Hardening technology for precipitation hardening stainless steel laser surface

A technology of precipitation hardening and stainless steel, which is applied in the field of metal surface hardening, can solve the problems of easy corrosion and peeling of the hardened layer, change the chemical composition of the material surface, etc., achieve good strength and toughness, improve surface hardness, and facilitate hardening treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

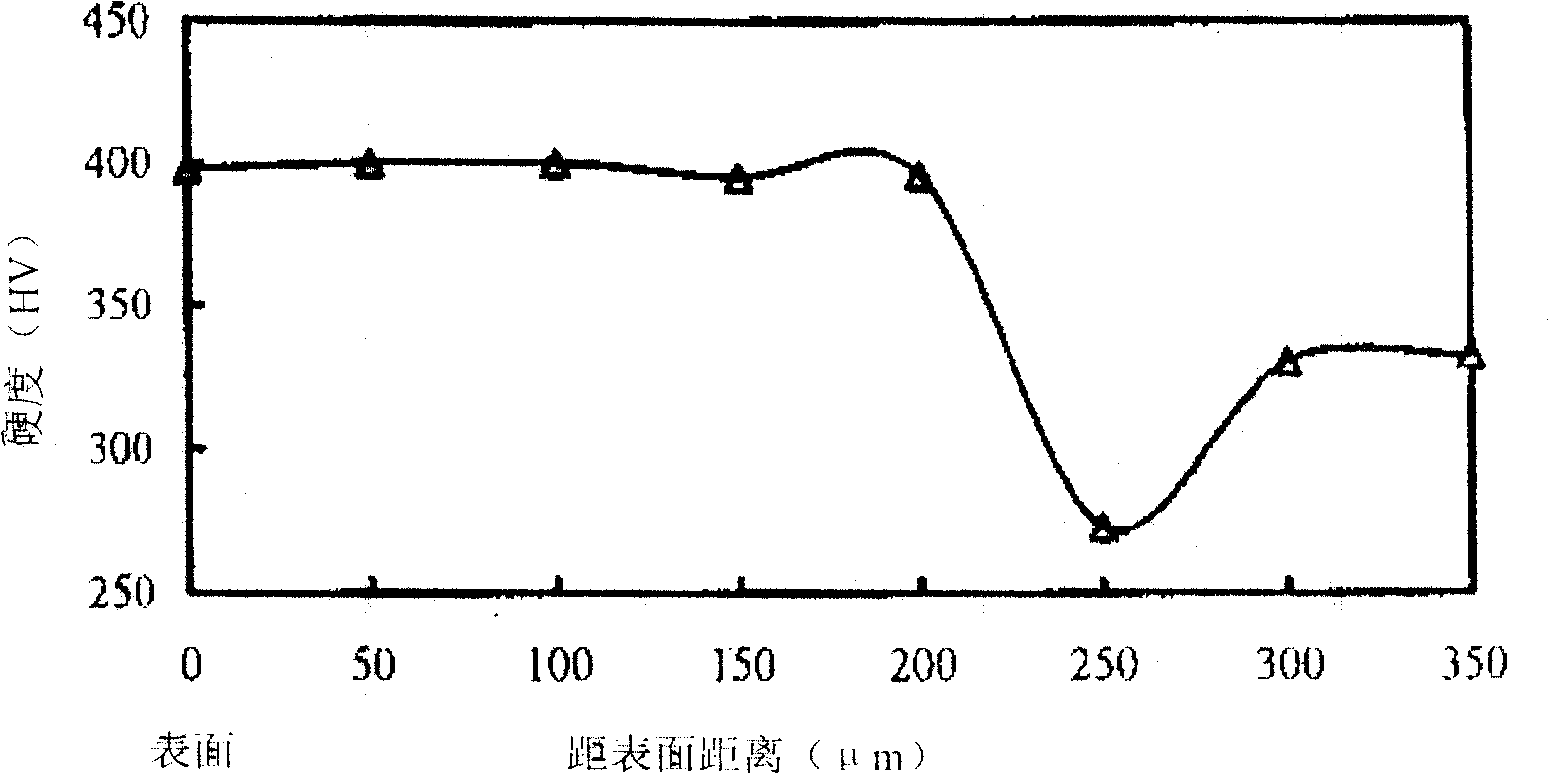

[0024] In this embodiment, laser hardening treatment is carried out on 17-4PH steel. First, the surface of precipitation hardened stainless steel is cleaned, and it is subjected to constant temperature treatment. After reaching the designed temperature, a beam of light spot is selected according to the geometric configuration of the treated surface for laser treatment. , so that the surface is rapidly fused, and at the same time cover the laser action area with a low-temperature protective gas to control the melting rate of the laser action area, and then perform heat treatment on the fusion area.

[0025] 1. Clean the surface of the treatment area: use acetone, alcohol or pine water to remove oil stains;

[0026] 2. Workpiece constant temperature treatment: temperature 20 ℃, holding time 0.5 hours;

[0027] 3. Laser treatment: continuous laser irradiation, optical power 500W, power density 10 4 W / cm 2 , scanning speed 3m / min; light spot Φ1.5mm, overlap 50%, 0 ℃ argon protec...

Embodiment 2

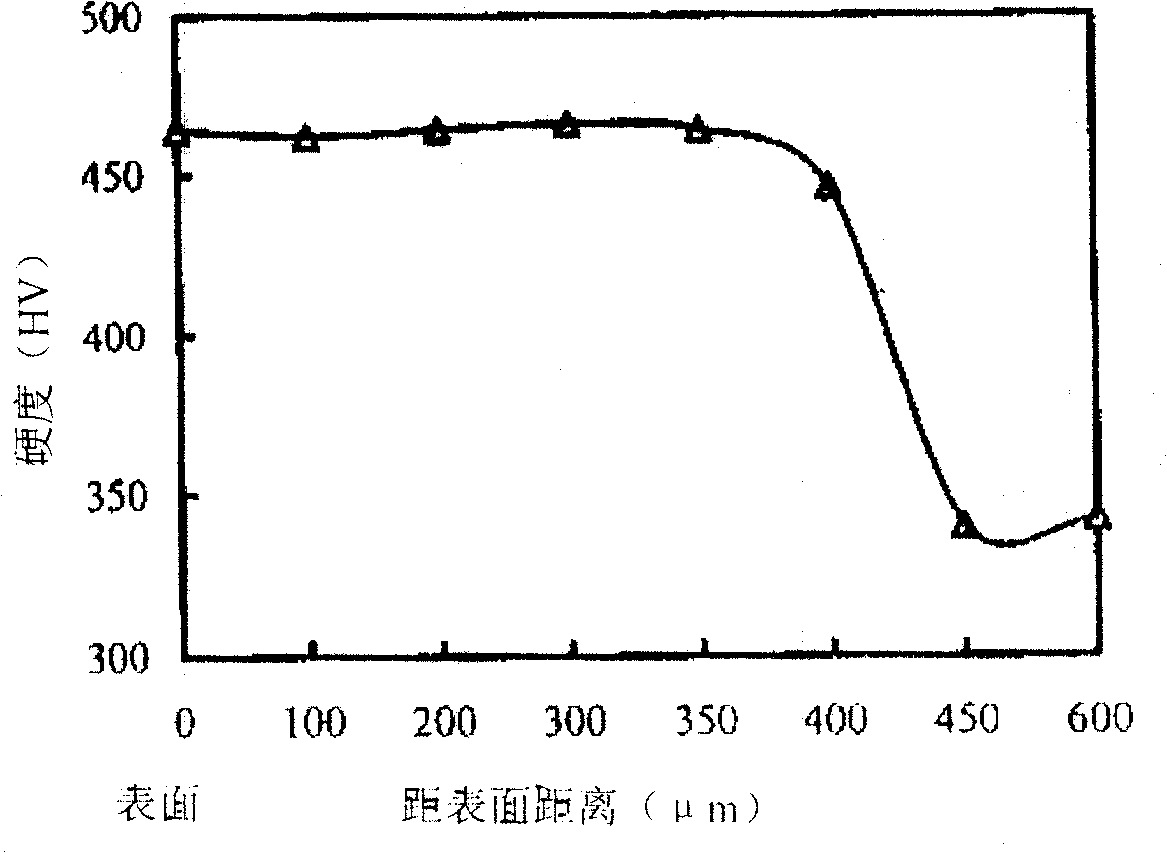

[0031] This embodiment carries out laser hardening treatment to 17-4PH steel, and the difference with embodiment 1 is:

[0032] 1. Workpiece constant temperature treatment: temperature 0 ℃, holding time 8 hours;

[0033] 2. Laser treatment: laser pulse irradiation, pulse energy 30J, pulse frequency 30Hz, pulse width 1ms, overlap 40%, irradiation spot Φ2mm; 4 ℃ argon gas protection;

[0034] 3. Auxiliary heat treatment: temperature 600 ℃, holding time 4 hours, air cooling, precipitation and uniform dispersion of ε-Cu phase;

[0035] Such as figure 2 As shown, the microhardness of the laser treatment area on the surface of the workpiece can reach HV470, and the depth of the hardened layer in this embodiment is 0.4mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com