Atomization core oil guide body assembling method, special tool and atomization core structure thereof

An assembly method and technology of an oil guide body, which are applied to tobacco and other directions, can solve the problems affecting the consistency of electronic cigarette products, the difference in the passing rate of e-liquid, and low production efficiency, so as to achieve consistency and uniformity, easy operation, and improved production efficiency. The effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

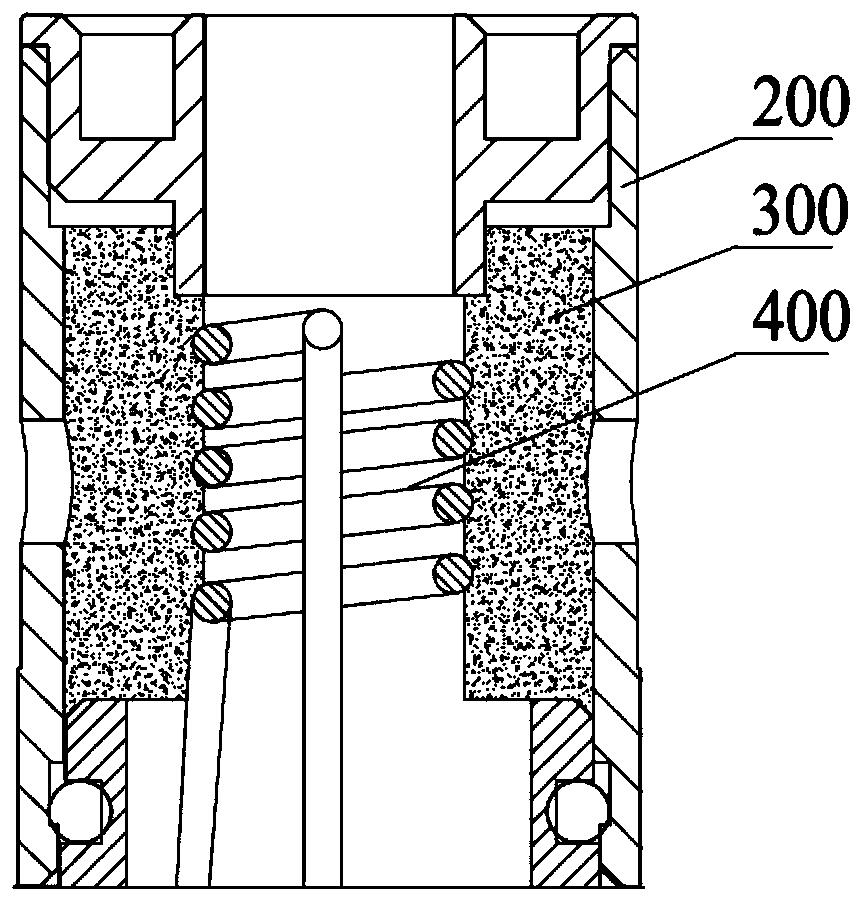

[0052] Firstly, the composition of the special jig set used in the assembly method of the present invention will be described. The special jig set of the present invention is composed of a first jig and a second jig.

[0053] like Figure 12 As shown, the main body of the first jig 4 is a cylindrical structure made of hard and smooth material, which may be metal material or PVC plastic material. It has a first end 43 and a second end 44, wherein the transition between the first end 43 and the second end 44 is a positioning shoulder 42, which is actually integrally formed.

[0054] Wherein the inner diameter of the first end 43 of the first jig is the same as the inner diameter of the atomizing core shell, so as to achieve smooth docking with the atomizing core shell, and an axial opening 41 is provided at the end of the first end 43, There can be one axial opening 41, two symmetrical openings, or multiple openings.

[0055] The second end 44 is a cylindrical structure, trans...

Embodiment 2

[0071] The method of this embodiment is basically the same as the set of special jigs, but the third jig 9 is added to the set of special jigs. like Figure 14 As shown, the third jig 9 is a rotary cutter. Specifically, the rotary cutter of the third jig 9 is a cylindrical structure, and the inner diameter is equivalent to the outer diameter of the first end 43 of the first jig 4, so that the first end 43 of the first jig can be inserted into the third jig. 9, an annular rotating blade 91 is set at one end of the third jig. When the first end 43 of the first jig is inserted into the third jig 9 carrying the oil guide body, the rotating blade 91 will cut off the excess oil guide body 32 .

[0072] The resulting trimmed state is as follows Figure 17 As shown, the annular butt joint 311 of the cylindrical oil guide body 31 is originally the same flat surface of the strip oil guide body 1, so a good bonding effect can be achieved after compaction, and at the same time, there i...

Embodiment 3

[0074] This embodiment is also a change in the jig and method for cutting off the excess oil guide body 32 . In this embodiment, no special or general cutting tool is provided. But the structural change carried out on the basis of the first jig 4, such as Figure 15 As shown, axial inclined blades 411 and 412 are arranged at the bottom end of the axial opening 41 of the first jig first end 43, and the inclined blades 411 and 412 continue to extend axially inward from the bottom end of the opening 41 and intersect with A little, forming a triangular cut. Therefore, this embodiment can omit the cutting process of the fifth step, and directly enter the sixth step to insert the second jig 8. While inserting, relying on the downward movement of the cylindrical oil guide body 31, the remaining oil guide body 32 Cut out by a triangular cut, not only is the structure simple, but the steps are also simple.

[0075] The sectional view of the final formed atomizing core oil guide body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com