Rotary-disc flame welding machine and welding method thereof

A turntable, flame technology, used in welding equipment, electric heating devices, tin feeding devices, etc., can solve the problems of inability to flexibly adjust the position of the gun head, inability to improve welding accuracy, and poor flexibility in use, to eliminate the small heating range and facilitate the The effect of assembly line processing and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

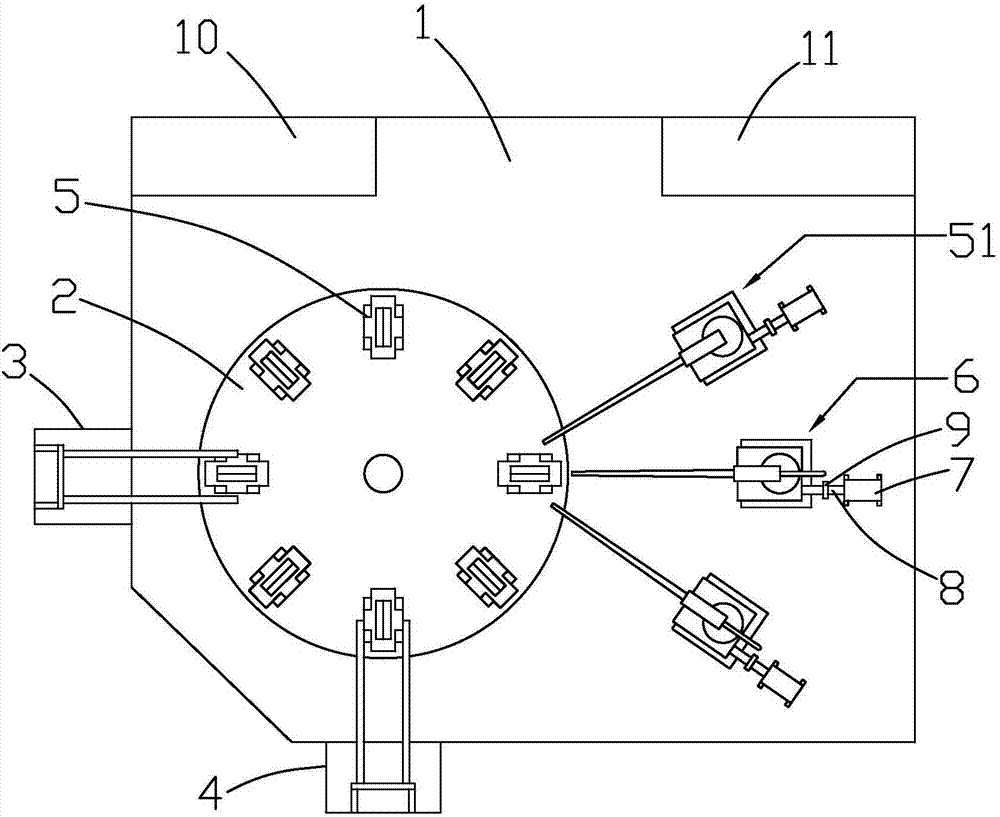

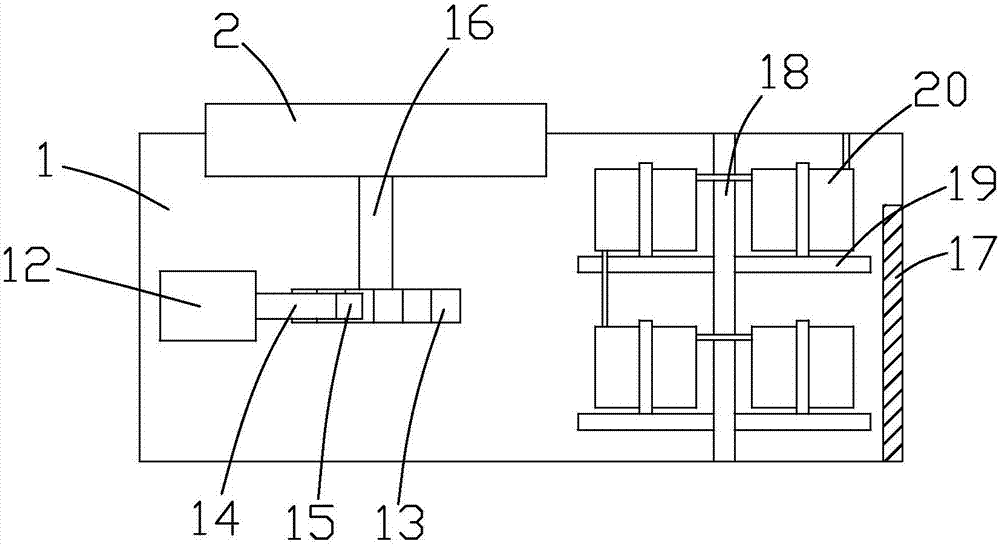

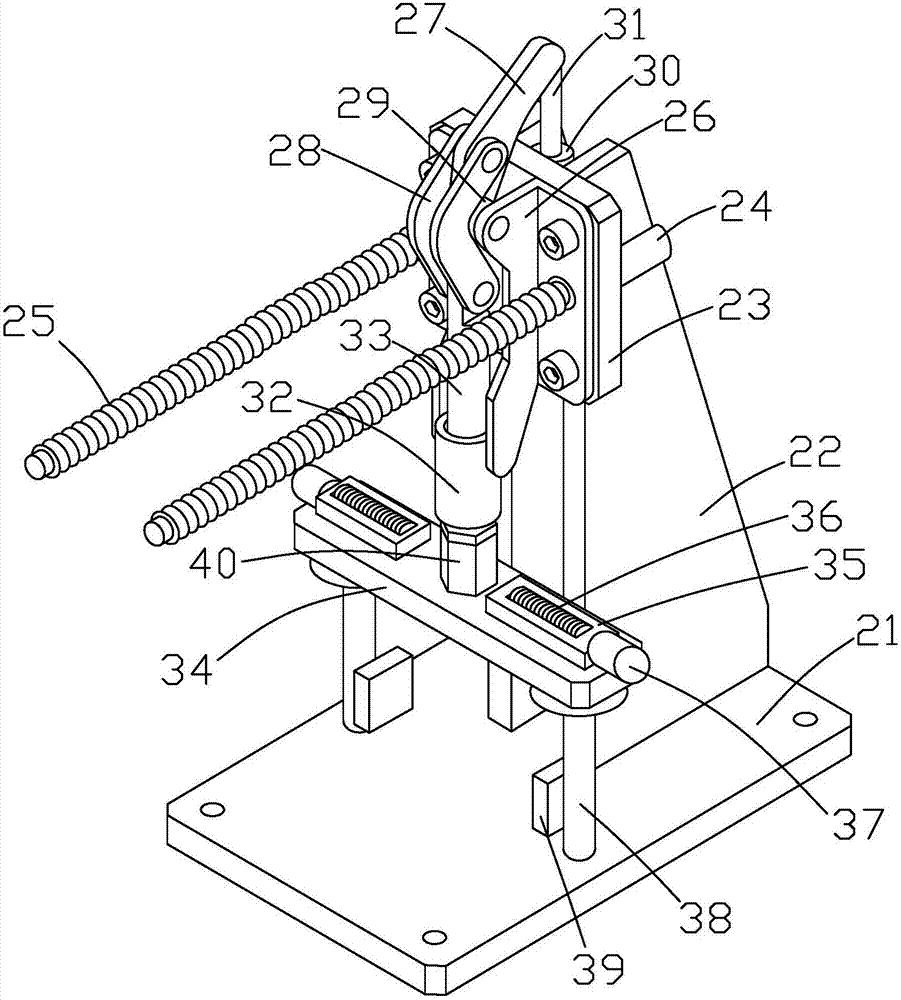

[0043] Such as Figure 1 to Figure 4 As shown, it is a rotary table flame welding machine of the present invention, comprising a body 1, a rotary table 2, an electrical control box 10, a gas control box 11, a wire feeding mechanism 6 and a welding heat gun 51 are arranged on the top surface of the body 1, and the electrical The control box 10 and the gas control box 11 are located on one side of the machine body 1, the wire feeding mechanism 6 and the welding heating gun 51 are distributed on one side of the turntable 2, and the clamping block 5 is uniformly arranged on the turntable 2, the wire feeding mechanism 6 and the welding heating gun The guns 51 are all connected with the first cylinder 7 through the first piston rod 8, the first piston rod 8 is provided with a positioning frame 9, the setting of the first cylinder 7 can facilitate the adjustment of the wire feeding mechanism 6, the welding heating gun 51 and the turntable 2 The distance between them can meet the weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com