Processing equipment for magnetic rod coils

A technology for processing equipment and magnetic rod coils, which is applied in the field of processing equipment for magnetic rod coils, can solve the problems of high labor intensity for operators, and achieve the effects of saving labor costs, improving orderliness, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

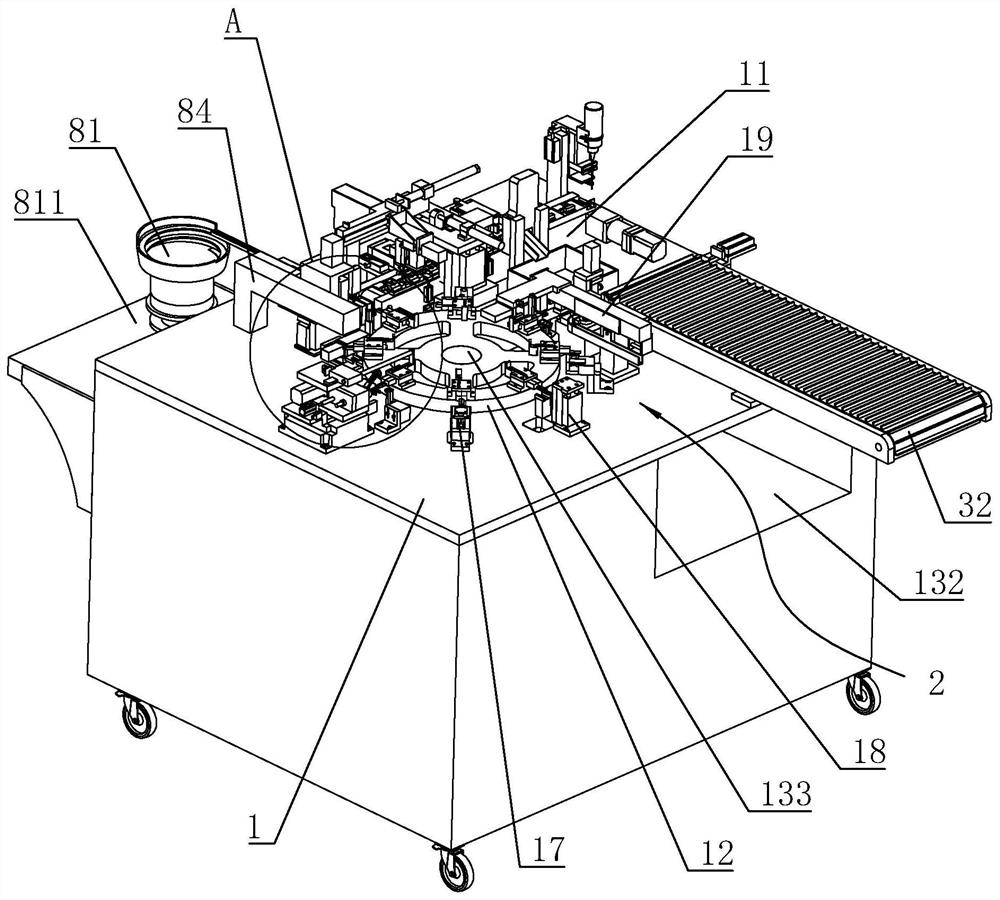

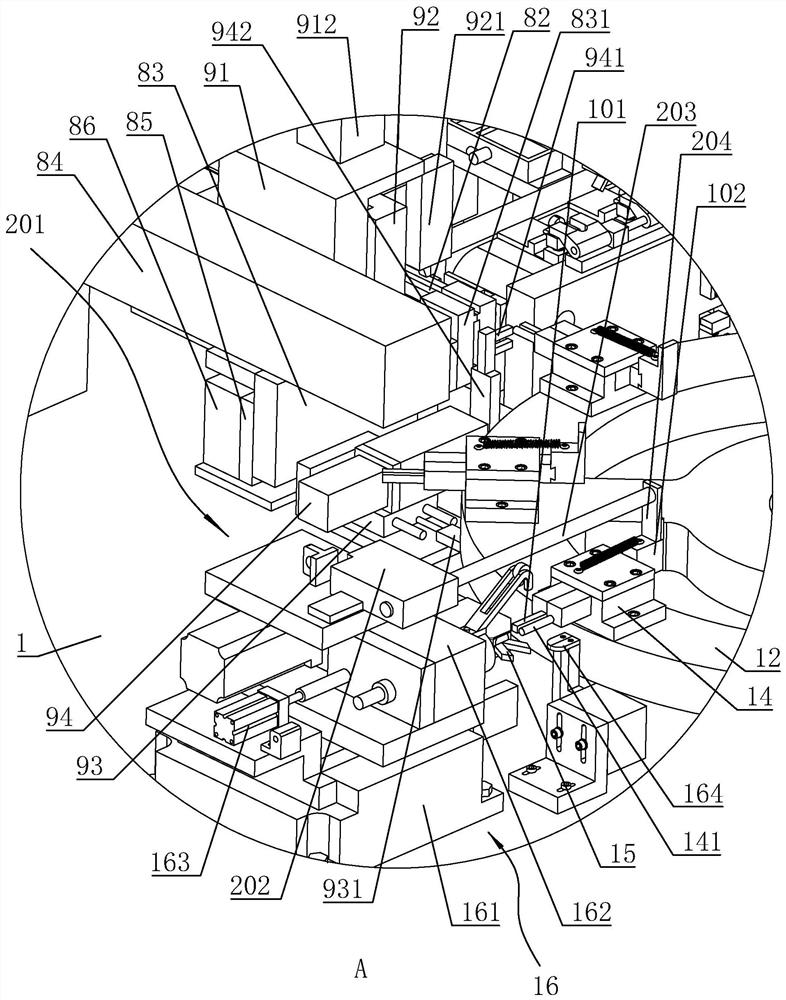

[0039] Embodiment: a kind of processing equipment of magnetic bar coil, as figure 1 As shown, it includes a workbench 1, a belt conveyor 11, a station disc 12 rotatably connected to the workbench 1 and a drive member 13 for driving the station disc 12 to rotate (such as Figure 6 ), the workbench 1 is supported on the ground, the belt conveyor 11 is fixed on the workbench 1 , and the side wall of the workbench 1 is provided with an operation slot 132 .

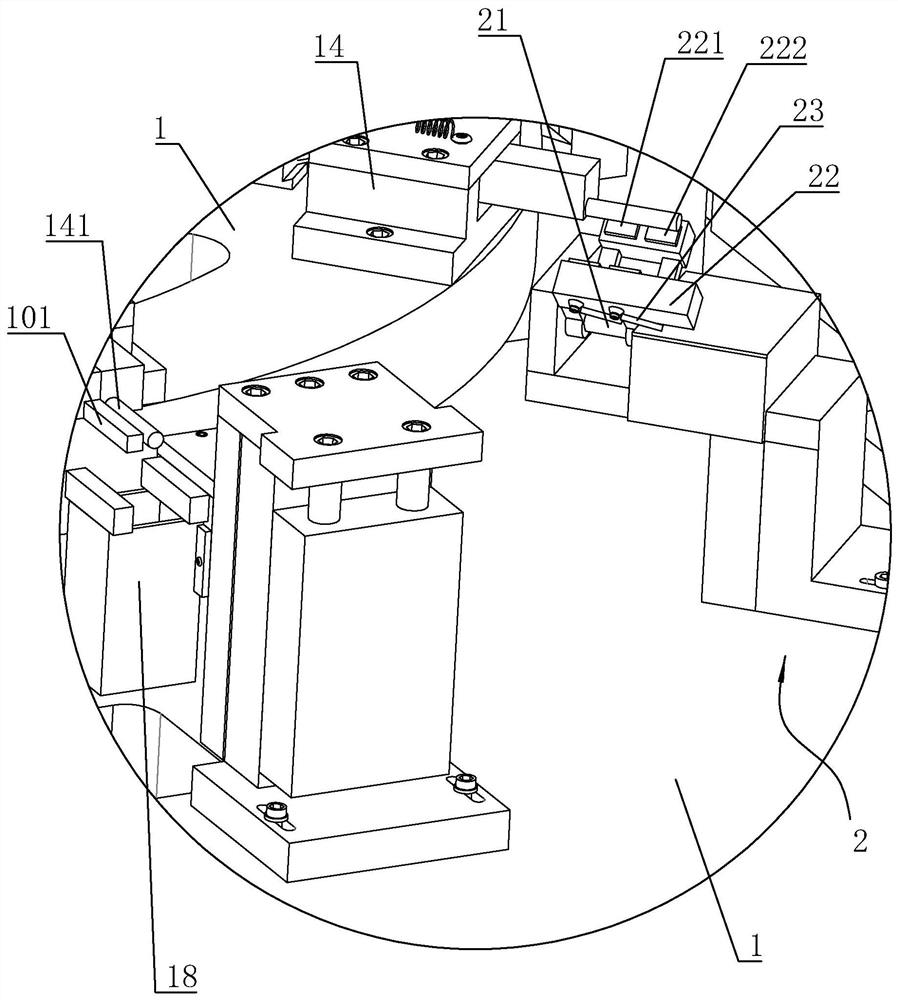

[0040] Such as Figure 9 As shown, the station disk 12 is provided with a number of station seats 14 distributed along the circumferential direction of its axis, and each station seat 14 is provided with a polished rod 141 at the end away from the axis of the station disk 12, and the polished rod 141 is arranged along the axis of the station disk 12. The radial extension of the workbench 1 is provided with the first coil pneumatic shear 15, the winding mechanism 16, the second coil pneumatic shear 17, the third coil pneumatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com