Expansion type centered clamping and milling device

A milling device and expansion technology, applied in the field of machinery, can solve the problems of affecting the processing precision, operator's hand burns, unsuitable batch processing, etc., and achieve the effects of improving efficiency, reliable work, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

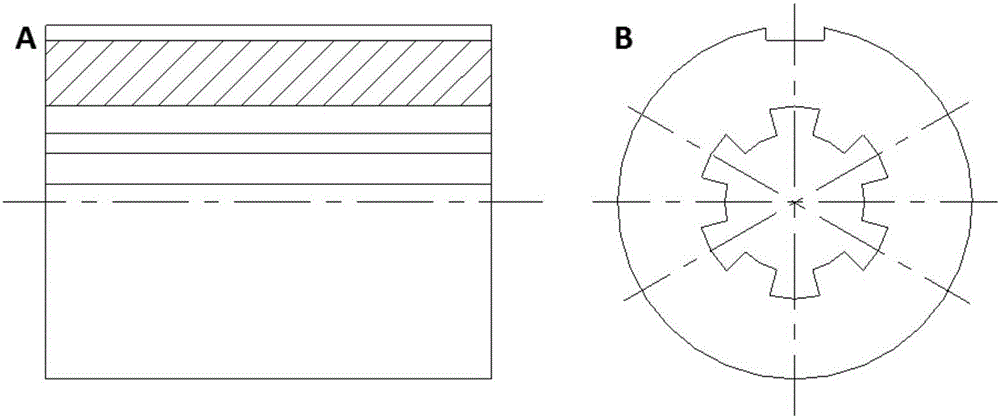

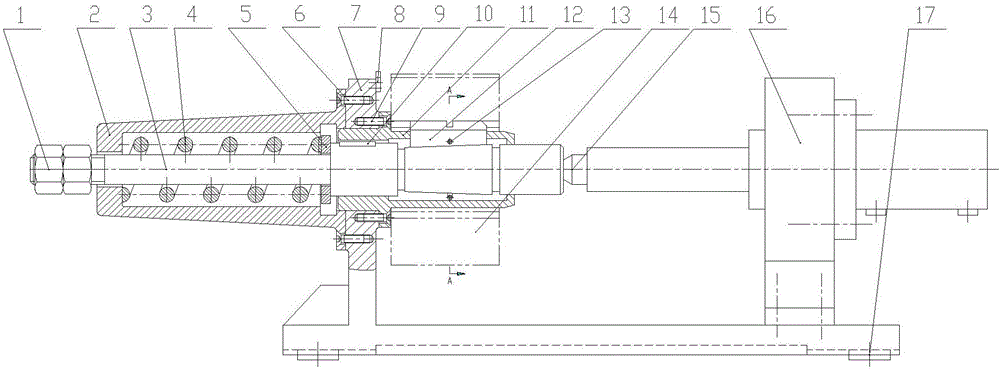

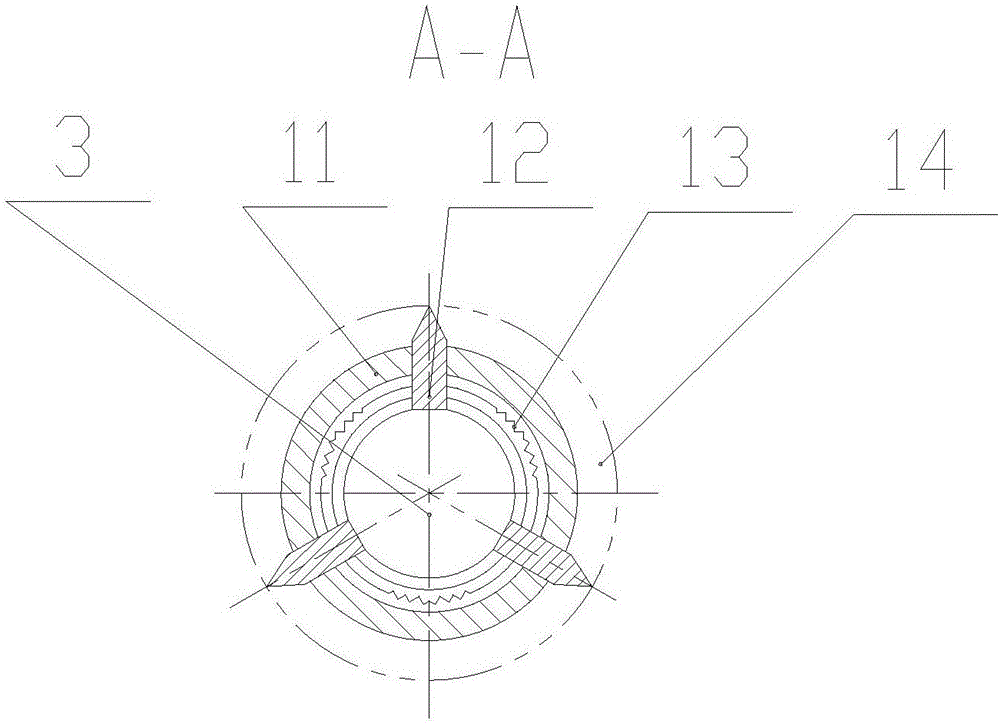

[0035] An expansion type centering and clamping milling device of the present invention is shown in figure 2 , mainly composed of locking nut 1, spring box 2, mandrel 3, return spring 4, spring seat plate 5, first screw 6, clamping body 7, tool setting block 8, second screw 9, key 10, support sleeve 11 , positioning support plate 12, shaped spring 13, top 15, pneumatic components 16 and directional keys 17 and other components.

[0036] The clamp body 7 is connected to the spring case 2 by the first screw 6 . The inner hole surface on the spring case 2 cooperates with the support sleeve 11 to realize the centering effect of the two axes. The expandable centering and clamping milling device further includes a tool setting block 8, which is installed on the upper part of the clamping body 7 at the position of the milling groove to realize the function of tool setting. The support sleeve 11 is mounted on the clamp body 7 and fixed with the second screw 9 . The support sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com