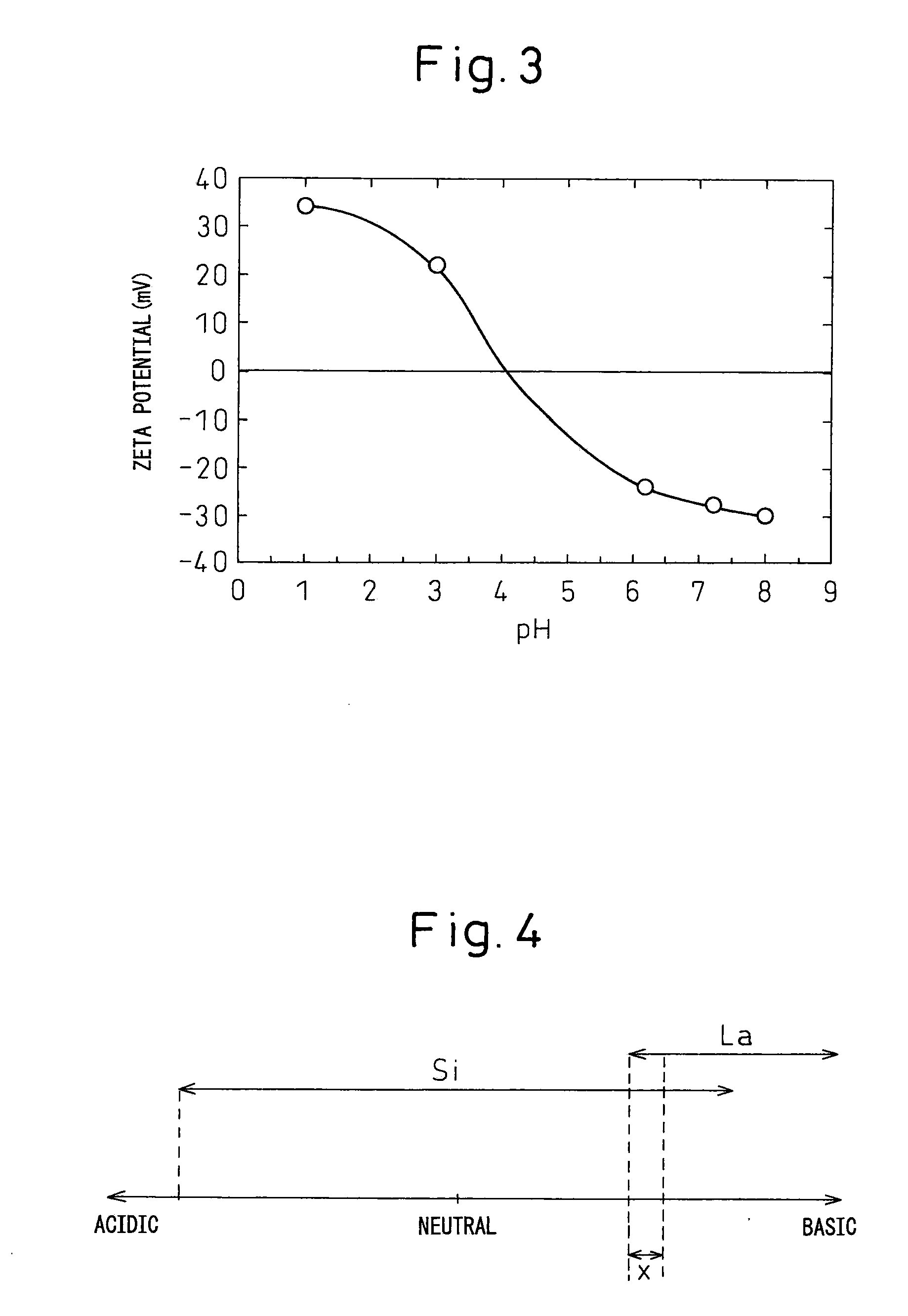

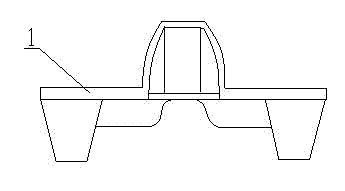

ActiveUS20090264286A1Improve heat resistanceStrong acidCatalyst carriersOxygen/ozone/oxide/hydroxideZeta potentialAqueous solution

A process for producing a composite metal oxide of an acidic metal oxide and a basic metal oxide, wherein the process comprises (a) providing an aqueous solution containing a colloidal particle of the acidic metal oxide and a salt of the basic metal, (b) adjusting the pH of the aqueous solution to a pH at which a part of the basic metal dissolves in the aqueous solution, the remaining of the basic metal precipitates as a hydroxide and has a positive zeta potential, and the colloidal particle of the acidic metal oxide is not dissolved and has a negative surface potential, and then maintaining this pH over a predetermined time to obtain a precursor of the composite metal oxide, and (c) drying and firing the precursor of the composite metal oxide obtained.

Owner:TOYOTA JIDOSHA KK

Method for forming nickel silicide with microwave annealing

InactiveCN102446730AHigh activityFacilitate rearrangementSemiconductor/solid-state device manufacturingSemiconductor devicesHigh resistanceSalicide

The invention discloses a method for forming nickel silicide with microwave annealing. The method comprises the following steps of: pre-cleaning the surface of exposed silicon for removing natural oxide; depositing nickel or nickel alloy and coating a layer of barrier layer on the surface of the nickel or nickel alloy; utilizing microwave radiation so that a part of the nickel or nickel alloy is reacted with the silicon to form high-resistance one-silication two-nickel in the process of heating a wafer to a first temperature at the same time; removing the barrier layer of the surface of the nickel or nickel alloy and unreacted nickel or nickel alloy; and utilizing microwave radiation so that the high-resistance one-silication two-nickel is changed to low-resistance nickle silicide in the process of heating the wafer to a second temperature at the same time. In the method, the surface of a silicon wafer is radiated by utilizing the microwave during heating at the same time, therefore, the activity of atomic motion is improved, and atomic realignment is promoted. The first temperature for heating is reduced so that the first step of diffusion of nickel is limited. The activity of the atomic motion is improved on the basis of the second temperature, therefore, the atomic realignment is promoted, the uniformity of the nickle silicide is helped to be improved, and the performance of devices is improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Pulverized coal activator and coking coal prepared from same

InactiveCN101705104AIncreased anisotropic tissue contentHigh strengthCoke ovensSodium stearateCholesterol

The invention provides a pulverized coal activator, which comprises the following components in percentage by weight: 1 to 14 percent of resin clay, 5 to 26 percent of glucose, 0.5 to 5 percent of cobalt molybdate, 0.5 to 29 percent of cholesterol ester benzoate, 1 to 29 percent of boron anhydrous, 1 to 15 percent of clay, 1 to 15 percent of titanium dioxide, 1 to 17 percent of sodium stearate, 1 to 5 percent of ferric chloride, 1 to 10 percent of argil, 1 to 26 percent of anhydrous borax, 1 to 16 percent of modified starch , and 1 to 25 percent of tar residue. The pulverized coal activator added can be directly mixed with matched coal so as to ensure that active components and inert components of the matched coal can be easier to combine together during carbonization and raise the anisotropic tissue content of coke. The increase in coal fluidity is beneficial to intermediate phase for forming staged molecular rearrangement, promotes the transformation process of the intermediate phase, and forms higher-strength coke capable of replacing or partially replacing coking coal for coking. The pulverized coal activator has the advantages of small adding dose, high benefit and low comprehensive cost.

Owner:重庆汉砧科技有限公司

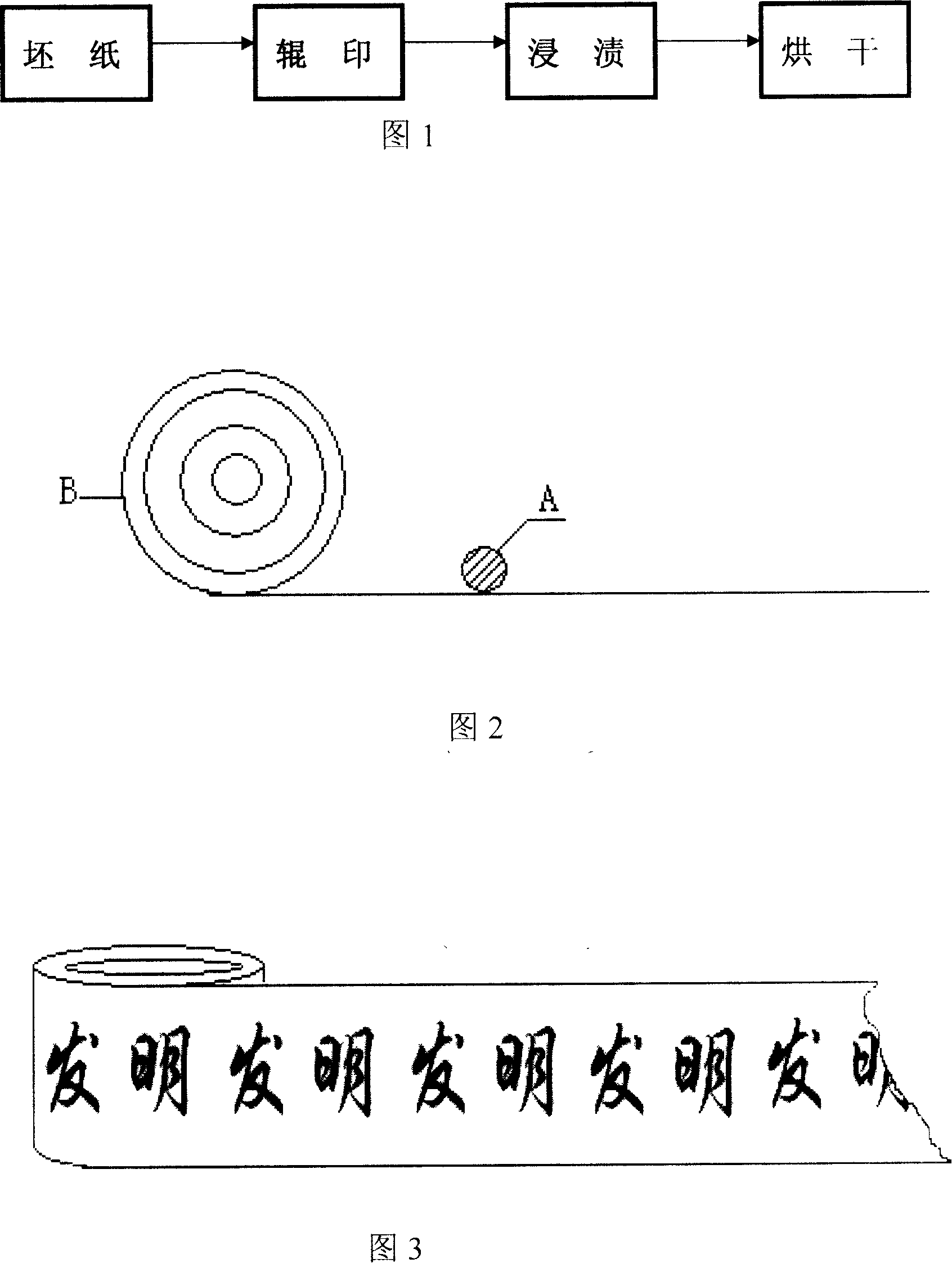

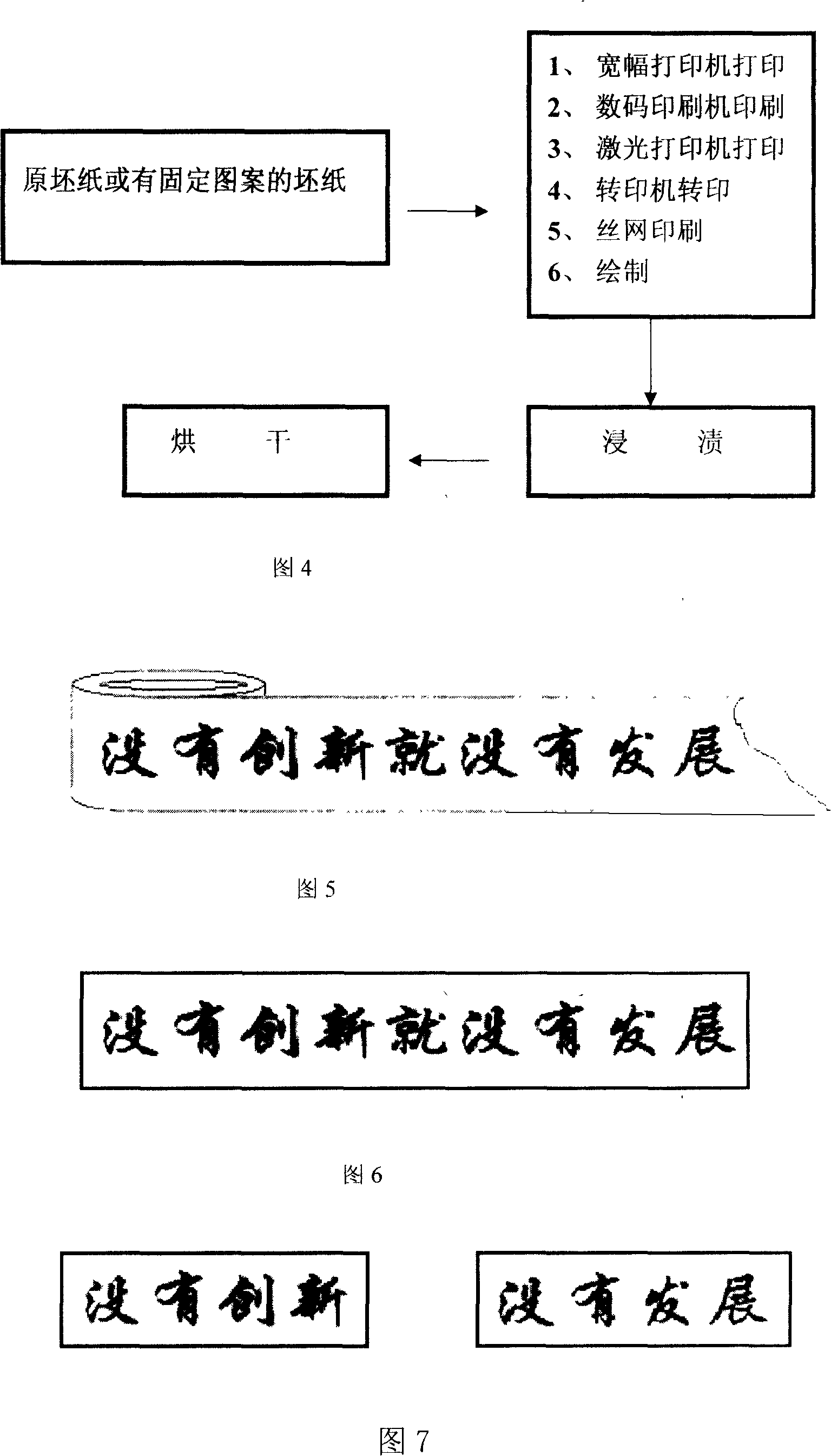

Multi-pattern melamine dipping decorative paper, manufacturing method and application thereof

InactiveCN101148848AFacilitate rearrangementEasy to combineNon-fibrous pulp additionSpecial paperMelamine resinPolyresin

The present invention is one kind of melamine dipped decoration paper with different patterns and its making process and application. The melamine dipped decoration paper with different patterns is made with a paper base of 5-5000 m length, and through printing and / or drawing to form texts and / or graphics, and dipping in urea-formaldehyde glue, melamine glue or melamine resin to form protective polymer layer. It is applied as the decoration material for furniture and artificial board.

Owner:赵国强

Method for preparing inorganic polymer composite material by low-temperature cold burning and ceramization application thereof

The invention discloses a method for preparing an inorganic polymer composite material by low-temperature cold burning and ceramization application thereof. The invention relates to a method for preparing an inorganic polymer composite material and the application thereof in order to solve the problems of low mechanical property and high sintering temperature of an existing inorganic polymer. Thepreparation method comprises the following steps: I, mixing a silicate powder, an aluminosilicate powder and a second phase material by adopting a high-energy ball milling process; II, adding water and a water reducing agent in to an inorganic polymer composite material dry powder, and mechanically stirring uniformly to obtain a plastic inorganic polymer green body; III, pressurizing and thermallyinsulating the green body, and controlling a pressure for pressure forming to be 250 to 600 Mpa; IV, putting a molded sample into an oven for curing to obtain the inorganic polymer composite material. The inorganic polymer composite material is subjected to high-temperature ceramization treatment at a temperature of 400 to 800 DEG C to obtain a ceramized product. The inorganic polymer composite material prepared by the method has excellent mechanical properties and low temperature for high-temperature ceramization.

Owner:HARBIN INST OF TECH

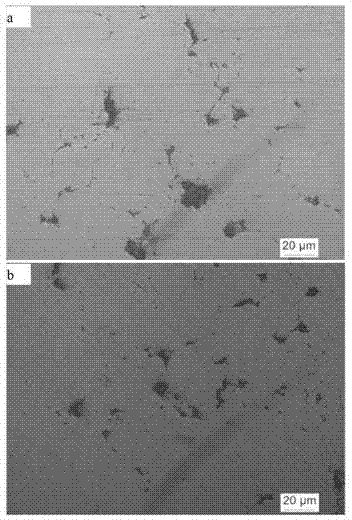

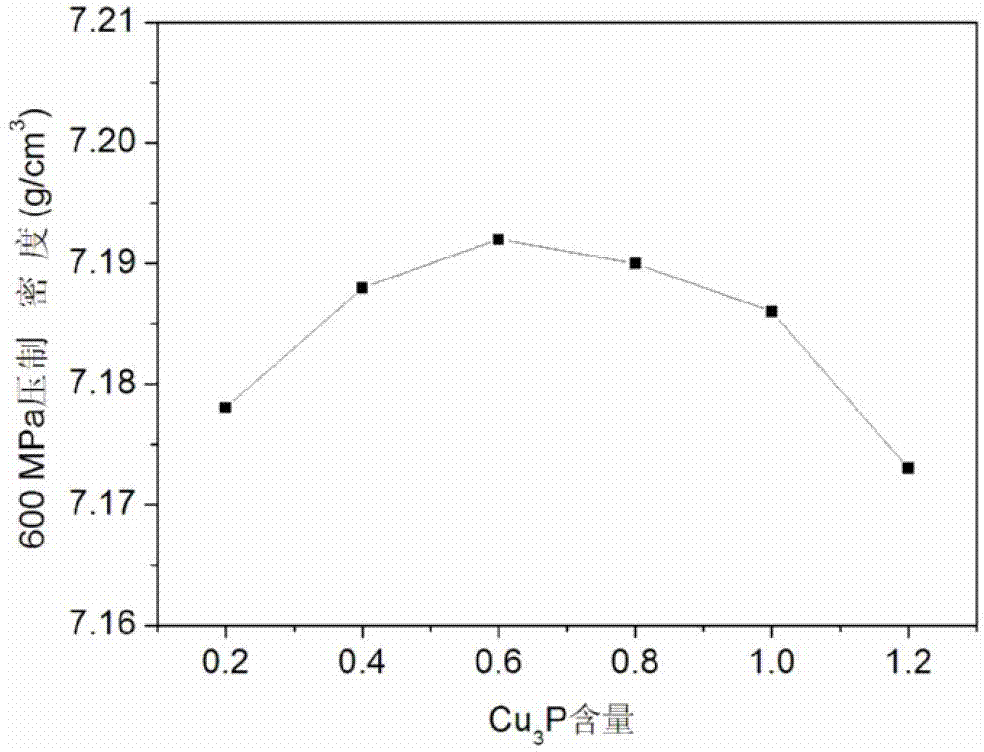

Additive activated low-alloy-content iron-based powder and preparation method of sintered materials

The invention discloses an additive activated low-alloy-content iron-based powder and preparation method of sintered materials. A small amount of superfine powders of copper and phosphorization cuprous are added into atomized iron powder or alloyed powder such as nickel. The preparation method of the iron-base alloy sintered materials is that the uniform mixed power is conducted single press and single sintering for one time, or the power is conducted pre-sintering in low temperature and then is carried out re-pressing and after-combustion. The superfine phosphorization cuprous power in the iron-based mixed powder can effectively improve pressing lubricity of iron powder, facilitate balling of hole gaps in matrix in a relative low temperature, and improve density of a sintering body. The density of products which are made by single press and single sintering can achieve 7.22g per cubic centimeter on the condition of 600MPa to 700MPa, density of products which are made by re-pressing and after-combustion can achieve 7.52g per cubic centimeter under the condition of 700MPa to 800MPa, and higher mechanical property is realized.

Owner:CENT SOUTH UNIV

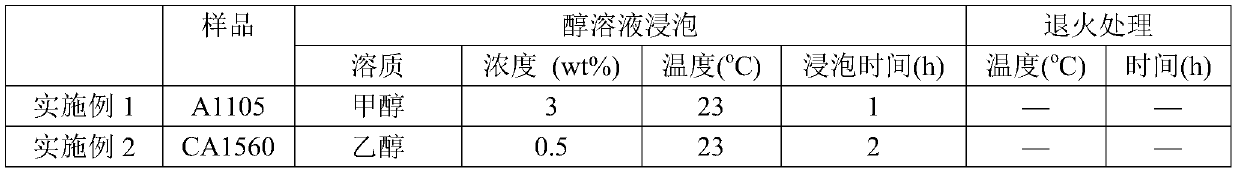

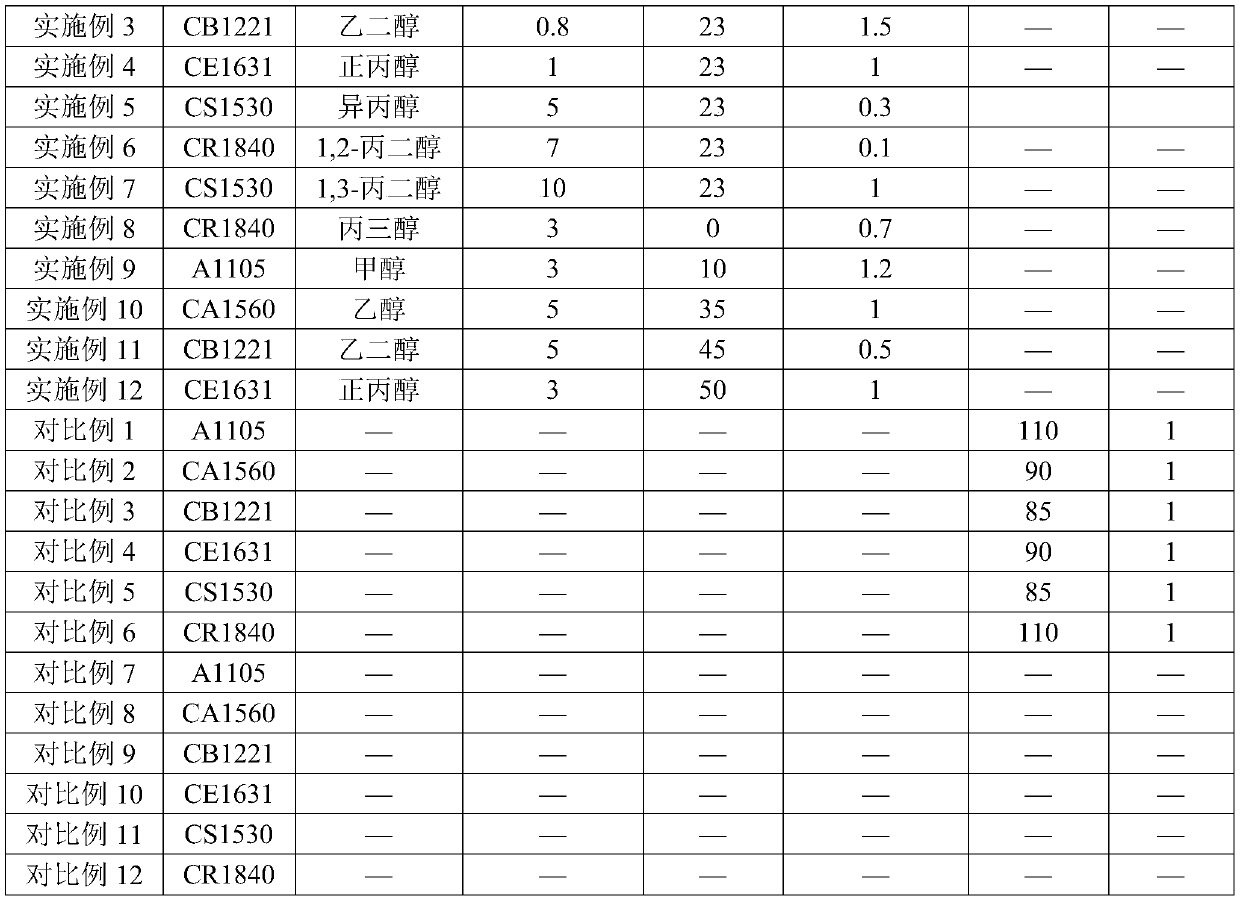

Method for reducing internal stress of polycarbonate and modified product thereof

The invention provides a method for reducing internal stress of polycarbonate and a modified product thereof, wherein the method comprises the following steps: soaking polycarbonate or the modified product thereof in an alcoholic solution for 0.1-2 h at the temperature of 0-50 DEG C. Researches find that a low-concentration small molecular alcoholic solution can promote molecular chain rearrangement of stress concentration points of polycarbonate and the modified product thereof, and thus, the internal stress of polycarbonate and the modified product thereof is reduced, the internal stress ofthe product is improved under the condition that the dimensional stability of the product is not influenced, and the phenomena of warping deformation, crazing, poor impact resistance and the like of the product caused by large internal stress are prevented.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +1

High-oxidation-resistance non-cement bonded Al2O3-SiC-C refractory castable and preparation method thereof

ActiveCN112608138AReduce lossesImprove antioxidant capacityCeramic materials productionMetallic aluminumSlag

The invention discloses a high-oxidation-resistance non-cement-bonded Al2O3-SiC-C refractory castable and a preparation method thereof, and belongs to the field of amorphous refractory materials. The preparation method comprises the following steps: taking 50.0-60.0 wt% of brown fused alumina aggregate, 15.0-20.0 wt% of silicon carbide, 3.0-5.0 wt% of spherical asphalt, 5.0-10.0 wt% of corundum fine powder, 5.0-10.0 wt% of active alpha aluminum oxide micro powder, 3.0-5.0 wt% of mullite sol, 2.0-4.0 wt% of silicon micro powder, 0.5-2.0 wt% of lithium-containing aluminosilicate and 1.0-2.0 wt% of metal aluminum powder / monatomic silicon powder compound antioxidant as raw materials; and adding 0.20-0.30 wt% of a water reducing agent and 6-8wt% of water into the raw materials, carrying out stirring, pouring, molding, and subsequent heat treatment to obtain the high-oxidation-resistance non-cement-bonded Al2O3-SiC-C refractory castable for the large-scale blast furnace tapping channel. The prepared castable has extremely outstanding in oxidation resistance and excellent in normal-temperature / high-temperature mechanical property, thermal shock resistance and slag corrosion resistance, so that the safety coefficient and the service life of the tapping channel of the large blast furnace can be greatly improved, and the stable operation of the whole ironmaking process flow is guaranteed.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

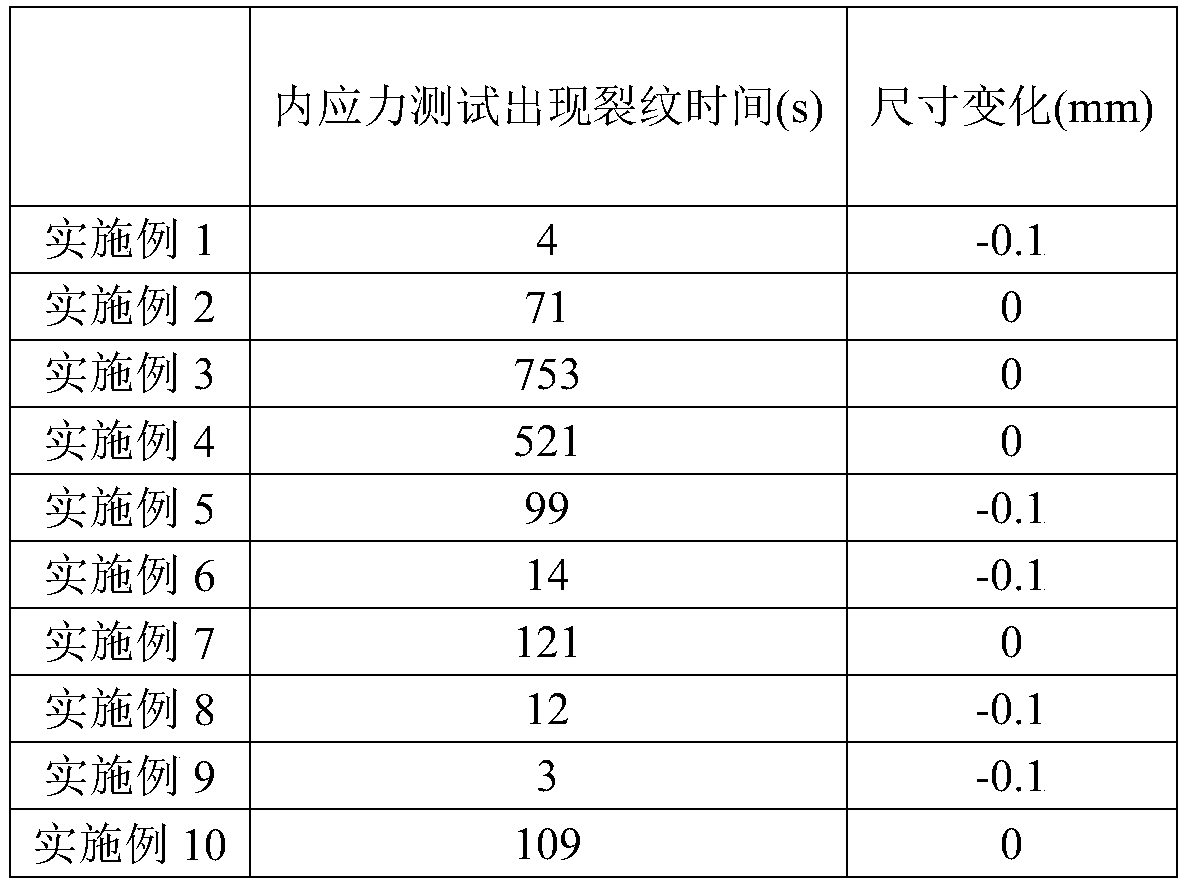

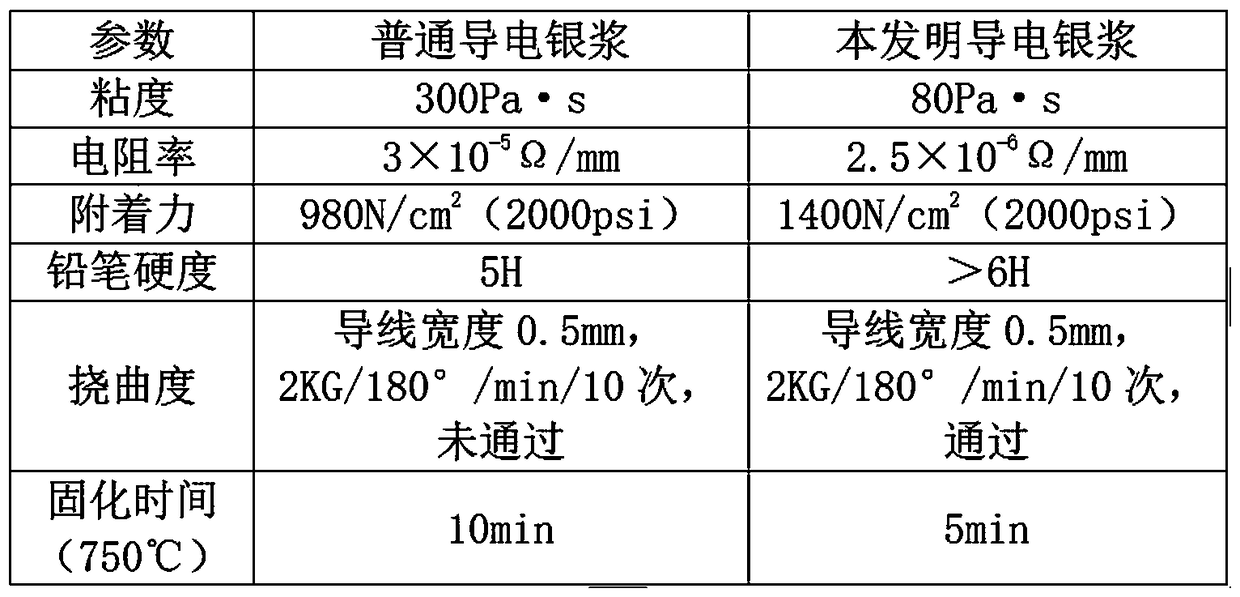

High-temperature sintered conductive silver paste and preparation method thereof

InactiveCN109461515AImprove adhesionImprove Capacitive PerformanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteWater baths

The invention discloses a high-temperature sintered conductive silver paste, which consists of the following components in parts by weight: 65 to 70 parts of silver powder, 6 to 12 parts of lead-freelow temperature melted glass dust, 0.5 to 1 part of organic carrier and 5 to 15 parts of organic solvent. According to the invention, the high-temperature sintered conductive silver paste is obtainedby mixing, constant temperature water bath, high speed dispersion, grinding and other processes. The high-temperature sintered conductive silver paste and the preparation method thereof provided by the invention are beneficial to the rearrangement of silver powder, the enhancement of conductivity, the adhesion of conductive silver paste and the enhancement of the capacitance and the service life of conductive silver paste, and when the high-temperature sintered conductive silver paste is used as an electrode, the capacitance performance can be improved and the capacitance can be maintained.

Owner:刘紫嫣 +2

High-specific-gravity tungsten-based alloy formation method based on pre-alloyed powder

ActiveCN110315076APromote meltingNot easy to melt and formAdditive manufacturing apparatusIncreasing energy efficiencyManufactured formSolid solution

The invention discloses a high-specific-gravity tungsten-based alloy formation method based on pre-alloyed powder. The high-specific-gravity tungsten-based alloy formation method based on the pre-alloyed powder comprises the steps that firstly, according to the designed ingredients and proportion of the high-specific-gravity tungsten-based alloy, material mixing, pressing, vacuum sintering and forging machining are sequentially conducted, then a tungsten-based alloy rod is obtained, and pre-alloyed powder is obtained through a plasma-rotating electrode powder manufacturing method; secondly, athree-dimensional model of the high-specific-gravity tungsten-based alloy is established, slicing and designing are conducted, and then slice layers and scanning data are obtained; thirdly, with the pre-alloyed powder as the raw material, according to the slice layers and the scanning data, a powder bed type electron beam additive manufacturing forming device is adopted to form the high-specific-gravity tungsten-based alloy. According to the high-specific-gravity tungsten-based alloy formation method based on the pre-alloyed powder, by utilizing the different melting points between tungsten and other elements in the high-specific-gravity tungsten-based alloy, the pre-alloyed powder with tungsten powder particles being wrapped inside low-melting-point element solid solution is prepared, sothat the shells of the pre-alloyed powder are easy to melt and adhere to one another for formation, and therefore the formation difficulty of the pre-alloyed powder is lowered; and with the pre-alloyed powder as the raw material, preparation of the high-specific-gravity tungsten-based alloy is achieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

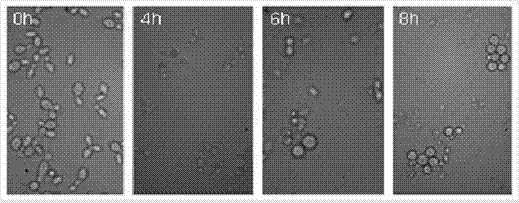

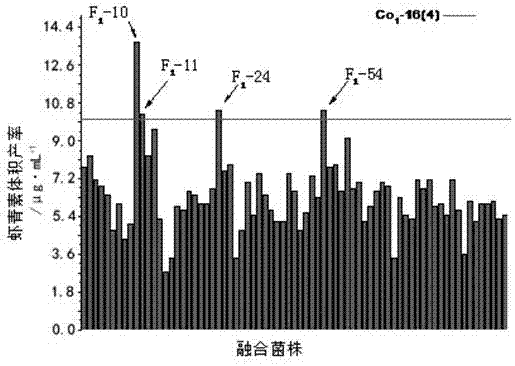

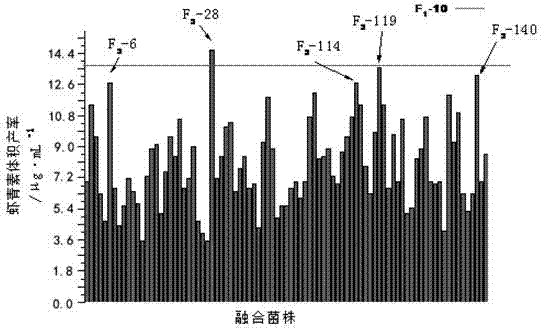

Co-production fermentation method for astaxanthin and mannan and application of astaxanthin and mannan

PendingCN107974447ARealize co-production fermentationEffective thinningOrganic chemistryMicroorganism based processesAdhesiveBetaxanthins

The invention discloses a co-production fermentation method for astaxanthin and mannan and application of the astaxanthin and the mannan. The co-production fermentation method for the astaxanthin andthe mannan comprises: mutagenesis, preparation of protoplast, genome rearrangement, obtainment of the astaxanthin and extraction of the mannan. The astaxanthin is applied as an antioxidant additive infeeds, food and cosmetics; and the mannan can be applied in adhesives, fixatives, feed additives, cosmetic additives, embedding materials in wastewater treatment, dust preventives, chromatographic packing materials and food preservation. The beneficial effects are as follows: high-yield phaffia rhodozyma strains are obtained by a dual induction method, a strain for the high yield of the astaxanthin is screened out by a genome rearrangement and cell fusion method, so that a genetically stable phaffia rhodozyma strain is obtained, and the astaxanthin and the mannan are obtained by co-productionfermentation; the application ranges of the astaxanthin and the mannan are wide, and economic value is high.

Owner:杭州皇冠农业生物工程技术研究中心有限公司

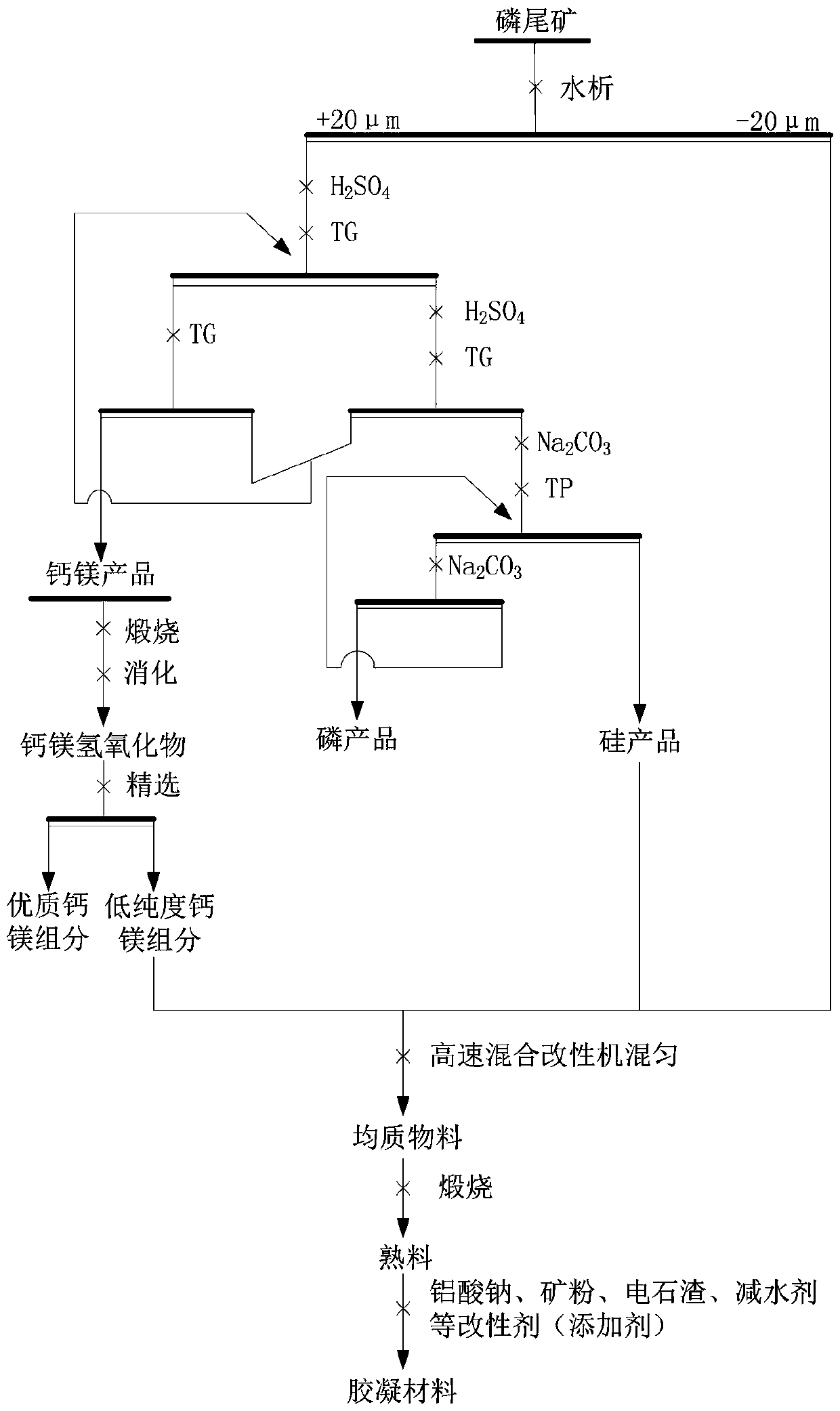

Method for preparing high-performance cementing material from modified calcium-magnesium phosphate rock tailings

ActiveCN111138098AIncrease consumptionReduce inventory pressureCement productionFlotationMagnesium phosphateMagnesium orthophosphate

The invention provides a method for preparing a high-performance cementing material from modified calcium-magnesium phosphate rock tailings. The method comprises the following steps: separating out aphosphate tailing sample with the particle size of 20 [mu]m or less for later use; sequentially carrying out magnesium flotation and phosphorus flotation on slime with the particle size of 20 [mu]m orabove, and dividing the slime into three parts, namely a magnesium-calcium component, a phosphorus component and a siliceous component; calcining the magnesian component, stirring and mixing the partof which the MgO grade is lower than 20%, the siliceous component and slime of which the particle size is less than 20 [mu]m, and aging and calcining to obtain clinker; and cooling the calcined clinker to room temperature under a dry condition, adding silica fume, mineral powder, carbide slag, sodium metaaluminate, polyaluminium chloride and a water reducing agent modifier, and preparing the cementing material at a certain water-cement ratio. The phosphate tailings are treated and then combined with different components to obtain the phosphate tailing-based cementing material, so that industrial solid wastes which are the phosphate tailings are changed into a characteristic resource and are completely and comprehensively utilized, the purpose of zero emission of the phosphate tailings isachieved, and green development and sustainable development of phosphorus chemical enterprises are promoted.

Owner:湖北冶金地质研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com