Method for preparing transparent calcium fluoride ceramic

A technology of transparent ceramics and calcium fluoride, which is applied in the field of preparation of transparent calcium fluoride ceramics, which can solve the problems of inability to mass-produce and low output, and achieve the effect of light agglomeration, uniform distribution and improved densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

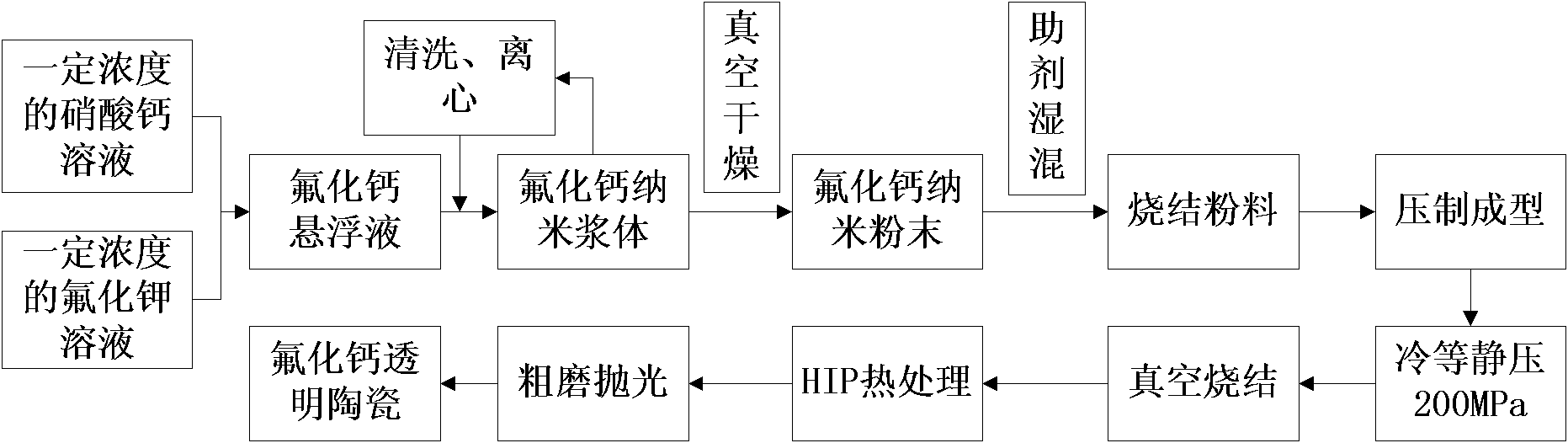

[0040] According to the preparation process figure 1 As shown, take the same volume of 2M Ca(NO 3 ) 2 Solution and 4M KF solution, using direct chemical precipitation method to remove Ca(NO 3 ) 2 The solution was slowly poured into the KF solution, and at the same time, the suspension of calcium fluoride nanopowder was obtained by the mixing method of magnetic stirring at a speed of 400 rpm, and then stood for 20 hours, washed with water or alcohol, centrifuged, and dried under vacuum at 80°C And other steps to prepare calcium fluoride nano-powder with an average crystal grain size of 25 nm. The content of the obtained calcium fluoride nano powder and the sintering aid is n(CaF 2 ): n(LiF):n(NaF)=97:2.5:0.5; mix evenly with alcohol in a mortar, put it in a mold, and press molding with an axial pressure of 30MPa to obtain a blank with a diameter of 16mm. The green body is kept at 500℃ for 2 hours at a heating rate of 10℃ / min in a vacuum sintering furnace, and the vacuum degree i...

Embodiment 2

[0043] According to the preparation process figure 1 , Take the same volume of 2M Ca(NO 3 ) 2 Solution and 4M KF solution, the nano powder preparation process was as described in Example 1, and the calcium fluoride nano powder with an average crystal grain size of 25 nm was prepared. The molar ratio of sintered powder is n(CaF 2 ):n(LiF):n(NaF)=97:0.5:2.5; Use alcohol to mix evenly in a mortar, put it into a mold, and press it into a shape with an axial pressure of 30MPa to obtain a blank with a diameter of 16mm. The green body is heated to 10 o C / min heating rate, heat preservation at 500℃ for 2 hours, vacuum degree is 10 -3 Pa; The obtained semi-finished product is placed in a hot isostatic pressing furnace at a temperature rise rate of 20°C / min, kept at 800°C for 2 hours, the pressurizing medium is nitrogen, the pressure is 200MPa, and the temperature is reduced to room temperature at a rate of 15°C / min.

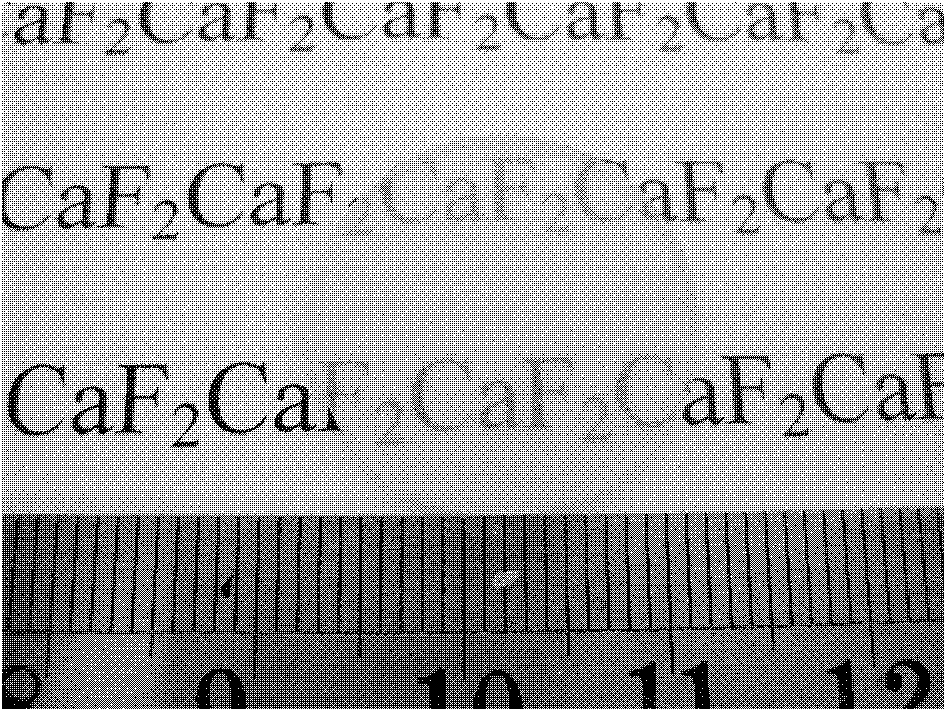

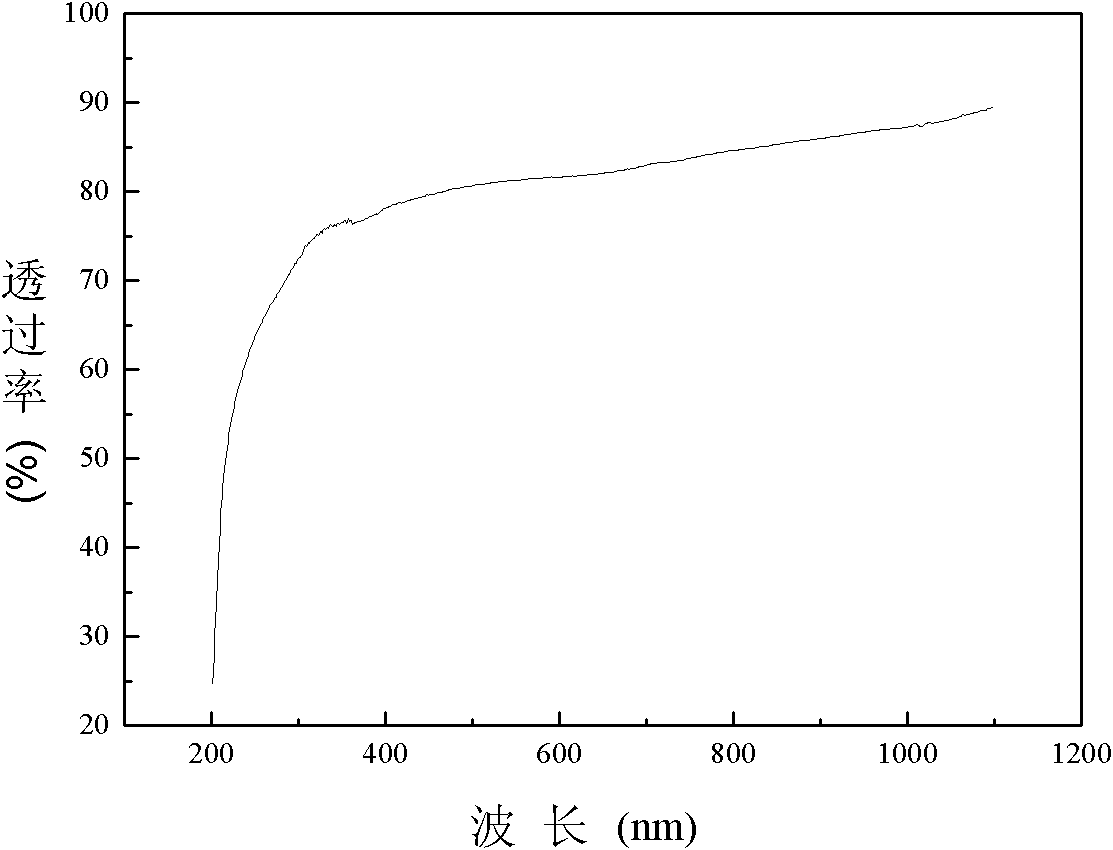

[0044] After the obtained samples are rough-grinded with different type...

Embodiment 3

[0046] According to the preparation process figure 1 , Take the same volume of 2M Ca(NO 3 ) 2 Solution and 4M KF solution, the nano powder preparation process was as described in Example 1, and the calcium fluoride nano powder with an average crystal grain size of 25 nm was prepared. The molar ratio of sintered powder is n(CaF 2 ):n(LiF):n(NaF)=97:2:1; Use alcohol to mix evenly in a mortar, put it in a mold, and press it into a shape with an axial pressure of 30MPa to obtain a blank with a diameter of 16mm. The green body is kept at 500℃ for 2 hours at a heating rate of 10℃ / min in a vacuum sintering furnace, and the vacuum degree is 10 -3 Pa; The obtained semi-finished product is placed in a hot isostatic pressing furnace at a temperature rise rate of 20°C / min, kept at 800°C for 2 hours, the pressurizing medium is nitrogen, the pressure is 200MPa, and the temperature is reduced to room temperature at a rate of 15°C / min.

[0047] After rough grinding of the obtained samples with d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com