Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Realize automatic processing and production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

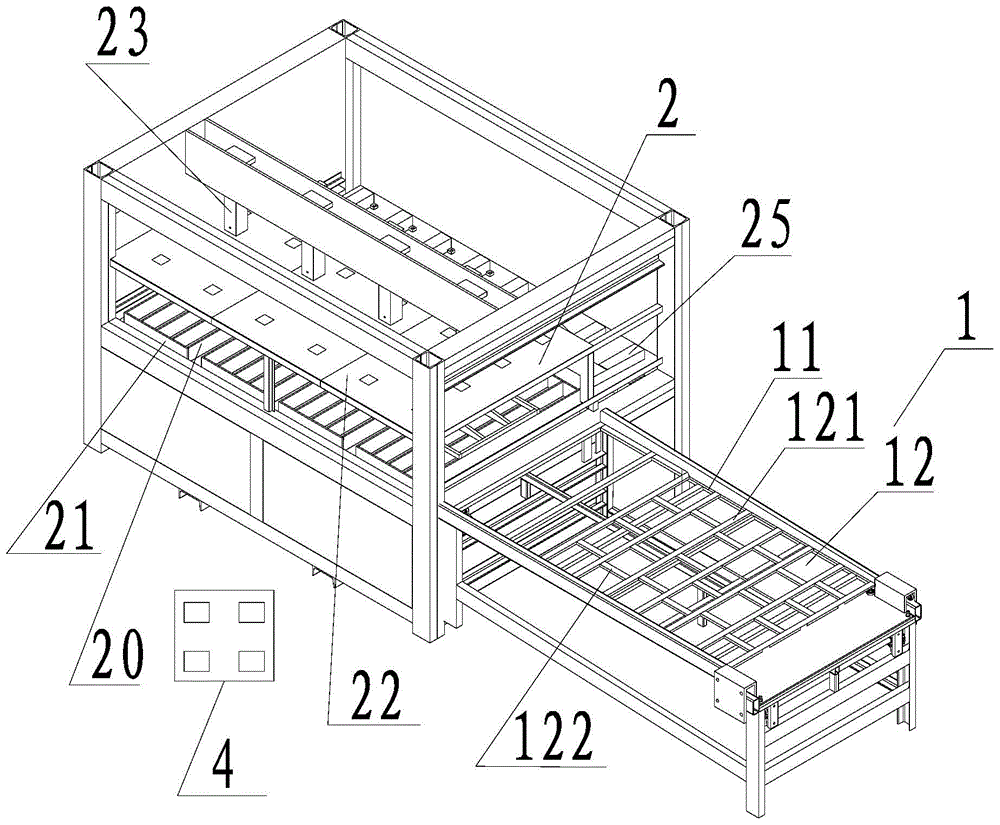

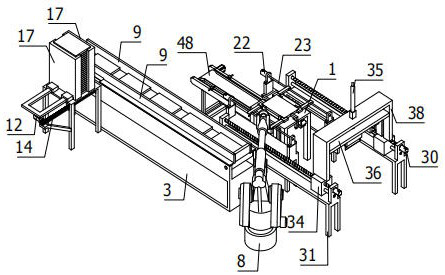

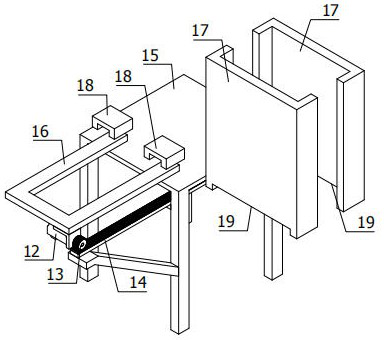

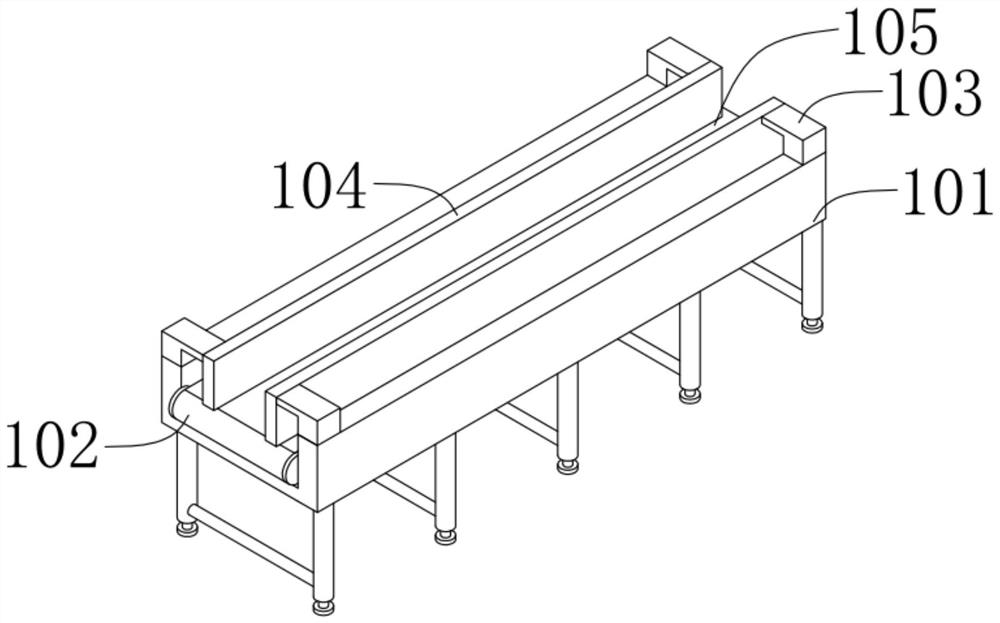

Wood board splicing machine and board splicing method thereof

InactiveCN103600384AImprove production efficiency and production qualitySave human effortPlywood pressesVeneer pressesProduction qualityNumerical control

A wood board splicing machine comprises a feeding device, a pressing device and a heating device. The feeding device is connected with the pressing device, and the heating device is arranged above the pressing device. The wood board splicing machine further comprises a numerical control device, and the numerical control device is connected with the feeding device, the pressing device and the heating device and controls operation of the feeding device, the pressing device and the heating device. By the wood board splicing machine, labor is liberated fully, boards are automatically processed and produced, and production efficiency and production quality are improved effectively.

Owner:刘吉超

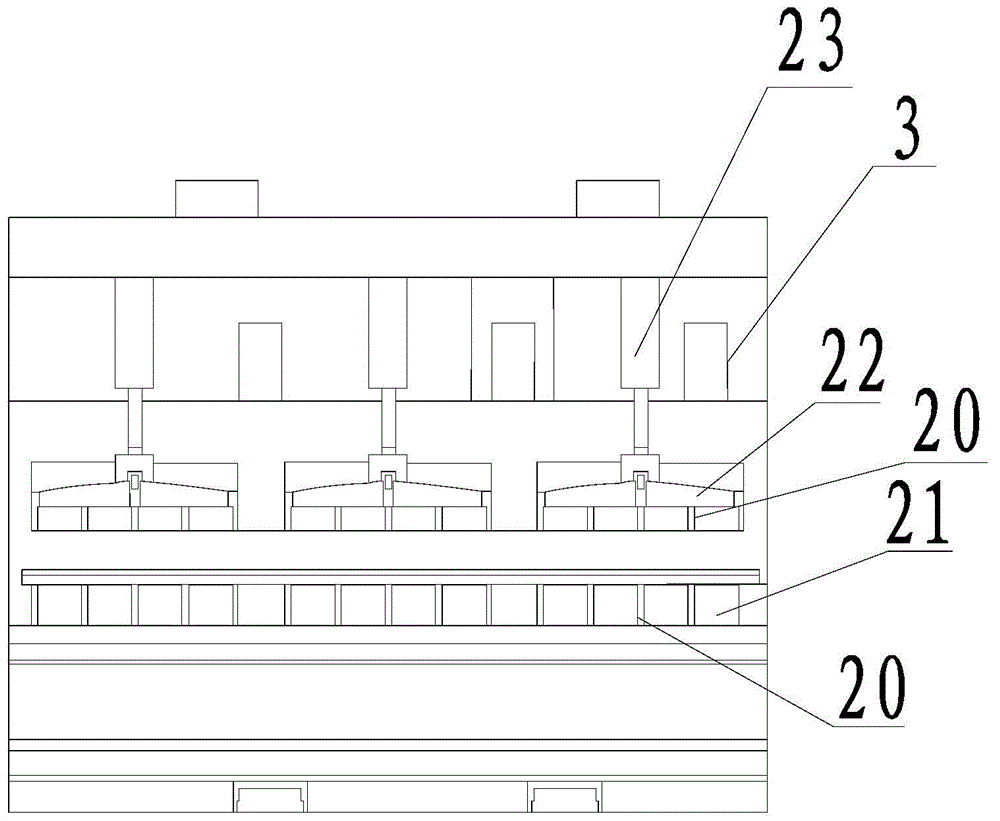

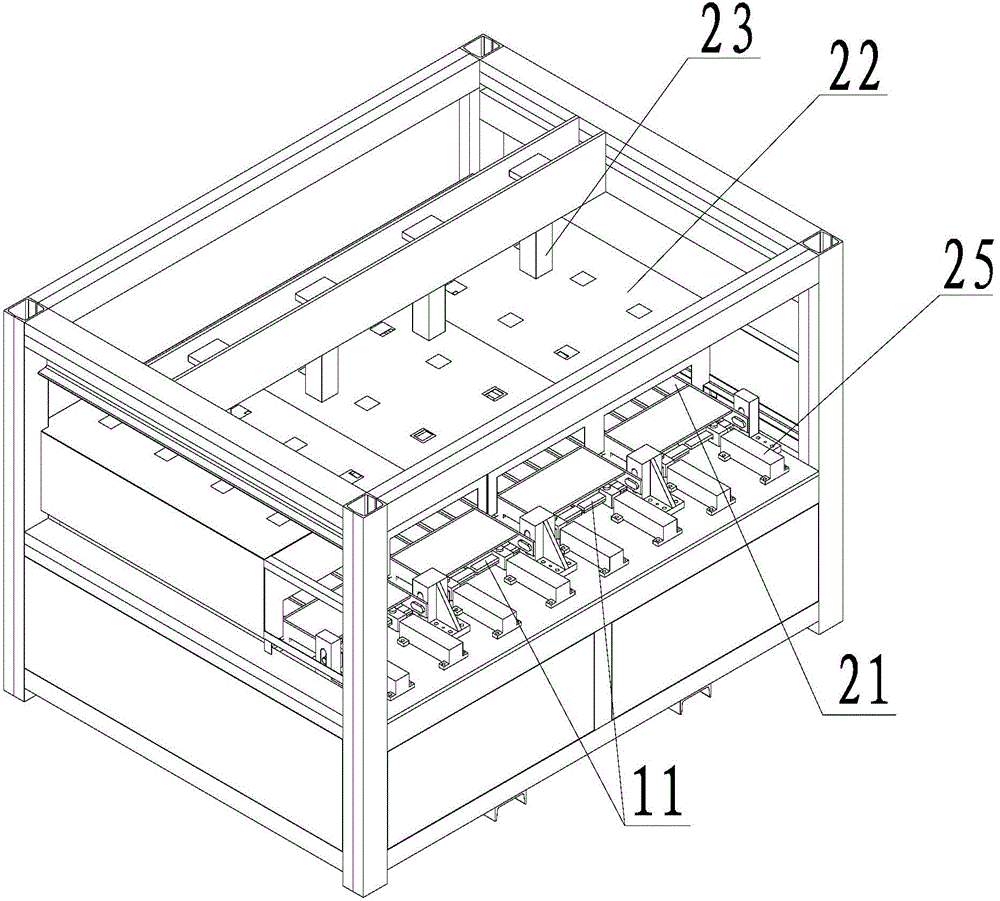

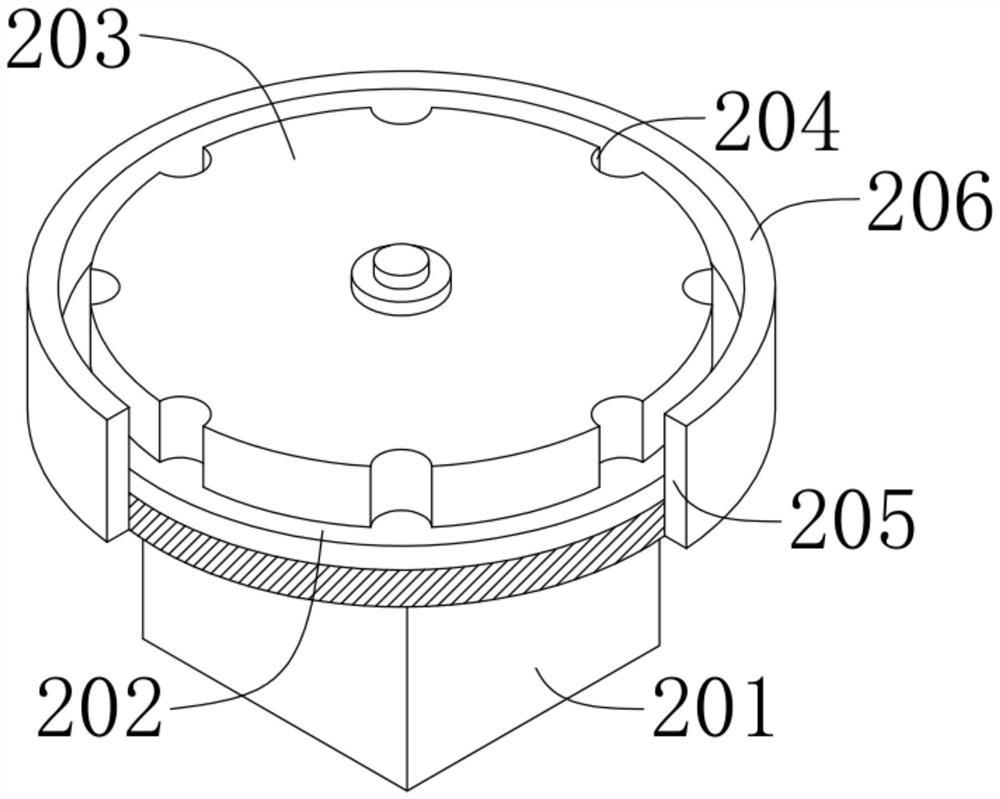

Pump body shell production line

PendingCN109014959ARealize automatic processing and productionReduce uncertaintyOther manufacturing equipments/toolsProduction lineEngineering

The invention discloses a pump body shell production line. The pump body shell production line comprises the production procedures of shape milling and grinding, stepped hole boring and milling, bearing hole machining, water mouth lathing, overflow hole drilling, installation hole drilling, bolt platform drilling and milling and water seal platform finish lathing and further comprises a material feeding line, a chain plate line and a transfer robot, wherein the shape milling and grinding further comprises milling and grinding detection, and the stepped hole boring and milling are performed through delivery of the material feeding line after the milling and grinding detection; and between the stepped hole boring and milling and the material feeding line, a first module actuator performs detection with a detection device, and meanwhile, pump body shells are transferred. By means of the pump body shell production line, automation machining production of the pump body shells is realized, meanwhile, automatic detection can be performed, and staying between working procedures and working procedure errors appearing in working procedure transfer connection are avoided; and by means of programmed operations, the uncertainty of manual operations is reduced, meanwhile, the efficiency is improved, high-quality operations and detection are realized, and the market competitiveness is improved.

Owner:深圳市祁科作物科技有限公司

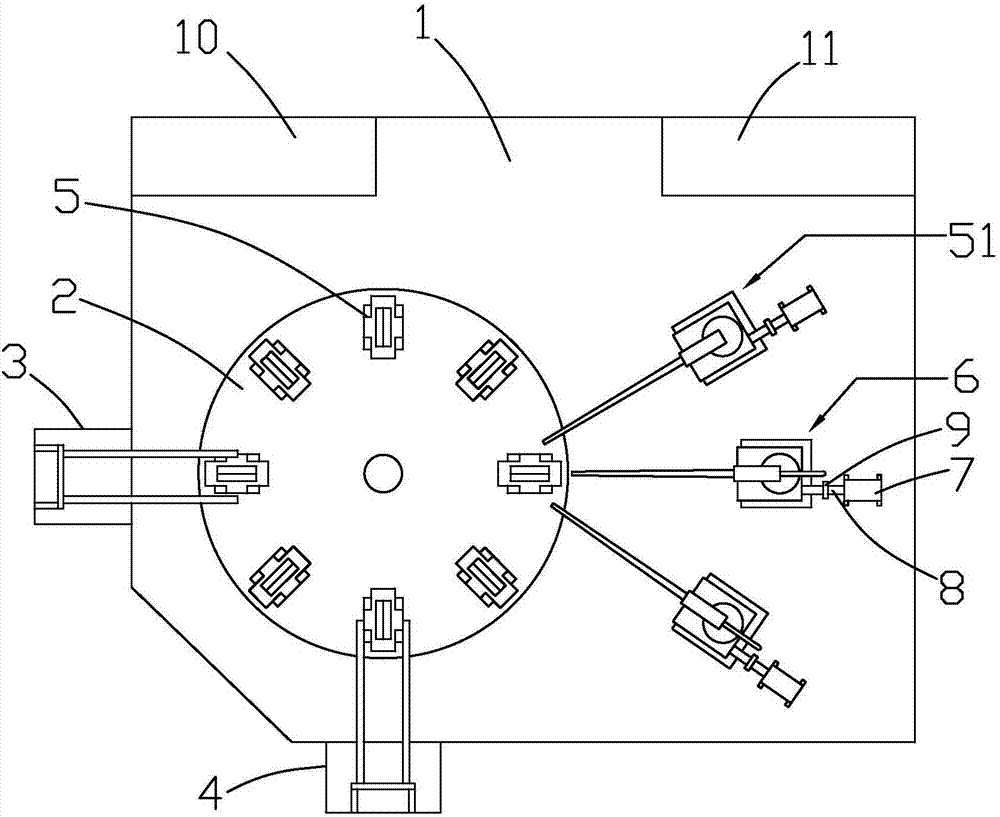

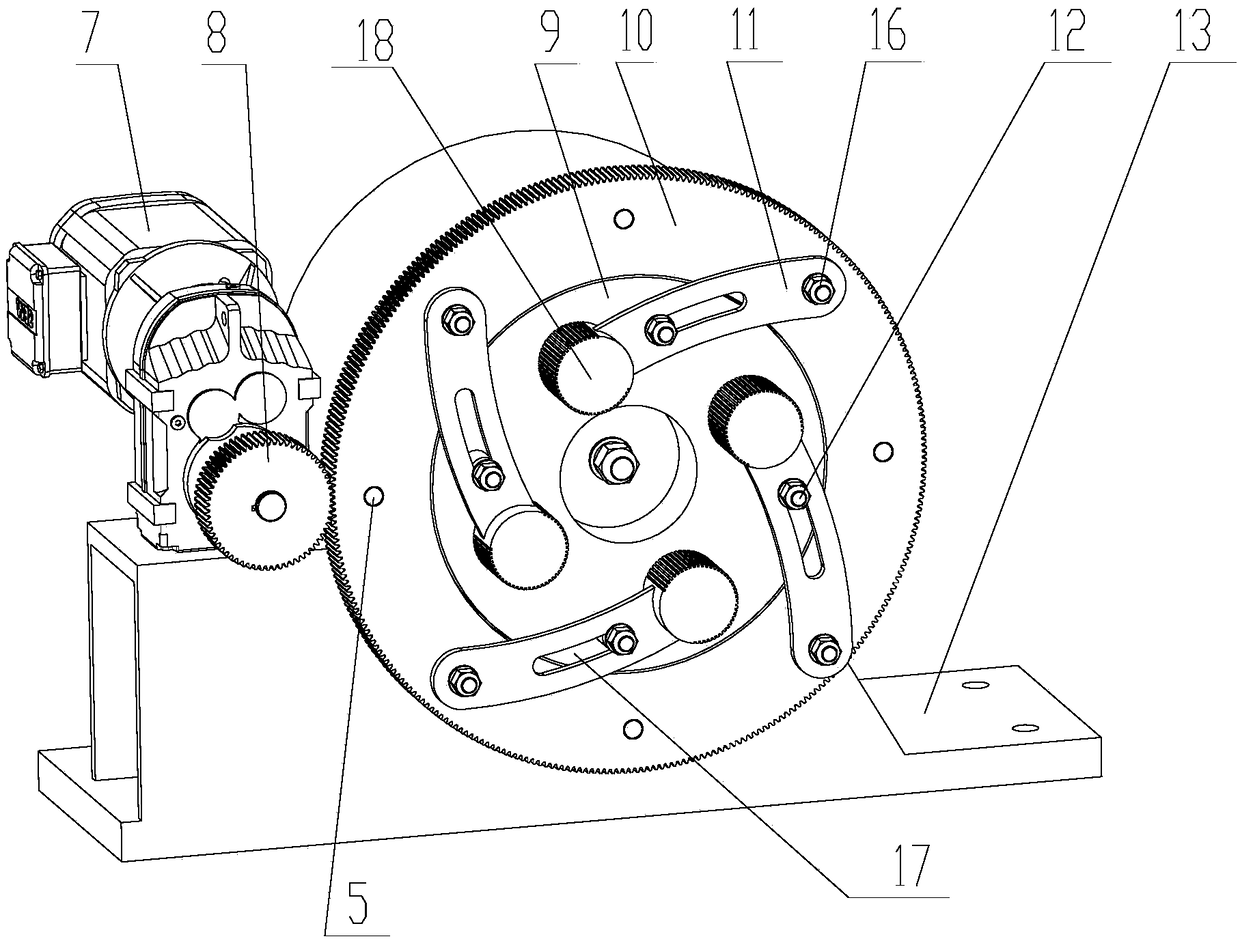

Rotary-disc flame welding machine and welding method thereof

ActiveCN107159994AAdjustable positionImprove welding precisionHeating appliancesSolder feeding devicesEngineeringElectric control

Owner:XINCHANG KECHUANG AUTOMATION EQUIP

Automatic hook nail machining and forming equipment and machining method thereof

The invention relates to the technical field of hook nail machining and forming equipment, in particular to automatic hook nail machining and forming equipment and a machining method thereof. The automatic hook nail machining and forming equipment is characterized by comprising a punch press and an intermittent rotating table, wherein a punch forming male die is fixedly arranged on the lower end face of a punch of the punch press, a plurality of female dies are arranged on the intermittent rotating table, the intermittent rotating table is used for sequentially and intermittently rotating thefemale dies to the position under the punch forming male die, the female dies are used for containing nail body initial blanks, and when a sheet enters the position between the punch forming male dieand the female dies, the punch forming male die extrudes the sheet into a connecting arm of a bent structure under the cooperation of the female dies and is riveted to the nail body initial blanks correspondingly. According to the automatic hook nail machining and forming equipment and the machining method thereof, the whole structure is novel and practical, continuous and automatical process andproduction can be conducted, the overall firmness of a hook nail is effectively ensured, the quality of a finished product is ensured, the processing procedure of the hook nail is simple, the production efficiency is greatly improved, the labor cost is reduced, and greater economic benefits can be brought.

Owner:泉州市建明环保科技有限公司

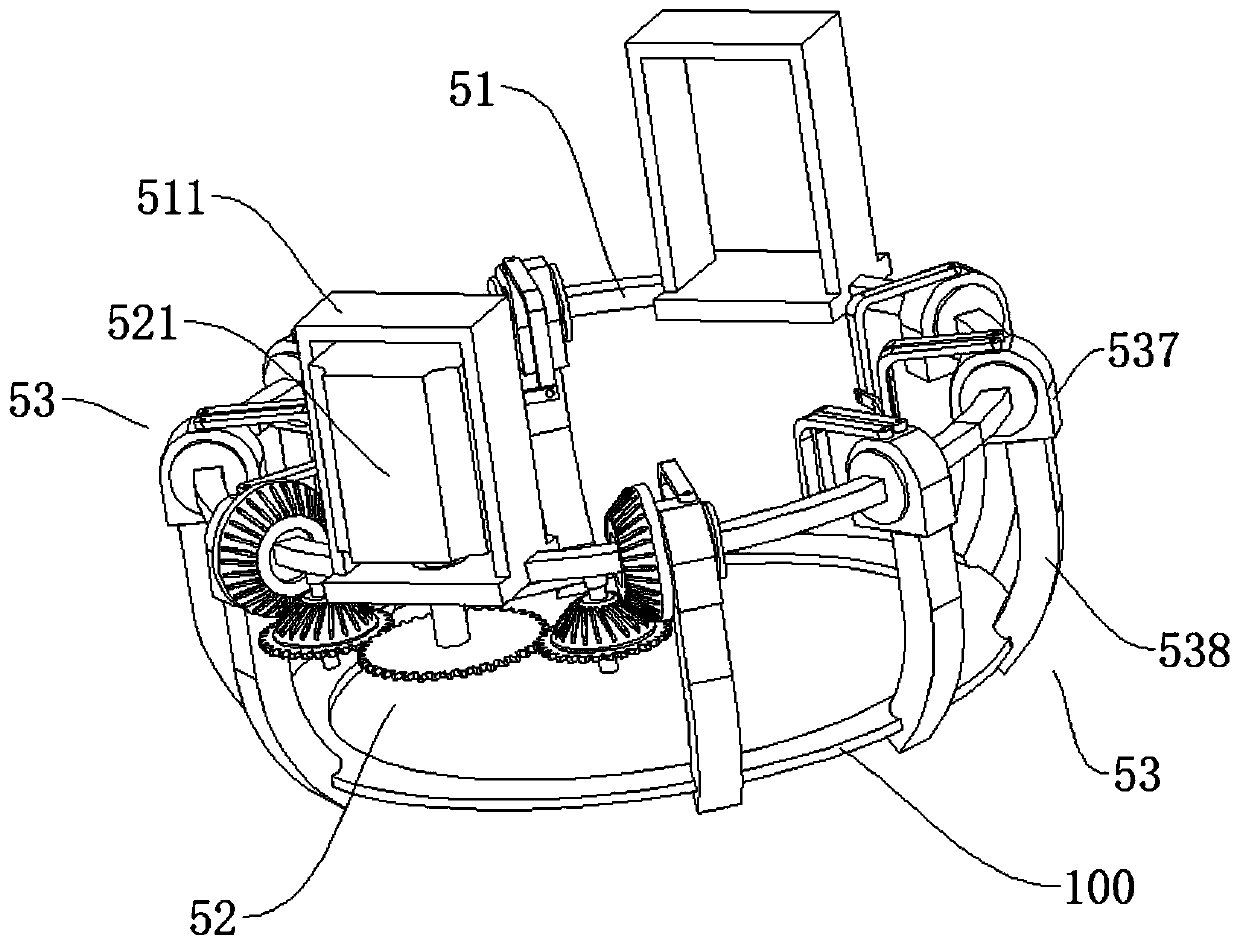

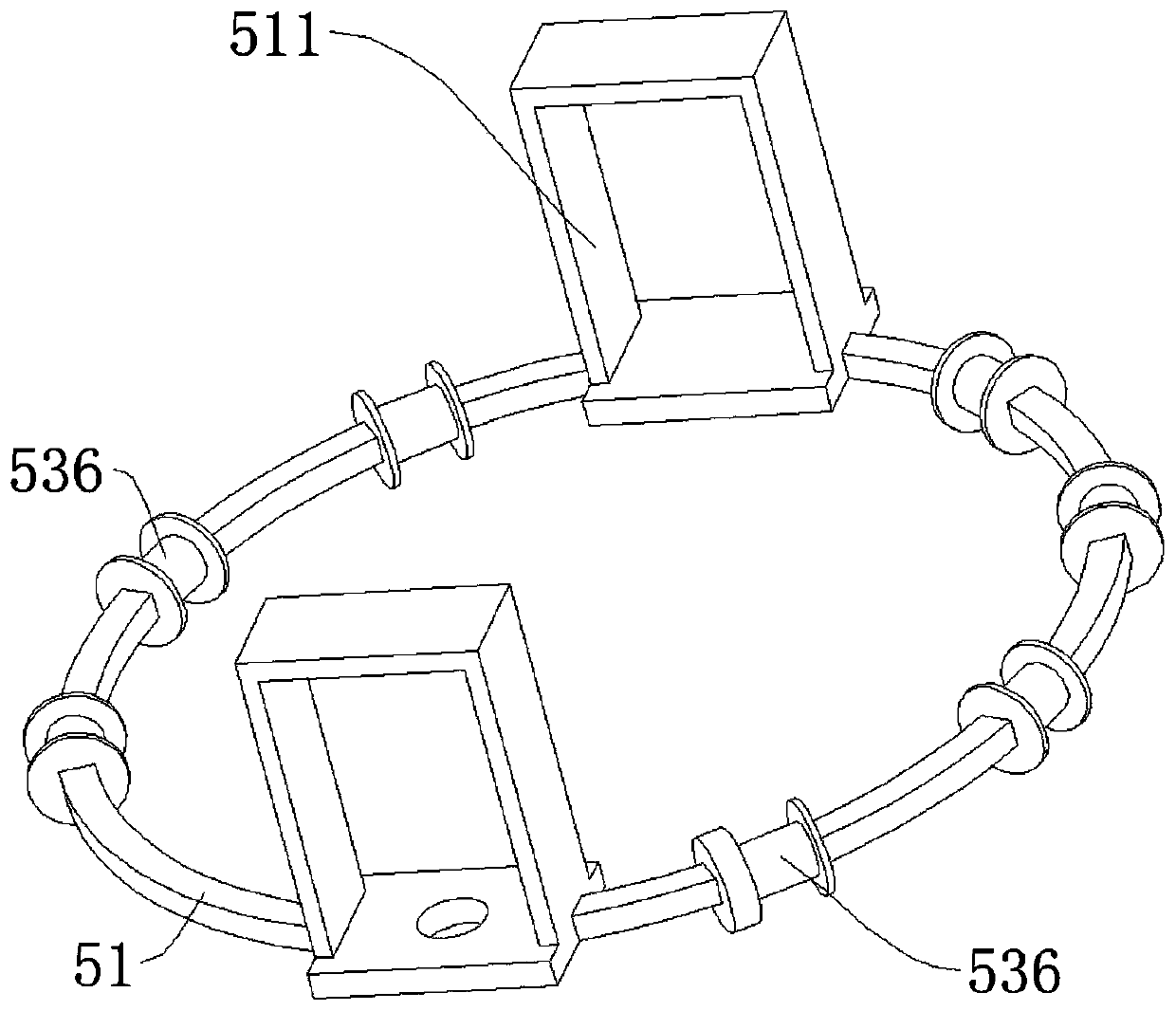

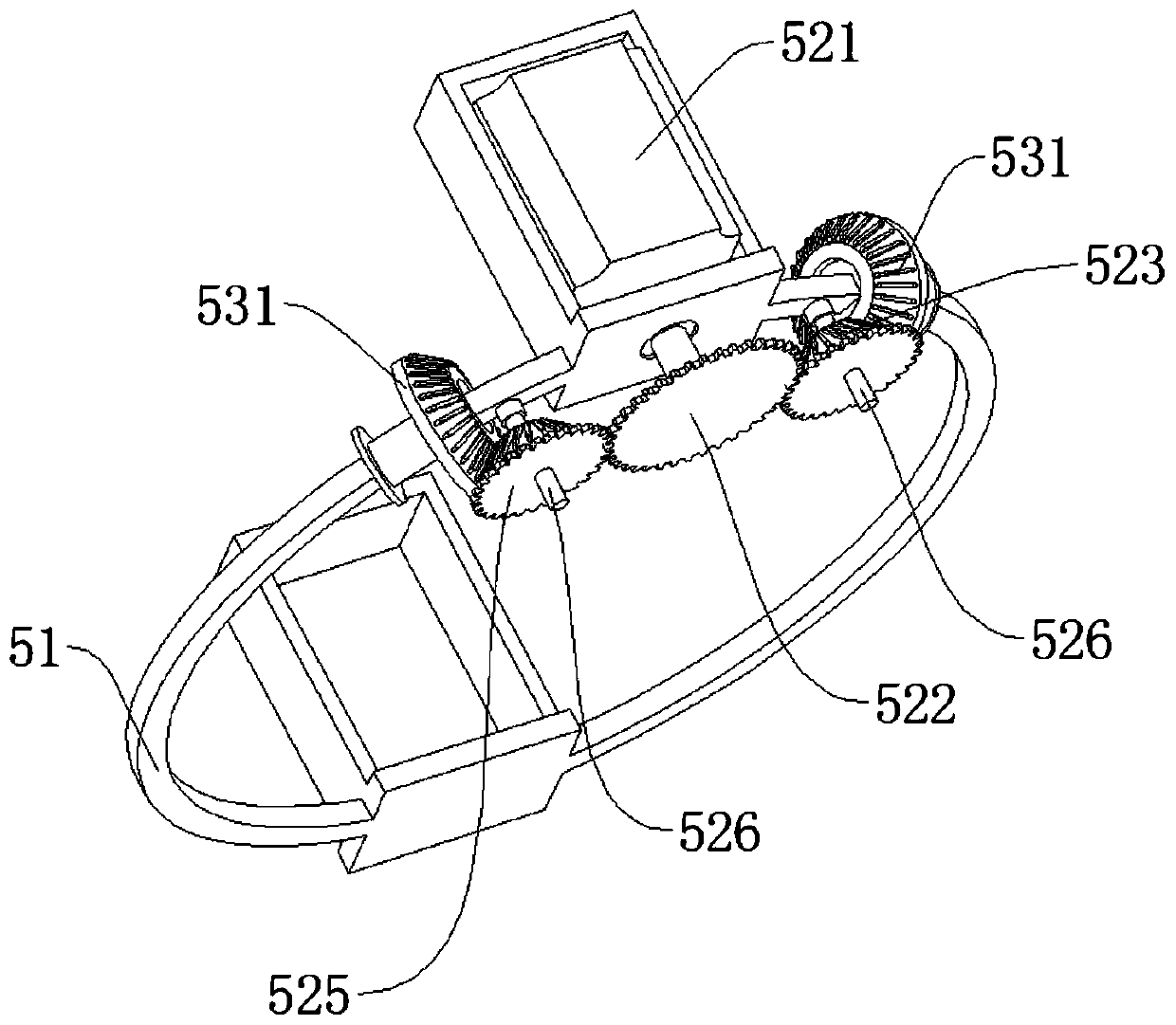

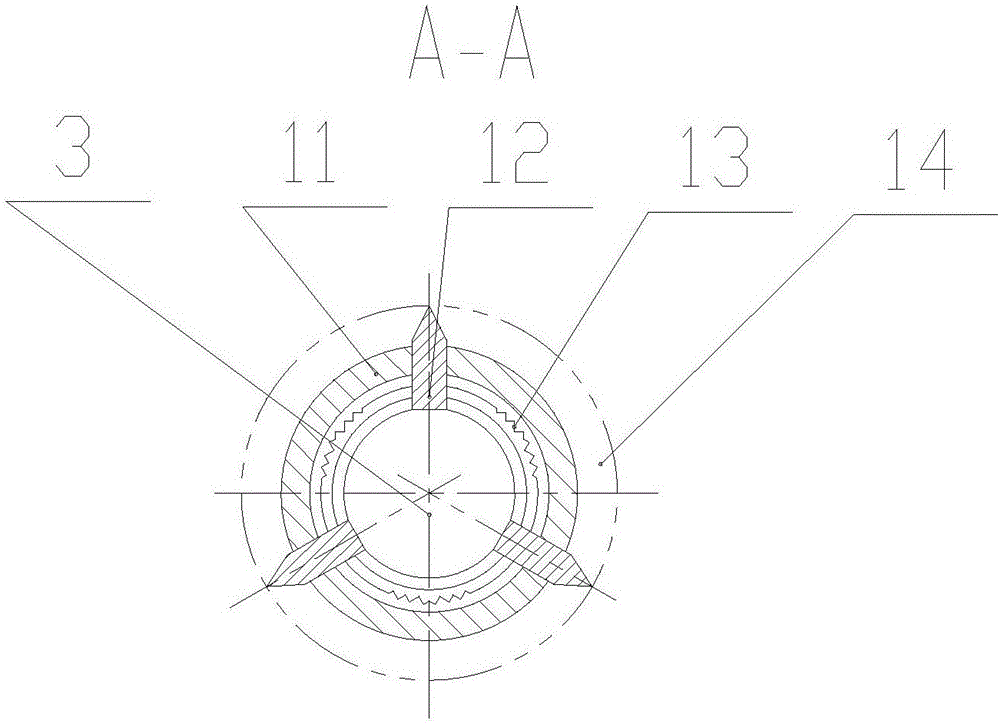

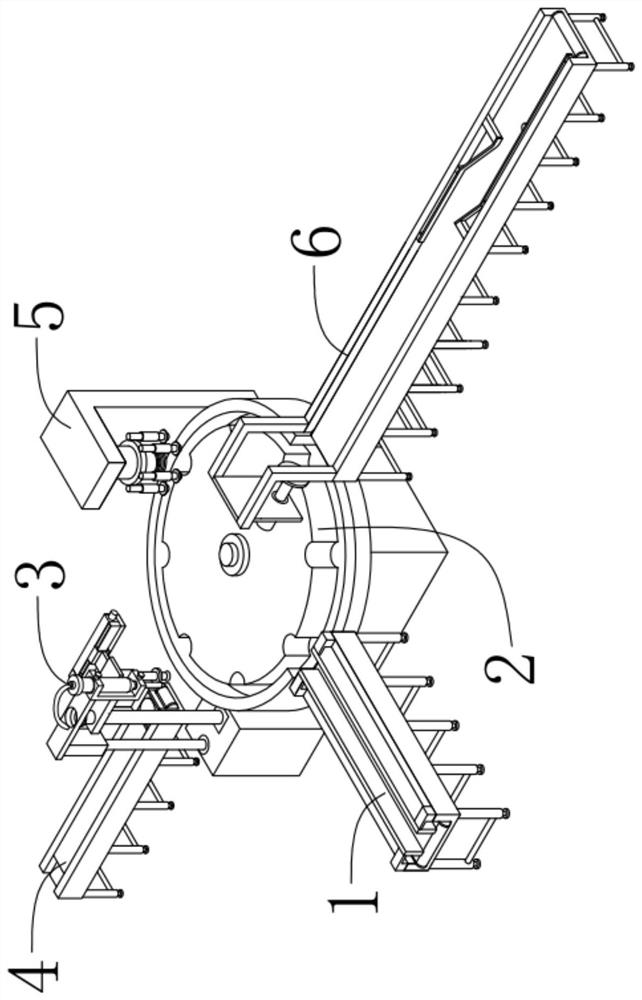

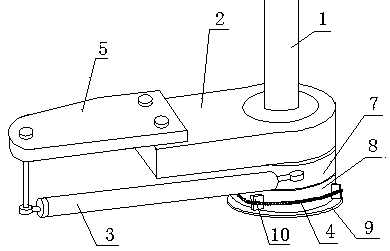

Mechanical ripper and multi-station working table

The invention discloses a mechanical gripper, comprising an annular rack, grabbing assemblies supported on the annular rack to grab or release a workpiece, and a driving assembly supported on the annular rack to drive the grabbing assembly to finish the actions of grabbing or releasing, wherein two sets of grabbing assemblies are arranged, and each set of grabbing assembly comprises four jaws rotatably arranged on the annular rack, and the distance between every two adjacent jaws is the same and every two adjacent jaws can be in transmission connection with each other, and free ends of the jaws are bent towards the center of the annular rack; the driving assembly is connected with one of the jaws in each set of grabbing assembly. The gripper is able to grip a circular part.

Owner:广州益图机电科技有限公司

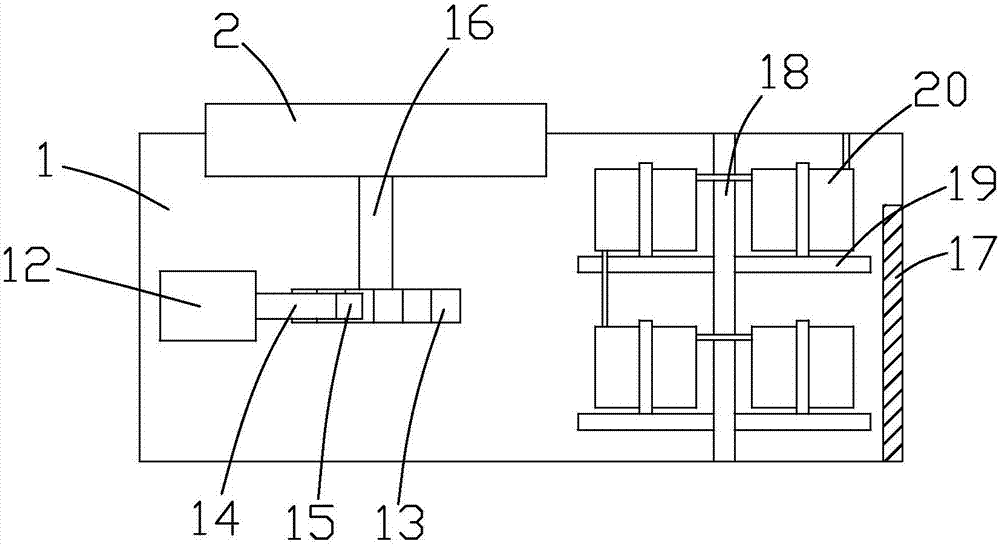

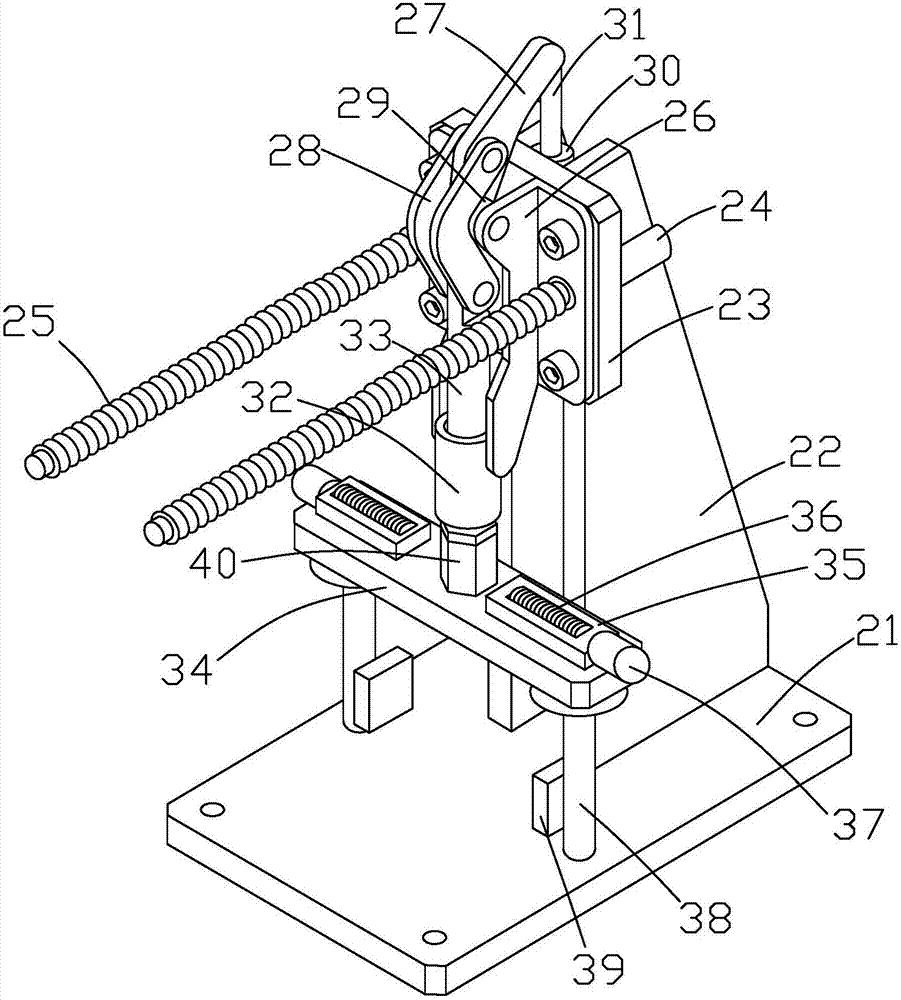

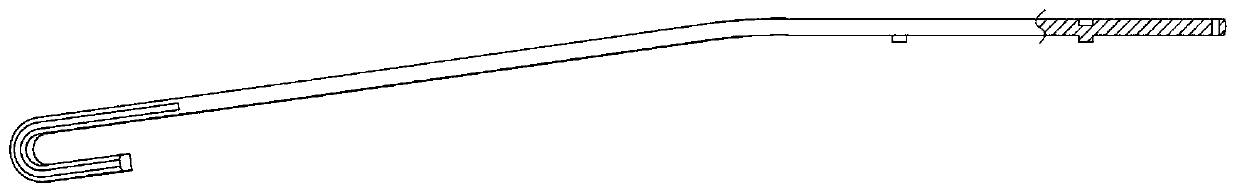

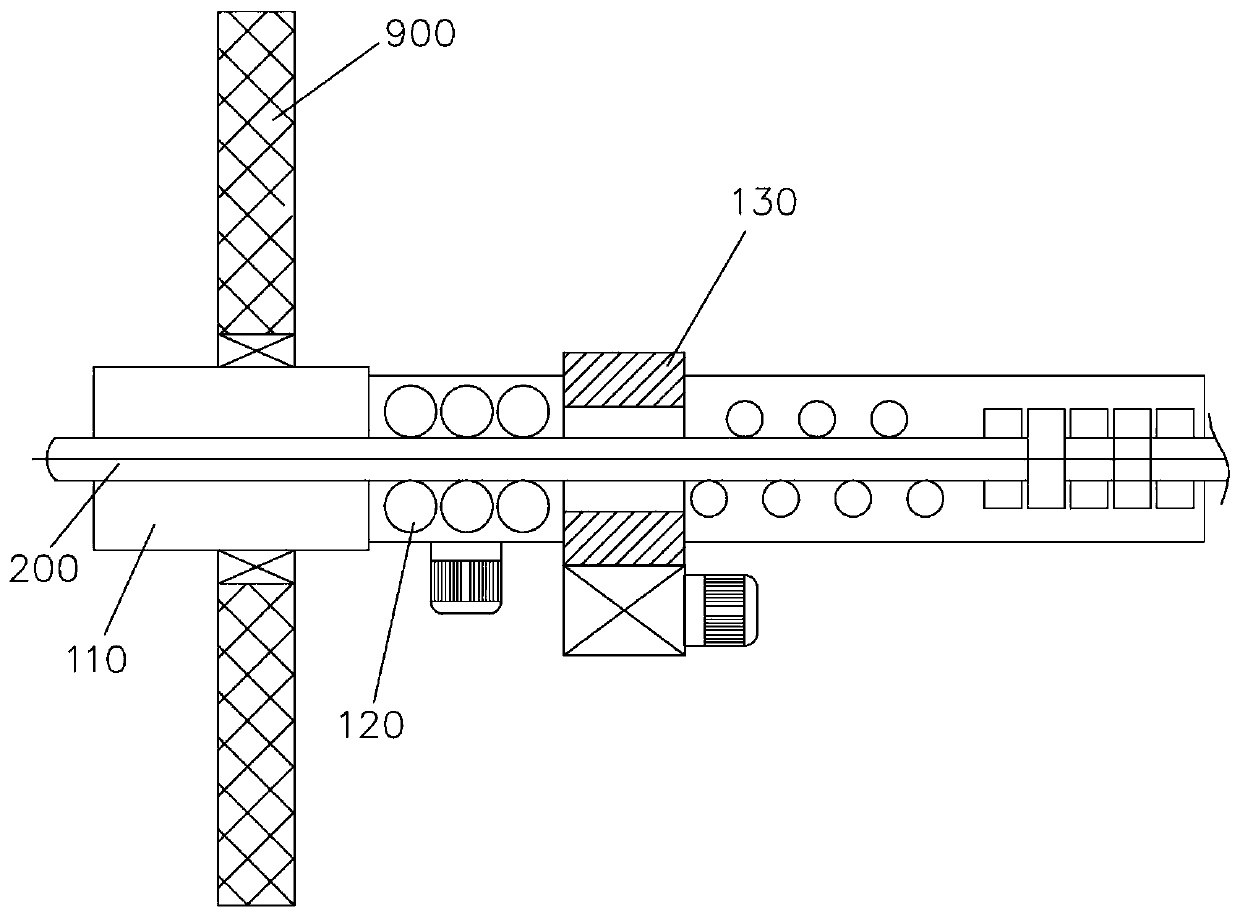

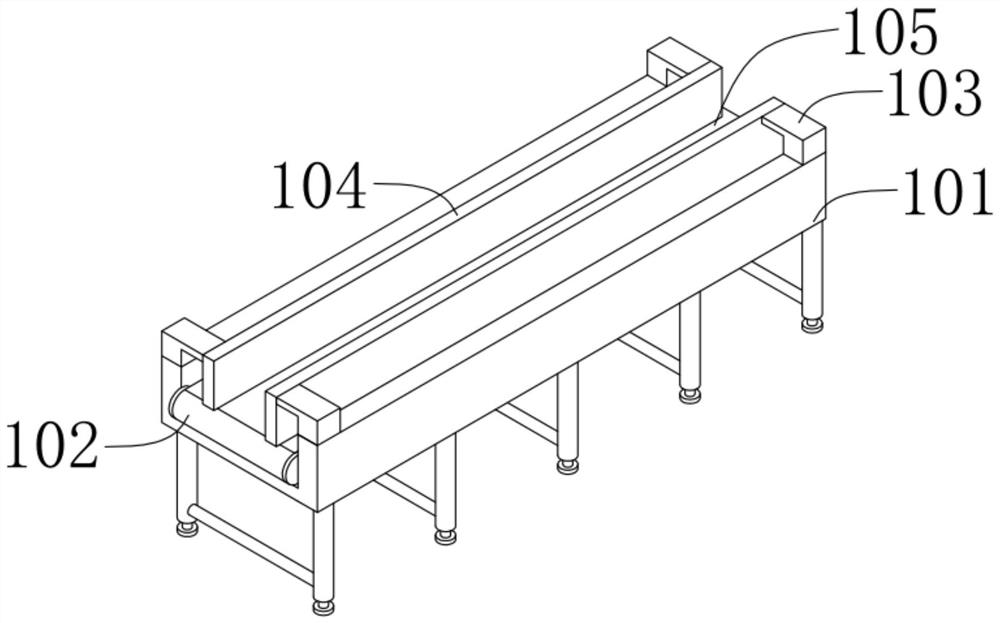

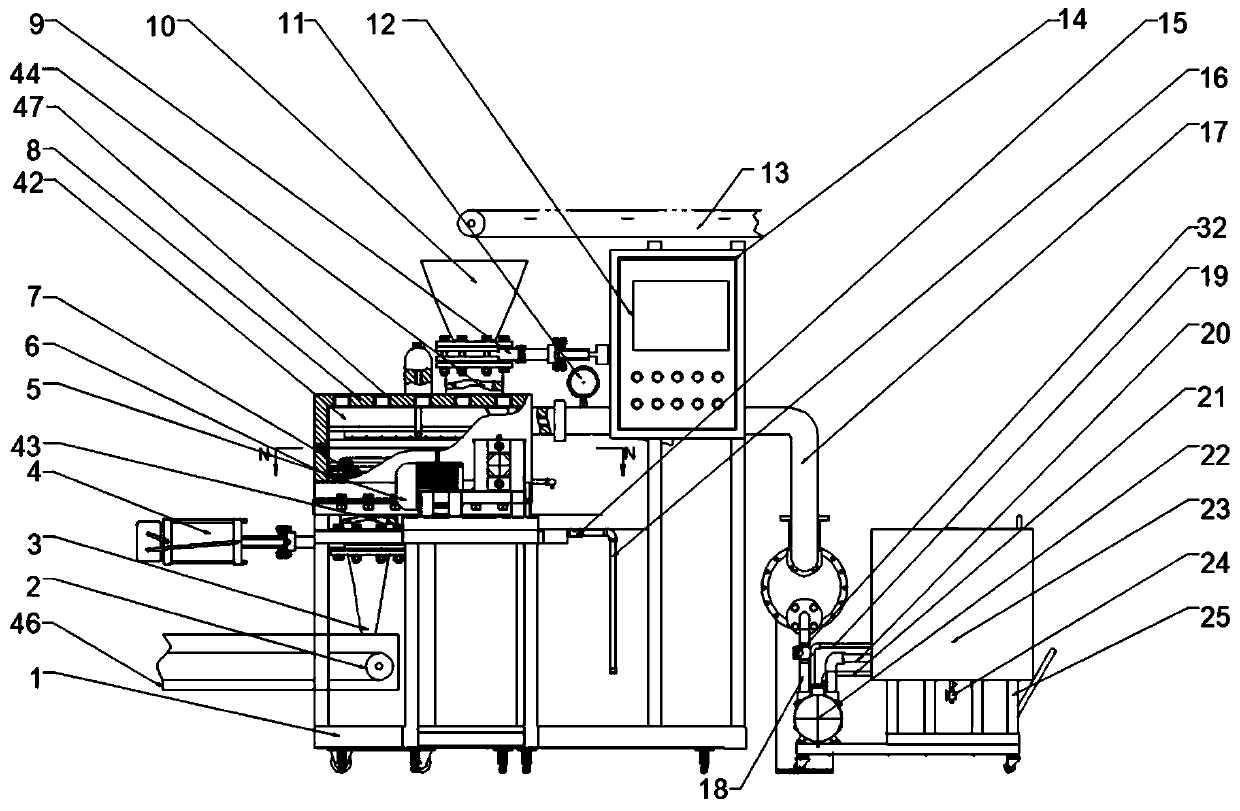

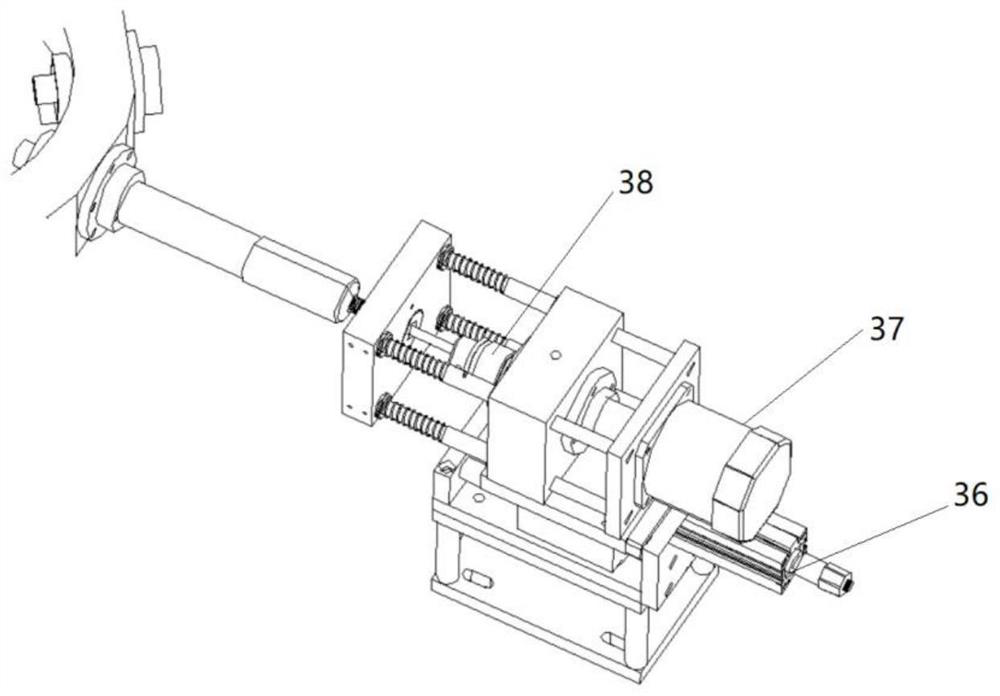

Device for thread machining and sleeve installation of reinforcing steel bars

PendingCN108723266AGuaranteed StrengthTroubleshoot technical issues with installationMetal-working feeding devicesScrew-threads articlesArchitectural engineeringRebar

The invention relates to a device for thread machining and sleeve installation of reinforcing steel bars. The device comprises a reinforcing steel bar input mechanism, a reinforcing steel bar output mechanism, a reinforcing steel bar fixing mechanism, a sleeve installation mechanism and a thread chasing mechanism, wherein the sleeve installation mechanism, the thread chasing mechanism and the reinforcing steel bar fixing mechanism are arranged between the reinforcing steel bar input mechanism and the reinforcing steel bar output mechanism; the sleeve installation mechanism and the thread chasing mechanism can move relative to the reinforcing steel bar fixing mechanism. The device integrates the thread machining and the sleeve installation of the reinforcing steel bars, realizes the automatic processing production of the straight reinforcing steel bars, reduces the processes, greatly reduces the labor cost and improves the construction efficiency.

Owner:CHINA MINSHENG ZHUYOU

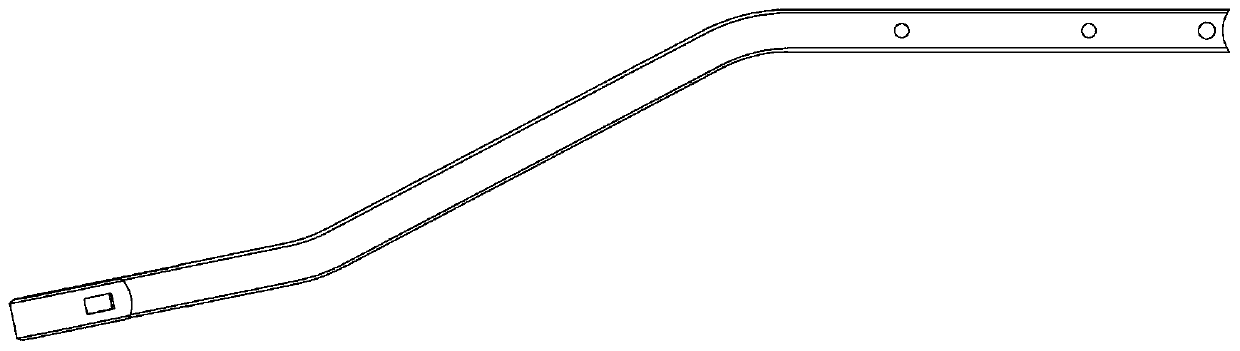

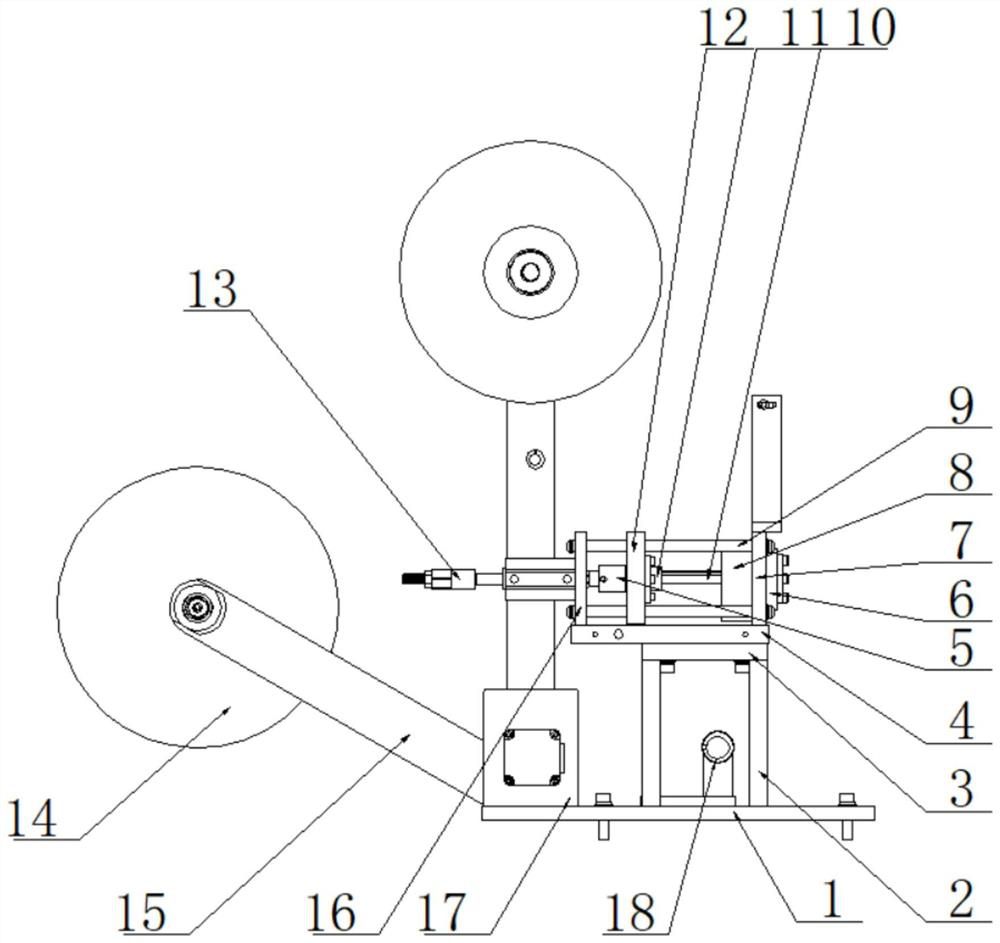

Automatic forming equipment for connecting rod of windscreen wiper

ActiveCN110340222ARealize automatic processing and productionImprove efficiencyVehicle componentsPunchingEngineering

The invention provides automatic forming equipment for a connecting rod of a windscreen wiper. The automatic forming equipment comprises a feeding shaft and a plurality of forming mechanisms distributed in the circumferential direction of the feeding shaft; the forming mechanism comprises a horizontal bending mechanism, a flattening and forming mechanism, an inclined bending mechanism, a convex point punching mechanism, a punching mechanism and a blanking mechanism, wherein the horizontal bending mechanism is used for bending the end part of a plate wire rod in the thickness direction; the flattening and forming mechanism is used for flattening and forming the end part of the bent plate wire rod in the width direction; the inclined bending mechanism is used for bending the plate wire rod in the width direction; the convex point punching mechanism is used for punching and forming the plate wire rod in the thickness direction; the punching mechanism is used for punching in the thicknessdirection of the plate wire rod; and the blanking mechanism is used for cutting off the plate wire rod in the thickness direction. According to the automatic forming equipment, the problems that the production efficiency is low, the material is wasted and the size precision is poor in the traditional production process are solved, the automatic processing production is realized, the one-time forming is realized, the efficiency is high, the product quality is reliable, and the cost is low.

Owner:苏州兆能精密弹簧五金有限公司

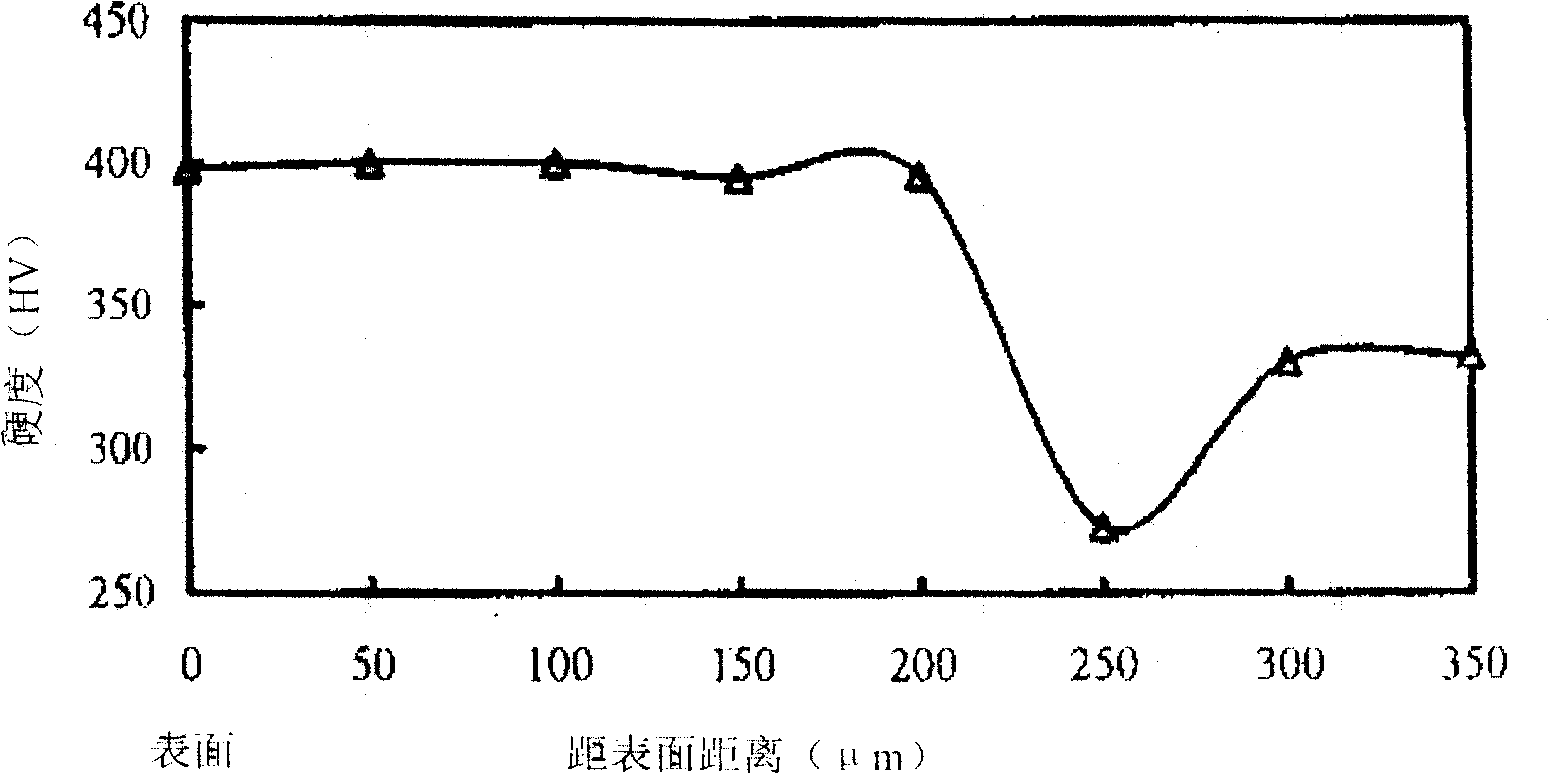

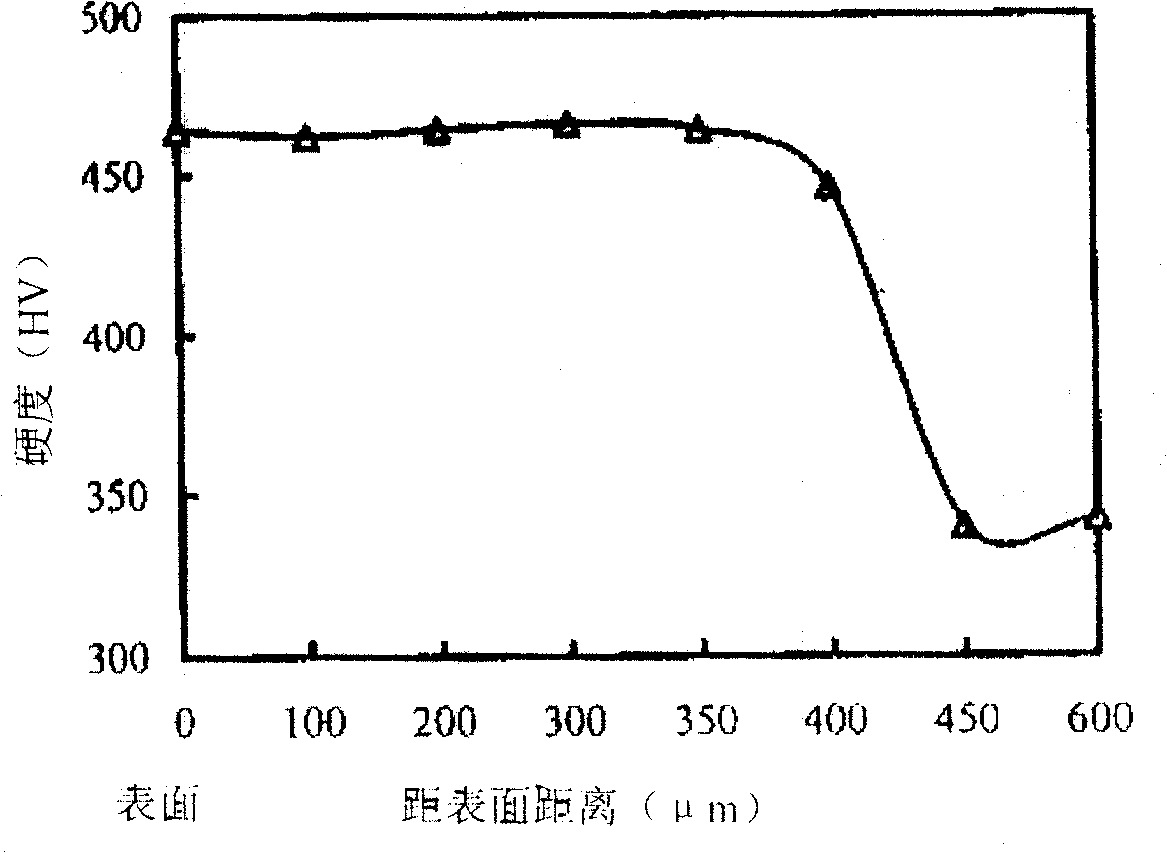

Hardening technology for precipitation hardening stainless steel laser surface

InactiveCN100443597CHigh hardnessMechanical properties unchangedHeat treatment process controlShielding gasCase hardening

In the invention, a specific wave-length laser is used for scanning radiation on the surface of the precipitation hardening stainless steel within a certain condition, so, making the surface of said steel to smelt. Low temperature shield gas is used for being cover onto the scanned area, for speeding-up the cooling. After that, the steel is subjected to heat treatment, so the hardness of the surface in a certain thickness is harder than that of the main body of the steel.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

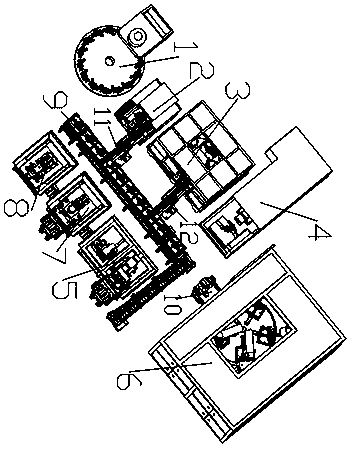

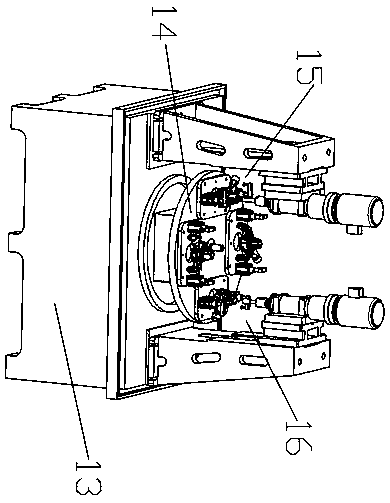

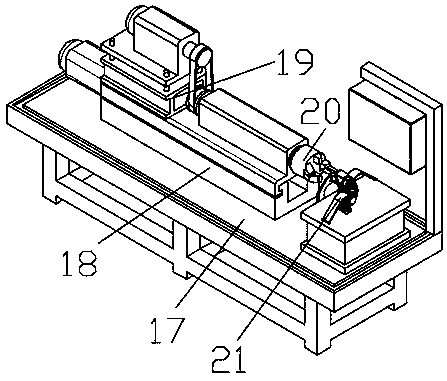

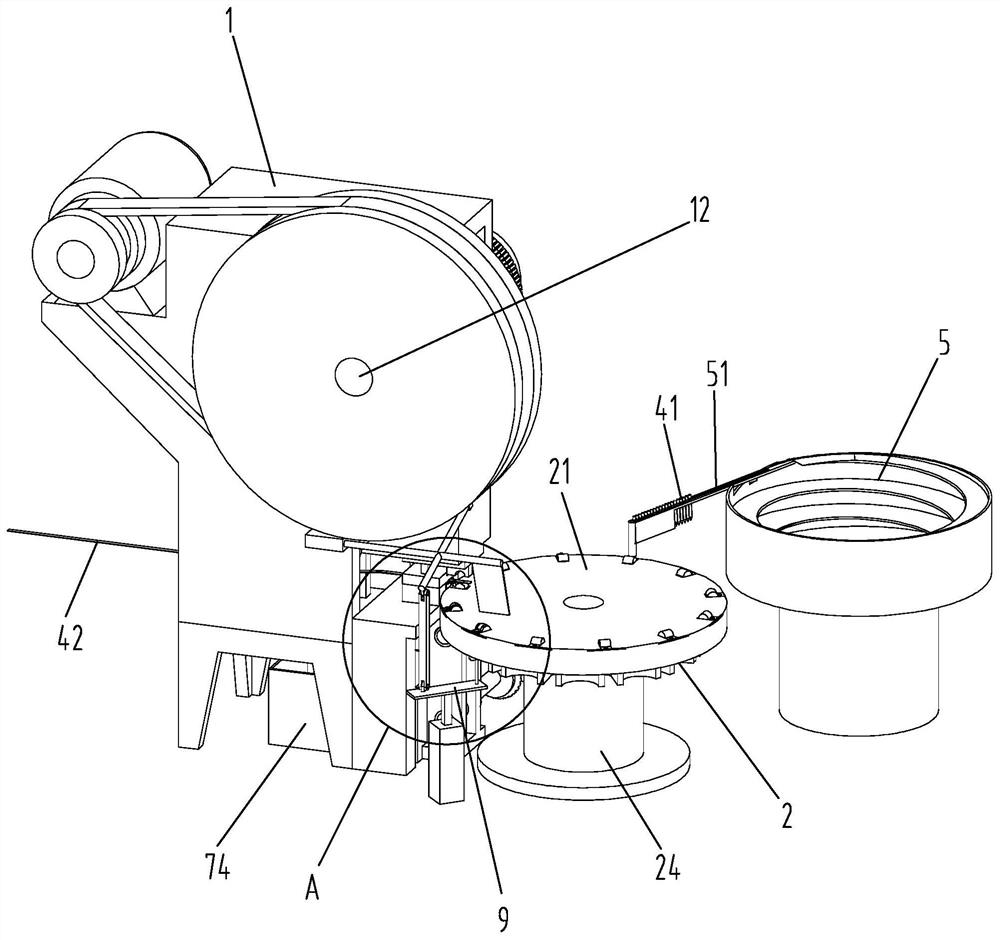

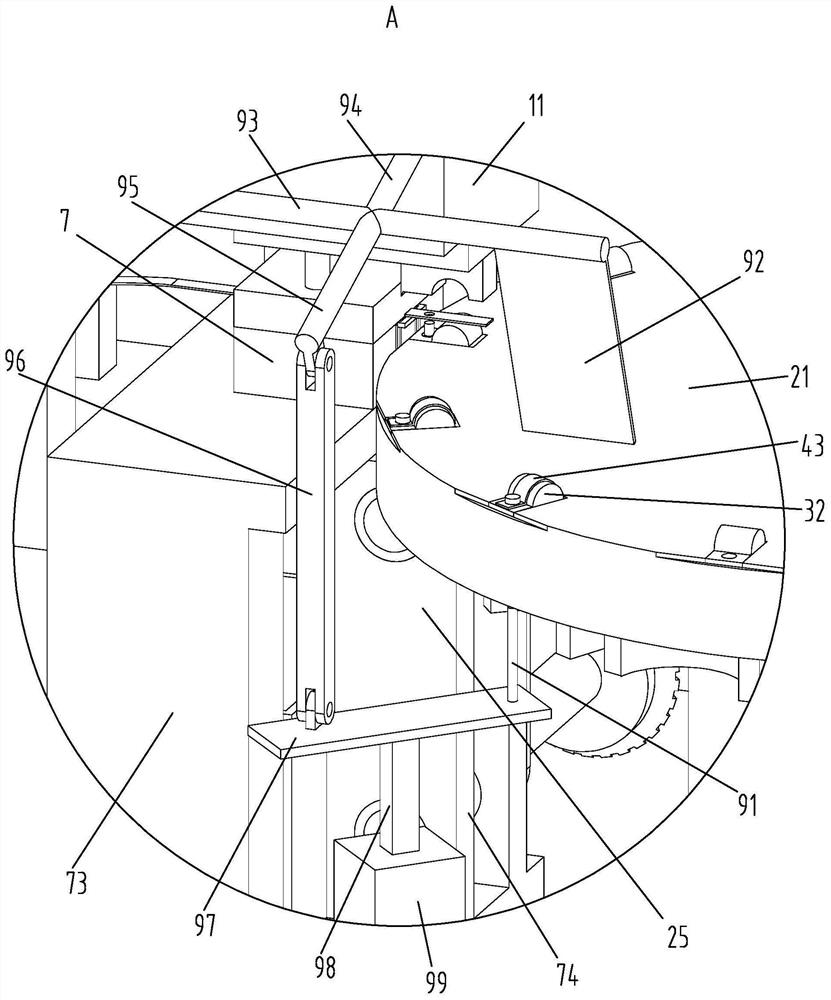

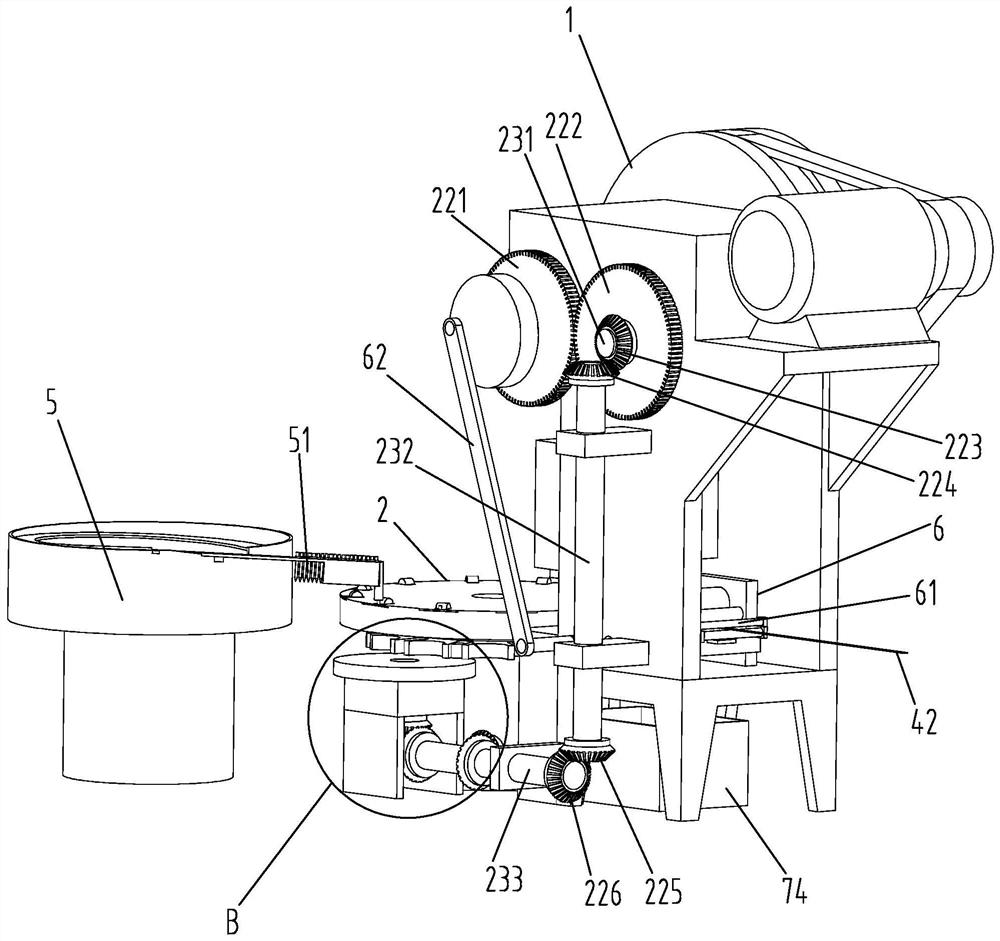

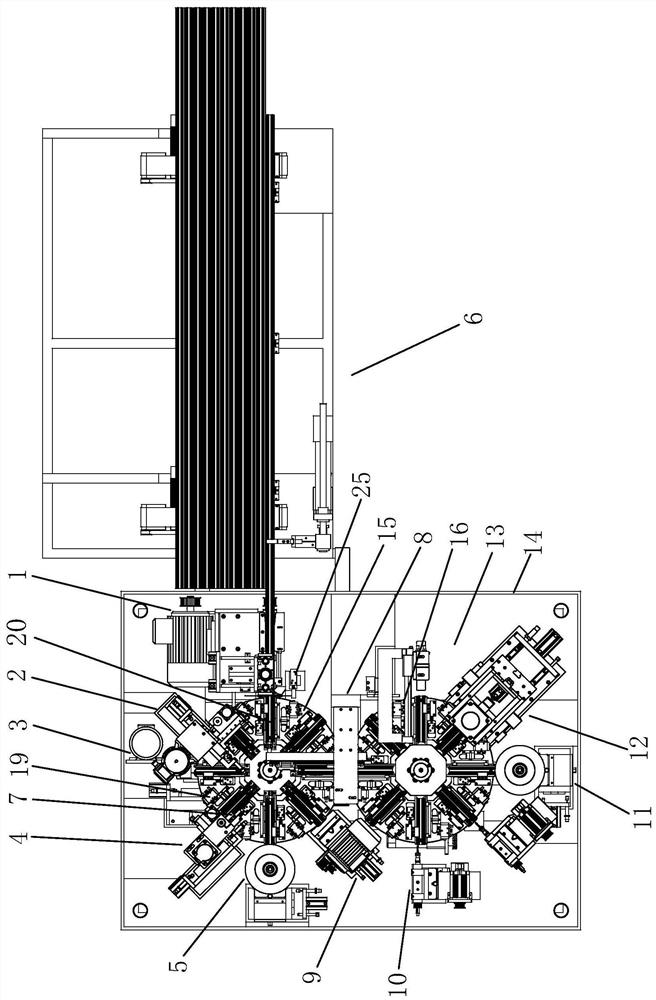

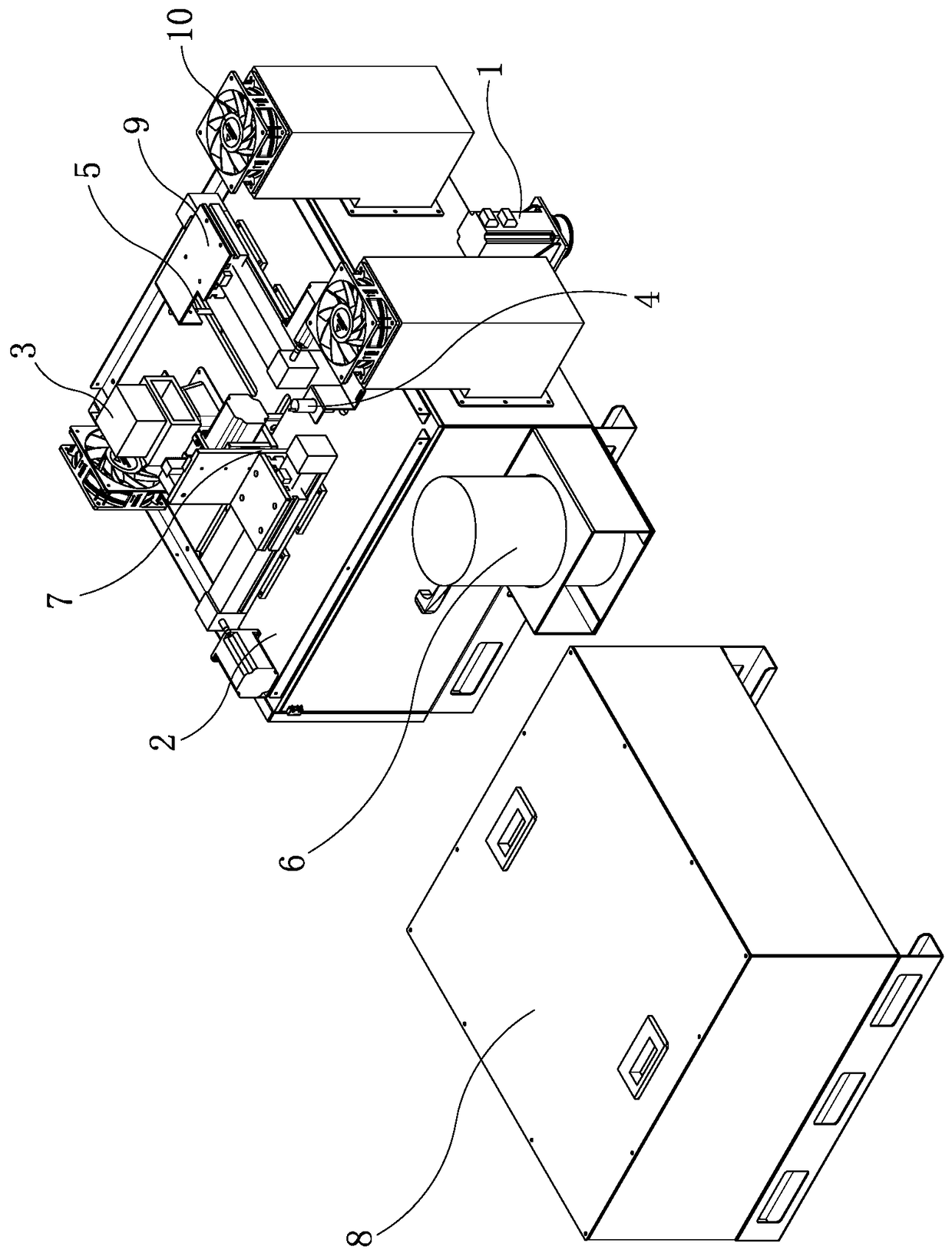

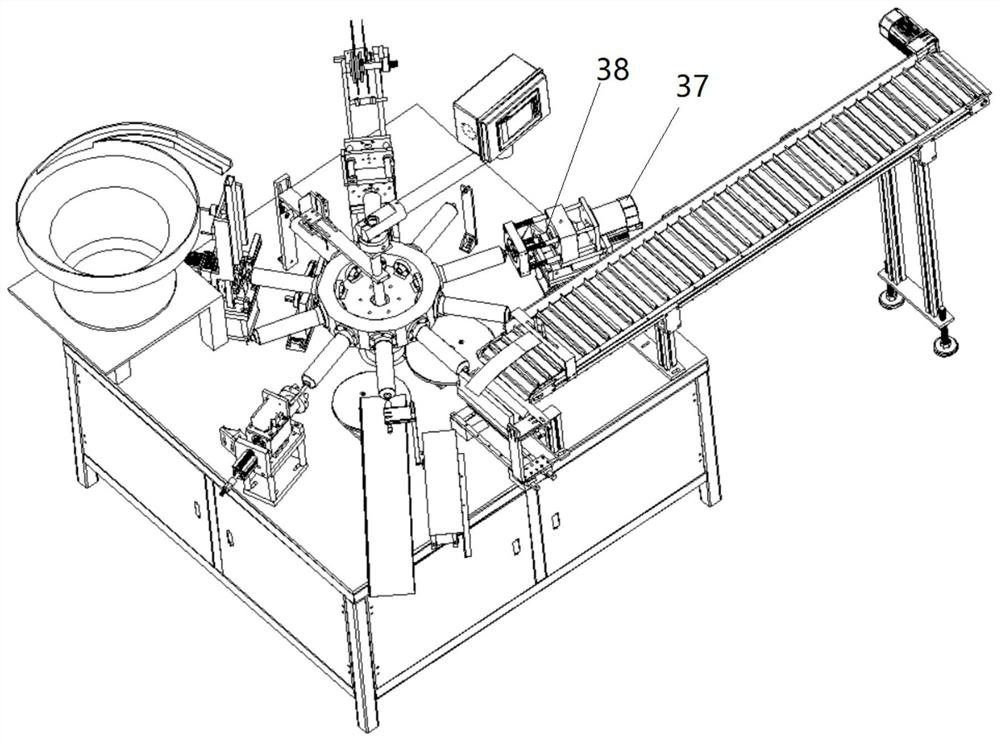

Rotating disc type automatic processing machine

InactiveCN112894363ARealize automatic processing and productionImprove work efficiencyWork clamping meansOther manufacturing equipments/toolsEngineeringMachine

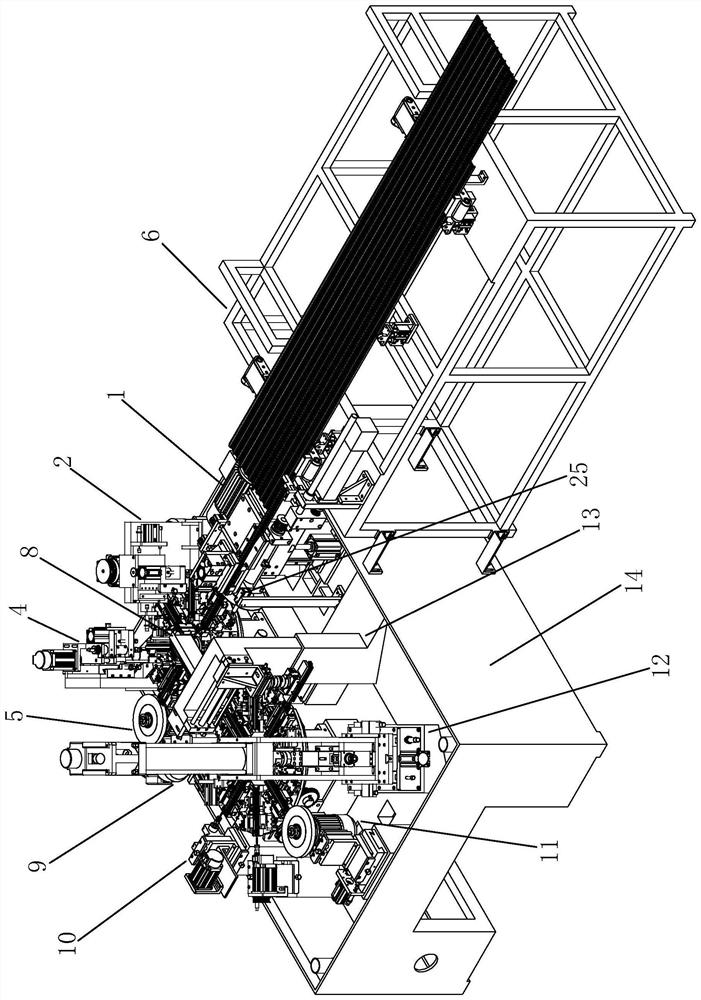

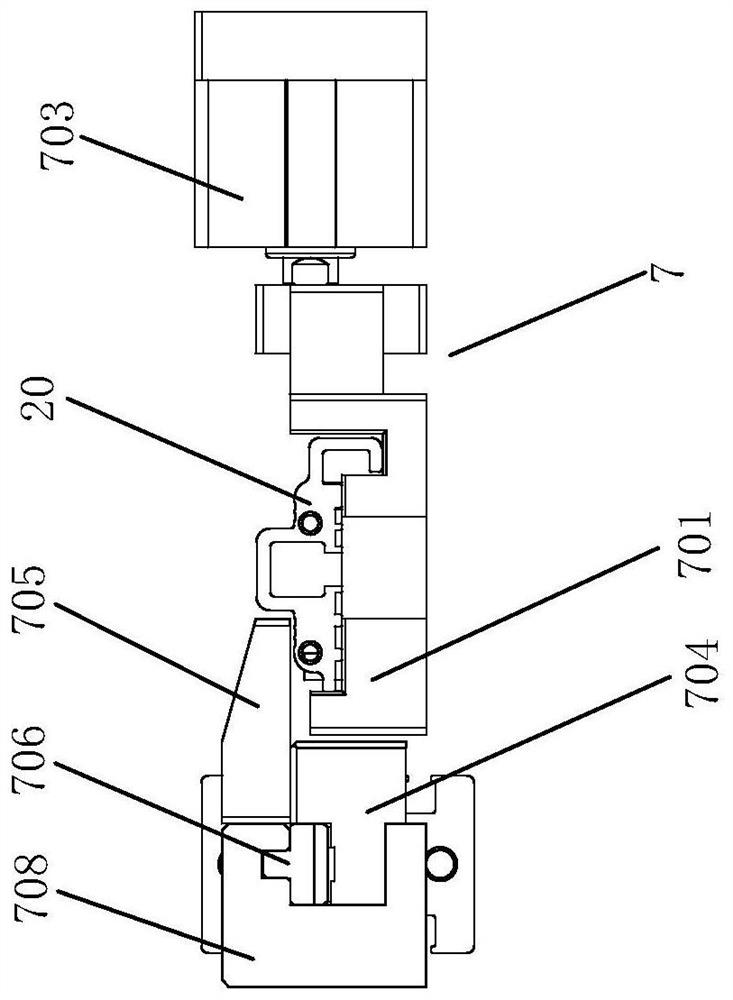

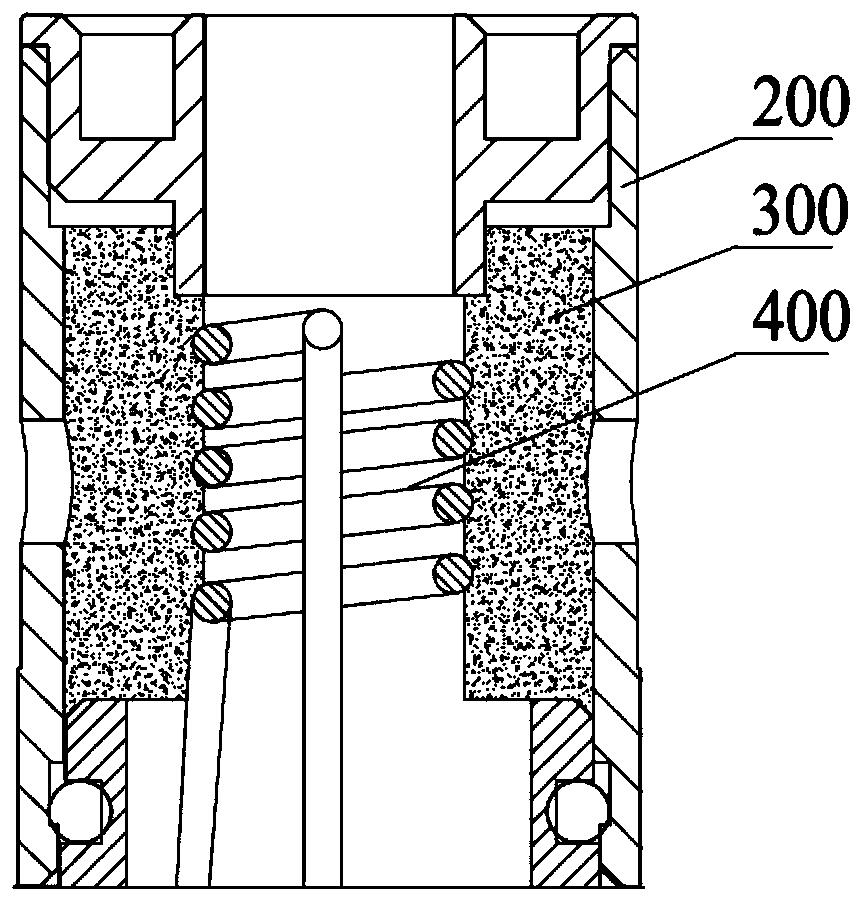

The invention discloses a rotating disc type automatic processing machine, and belongs to the technical field of machining equipment. The machine comprises a rack I (14), a rotating disc I (15) and a rotating disc II (16) are arranged above the rack I (14), and clamps I (7) are arranged on the rotating disc I (15) and the rotating disc II (16); a pressing and cutting mechanism (1), a longitudinal drilling mechanism (2), a chamfering mechanism (3), a longitudinal tapping mechanism (4), a polishing mechanism I (5) and a transferring mechanism (8) are arranged outside the rotating disc I (15), a feeding mechanism (6) is arranged on one side of the pressing and cutting mechanism (1), and a transverse drilling mechanism (9), a transverse tapping mechanism (10), a polishing mechanism II (11), a punching mechanism (12) and a discharging mechanism (13) are arranged outside the rotating disc II (16). According to the machine, the machining procedures of drilling, chamfering, tapping, polishing, deburring and the like of profiles can be fully automatically completed, and the production efficiency can be effectively improved.

Owner:浙江盛业科技有限公司

Atomization core oil guide body assembling method, special tool and atomization core structure thereof

ActiveCN111096495AUniform distribution of poresNeat and consistent crimping gapTobaccoFiberMechanical engineering

The invention discloses an atomization core oil guide body assembling method, a special tool and an atomization core structure, which are suitable for a fiber oil guide material, and comprise the following steps of: pressing and cutting the fiber oil guide material to prepare a strip-shaped oil guide body; wrapping an atomization core heating body with the strip-shaped oil guide body, and rollinginto a cylinder shape;inserting the cylindrical oil guide body covering the heating body into a first tool; performing abutting joint on the first tool with the cylindrical oil guide body with the atomization core shell; ejecting the cylindrical oil guide body wrapping the heating body by a second tool , and separating the cylindrical oil guide body from the first tool and entering the atomization core shell. According to the oil guide body assembled through the method, due to the fact that the oil guide body is not manually processed any more in the middle process, the uniformity and consistency of the oil guide body can be guaranteed.

Owner:INNOKIN TECH

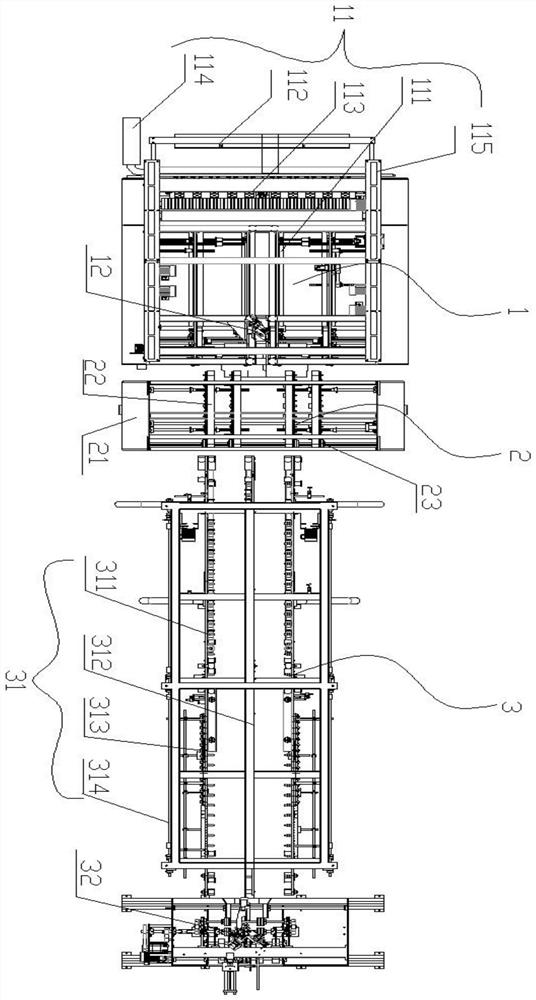

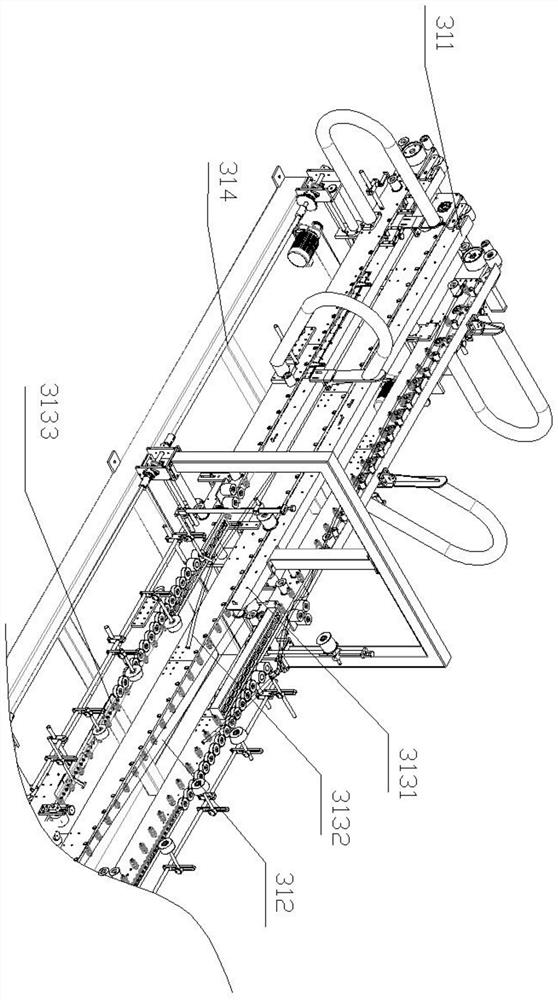

A double-piece high-speed automatic nail box machine

ActiveCN112192900BReduce investmentRealize automatic processing and productionBox making operationsPaper-makingCartonFront edge

The invention discloses a double-piece high-speed automatic nail box machine, which comprises a paper feeding splicing and nailing mechanism and a folding nailing mechanism; the paper feeding splicing and nailing mechanism comprises a paper feeding device and a first swing nailing device, It is arranged at the front end of the first swinging nailing device; the paper feeding device is provided with two left and right independent transmission front edge belts; the folding and nailing mechanism includes a conveying folding device and a second swinging nailing device; The two pieces of carton board after being nailed by the swing nailing device are bent along the bending line of the carton board and placed on the threading pad. The second swinging nailing device is arranged at the end of the transmission chain, and the threading pad extends to the second swinging pad. Nail device. The invention utilizes the paper feeding, splicing and nailing mechanism to combine the two carton boards and bind them for the first time, and then uses the folding and nailing mechanism to fold the bound two carton boards and perform the second binding to complete the carton box. Automated DingTalk has strong versatility and high degree of automation.

Owner:河北守仁纸箱设备制造有限公司

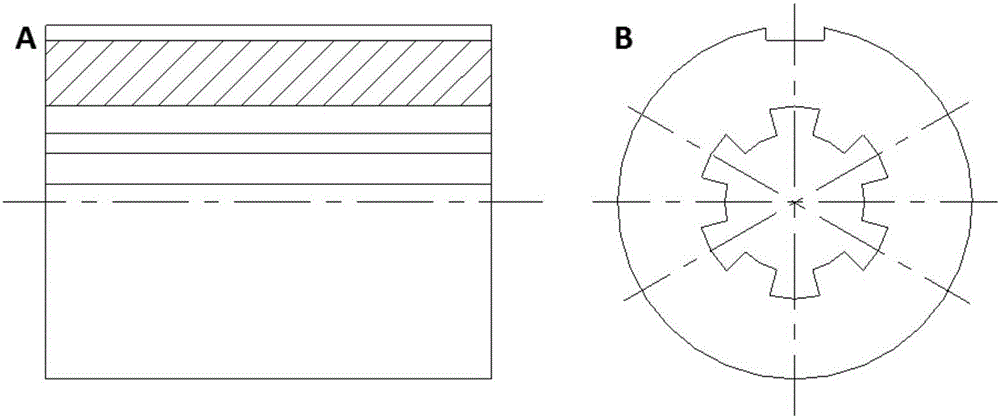

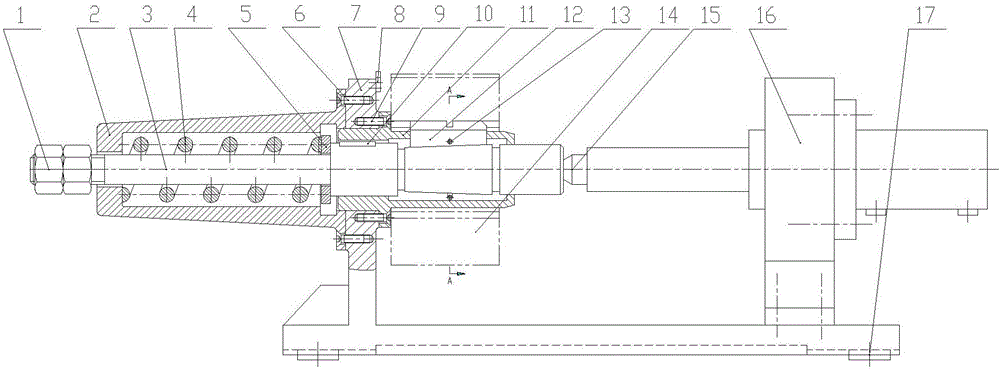

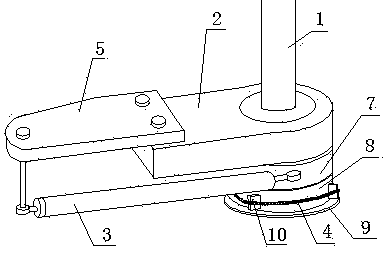

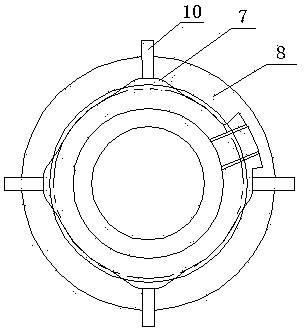

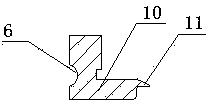

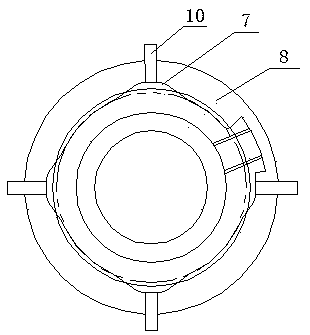

Expansion type centered clamping and milling device

InactiveCN106736780ANovel structureLow costPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses an expansion type centered clamping and milling device, and belongs to the technical field of machines. The expansion type centered clamping and milling device comprises a locking nut, a spring box, a mandrel, a reset spring, a spring seat plate, a clamp body, a bearing sleeve, a positioning supporting plate, a steel wire and a pneumatic assembly; the mandrel penetrates the spring box; the reset spring is mounted in the spring box, the end, pointing to the pneumatic assembly, of the reset spring is connected with the spring seat plate, the clamp body is located between the spring box and the pneumatic assembly, the bearing sleeve is mounted on the clamp body, and guide grooves which are evenly formed in the radial direction are formed in the bearing sleeve, and the positioning supporting plate is mounted in the guide grooves of the bearing sleeve; the steel wire penetrates a mounting hole in the positioning supporting plate, and the bottom circular-arc slope of the positioning supporting plate makes contact with the conical face of the mandrel. Involute spline holes are adopted in the milling device for positioning, the structure is novel and simple, cost is low, centered clamping can be achieved, and the efficiency is high; and work is reliable, and automatic upgrading and reconstruction are facilitated.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

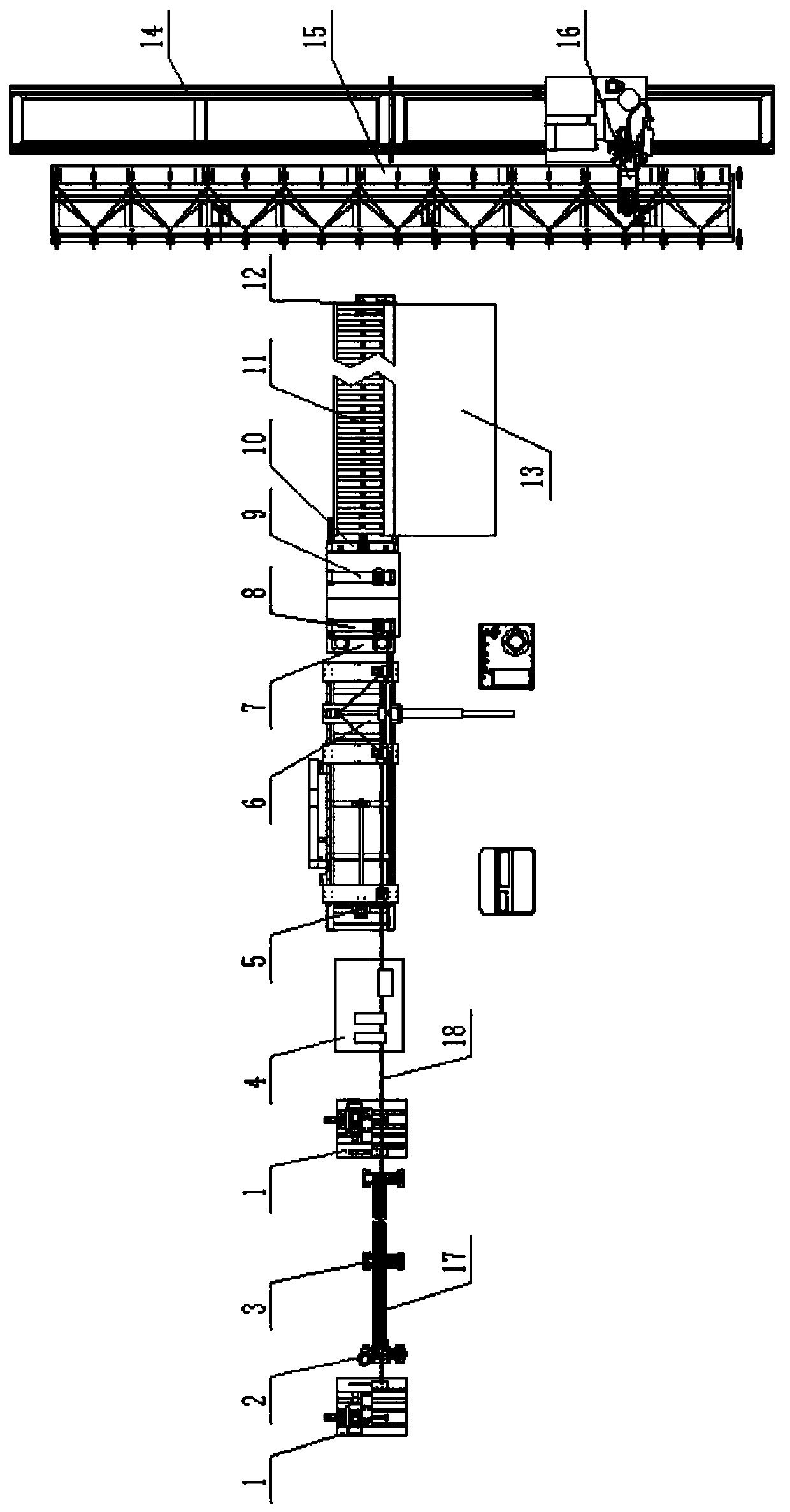

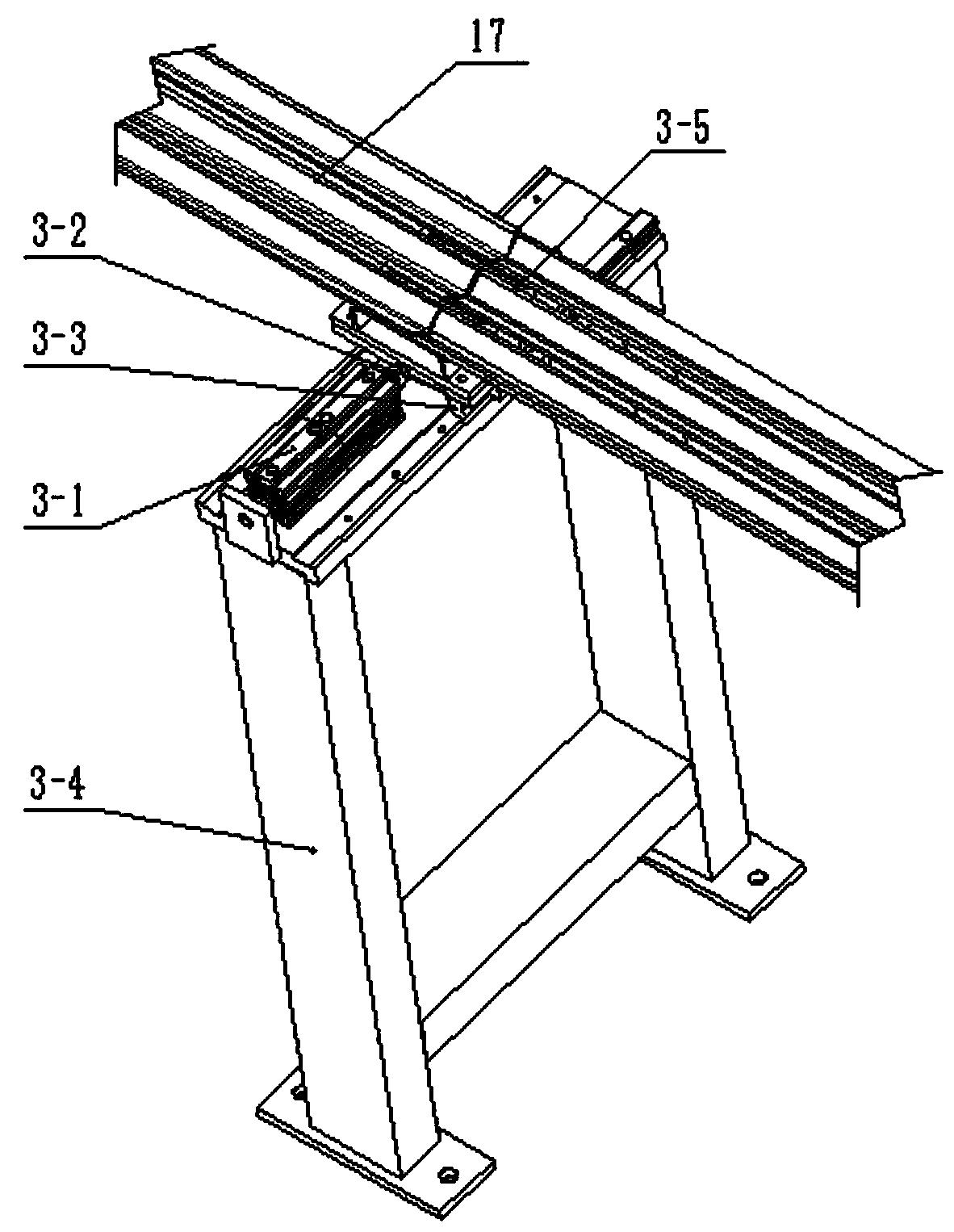

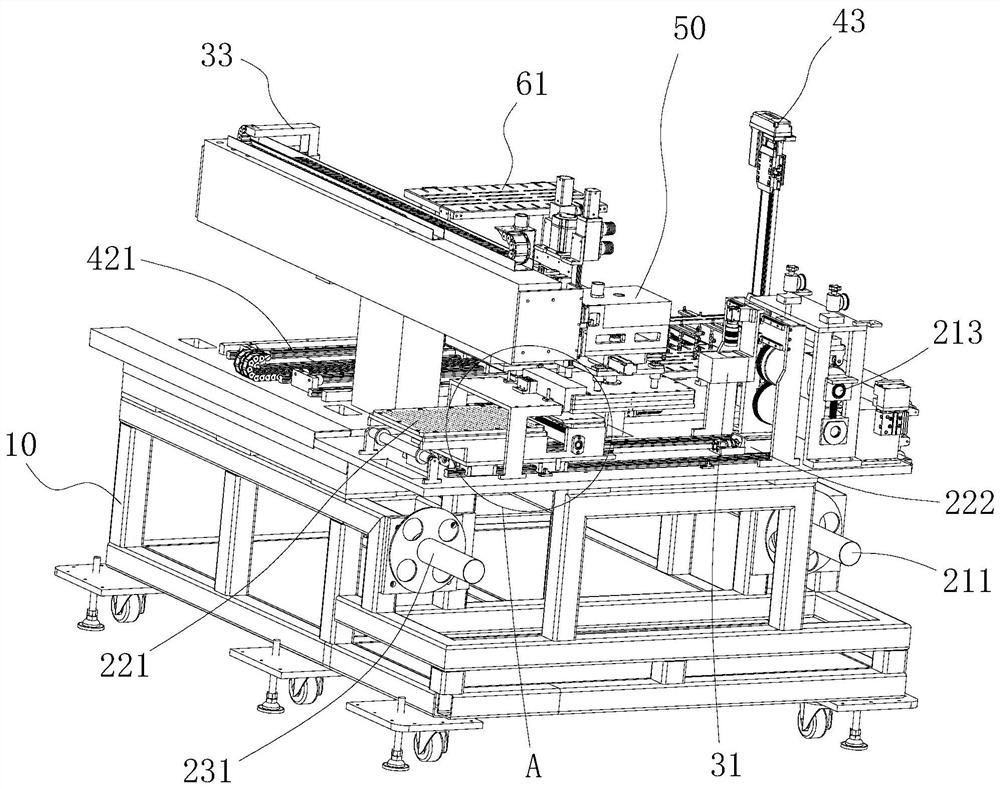

Automatic production system of steel bar welding and production method

PendingCN111266498ARealize automatic processing and productionMeet increasingly diverse needsWire networkButt weldingRebar

The invention discloses an automatic production system of steel bar welding and a production method. The system involves steel bar double-end milling devices, a steel bar butt welding machine, a feeding and bending integrated device, a hoop bending device, a transferring device and an automatic welding device which are sequentially arranged. According to the system and the method, the steel bar machining process is divided into five procedures of steel bar aligning, bending, end hoop bending, turning-over and welding, and automatic machining and production of steel bars from raw material to steel bar cages are achieved; and through the system and method, the increasingly diversified requirements of existing steel bar cages can be met, the manual operation is replaced, the production efficiency is improved, the machining period is shortened, and meanwhile, the production quality of products is ensured.

Owner:济南纽兰数控机械有限公司

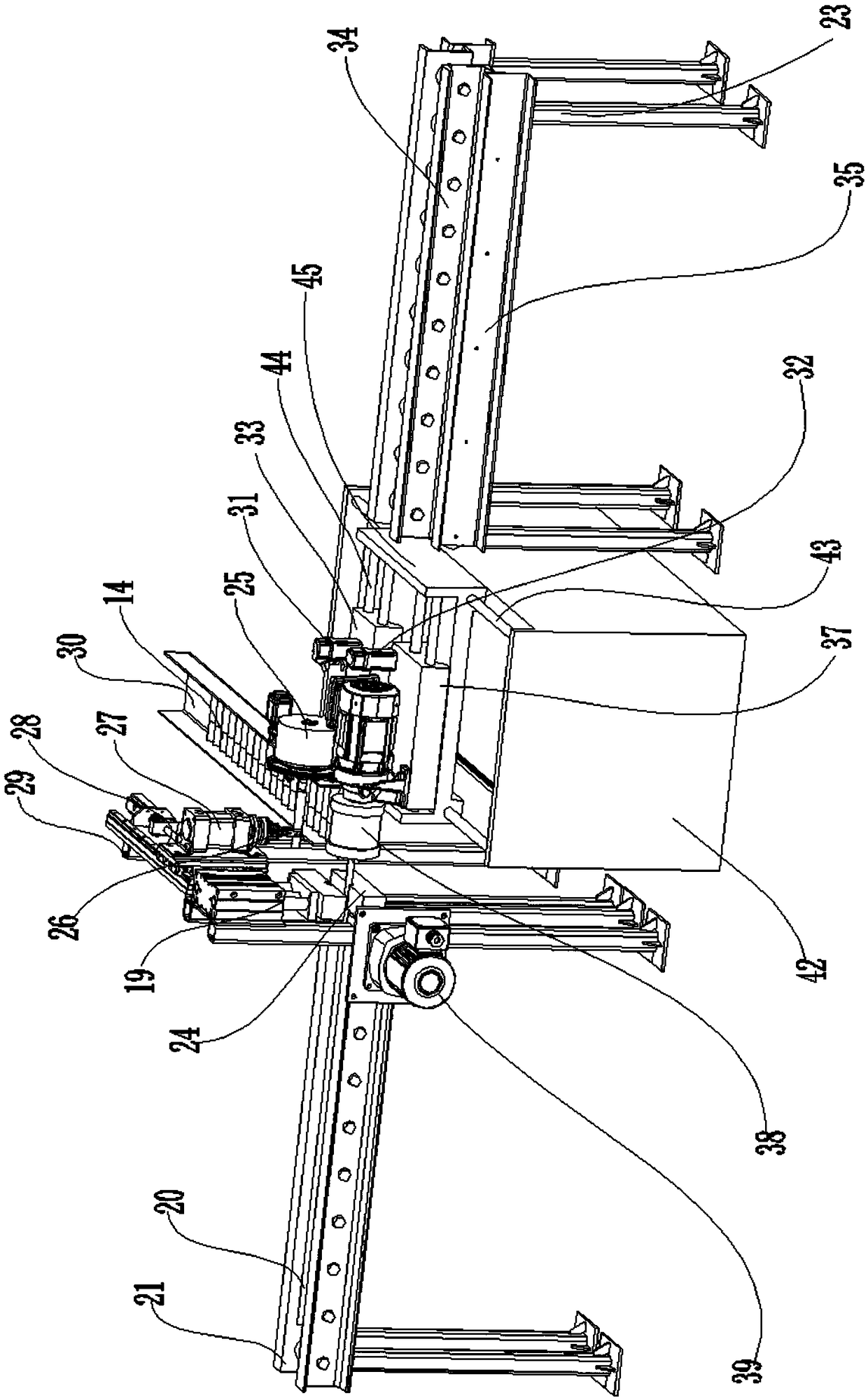

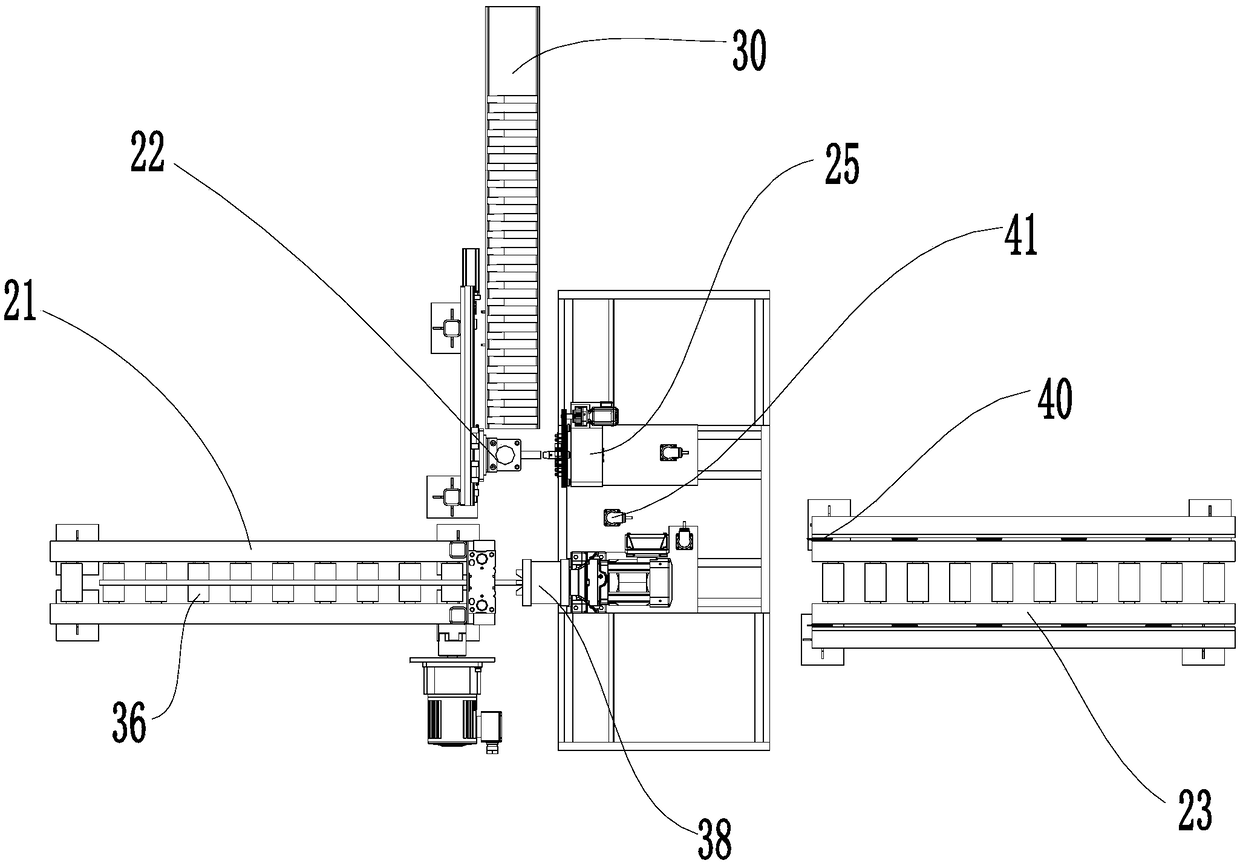

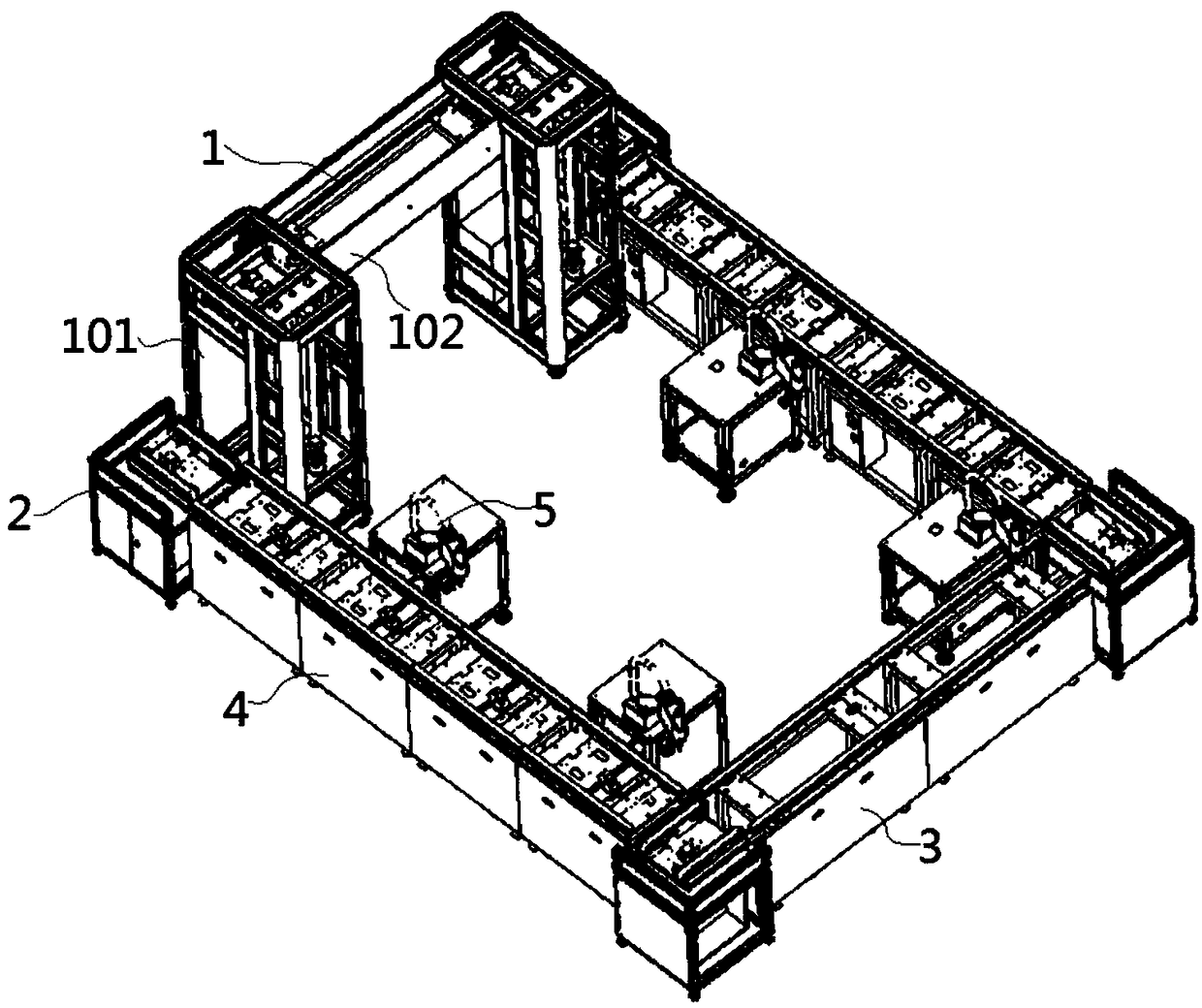

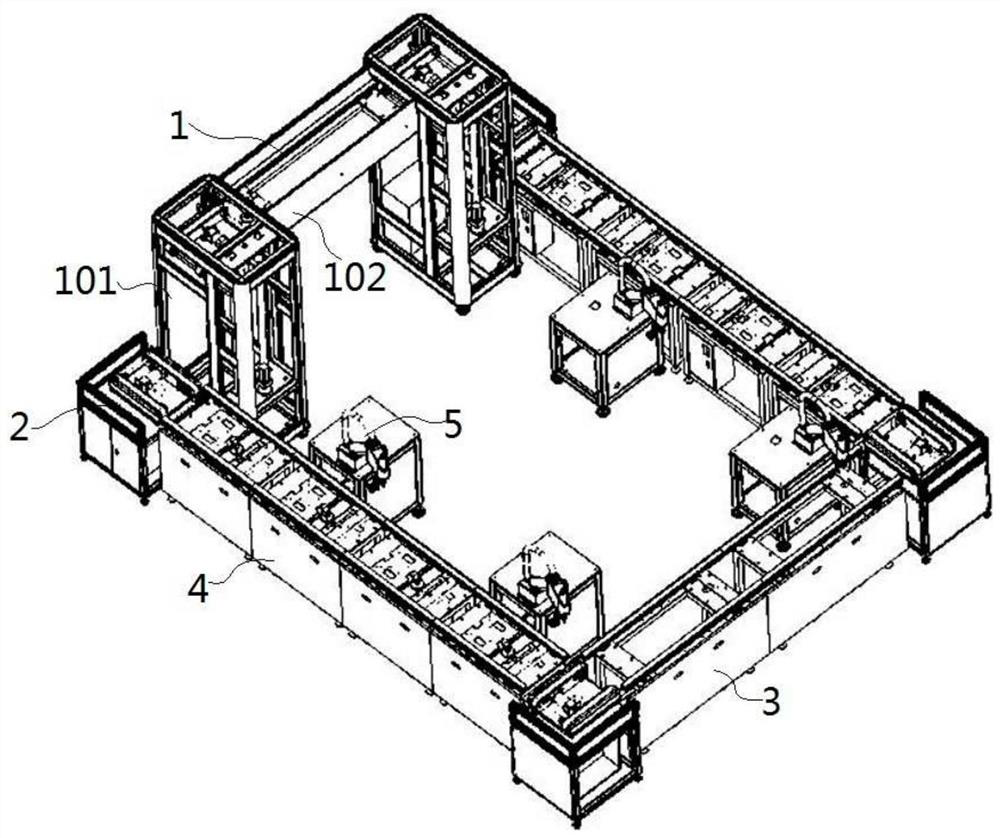

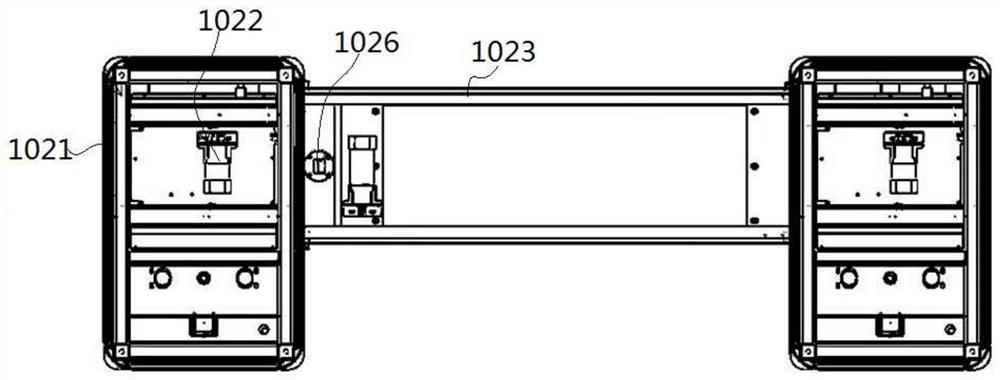

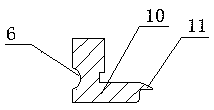

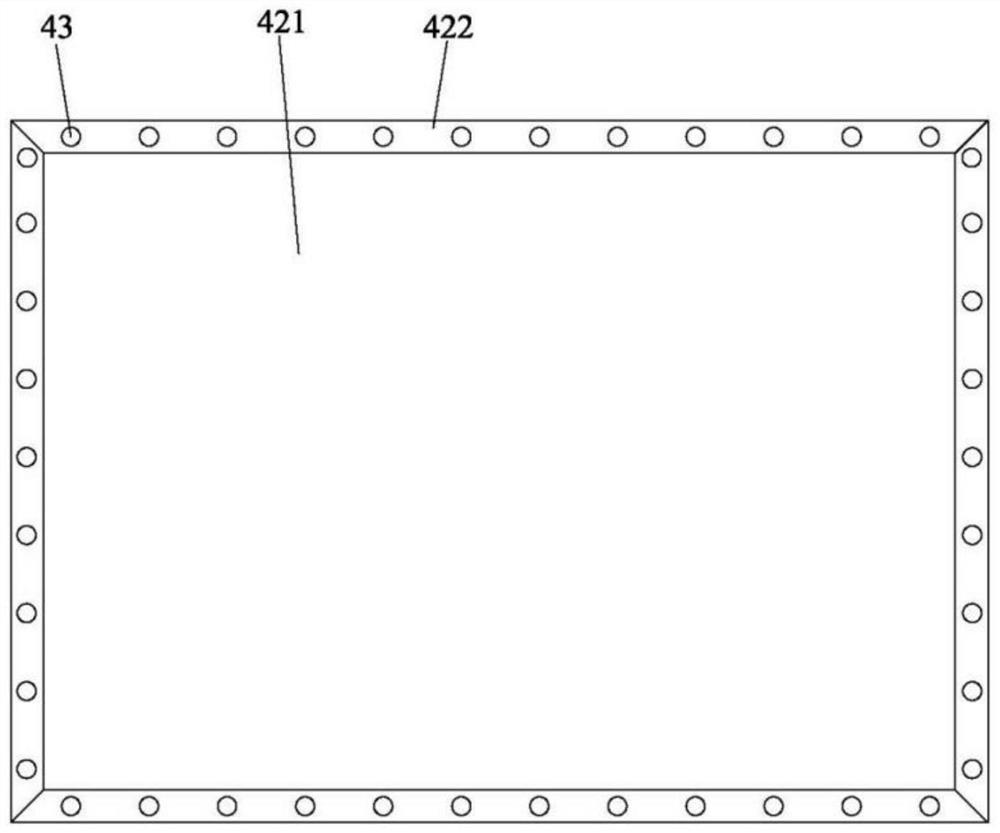

Flexible automatic production line

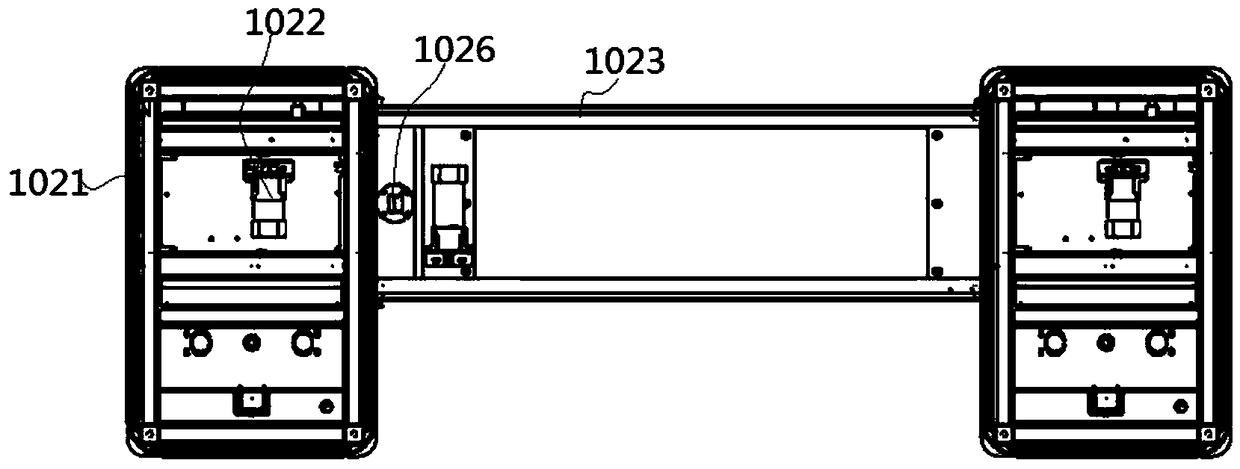

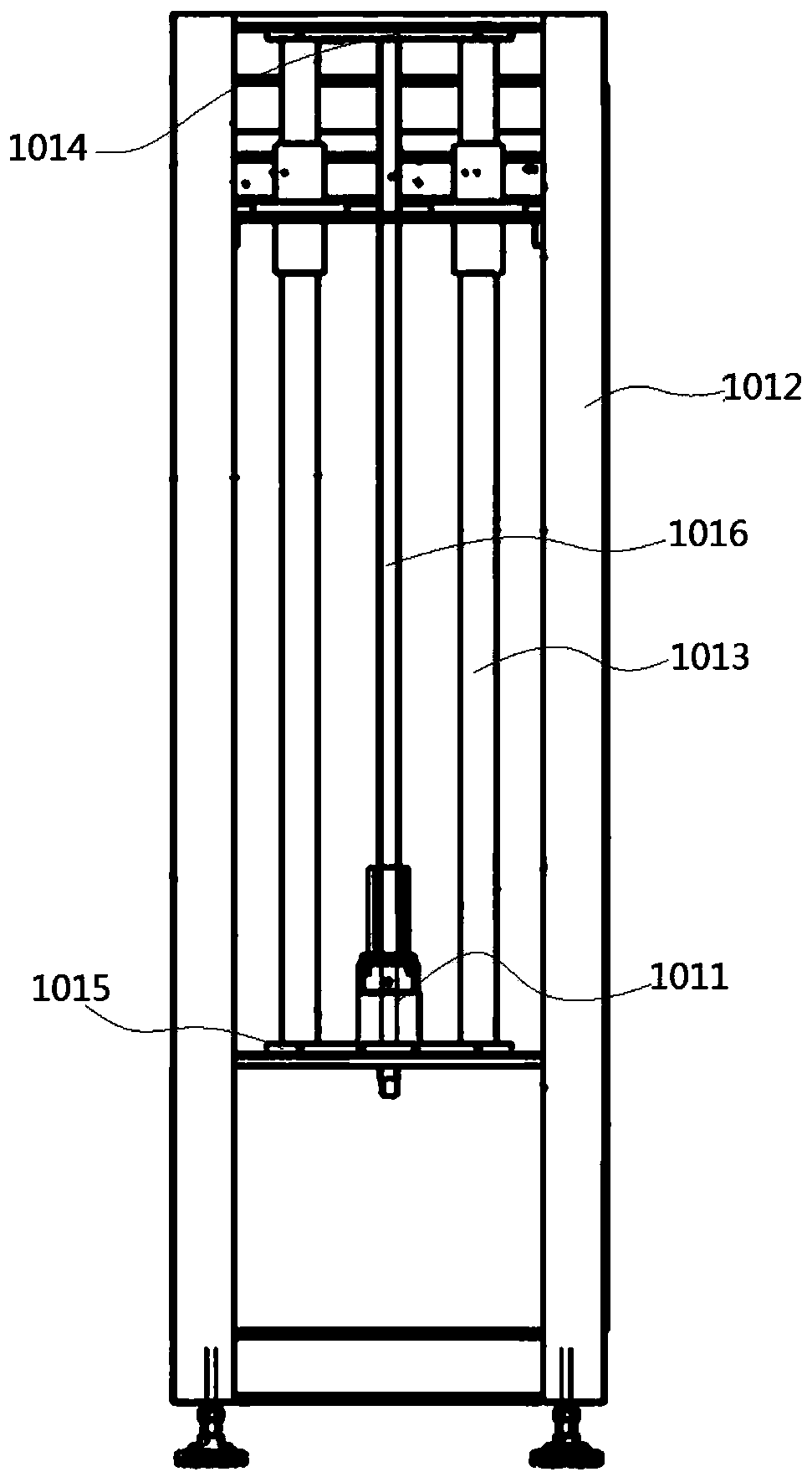

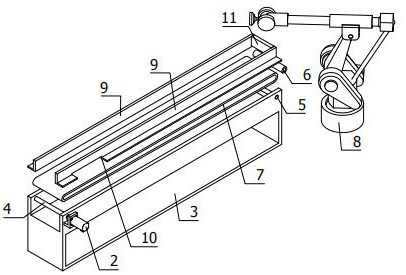

ActiveCN108861410AImprove flexibilityRealize automatic processing and productionConveyor partsMechanical conveyorsProduction lineComputer module

The invention discloses a flexible automatic production line, which comprises a lifting mechanism, corner modules, long line modules, short line modules and manipulator modules. Any two of the liftingmechanism, the corner modules, the long line modules, the short line modules and the manipulator modules are in end-to-end connection. Each long line module and the adjacent long line module are available for extension splicing, each short line module and the adjacent short line module are available for extension splicing, and each manipulator module is arranged on one side of the corresponding short line module. The flexible automatic production line is high in flexibility, demands of different processing places can be met, efficient and quick transmission at any positions can be realized, and automatic processing and production of materials can be realized by the aid of manipulators, so that production efficiency is greatly improved, production cost is reduced, and reliability is improved.

Owner:SHENZHEN SONGJIAN ROBOT CO LTD

Wood board machining planing tool device in building field

InactiveCN112873427AHigh precisionReduce investmentWood feeding arangementsArchitectural engineeringStructural engineering

The invention relates to the field of building board machining, in particular to a wood board machining planing tool device in the building field. The device comprises a working frame, a feeding mechanism, a driving mechanism, a stabilizing component, a rotary leveling mechanism, a planing component and a discharging mechanism, wherein the driving mechanism is arranged beside the working frame; the output direction of the feeding mechanism is perpendicular to the output direction of the driving mechanism; the output direction of the rotary leveling mechanism is perpendicular to the output direction of the stabilizing component; the planing component comprises a slicing mechanism, a pushing mechanism and a translation mechanism; through operation of the pushing mechanism and the slicing mechanism, adjustment can be conducted according to the thickness of a board and the slicing size of the board; the device is suitable for wood of different sizes, the operation efficiency and batch production are improved, automatic machining production is achieved through cooperative operation of the feeding mechanism, the driving mechanism and the discharging mechanism, and the labor input of a factory is reduced; and the slicing direction of the slicing mechanism is controlled through the translation mechanism, and the board slicing precision is improved.

Owner:冯祥

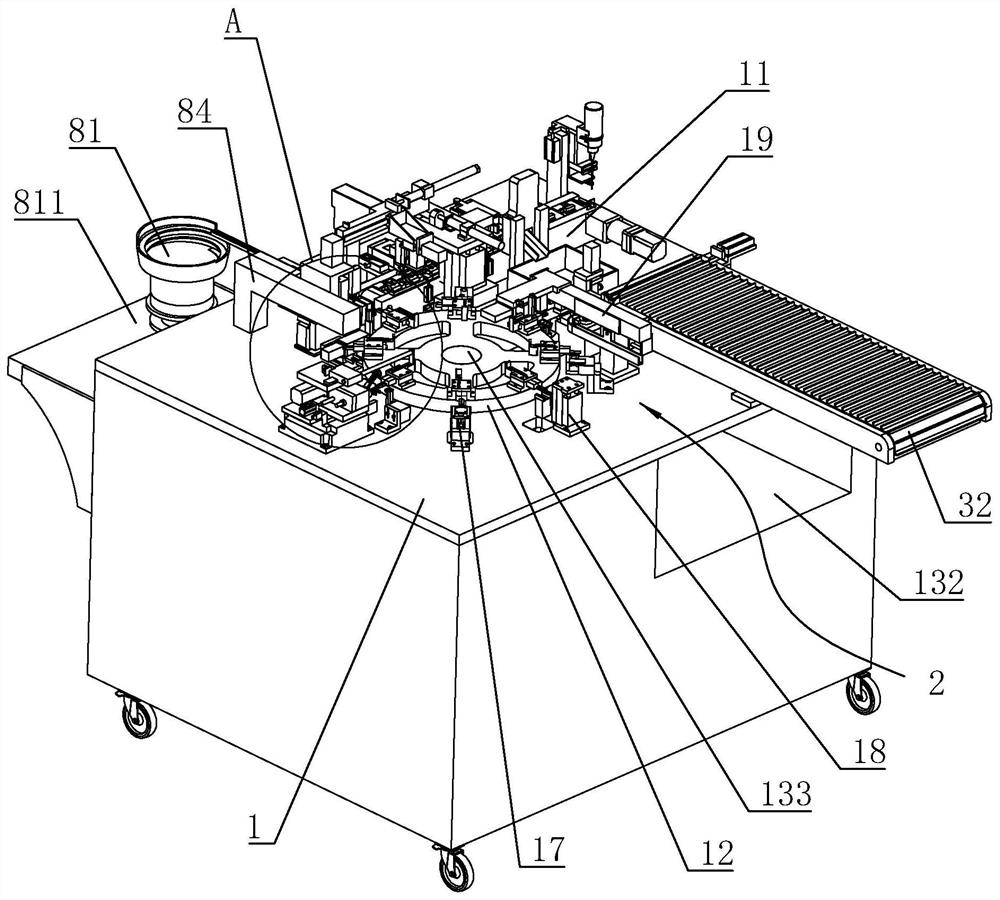

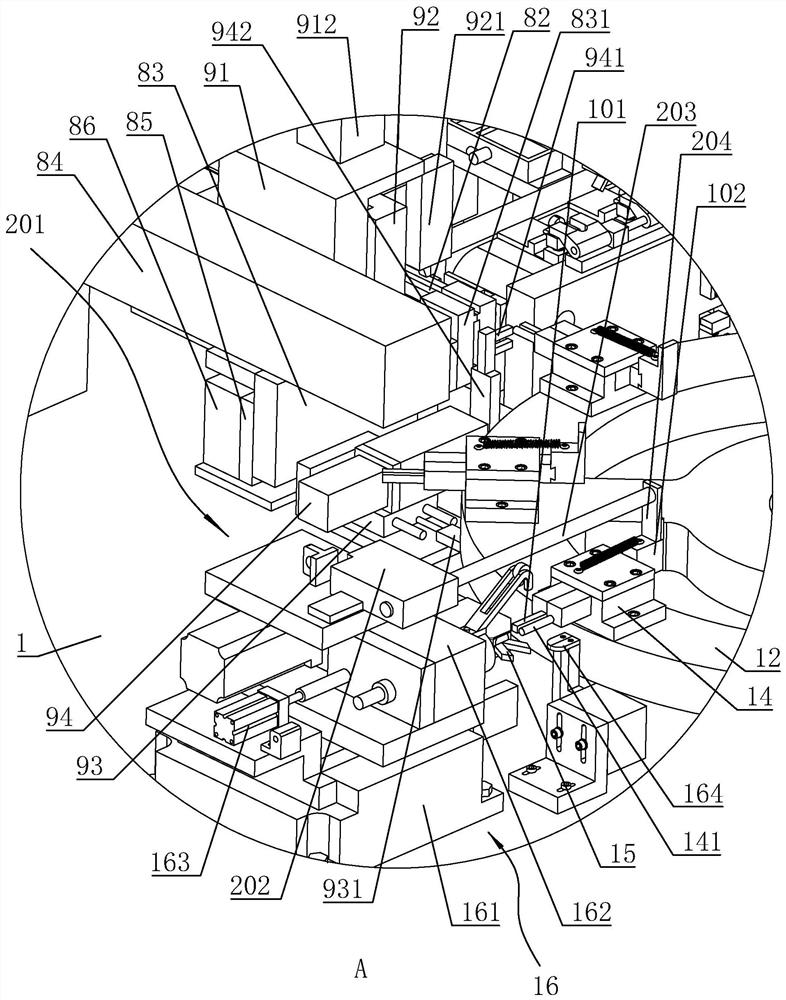

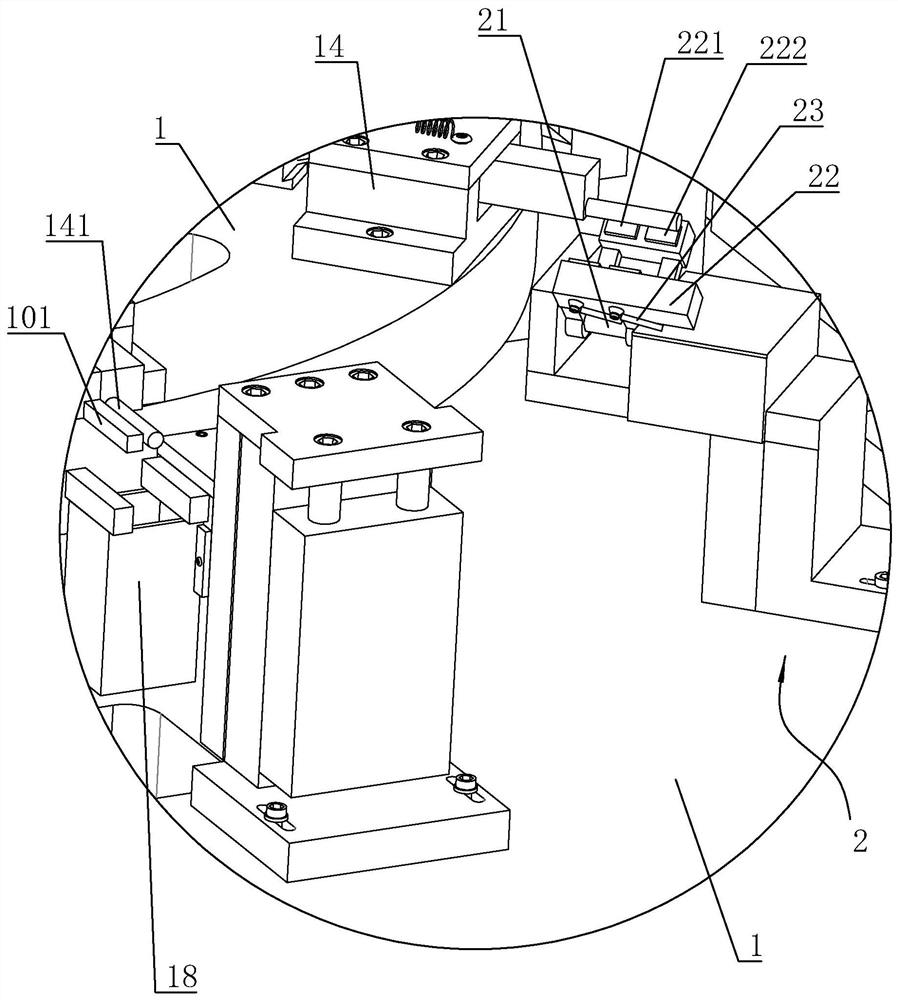

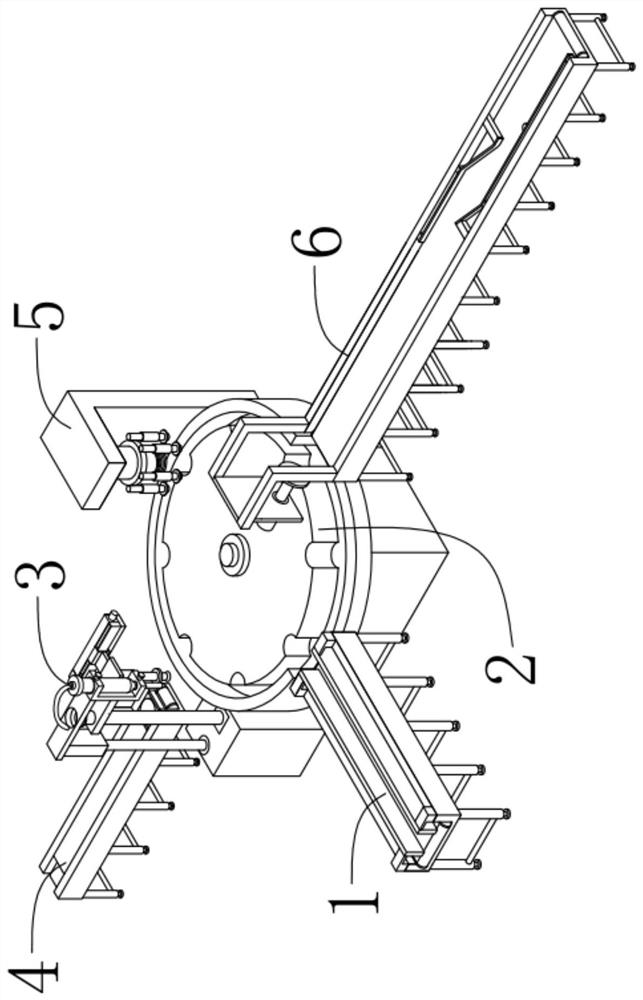

Biological medicine preparation system

The invention discloses a biological medicine preparation system which comprises a feeding mechanism, a rotary feeding mechanism, a liquid injection mechanism, a bottle cap feeding mechanism, a cap screwing mechanism and a discharging mechanism. The feeding mechanism is used for automatic feeding of liquid injection bottles, and the rotary feeding mechanism is used for feeding of the liquid injection bottles and sequentially feeding the liquid injection bottles to a liquid injection station, a cap feeding station, a cap screwing station and a discharging station, and the liquid injection mechanism is used for completing automatic filling of the liquid injection bottles. A first special-shaped guide rod (609) and a second special-shaped guide rod (611) are both arranged on the top of a second longitudinal automatic conveying belt (602) and do not make contact with the second longitudinal automatic conveying belt (602). According to the biological medicine preparation system, automatic medicine processing production can be achieved, namely, automatic medicine bottle feeding, automatic medicine bottle filling, automatic medicine bottle cap feeding and cap screwing and automatic medicine bottle feeding can be achieved, the medicine production efficiency is greatly improved, and the manual labor force is greatly reduced.

Owner:徐文霞

Automatic rivet installation placement device for silence retainers

The invention provides an automatic rivet installation placement device for silence retainers. The automatic rivet installation placement device for silence retainers comprises a guide pipe, an external member, an air cylinder, a placement assembly and a tension spring for reset of the placement assembly. The piston end of the air cylinder is connected with the placement assembly. A base of the air cylinder is movably connected with a deflecting plate. The deflecting plate is fixed to the external member. The external member is provided with a through hole allowing the guide pipe to pass through. The placement assembly is arranged below the external member and comprises a plurality of stop pins, a cam for controlling the stop pins to stretch and retract, a disc and a base plate. The disc is provided with wall holes allowing the stop pins to pass through. The cam is movably connected with a piston rod of the air cylinder. An inner hole allowing silence retainers to pass through is formed in the cam. The stop pins are arranged outside the cam. Conical teeth for separating silence retainers are arranged at the ends of the stop pins. The automatic rivet installation placement device for silence retainers can automatically place silence retainers one by one, and is convenient to use.

Owner:江苏盐新汽车产业投资发展有限公司

Molecular sieve particle spray processing equipment

InactiveCN108940665ASimple structureEasy to operateSpraying apparatusPretreated surfacesMolecular sieveTemperature measurement

The invention discloses molecular sieve particle spray processing equipment. The molecular sieve particle spray processing equipment comprises a motor, a rotary disc, a heater, a temperature measurement head, a sprinkling head, a stirrer and a controller, wherein the motor drives the rotary disc and the stirrer to rotate; the stirrer, the heater, the temperature measurement head and the sprinklinghead are mounted above the rotary disc; the motor, the heater, the temperature measurement head, the sprinkling head and the stirrer are connected with the controller; and the controller controls theheater to heat raw materials on the rotary disc according to the temperature measured by the temperature measurement head, and further controls the sprinkling head to perform sprinkling on the raw materials on the rotary disc and controls the motor to drive the stirrer to stir the raw materials on the rotary disc. The molecular sieve particle spray processing equipment is simple in structure, quite convenient to operate, capable of achieving more uniform spraying, excellent effect and automatic processing production, and high in production efficiency.

Owner:XIAMEN BANGZHONG TECH

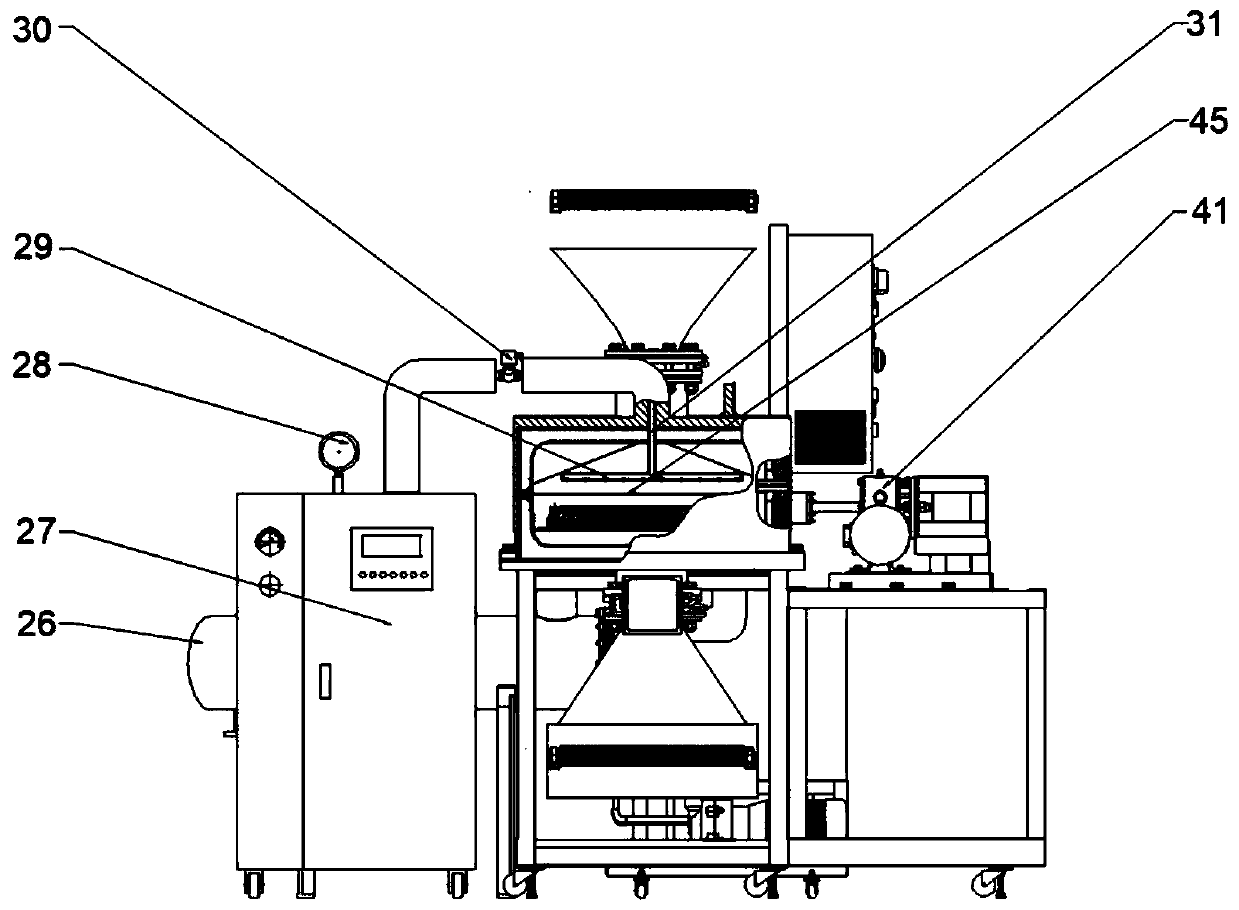

Full-automatic conveying-belt-type vacuum steam blanching equipment

PendingCN110338213AReduce heating rateImprove work efficiencyFood processingFruits/vegetable preservation by heatingAutomatic controlSemi automatic

The invention discloses full-automatic conveying-belt-type vacuum steam blanching equipment and belongs to the technical field of agricultural product processing. An automatic control system controlsa steam generation system, a vacuum system, a drainage system and a material conveying device, steam is adopted for continuously blanching materials, and the equipment is simple in structure and reasonable in design and can be conveniently integrated with a processing production line; a waste heat recoverer is adopted for conducting waste heat recovery on the steam obtained after material blanching before the steam is pumped to a water ring vacuum pump, the waste heat is used for heating water introduced into the steam generation system, and the processing energy consumption is obviously lowered; in addition, the temperature increase speed of the water ring vacuum pump is lowered, and the working efficiency of the water ring vacuum pump is guaranteed. The problems are solved that existingvacuum pulse blanching equipment is in semi-automatic manual intermittent operation, the industrial continuous production demand cannot be met, the processing energy consumption is large, the production efficiency is low, and secondary pollution is easily caused.

Owner:SHAANXI UNIV OF SCI & TECH

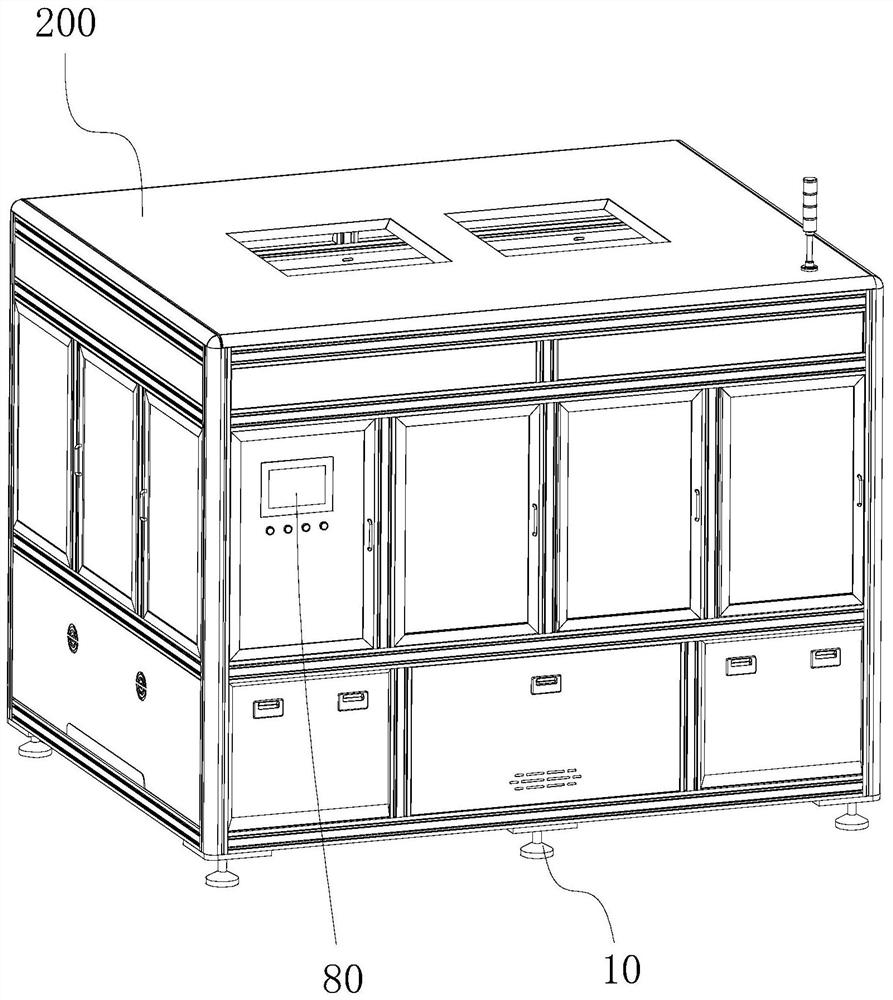

Film sticking machine

PendingCN112040648ARealize automatic processing and productionReduce labor costsPrinted circuit manufactureRolling paperCopper foil

The invention belongs to the technical field of circuit board production equipment, and particularly relates to a film sticking machine. The film sticking machine comprises a rack, a material roll output mechanism, a first feeding mechanism, a roll paper winding mechanism, a second feeding mechanism, a film sticking mechanism and a discharging base, wherein a material roll is discharged and conveyed to a containing base through the material roll output mechanism, the first feeding mechanism and the roll paper winding mechanism; a circuit board is placed in a circuit board storage base and conveyed to a middle platform through a conveying structure; then a copper foil film material is adsorbed through the film sticking mechanism and conveyed to the middle platform for to film sticking operation; a product is obtained after film sticking operation is completed, and finally, the product is conveyed to the discharging base for storage through the conveying structure; and the whole machining process of feeding, film sticking and product discharging is cyclically repeated in the same manner to realize continuous processing and production. By applying the technical scheme, the problems ofdependence on manual participation and low production efficiency in the process of mounting copper foil film materials on circuit boards in the prior art are solved.

Owner:深圳市火焱激光设备有限公司

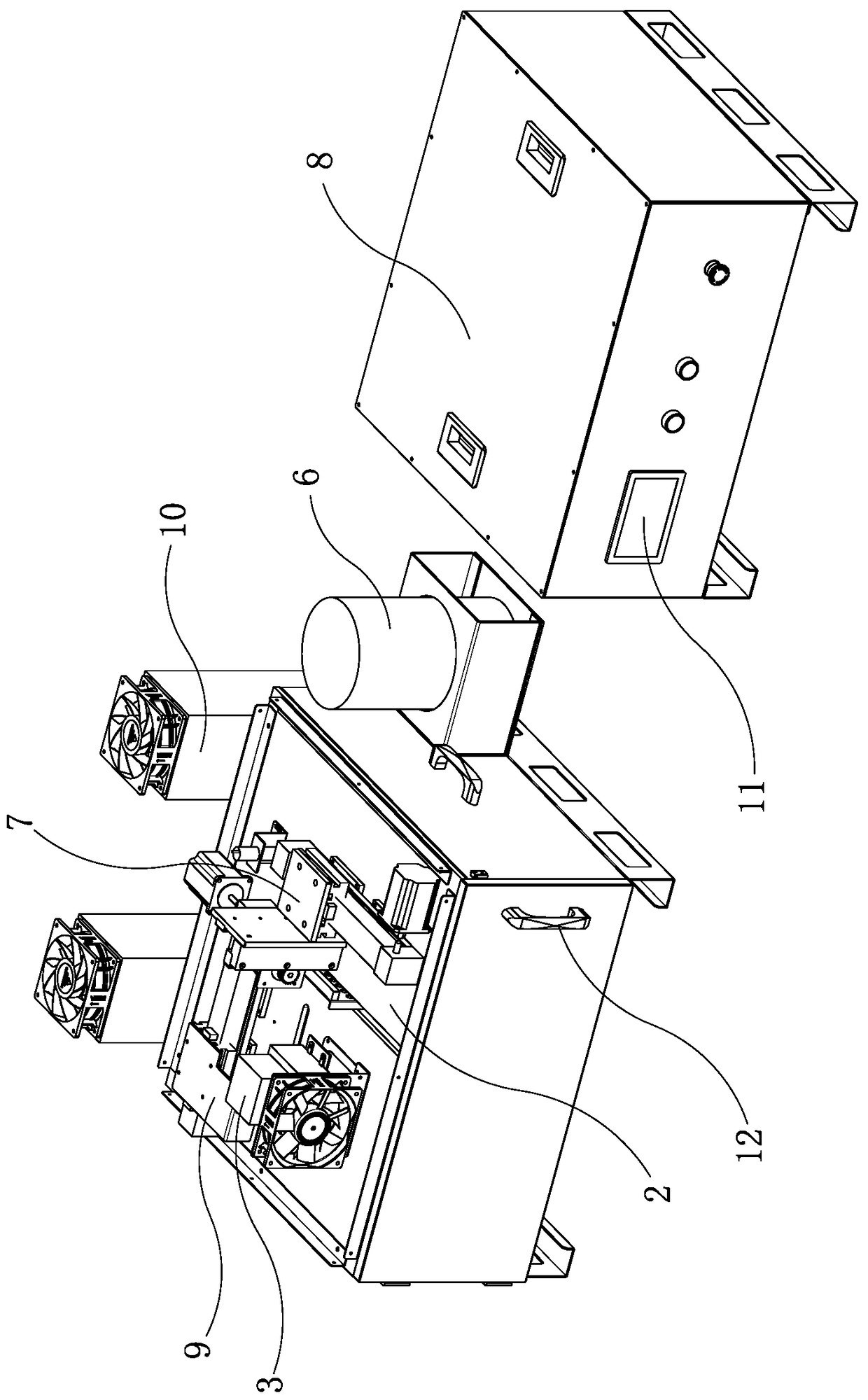

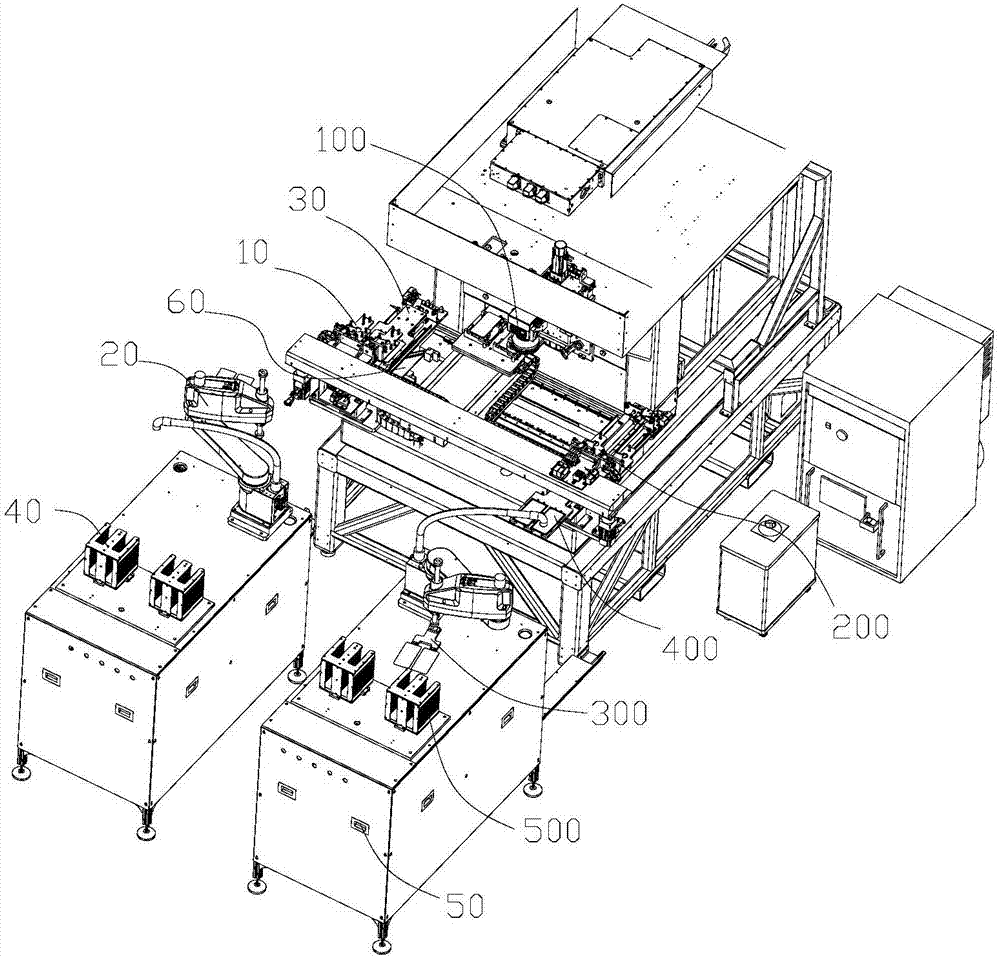

Laser processing system

PendingCN107953039AEasy maintenanceImprove stabilityWelding/soldering/cutting articlesLaser beam welding apparatusLaser processingProcess engineering

The invention provides a laser processing system, which comprises a laser processing unit, a blank transporting unit and a finished product transporting unit; the blank transporting unit is used for transporting a blank to a to-be-processed position of the laser processing unit, and the laser processing unit is used for processing the blank located at the to-be-processed position to form a finished product; the finished product transporting unit is used for taking away the finished product at the to-be-processed position. The laser processing system integrates the features of easy maintenance,high stability, high integration, flexible exchange, high precision of loading and unloading, and high exchanging efficiency of automatic loading and unloading mechanism inside and outside the machine; the laser processing system has the advantages of meeting a short tempo requirement of laser processing, saving floor area, saving labor cost, and promoting the product quality and production efficiency.

Owner:南京魔迪多维数码科技有限公司

Molecular sieve particle spraying processing equipment

PendingCN110394259ASpray evenlySimple structureShaking/oscillating/vibrating mixersTransportation and packagingMolecular sieveEngineering

The invention discloses molecular sieve particle spraying processing equipment. The molecular sieve particle spraying processing equipment comprises a motor, a rotating disc, a heater, a temperature measuring head, a spraying head, a stirrer and a controller, wherein the motor is in transmission tothe rotating disc and the stirrer to rotate, and the stirrer, the heater, the temperature measuring head and the spraying head are arranged above the rotating disc; the motor, the heater, the temperature measuring head, the spraying head and the stirrer are connected with the controller, and the controller controls the heater to heat raw materials on the rotating disc according to the temperature measured by the temperature measuring head; and the controller further controls the spraying head tospray the raw materials on the rotating disc and controls the motor to drive the stirrer to stir the raw materials on the rotating disc. The molecular sieve particle spraying processing equipment is simple in structure, convenient to operate, uniform in spraying and good in effect, automatic processing production is achieved, and the production efficiency is high.

Owner:XIAMEN BANGZHONG TECH

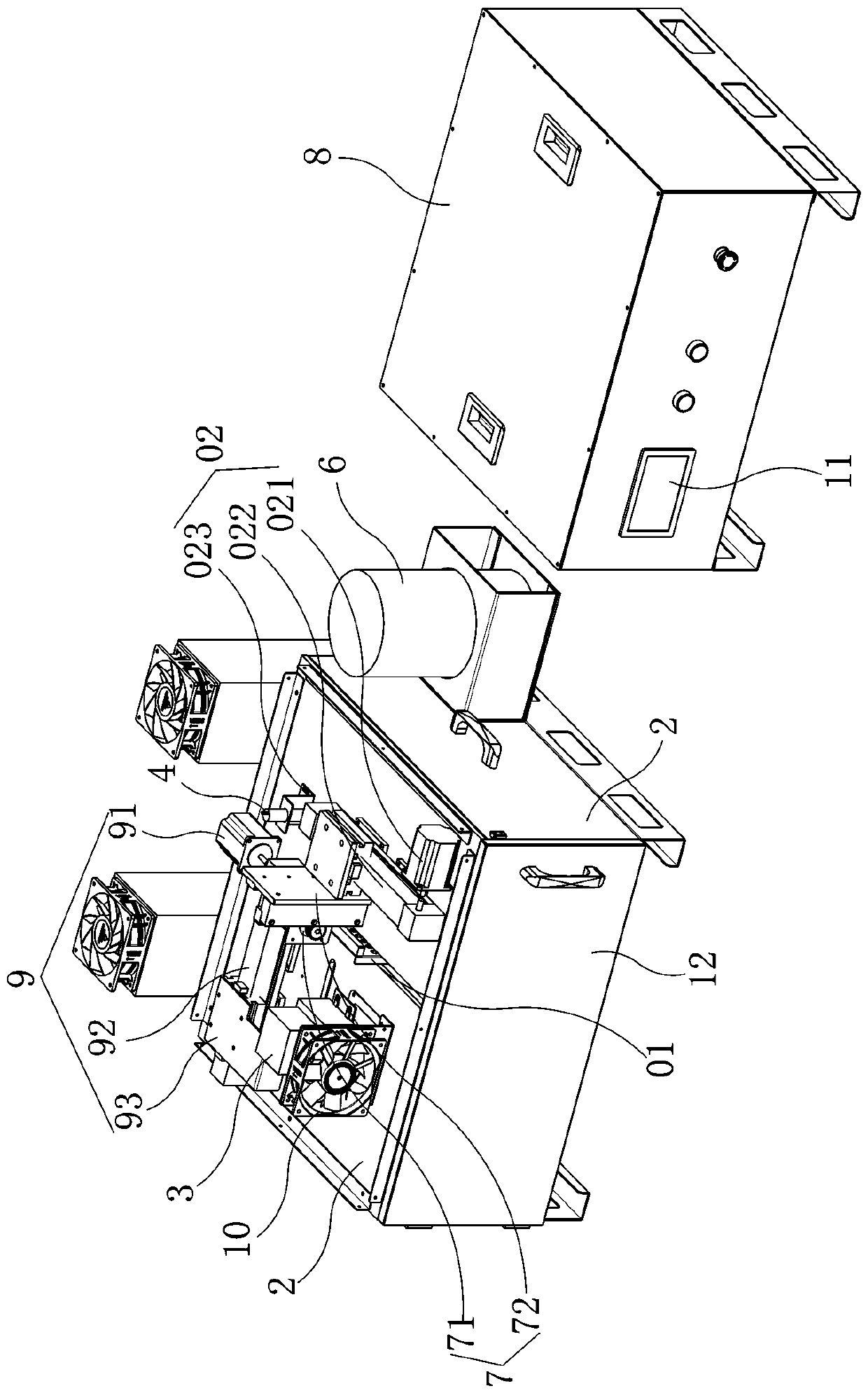

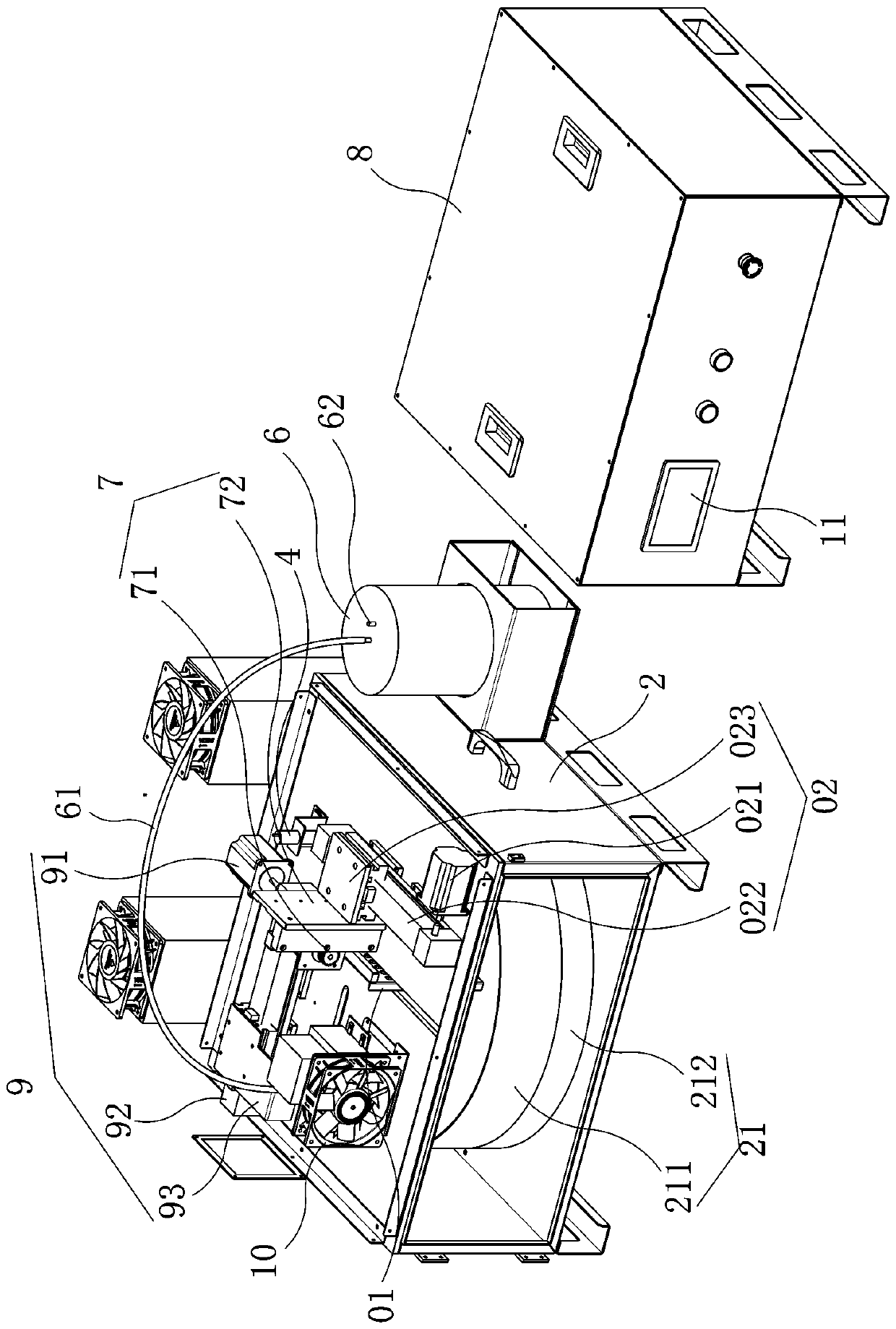

Full-automatic wire harness production equipment

ActiveCN113540931ARealize automatic processing and productionIncrease productivityLine/current collector detailsConveyor partsWire cuttingElectric machinery

The invention discloses full-automatic wire harness production equipment, which comprises a bearing cabinet, wherein a mounting plate is fixedly connected to one side of the top of the bearing cabinet, a mounting frame is fixedly connected to one side of the top of the mounting plate, a wire cutting device is mounted on the mounting frame, a material picking device is mounted on the mounting frame, a conveying device comprises a bearing plate, the bearing plate is slidably connected to the top of the mounting plate, the bearing plate is fixedly connected with a wire feeding block, a wire hole is formed in the top of one side of the wire feeding block, the wire cutting device comprises two cutting knives, the two cutting knives are symmetrically arranged, a wire pulling device comprises a linear motor, the output end of the linear motor is in transmission connection with a third air cylinder, and clamping jaws are symmetrically arranged at one end of the third air cylinder. According to the invention, a conveying device, a wire cutting device, a wire pulling device and a material picking device are matched for use, and the conveying device can move the wire harness direction, so that the wire harness can be automatically processed and produced with the wire cutting device, the wire pulling device and the material picking device, and the production efficiency is improved.

Owner:SUZHOU SHUOHUI ELECTRONICS TECH

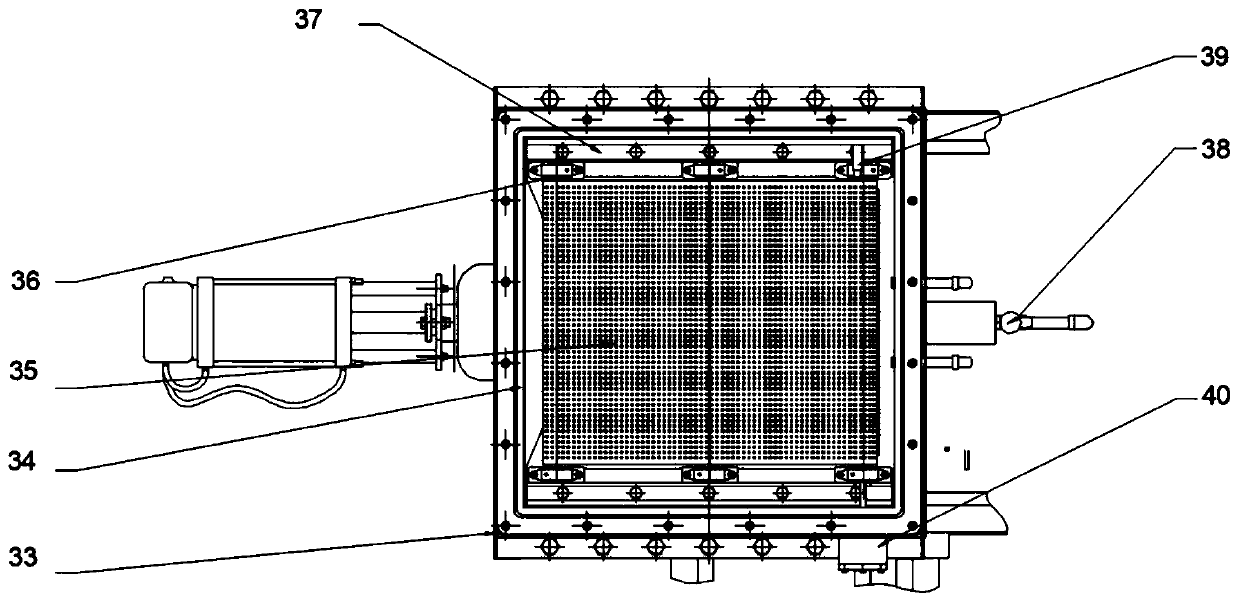

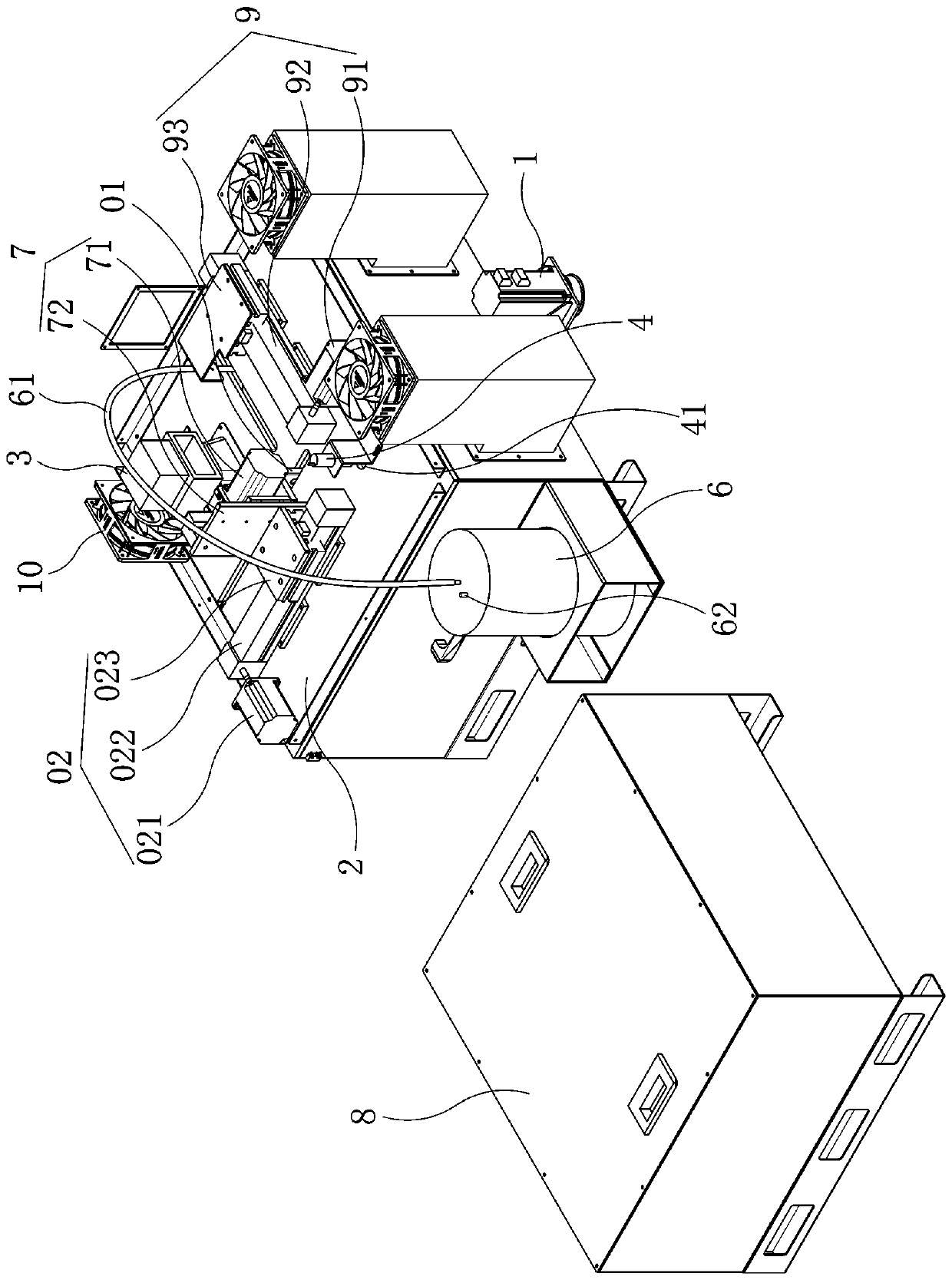

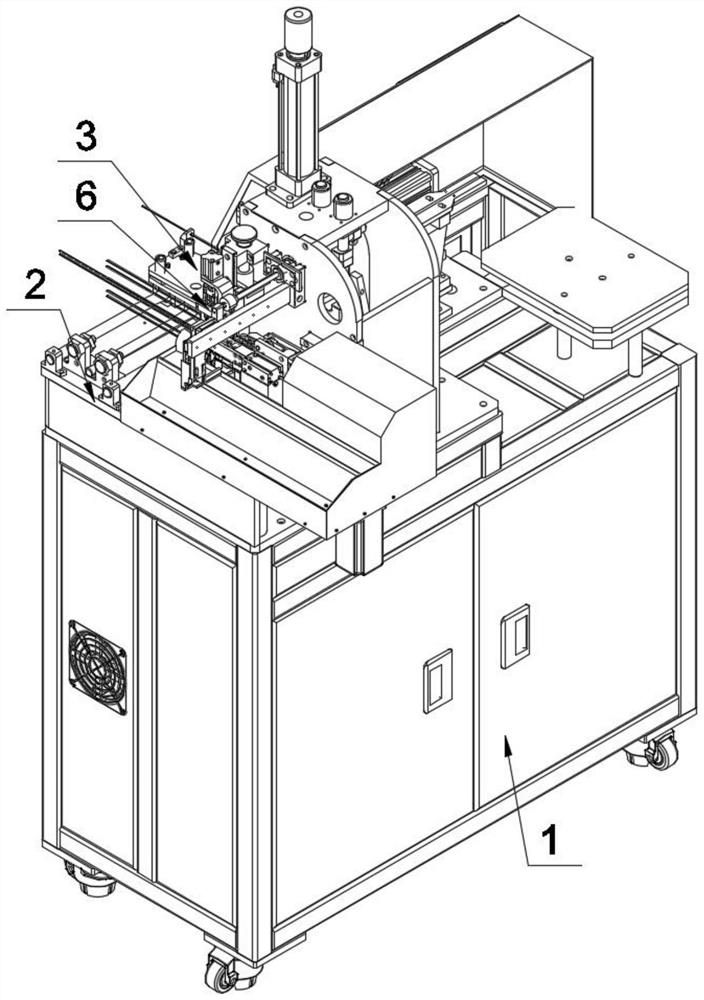

Processing equipment for magnetic rod coils

ActiveCN110517876BIncrease flexibilityIncrease productivityLine/current collector detailsCoils manufactureCapacitanceWinding machine

The invention relates to a processing equipment for magnetic rod coils, which is applied in the technical field of magnetic rod coil production. There are a number of station seats in the circumferential direction of the station disk, each station seat is equipped with a polished rod, and the workbench is equipped with the first coil pneumatic shears and winding mechanisms arranged in sequence along the rotation direction of the station disk. The second coil pneumatic shear, the third coil pneumatic shear, the electrification mechanism, the capacitor twisting mechanism, the capacitor pin pneumatic shear and the plug-in magnetic rod mechanism; its advantages are: the labor intensity of the operator is reduced when mass production of magnetic rod coils .

Owner:惠州市天捷宝自动化设备有限公司

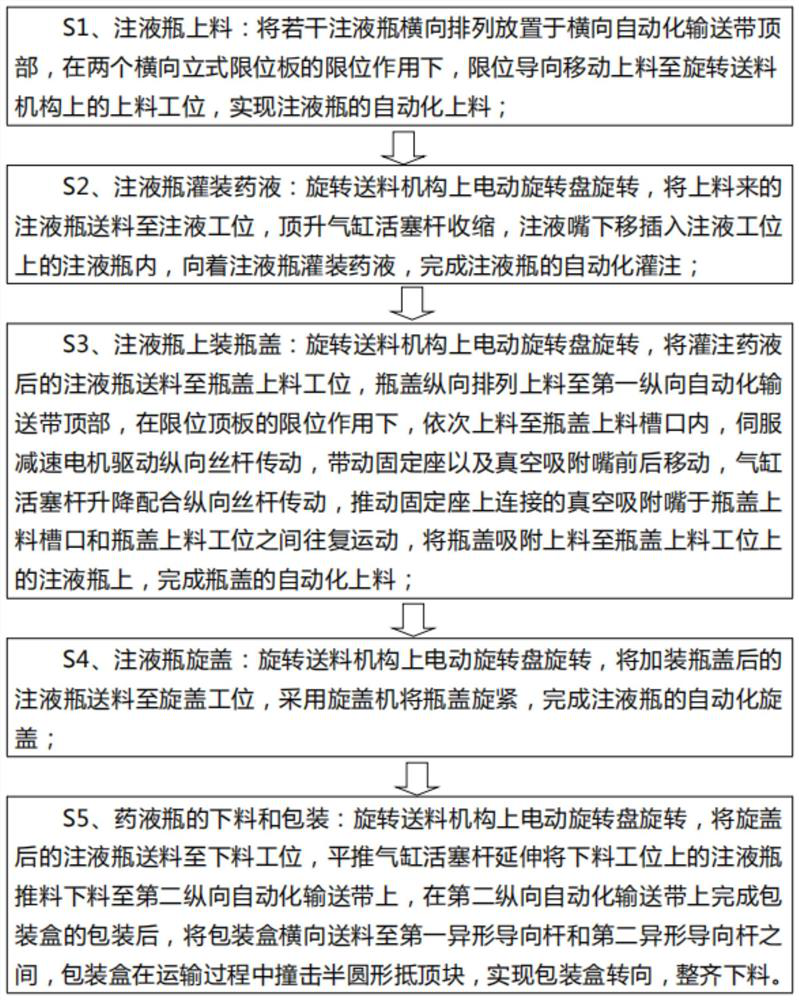

Biological medicine preparation method

PendingCN113120833ARealize automatic processing and productionRealize automatic feedingCapsThreaded caps applicationMedicine bottle capScrew cap

The invention discloses a biological medicine preparation method which comprises the following steps: S1, feeding liquid injection bottles: transversely arranging a plurality of liquid injection bottles at the top of a transverse automatic conveying belt, and feeding the liquid injection bottles to a feeding station on a rotary feeding mechanism in a limiting, guiding and moving manner under the limiting action of two transverse vertical limiting plates, so as to realize automatic feeding of the liquid injection bottles; S2, filling the liquid injection bottles with liquid medicine; S3, installing bottle caps on the liquid injection bottles; S4, screwing caps of the liquid injection bottles: rotating an electric rotating disc on the rotary feeding mechanism, feeding the liquid injection bottles with the added bottle caps to a cap screwing station, and screwing the bottle caps by adopting a cap screwing machine to complete automatic cap screwing of the liquid injection bottles; and S5, discharging and packaging the liquid medicine bottles. According to the method, automatic medicine processing production can be achieved, namely, automatic medicine bottle feeding, automatic medicine bottle filling, automatic medicine bottle capping and cap screwing and automatic medicine bottle feeding can be achieved, the medicine production efficiency is greatly improved, and the manual labor force is greatly reduced.

Owner:徐文霞

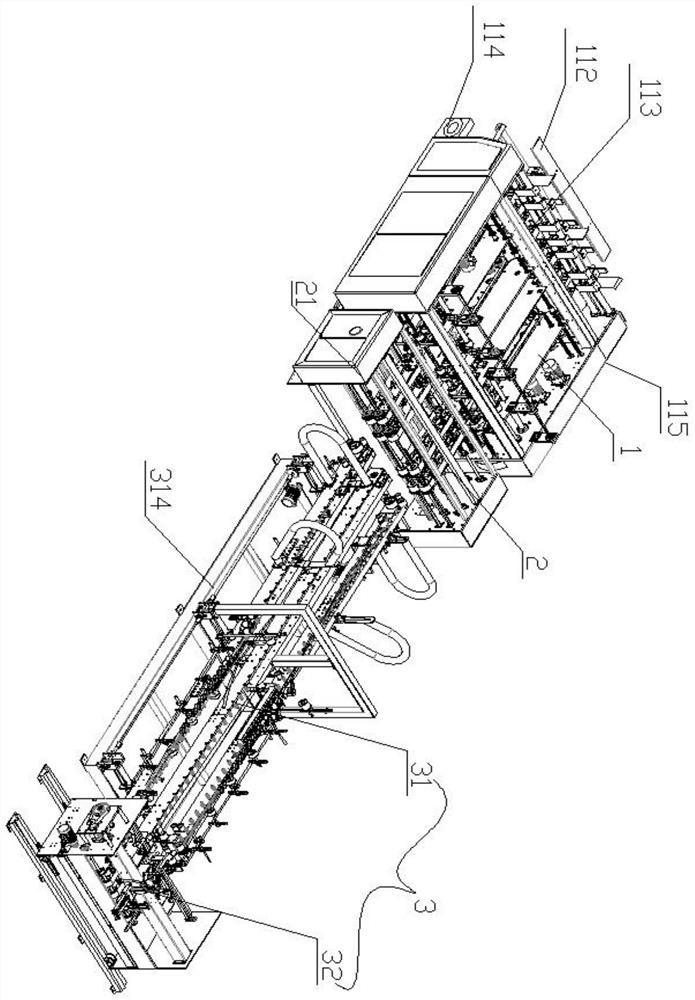

A flexible automatic production line

ActiveCN108861410BImprove flexibilityRealize automatic processing and productionConveyor partsMechanical conveyorsProduction lineRobot hand

The invention discloses a flexible automatic production line, which comprises a lifting mechanism, corner modules, long line modules, short line modules and manipulator modules. Any two of the liftingmechanism, the corner modules, the long line modules, the short line modules and the manipulator modules are in end-to-end connection. Each long line module and the adjacent long line module are available for extension splicing, each short line module and the adjacent short line module are available for extension splicing, and each manipulator module is arranged on one side of the corresponding short line module. The flexible automatic production line is high in flexibility, demands of different processing places can be met, efficient and quick transmission at any positions can be realized, and automatic processing and production of materials can be realized by the aid of manipulators, so that production efficiency is greatly improved, production cost is reduced, and reliability is improved.

Owner:SHENZHEN SONGJIAN ROBOT CO LTD

Automatic staple feeding device for silent retainer

Owner:江苏盐新汽车产业投资发展集团有限公司

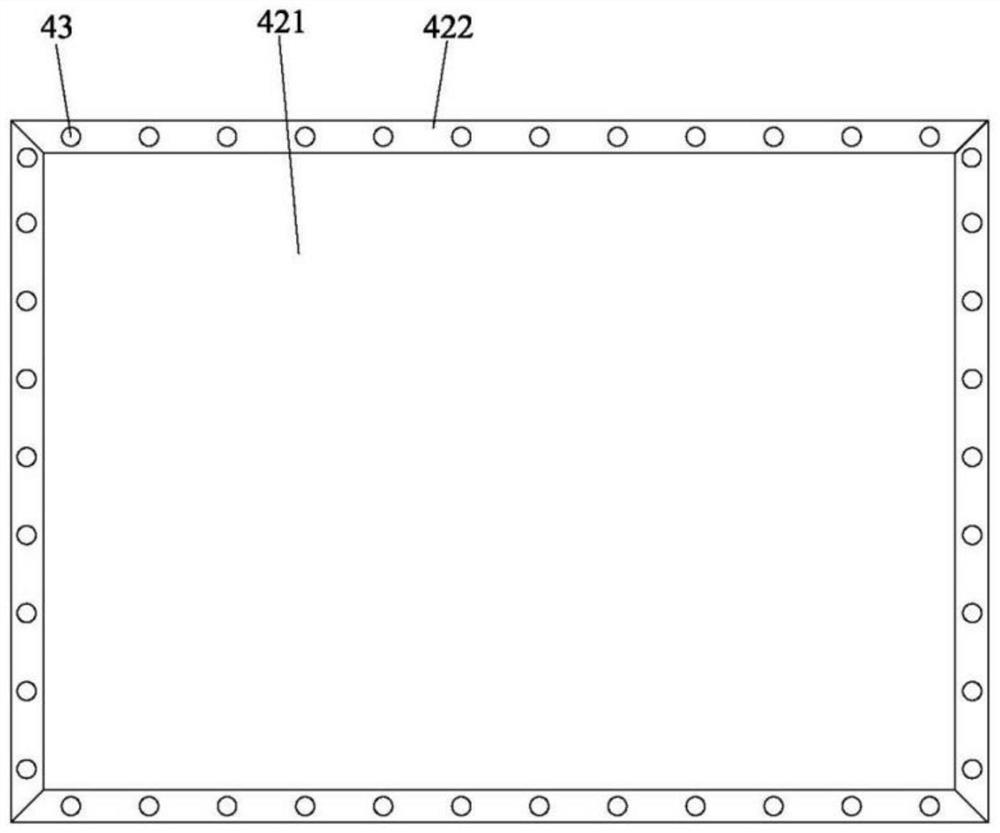

A processing equipment and processing technology for signs and display props

ActiveCN111843625BExtended service lifeImprove stabilityGlass productionSignsVisual recognitionMaterial resources

The invention discloses a processing equipment for signs and display props and a processing technology thereof, comprising a base, a fixing device and a molding device, the molding device is arranged on the periphery of a frame-shaped product, and the molding device includes a mold installation part, a vacuum part and a molding device. The heating part, the middle part of the plate is provided with a groove for placing the medium, the periphery of the groove is provided with a limit part, the vacuum pump drives the vacuum part to fix the medium on the mold mounting part, the heating part includes a base plate and a set on the base plate. The arc-shaped heating wire between the mold mounting plate and the base plate is arranged at one end away from the medium. The panel is formed on the stainless steel plate of the frame-shaped product through the processing equipment, so that the appearance of the frame-shaped product will not have uncoordinated edges. Through the AI intelligent control terminal, the visual recognition device can be used to identify whether the processed products meet the standards in real time. Even without operators on site, remote control can be realized to realize the automatic processing and production of products, which effectively saves manpower and material resources.

Owner:上海鑫铭锐标识制作有限公司

Identifying and display prop processing equipment and processing technology thereof

ActiveCN111843625AExtended service lifeImprove stabilityGlass productionSignsMaterial resourcesVisual recognition

The invention discloses identifying and display prop processing equipment and a processing technology thereof. The identifying and display prop processing equipment comprises a base, a fixing device and a forming device; the forming device is arranged on the periphery of a frame shaped product and comprises a die mounting part, a vacuum part and a heating part; a groove for placing a medium is formed in the middle of a platy object; a limiting part is arranged on the periphery of the groove; a vacuum pump drives the vacuum part to fix the medium on the die mounting part; the heating part comprises a base plate and an arc shaped heater strip arranged between the base plate and a die mounting plate; and the base plate is arranged at the end far away from the medium. A panel is formed on a stainless steel plate of the frame shaped product to avoid the situation that the appearance of the frame shaped product is provided with unmatched edges through the processing equipment. A visual identifying device can be adopted to identify whether a processed product meets the standard in real time through an AI control terminal, remote control can be realized without an operator on the site, automatic processing and producing of the product are realized, and manpower and material resources are effectively saved.

Owner:上海鑫铭锐标识制作有限公司

A perforated film cover locking machine

Owner:广东希顿智能机器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com