Feeding mechanism

A technology of feeding mechanism and feeding port, which is applied in the field of feeding mechanism that can feed products one by one, can solve the problems of high extrusion force, product extrusion damage, poor feeding effect, etc., so as to reduce extrusion force and ensure The effect of smooth reclaiming and improving feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

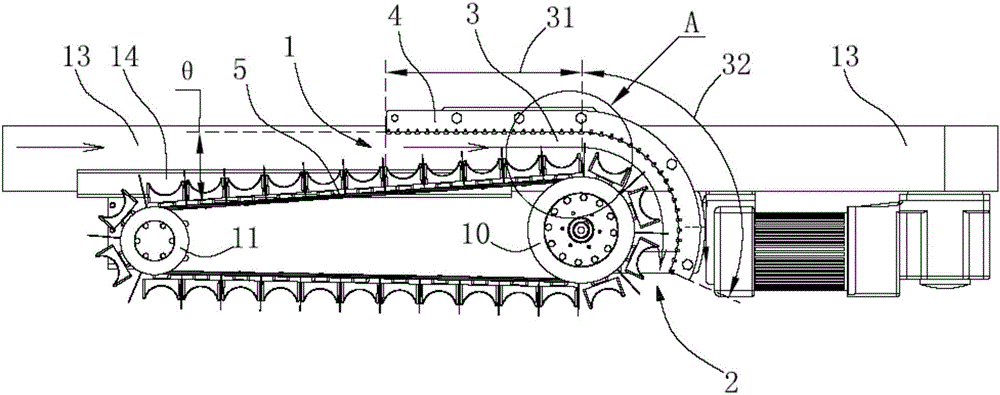

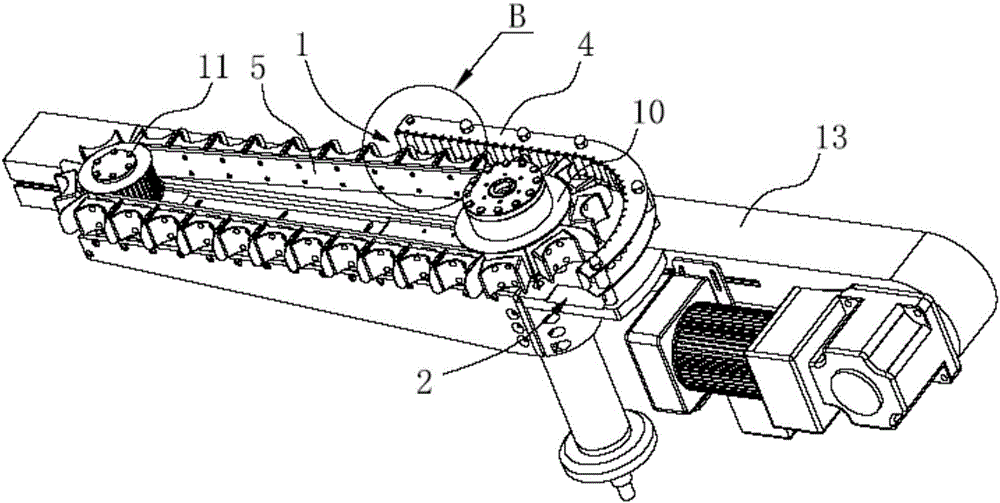

[0021] Such as Figure 1 to Figure 5 Shown in is a schematic diagram of a specific example of the feeding mechanism of the present invention; wherein the feeding mechanism includes a feed port 1 and a discharge port 2, and a delivery channel 3 is between the feed port 1 and the discharge port 2, The conveying channel 3 is used to transport corresponding products, that is, the product enters from the feed port, then moves along the conveying channel, and finally outputs from the discharge port 12, and the output product can be supplied to the next process; The conveying direction of the conveying channel 3 is provided with a fixed side wall 4 on one side of the conveying channel 3, and a movable side wall 5 that can move cyclically is provided on the other side of the conveying channel 3, and the movement of the movable side wall 5 corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com