Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Realize feeding one by one" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

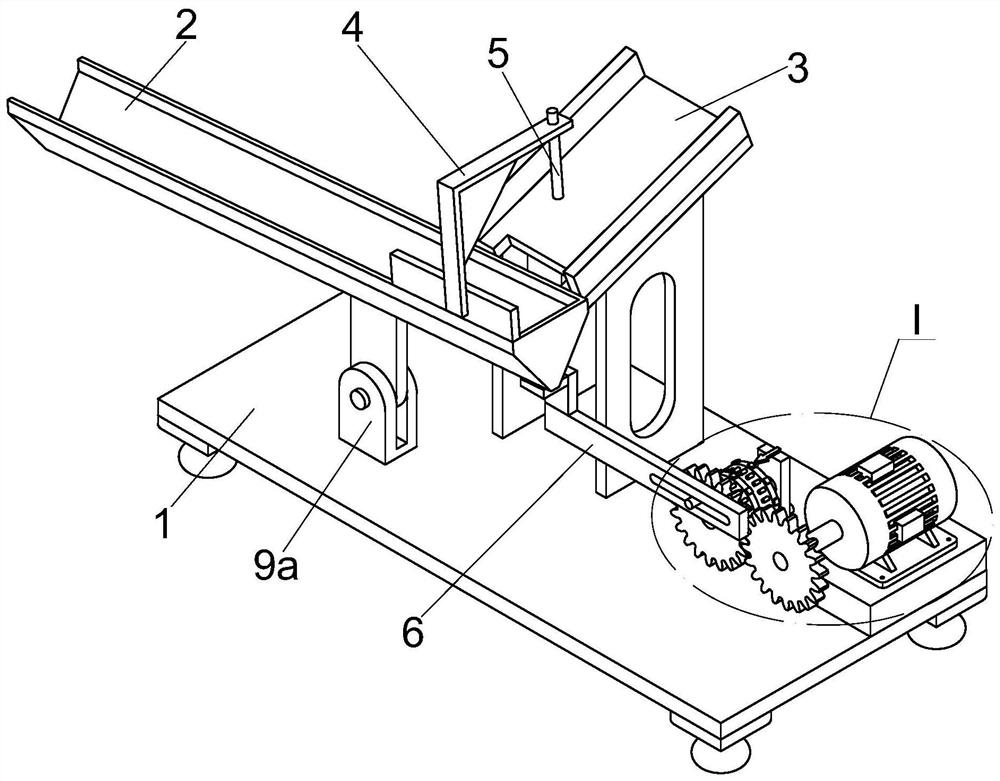

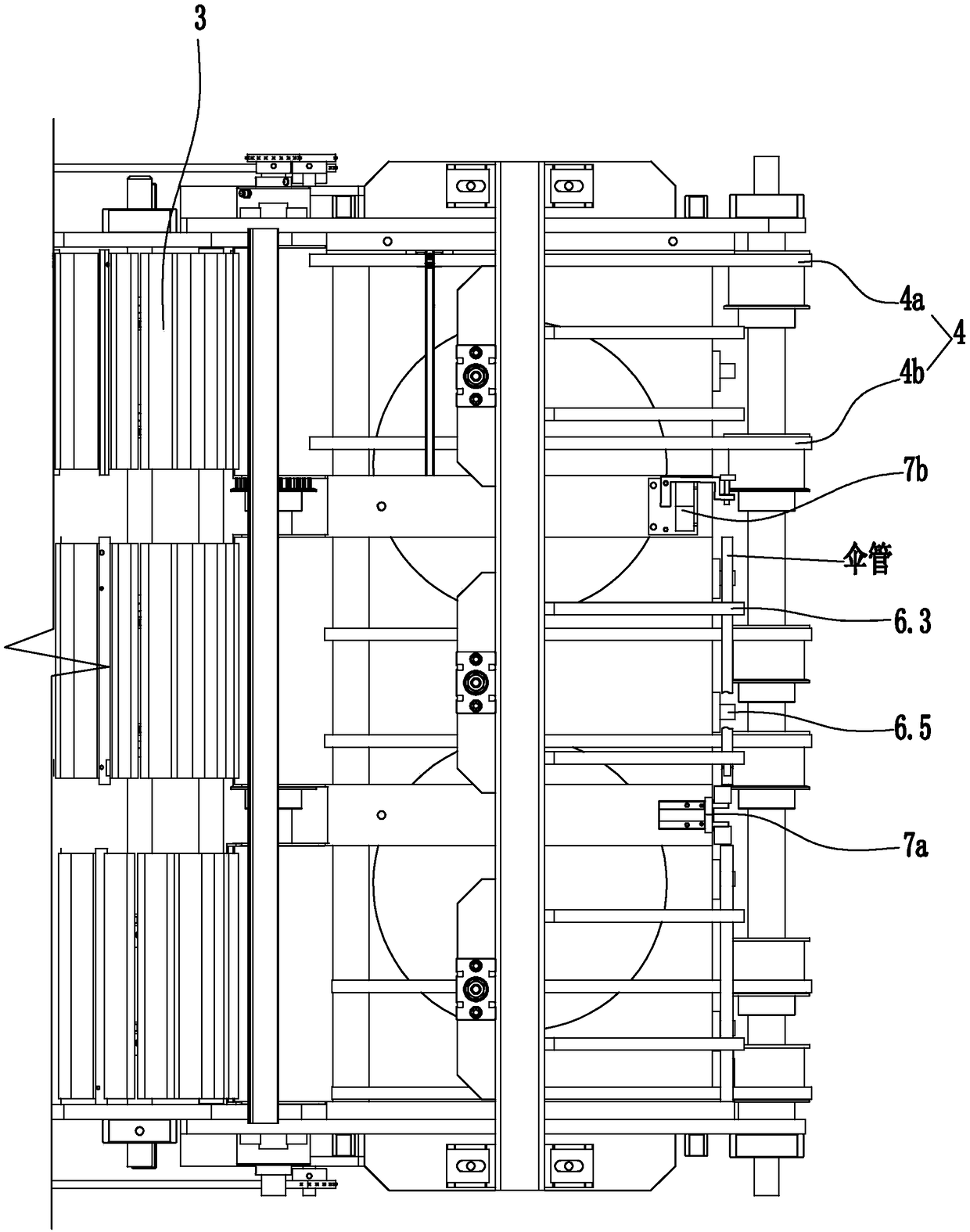

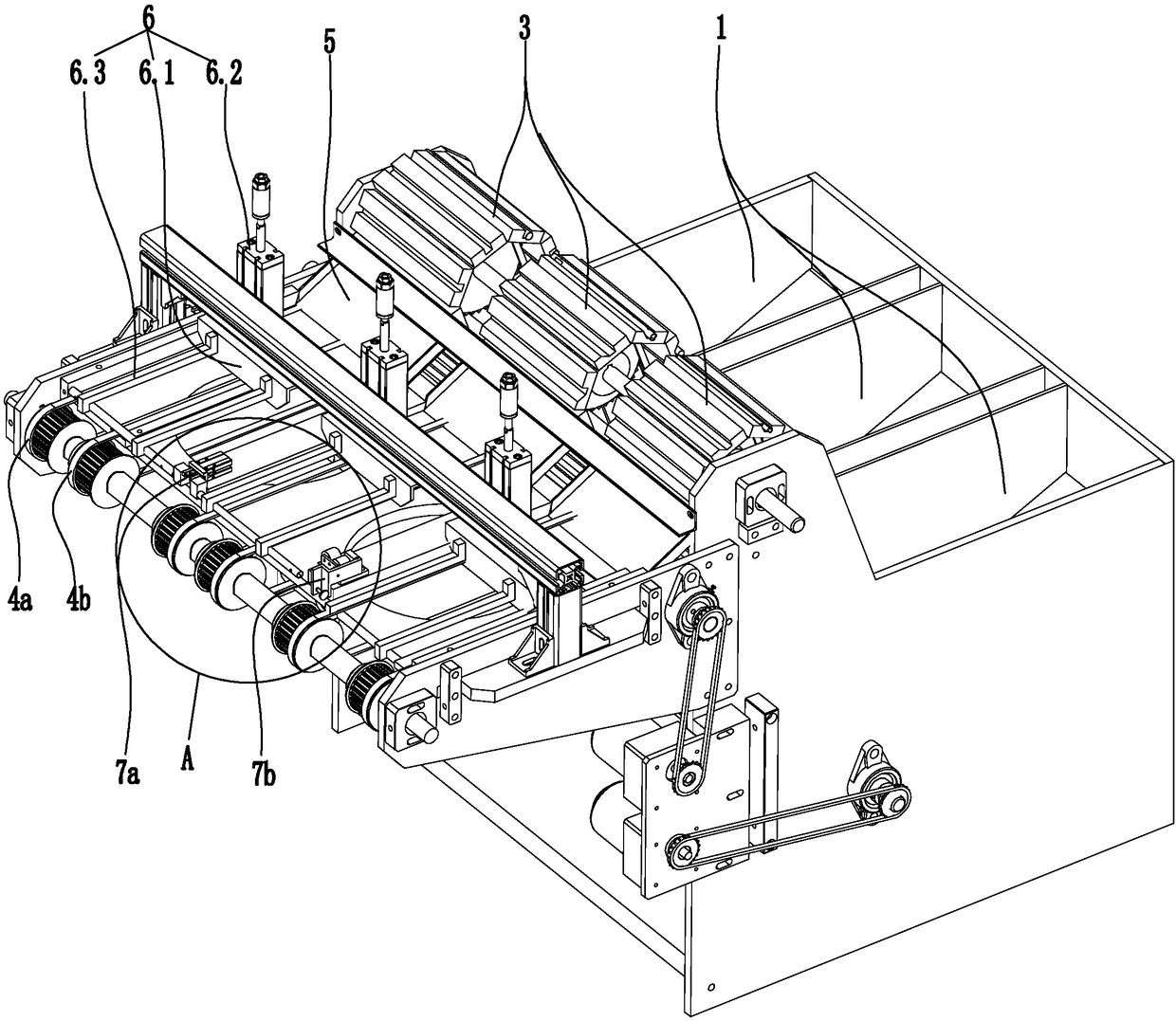

Umbrella pipe feeding and orientation mechanism

ActiveCN106736353ARealize feeding one by oneSolve the problem of set failureMetal working apparatusConveyor beltEngineering

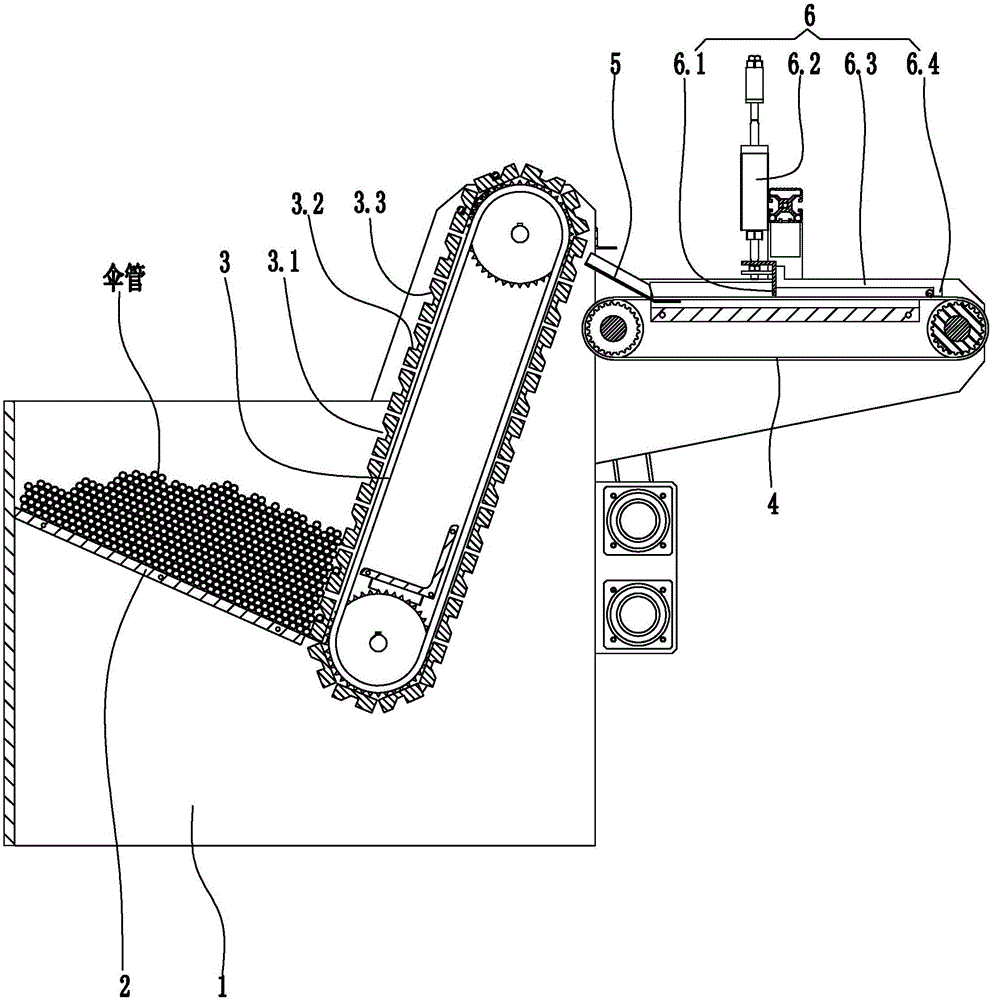

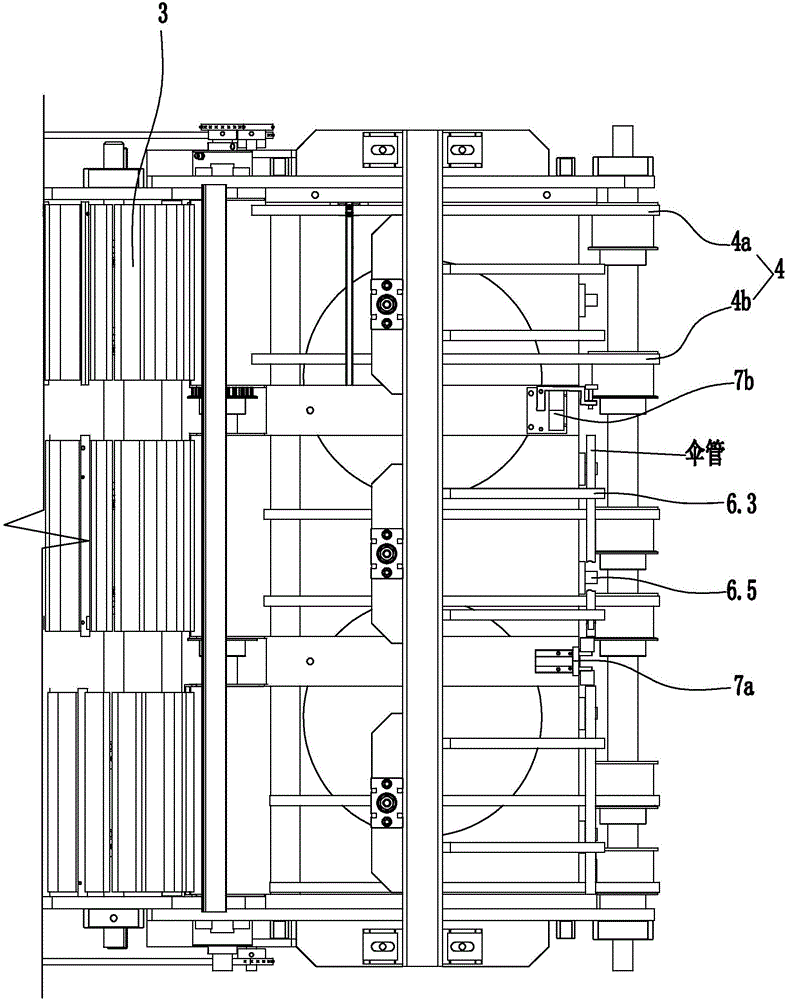

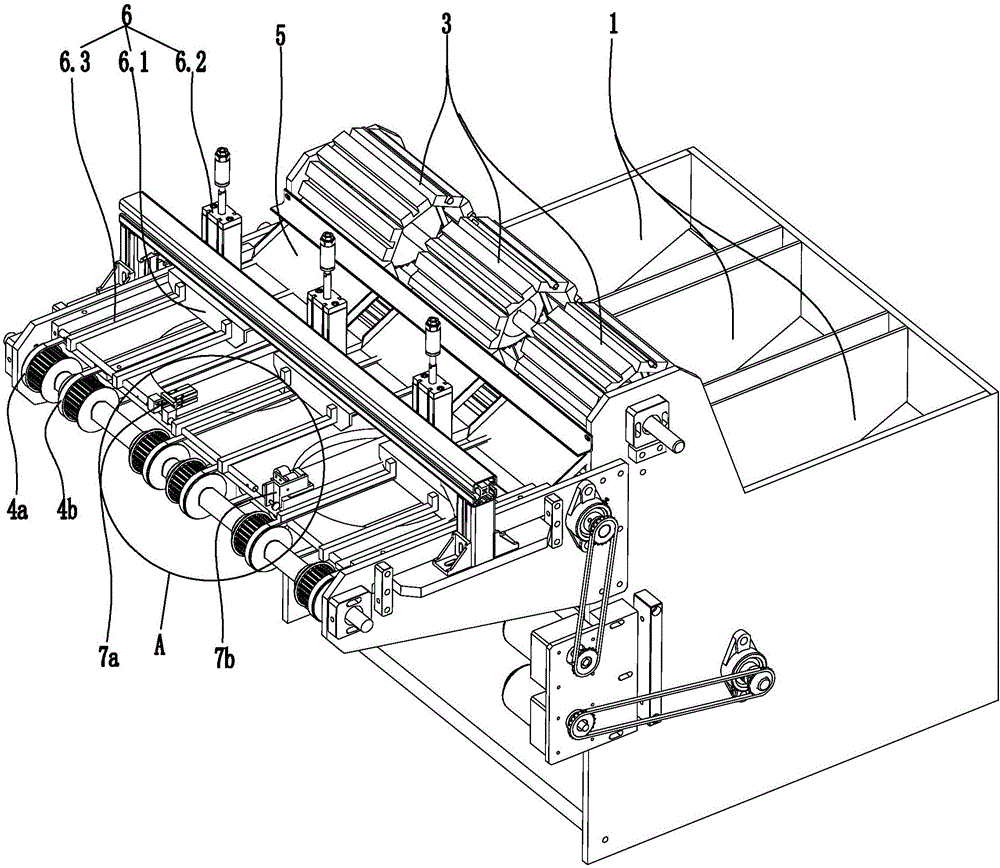

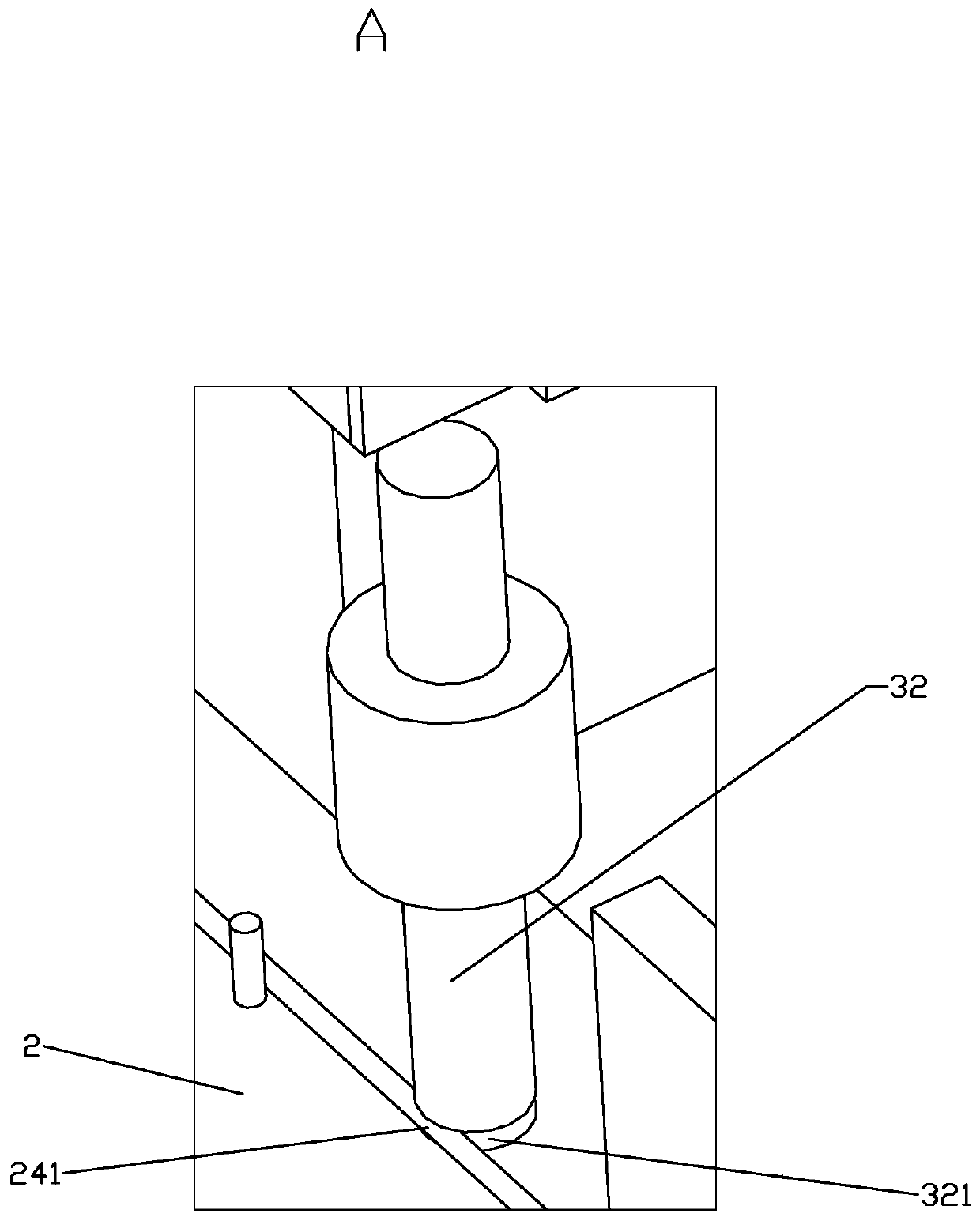

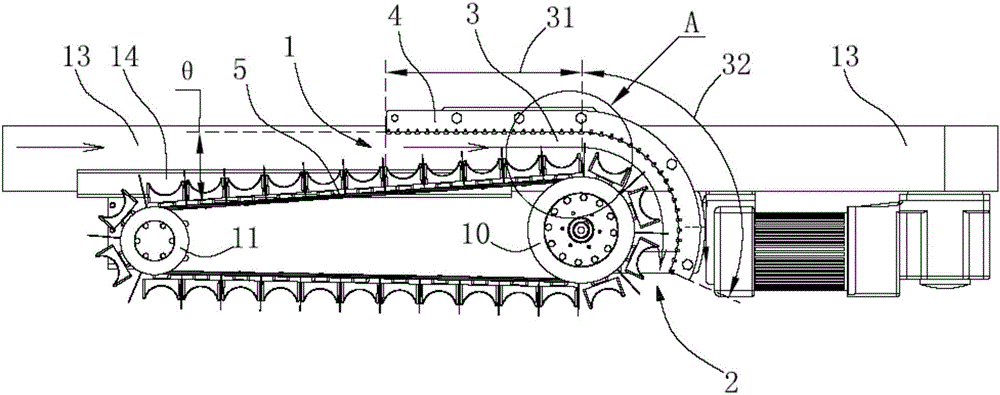

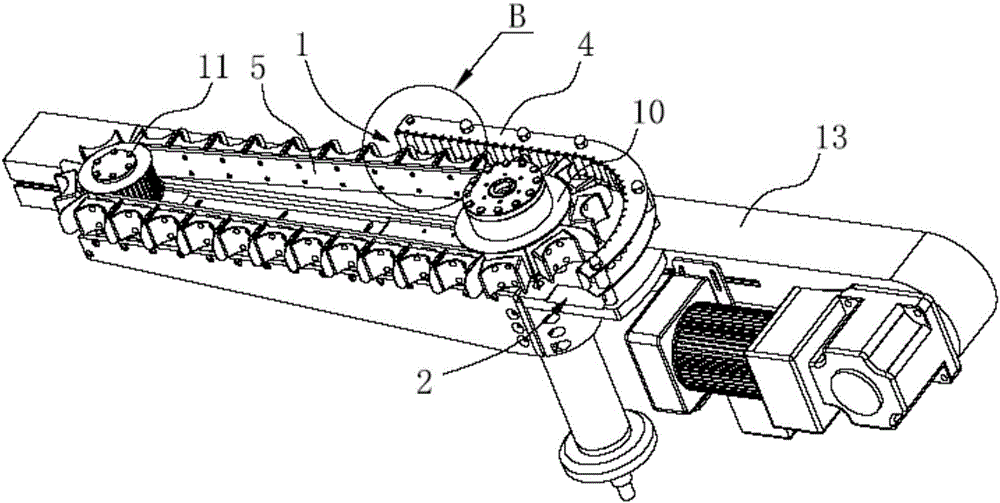

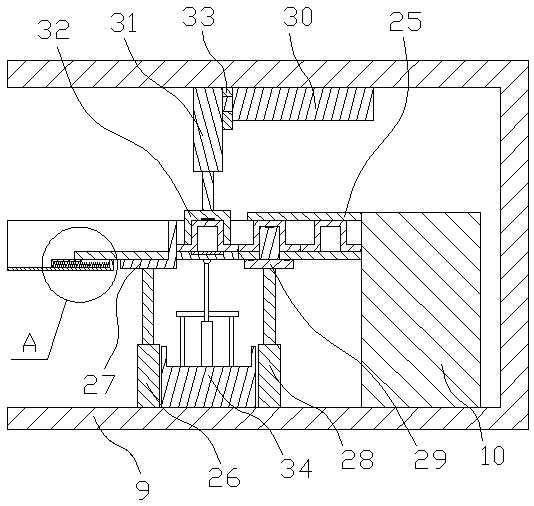

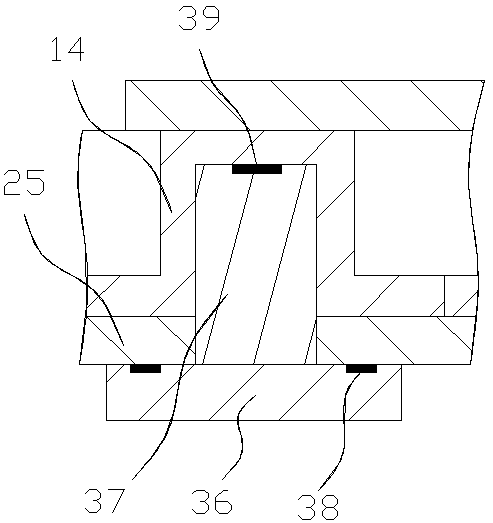

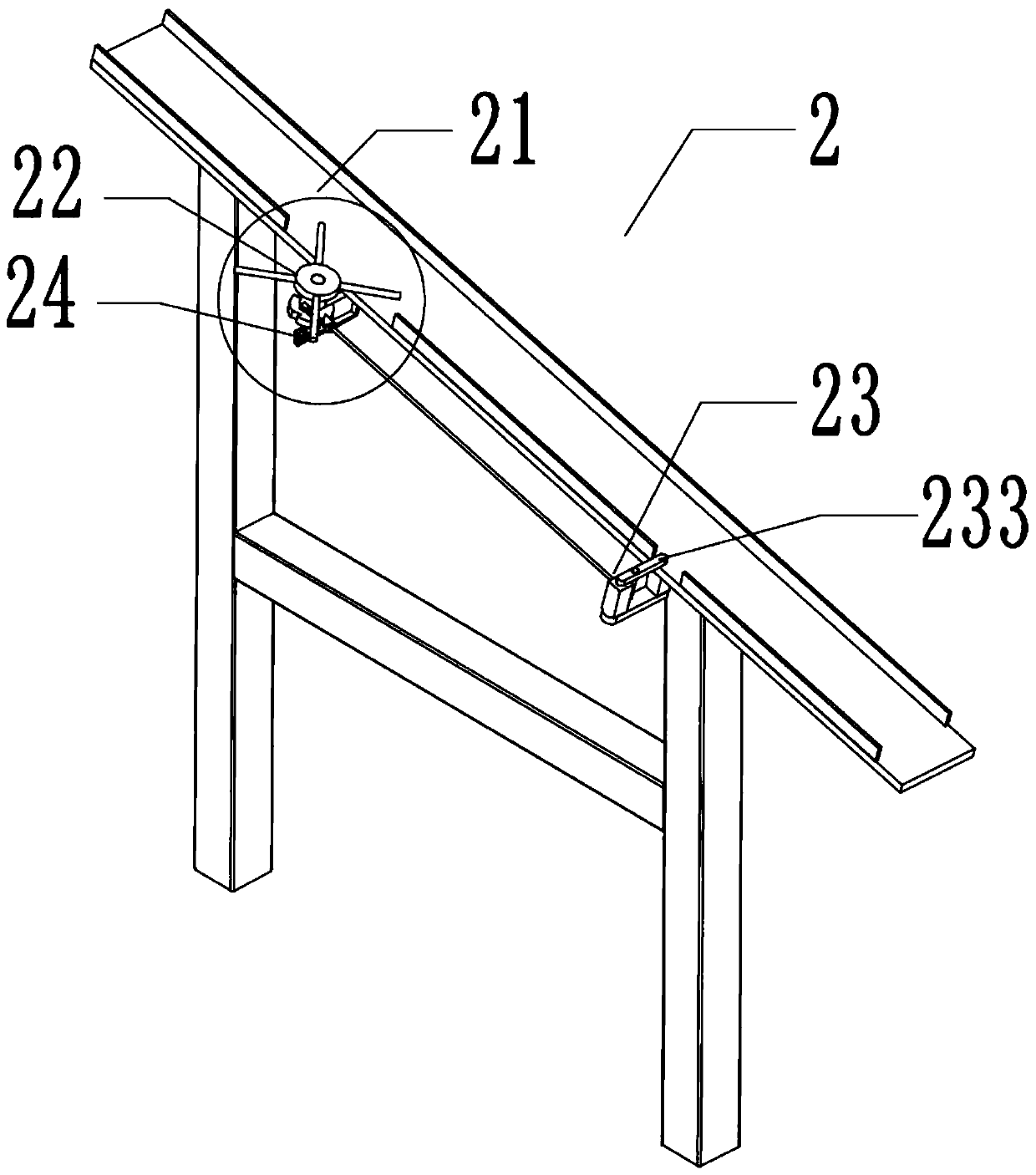

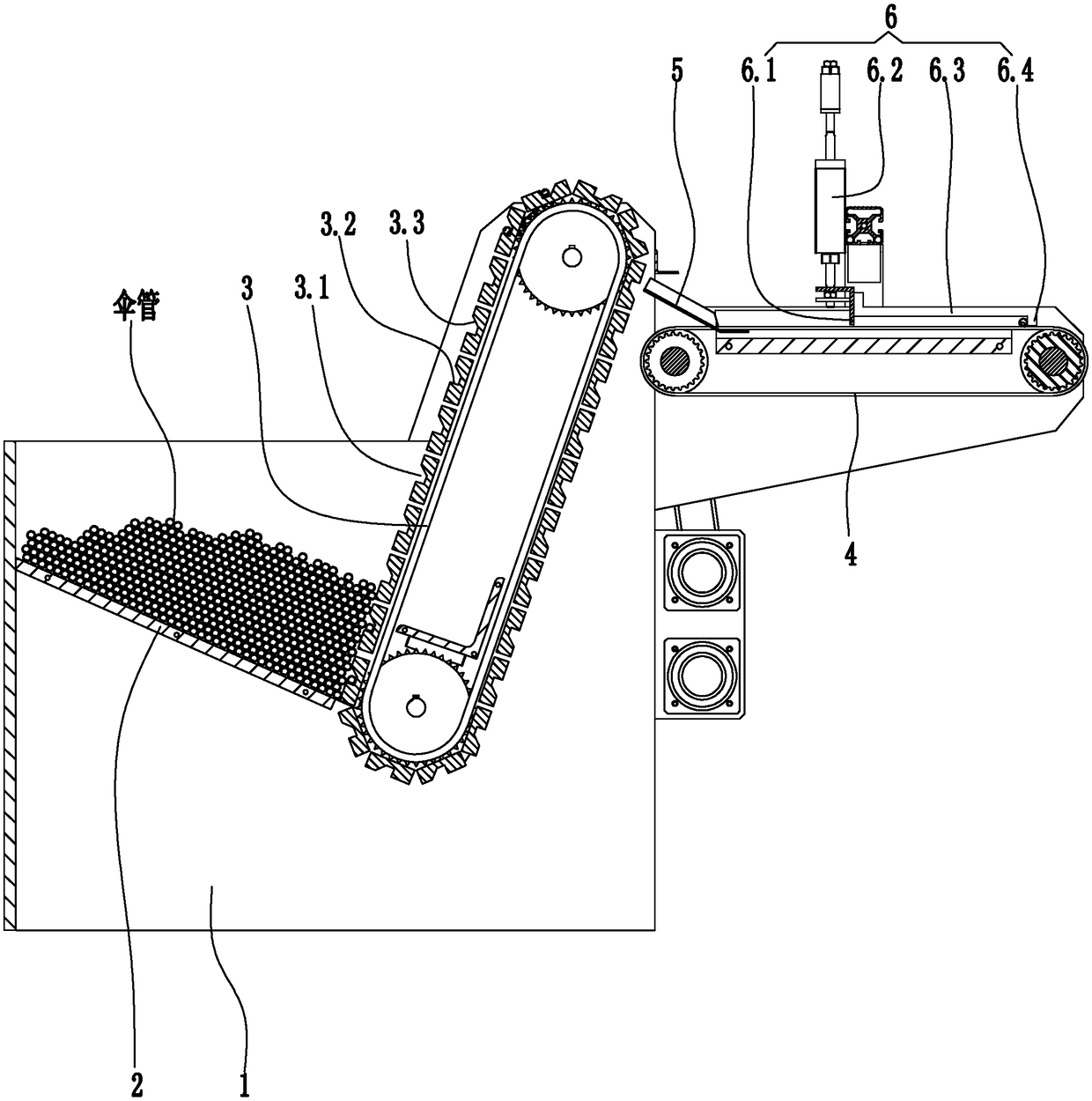

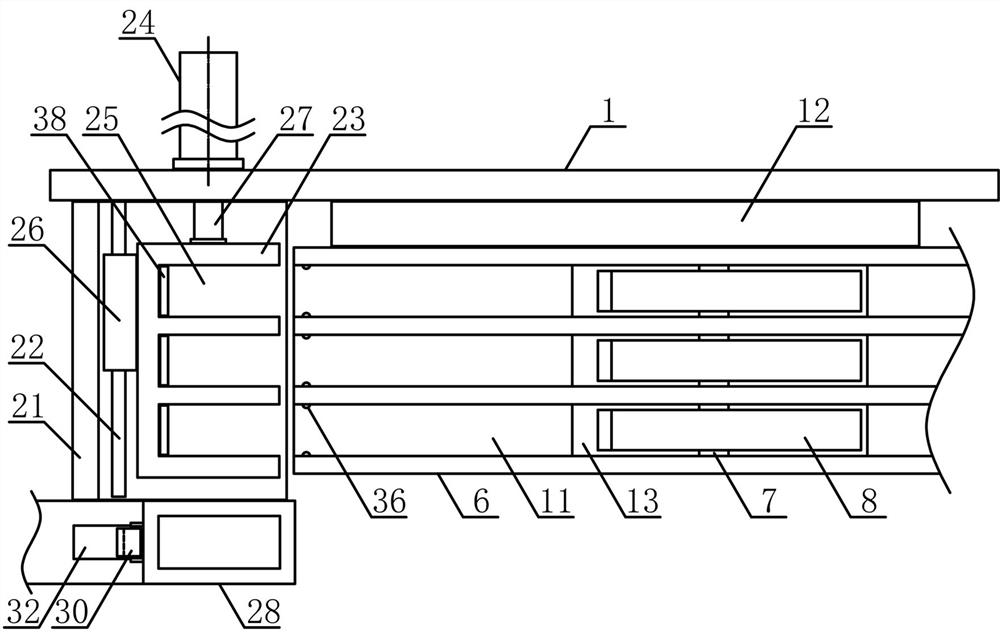

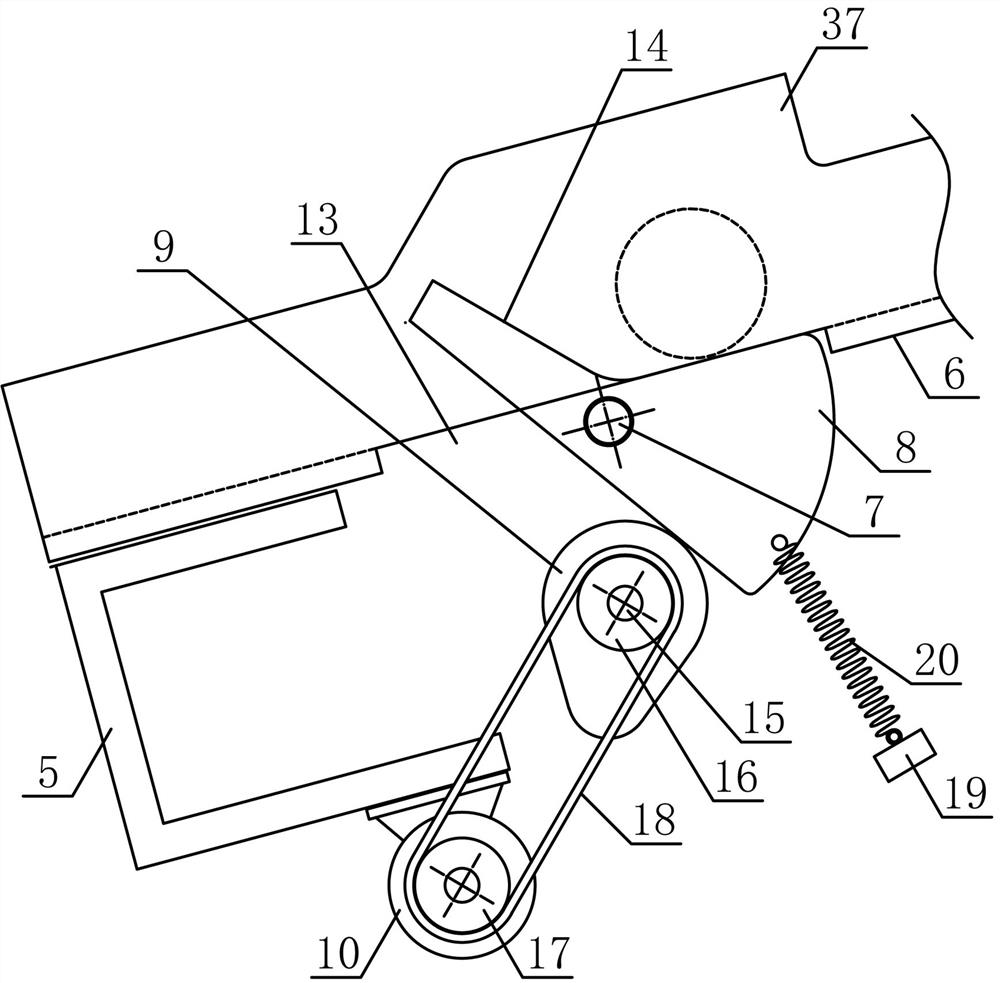

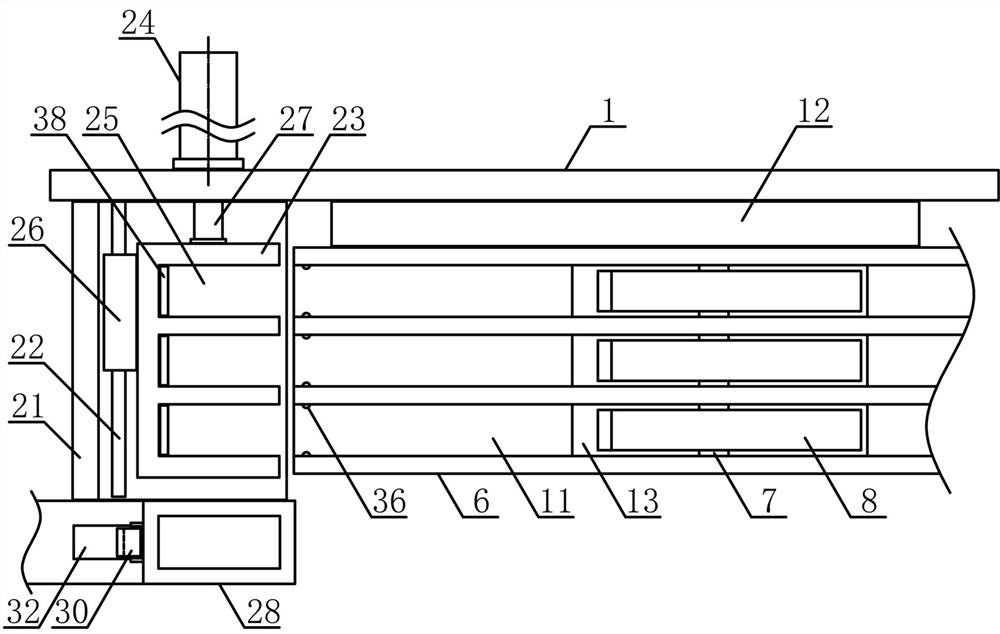

The invention discloses an umbrella pipe feeding and orientation mechanism which not only can feed umbrella pipes one by one but also can achieve orientation of the umbrella pipes. The umbrella pipe feeding and orientation mechanism comprises umbrella pipe bins, obliquely extending chain plate conveyor belts in one-to-one correspondence with the umbrella pipe bins, umbrella pipe transfer belts in one-to-one correspondence with the chain plate conveyor belts and umbrella pipe orientation mechanisms in one-to-one correspondence with the umbrella pipe transfer belts. An umbrella pipe storage plate for storing umbrella pipes is arranged in each umbrella pipe bin. The lower ends of the chain plate conveyor belts extend into the corresponding umbrella pipe bins. The upper ends of the chain plate conveyor belts are located above the corresponding umbrella pipe bins. Chain plates of the chain plate conveyor belts are provided with umbrella pipe storing tanks. The input ends of the umbrella pipe transfer belts are located below the upper ends of the corresponding chain plate conveyor belts. Each umbrella pipe orientation mechanism comprises an umbrella pipe baffle located above the corresponding umbrella pipe transfer belt, and a lifting air cylinder used for lifting the umbrella pipe baffle.

Owner:杭州宝桐科技有限公司

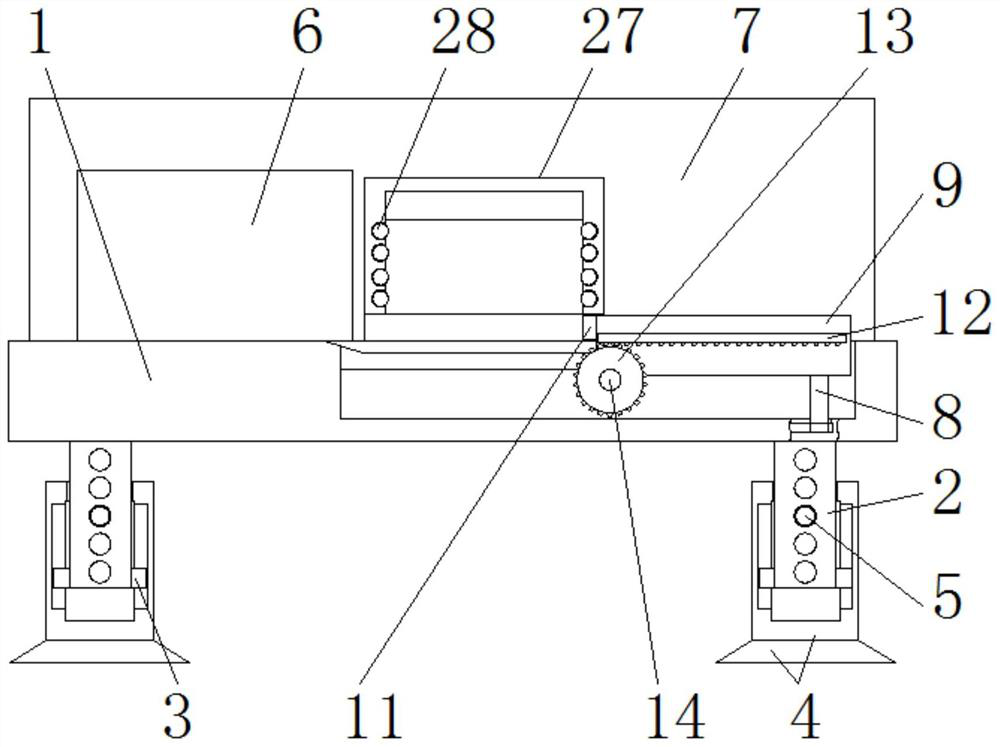

Automatic feeding device of spring grinding machine

ActiveCN110355689ASmooth swingFully protectedGrinding feed controlGrinding feedersEngineeringMechanical engineering

The invention relates to an automatic feeding device of a spring grinding machine. The automatic feeding device comprises a feeding platform, a linkage arm, a side swing arm, a movable feeding pipeline, a fixed feeding pipeline, a lifting seat, a first induction mechanism, a second induction mechanism, a lifting device and a first alarm mechanism, wherein the lifting device is arranged between thelifting seat and the feeding platform, and used for lifting the lifting seat upwards; a swing cavity penetrating through vertically is formed in the feeding platform; the linkage arm is used for linking the side swing arm with the lifting seat; the side swing arm horizontally swings in the swing cavity; a fixed feeding pipeline is arranged on the side swing arm; the two ends of the horizontal swing track of the side swing arm are respectively a first position and a second position; and when a spring to be processed is clamped between the tail end of the movable feeding pipeline and a clamp, the side swing arm is driven to swing to the second position, and the lifting seat is lifted by the lifting device to separate the spring to be processed from the clamp. By adopting the scheme, the automatic feeding device is high in feeding efficiency and capable of avoiding spring deformation and equipment damage.

Owner:TIANJIN SAIXIANG M&E ENG CO LTD

Combined guiding mechanism for annular workpieces

ActiveCN110451224ACombined transmissionReasonable structural designConveyor partsEngineeringMechanical equipment

The invention discloses a combined guiding mechanism for annular workpieces, and belongs to the field of workpiece transfer machining mechanical equipment. The mechanism is characterized in that the upper side of a conveying bracket is sequentially provided with a plurality of guiding chutes along the inclination direction, a guiding rotary shaft is sequentially, vertically and fixedly provided with a plurality of guiding rotary plates along the horizontal direction, and a pushing bracket is sequentially and uniformly provided with a plurality of bearing clamp grooves matched with the guidingchutes in sizes and specifications along the side of the conveying bracket; and a pushing piston rod of a horizontal pushing air cylinder output end is fixedly connected with the middle of one side ofthe pushing bracket, a guiding pipe is vertically and fixedly arranged on a guiding bracket on one side of a bearing bracket, and a baffler placing groove positioned on one side below the guiding pipe is internally provided with a falling baffler. The combined guiding mechanism for the annular workpieces has the advantages that structure design is reasonable, combined conveying of a plurality ofannular workpieces is achieved, and the annular workpieces can be unloaded and conveyed one by one, thus improving conveying and machining automation degree of the workpieces as well as meeting usingrequirements of machining.

Owner:滨州市沾化区蓝乔生物科技有限公司

Buffer feeding device of air valve

ActiveCN104108599AAvoid Rigid CollisionsGuarantee the quality of production and testingConveyor partsEngineeringMaterial storage

The invention provides a buffer feeding device of an air vale. Automatic feeding in the air valve production and detection process is achieved, production efficiency is improved, rigid collision between air valves in the feeding process is effectively avoided, and air valve production and detection quality is guaranteed. The buffer feeding device of the air vale comprises material receiving plates on the two sides, the upper end of each material receiving plate is provided with a material storage rod, and then a material channel is formed. The buffer feeding device of the air vale is characterized in that rotary shafts are arranged corresponding to the lower ends of the material receiving plates, a plurality of material blocking bars are arranged on the rotary shafts, and the adjacent material blocking bars are arranged in an intersection mode.

Owner:WUXI SHUANGYI PRECISION MACHINERY

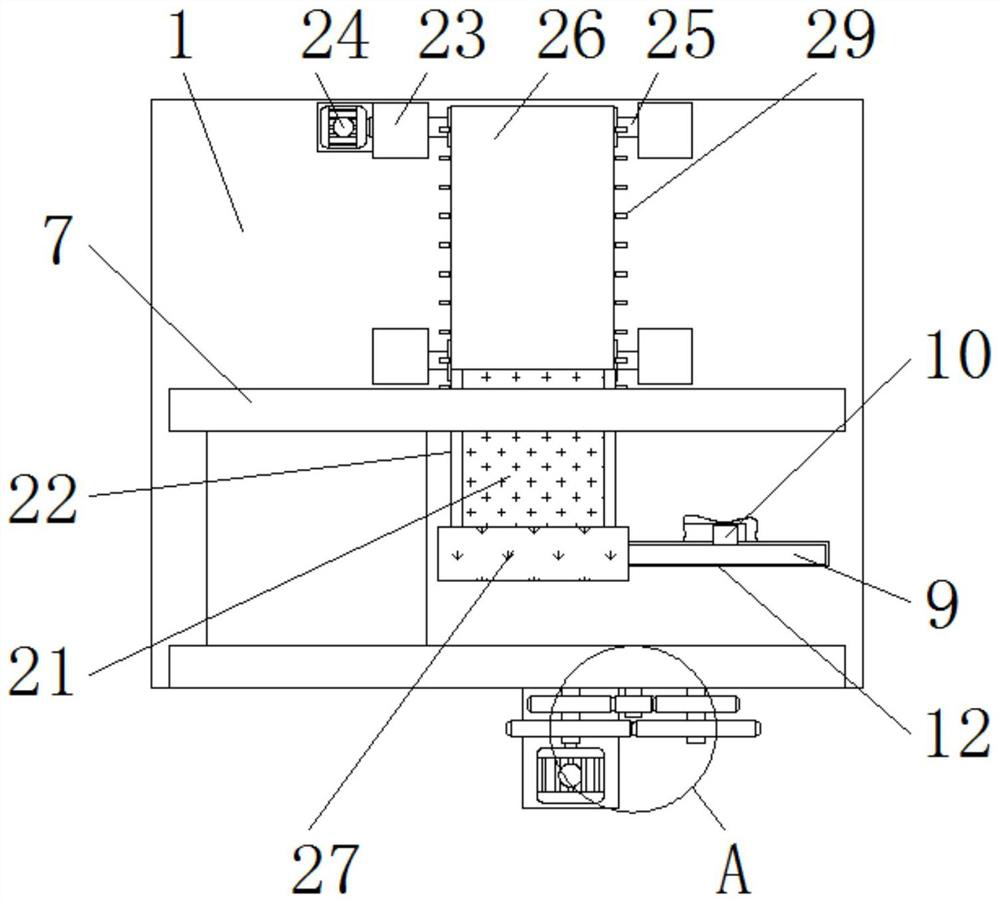

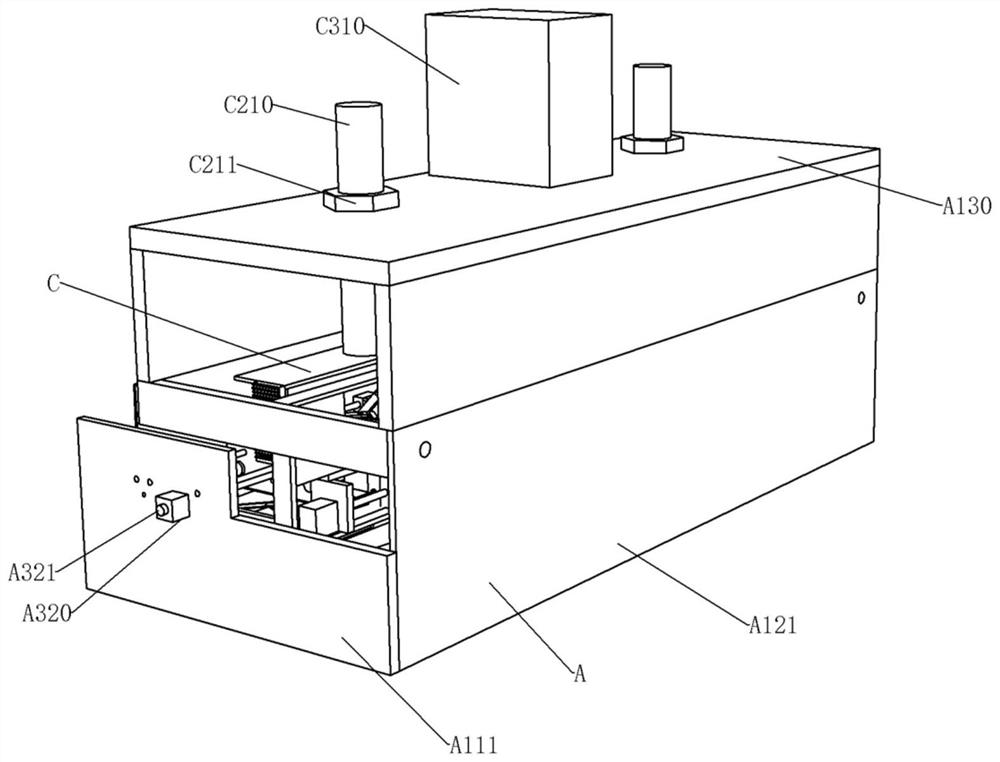

Green plum sorting production line and sorting method

ActiveCN110584164AHigh economic valueHigh sorting productivityClimate change adaptationSortingProduction lineEngineering

The invention discloses a green plum sorting production line and a sorting method. The green plum sorting production line comprises a cleaning module, a feeding module, a blow-drying module, a discharging module, a weighing module and a sorting module, wherein the cleaning module comprises a water tank; an oblique bevel is arranged in the water tank; the feeding module comprises a feeding conveyorbelt; the feeding conveyor belt is arranged in a sloped manner; a plurality of feeding baffle plates are uniformly arranged on the feeding conveyor belt; the blow-drying module comprises a sieve plate; the lower end of the sieve plate extends to the discharging module; the discharging module comprises a rotary discharging device and a discharging conveyor belt; and the weighing module comprises aplurality of weighing machines and a weighing conveyor belt. Through the adoption of the green plum sorting production line which integrates cleaning, feeding, blow-drying, discharging, weighing andsorting of green plums provided by the invention, the green plums processed by the production line can be sorted according to quality and weight, so that deep processing can be further performed on the green plums of different quality and different weight to increase the economic value of the green plums; and the sorting production efficiency is high, and the labor cost is low.

Owner:NANJING FORESTRY UNIV

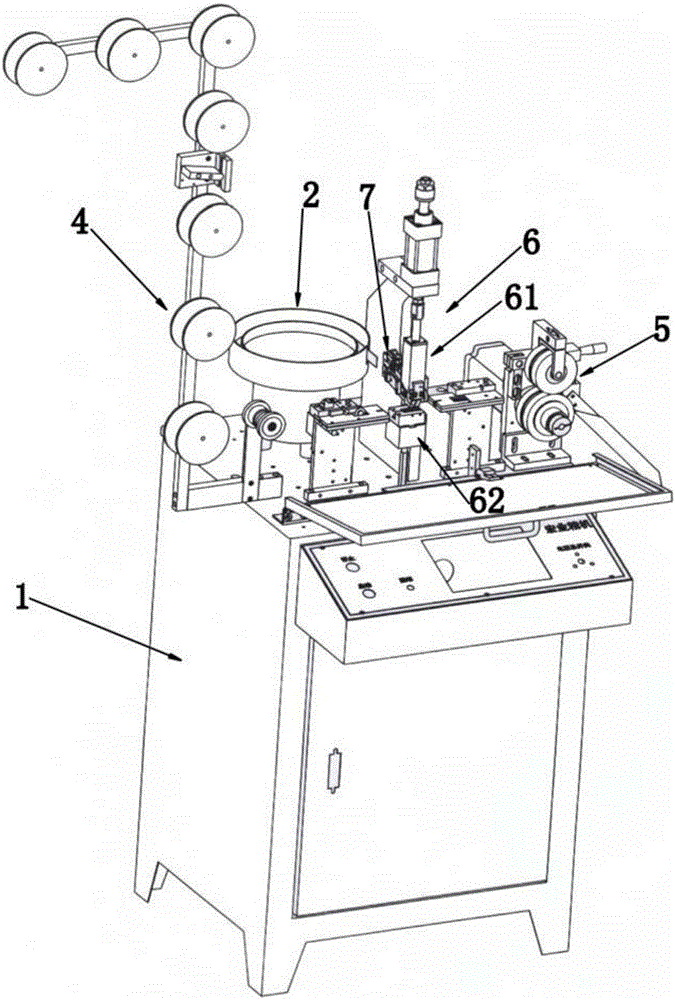

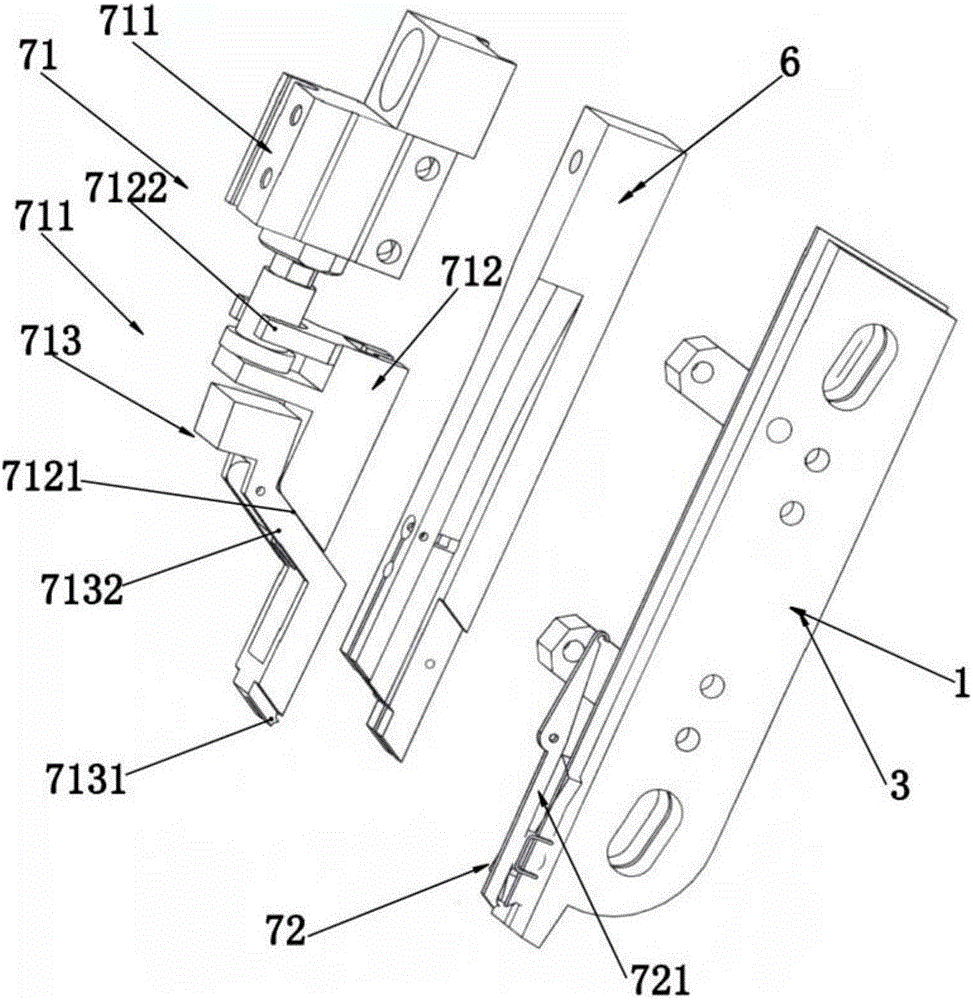

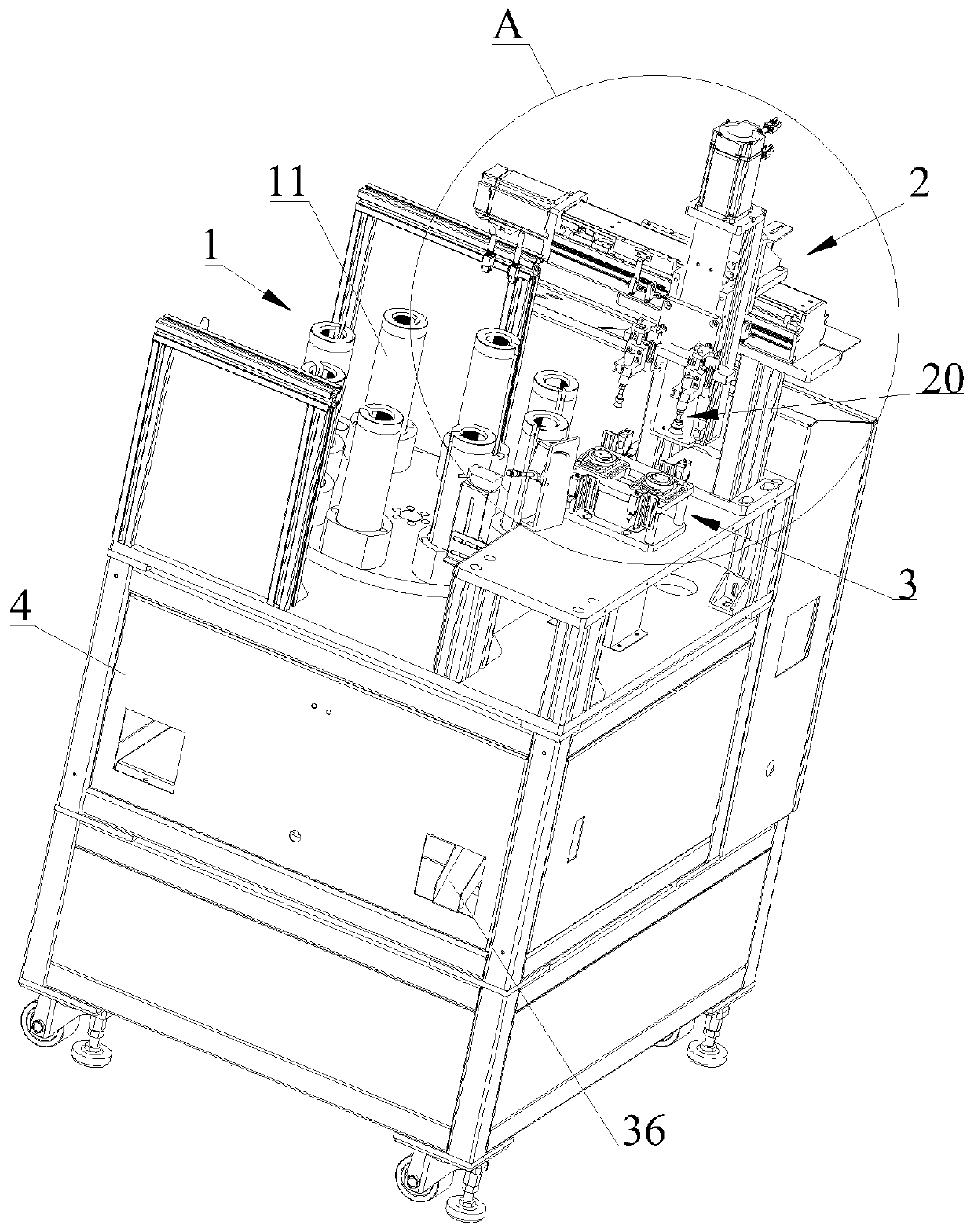

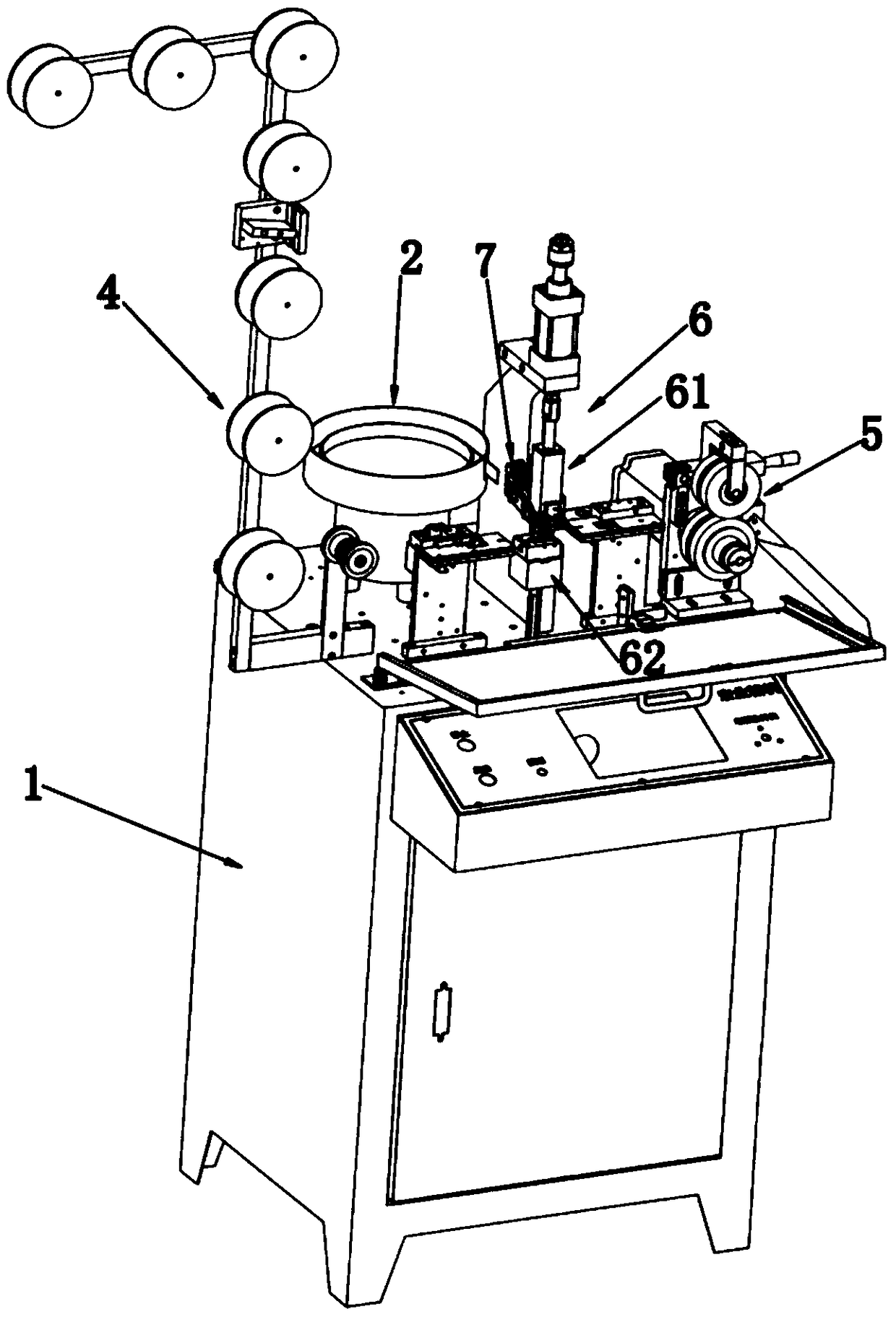

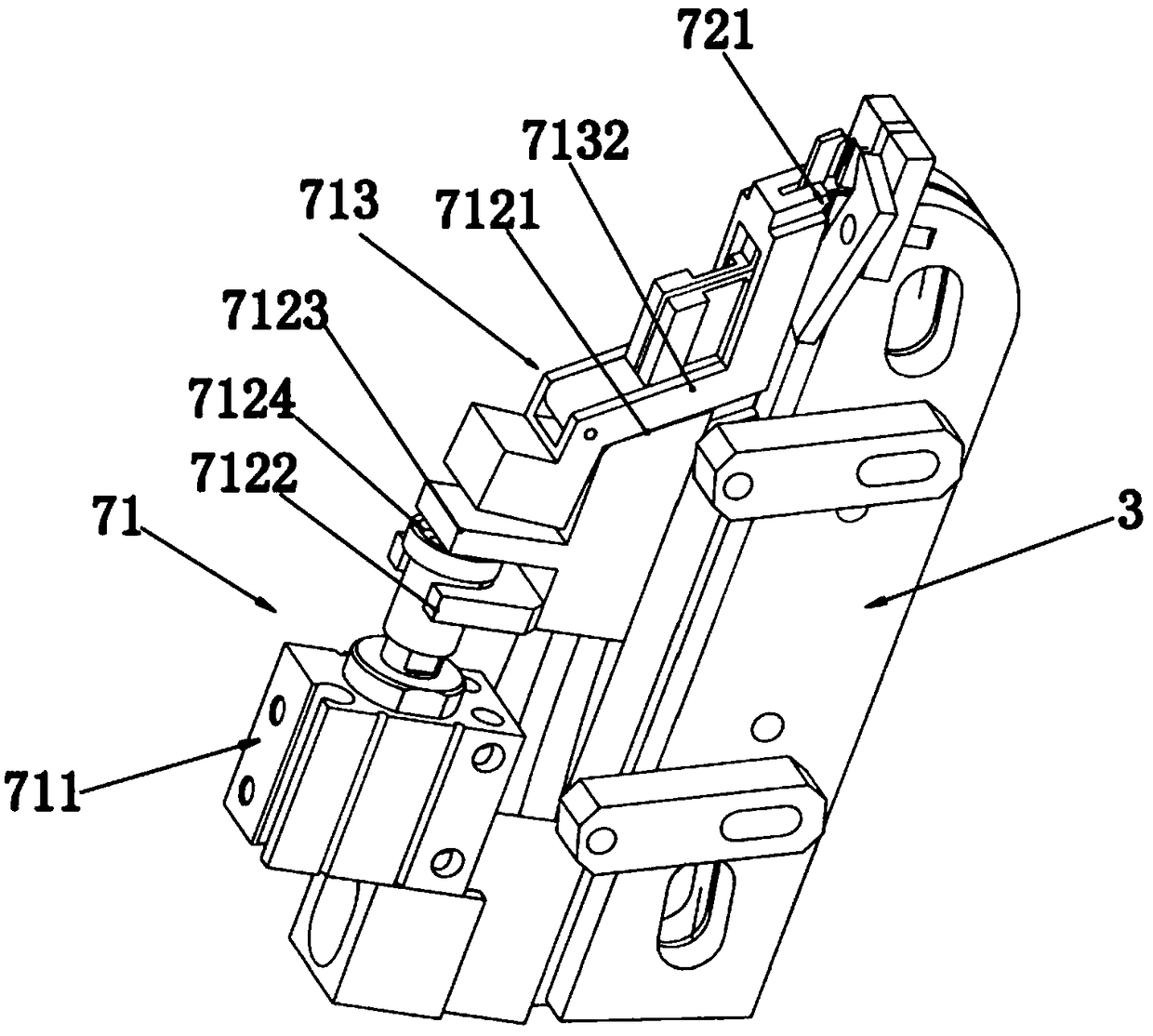

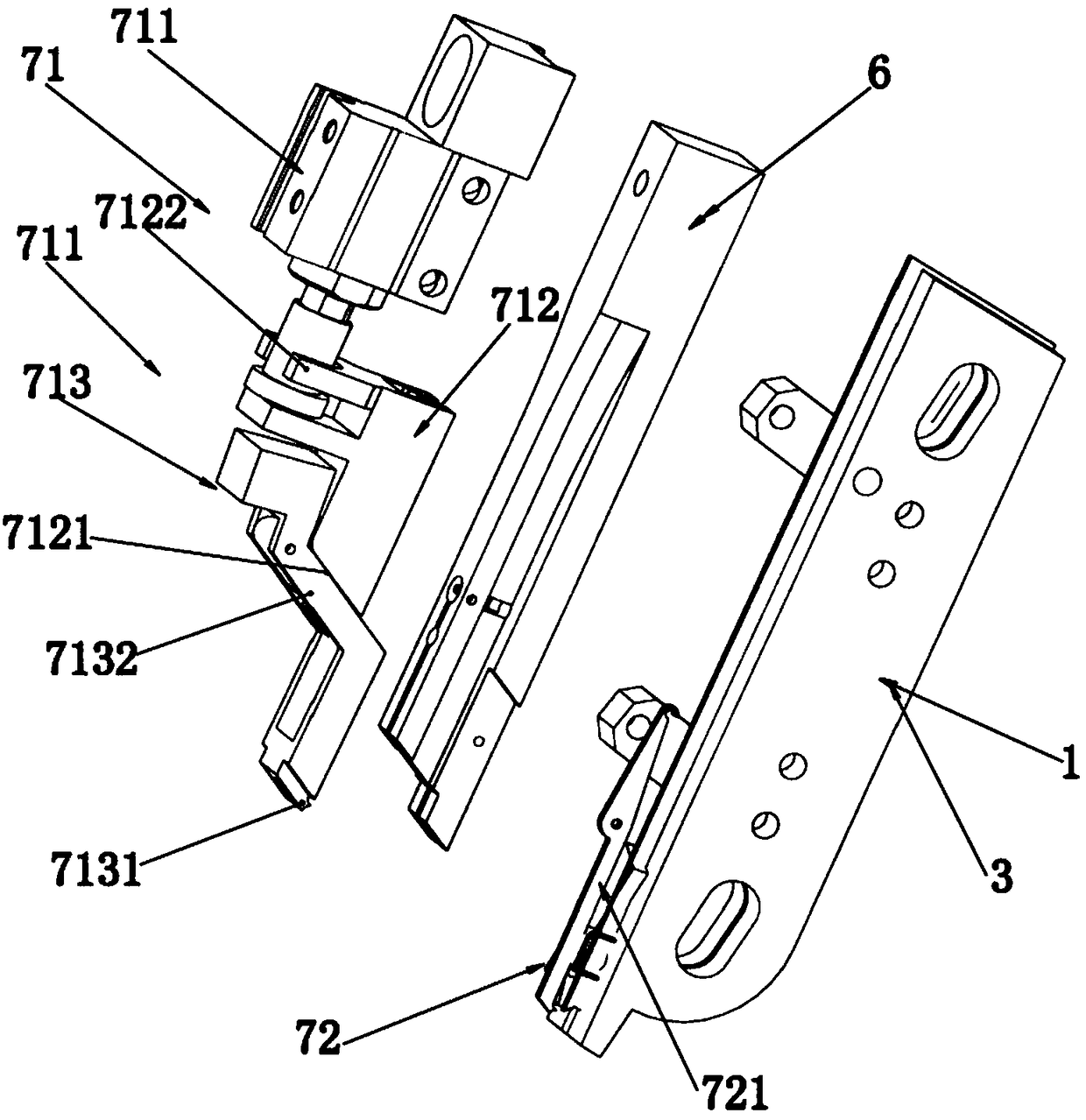

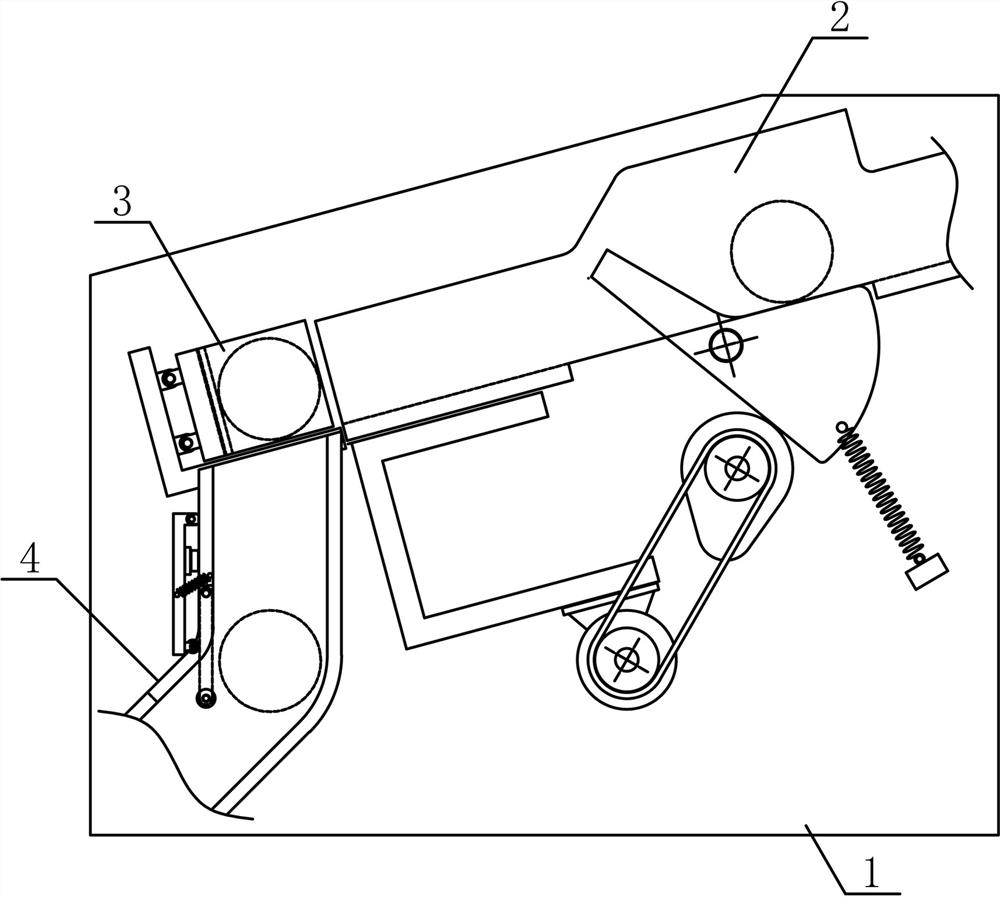

Full-automatic conceal zipper movable code loading equipment

The invention relates to zipper code loading equipment, in particular to full-automatic conceal zipper movable code loading equipment. According to the technical scheme, the full-automatic conceal zipper movable code loading equipment comprises a machine body, a vibration tray, a limiting code conveying rail, a zipper belt conveying mechanism, a zipper belt traction mechanism and a punching code loading mold; a limiting code conveying assembly is arranged between the limiting code conveying rail and the punching code loading mold, and includes a limiting code one-by-one feeding and positioning device and a limiting code limiting device; the limiting code limiting device includes a clamping bar erected on the limiting code conveying rail and suffered from external force to swing on the limiting code conveying rail; and the limiting code one-by-one feeding and positioning device includes a driving source erected above the limiting code conveying rail, a slide base and a clamping arm hinged with the slide base. By means of the technical scheme, the full-automatic conceal zipper movable code loading equipment urges limiting codes to enter the mold one by one in sequence, and is simple in structure and high in sensitivity.

Owner:WENZHOU HONGYE PRECISE MACHINERY

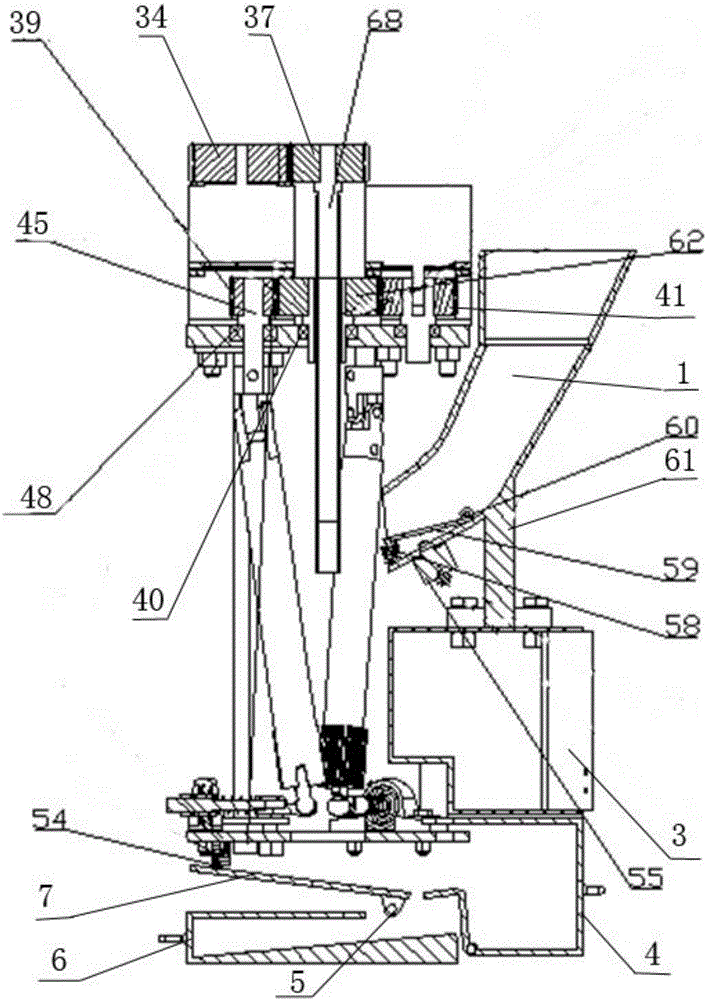

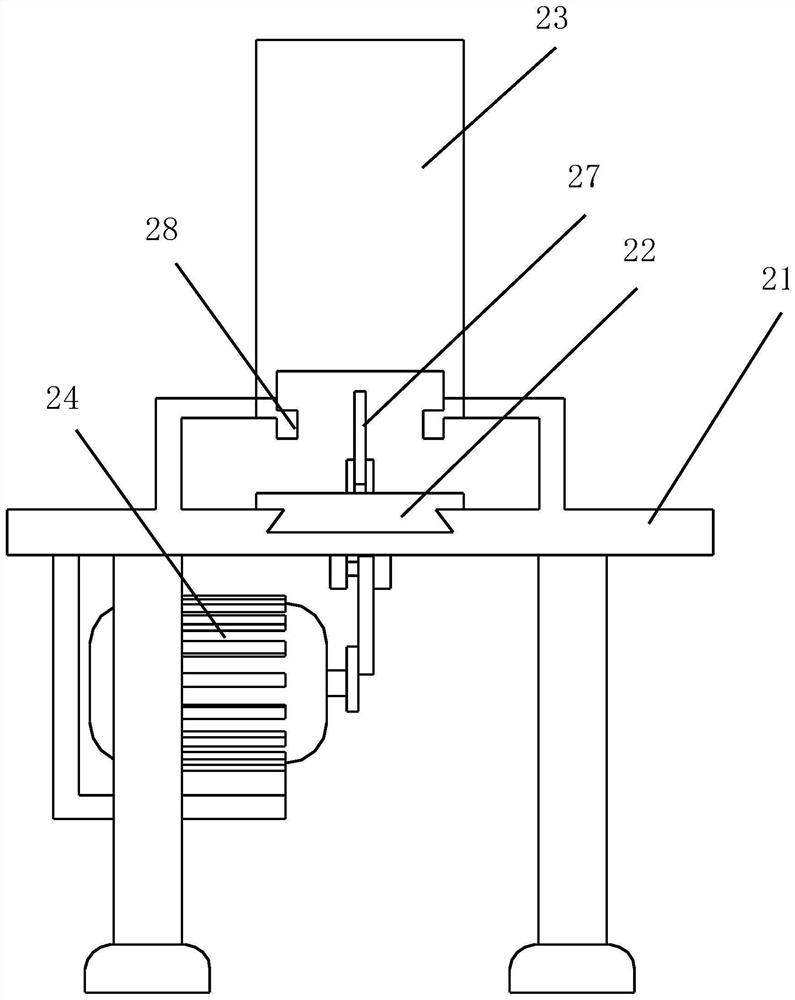

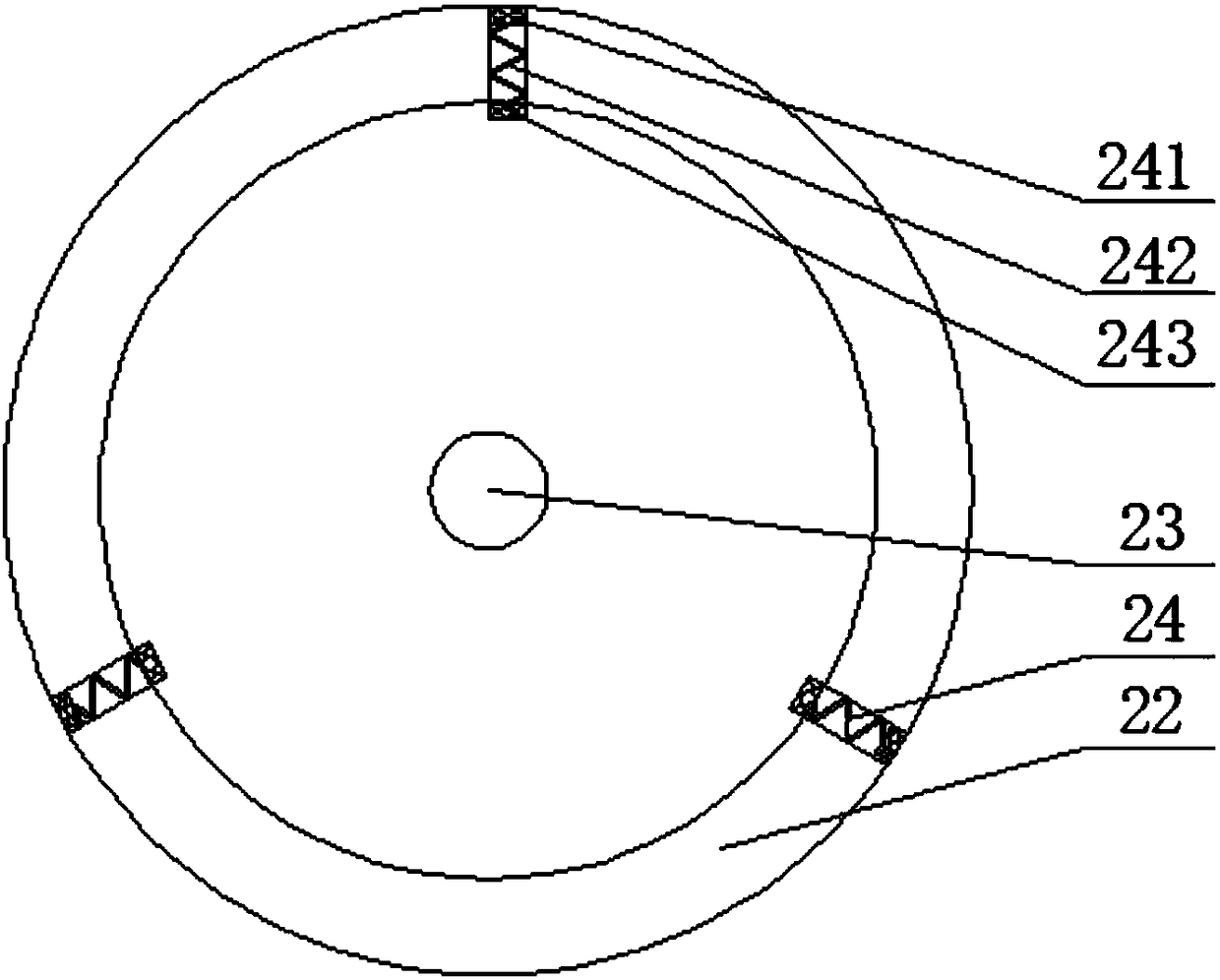

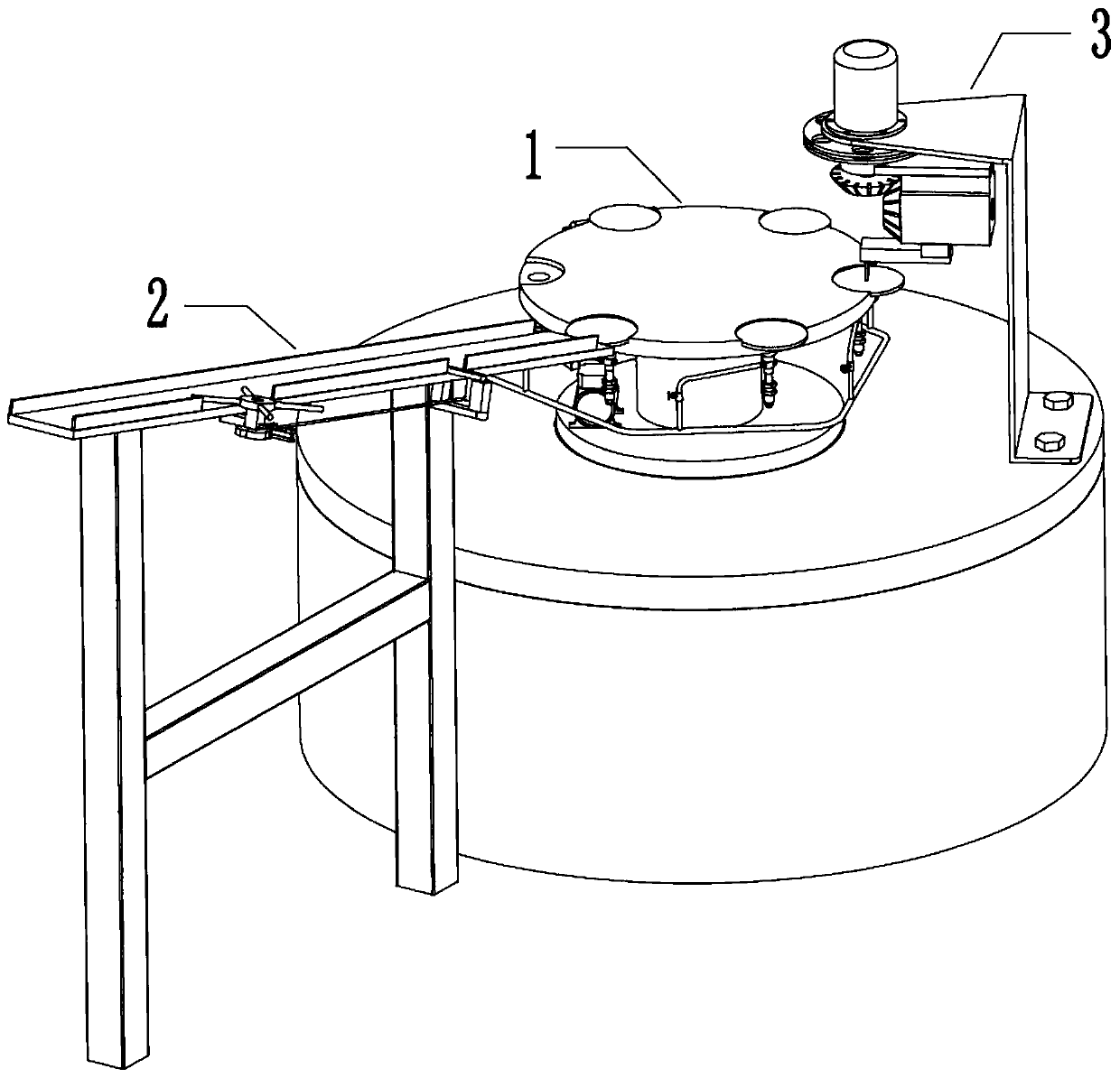

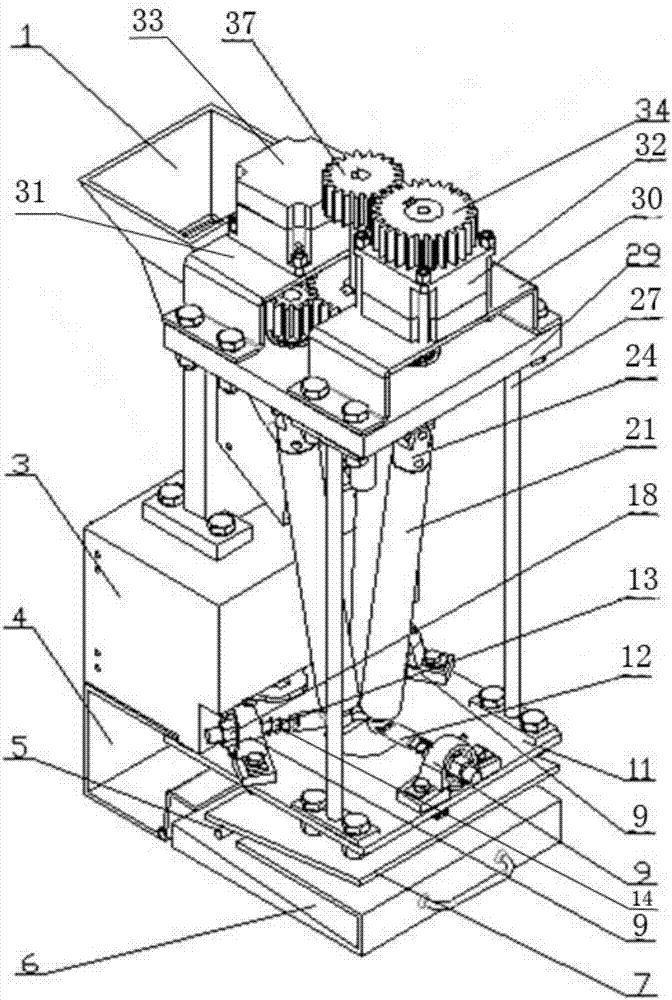

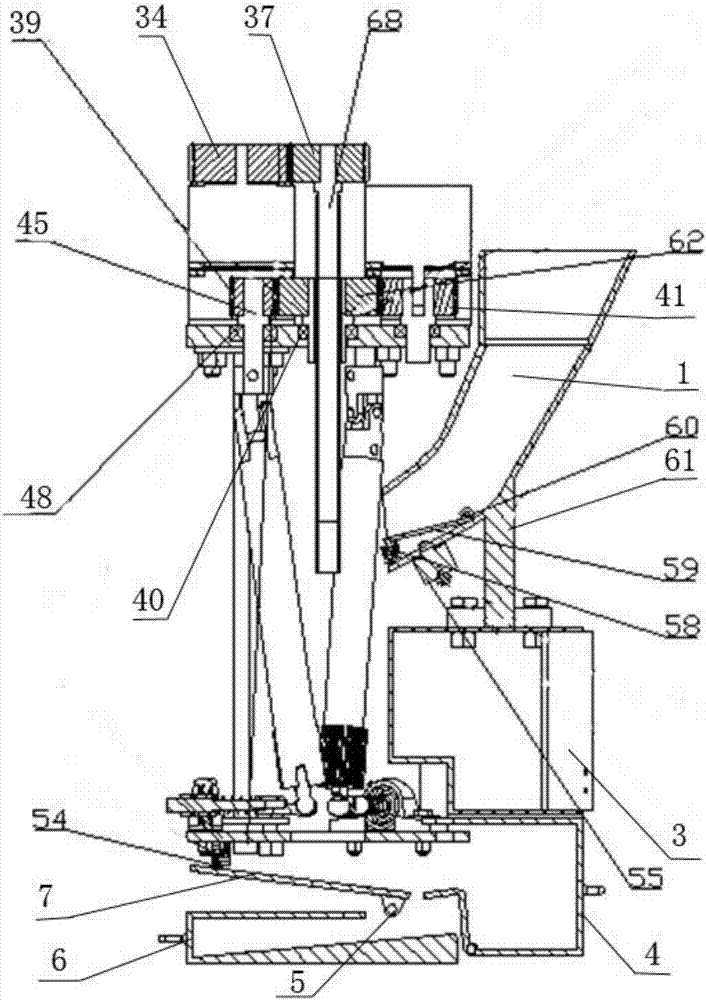

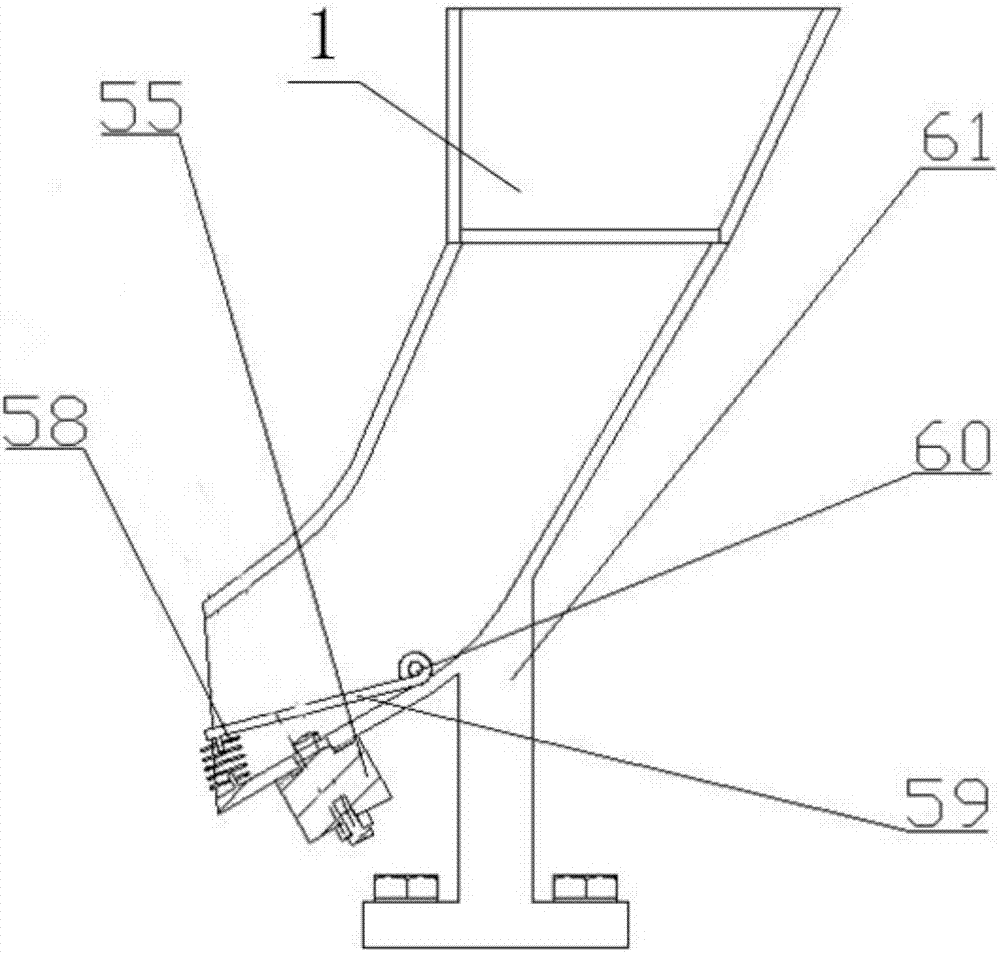

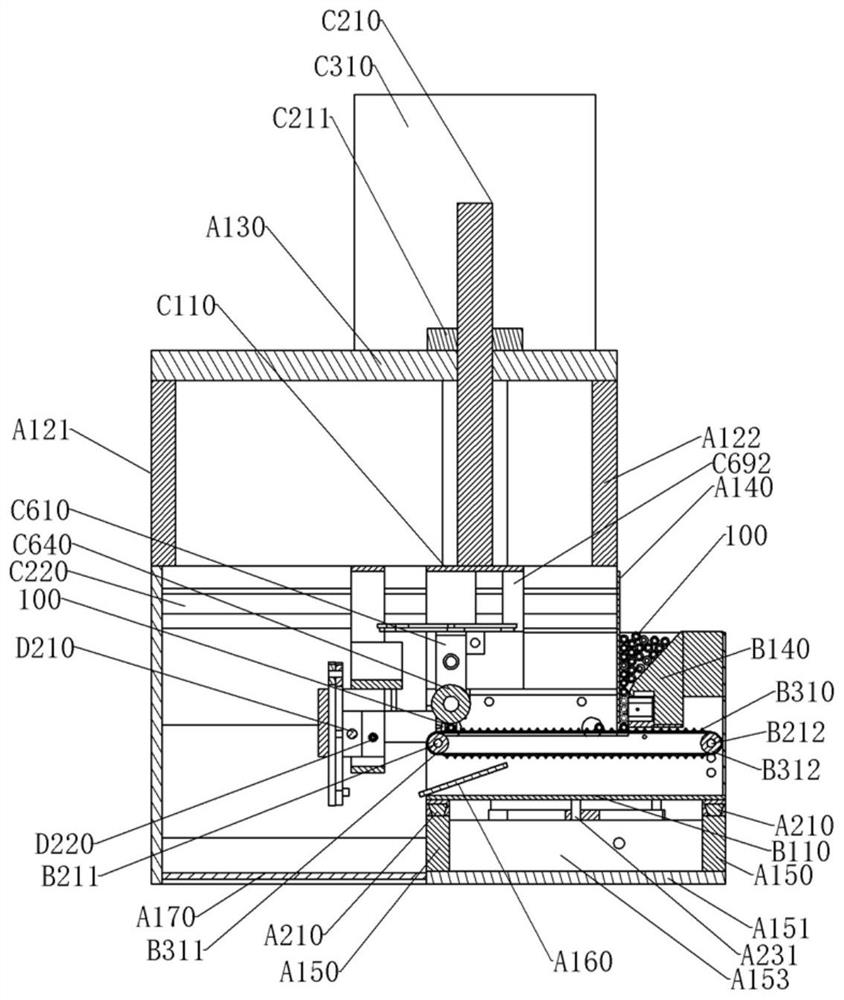

Pitting machine for green jujubes

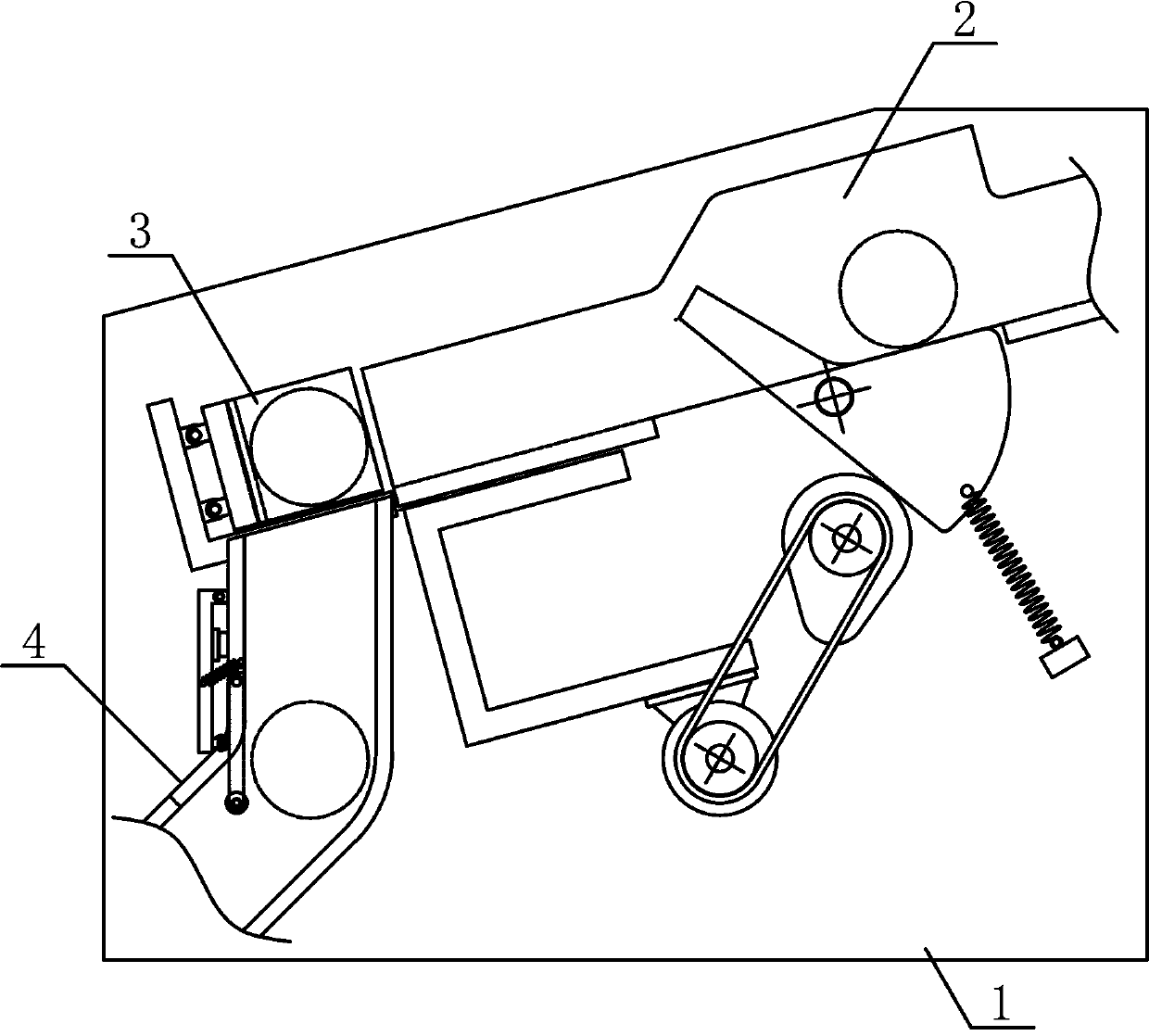

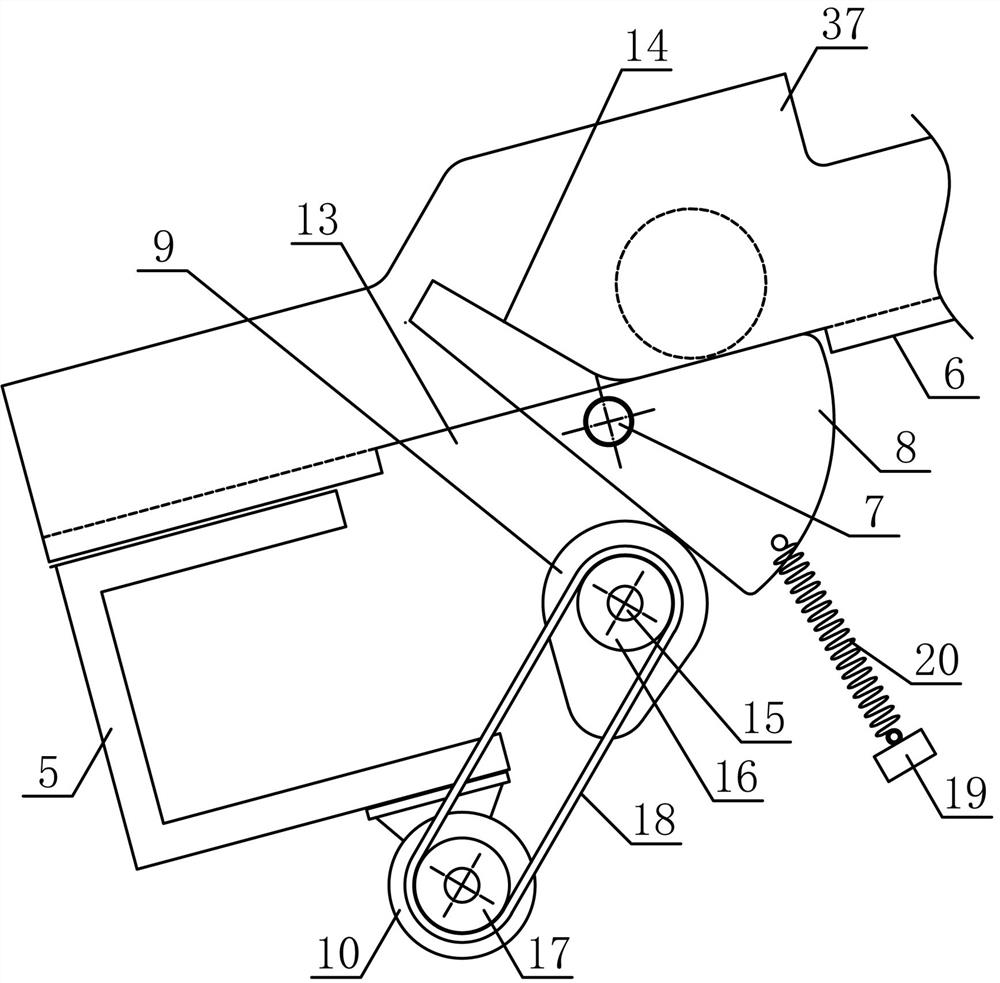

InactiveCN105942543ARealize feeding one by oneAccurate and fast sequence positioningFruit stoningEngineeringElectric control

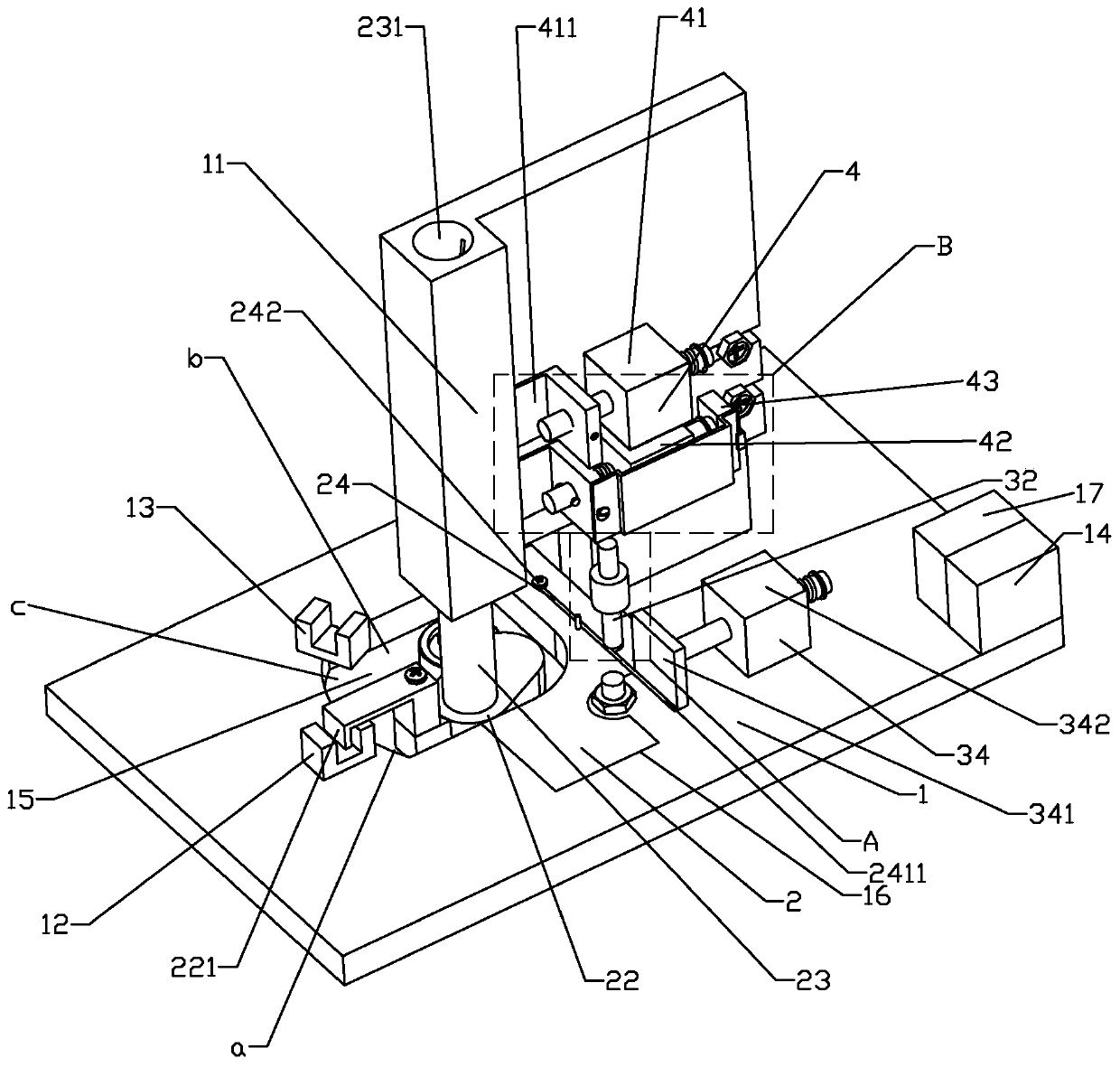

The invention discloses a pitting machine for green jujubes. The pitting machine comprises a sequencing system, a power system located at the top of the sequencing system, a discharge system located at the bottom of the sequencing system, an electric control cabinet, a feeding system and a pitting system. The electric control cabinet, the feeding system and the pitting system are located on one side of the sequencing system. The pitting machine for green jujubes has following beneficial effects: an intermittent mechanism is adopted for feeding so that jujubes can be fed one by one; jujubes are accurately and rapidly sequenced and located; by limiting nuts and spring structures, sequencing and pitting of differently-sized jujubes are achieved; the pitting machine for green jujubes has a wide application scope; a hollow sleeve rod structure is utilized for pitting; the structure is simple; the pitting machine is used conveniently, practically and efficiently; ADAMS emulation verification and experimental verification are obtained so that the pitting machine for green jujubes can accurately and vertically sequence green jujubes within one second; after sequencing and pitting, green jujubes have complete shapes and waste of jujube flesh is little.

Owner:嘉善宁远农业开发有限公司

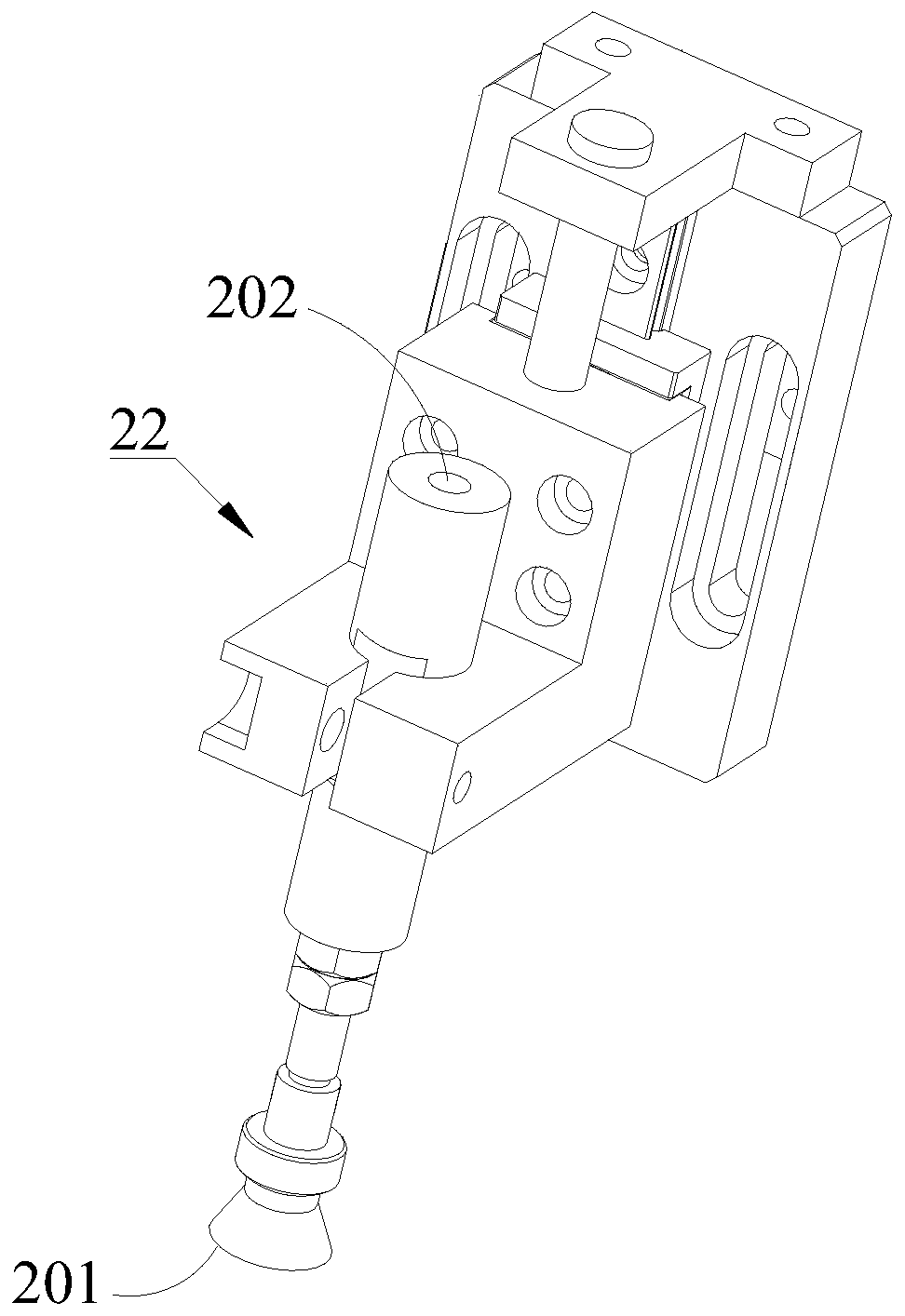

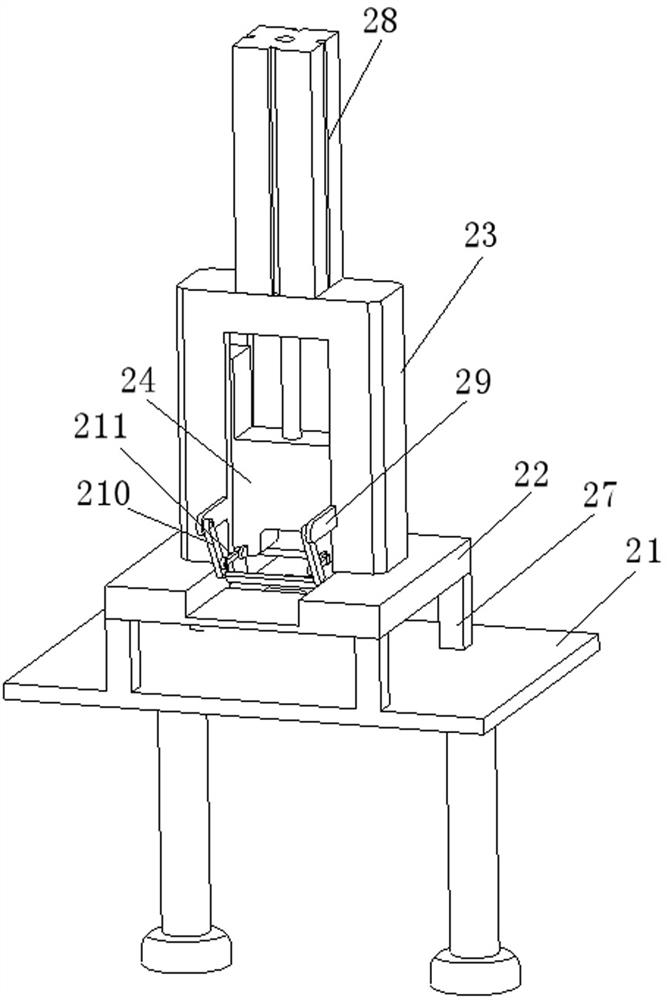

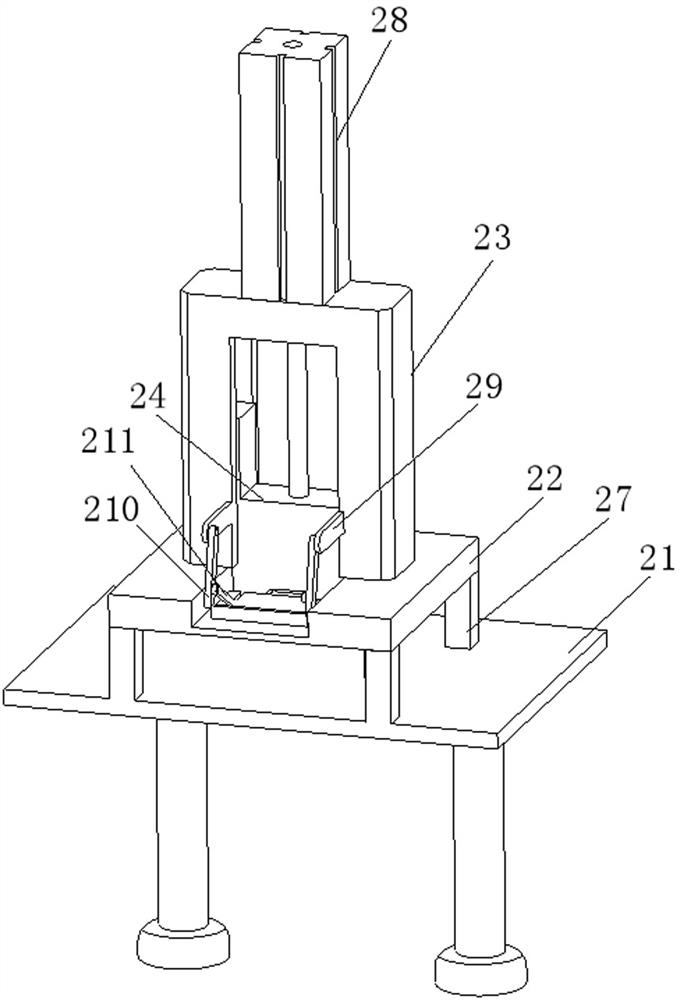

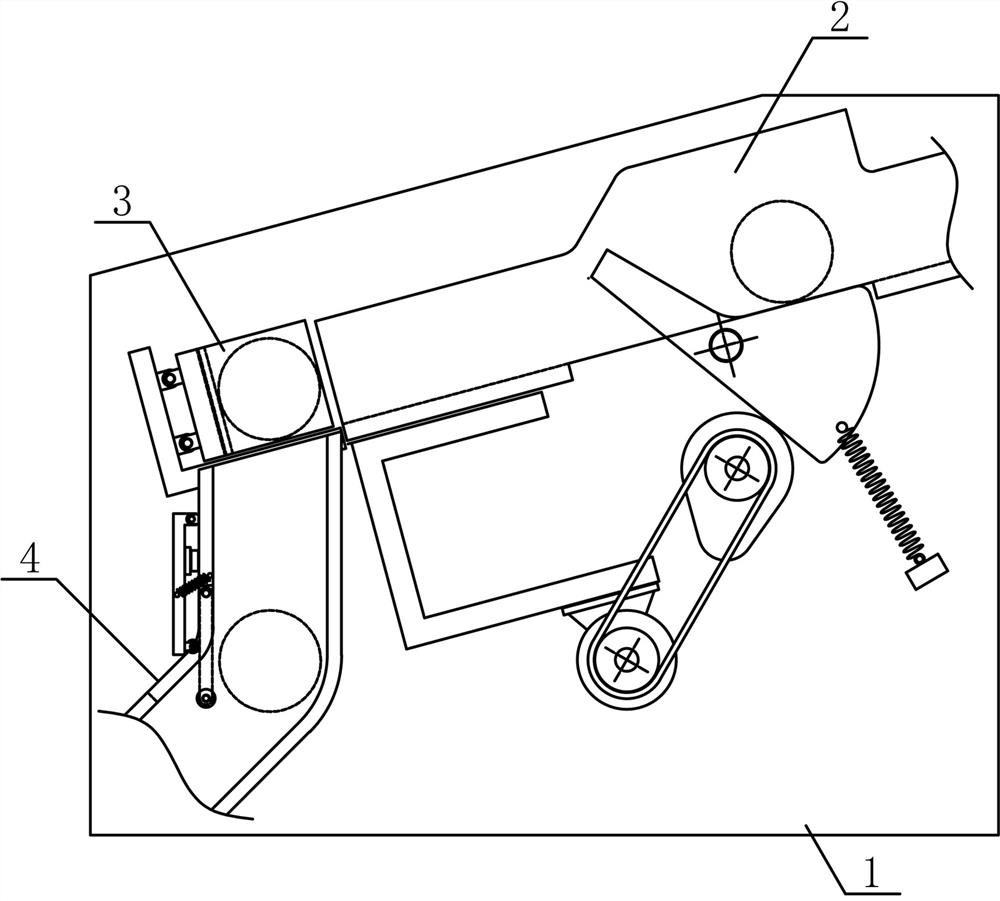

Feeding device for loudspeaker dust caps

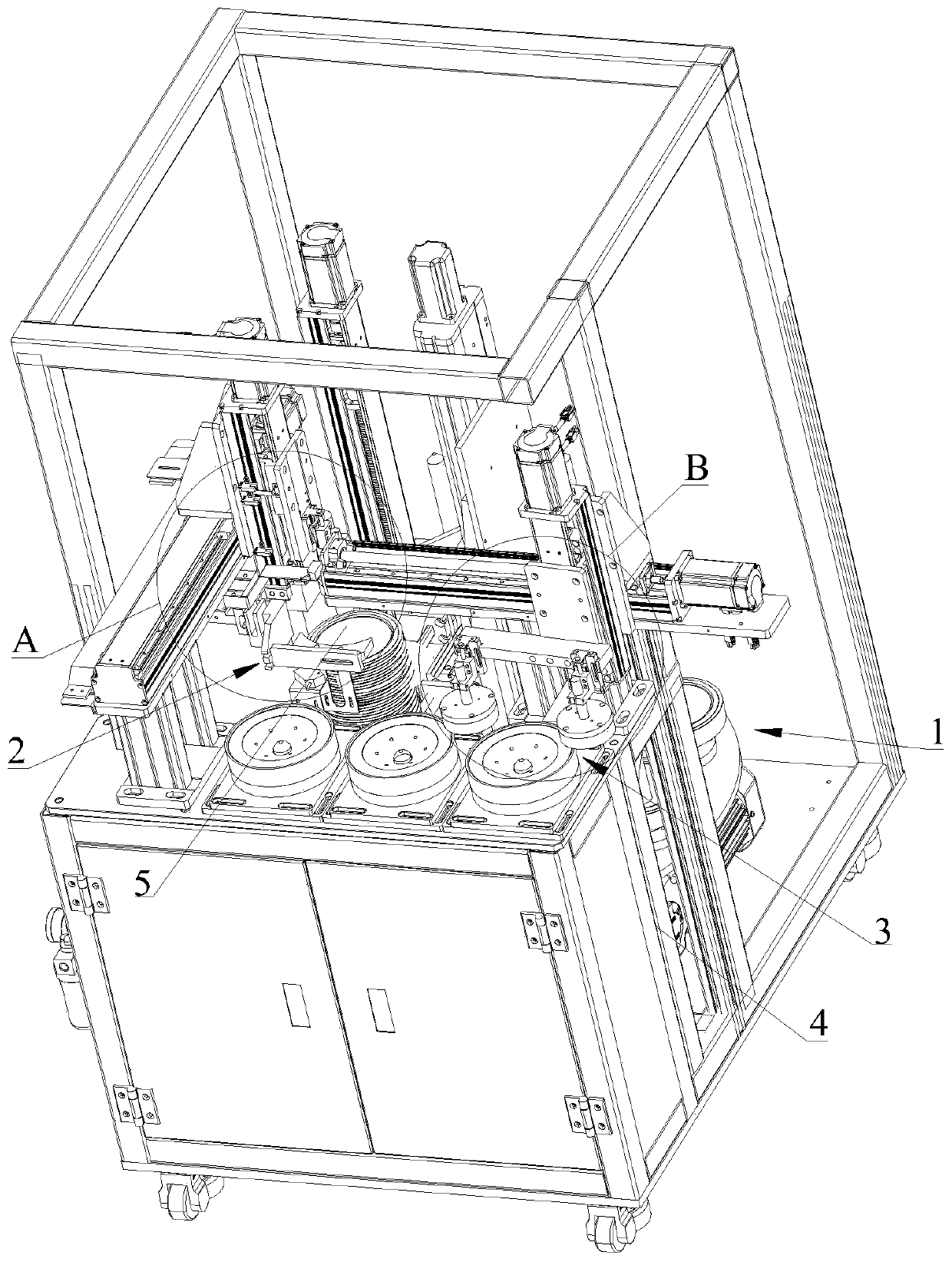

PendingCN111302052ARealize feeding one by oneImprove assembly yieldElectrical transducersDe-stacking articlesEngineeringReclaimer

The invention discloses a feeding device for loudspeaker dust caps. The feeding device includes a material storage mechanism, a material taking mechanism and a material distributing mechanism; the material storage mechanism includes at least one stock bin for storing a plurality of up and down stacked dust caps, and the upper end of the stock bin is open; the material taking mechanism includes a movable material taking assembly for taking the upper dust caps from the stock bin; and the material distributing mechanism includes at least one material support for placing the dust caps transportedby the material taking assembly for feeding; and the material distributing mechanism has a material distributing state, and when the material distributing mechanism is in the material distributing state, the material support has negative pressure for absorbing the dust caps. The feeding device for the loudspeaker dust caps can realize the separate feeding of the loudspeaker dust caps one by one.

Owner:SUZHOU SONAVOX ELECTRONICS

Feeding mechanism

InactiveCN106241337AImprove feeding effectRealize feeding one by oneConveyor partsRotating discConstant speed

The invention discloses a feeding mechanism and belongs to the field of feeding mechanisms. The feeding mechanism comprises a feed inlet and a discharge outlet. A conveying channel is formed between the feed inlet and the discharge outlet. In the conveying direction of the conveying channel, a fixed side wall is arranged on one side of the conveying channel, and a movable side wall capable of moving circularly is arranged on the other side of the conveying channel. Separating plates are arranged on the side, facing the conveying channel, of the movable side wall at intervals. The conveying channel is divided into a buffering section and a feeding section in sequence from the feed inlet to the discharge outlet. In the buffering section, the distance between the fixed side wall and the movable side wall is gradually decreased in the conveying direction of the conveying channel. The feeding mechanism can feed products one by one at a constant speed; the problem that the products are accumulated at the feed inlet can be effectively solved; and compared with a rotating-disc type material taking mode, the extrusion force on the products in the material taking process can be greatly lowered, and the products are protected against damage.

Owner:CHENGDU HONGRUI TECH

Blocking cap feeding mechanism used for battery processing

The invention relates to a blocking cap feeding mechanism used for battery processing. The blocking cap feeding mechanism comprises a feeding rack, a vibration feeding disc and a feeding trough. A feeding interception air cylinder and a feeding clamping air cylinder are arranged on the portion, located below the feeding trough, of the feeding rack. A feeding interception inserting block capable ofpenetrating through an interception opening formed in a lower bottom plate of the feeding trough is connected to the feeding interception air cylinder. A feeding clamping device capable of penetrating through a clamping opening formed in the lower bottom plate of the feeding trough is connected to the upper portion of the feeding clamping air cylinder, and the size of the clamping opening is consistent with that of an inner hole of a blocking cap. The feeding clamping device cooperates with an inner hole of a second blocking cap intercepted by the feeding interception inserting block in an inserted and sleeved manner. A feed device cooperates with a first blocking cap intercepted by the feeding interception inserting block is arranged above the feeding rack. According to the blocking capfeeding mechanism, a conveying trough cooperates with the feeding interception inserting block and the feeding clamping device at the same time, interception is achieved, meanwhile, blocking caps except for the first blocking cap are clamped, the blocking caps descend by cooperating with the feed device and the feeding interception block, and the single blocking caps are fed one by one.

Owner:DONGGUAN UNIV OF TECH

Automobile buckle stamping device

ActiveCN112893681ARealize automatic stampingStamping precisionMetal-working feeding devicesVehicle componentsStructural engineeringIndustrial engineering

The invention discloses an automobile buckle stamping device, and belongs to the technical field of stamping equipment. The automobile buckle stamping device comprises feeding equipment and stamping equipment, wherein the feeding equipment is arranged on the right side of the stamping equipment, and the stamping equipment comprises a stamping base, a stamping plate, a stamping shell, an upper stamping die, a lower stamping die and a feeding plate; when the feeding equipment conveys buckle raw materials to the stamping plate, a stamping machine works to drive the upper stamping die to slide upwards in the stamping shell, and at the moment, the feeding plate works to push the buckle raw materials on the stamping plate to the top of the lower stamping die; and the stamping machine reversely works to drive the upper stamping die to move downwards to be matched with the lower stamping die to complete stamping, at the moment, the feeding plate is reset, during repeated work, the feeding plate drives the next buckle raw material to move to the top of the lower stamping die, the stamped automobile buckle is extruded out of the lower stamping die, and automatic stamping is achieved.

Owner:湖北天成汽车配件有限公司

Round hole spacing detection device for machining

InactiveCN112161596AImprove feed structureRealize feeding one by oneMeasurement devicesStructural engineeringMachining

The invention provides a round hole spacing detection device for machining, relates to the technical field of detection devices, and solves the problems that continuous detection cannot be realized through structural improvement, and continuous feeding and continuous detection are in mutual linkage work in the continuous detection process. And rapid adjustment of the detection head and automatic locking after adjustment cannot be realized through structural improvement. The invention discloses a round hole spacing detection device for machining. The device comprises a mounting main body, a material storage barrel is installed on the mounting main body, material plates are stacked in the material storage barrel, and a detection structure is installed on the material storage barrel. Two limiting blocks are welded on the mounting main body; a feeding block comprises a rectangular block, two rectangular blocks are symmetrically welded to the feeding block, when the elastic piece elastically stretches, the two rectangular blocks make contact with the limiting block, the head end of the feeding block is flush with the tail end of the limiting block at the moment, so that accurate feedingof the material plate is achieved.

Owner:李庆磊

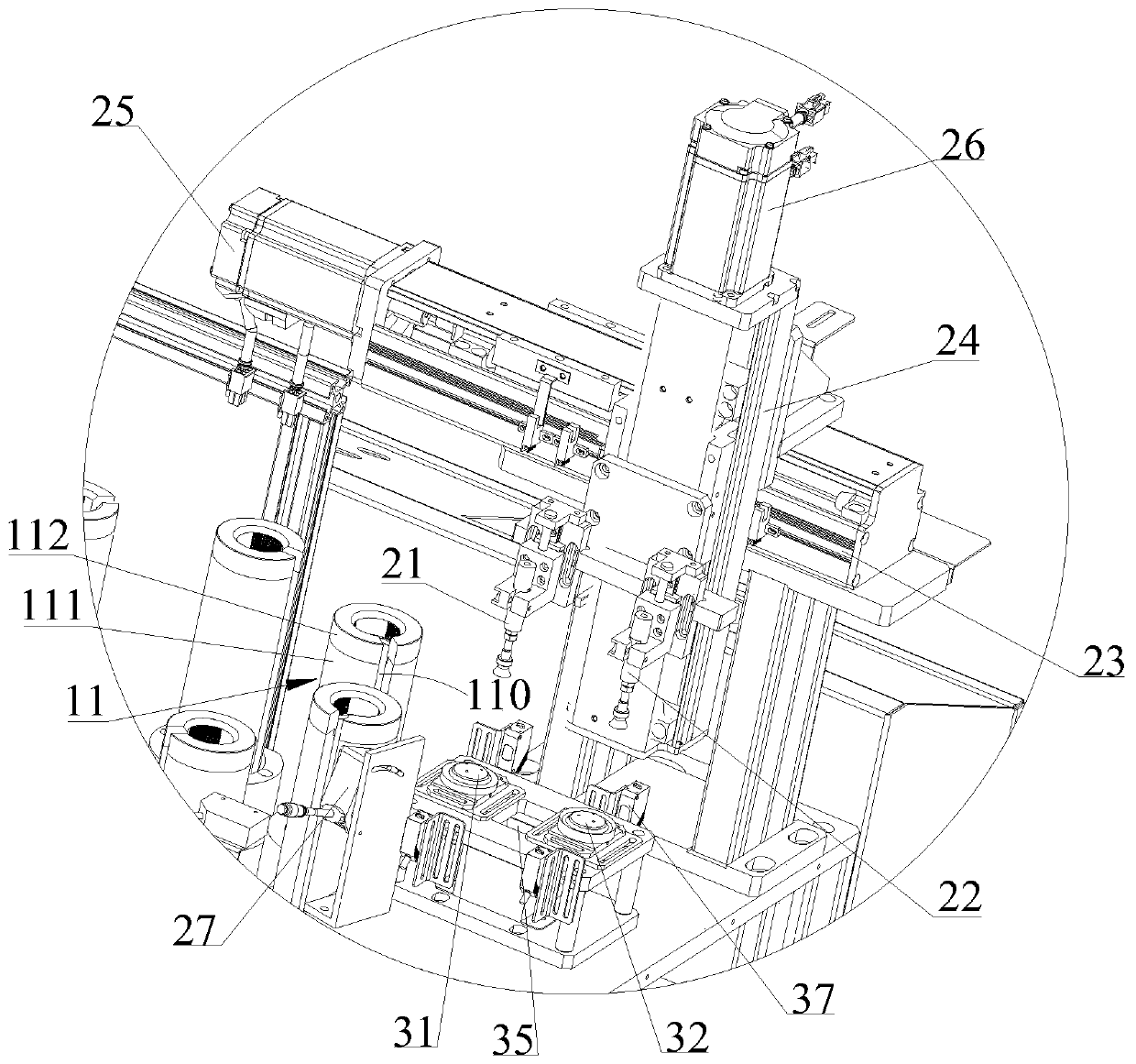

Automatic device used for assembling component provided with magnetic ring

The invention relates to the technical field of automatic devices, in particular to an automatic device used for assembling a component provided with a magnetic ring. The automatic device comprises aconveying line, a plastic base feeding mechanism, a magnetic ring feeding mechanism, a magnetic ring assembling mechanism, an end plug assembling mechanism, a hot-melting mechanism and a lock catch assembling mechanism, wherein the plastic base feeding mechanism, the magnetic ring feeding mechanism, the magnetic ring assembling mechanism, the end plug assembling mechanism, the hot-melting mechanism and the lock catch assembling mechanism are sequentially arranged on the conveying line in the assembling sequence. The magnetic ring feeding mechanism comprises a lower disc, an upper disc arrangedon the lower disc, a first driving device used for driving the upper disc to rotate, a plurality of magnetic ring tubes arranged on the upper disc and made of plastic, a discharging port formed in the lower disc and communicating with the magnetic ring tubes, a first feeding base arranged at the bottom of the lower disc, a first feeding channel formed in the first feeding base and communicating with the discharging port, a first push rod arranged in the first feeding channel, and a second driving device used for driving the first push rod to push the magnetic ring out of the first feeding channel. By the adoption of the automatic device, automatic assembling and machining of the component provided with the magnetic ring is achieved, and the assembling efficiency is high; and meanwhile, through the design of the magnetic ring feeding mechanism, magnetic rings can be fed one by one.

Owner:东莞明控自动化有限公司

Stamping die feeding device

PendingCN112588985ARealize feeding one by oneRealize unloadingMetal-working feeding devicesPositioning devicesMachineIndustrial engineering

The invention discloses a stamping die feeding device, and belongs to the technical field of stamping processing. The device comprises feeding equipment, a stamping machine and discharging equipment,wherein the feeding equipment is arranged on the right side of the stamping machine, the feeding equipment is used for feeding the stamping machine, and the discharging equipment is arranged on the left side of the stamping machine. The discharging equipment is used for discharging materials subjected to the stamping procedure. The technical problems that in the prior art, to-be-machined materialscannot be sequentially fed one by one, and if a stamping machine breaks down, a feeding device may be affected are solved.

Owner:德清县宝华氟塑料工贸有限公司

Household paper conveying device

InactiveCN108127713ARealize the function of cutting paper rollRealize automatic alternate continuous cuttingMetal working apparatusPaper productionPulp and paper industry

The invention discloses a household paper conveying device and belongs to the field of household paper production equipment. The household paper conveying device comprises a working table, a band sawpaper cutter, paper roll feeding mechanisms, a paper roll clamping mechanism, a paper roll pushing mechanism and a paper roll discharging mechanism, wherein a workbench I is arranged on the working table, a workbench II and a workbench III which are arranged in parallel are fixed on the workbench I, the band saw paper cutter is arranged at the front end of the working table in length direction, aband saw of the band saw paper cutter is longitudinally and vertically arranged on the working table and is arranged in front of the workbench II or the workbench III, the band saw is a double-faced blade band saw, a paper roll placing groove arranged along the length direction is formed in the workbench II and the workbench III respectively, and the paper roll feeding mechanisms are arranged at opposite far sides of the workbench II and the workbench III respectively. The household paper conveying device disclosed by the invention is simple, reasonable and smart in structure, has a bidirectional cutting function, can realize automatic alternate continuous cutting of two paper rolls and realizes automatic line production, so that the working efficiency is improved.

Owner:尹晓晗

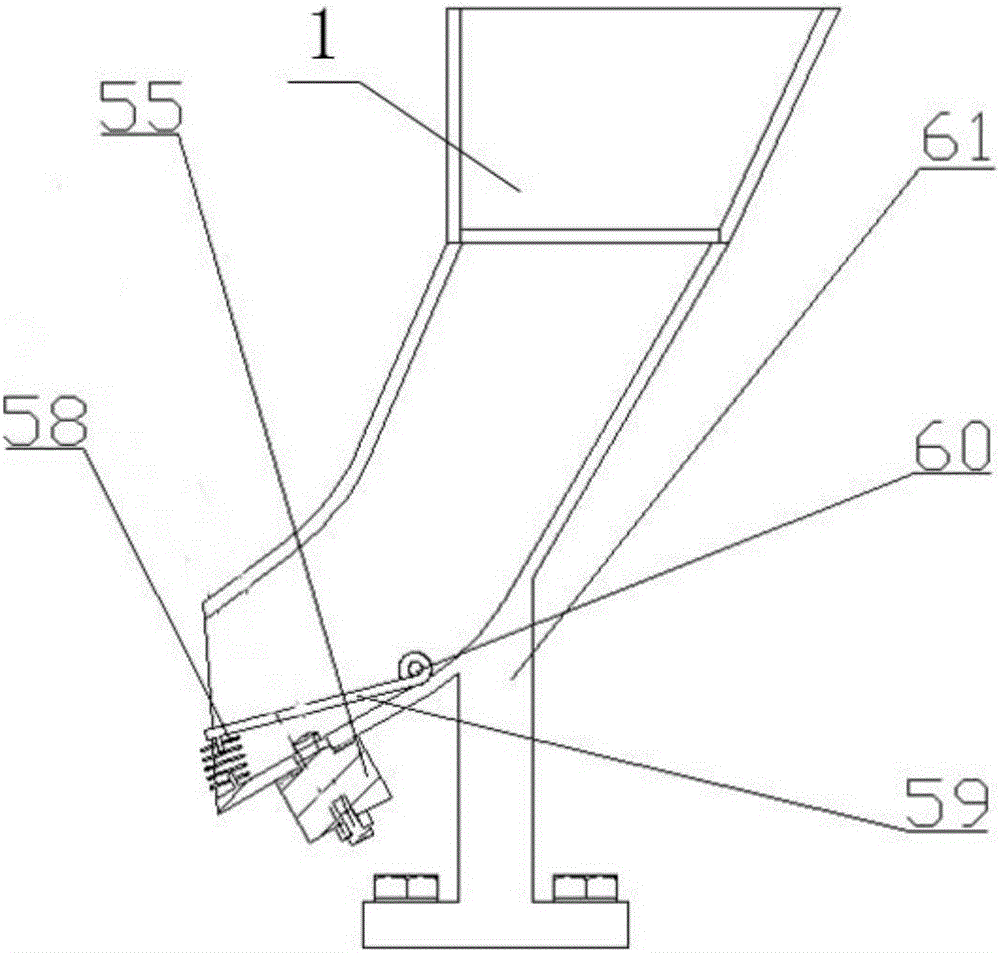

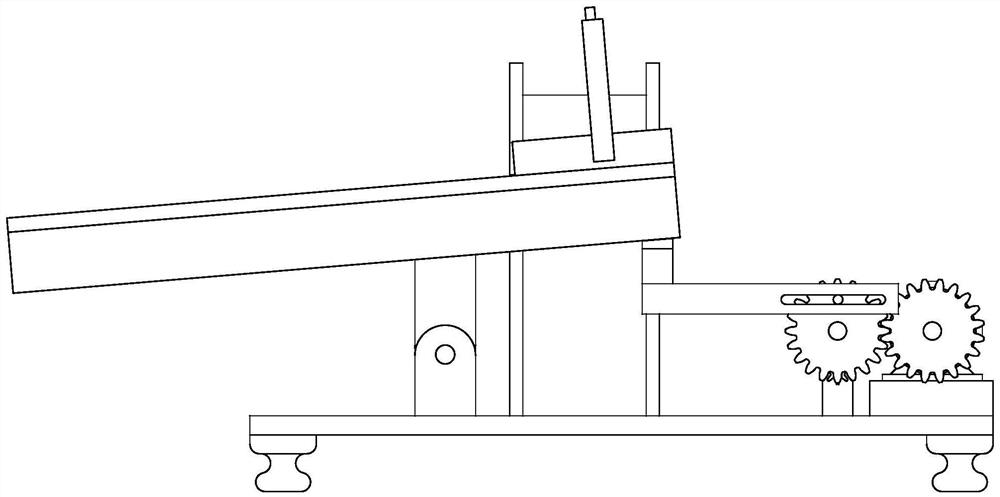

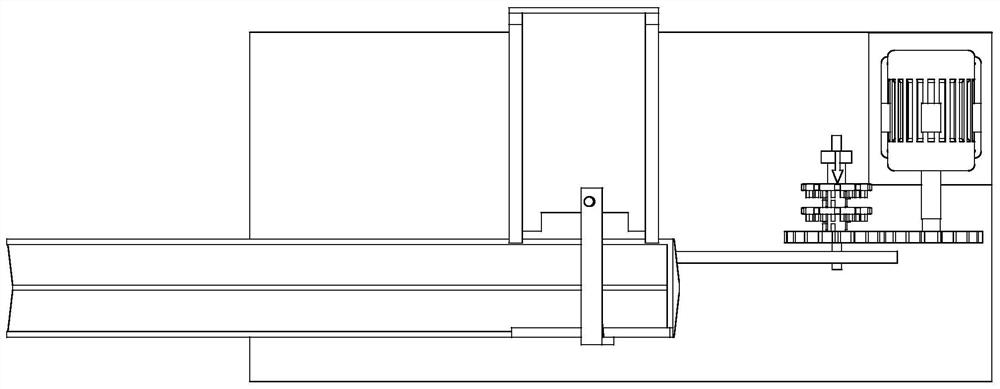

Counting type supply device for flexible mineral insulated cable product connectors

ActiveCN112693804AHigh degree of automationPracticalConveyorsControl devices for conveyorsControl theoryElectric cables

The invention relates to a counting type supply device for flexible mineral insulated cable product connectors. The counting type supply device comprises a base and a supply slideway installed on the upper left side of the base in a hinged mode. An inclined supply material passageway is installed on the rear part of the base, and the front end of the inclined supply material passageway abuts against the rear side wall of the right part of the supply slideway. A linkage block is installed at the right end of the supply slideway. The linkage block is connected with a swing driving assembly. The swing driving assembly is matched with a counting assembly. The counting type supply device is high in automation degree, and the supply slidingway can be controlled to swing to control the cable product connectors to be fed one by one; and during each time of feeding, the feeding counting function can be achieved through the manner of controlling a first rotating wheel to rotate and controlling a second rotating wheel to rotate in a carry mode, and practicability is high.

Owner:ANHUI STAR CABLE

Feeding device capable of preventing tubular parts from sliding off and used for electromechanical equipment machining

ActiveCN112124914APrevent slippingImprove work efficiencyConveyorsDe-stacking articlesStructural engineeringMachining

The invention discloses a feeding device capable of preventing tubular parts from sliding off and used for electromechanical equipment machining. The feeding device comprises a workbench, positioningnails, a supporting rod, a protective pad and a first motor, wherein adjusting rods are installed at the lower end of the workbench, limiting blocks are installed on the adjusting rods, the limiting blocks are attached to supporting bases, the positioning nails are connected with the adjusting rods, the positioning nails are connected with the supporting bases, a machining device is mounted on theworkbench, a supporting partition plate is installed on the workbench, the supporting rod and the workbench are attached to each other, and the supporting rod is installed at the lower end of a movable plate. According to the feeding device capable of preventing the tubular parts from sliding off and used for electromechanical equipment machining, the tubular parts are fed through a feeding belt,so that manual careful alignment placement is not needed any more, more convenience and quickness are achieved, the working efficiency is improved, the tubular parts are pushed and fed through rotation of rotating wheels, and the situation that the tubular parts slide off in the feeding process can be effectively avoided.

Owner:RIZHAO POLYTECHNIC

Epitaxial wafer silicon slag scraping device for LED lamp production

PendingCN111048632AEasy to scrapeCompact structureSemiconductor/solid-state device manufacturingSemiconductor devicesLight fixtureLED lamp

The invention provides an epitaxial wafer silicon slag scraping device for LED lamp production. The silicon slag scraping device comprises a multi-station workbench, a feeding mechanism and a slag scraping mechanism. The feeding mechanism and the slag scraping mechanism are arranged beside the multi-station workbench. The multi-station workbench intermittently rotates; the feeding mechanism is used for singly feeding an epitaxial wafer which is about to be subjected to slag scraping; and the slag scraping mechanism is used for rotatably scraping slag from the epitaxial wafer which is about tobe subjected to slag scraping. By the adoption of the scraping device, continuous single feeding of the epitaxial wafer which is about to be subjected to slag scraping can be performed, rotary slag scraping can be performed, the scraping device is suitable for well scraping redundant silicon slags on the surface of an existing epitaxial wafer, an overall structure is compact, and working efficiency is high.

Owner:TIANJIN TIANXING ELECTRONICS

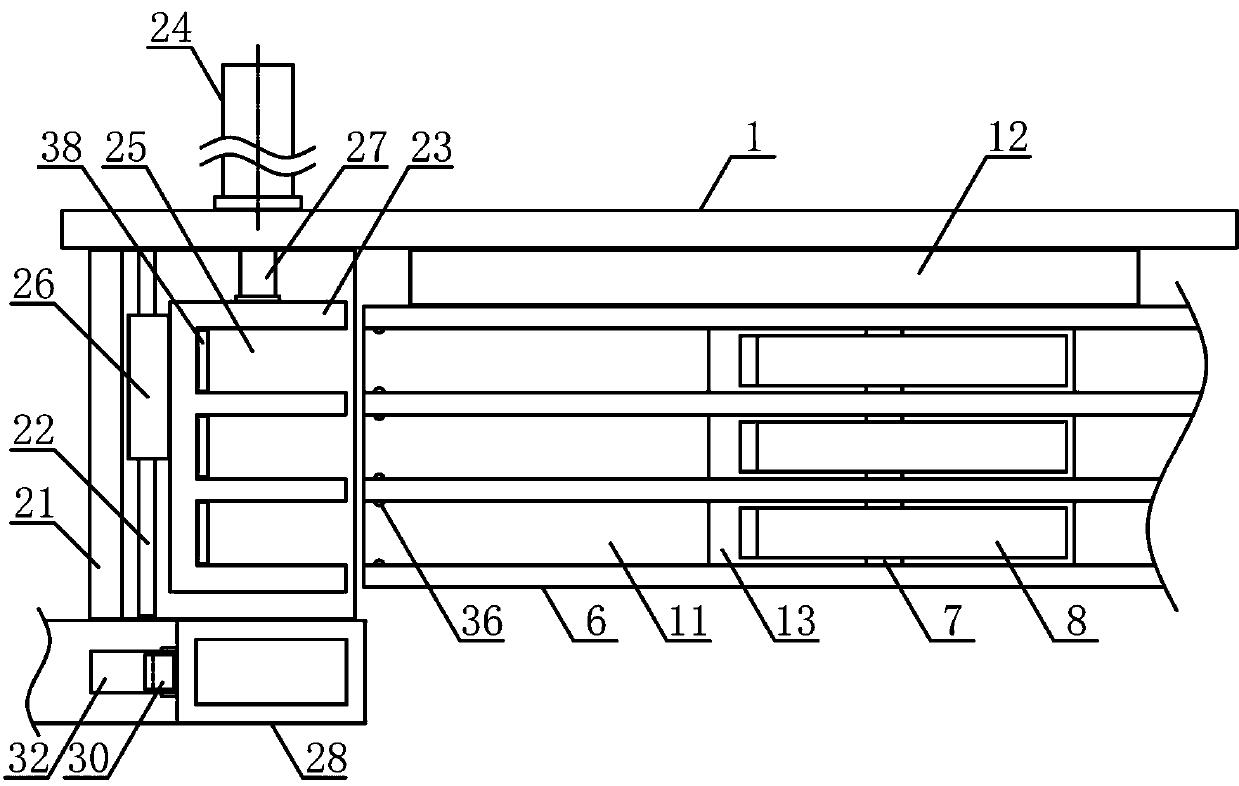

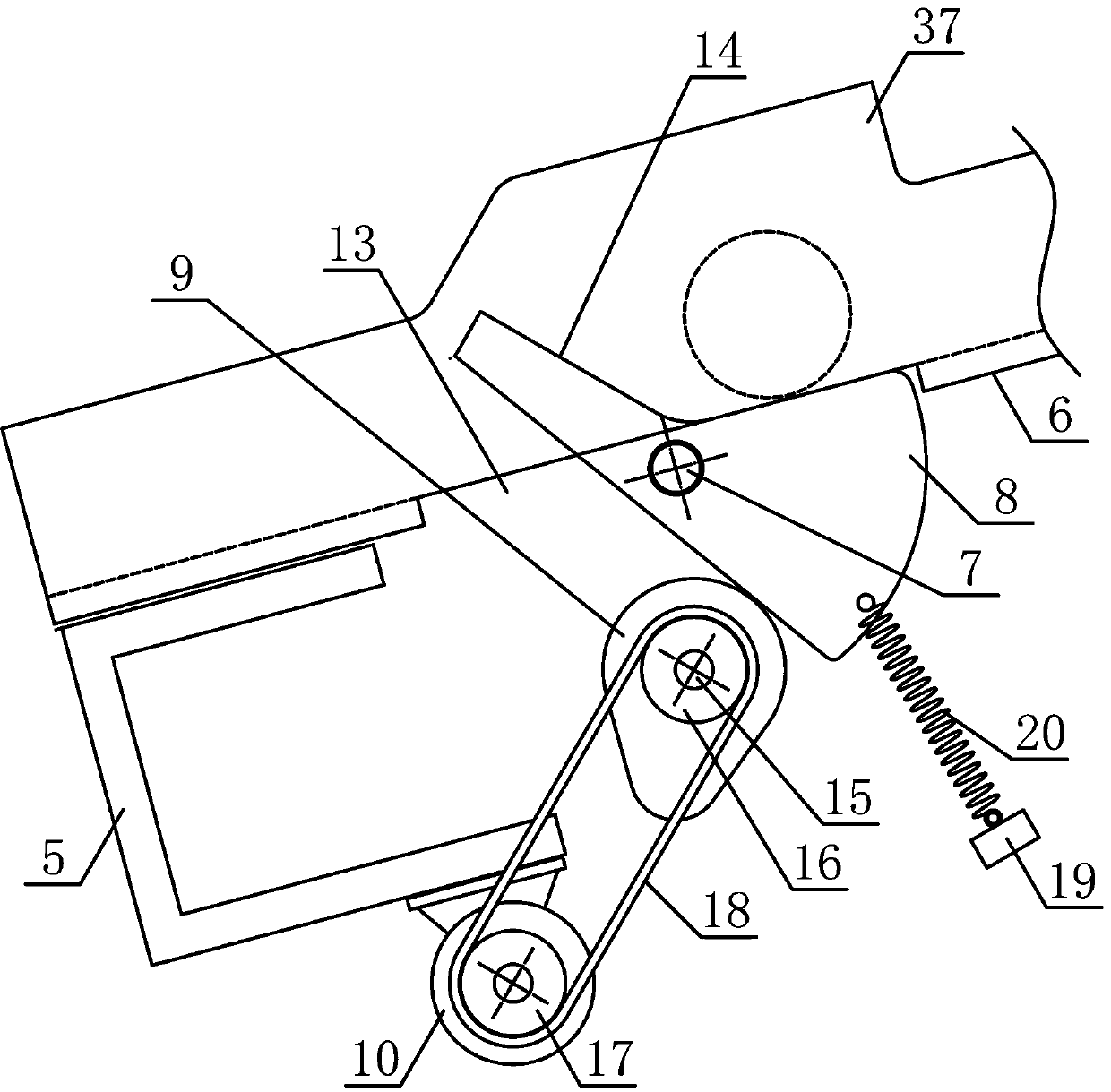

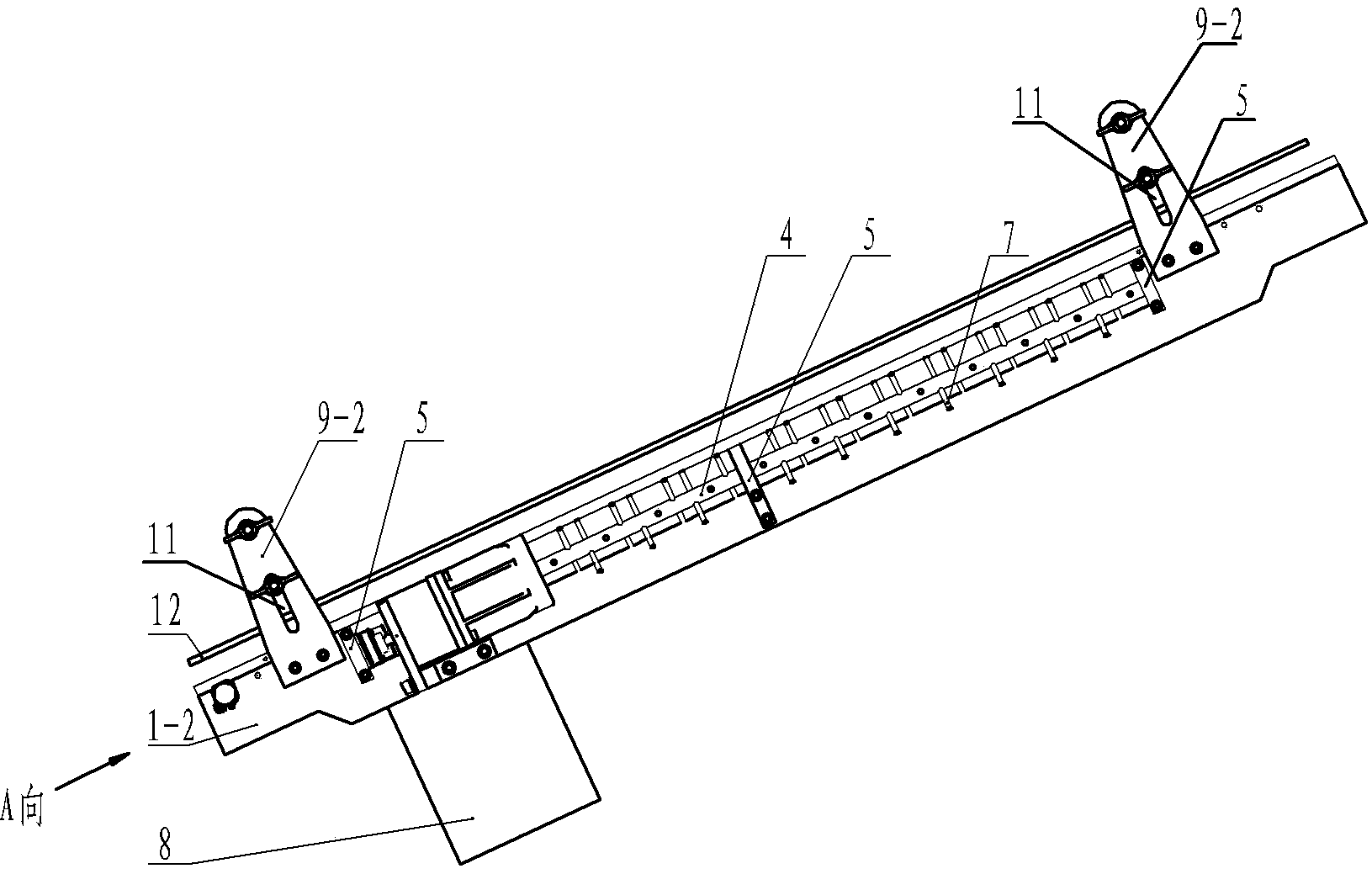

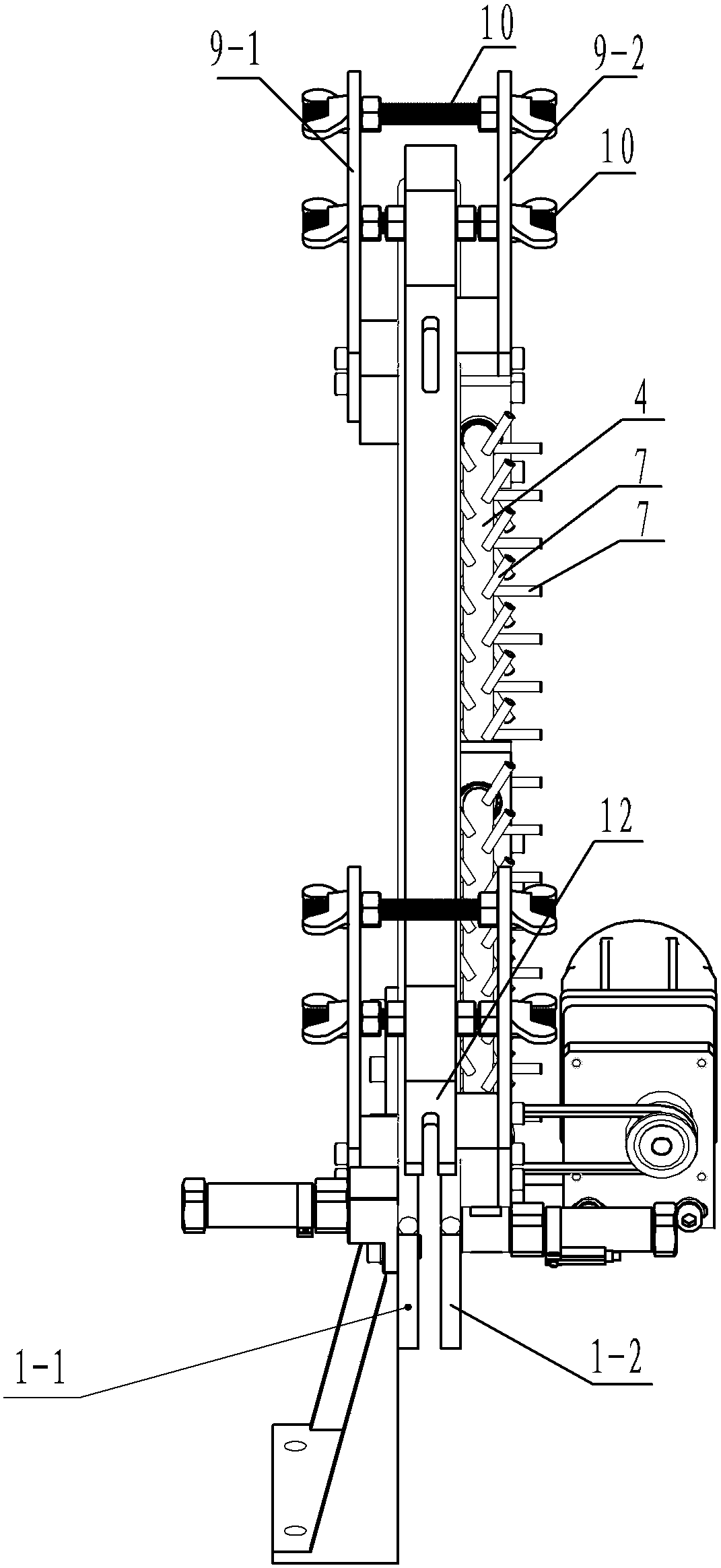

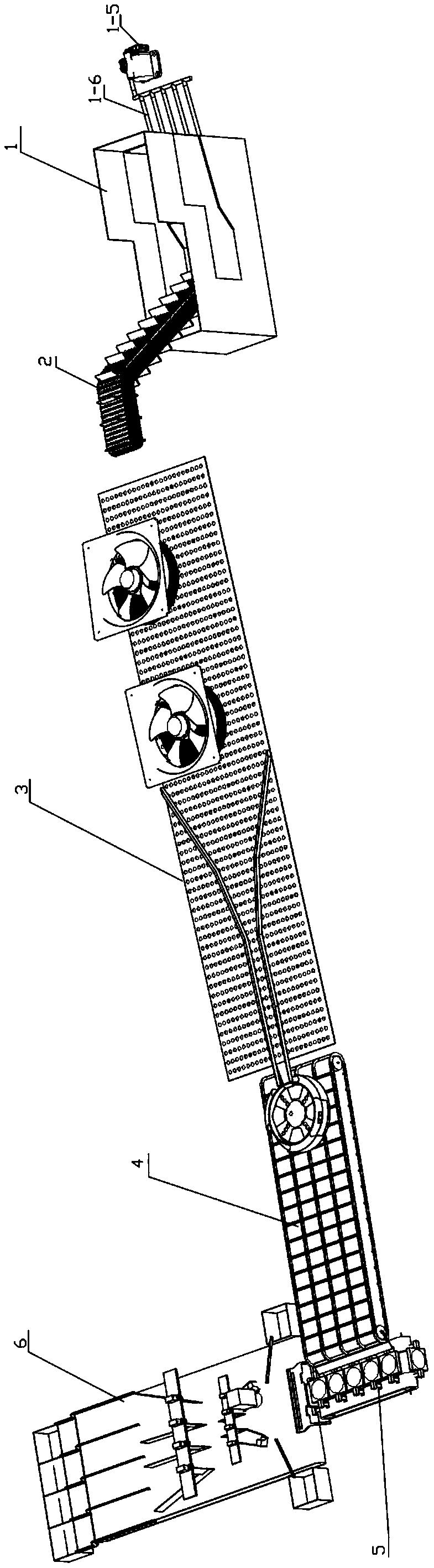

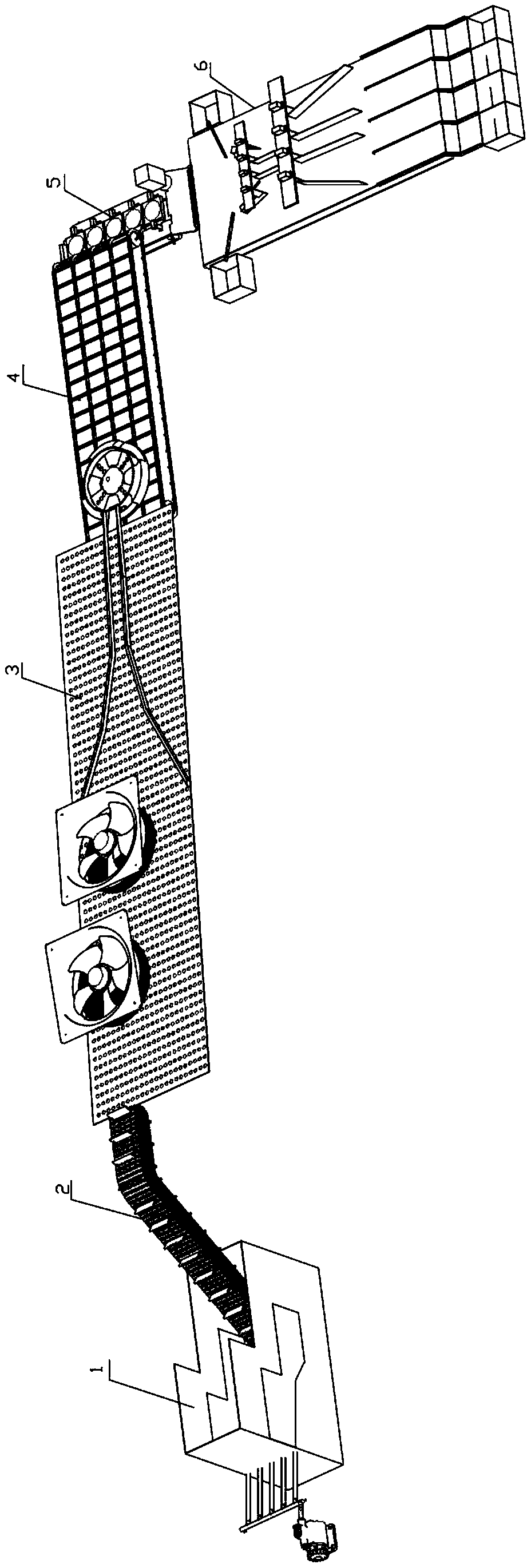

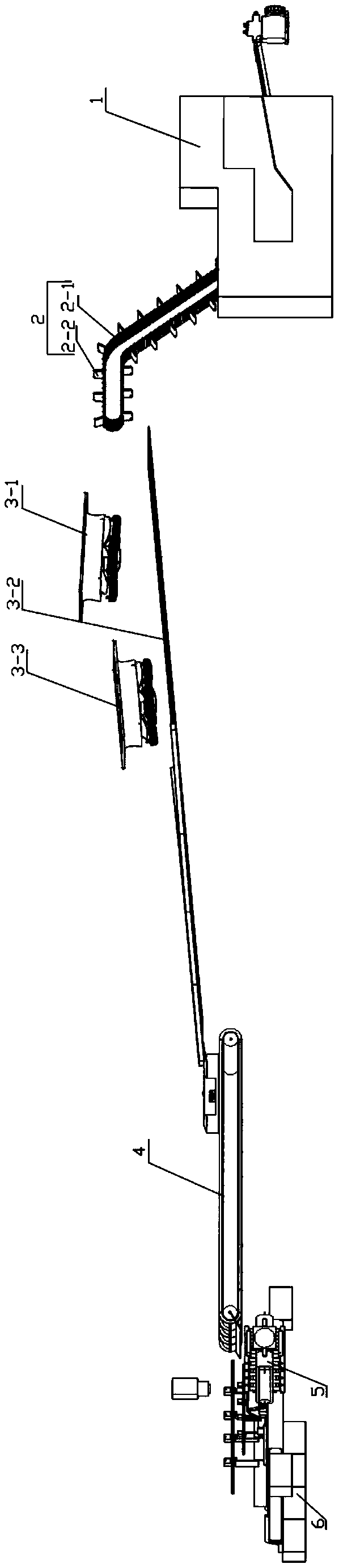

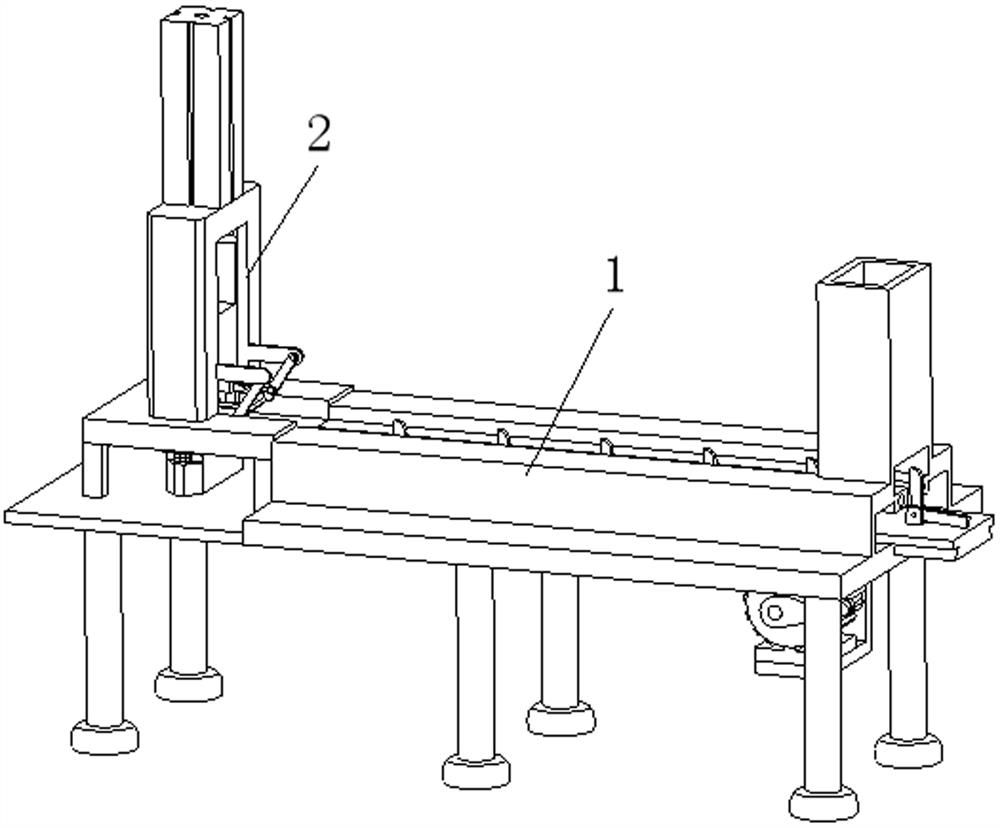

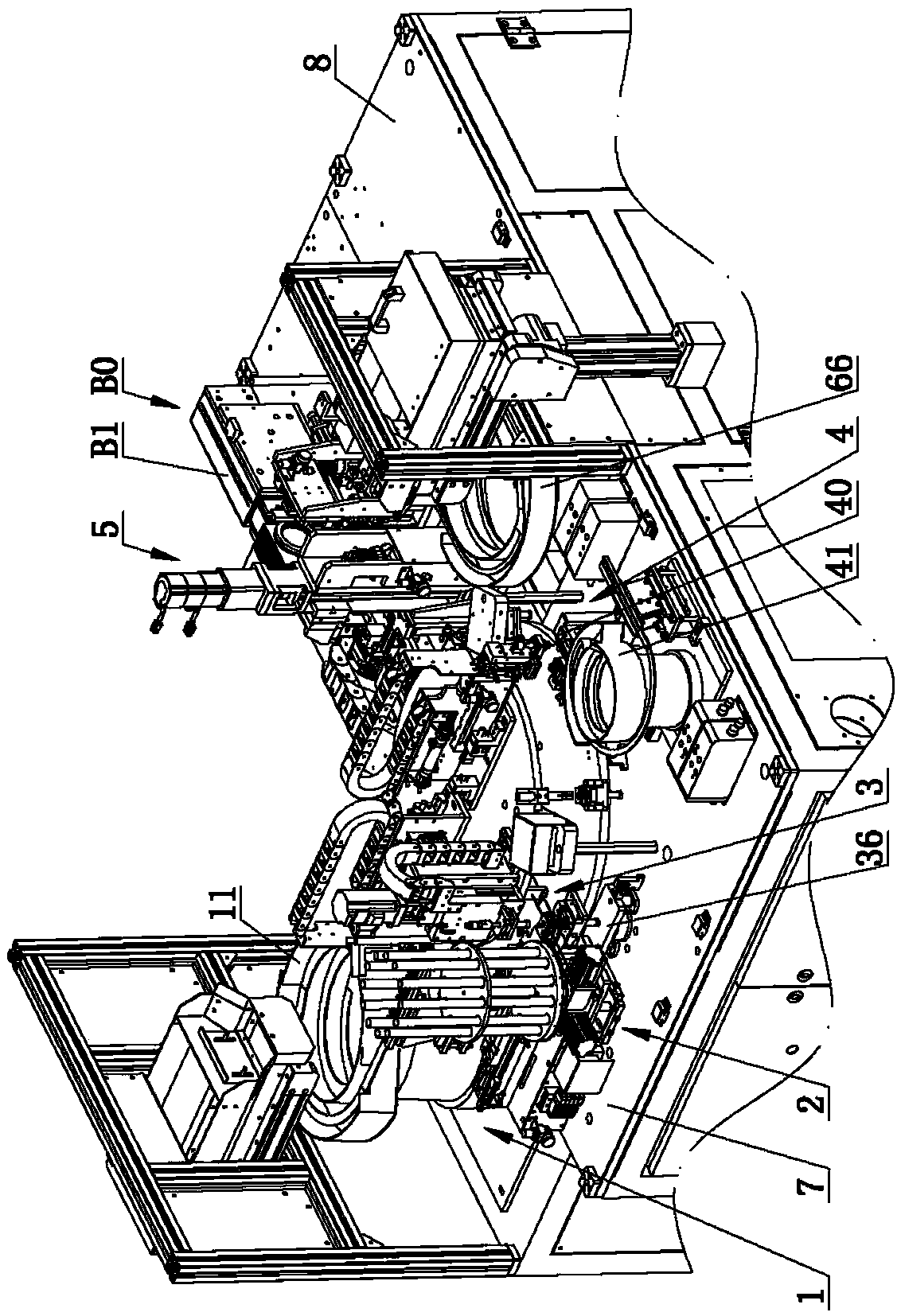

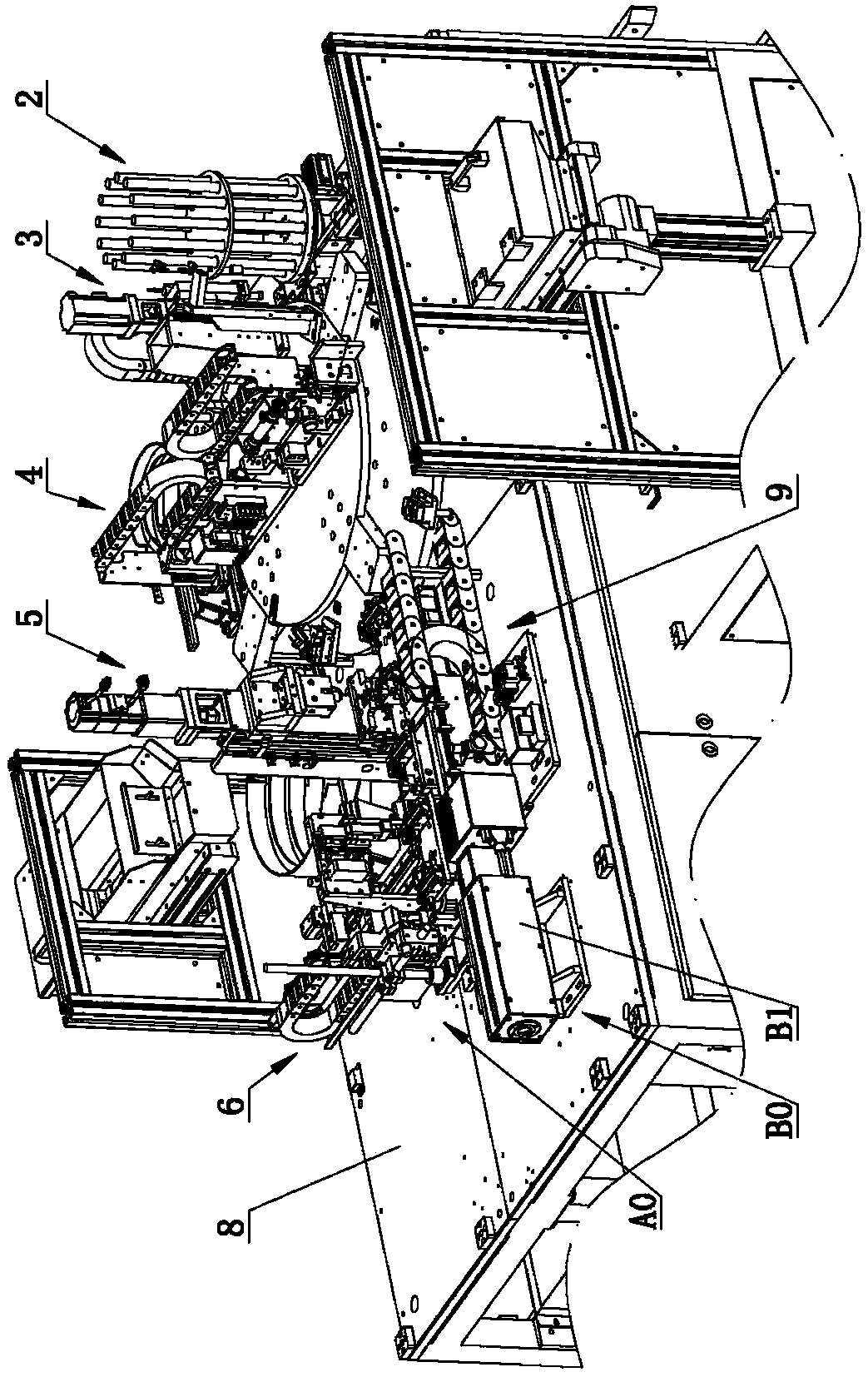

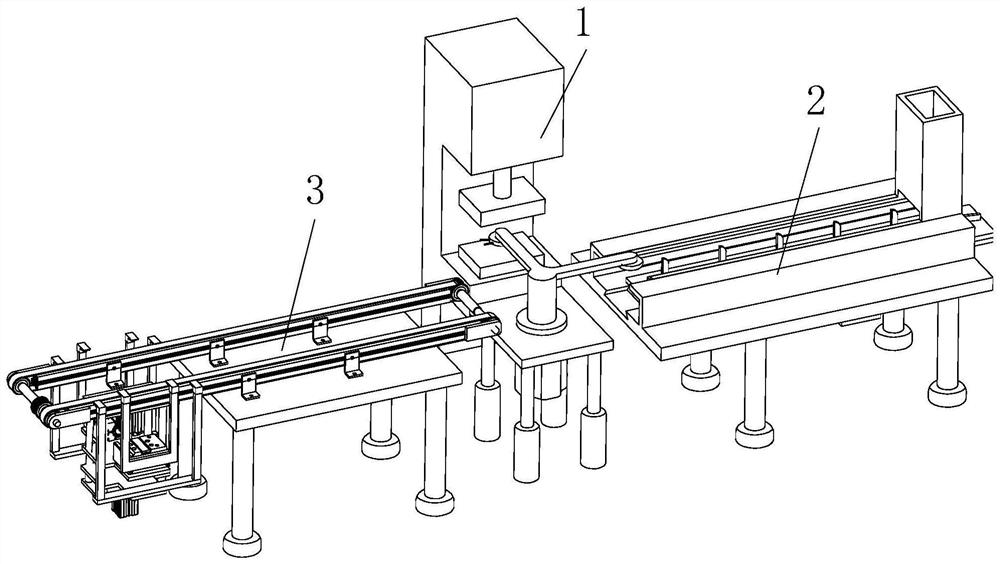

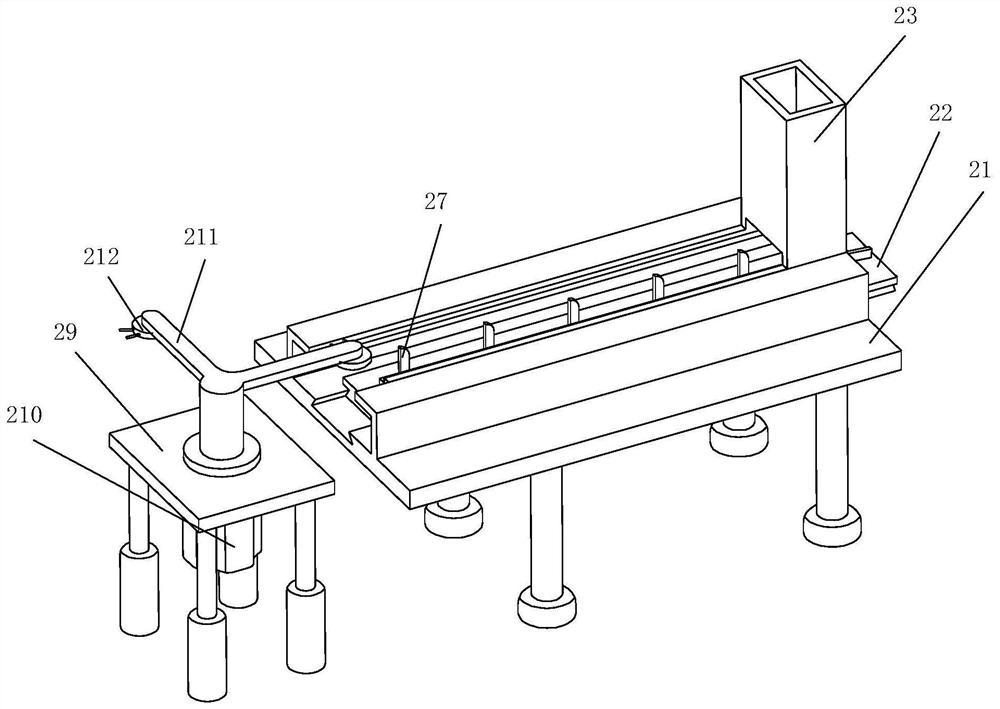

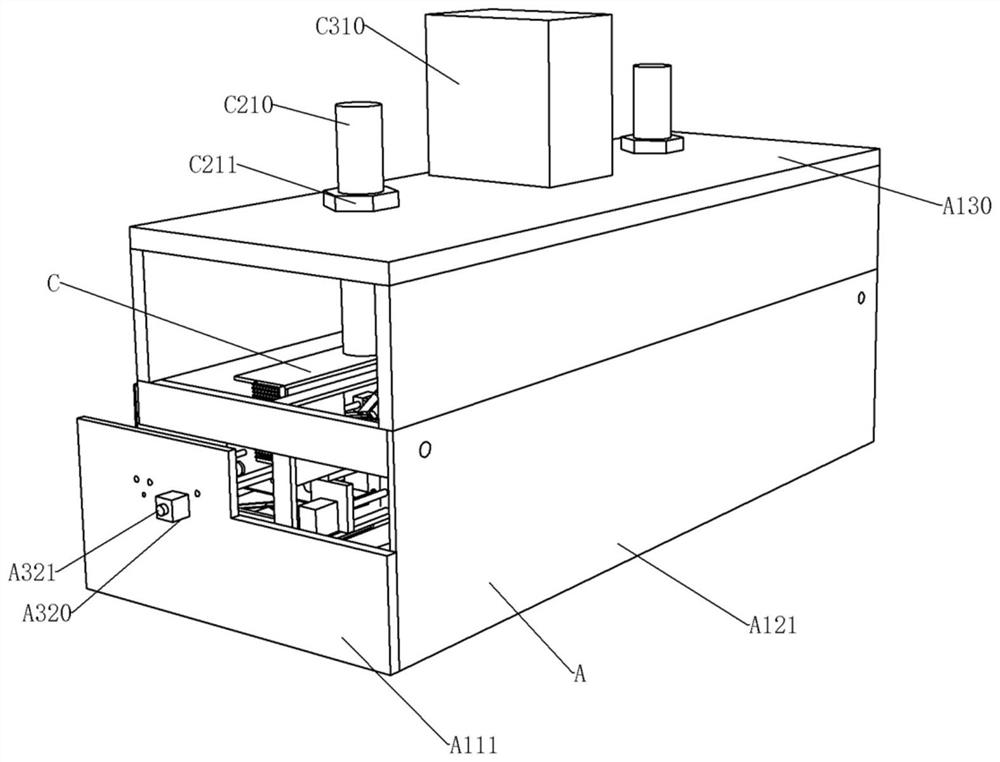

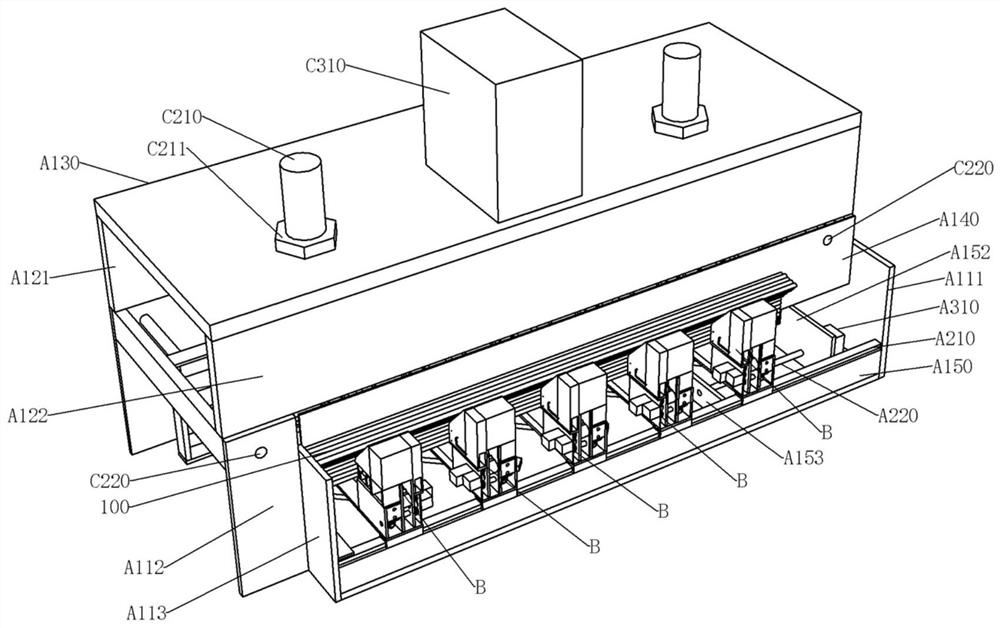

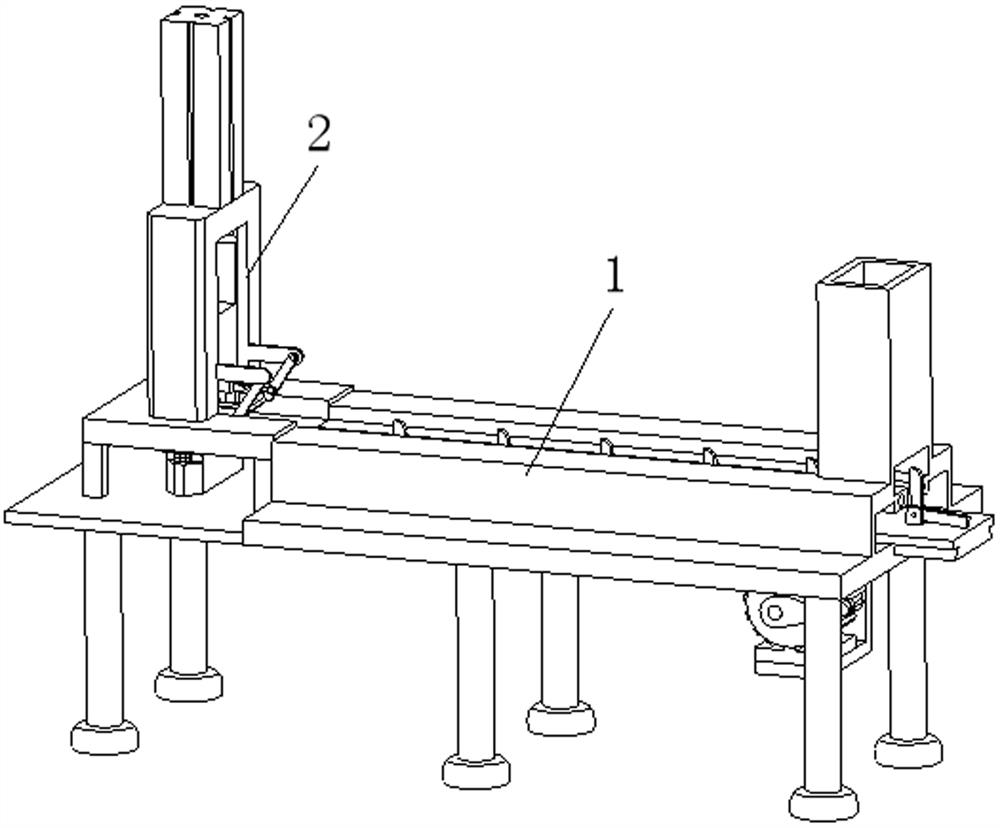

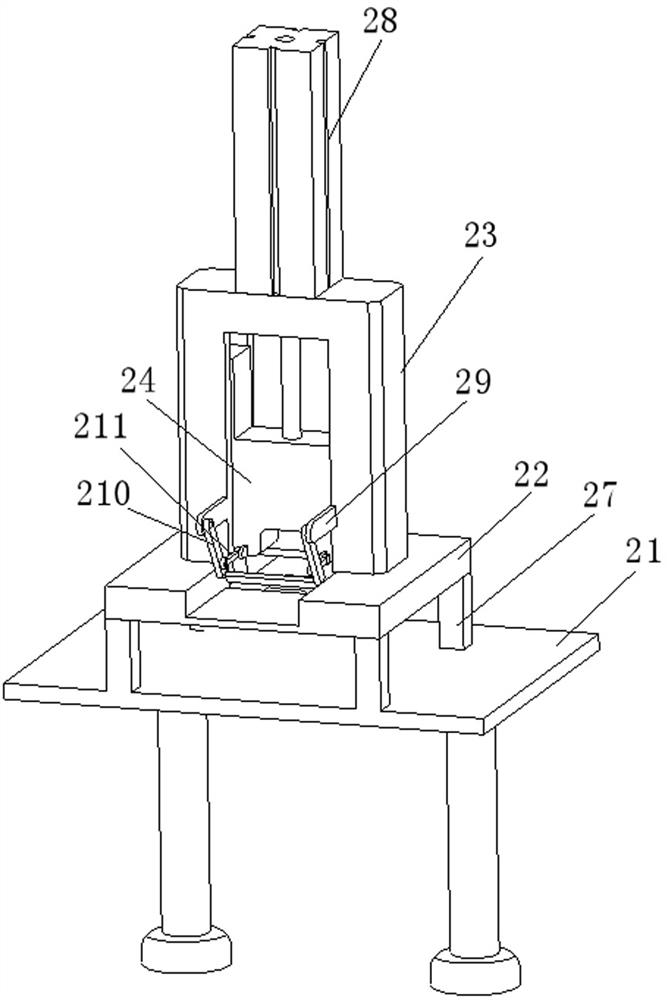

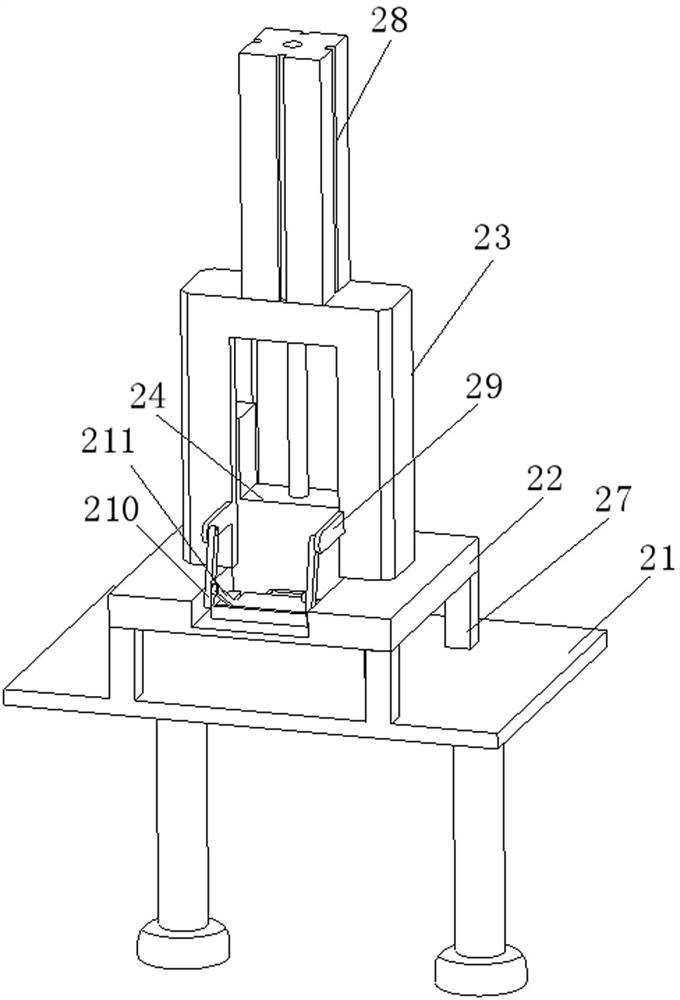

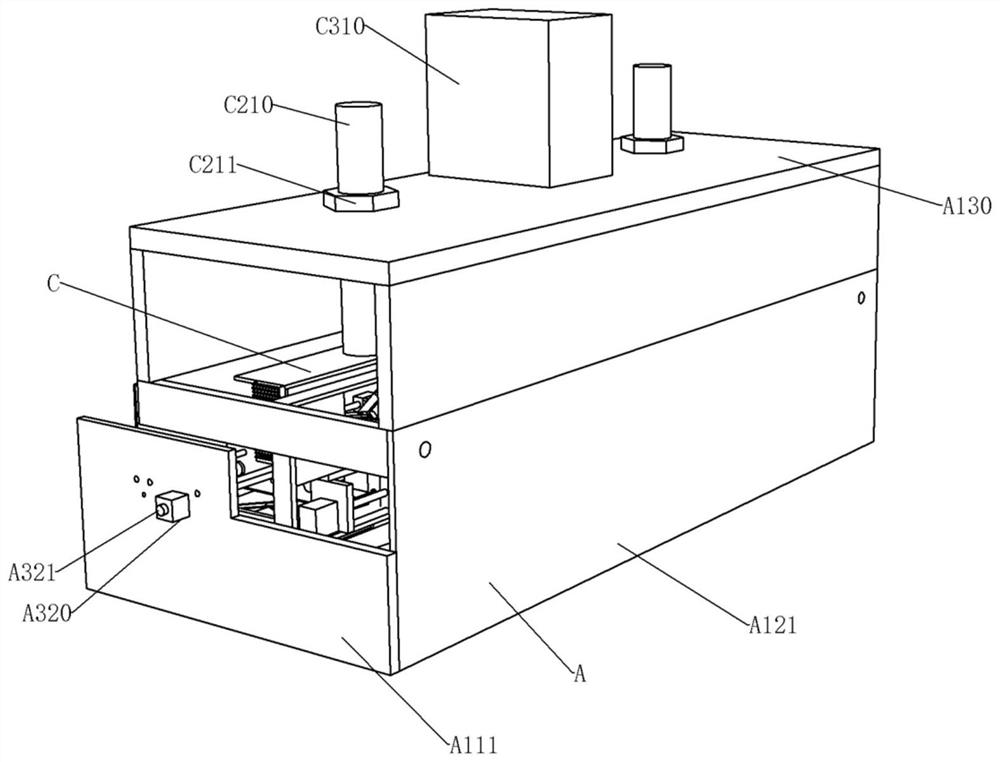

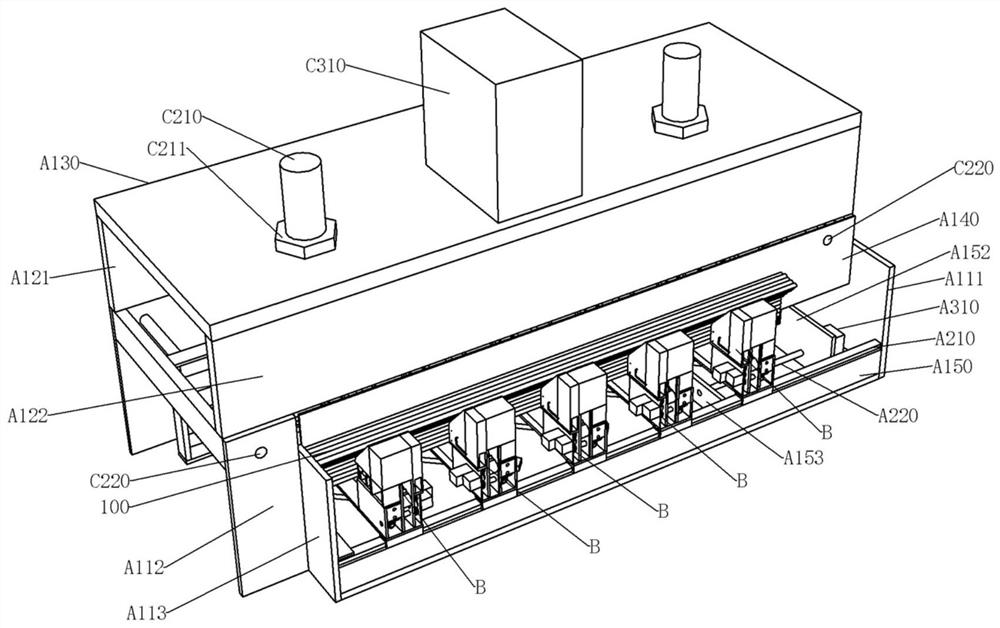

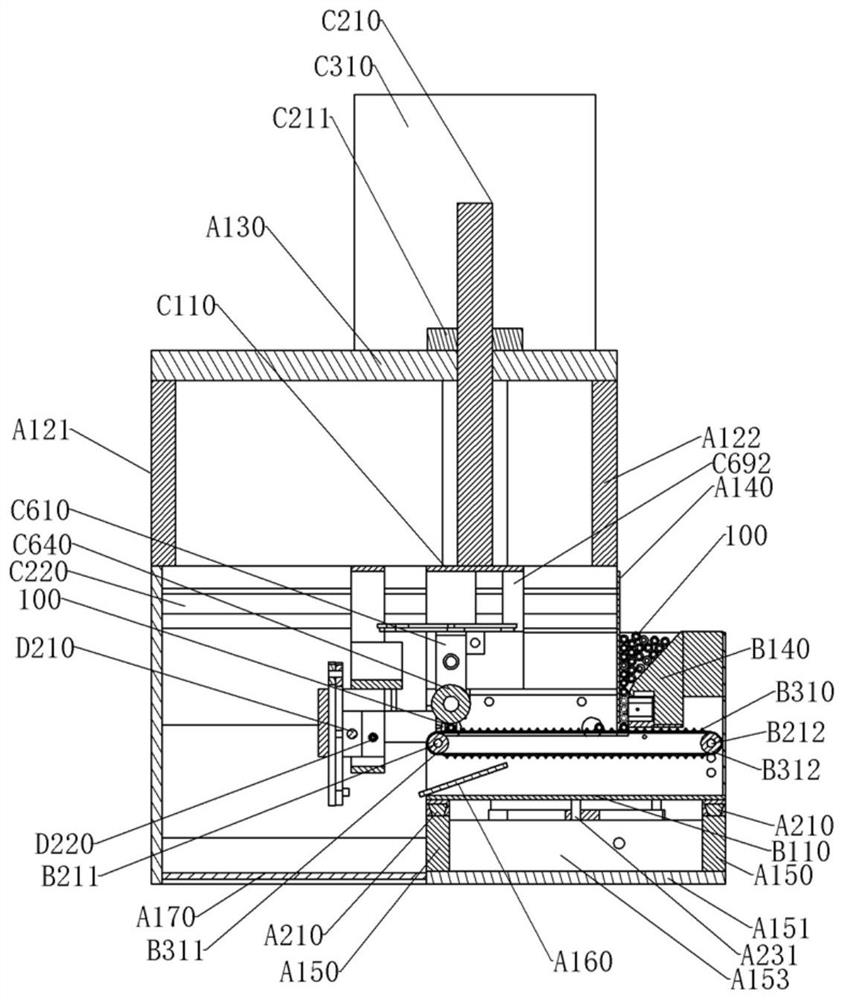

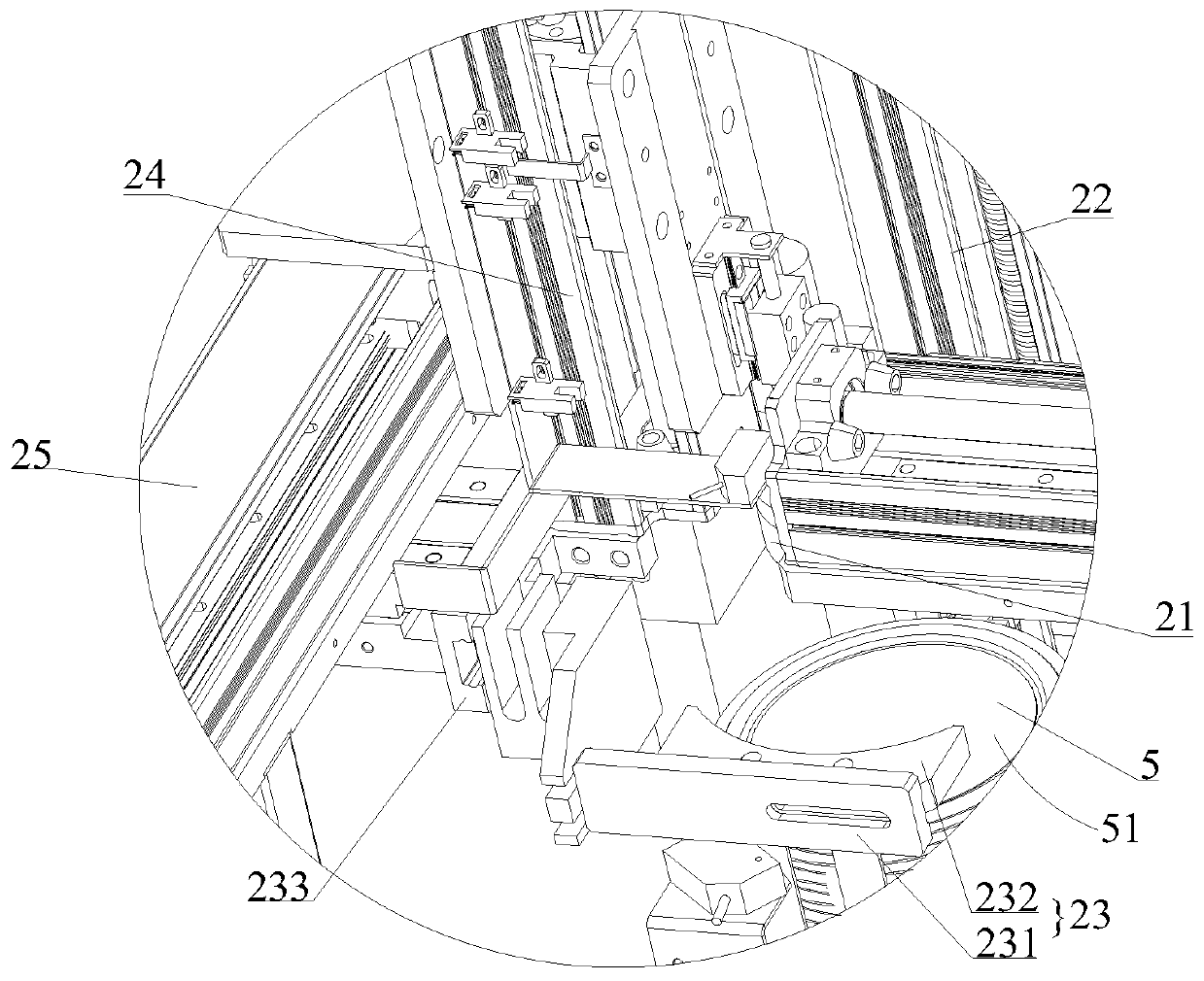

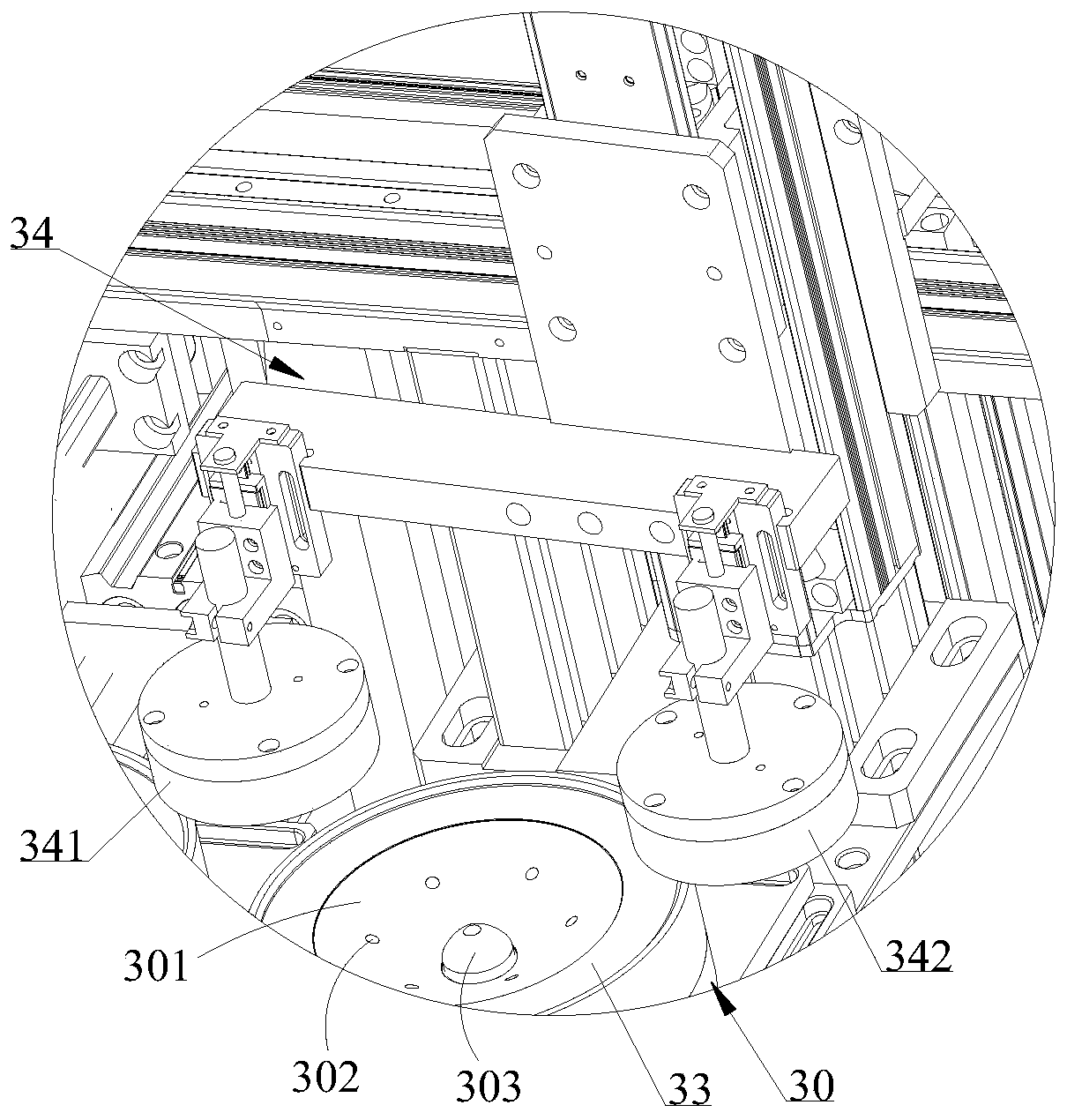

A main frame module and its intelligent laser pipe cutting machine

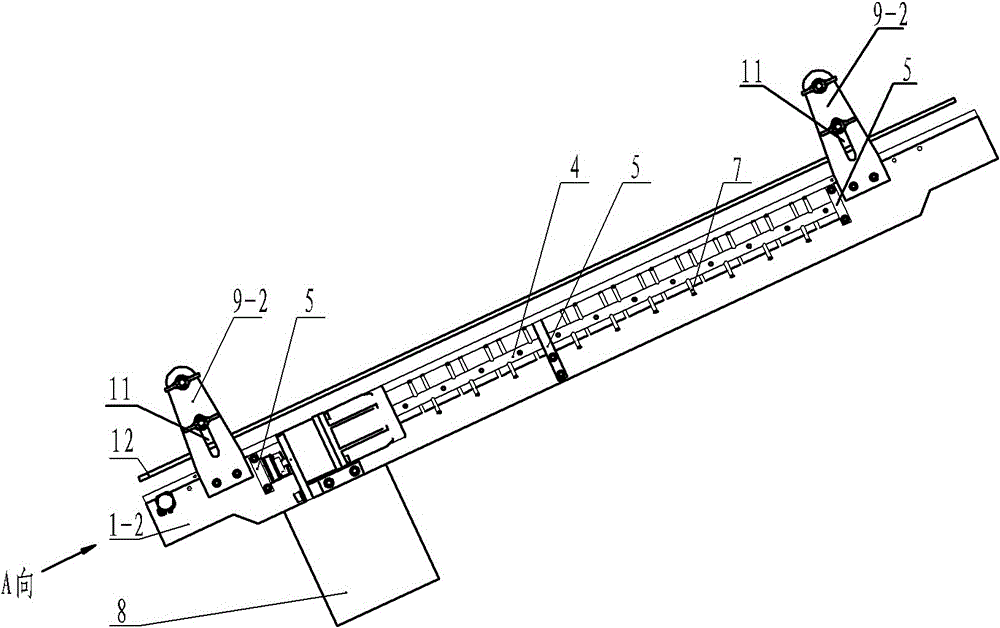

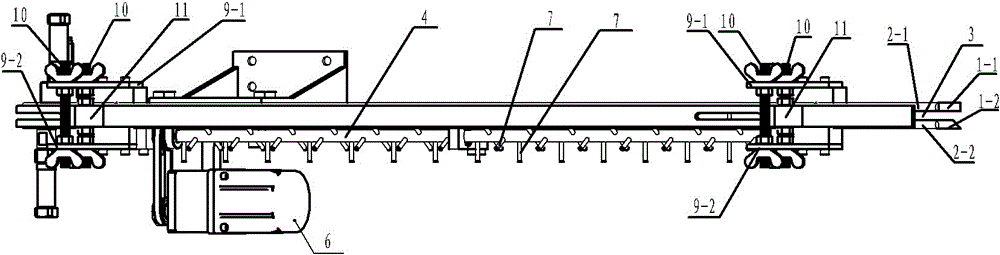

ActiveCN112207455BRealize automatic feeding processRealize automated productionMetal working apparatusLaser beam welding apparatusEngineeringLaser cutting

The invention discloses a main frame module and an intelligent laser pipe cutting machine thereof. The intelligent laser pipe cutting machine can realize automatic feeding, positioning, clamping, and cutting of pipes to be cut, and the whole process can be unmanned and intelligent. ;The intelligent laser pipe cutting machine includes: the main frame module, which is used to transport the pipes to be cut and align them axially, and output the cut pipes; the conveying module, which is used to convey the pipes to be cut to the cutting station one by one; The rotating module is used to rotate the pipe to be cut at the cutting station; the cutting module is used to emit laser light through the laser cutting head for laser cutting the pipe to be cut. The invention can realize five processes of automatic feeding, axial alignment, clamping, section cutting, and material discharge. Because multiple laser cutting heads are used, multiple sections of pipes to be cut can be cut synchronously, thereby greatly improving production efficiency. Moreover, the invention can realize fully automated production and provide a technical basis for subsequent unmanned factories and AI manufacturing.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

Umbrella tube feeding and orientation mechanism

ActiveCN106736353BRealize feeding one by oneSolve the problem of set failureMetal working apparatusEngineeringConveyor belt

The invention discloses an umbrella pipe feeding and orientation mechanism which not only can feed umbrella pipes one by one but also can achieve orientation of the umbrella pipes. The umbrella pipe feeding and orientation mechanism comprises umbrella pipe bins, obliquely extending chain plate conveyor belts in one-to-one correspondence with the umbrella pipe bins, umbrella pipe transfer belts in one-to-one correspondence with the chain plate conveyor belts and umbrella pipe orientation mechanisms in one-to-one correspondence with the umbrella pipe transfer belts. An umbrella pipe storage plate for storing umbrella pipes is arranged in each umbrella pipe bin. The lower ends of the chain plate conveyor belts extend into the corresponding umbrella pipe bins. The upper ends of the chain plate conveyor belts are located above the corresponding umbrella pipe bins. Chain plates of the chain plate conveyor belts are provided with umbrella pipe storing tanks. The input ends of the umbrella pipe transfer belts are located below the upper ends of the corresponding chain plate conveyor belts. Each umbrella pipe orientation mechanism comprises an umbrella pipe baffle located above the corresponding umbrella pipe transfer belt, and a lifting air cylinder used for lifting the umbrella pipe baffle.

Owner:杭州宝桐科技有限公司

A kind of jujube pitting machine

InactiveCN105942543BRealize feeding one by oneAccurate and fast sequence positioningFruit stoningEngineeringElectric control

The invention discloses a pitting machine for green jujubes. The pitting machine comprises a sequencing system, a power system located at the top of the sequencing system, a discharge system located at the bottom of the sequencing system, an electric control cabinet, a feeding system and a pitting system. The electric control cabinet, the feeding system and the pitting system are located on one side of the sequencing system. The pitting machine for green jujubes has following beneficial effects: an intermittent mechanism is adopted for feeding so that jujubes can be fed one by one; jujubes are accurately and rapidly sequenced and located; by limiting nuts and spring structures, sequencing and pitting of differently-sized jujubes are achieved; the pitting machine for green jujubes has a wide application scope; a hollow sleeve rod structure is utilized for pitting; the structure is simple; the pitting machine is used conveniently, practically and efficiently; ADAMS emulation verification and experimental verification are obtained so that the pitting machine for green jujubes can accurately and vertically sequence green jujubes within one second; after sequencing and pitting, green jujubes have complete shapes and waste of jujube flesh is little.

Owner:嘉善宁远农业开发有限公司

A car buckle stamping device

ActiveCN112893681BRealize automatic stampingStamping precisionMetal-working feeding devicesVehicle componentsStamping pressFastener

The invention discloses an automobile buckle stamping device, which belongs to the technical field of stamping equipment and includes a feeding equipment and a stamping equipment. The feeding equipment is arranged on the right side of the stamping equipment. The stamping equipment includes a stamping base, a stamping Plate, stamping shell, stamping upper die, stamping lower die and loading plate, when the feeding equipment transports the buckle raw materials to the stamping plate, the punching machine drives the stamping upper die on the stamping Slide upward in the housing, at this time, the work of the loading plate pushes the buckle raw material on the stamping plate to the top of the lower punching die, and the punching machine reverses to drive the upper punching die to move downward to meet with the lower punching die Cooperate to complete the stamping. At this time, the feeding plate is reset. When the work is repeated, the loading plate drives the next buckle raw material to move to the top of the stamping die, and the stamped automobile buckle is extruded from the stamping die to realize automatic stamping. .

Owner:湖北天成汽车配件有限公司

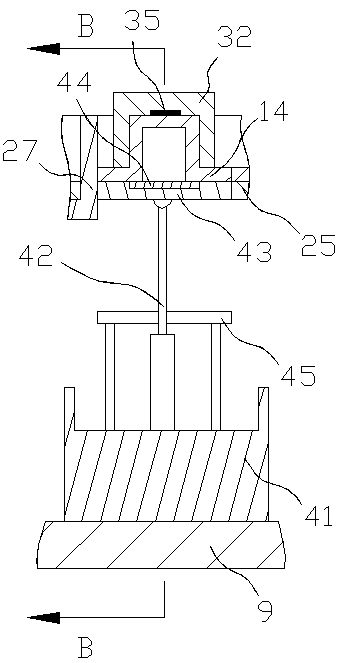

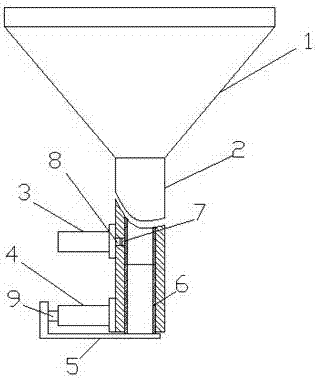

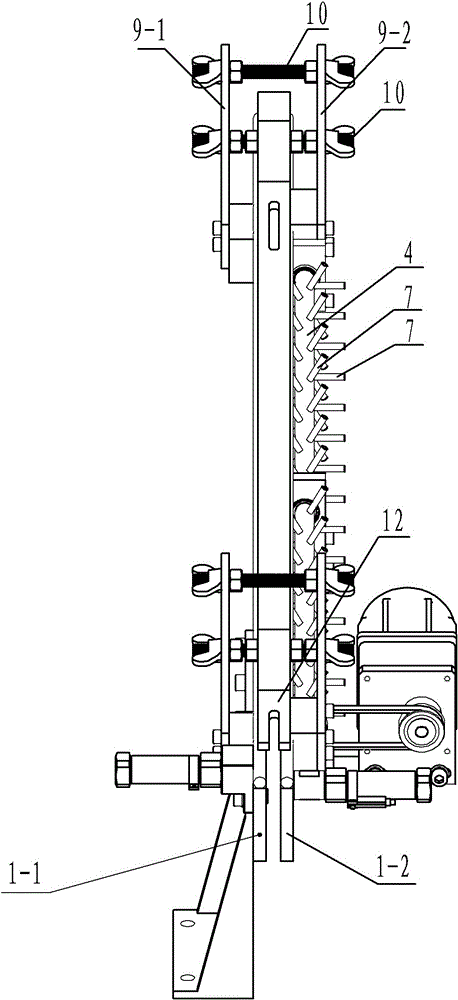

Single pipe interval one-by-one supply device

InactiveCN107214261ARealize feeding one by oneImprove stabilityMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses a single pipe interval one-by-one supply device. The device comprises a supply straight cylinder, a first extension driving device and a second extension driving device; the first extension driving device and the second extension driving device are vertically arranged on one side of the supply straight cylinder; the first extension driving device is positioned above the second extension driving device; the first extension driving device comprises a first extension rod for extending into the supply straight cylinder; the second extension driving device comprises a second extension rod for extending to the outer side in the radial direction of the supply straight cylinder; and a support plate for extending under the supply straight cylinder is arranged at the tail end of the second extension rod. Through the mode, in the single pipe interval one-by-one supply device, a straight pipe on the most lower side is stopped by the support plate for limitation, and the first extension driving device drives the first extension rod to elongate to butt against one side of a penultimate straight pipe for limitation to realize the interval one-by-one supply of the straight pipes, so that the stability is high, and the operation is safer.

Owner:张家港博洋机械制造有限公司

A cutting module and its intelligent laser pipe cutting machine

ActiveCN112207458BRealize automatic feeding processRealize automated productionMetal working apparatusLaser beam welding apparatusEngineeringLaser cutting

The invention discloses a cutting module and an intelligent laser pipe cutting machine. The intelligent laser pipe cutting machine can realize automatic feeding, positioning, clamping and cutting of pipes to be cut, and the whole process can be unmanned and intelligent; The intelligent laser pipe cutting machine includes: a main frame module for conveying and axially aligning the pipes to be cut, and outputting the cut pipes; a conveying module for conveying the pipes to be cut to the cutting station one by one; rotating The module is used for rotating the pipe to be cut in the cutting station; the cutting module is used for laser cutting the pipe to be cut through the laser cutting head. The present invention can realize five processes of automatic feeding, axial alignment, clamping, section cutting and discharging. Due to the use of multiple laser cutting heads, the pipe material to be cut can be cut synchronously in multiple sections, thereby greatly improving production efficiency. Moreover, the present invention can realize fully automated production, and provide a technical basis for subsequent unmanned factories and AI manufacturing.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

Fully automatic invisible zipper upper movable code equipment

Owner:WENZHOU HONGYE PRECISE MACHINERY

A Combined Material Guide Mechanism for Ring Workpieces

ActiveCN110451224BCombined transmissionReasonable structural designConveyor partsStructural engineeringMechanical equipment

The invention discloses a material-combining and guiding mechanism for annular workpieces, which belongs to the field of workpiece conveying and processing mechanical equipment. The upper side of the material transfer bracket of the invention is provided with a plurality of material guide chutes sequentially along the inclined direction, and a plurality of material guide rotating plates are fixed and vertically arranged on the material guide rotating shaft along the horizontal direction in sequence, and the material pusher bracket is sequentially arranged along the side of the material transfer bracket. A plurality of material holding slots matching the size and specifications of the material guide chute are evenly arranged, the pushing piston rod at the output end of the flat push cylinder is fixedly connected with the middle part of one side of the pushing material support, and the material guiding tube is fixed vertically on the supporting material The material guide bracket on one side of the material support, and the baffle swing groove on the side below the material guide tube are provided with a blanking baffle. The invention has a reasonable structural design, can realize multiple ring-shaped workpieces to be combined for transmission, and can ensure that the ring-shaped workpieces are unloaded and conveyed one by one, thereby improving the degree of automation of workpiece transmission and processing, and meeting the needs of processing and use.

Owner:滨州市沾化区蓝乔生物科技有限公司

A valve buffer feeding device

ActiveCN104108599BRealize feeding one by oneGuarantee product qualityConveyor partsEngineeringMechanical engineering

The invention provides a valve buffer feeding device, which realizes automatic material feeding in the process of valve production and detection, improves production efficiency, effectively avoids rigid collision between valves in the material feeding process, and ensures the quality of valve production and detection, which includes The material receiving plates on both sides, the upper ends of the material receiving plates are respectively provided with material storage rods to form a material channel, and it is characterized in that: a rotating shaft is arranged corresponding to the lower end of the material receiving plate, and a plurality of stoppers are arranged on the rotating shafts strips, and the adjacent said retaining strips are arranged crosswise.

Owner:WUXI SHUANGYI PRECISION MACHINERY

Cutting module and intelligent laser pipe cutting machine

ActiveCN112207458AIncrease productivityAvoid deformationMetal working apparatusLaser beam welding apparatusLaser cuttingMechanical engineering

The invention discloses a cutting module and an intelligent laser pipe cutting machine. According to the intelligent laser pipe cutting machine, automatic feeding, positioning, clamping and cutting ofpipes to be cut can be achieved, and unmanned and intelligent effects can be achieved in the whole process. The intelligent laser pipe cutting machine comprises a main frame module, a conveying module, a rotating module and the cutting module, wherein the main frame module is used for conveying the pipes to be cut, axially aligning the pipes to be cut and outputting the cut pipes; the conveying module is used for conveying the pipes to be cut to a cutting station one by one; the rotating module is used for rotating the pipes to be cut located at the cutting station; and the cutting module isused for carrying out laser cutting on the pipes to be cut through laser emitted by laser cutting heads. According to the cutting module and the intelligent laser pipe cutting machine, the five procedures of automatic feeding, axial alignment, clamping, section cutting and discharging can be achieved, due to the fact that the laser cutting heads are adopted, multi-section synchronous cutting can be carried out on the pipes to be cut, and therefore the production efficiency can be greatly improved. Full-automatic production can be achieved, and a technical basis is provided for subsequent unmanned factories and AI manufacturing.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

Annular workpiece guide device

InactiveCN112110169ACombined transmissionReasonable structural designConveyor partsStructural engineeringMechanical equipment

The invention discloses an annular workpiece guide device, and belongs to the field of workpiece transferring and machining equipment. A plurality of guide sliding grooves are formed in the upper sideof a transfer support in the oblique direction in sequence; a plurality of guide rotation plates are vertically and fixedly arranged on a guide rotation shaft in the horizontal direction in sequence;a plurality of bearing clamping grooves with the size matched with the size of the guide sliding grooves are uniformly formed in a push support along the transfer support; a push piston rod at the output end of a horizontal thrust air cylinder is fixedly connected with the middle of one side of the push support; a material guide pipe is vertically and fixedly arranged on the guide support which is arranged on one side of the bearing support; and a blanking baffle is arranged in a baffler swing groove in one side of the lower portion of the material guide pipe. The structural design is reasonable; it can be achieved that a plurality of annular workpieces are combined and transferred; it can be ensured that the annular workpieces are unloaded and transferred one by one; the degree of automation of transferring and machining of the workpieces is improved; and the requirements for machining and use are met.

Owner:郭煜萍

Feeding device for loudspeaker cones

PendingCN111302051AAchieve separationRealize feeding one by oneElectrical transducersDe-stacking articlesEngineeringLoudspeaker

The invention discloses a feeding device for loudspeaker cones. The feeding device comprises a material storage mechanism, a material taking mechanism and a material distributing mechanism; the material storage mechanism comprises at least one material storage unit for storing a plurality of sound cones which are nested up and down; the material taking mechanism comprises a material taking mechanical arm used for taking out the sound cones from the material storage units; the material distributing mechanism comprises at least one material bearing support used for bearing the sound cones takenout by the material taking mechanical arm, the material distributing mechanism has a material distributing state, when the material distributing mechanism is in the material distributing state, the number of the sound cones on the at least one material bearing support is larger than one, and the material bearing supports have negative pressure used for sucking the sound cones on the lower layers;and the material distributing mechanism further comprises at least one material distributing assembly used for moving away the sound cones from the material bearing supports. According to the feedingdevice for the loudspeaker cones, the loudspeaker cones can be separated and fed one by one.

Owner:SUZHOU SONAVOX ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com