Epitaxial wafer silicon slag scraping device for LED lamp production

A technology for LED lamps and scraping devices, which is applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as low work efficiency, reduced actual quality, and inability to achieve continuous processing of batch epitaxial wafers, and achieves high work efficiency and overall structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

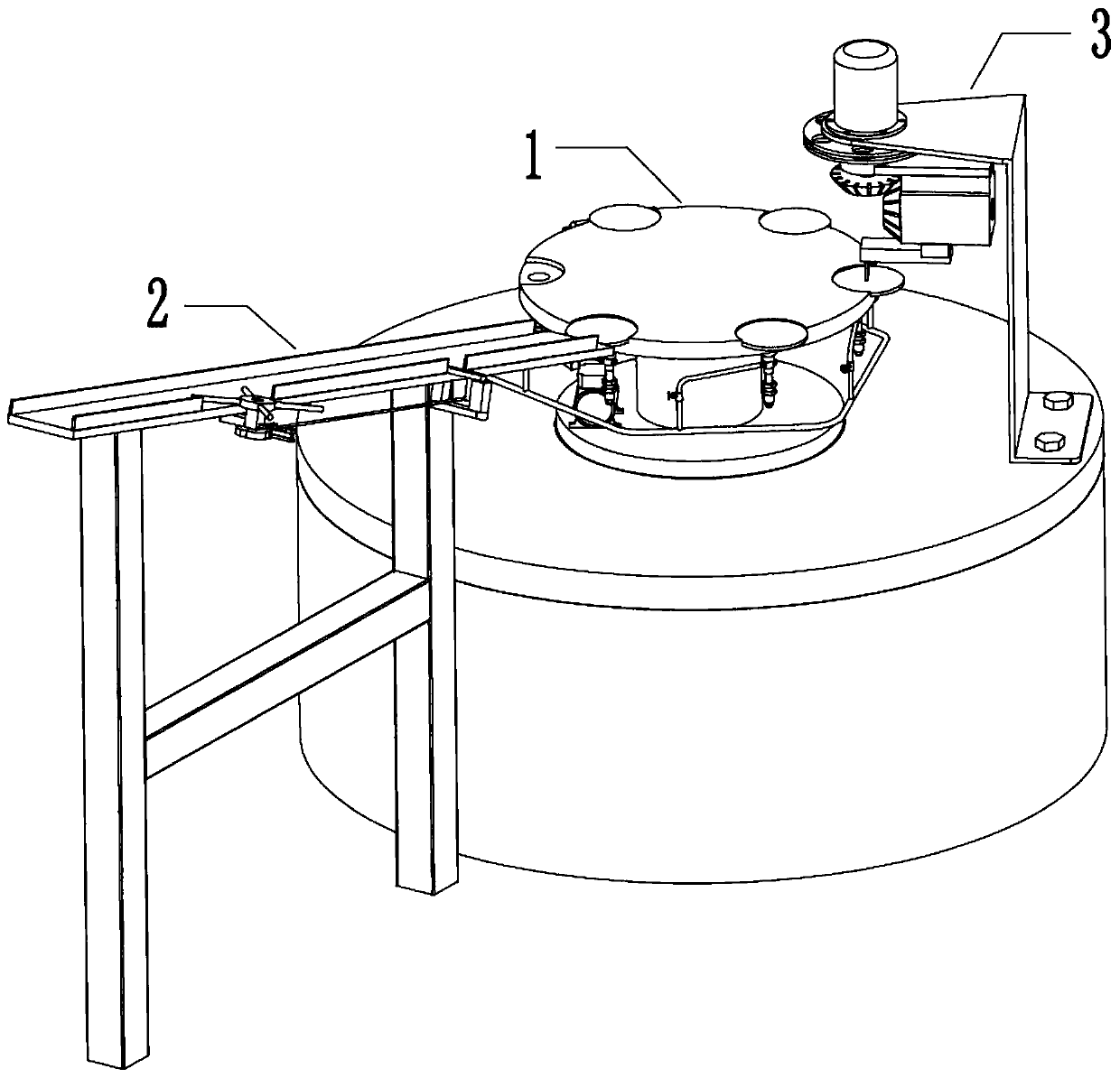

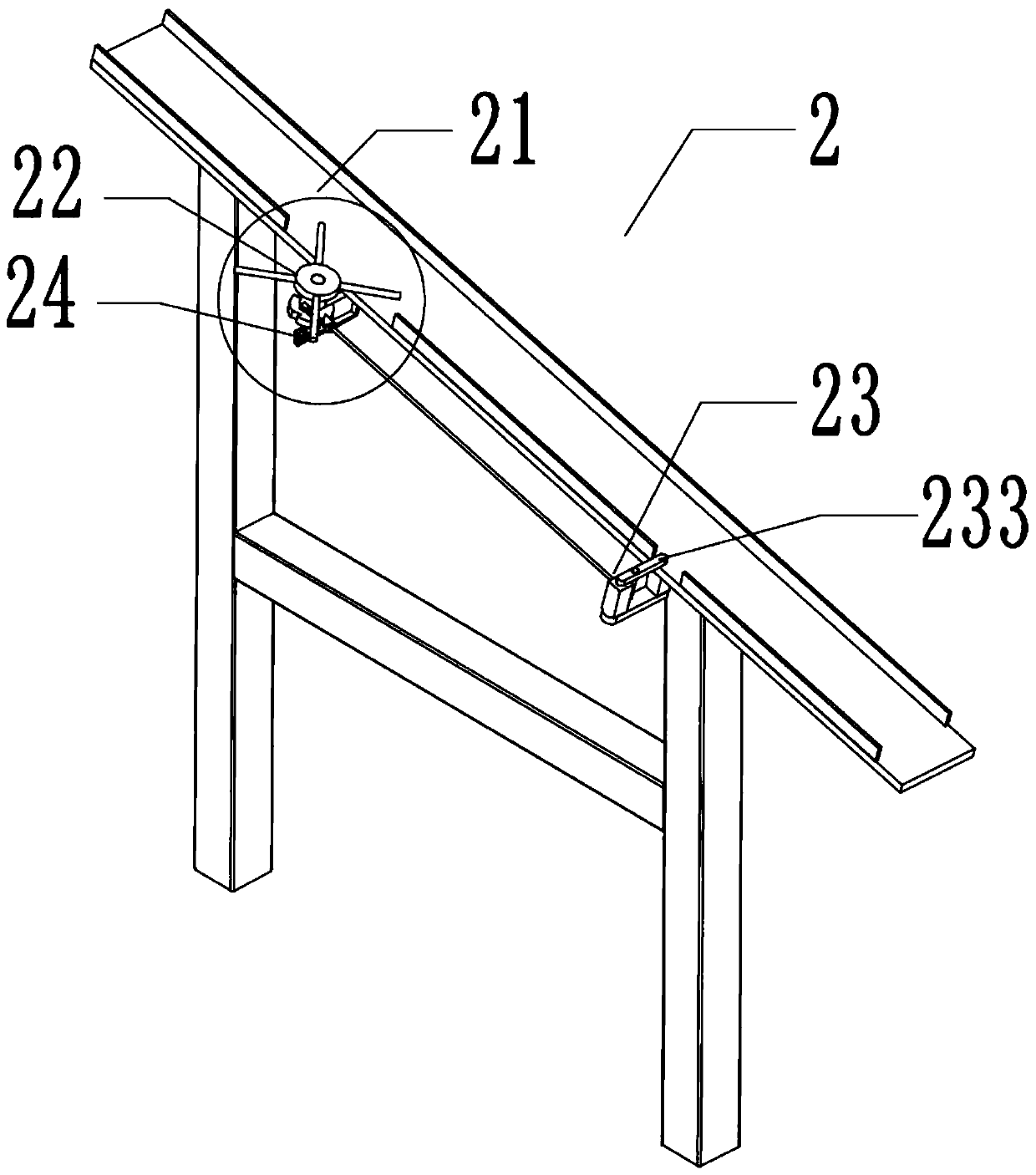

[0044]Such as figure 1 As shown, a silicon slag scraping device for epitaxial wafers used in the production of LED lamps includes a multi-station workbench 1, a feeding mechanism 2 and a slag scraping mechanism 3, and a feeding mechanism is set on the side of the multi-station workbench 1 2 and the slag scraping mechanism 3, and the multi-station workbench 1 rotates intermittently, the feeding mechanism 2 performs a single feeding of the epitaxial wafer to be scraped, and the slag scraping mechanism 3 rotates and scrapes the slag epitaxial sheet to be scraped, and passes through the multi-station The cooperation of the workbench 1, the feeding mechanism 2 and the slag scraping mechanism 3 can carry out continuous single feeding of the epitaxial wafers to be scraped, and the rotation of the slag scraping mechanism 3 ensures the removal of excess silicon slag on the surface of the existing epitaxial wafers. Good scraping, compact overall structure, high working efficiency.

[0...

Embodiment 2

[0066] Such as Figure 7 As shown, the difference from Embodiment 1 is that, further, an epitaxial wafer slag removal mechanism 4 is arranged beside the slag scraping mechanism 3, and the epitaxial wafer slag removal mechanism 4 cleans the silicon slag on the surface of the epitaxial wafer after the slag scraping, Reduce the impact of silicon slag on the surface of epitaxial wafers such as scratches.

[0067] Further, the epitaxial wafer slag removal mechanism 4 is set to include a support frame 2 41, a staggered transmission assembly 2 42, a linear movement assembly 2 43 and a brush 2 44, and the support frame 2 41 is arranged on the side of the multi-station workbench 1, And the support frame 2 41 is provided with a staggered transmission component 2 42 and a linear movement component 2 43 , the staggered transmission component 2 42 drives the linear movement component 43 to move in a straight line, and the output end of the linear movement component 43 is connected to the b...

Embodiment 3

[0073] Such as Figure 8 As shown, the difference from Embodiment 1 and Embodiment 2 is that, further, a lower feeding conveying mechanism 5 is arranged on the side of the epitaxial wafer slag removal mechanism 4, and the setting of the lower feeding conveying mechanism 5 further improves the performance of the scraping device. The automation performance facilitates the unloading of epitaxial wafers after scraping slag on the multi-station workbench 1.

[0074] Further, the blanking conveying mechanism 5 is set to include a conveyor 51 and a blanking frame 52, the conveyor 51 is arranged on the side of the multi-station workbench 1, and the end of the conveyor 51 is provided with a blanking frame 52, and the blanking frame 52 is arranged at the end of the conveyor 51. The end of the rack 52 extends above the conveying line of the next process, and the epitaxial wafer scraped at the station is unloaded and transported by the conveyor 51, and it is conveniently collected in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com