Easy-to-tear polypropylene packing bag and manufacturing method thereof

A polypropylene and packaging bag technology, applied in the field of plastic packaging, can solve the problems of reducing the mechanical and physical properties of the film, making it difficult to tear out the crack, and poor tearing effect, and achieve good surface properties, easy to tear, tear The effect of crack strength reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (embodiment 1, easy tear type polypropylene packaging bag)

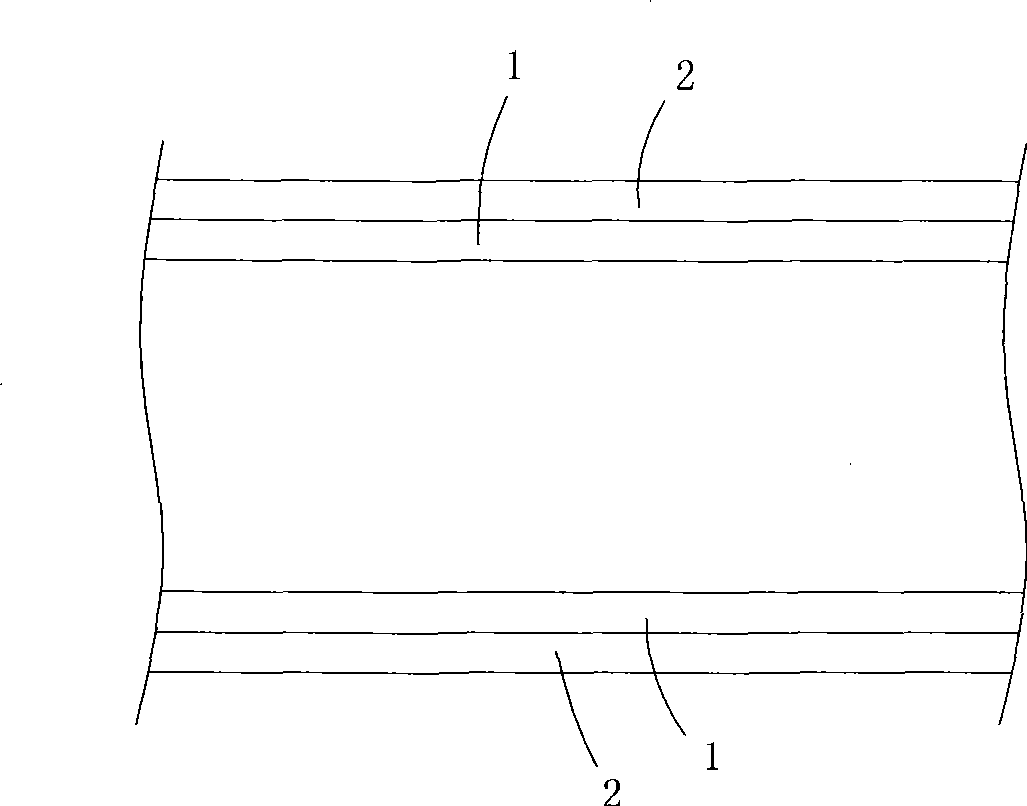

[0037] figure 1 It is a structural schematic diagram of the first structure of the product of the present invention, showing a specific embodiment of the product of the present invention.

[0038] See figure 1, this embodiment is an easy-to-tear polypropylene packaging bag, the packaging bag is a two-layer composite layer structure, from the inside to the outside are the heat-sealing layer 1 and the printing layer 2, the heat-sealing layer 1 is a one-way Directional stretched polypropylene film layer. The thickness of the heat-sealing layer 1 is 70 μm; the elongation at break of the heat-sealing layer 1 in the stretching direction is 30%, and the elongation at break in the unstretched direction is 490%. The stretching direction of the heat-sealing layer 1 is parallel to the bag opening direction.

[0039] The printing layer 2 in this embodiment is a polyethylene terephthalate layer, and in practice, a biax...

Embodiment 2

[0040] (embodiment 2, easy tear type polypropylene packaging bag)

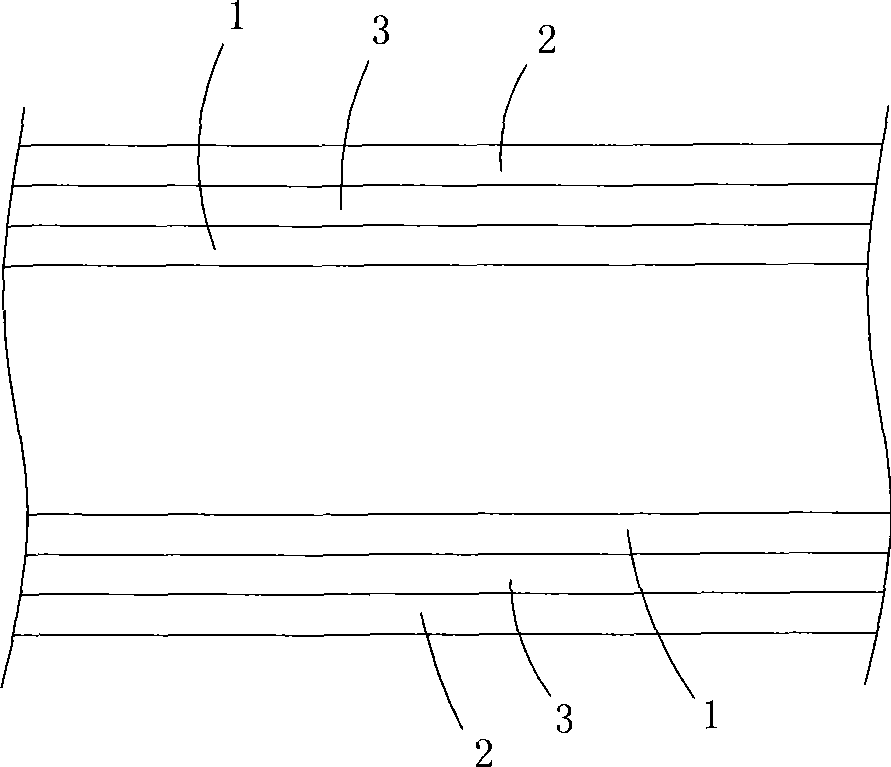

[0041] figure 2 It is a structural schematic diagram of the second structure of the product of the present invention, showing another specific embodiment of the product of the present invention.

[0042] See figure 2 , this embodiment is an easy-to-tear polypropylene packaging bag. When the packaging bag is a three-layer composite structure, the heat-sealing layer 1, the barrier layer 3, and the printing layer 2 are in sequence from the inside to the outside; The barrier layer 3 is an aluminum foil layer, and the printing layer 2 is a polyethylene terephthalate layer; in practice, a biaxially stretched polypropylene layer or a paper layer can also be used as the printing layer 2 . The thickness of the heat-sealing layer 1 is 100 μm; the elongation at break of the heat-sealing layer 1 in the stretching direction is 50%, and the elongation at break in the unstretched direction is 450%. The stretching direct...

Embodiment 3

[0043] (embodiment 3, easy tear type polypropylene packaging bag)

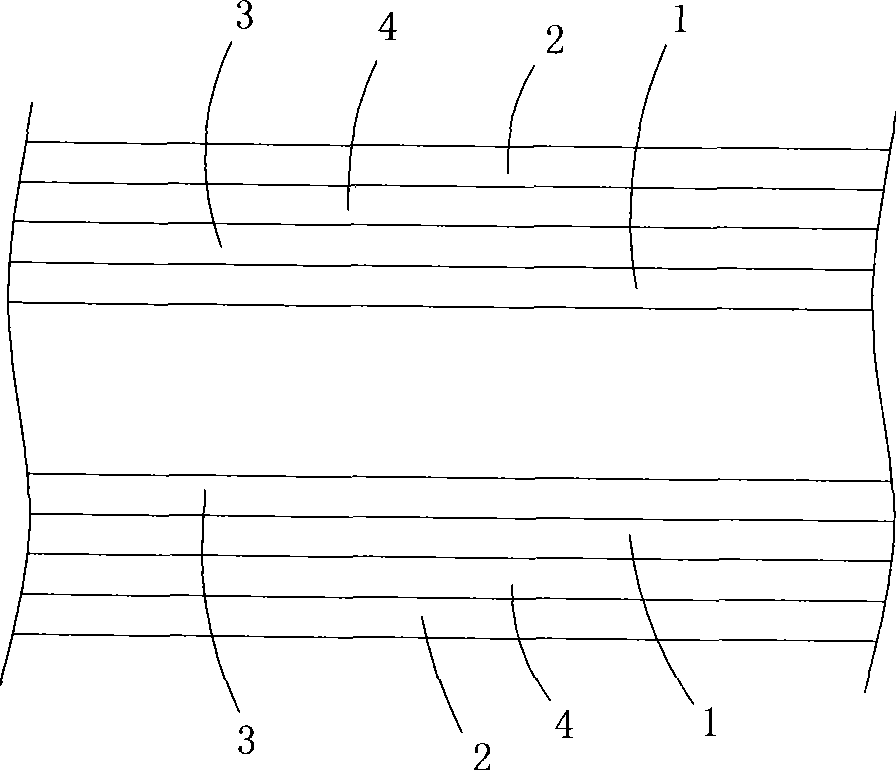

[0044] image 3 It is a structural schematic diagram of the third structure of the product of the present invention, showing the third embodiment of the product of the present invention.

[0045] See image 3 , this embodiment is an easy-to-tear polypropylene packaging bag. When the packaging bag is a four-layer composite structure, heat-sealing layer 1, barrier layer 3, reinforcing layer 4 and printing layer 2 are sequentially arranged from the inside to the outside, or Heat-sealing layer 1, reinforcing layer 4, barrier layer 3 and printing layer 2; the reinforcing layer 4 is a nylon layer, the barrier layer 3 is an aluminum foil layer, and the printing layer 2 is polyethylene terephthalate layer, in practice, a biaxially oriented polypropylene layer or a paper layer can also be used as the printing layer 2 . The thickness of the heat-sealing layer 1 is 40 μm; the elongation at break of the heat-sealing la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com