Additive activated low-alloy-content iron-based powder and preparation method of sintered materials

An iron-based powder, low-alloy technology, applied in the field of preparation of iron-based powder metallurgy materials, can solve the problems of lowering sintering temperature, limited liquid phase sintering effect, etc. Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

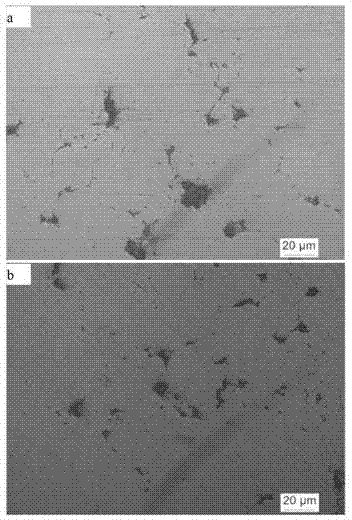

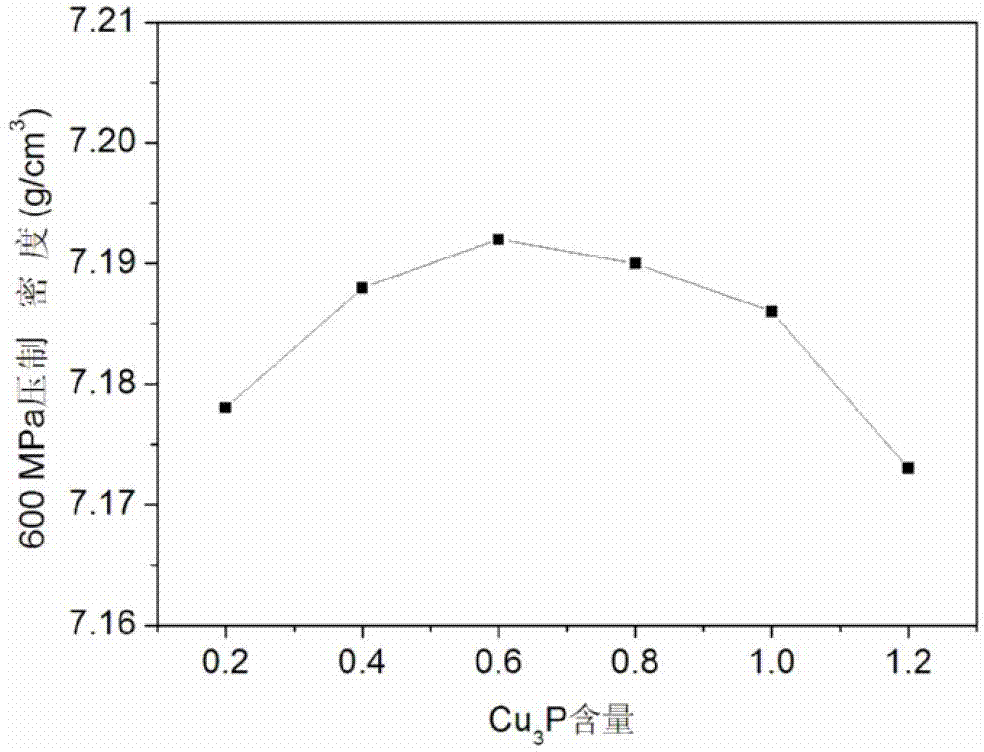

[0027] Water-atomized iron powder, carbonyl nickel powder, molybdenum powder (or water-atomized iron-molybdenum pre-alloyed powder instead of water-atomized iron powder and molybdenum powder), graphite, ultrafine cuprous phosphide powder and copper powder are used as raw materials , according to nickel 1.5wt.%, molybdenum 0.3wt.%, graphite 0.4wt.%, copper element 0.5wt%, cuprous phosphide accounts for about 0.2wt%, and 0.6wt.% lubricant ingredients, of which phosphide The particle size range of copper and copper is 0.05~0.2μm. Put each raw material into the mixing cylinder and seal it, and mix it evenly on the planetary mixer. Then carry out compression molding under the pressure of 600MPa, place the pressed green body in a hydrogen atmosphere sintering furnace, pre-fire at a temperature of 400~500°C for 0.5 hours, then raise the temperature to 650~850°C and keep it for 0.5~1 hour, and finally raise the temperature to Sintering at 1050~1200℃ for 0.5~1.5 hours, the density of t...

Embodiment 2

[0029] Water-atomized iron powder, carbonyl nickel powder, molybdenum powder (or water-atomized iron-molybdenum pre-alloyed powder instead of water-atomized iron powder and molybdenum powder), graphite, ultrafine cuprous phosphide powder and copper powder are used as raw materials , according to nickel 1.5wt.%, molybdenum 0.4wt.%, graphite 0.5wt.%, copper element 0.7wt%, cuprous phosphide accounts for about 0.4wt%, and 0.6wt.% lubricant ingredients, of which phosphide The particle size range of copper and copper is 0.1~1μm. Put each raw material into the mixing cylinder and seal it, and mix it evenly on the planetary mixer. Other conditions are the same as in Example 1, and the density of the obtained iron-based sintered material is 7.20g / cm 3 , the bending strength is 908MPa, and the hardness is 54.6HRB.

Embodiment 3

[0031] Water-atomized iron powder, carbonyl nickel powder, molybdenum powder (or water-atomized iron-molybdenum pre-alloyed powder instead of water-atomized iron powder and molybdenum powder), graphite, ultrafine cuprous phosphide powder and copper powder are used as raw materials , according to nickel 1.5wt.%, molybdenum 0.5wt.%, graphite 0.6wt.%, copper 0.9wt%, cuprous phosphide accounts for about 0.6wt%, and 0.6wt.% lubricant ingredients, of which phosphide The particle size range of copper and copper is 0.2~5μm. Put each raw material into the mixing barrel and seal it, and mix evenly on the planetary mixer. Other conditions are the same as in Example 1, and the density of the obtained iron-based sintered material is 7.21g / cm 3 , the bending strength is 916MPa, and the hardness is 55.1HRB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com