Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

404 results about "Precipitation hardening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

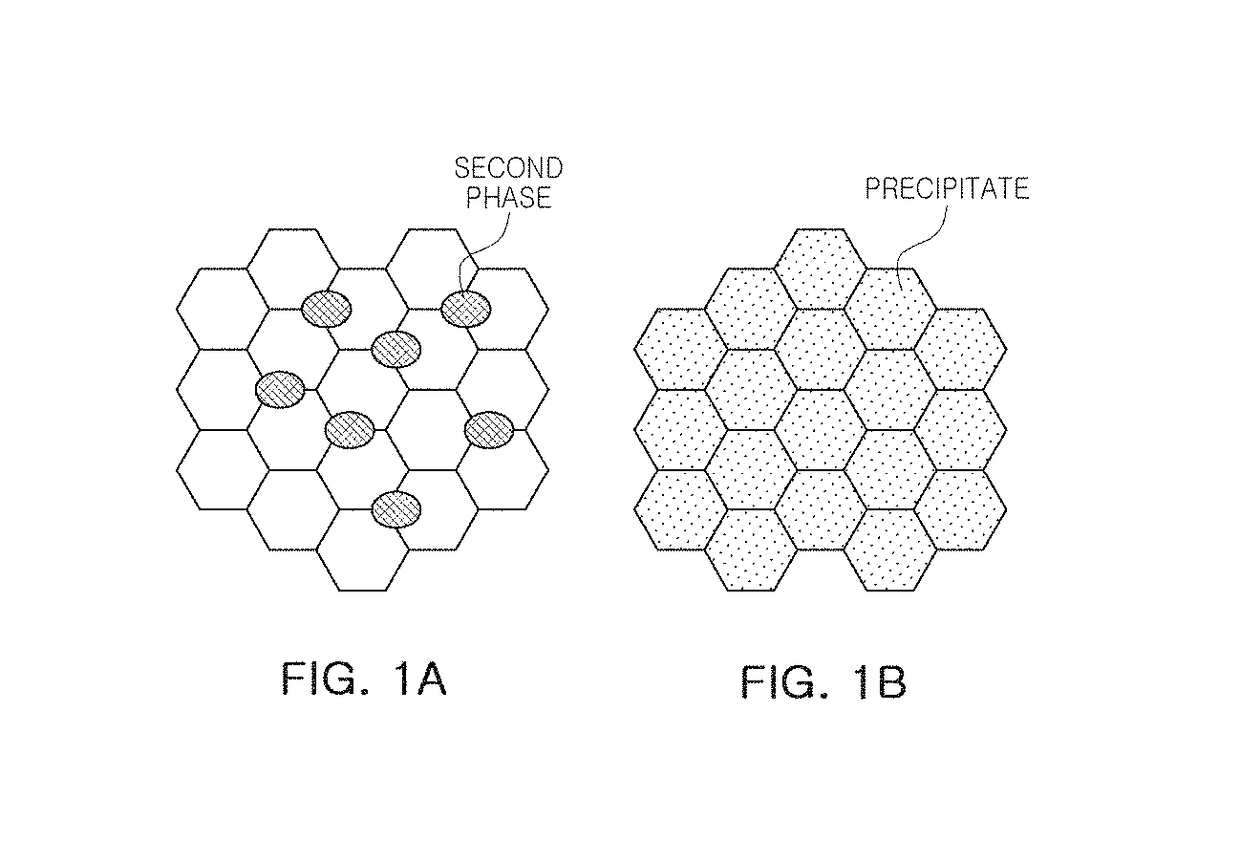

Precipitation hardening, also called age hardening or particle hardening, is a heat treatment technique used to increase the yield strength of malleable materials, including most structural alloys of aluminium, magnesium, nickel, titanium, and some steels and stainless steels. In superalloys, it is known to cause yield strength anomaly providing excellent high-temperature strength.

Precipitation Hardening High Entropy Alloy and Method of Manufacturing the Same

High-entropy alloy, particularly a precipitation hardening high entropy alloy, is provided as a component material used in electromagnetic, chemical, shipbuilding, mechanical, and other applications, a component material used in extreme environments requiring high strength and good corrosion resistance, and the like.

Owner:THE IND & ACADEMIC COOPERATION & CHUNGNAM NAT UNIV

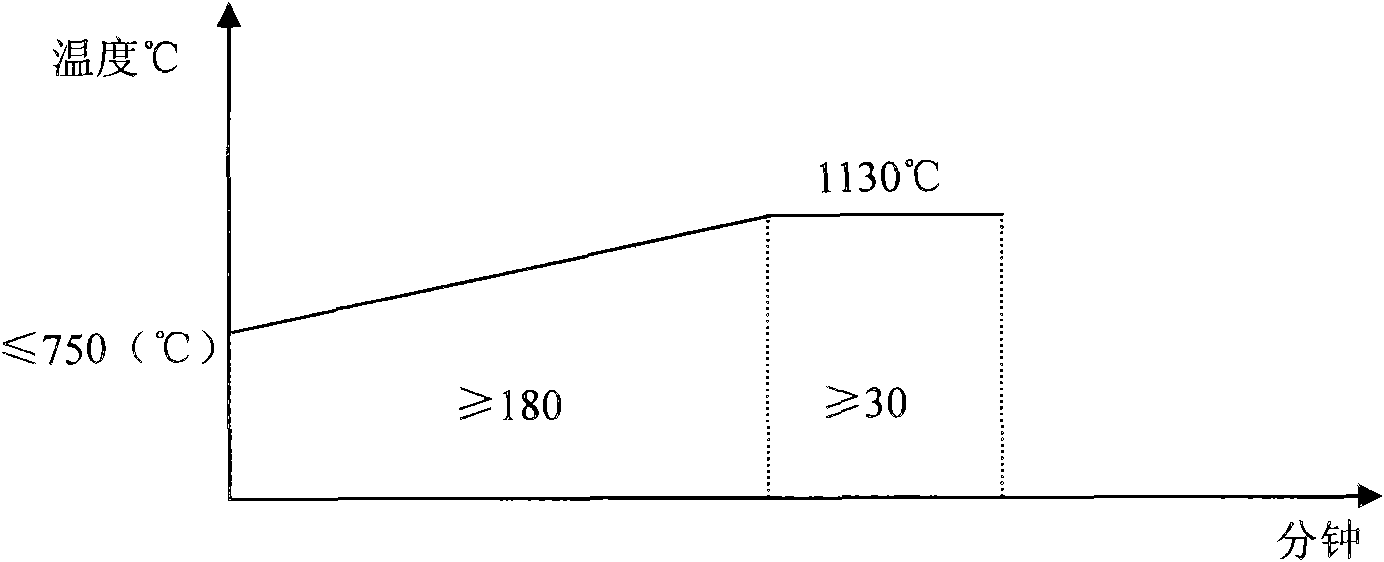

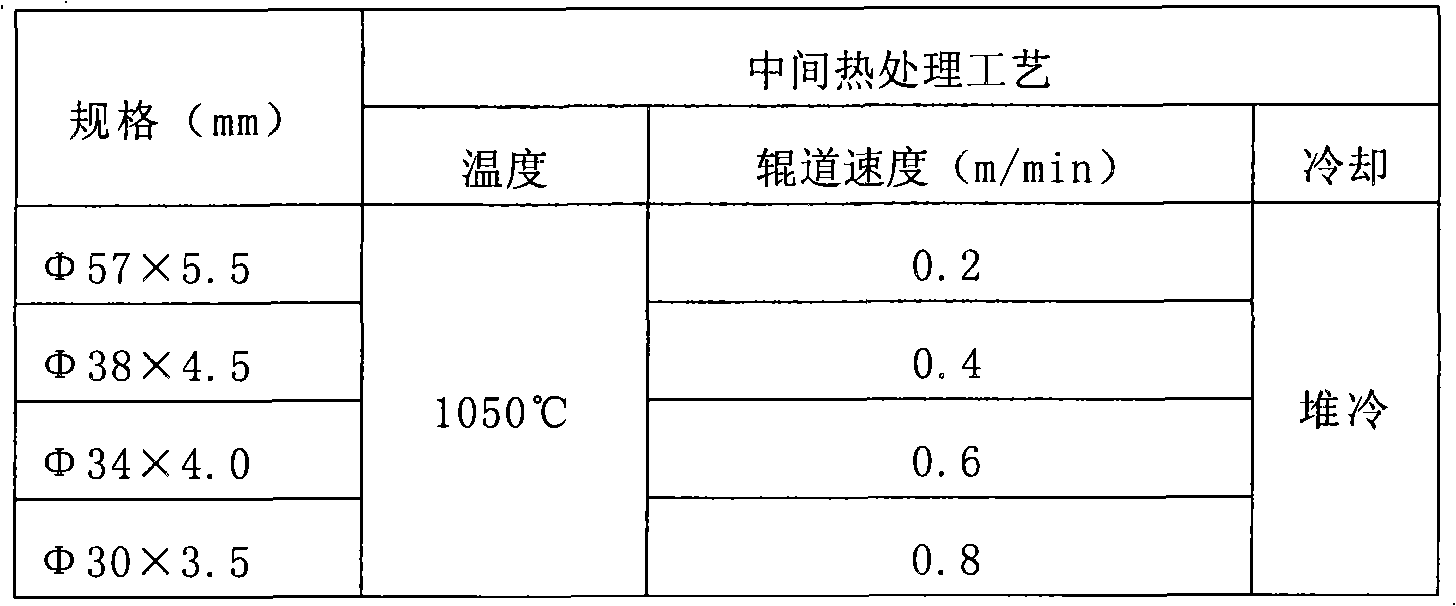

Method for preparing seamless steel tubes made of martensite precipitation hardening stainless steel

InactiveCN101612700AAvoid Surface Quality IssuesReduce lossFurnace typesMetal rolling arrangementsSolution treatmentProduct inspection

The invention discloses a method for preparing seamless steel tubes made of martensite precipitation hardening stainless steel, which comprises the following steps of billets, peeling, blanking, heating, hot punching, cooling, finishing, acid cleaning, lubricating, degreasing, heat treatment, straightening, tube cutting, acid cleaning, inspection, and packaging and warehousing. Compared with the prior art, the method has the following advantages that: pierced billets after hot punching are cooled in a pile so as to reduce working procedures and cost; the intermediate heat treatment adopts solution treatment, has short time and high efficiency, and improves surface quality; the tubes all adopt cold rolling process to improve yield; and vacuum aging treatment is adopted to improve the comprehensive mechanical property, the finished product inspection qualified rate reach 95 percent, and the yield from the billets to the finished products reach 51.31 percent.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

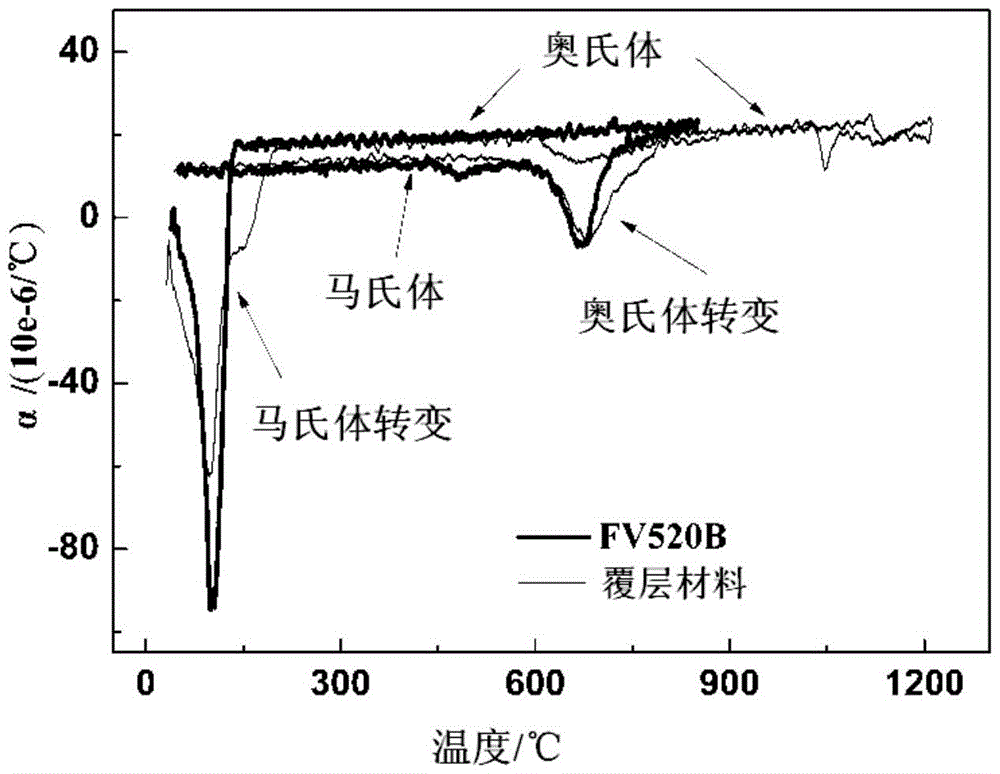

Alloy powder used for laser remanufacturing of martensitic stainless steel parts and preparation method

ActiveCN105039869ASolve and improve formabilitySolve and improve crack resistanceMetallic material coating processesSlagMartensitic stainless steel

The invention provides alloy powder used for laser remanufacturing of FV520B martensitic stainless steel parts and a preparation method. The chemical components of the alloy powder include, by weight percentage, 0.01-0.3% of C, 12-17% of Cr, 3-7% of Ni, 0.4-2% of Mo, 0.1-2% of Mn, 0.15-0.55% of Nb, 0-3% of Cu, 0.05-2% of Si, 0-1.6% of B and the balance Fe. The preparation method of the alloy powder is a vacuum melting-high pressure gas atomization method. The alloy powder can have the density and the thermal expansion coefficient which are similar to those of FV520B materials when precipitation hardening elements, deoxygenation slag forming elements and elements used for lowering the martensite phase transformation point are added and the weight percent content of all the elements are regulated; the residual stress level is lowered through the martensite phase transformation accompanying effect; and therefore the problems of cracks, deformation and the like are greatly relieved, and the forming property, the anti-cracking property and the process stability are achieved and improved when the FV520B parts are subjected to laser remanufacturing through the alloy powder.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

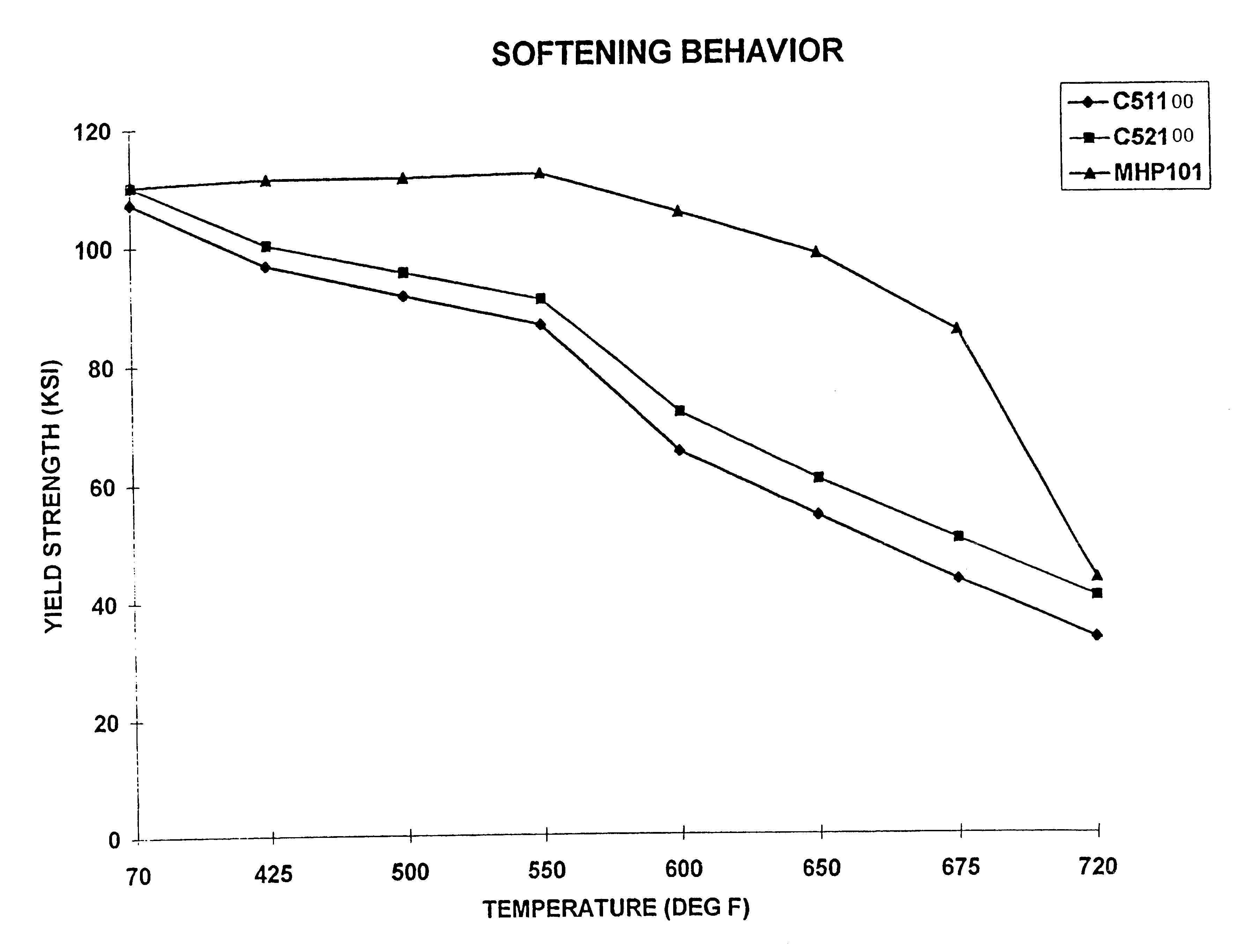

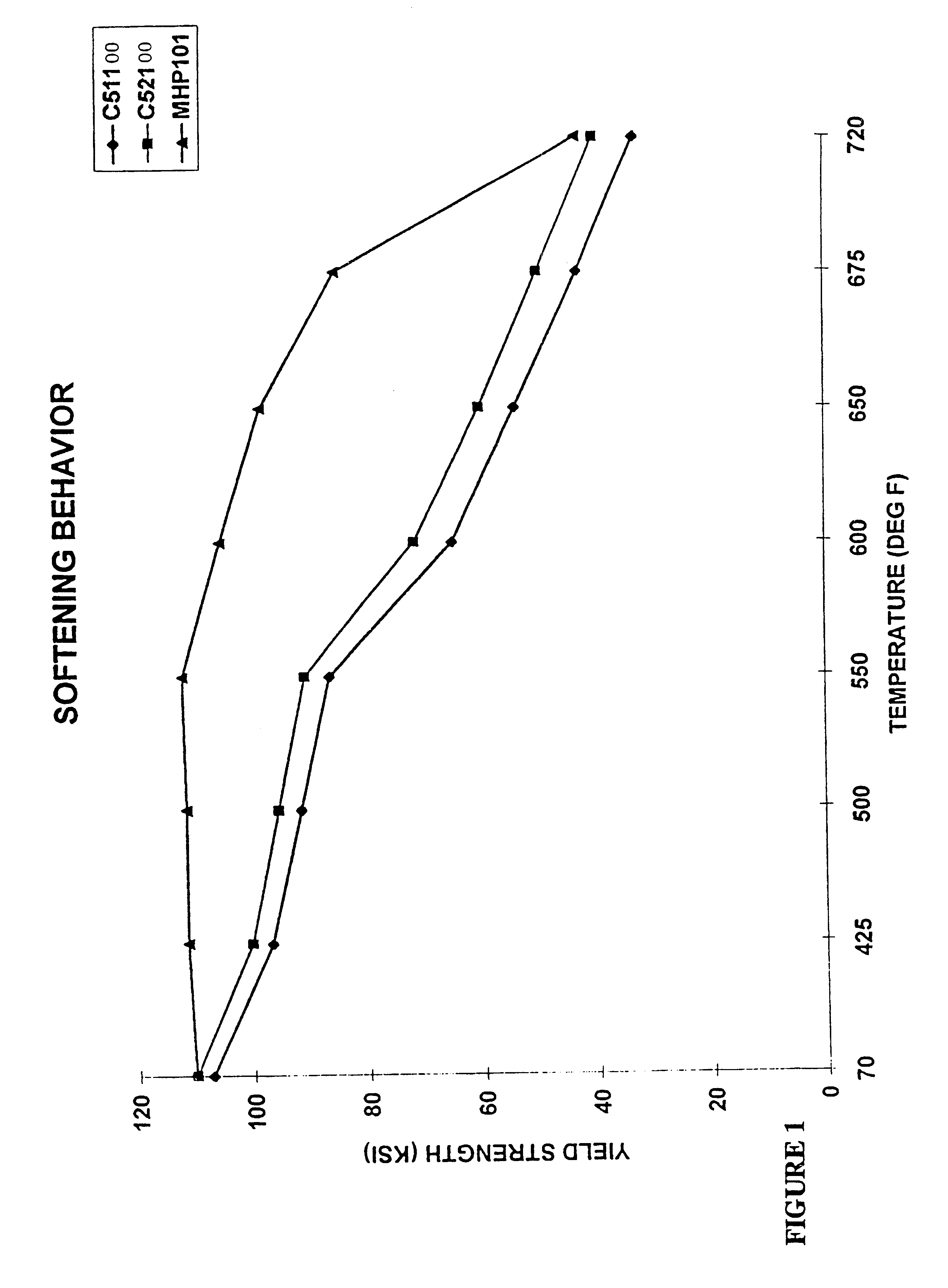

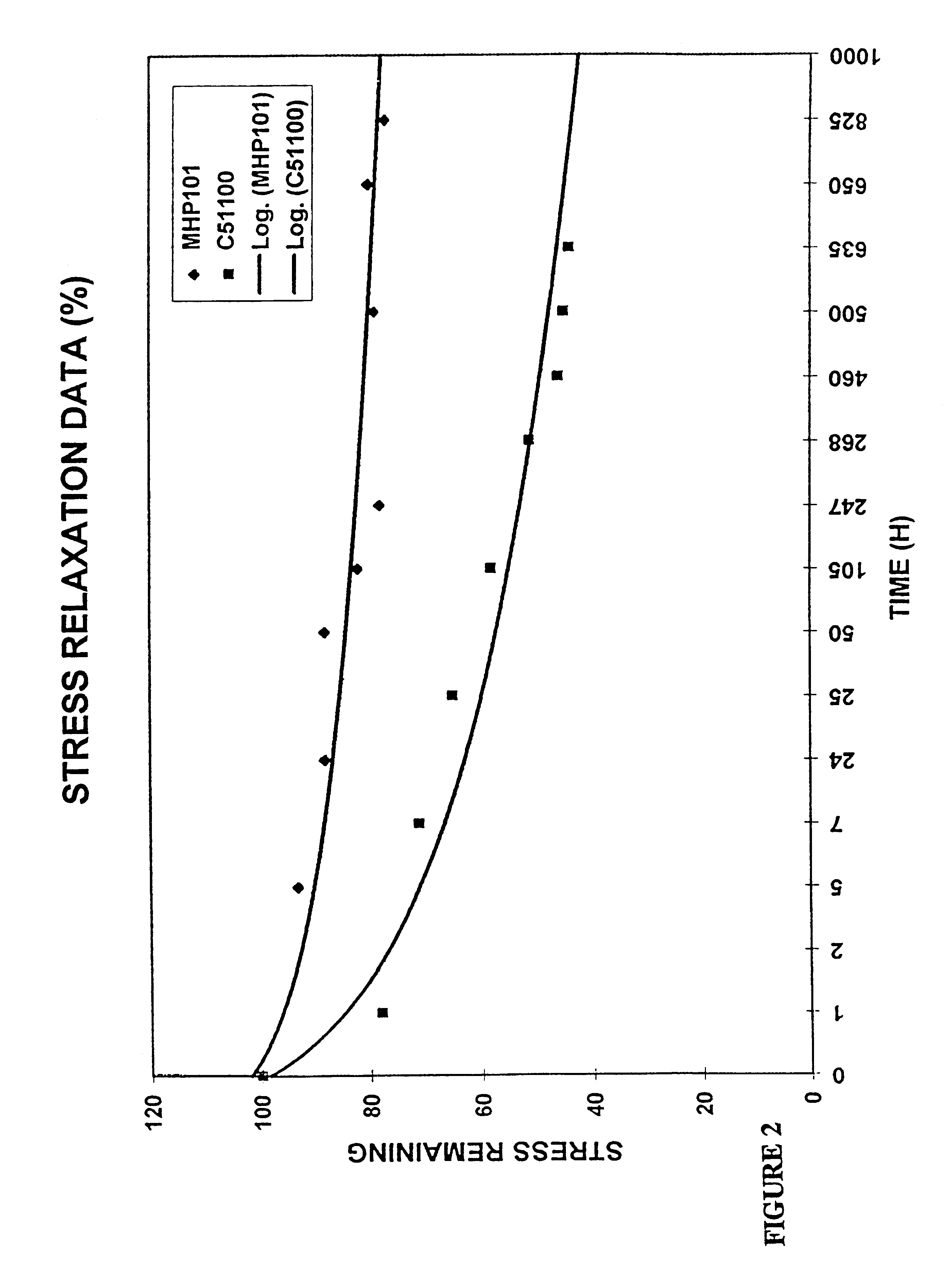

Copper based alloy featuring precipitation hardening and solid-solution hardening

InactiveUS6379478B1Good molding effectOptimal spring propertyCoupling contact membersPhosphor bronzeSolid solution

Owner:MILLER THE

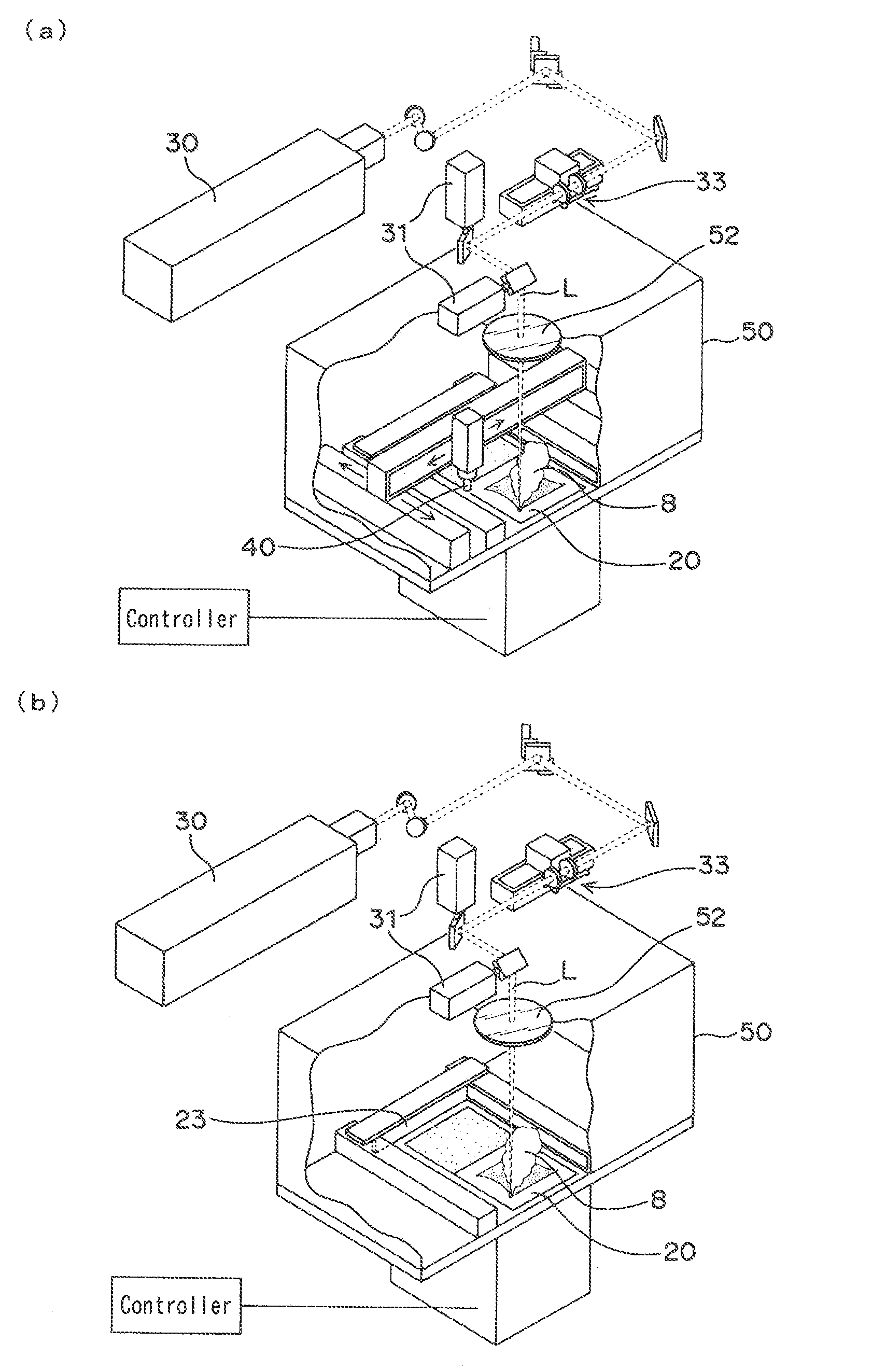

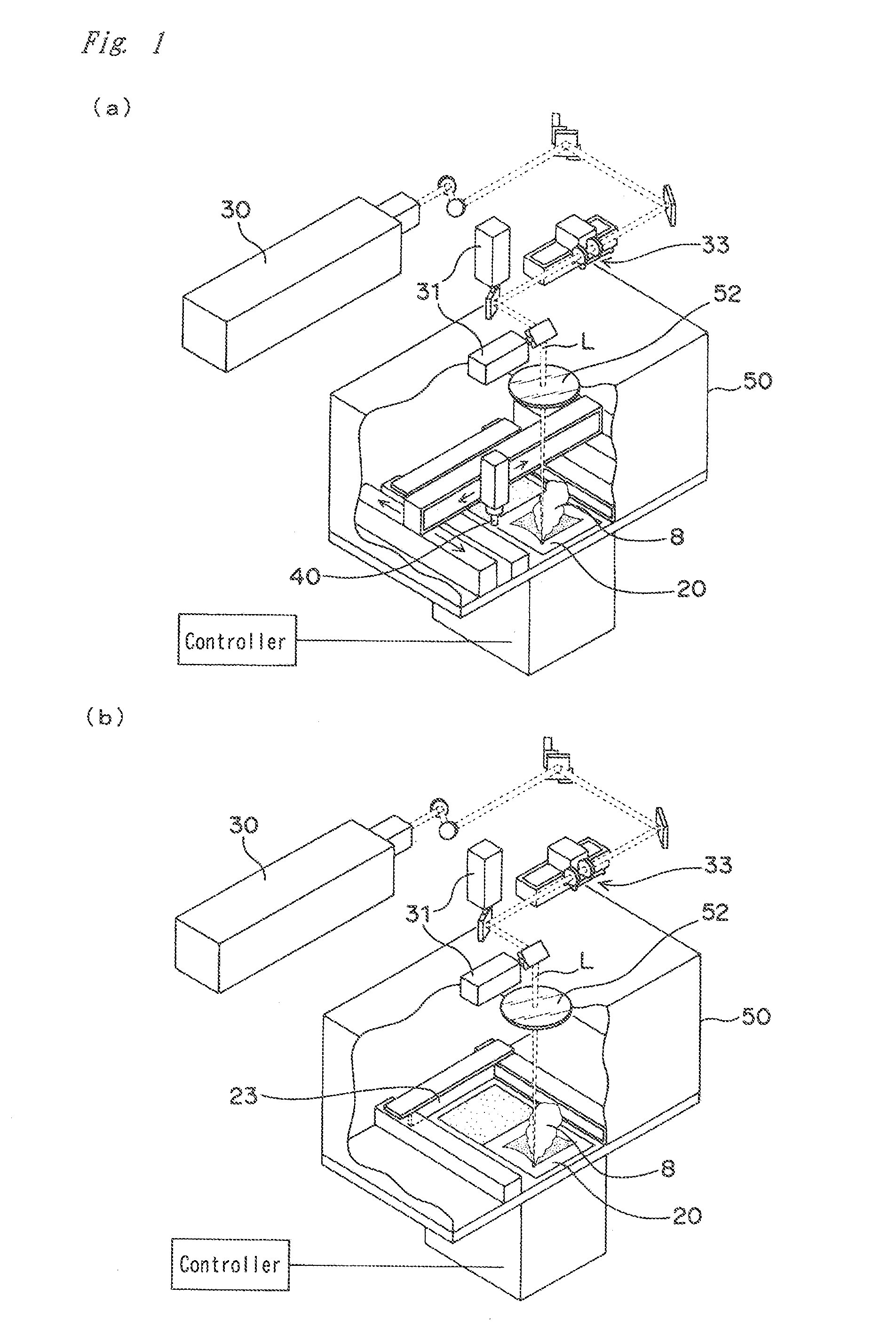

Metal powder for selective laser sintering, method for manufacturing three-dimensional shaped object by using the same, and three-dimensional shaped object obtained therefrom

InactiveUS20130065073A1Reduce warpingReduce deformationAdditive manufacturing apparatusPig casting plantsSelective laser sinteringPowder mixture

There is provided a metal powder for use in a selective laser sintering method for producing a three-dimensional shaped object, wherein the metal powder comprises a powder mixture of a precipitation-hardening metal composition. In particular, the metal powder of the present invention is configured to have a Fe-based component powder and a Ni-based component powder which are individually included in the powder mixture wherein a powder made of an alloy of Fe-based and Ni-based components is not included as a main powder in the powder mixture.

Owner:PANASONIC CORP

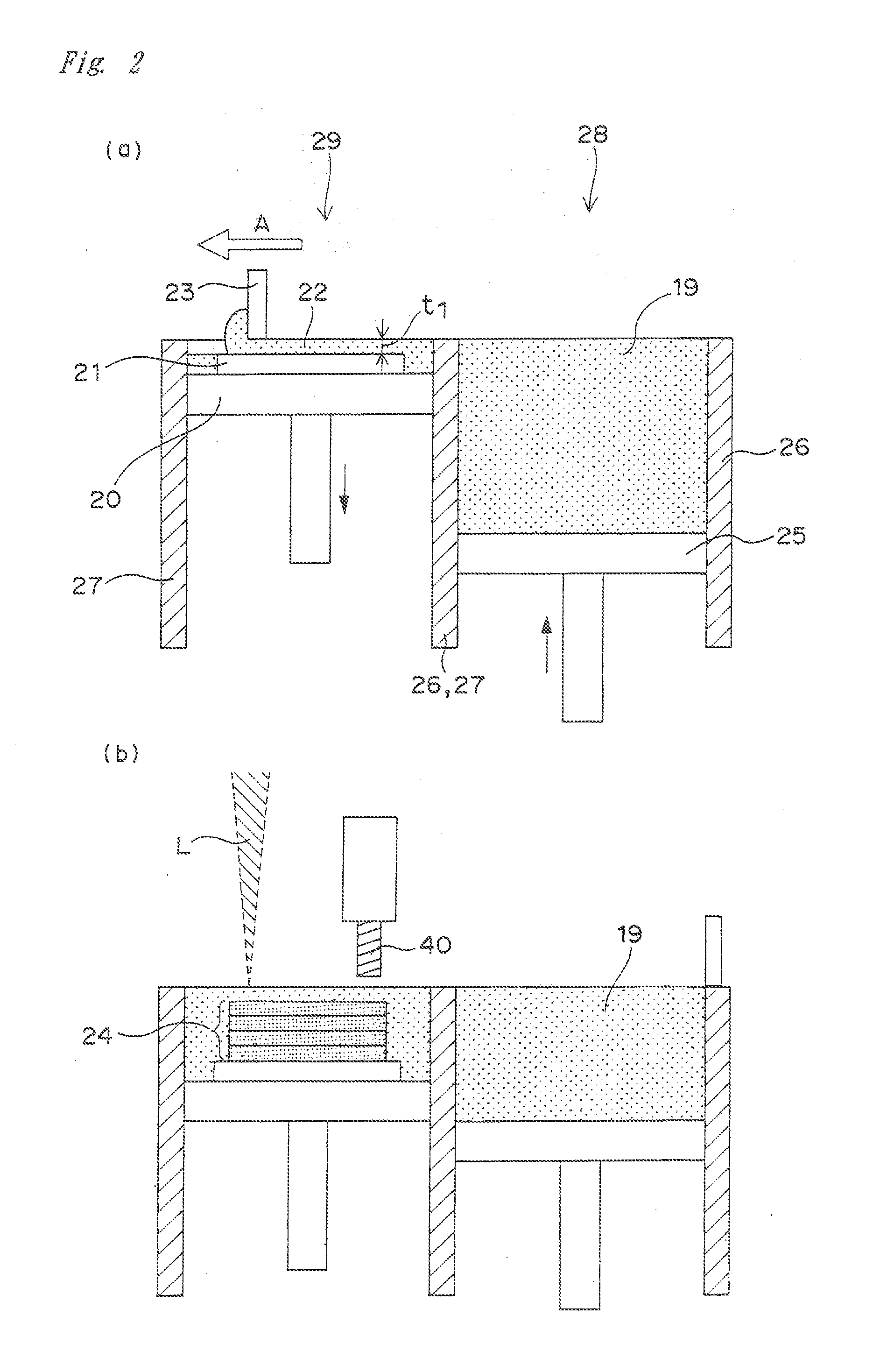

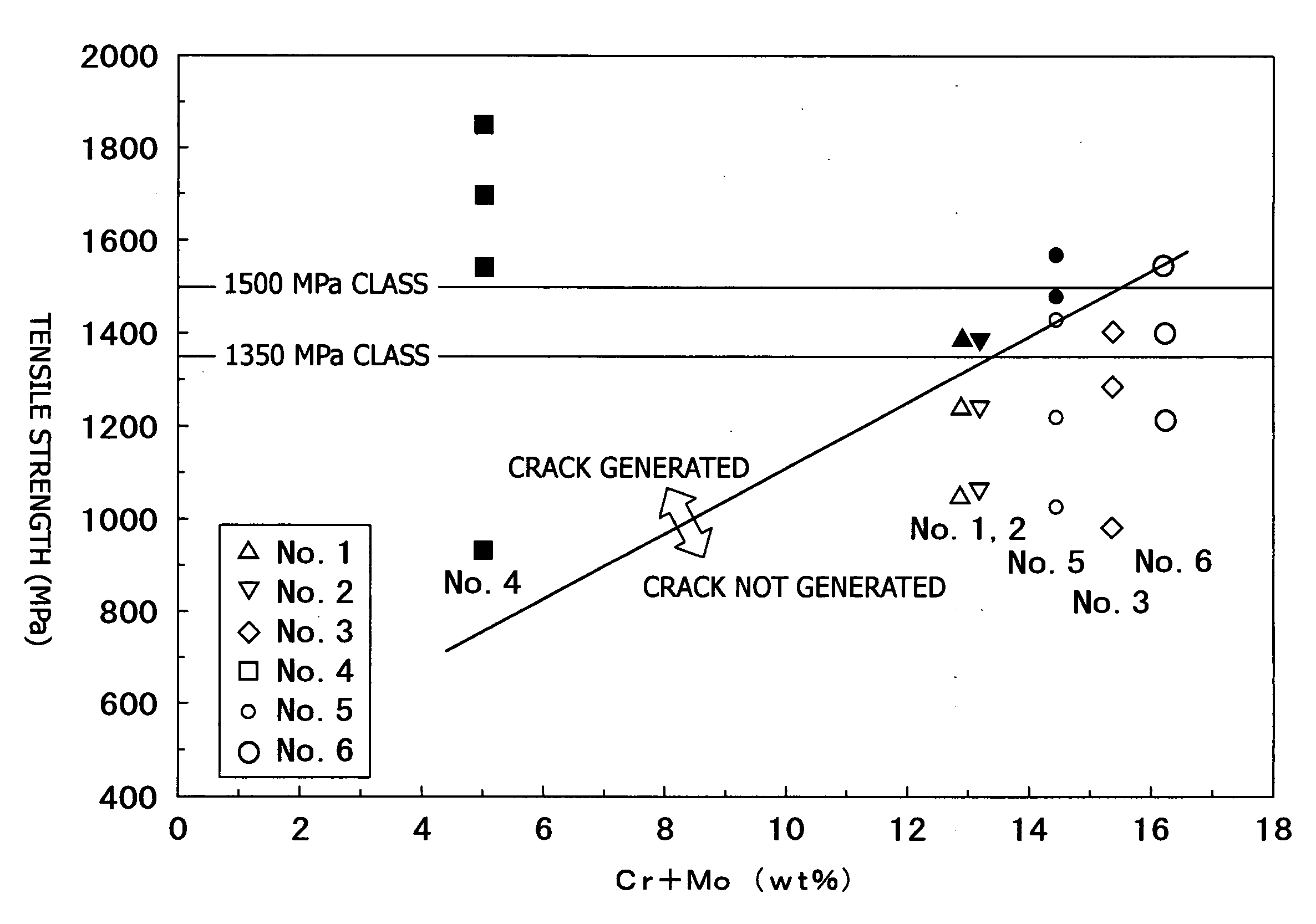

Precipitation hardened martensitic stainless steel, manufacturing method therefor, and turbine moving blade and steam turbine using the same

InactiveUS20060118215A1High strengthImprove toughnessBlade accessoriesFurnace typesMetallurgyMartensitic stainless steel

The precipitation hardened martensitic stainless steel is characterized by containing, in percent by weight, 12.25 to 14.25% Cr, 7.5 to 8.5% Ni, 1.0 to 2.5% Mo, 0.05% or less C, 0.2% or less Si, 0.4% or less Mn, 0.03% or less P, 0.005% or less S, 0.008% or less N, 0.90 to 2.25% Al, the balance substantially being Fe, and the total content of Cr and Mo being 14.25 to 16.75%. A turbine moving blade and a steam turbine are manufactured by using this martensitic stainless steel.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

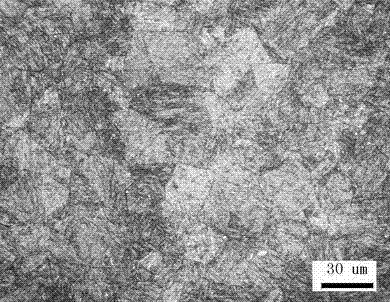

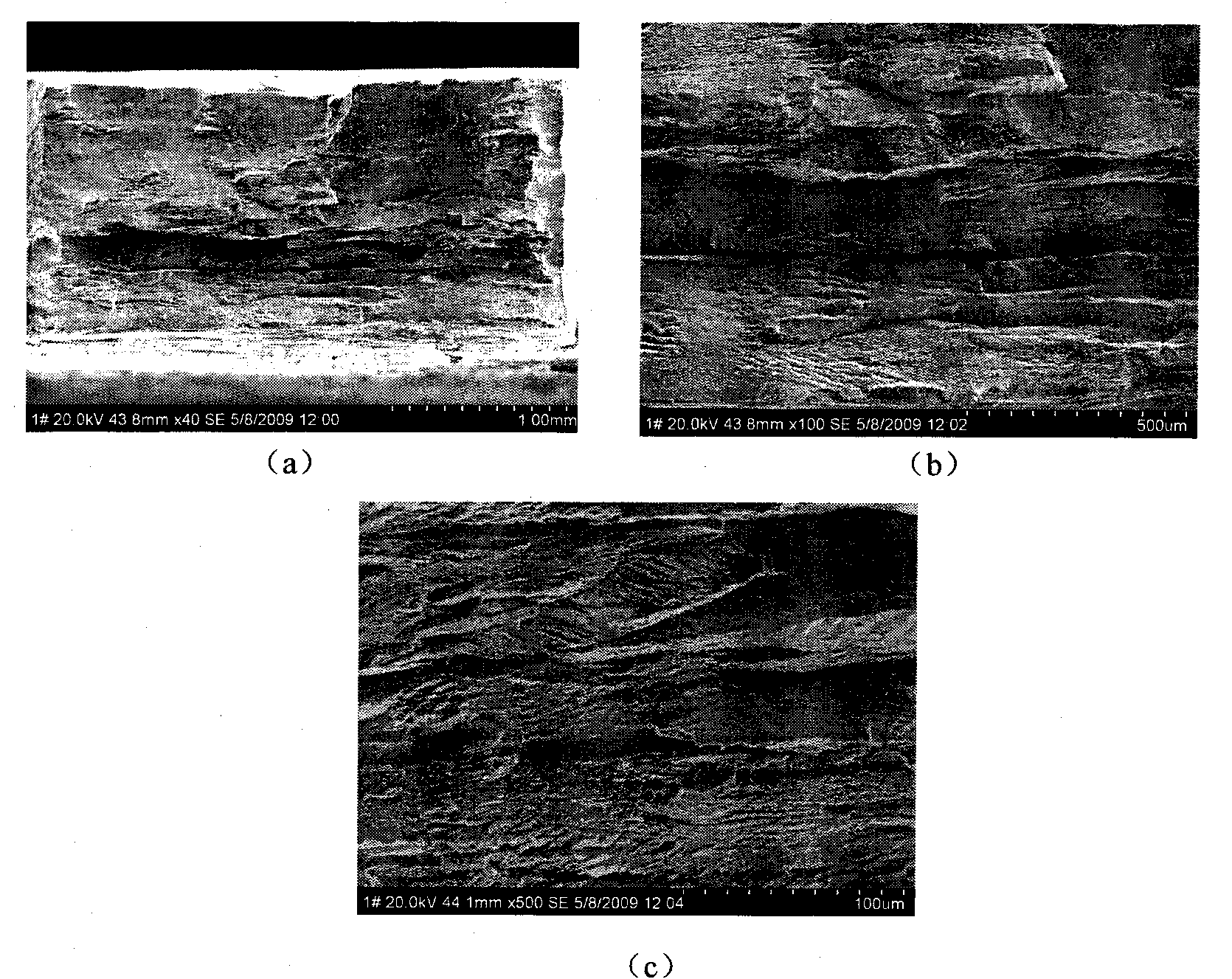

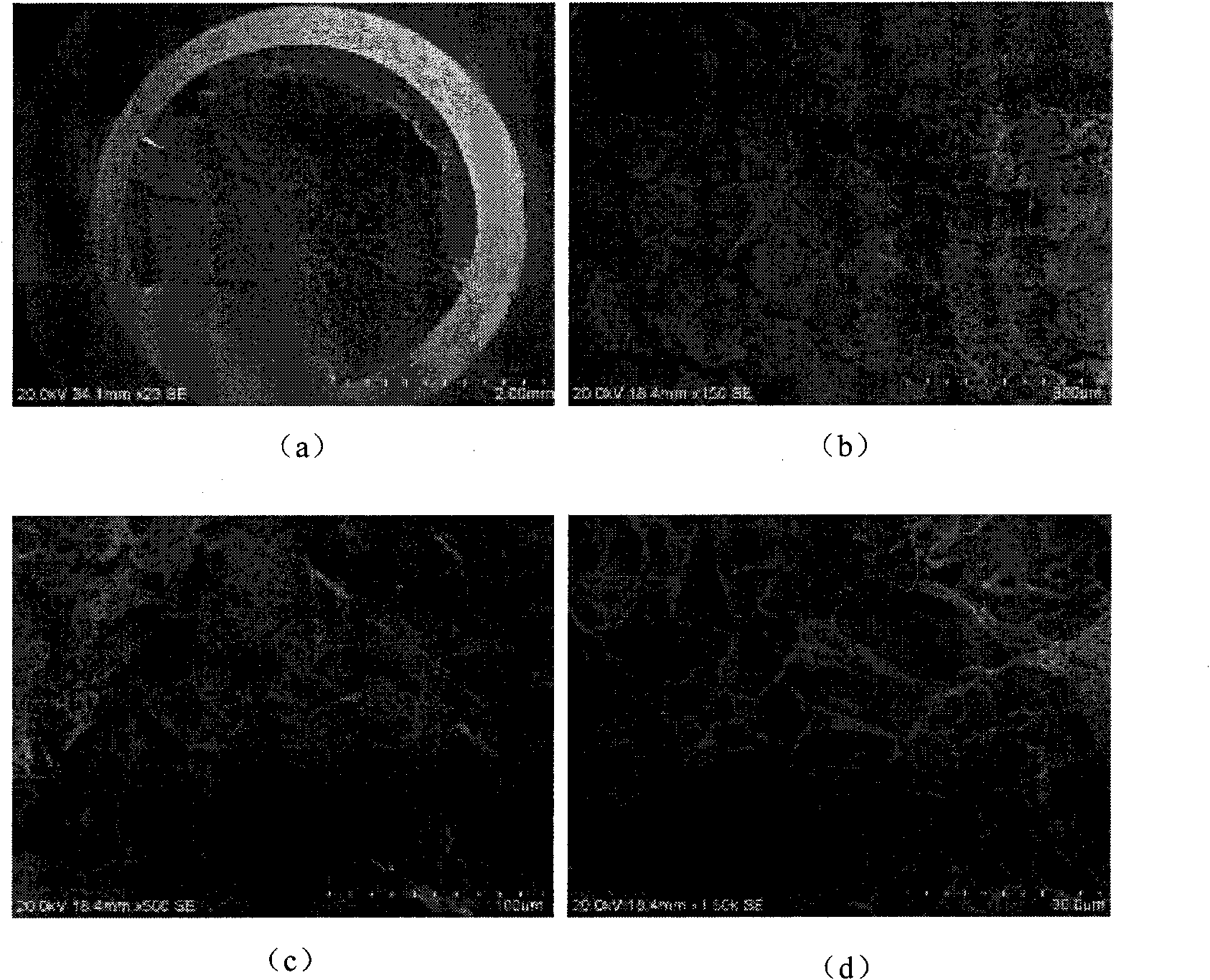

Metallographic corrosion method for martensitic precipitation hardening stainless steel crystal boundary

InactiveCN102443803ADoes not affect observationNo heating requiredPreparing sample for investigationMartensiteHigh-temperature corrosion

The invention discloses a metallographic corrosion method for a martensitic precipitation hardening stainless steel crystal boundary, wherein the stainless steel is 05Cr17Ni4Cu4Nb martensitic precipitation hardening stainless steel. The method comprises the following steps: 1, coarsely grinding, finely grinding, polishing, cleaning and drying a metallographic sample to obtain a shine scratch-freepolished surface; and 2, picking up a corrosive agent, wiping the polished surface for 15-20s, flushing, and drying, wherein the corrosive agent is prepared by pouring 2-3ml of concentrated hydrochloric acid into 30ml of concentrated nitric acid, uniformly stirring and allowing the obtained solution to stand for above 5min. According to the invention, the 05Cr17Ni4Cu4Nb martensitic precipitation hardening stainless steel crystal boundary can be intelligibly and completely displayed, and the color and the morphology of the tissue have no influences on the observation of the contour of the crystal boundary. The method has the following advantages: the crystal boundary display effect is excellent; normal temperature corrosion and no need of heating are realized; and the corrosion time is short, and only 15-20 seconds are needed.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

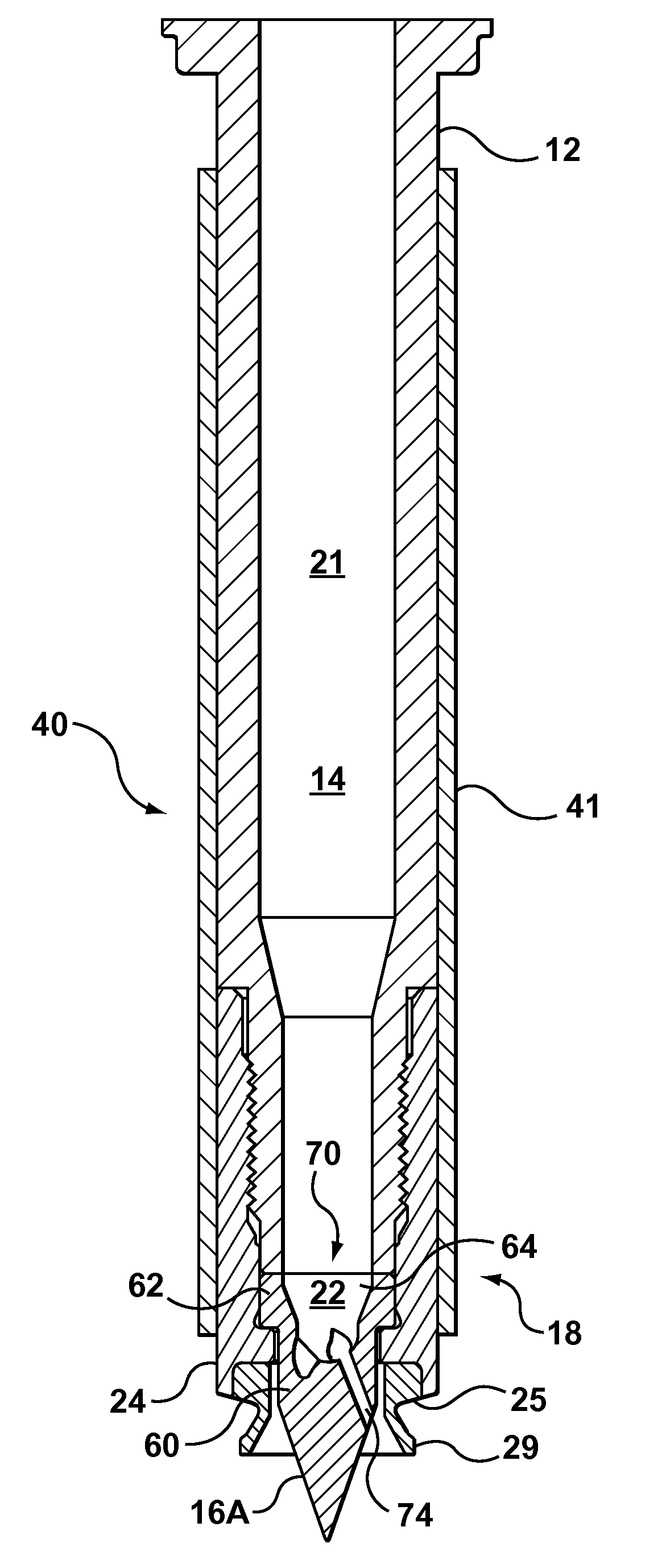

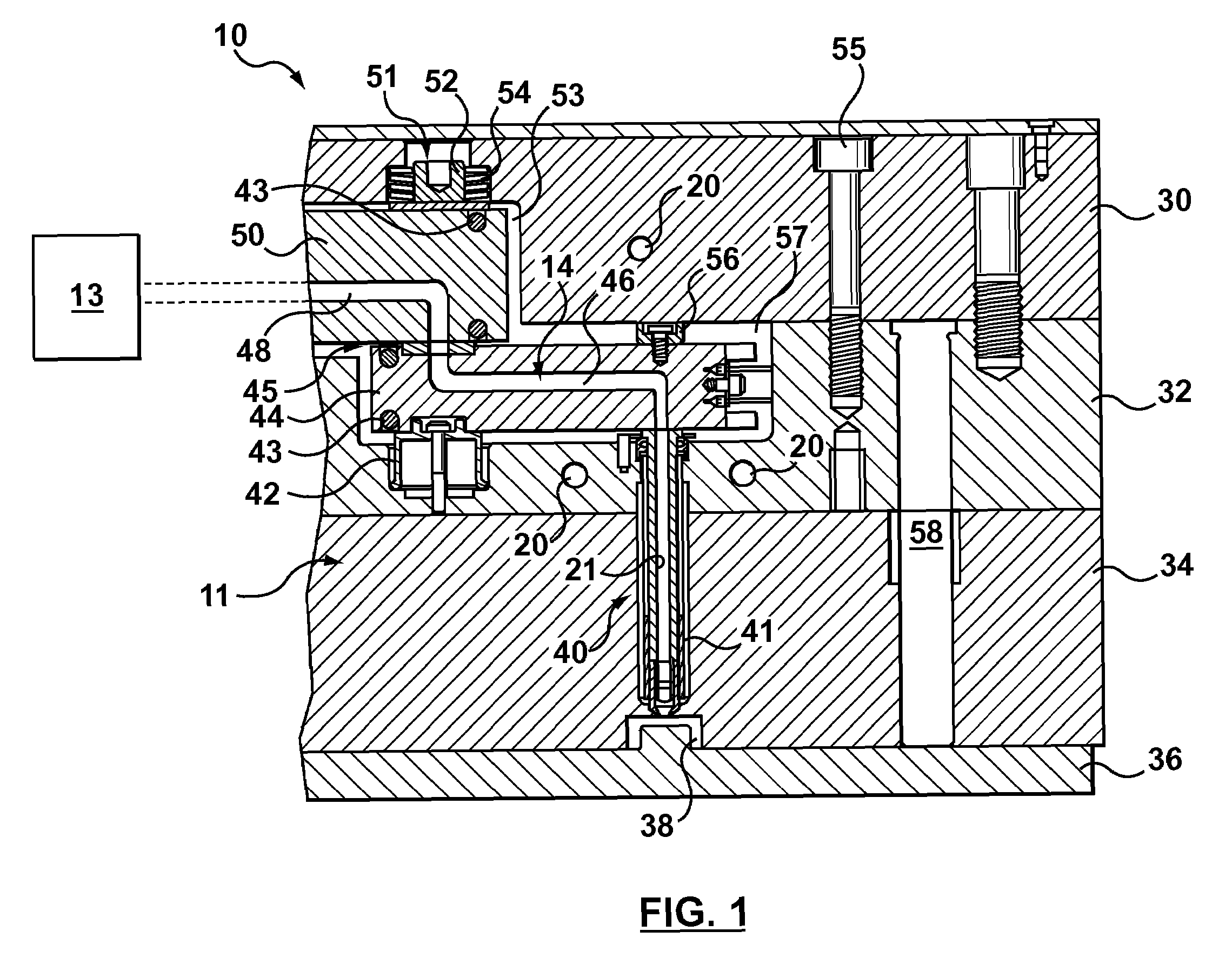

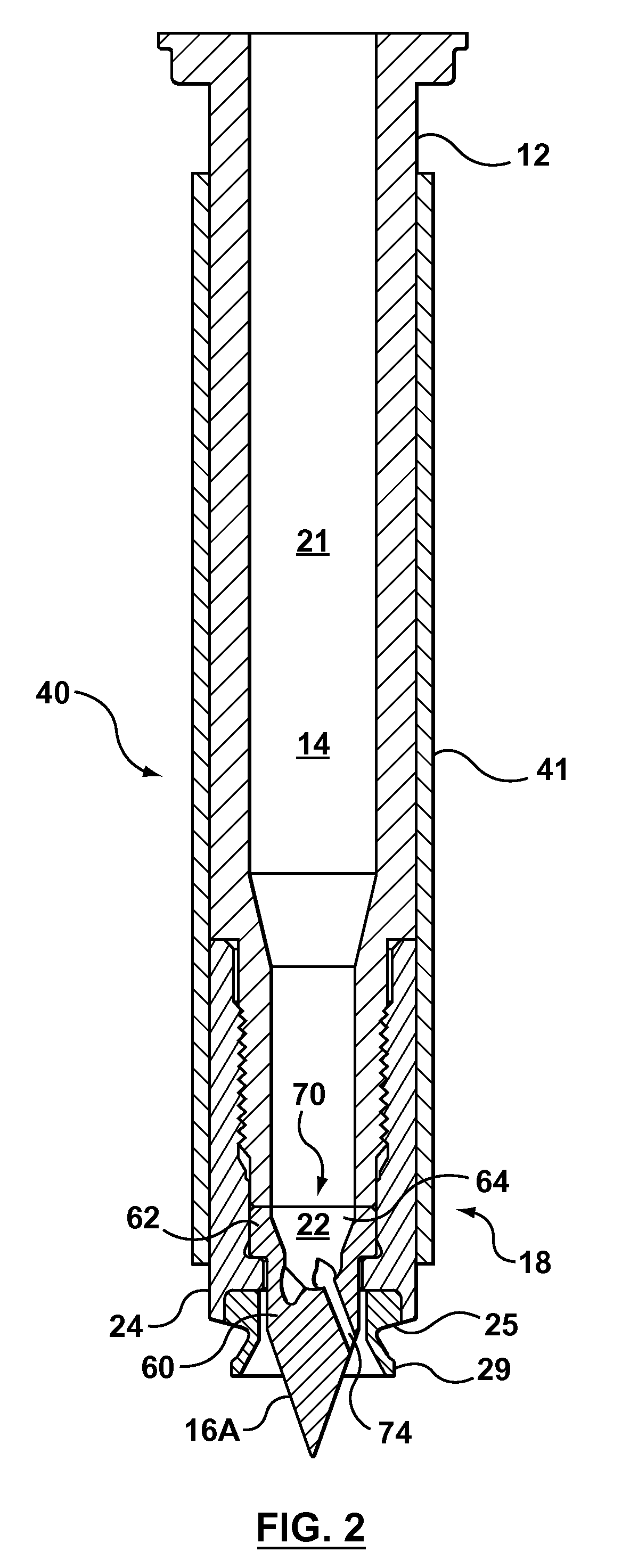

Composite Nozzle Tip Method

InactiveUS20080206394A1High thermal conductivity materialHigh strengthFurnace typesFood shapingHigh intensityUltimate tensile strength

A composite nozzle tip for an injection molding assembly includes a body, having a bore extending therethrough, adapted for connection to the injection molding assembly. The body is formed of a precipitation hardened, high thermal conductivity material and a precipitation hardened, high strength material, which are integrally joined together to form the body. The thermal conductivity of the high thermal conductivity material is greater than the thermal conductivity of the high strength material, and the strength of the high strength material is greater than the strength of the high thermal conductivity material. The high thermal conductivity material and the high strength material can be precipitation hardened together under the same precipitation hardening conditions to achieve increases in the value of at least one strength aspect of the high thermal conductivity material and the value of at least one strength aspect of the high strength material, relative to their respective unhardened conditions.

Owner:HUSKY INJECTION MOLDING SYST LTD

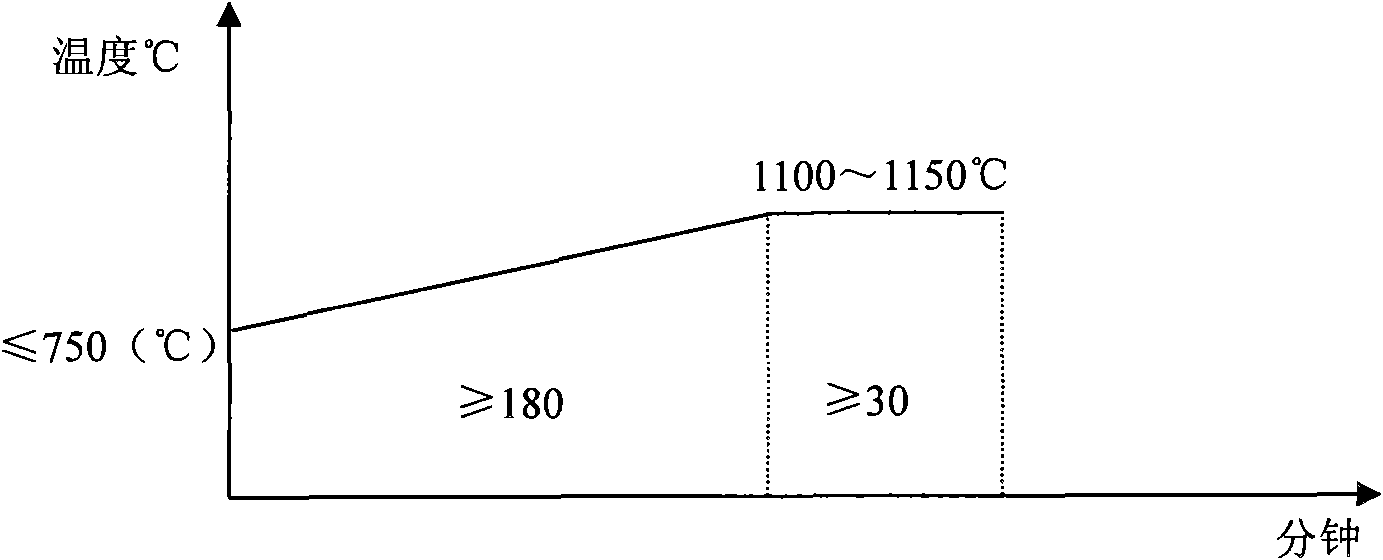

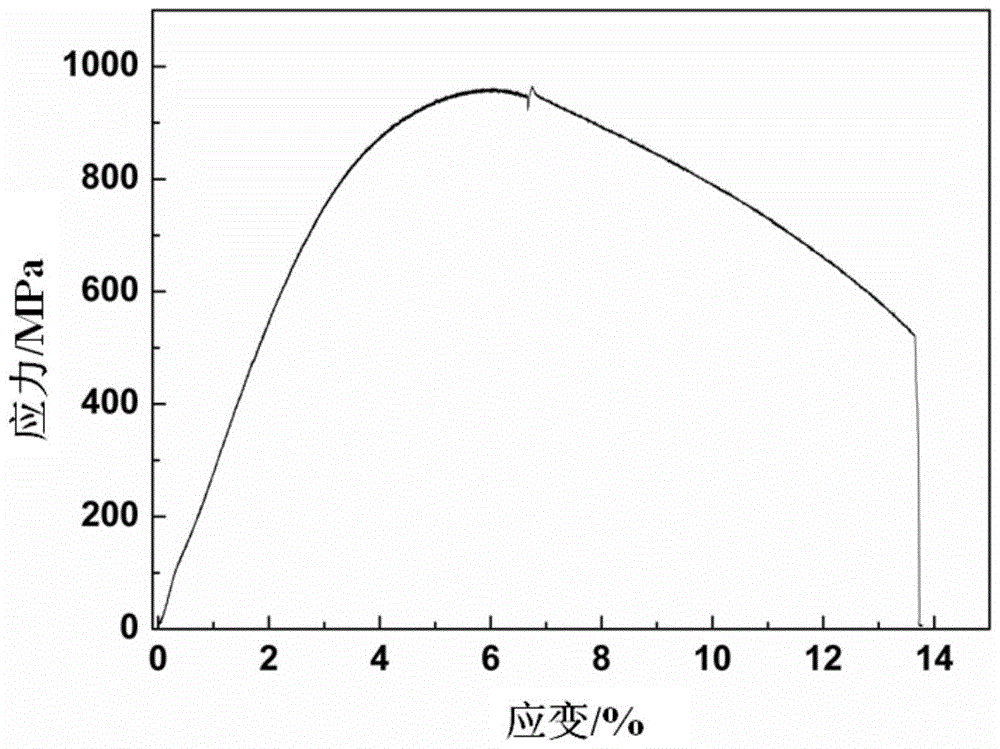

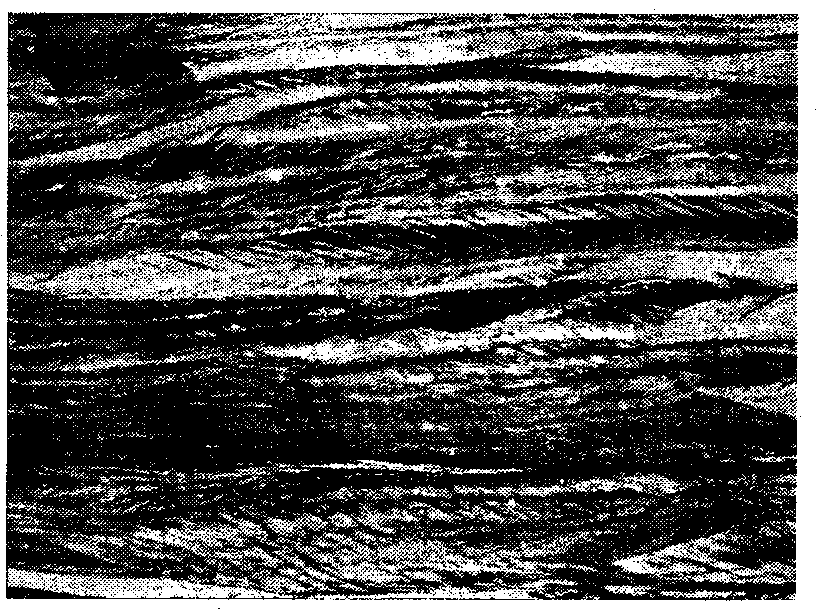

Deformation induced maraging stainless steel and machining process thereof

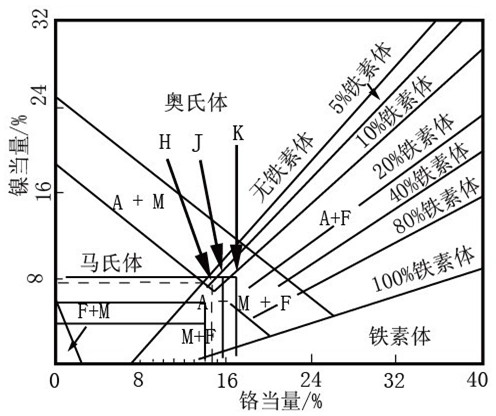

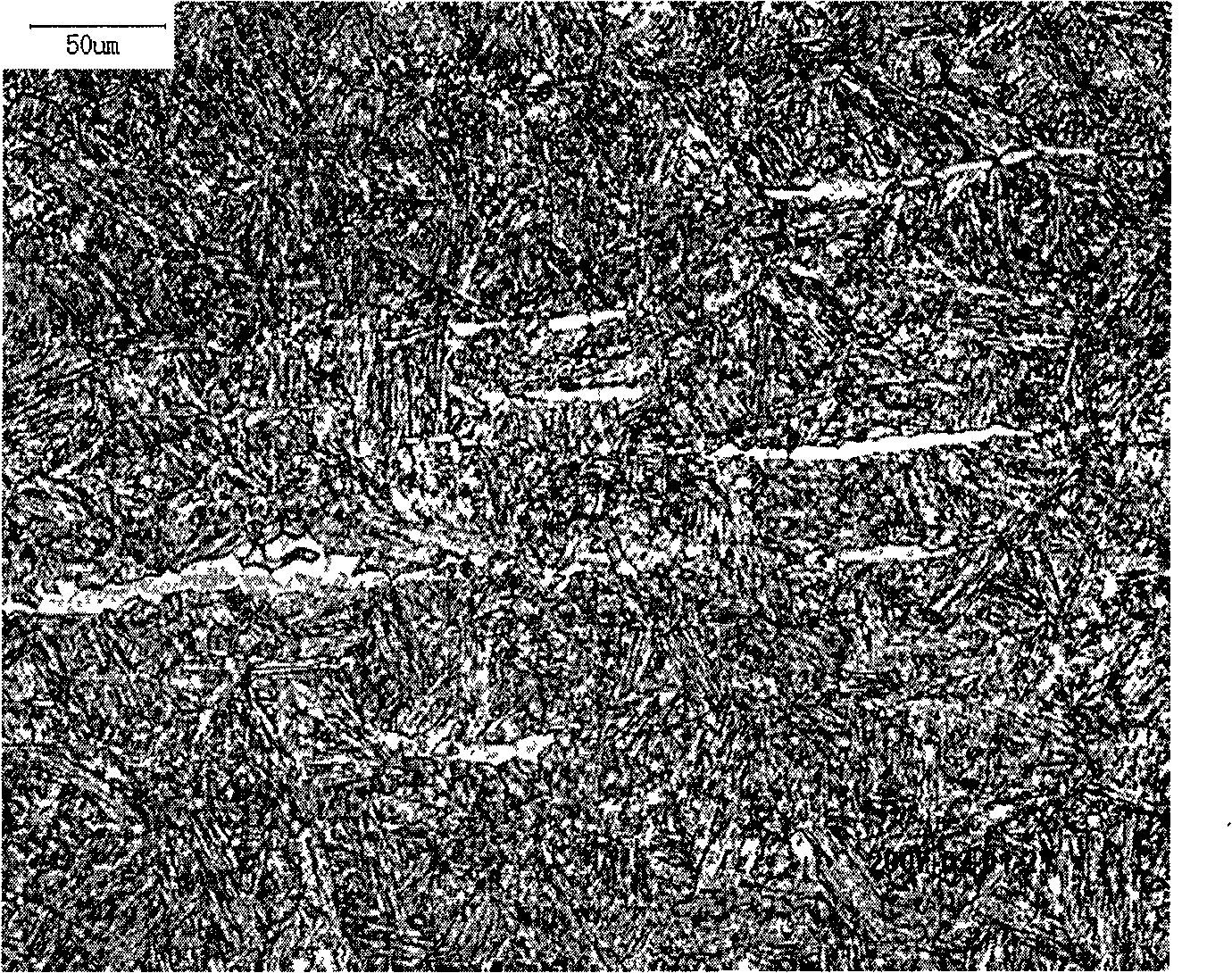

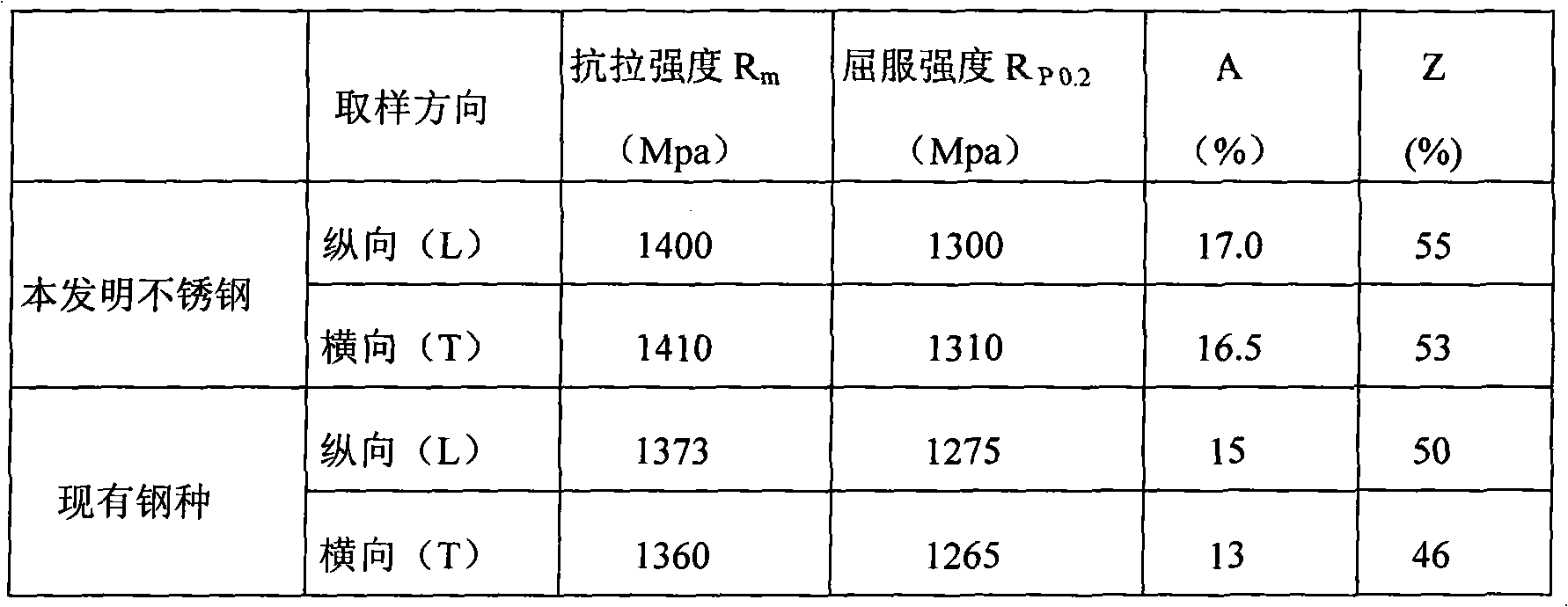

The invention belongs to the field of iron nickel-based martensite precipitation hardening-type alloys, and in particular relates to deformation induced maraging stainless steel with high strength, high toughness and high corrosion resistance and a machining process thereof. The stainless steel is a novel material mainly applied to the important fields of aviation, spaceflight, machinofacture, atomic energy and the like. The steel comprises the following components in percentage by weight: 11.0-13.0 percent of Cr, 11.0-14.0 percent of Ni, 1.5-2.1 percent of Ti, 0.1-1.0 percent of Mo, 0.5-2.0 percent of Cu, 1.5-2.2 percent of Co, 0.5-1.5 percent of Mn, 0.1-1.0 percent of Si, 1.0-2.0 percent of Al, less than 0.01 percent of Nb, less than 0.01 percent of C, less than 0.01 percent of N, less than 0.01 percent of V and the balance of Fe. The machining process comprises the following steps of: (1) heating and forging in an austenite single phase zone, and air-cooling to the room temperature after the forging is ended, wherein the forge and press ratio is 6-9; (2) hot-rolling after the forging is ended and air-cooling to the room temperature after the rolling is ended, wherein the blooming temperature is 1100-1200 DEG C, and the finished rolling temperature is 800-900 DEG C. The invention obtains a martensite matrix with high-order dislocation density through deformation induced martensite phase change and simultaneously obtains high strength, high toughness and high corrosion resistance through adding the proper matching of precipitation strength elements, such as Ni, Ti, Mo, Cu and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Manufacturing process of forging stock of steel forging piece for oil extraction equipment in deep sea

The invention discloses a manufacturing process of a forging stock of a steel forging piece for oil extracting equipment in a deep sea, which comprises the following steps of: with martensite precipitation hardening type stainless steel as a steel forging piece material, selecting a square ingot, heating to 1180DEG C, cogging along the length direction of the steel ingot to obtain an octagonal section steel billet, wherein the forging ratio is 2.0-2.2; heating the octagonal section steel billet to 1040DEG C and preserving heat for 360 minutes; carrying out oil cooling below 32DEG C; taking an intermediate section as a billet; axially upsetting the billet from the initial forging temperature of 1150DEG C to the final forging temperature of 990DEG C; when the billet is upset to half of the height of the original billet, drawing out the octagonal section of the upset billet according to the original axial direction; axially upsetting when the billet is drawn to the length of the original billet; when the billet is upset to half of the height of the original billet, drawing out the octagonal section of the upset billet according to the original axial direction; when axially forging and shaping the billet when the billet is upset to half of the height of the original billet, enabling the total forging ratio to be 5.5 and obtaining a rectangular forging piece; and air cooling to be 340-360DEG C, carrying out furnace insulating for 120 minutes and then carrying out furnace cooling to the room temperature.

Owner:NANJING DEV ADVANCED MFG

Martensite precipitation hardening stainless steel for structural member and manufacturing method thereof

The invention provides a martensite precipitation hardening stainless steel for structural member and a manufacturing method thereof. The martensite precipitation hardening stainless steel comprises the following chemical components in percentage by weight: less than or equal to 0.05 percent of C, 13.50 to 15.50 percent of Cr, 2.5 to 4.0 percent of Cu, 3.0 to 5.0 percent of Ni, 0.15 to 0.40 percent of Nb and Ta, 0.010 to 0.040 percent of N, 0.050 to 0.15 percent of V, less than or equal to 0.80 percent of Si, less than or equal to 1.00 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, and the balance of Fe and inevitable impurities. The stainless steel is smelted by combining an electric furnace, AOD refining and vacuum self-consuming technology, so the stainless steel has the characteristics of high strength, good plasticity, good corrosion resistance and the like, and can meet the requirements of high-strength components such as high-pressure values, oil drill, efficient heavy-duty machinery and the like on material performance.

Owner:宝武特种冶金有限公司

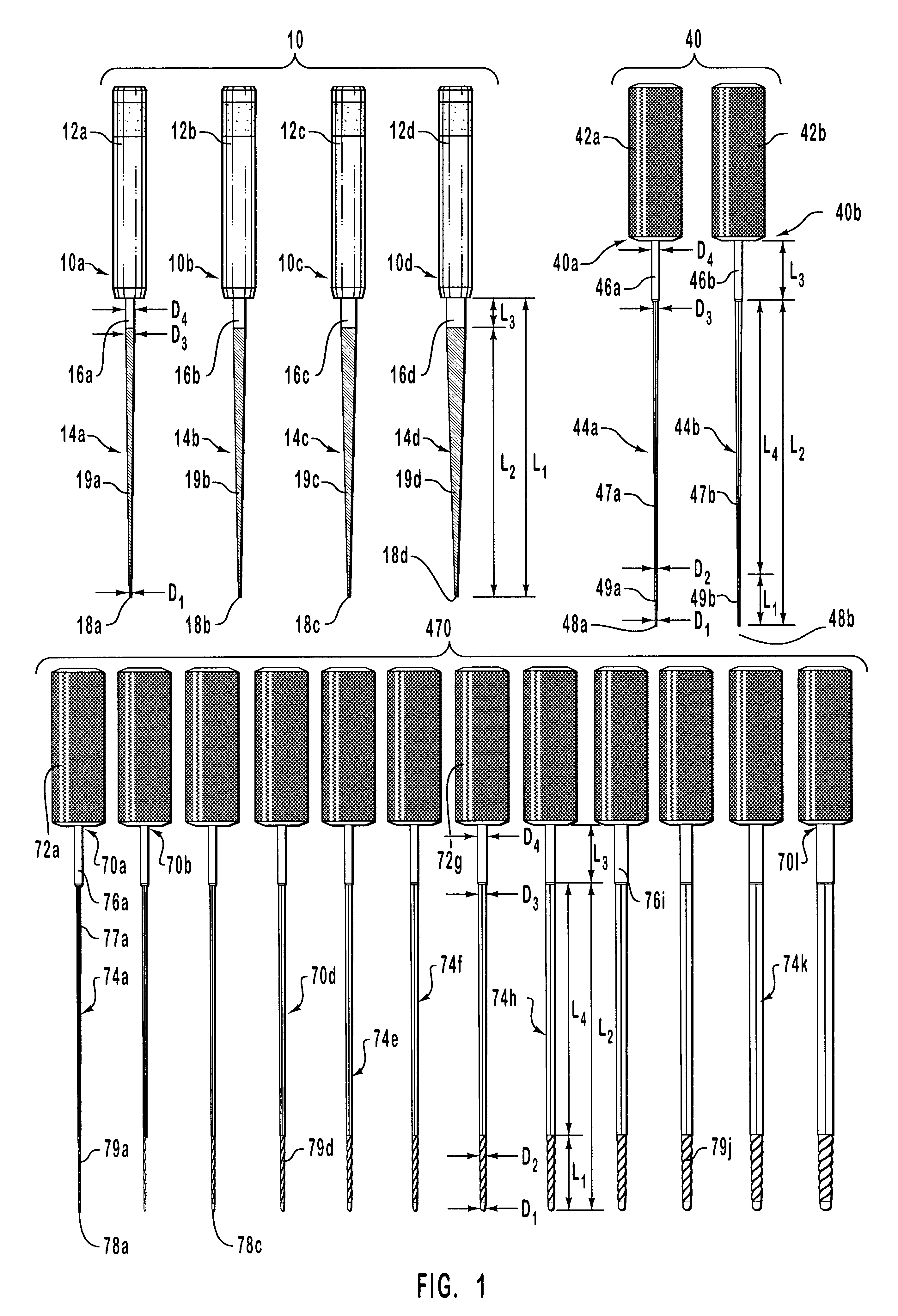

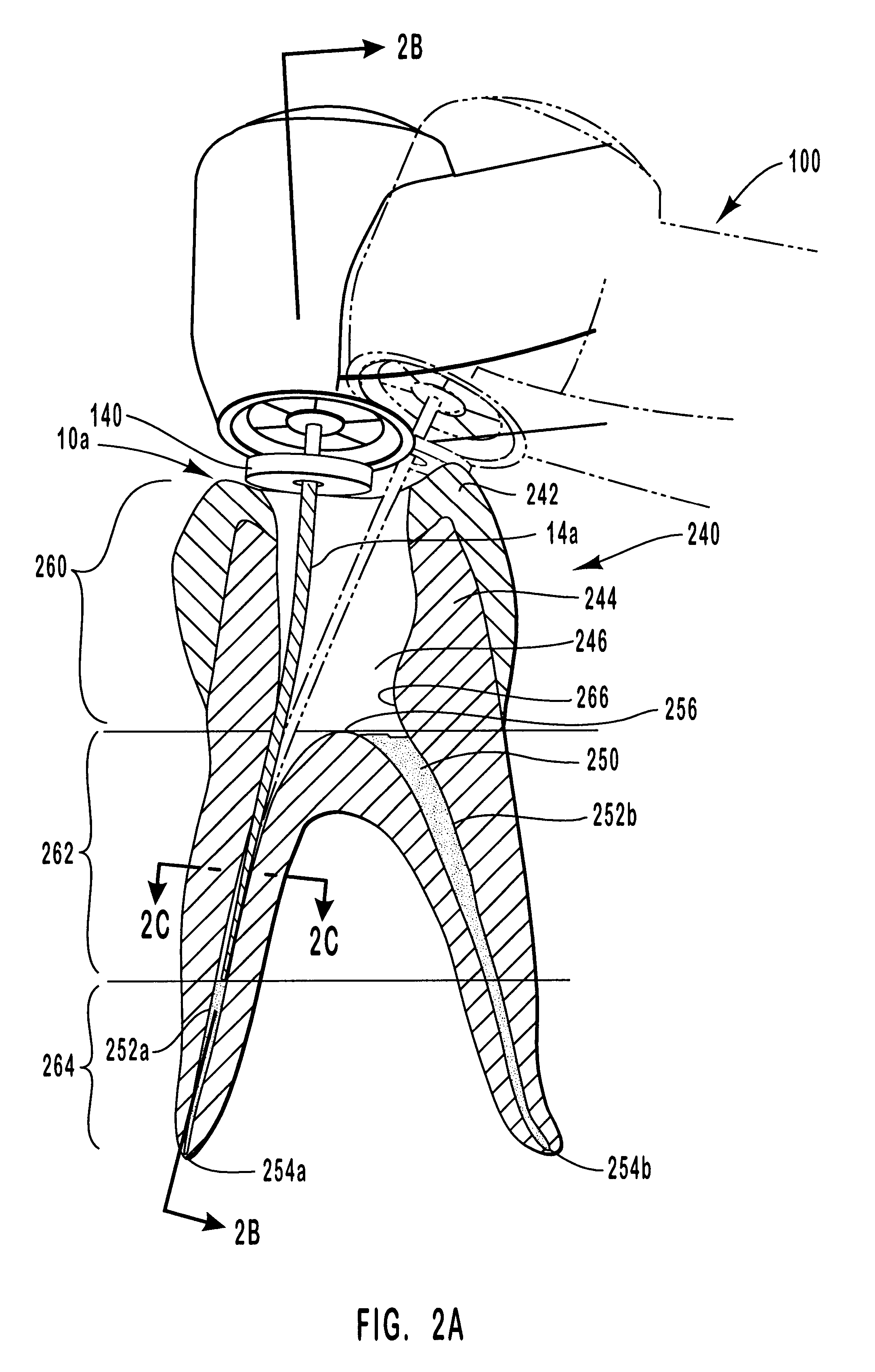

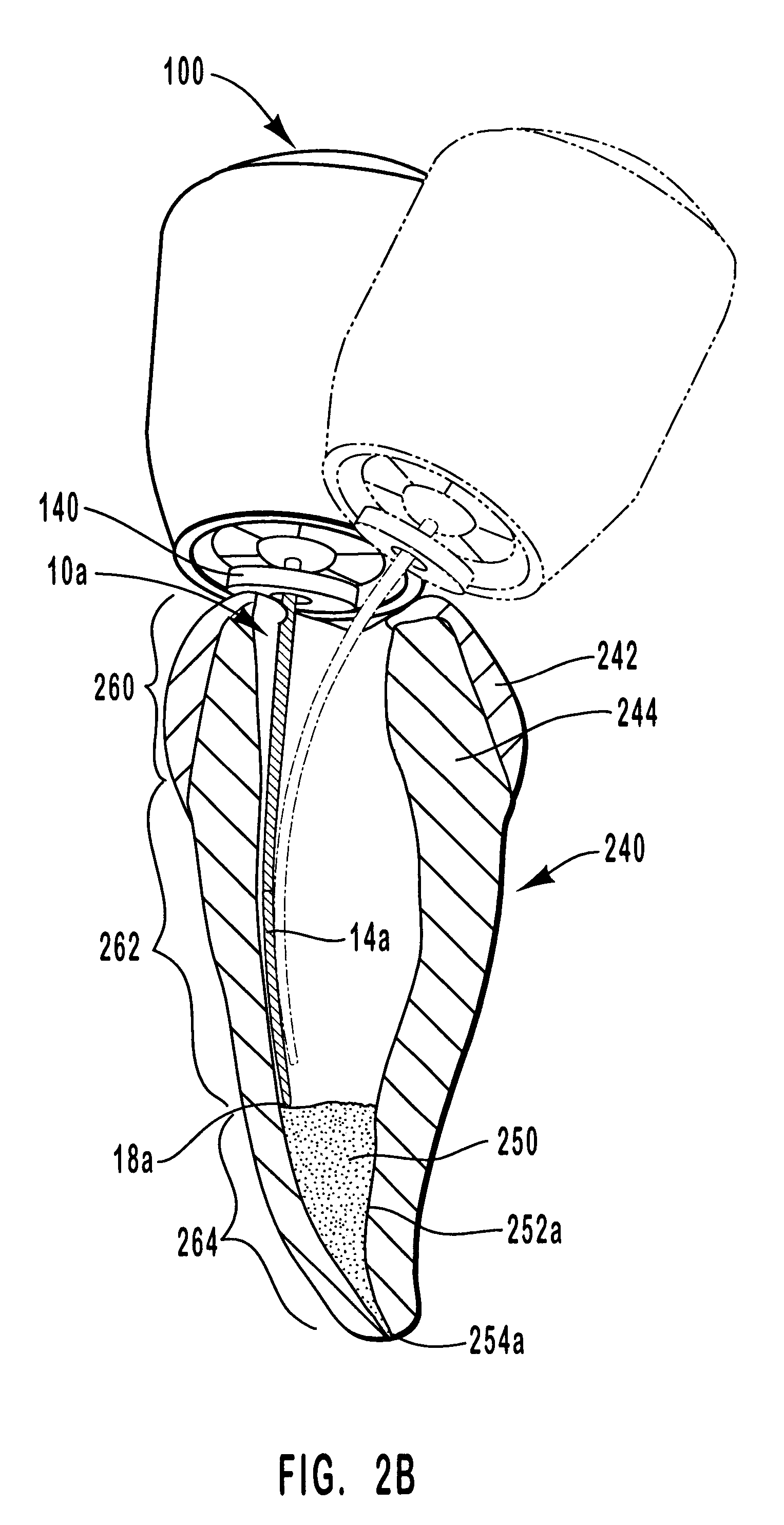

Precipitation hardenable stainless steel endodontic instruments and methods for manufacturing and using the instruments

InactiveUS6514076B1Resistant to wearEasy to useTeeth cappingTeeth nerve/root treatment implementsEndodontic filesChromium nickel

Precipitation hardenable stainless steel endodontic files and methods for their manufacture, wherein the most preferred precipitation hardenable stainless steel is 17-4PH and aging is preferably not one of the manufacturing steps. Precipitation hardenable stainless steels used in embodiments of this invention are iron-chromium-nickel grades that have the desired properties of flexibility, strength, hardness, wear resistance, stiffness, resistance to permanent deformation, resistance to variable torque, and biocompatibility for endodontic files.

Owner:ULTRADENT PROD INC

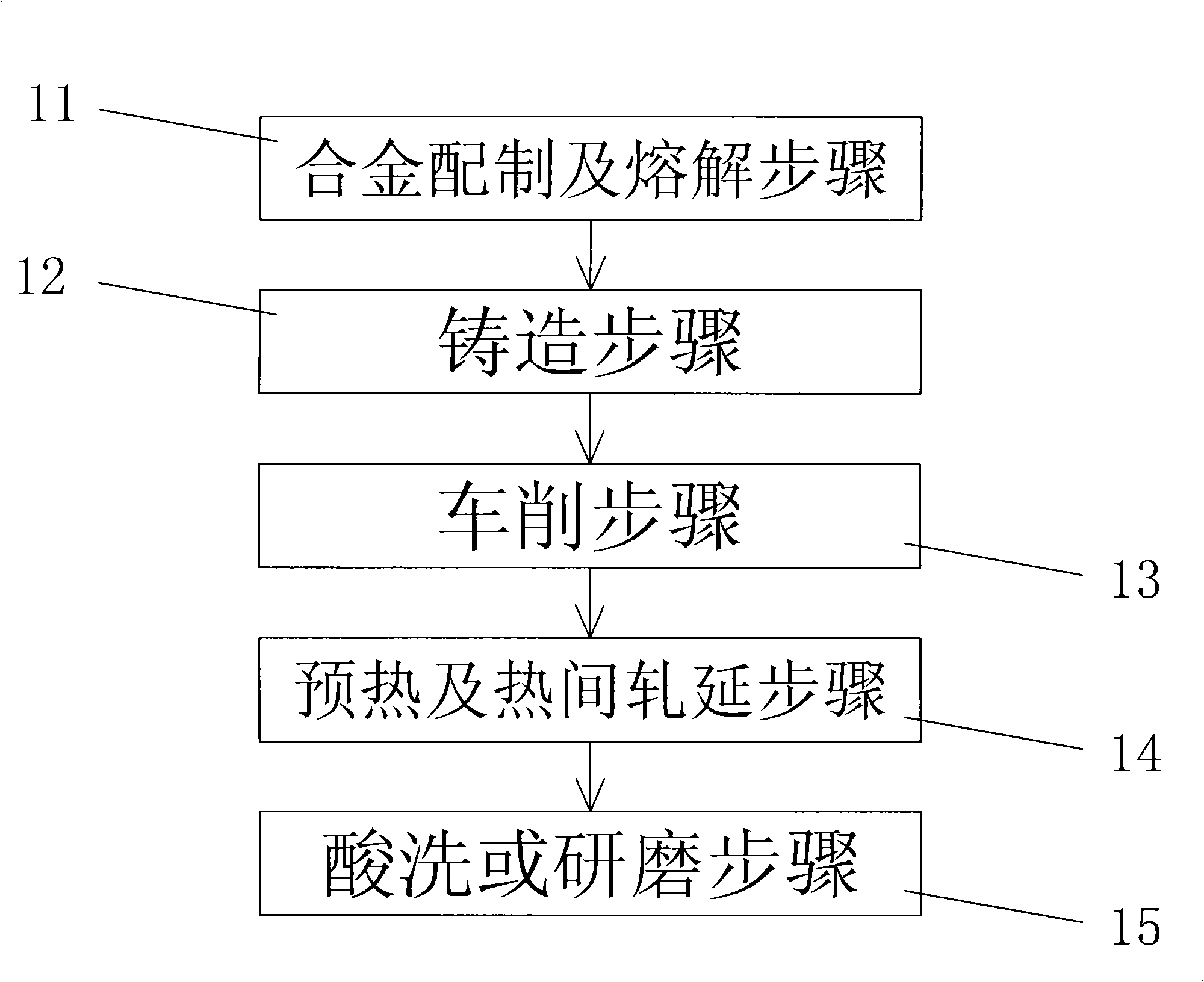

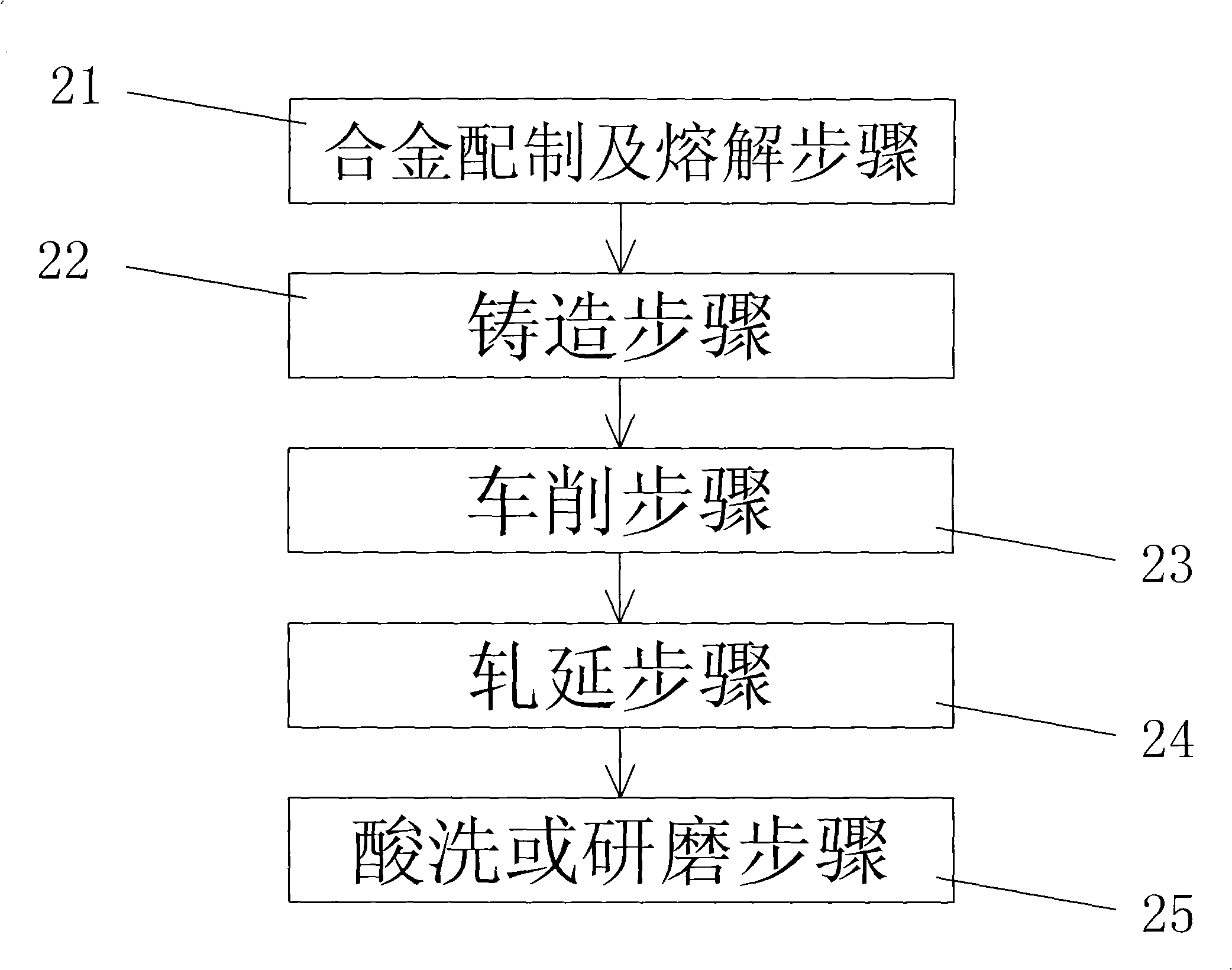

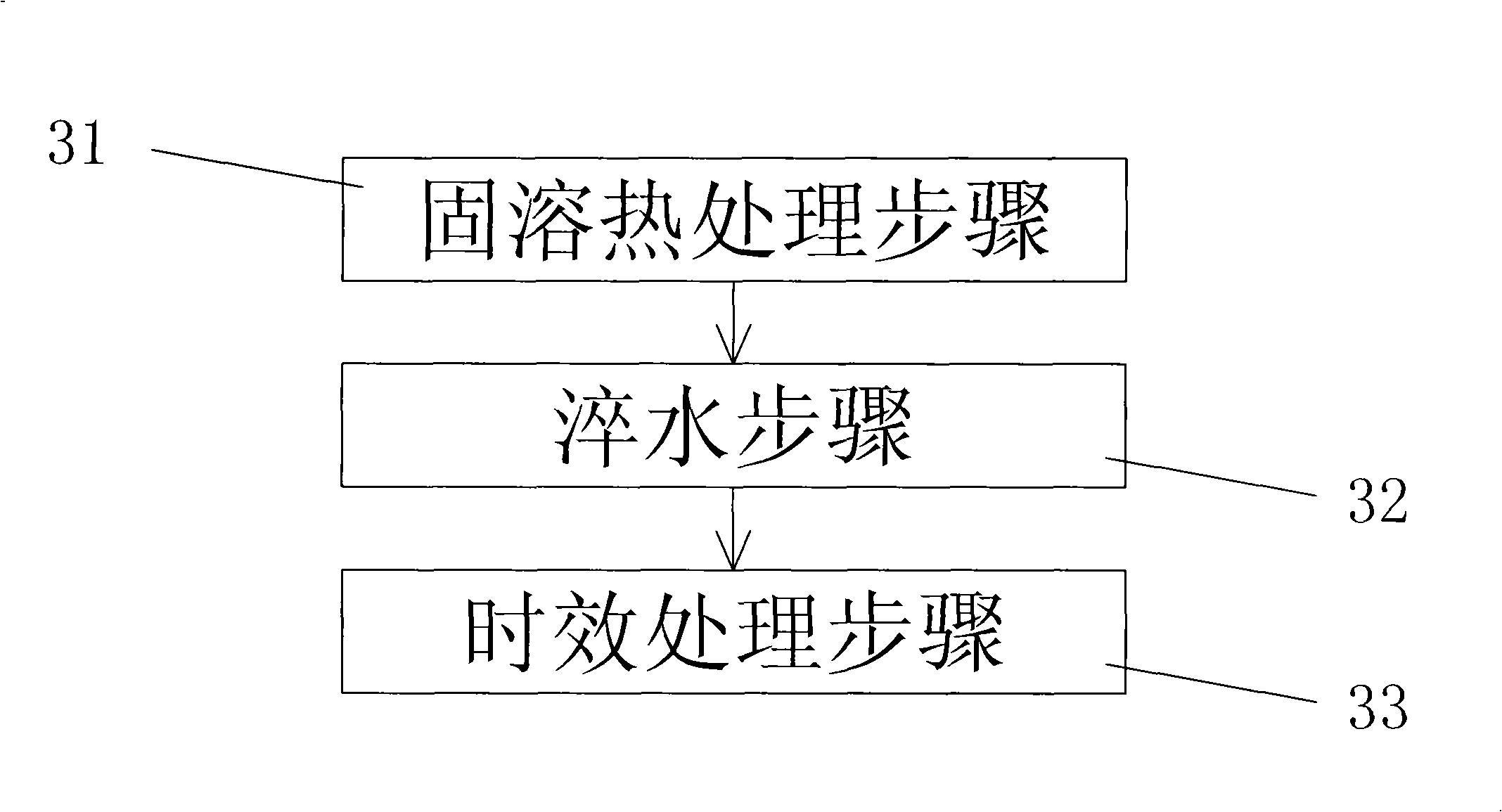

Precipitation-hardened stainless steel for cutting tool and manufacturing method of precipitation-hardened stainless steel

The invention discloses a precipitation-hardened stainless steel for a surgical instrument with excellent corrosion resistance and mechanical performance and a manufacturing method of the precipitation-hardened stainless steel. The indexes of the hardness, the toughness, the corrosion resistance, the mold resistance and the like of the precipitation-hardened stainless steel are all superior to martensitic stainless steel of the same kind. The precipitation-hardened stainless steel comprises the following components of, by weight, 0.005-0.08% of C, less than or equal to 0.05% of N, less than orequal to 1.0% of Si, 0.5-2.5% of Mn, less than or equal to 0.04% of P, less than or equal to 0.01% of S, 11.0-13.0% of Cr, 8.0-10.0% of Ni, greater than or equal to 0.03% and less than or equal to 0.10% of the sum of C and N, 2.0-5.0% of Mo, 1.0-4.0% of Cu, 0.5-2.0% of Ti, 0.15-1.5% of Al, less than or equal to (5*10<-4>)% of the product of Ti and N and the balance unavoidable impurities and Fe.The preparation method comprises the steps that (1) the set components are subjected to alloy smelting by adopting an electric furnace and an external refining mode, so that a steel ingot is formed; (2) the steel ingot is forged to be a steel slab after scalping is conducted, the heating temperature of the forging process is 1050-1250 DEG C, the heating time is 2-5 hours, and the finish forging temperature is 900-980 DEG C; (3) the steel slab is subjected to hot rolling by using a hot rolling machine, so that a hot rolled steel plate or steel belt is prepared, the hot rolling heating temperature is 1000-1200 DEG C, the heat preservation time is 2-5 hours, and the finish rolling temperature is 850-930 DEG C; (4) high-temperature solution treatment is conducted on the steel plate by adoptingsolid solution annealing furnace equipment, the solid solution temperature is 1000-1200 DEG C, the solid solution heat preservation time is 15-30 min, and a cooling mode is water cooling; and (5) aging treatment is conducted on the steel plate which is subjected to solid solution by adopting a heat treatment technology scheme at the temperature of 300-650 DEG C, the aging time is 2-8 hours, and the cooling mode is air cooling after ageing is conducted.

Owner:上海落日新材料科技有限公司 +1

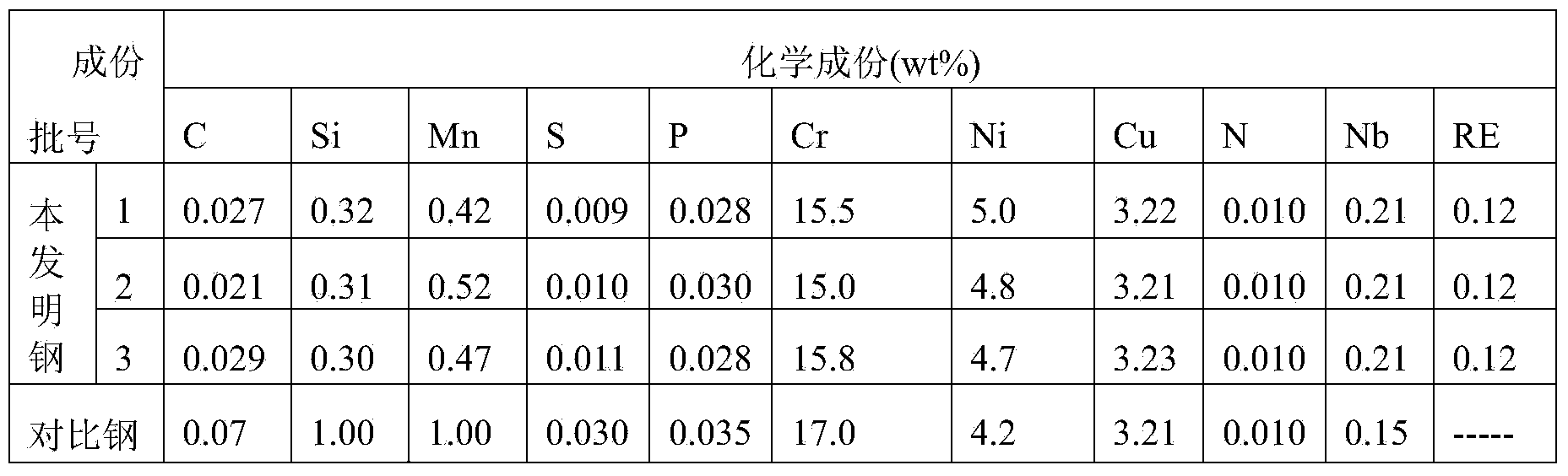

Rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel and preparation method thereof

ActiveCN104328353ARefining solidified tissueImprove performanceSolution treatmentMartensitic stainless steel

The invention discloses rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel. The rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel is characterized by comprising the following chemical components in percentage by weight: less than or equal to 0.07% of C, less than or equal to 1% of Si, less than or equal to 1% of Mn, less than or equal to 0.035% of P, less than or equal to 0.03% of S, 3.00-5.00% of Ni, 15.5-17.5% of Cr, 3.00-5.00% of Cu, 0.15-0.45% of Nb, 0.05-0.25% of Re and the balance of Fe and belongs to the field of alloy steels. The invention also discloses a preparation method of the rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel. The preparation method comprises the steps of smelting, casting, carrying out electroslag remelting, casting ingots, forging or rolling, carrying out solution treatment and the like. The rare-earth-type 0Cr17Ni4Cu4Nb special steel, which is disclosed by the invention, as one of precipitation-hardening martensitic stainless steel, has the characteristics of high strength, high hardness, corrosion resistance and the like and is suitable for various technical fields, such as chemical machinery, food machinery, papermaking machinery, aerospace and marine.

Owner:什邡新工金属材料有限公司

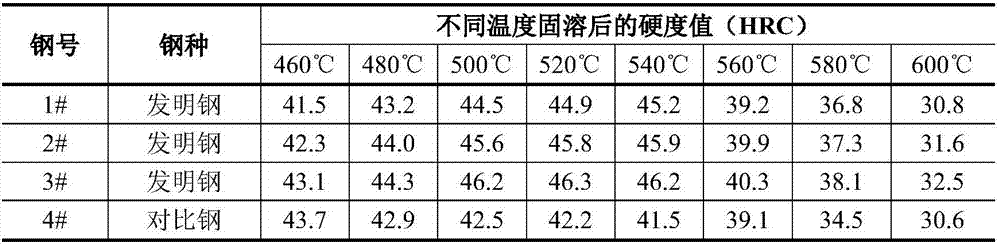

Precipitation hardening type plastic die steel and preparation method thereof

InactiveCN106978564AImprove acceleration performanceImprove precipitation hardening hardnessUser needsChemical composition

The invention relates to precipitation hardening type plastic die steel and a preparation method thereof, and belongs to the field of die steel. The steel is specifically prepared from, by weight percent, 0.08%-0.25% of C, 0.8%-1.5% of Si, not larger than 0.030% of S, not larger than 0.030% of P, 0.4%-0.8% of Mn, 2.0%-4.0% of Ni, 0-1.5% of Mo, 1.0%-2.8% of Cr, 0.5%-1.5% of Cu, 0.5%-2.0% of Al, 0-0.2% of V and the balance Fe and inevitable impurities. Compared with the prior art, the precipitation hardening type plastic die steel has higher obdurability and corrosion resistance and is good in comprehensive performance. Through age hardening treatment, the steel can obtain higher use hardness, higher impact toughness and more excellent corrosion resistance relative to existing Ni-Cu-Al-series precipitation hardening steel, and the comprehensive performance is more excellent. Through implementation of the above technology, the material comprehensive performance can be effectively improved, and user needs can be met.

Owner:CENT IRON & STEEL RES INST

Preparation of high-strength aluminum alloy for outer casing of electronic product

The invention relate to a manufacturing method of a high strength aluminum alloy used as the outer casing part of the electronic product, which comprises the following steps: the material preparation step that an aluminum alloy which comprises 1.1 to 2.5 wt percent of copper, 0.7 to 1.3 wt percent of magnesium, 0.7 to 1.3 wt percent of silicon, and residual aluminum and unavoidable foreign substance is provided, the solid-solution treatment step that the aluminum alloy is warmed up to 540 DEG C plus or minus 10 DEG C and is kept for 30 to 90 minutes, the hardening step that the aluminum alloy is rapidly cooled down, the preheating step that the aluminum alloy is warmed up to 100 to 150 DEG C and is kept for 5 to 50 minutes, the integrating step that the aluminum alloy plate is moulded through pressing and the aging treatment step that the aluminum alloy is warmed up to 175 to 195 DEG C and is kept for 2 to 8 hours. The invention ensures the aluminum alloy sheet or forging bar section with specific components to have the best precipitation hardening property.

Owner:ADVANCED MATERIAL SPECIALTY

Ultra-high strength steels with excellent cryogenic temp. toughness

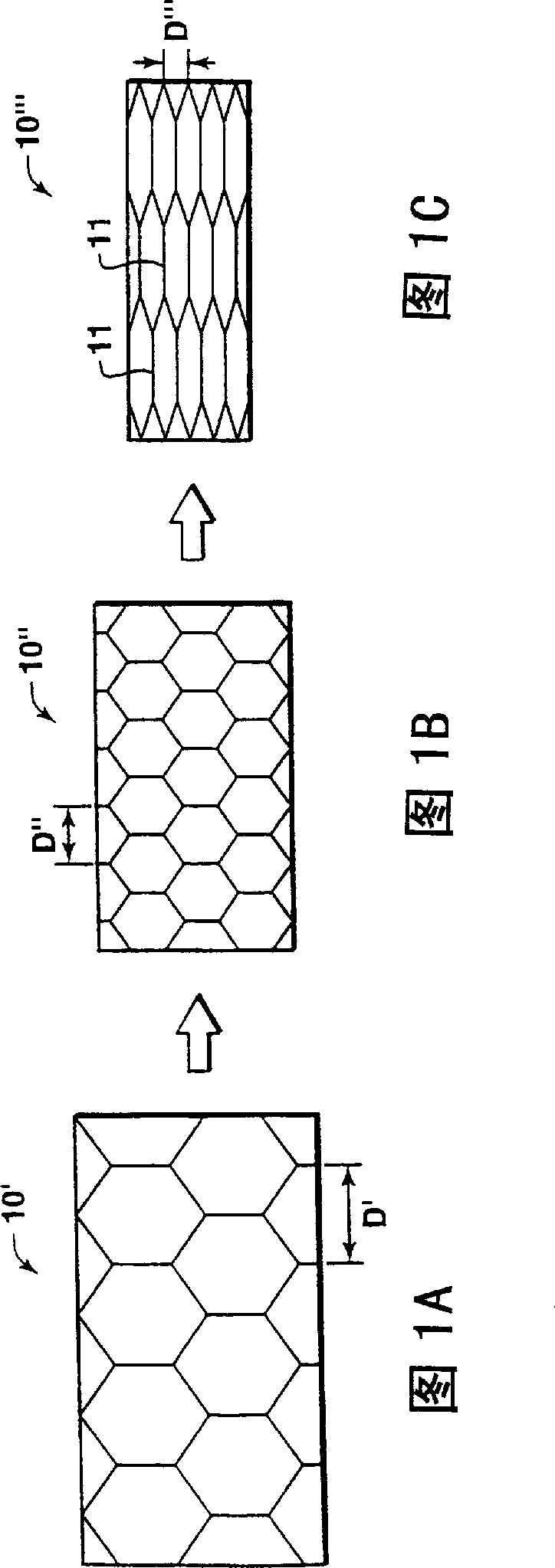

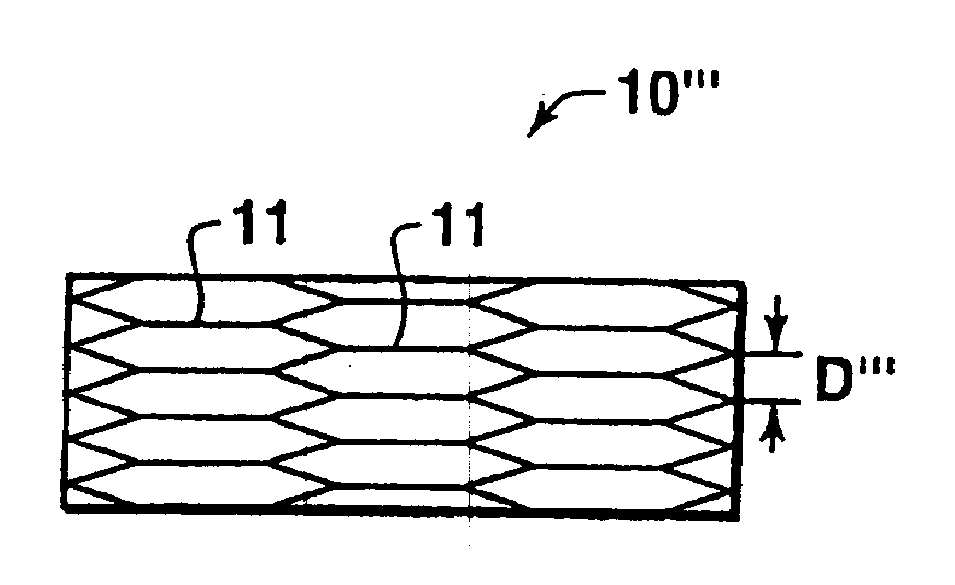

An ultra-high strength, weldable, low alloy steel, containing less than 9 wt.% nickel, with excellent cryogenic temperature toughness in the base plate and in the heat affected zone (HAZ) when welded, having a tensile strength greater than 830 MPa (120 ksi) and a microstructure comprising predominantly fine-grained lath martensite and / or fine-grained lower bainite, is prepared by heating a steel slab comprising iron and some or all of the additives carbon, manganese, nickel, nitrogen, copper, chrominum, molybdenum, silicon, niobium, vanadium, titanium, aluminum, and boron; reducing the slab to form plate in one or more passes in a temperature range in which austenite recrystallizes; finish rolling the plate in one or more passes in a temperature range below the austenite recrystallization temperature and above the Ar3 transformation temperature; quenching the finish rolled plate (10''') to at a suitable Quench Stop temperature; stopping the quenching; and tempering the plate (10''') at a suitable temperature for a period of time sufficient to cause precipitation of hardening particles.

Owner:EXXONMOBIL UPSTREAM RES CO

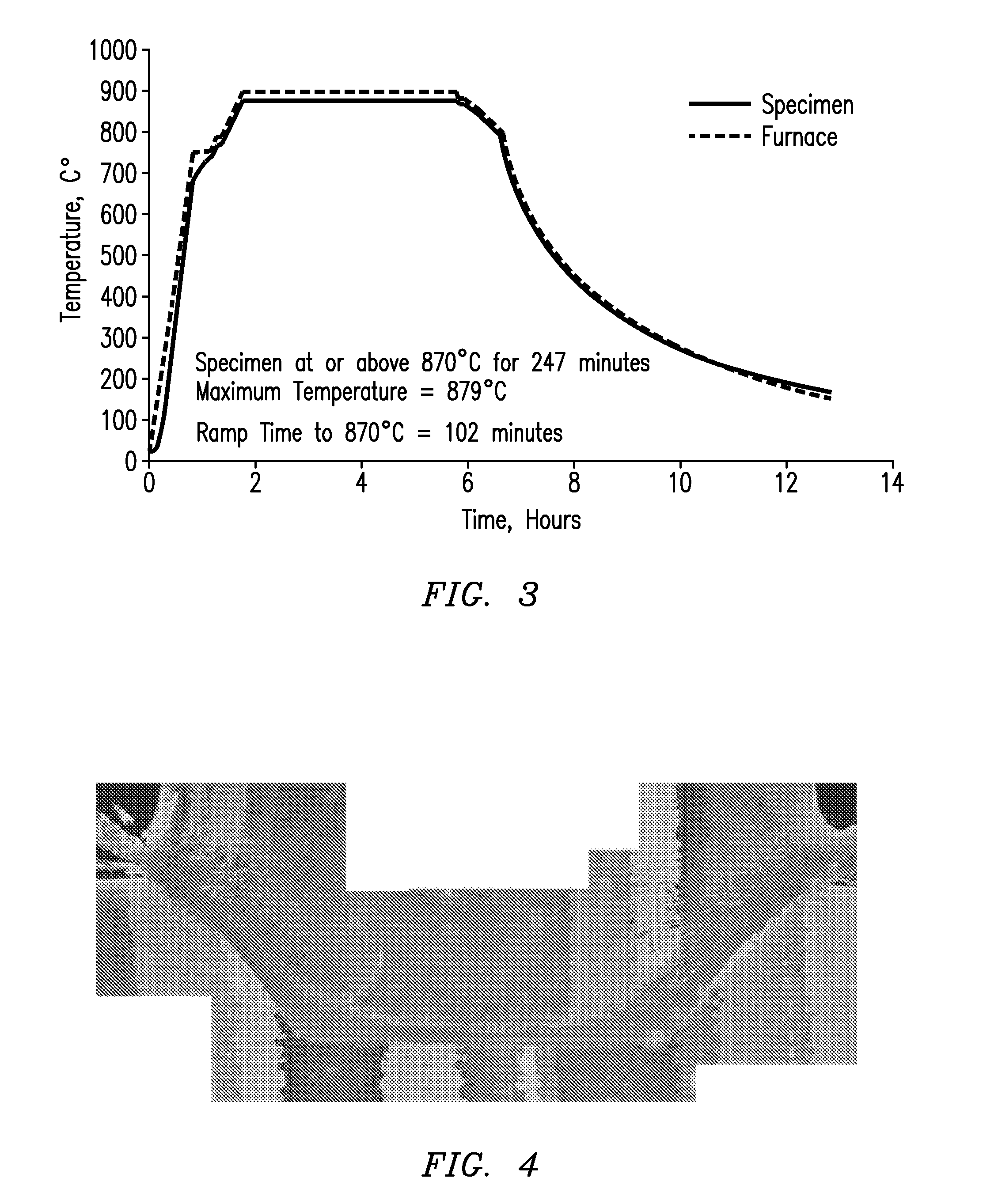

Inertia friction weld of superalloy with enhanced post weld heat treatment

A method of inertia friction welding a superalloy substrate, the method including: rotating and forcing a deposit material (110) against the superalloy substrate (100); plastically deforming at least one of the deposit material (110) and the superalloy substrate (100) to form a weld joining the deposit material (110) to the superalloy substrate (100), thereby forming an assembly; and heat-treating the assembly. Heat-treating includes: a post-weld intermediate stress-relief (ISR) treatment; a solutionizing treatment; and a precipitation hardening heat treatment.

Owner:SIEMENS ENERGY INC

Processing method for stainless steel high-strength bolt

The invention discloses a processing method for a stainless steel high-strength bolt. The method comprises blanking, lubricating, thermal heading, solution treatment, cooling, descaling, processing of diameter of a threaded rolled thread billet, aging treatment, polishing, rolling of a thread and an arc at the connection part of a head part and a rod, flaw detection, cleaning and passivating. According to the method, precipitation hardening stainless steel is taken as a part blank, the head part is formed in one step through thermal heading, the processing period is greatly shortened, the diameter of the thread billet is processed by a shortening rod, the thread is rolled after aging treatment, the use strength of a thread part of a product is improved, flaw detection is carried out after thread rolling, a cracked product resulting from procedures like thermal heading, thermal treatment and thread rolling is prevented from going to the procedures like assembly and use as well as rolling of the arc R below a bolt head, so as to improve the connection strength of the head part and the rod part of the product, the strength of the bolt is greatly enhanced, and the fabricated part has relatively strong impact toughness and yield strength.

Owner:GUIZHOU JINGLI HANGTAI TECH

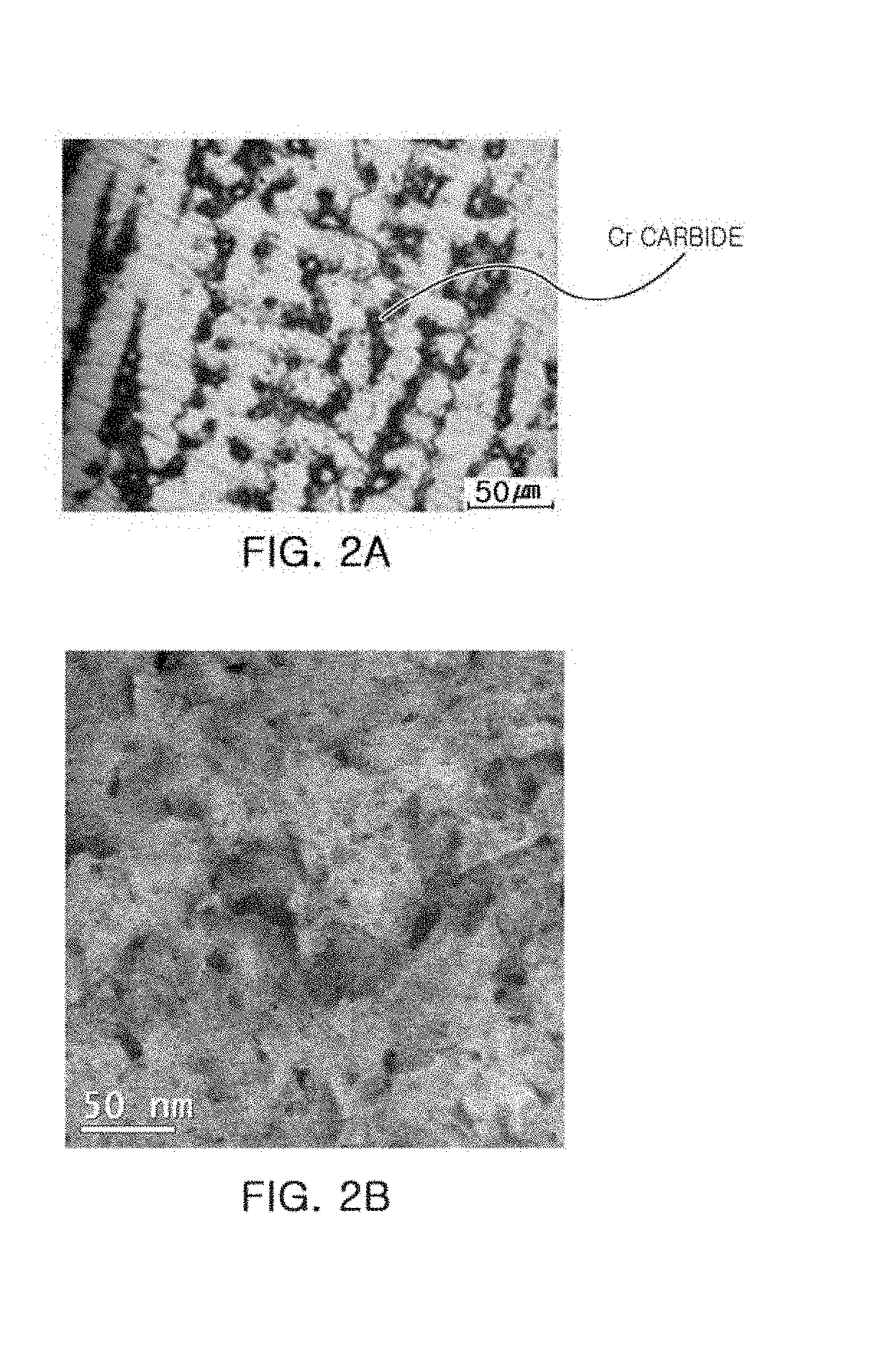

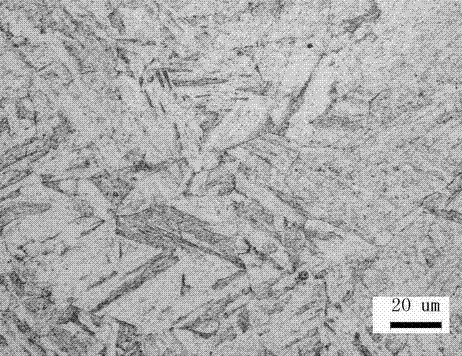

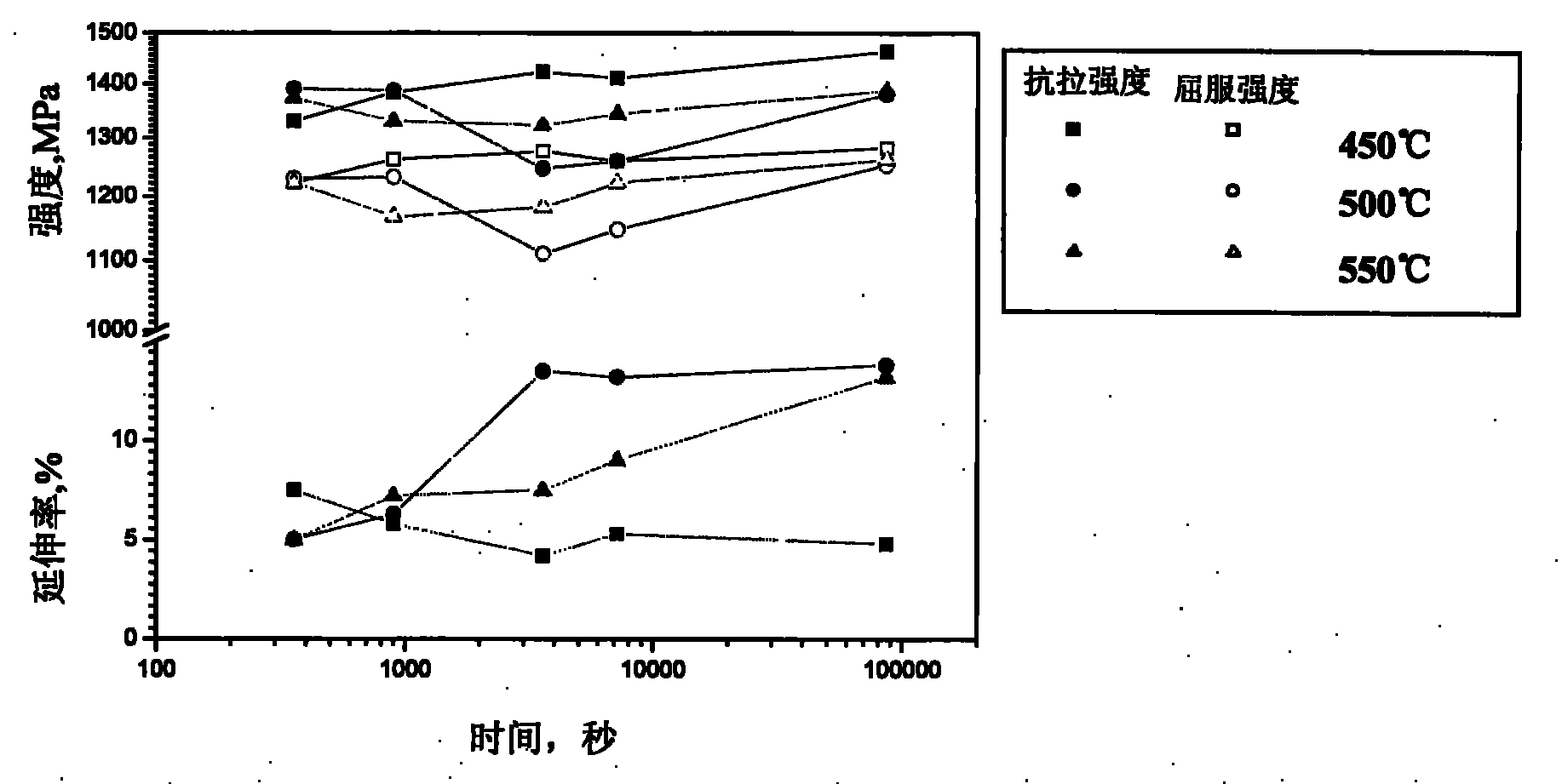

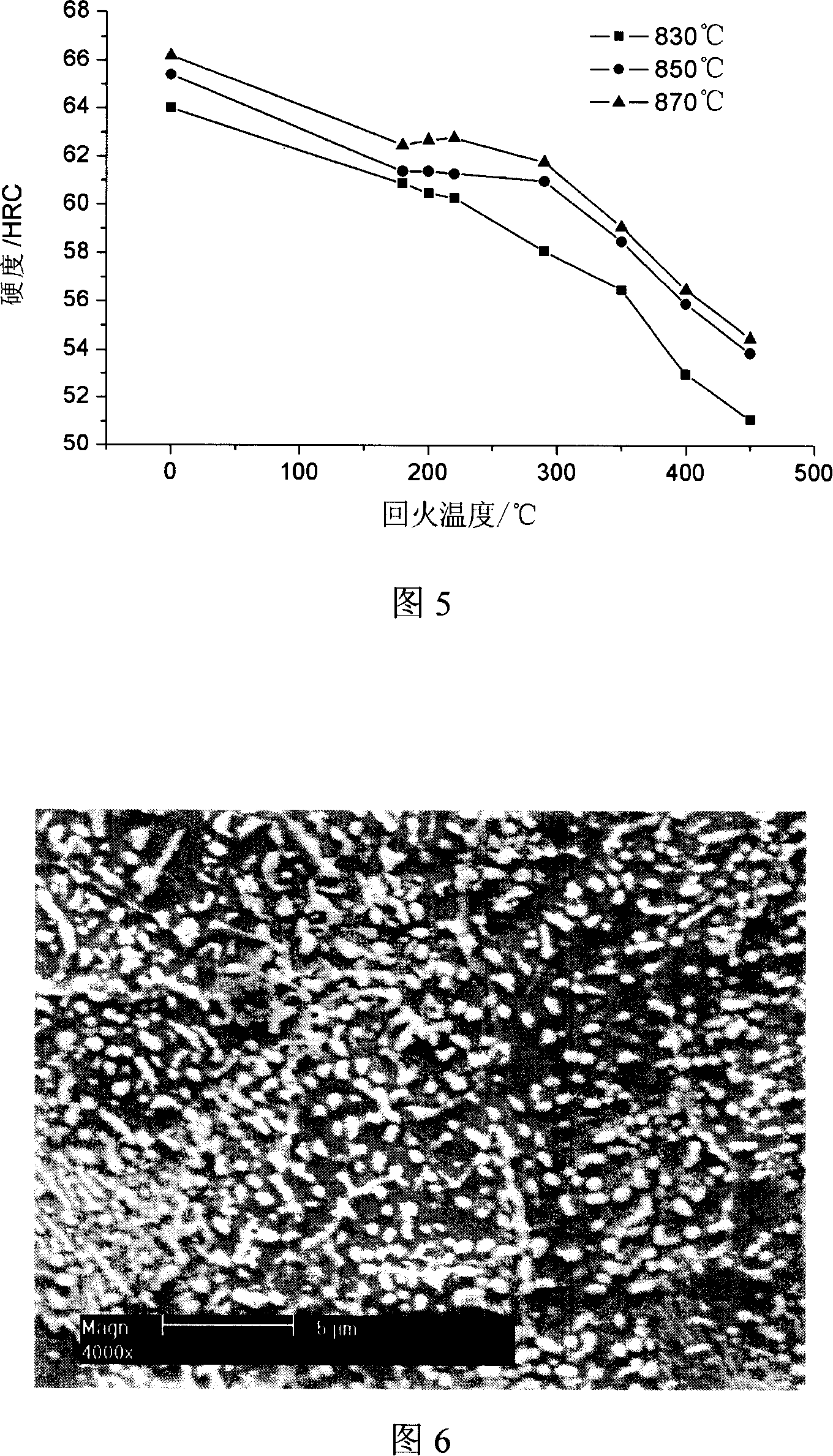

Thermal treatment method for precipitation hardening of martensitic stainless steel FV520B

InactiveCN101509056AHigh strengthImprove toughnessMartensitic stainless steelUltimate tensile strength

The invention provides a method for heat-treating precipitation-hardened martensitic stainless steel FV520B, particularly a method adopting the following manner: tempering the precipitation-hardened martensitic stainless steel FV520B at a higher temperature for a short time and then slowly cooling, to lead the precipitation-hardened martensitic stainless steel FV520B to have the advantage of good combination of toughness and strength, and solve the following problems of the existing heat treatment processes: the high-temperature tempering strength is low and the low-temperature tempering toughness is low; as a result, the high strength and the high toughness cannot be achieved at the same time.

Owner:NORTHEASTERN UNIV

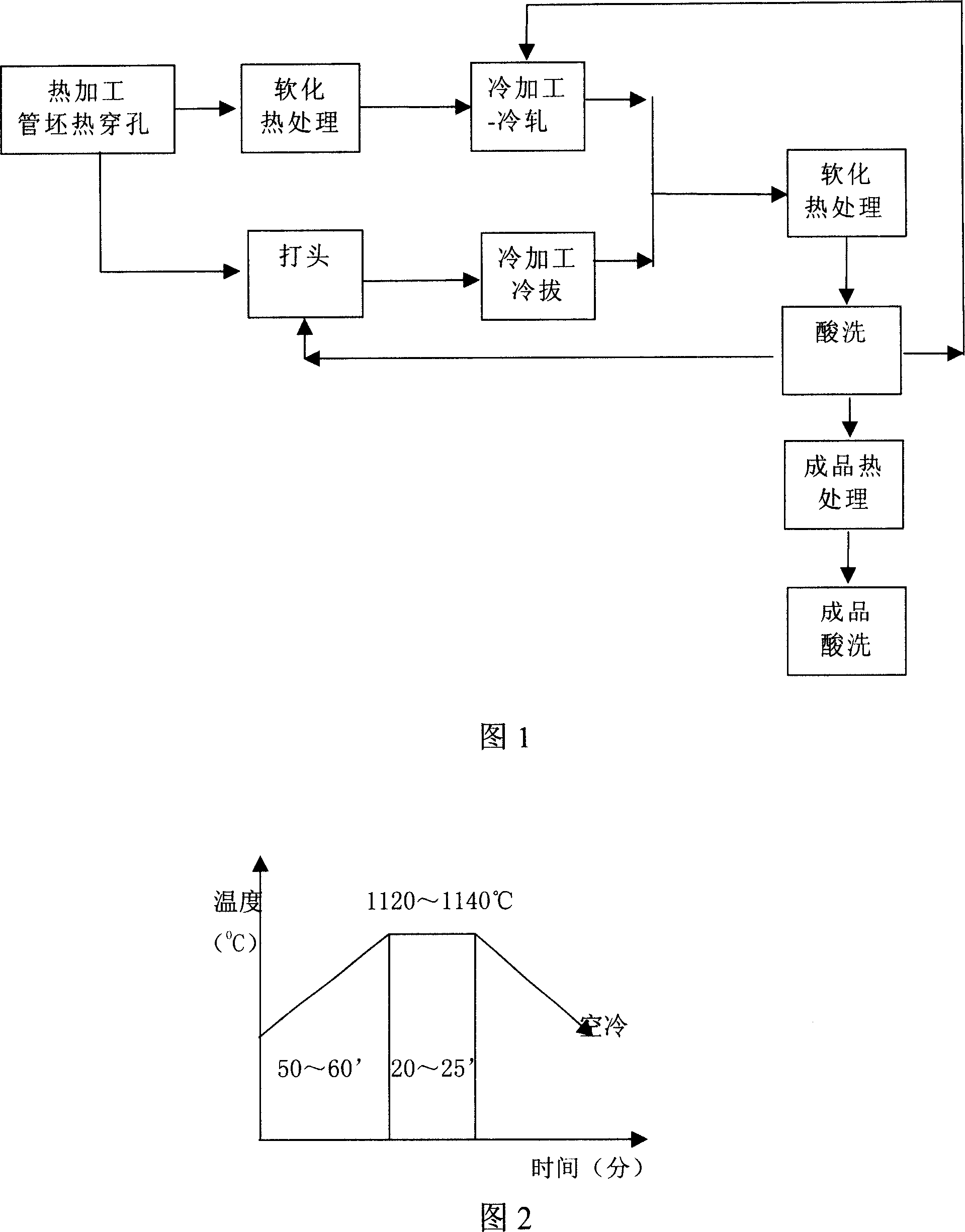

Manufacturing method of 17-4PH steel pipe

InactiveCN101007384ASolve the unclear picklingSolve the problem of overacidFurnace typesOther manufacturing equipments/toolsAcid washingHeating temperature

17-4PH steel pipe manufacturing method includes the following steps: a. thermal processing and pipe blank heat perforating: heating temperature is 1090 ~ 1150 degree C and insulation time is 15 ~ 35 minutes; b. softening heat treatment: temperature is 650 ~ 700 degree C, insulation time is 4~5.5 hours; c. cold-working: cold rolling; d. softening heat treatment: temperature is 650 ~ 700 degree C, insulation time is 4 ~ 5.5 hours; e. acid-washing; f. repeating steps c ~ e cycles rolling until finished product size; g . finished product heat treatment: solid solution treatment 1020 ~ 1050 degree C +15 ~30 minutes, precipitation hardening treatment 450-630DEG C+3.5-4.5 hours, the finished product forms precipitation hardening martensitic structure with high strength and excellent corrosion resistance; h. finished product acid-washing. The invention replaces the original pipe elements art through boring and turning the pipe elements to reaching the required diameter and wall thickness with the technology of cold-working to getting the required diameter and wall thickness after heat perforating, it shortens production cycles, reduces production costs, improves product metal yield rate and increases economic efficiency.

Owner:BAOSHAN IRON & STEEL CO LTD

Low carbon martensite aged stainless steel with high strength high toughness and high decay resistance performances

InactiveCN101886228AHigh strengthImprove corrosion resistanceUltimate tensile strengthPrecipitation hardening

The invention belongs to the ferronickel base martensite precipitation-hardening alloy technical field, in particular relates to a low carbon martensite aged stainless steel with high strength high toughness and high decay resistance performances, novel material mainly applied to the important fields of aviation, space flight, machinery manufacturing and atomic energy. The steel comprises the following components by weight percent: 0.08-0.15% of C, 11.0-12.0% of Cr, 4.0-5.0% of Ni, 0.2-1.0% of Ti, 0.5-1.0% of Mo, 2.0-3.0% of Cu, 2.0-3.0% of Co, 0.1-0.5% of Nb, 0.5-1.5% of Mn, 0.5-1.5% of Si, less than 0.01% of N, less than 0.01% of V, less than 0.01% of Al and balance of Fe. The invention can obtain high strength high toughness and decay resistance performances by appropriate collocation of five precipitation strength elements of Ni, Ti, Mo, Cu and Nb.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

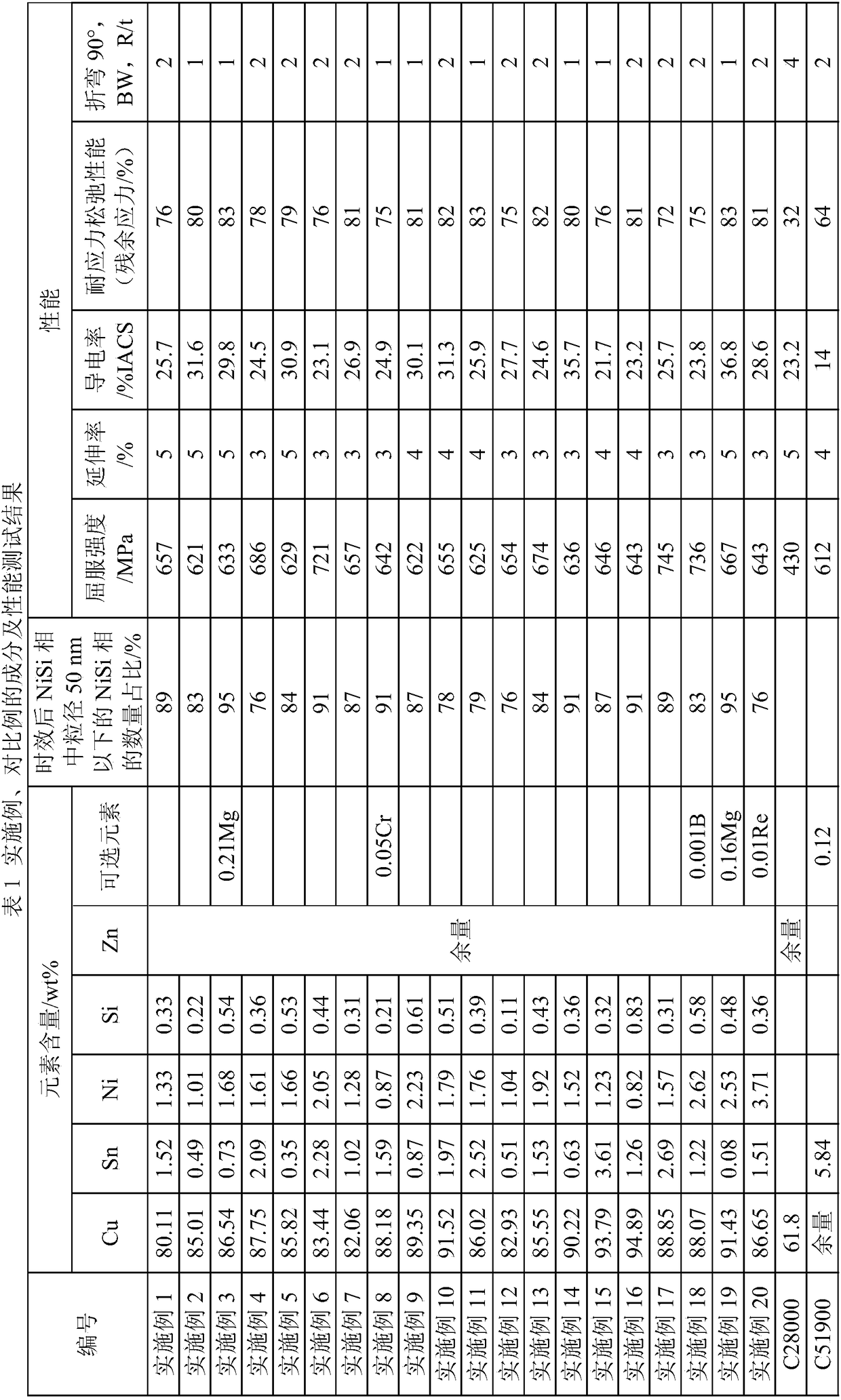

Precipitation-hardening copper alloy and application thereof

ActiveCN108285988AHigh strengthLittle effect on conductivityConductive materialMetal/alloy conductorsStress relaxationMatrix strength

The invention discloses a precipitation-hardening copper alloy which is prepared from the components in percentage by weight: 80 percent to 95 percent of Cu, 0.05 percent of to 4.0 percent of Sn, 0.01percent of to 3.0 percent of Ni, 0.01 to 1.0 percent of Si, and the balance Zn and inevitable impurities. According to the precipitation-hardening copper alloy provided by the invention, through solid solution strengthening and precipitation hardening, a combination performance of the alloy is improved, the matrix strength is improved, meanwhile, the influence on the conductivity of the alloy isless, a bending processing performance meets the requirement, and the alloy has a stress relaxation property as same as tin-phosphor bronze. The alloy provided by the invention has a better combination performance than C51900, is low in raw material cost, has remarkable advantages in welding and electroplating, can solve the utilization problem of multiple waste materials, and is widely applied toelectronic and electrical industry products such as connectors and connector assemblies.

Owner:NINGBO POWERWAY ALLOY MATERIAL

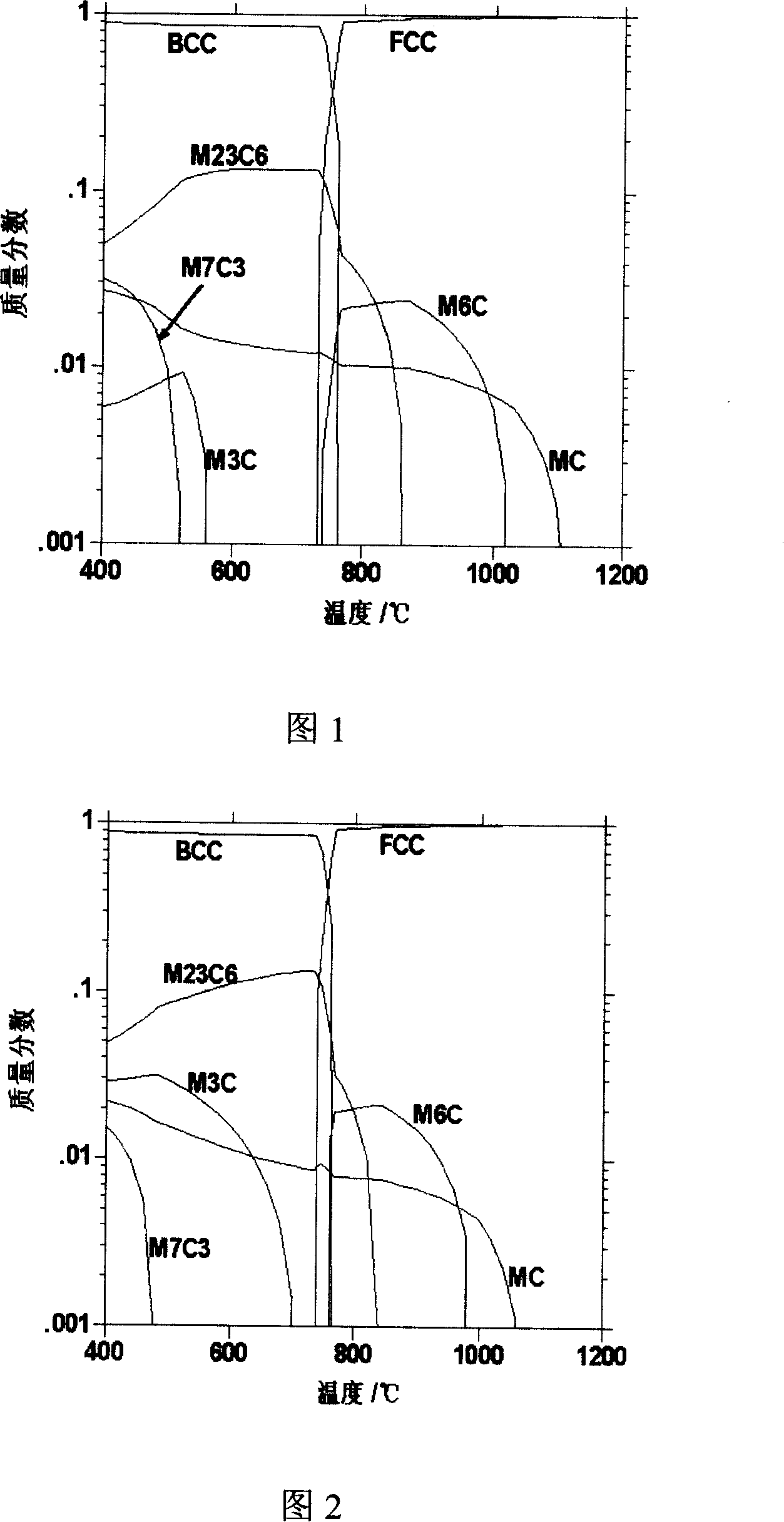

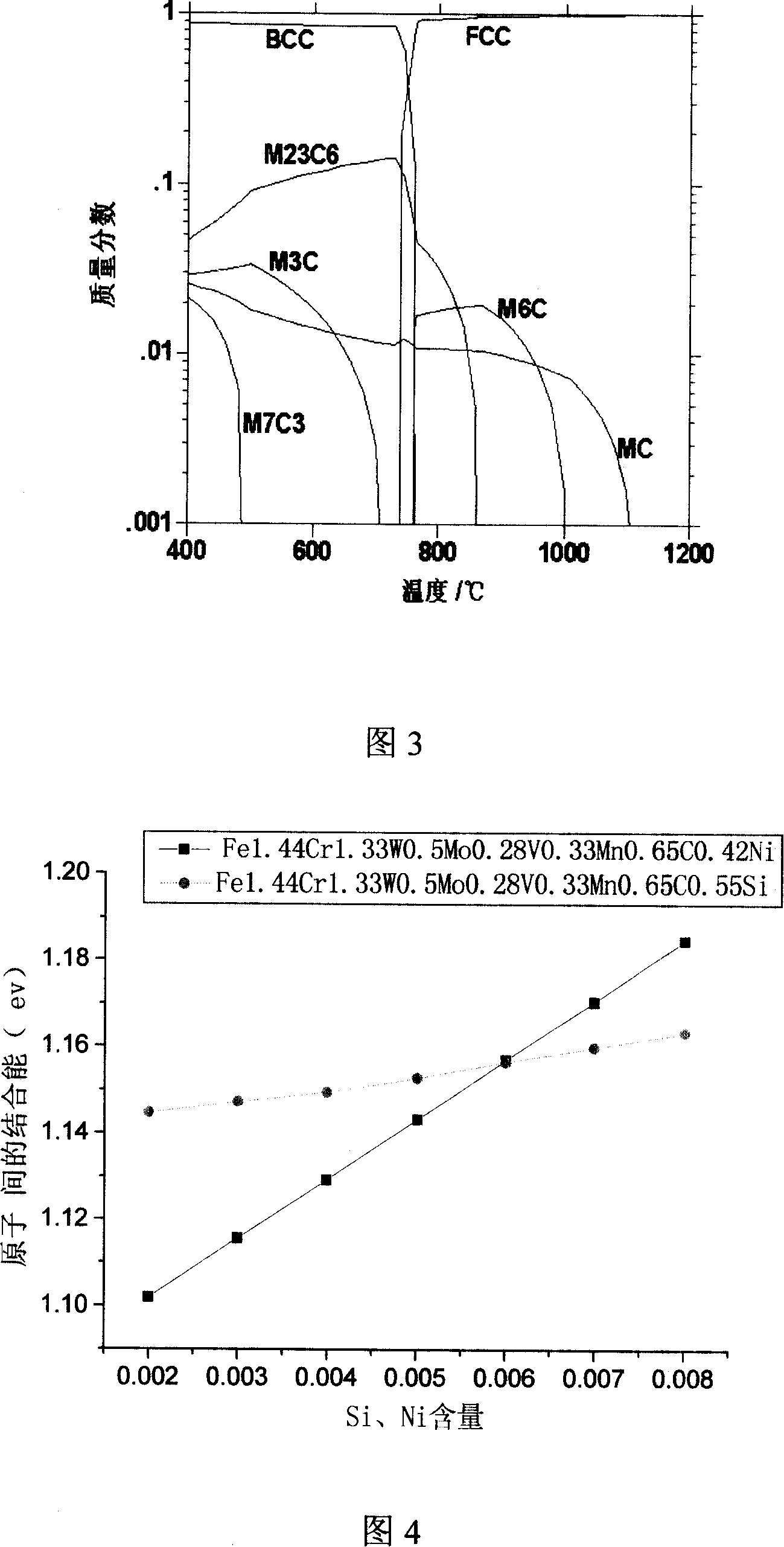

Alloy tool steel in multi-type super-fine carbonates

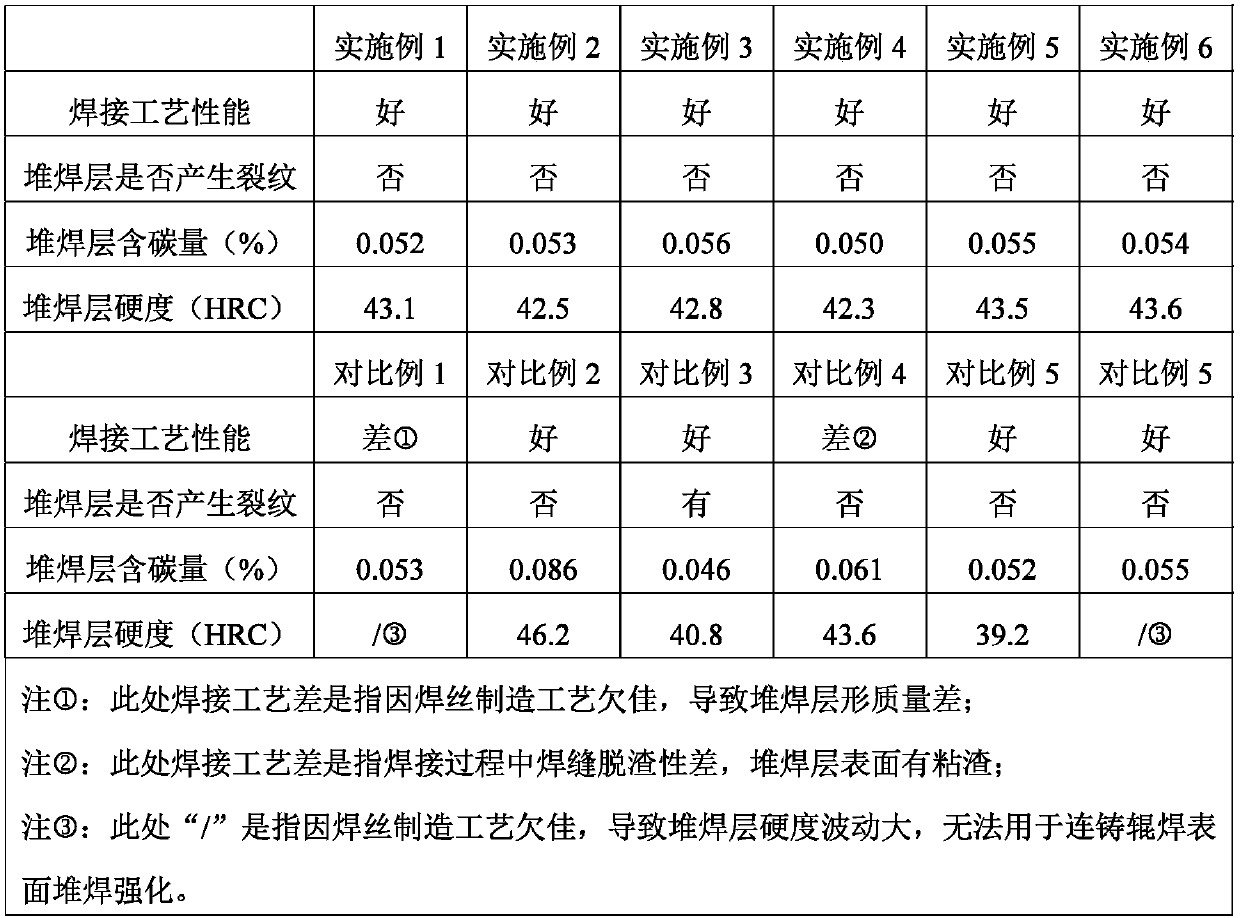

InactiveCN101070580AHigh hardnessImprove wear resistanceHeat treatment process controlHigh carbonQuenching

This invention relates to alloying and heat treatment craft of tool die steel, it belongs to one kind of DM8B-2 multi-types superfine carbide high carbon alloy tool steel. Using alloy design method which voluntarily developing, do the phase equilibrium thermo dynamics, electronic / atom level binding energy computation,quenching and the tempered hardness computation as well as to synthesis appraisal its toughness and sintensity. Its ingredient characteristic is appropriate C quantity and Cr / (W+Mo) ratio, reasonable Si, Mn as well as few Ni; Its microstructure characteristic has the superfine carbide, annealing carbide size is between 0.05-0.8mum, when quenching, the undissolved carbide size should not to be smaller than 0.5mum. after quenching to add 200degree C-300degree C, tempering may enable the tempering hardness to achieve 61-64HRC by using carbide precipitation hardening. It has high yield strength and the impact toughness.In the thin edge cutting tool, cutting die and weightily attacking die areas, it has widespread application prospect.

Owner:DALIAN MARITIME UNIVERSITY

Precipitation hardening stainless steel flux-cored wire for continuous roller submerged arc overlaying and preparation method thereof

ActiveCN108015447AImprove performanceGood resistance to high temperature tempering softeningWelding/cutting media/materialsSoldering mediaNiobiumManganese

The invention discloses a precipitation hardening stainless steel flux-cored wire for continuous roller submerged arc overlaying and a preparation method thereof. The flux-cored wire consists of chemical powder and an external carbon steel strip; the chemical powder is 35.0-38.0% of the total weight of the wire; and the chemical powder comprises the following components in percentage by weight: 29.0-31.0% of metal chromium powder, 25.0-26.5% of low-carbon ferrochromium, 12.0-13.0% of metal nickel powder, 10.0-11.5% of metal copper powder, 0.8-1.2% of electrolytic metal manganese, 1.0-1.5% of ferroniobium, 0.1-0.8% of metal molybdenum powder, 0.3-0.6% of ferrotitanium, 2.0-2.5% of rare earth ferrosilicon, 0.3-0.6% of metal aluminum powder, 8.0-10.0% of barium fluoride, and the balance ironpowder. In the flux-cored wire, an overlaying layer achieves excellent wear resistance, corrosion resistance, cold and hot fatigue resistance and tempering softening resistance, so that the service life of continuous rollers can be prominently prolonged.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

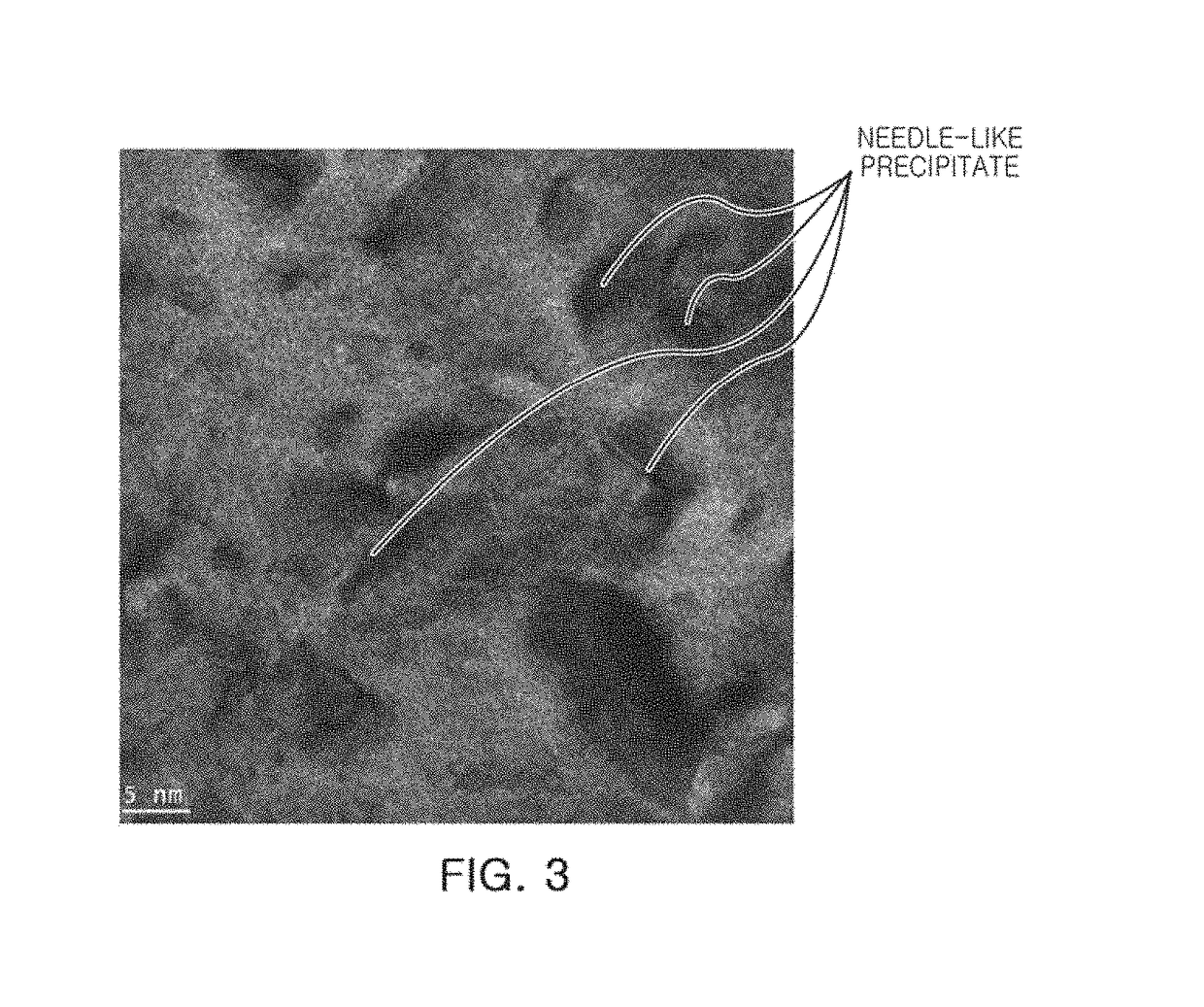

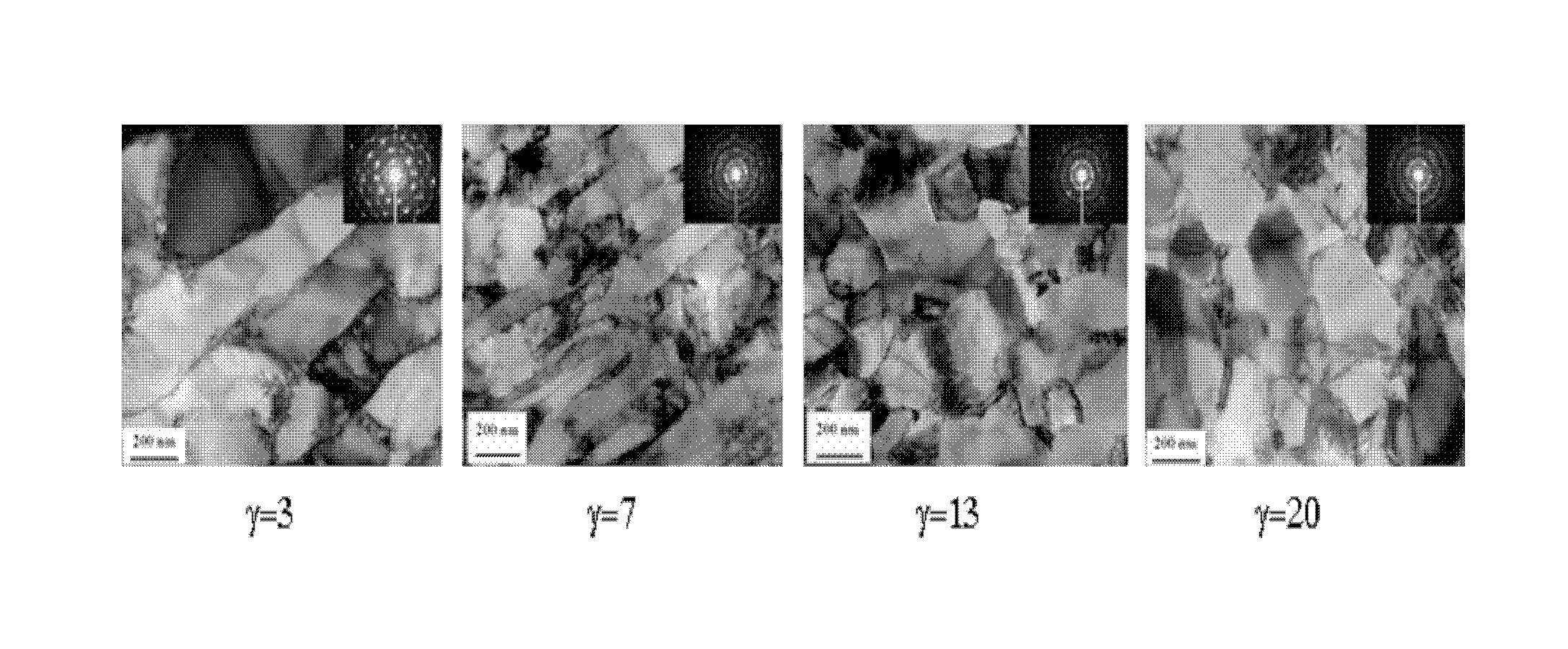

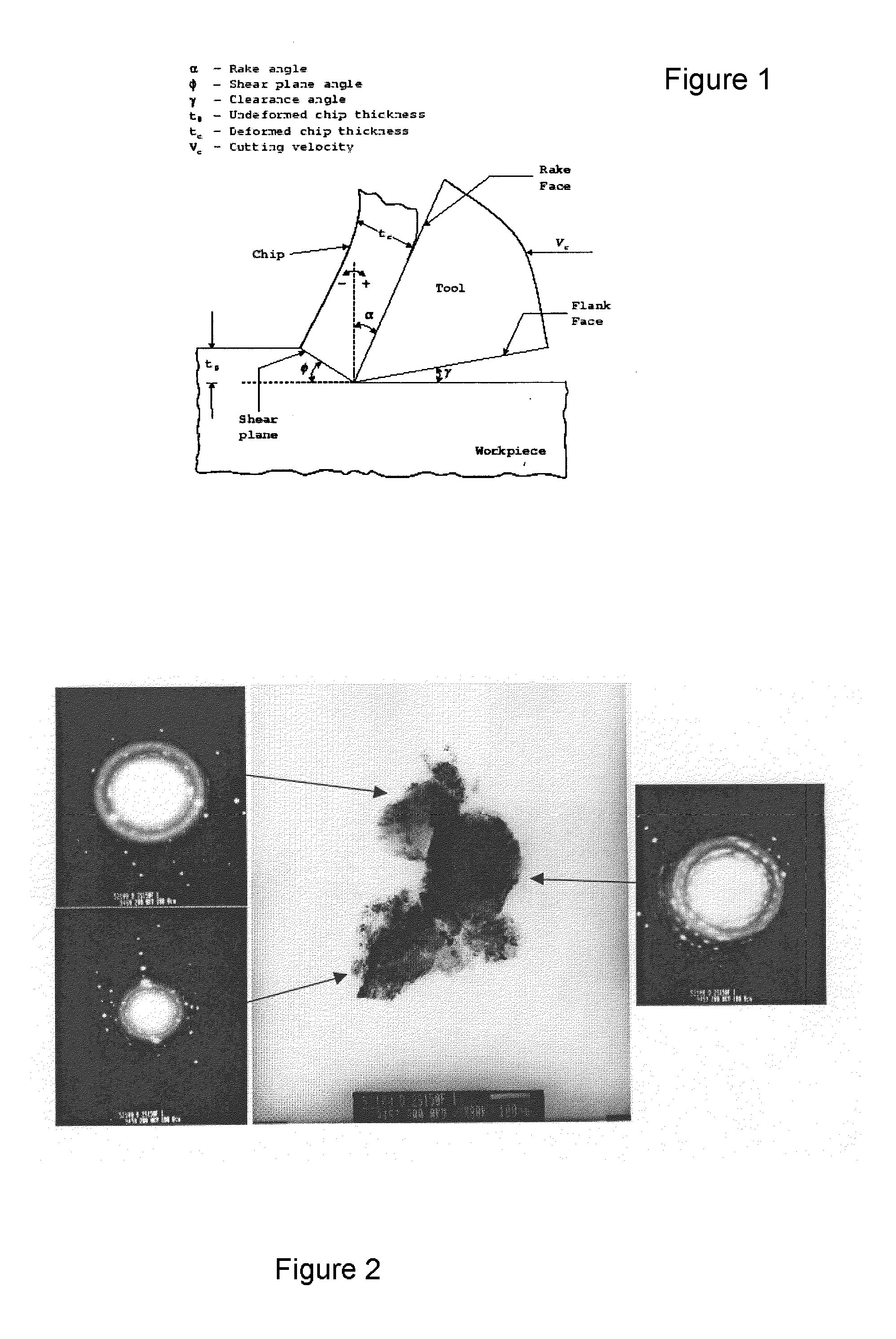

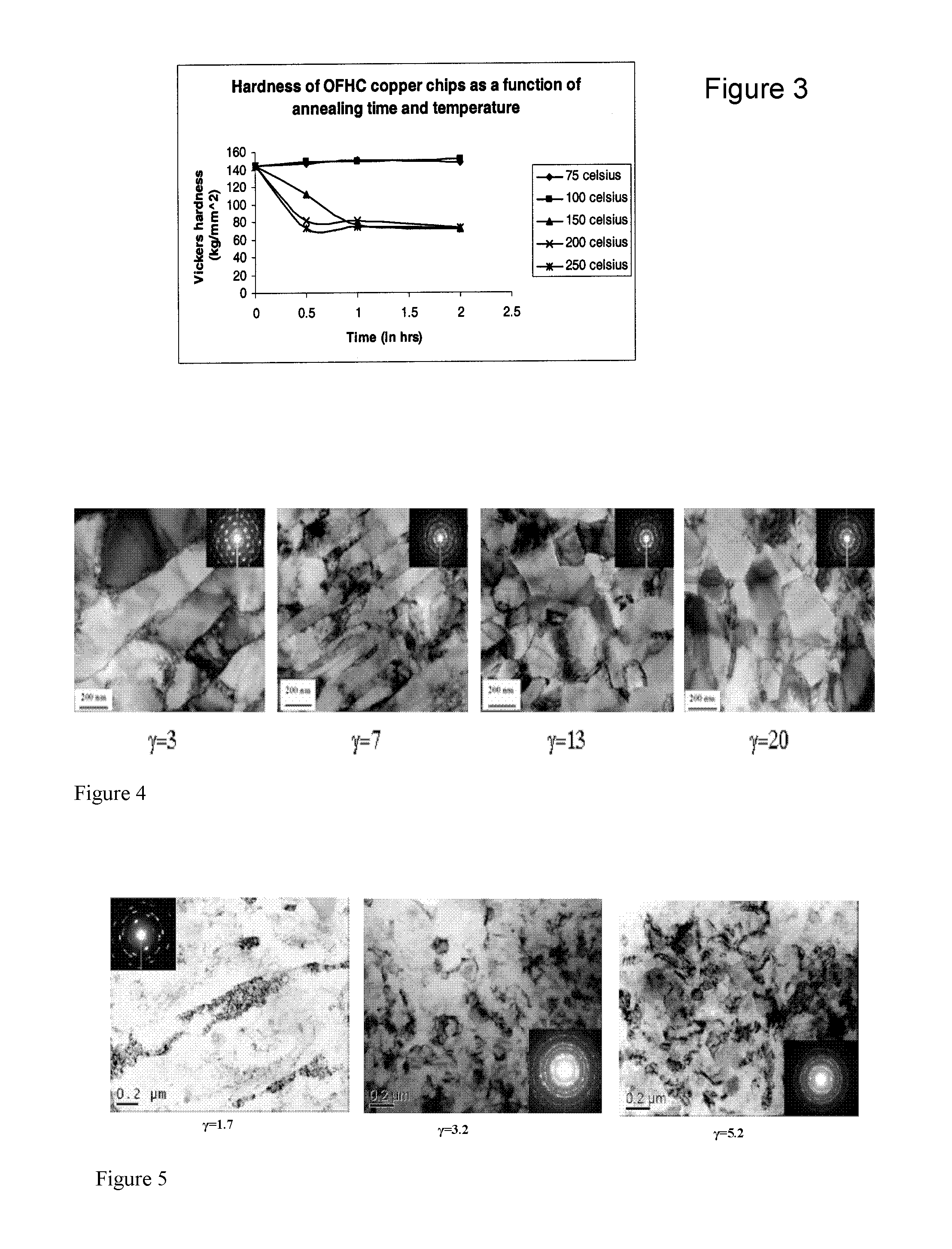

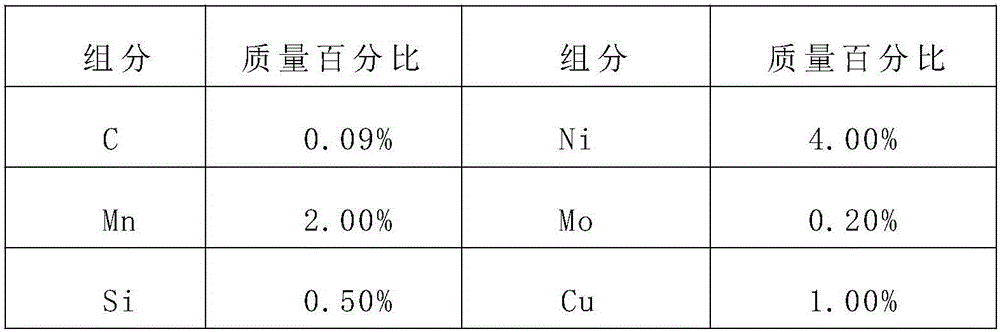

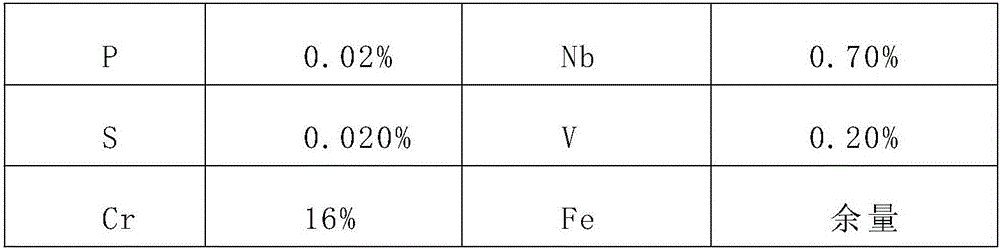

Method of consolidating precipitation-hardenable alloys to form consolidated articles with ultra-fine grain microstructures

InactiveUS20060278308A1Low costEasy to useTransportation and packagingMetal-working apparatusUltra fineSupersaturated solid solution

A method by which consolidated articles can be produced from nanocrystalline materials to have mechanical properties that can be improved through thermal treatment. The method entails machining a body to produce polycrystalline chips having nanocrystalline microstructures, and then consolidating the chips to form a consolidated article having mechanical properties that exceed that of the body from which the chips were formed. In particular, consolidation of nanocrystalline chips formed by machining a supersaturated solid-solution body causes precipitation of a fine dispersion of precipitates in the consolidated article, with the potential for certain properties to even improve during consolidation or subsequent thermal treatment of the consolidated article.

Owner:PURDUE RES FOUND INC

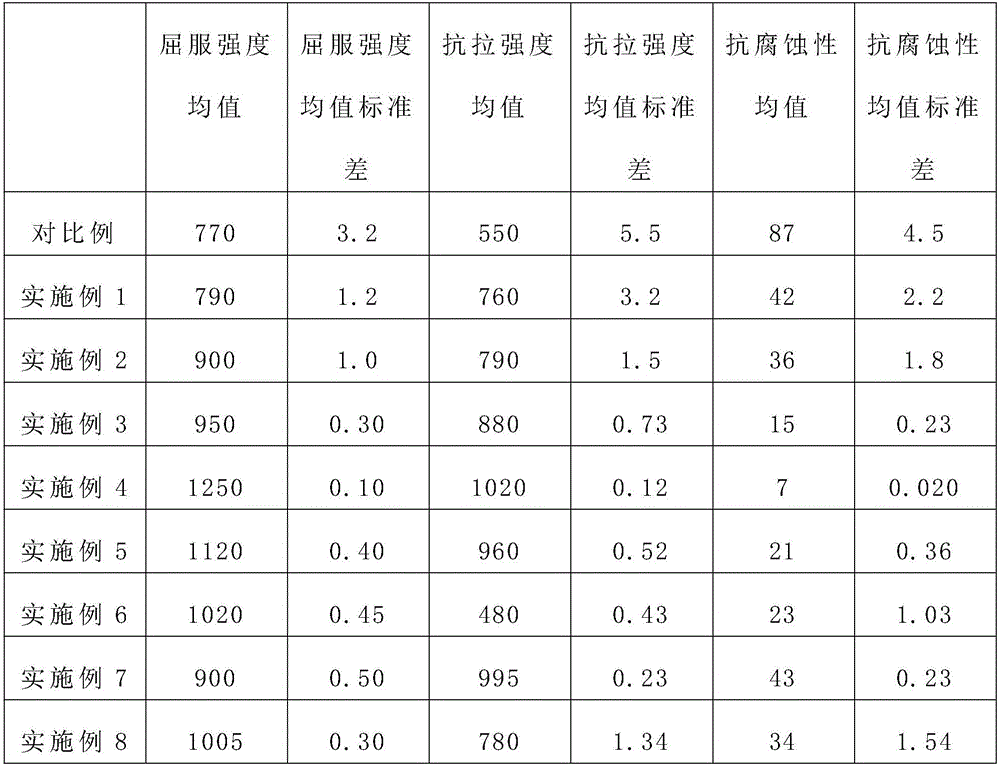

Austenitic precipitation hardening stainless steel forge piece and machining method thereof

The invention discloses an austenitic precipitation hardening stainless steel forge piece and a machining method thereof. The problem that according to an existing machining method, a manufactured austenitic stainless steel forge piece is low in comprehensive performance is solved. According to the technical scheme, the austenitic precipitation hardening stainless steel forge piece comprises chemical components including, by mass percent, not larger than 0.09% of C, not larger than 2.00% of Mn, not larger than 1.00% of Si, not larger than 0.025% of P, 4.00% to 8.00% of Ni, 0.20% to 0.80% of Mo, 1.00% to 4.00% of Cu, not larger than 0.70% of Nb, not larger than 0.20% of V and the balance Fe. The manufactured forge piece has the beneficial effects of being high in strength, high in toughness, resistant to corrosion and wear, high in weather resistance, resistant to high temperature and low temperature, high in stability and the like.

Owner:陆照福

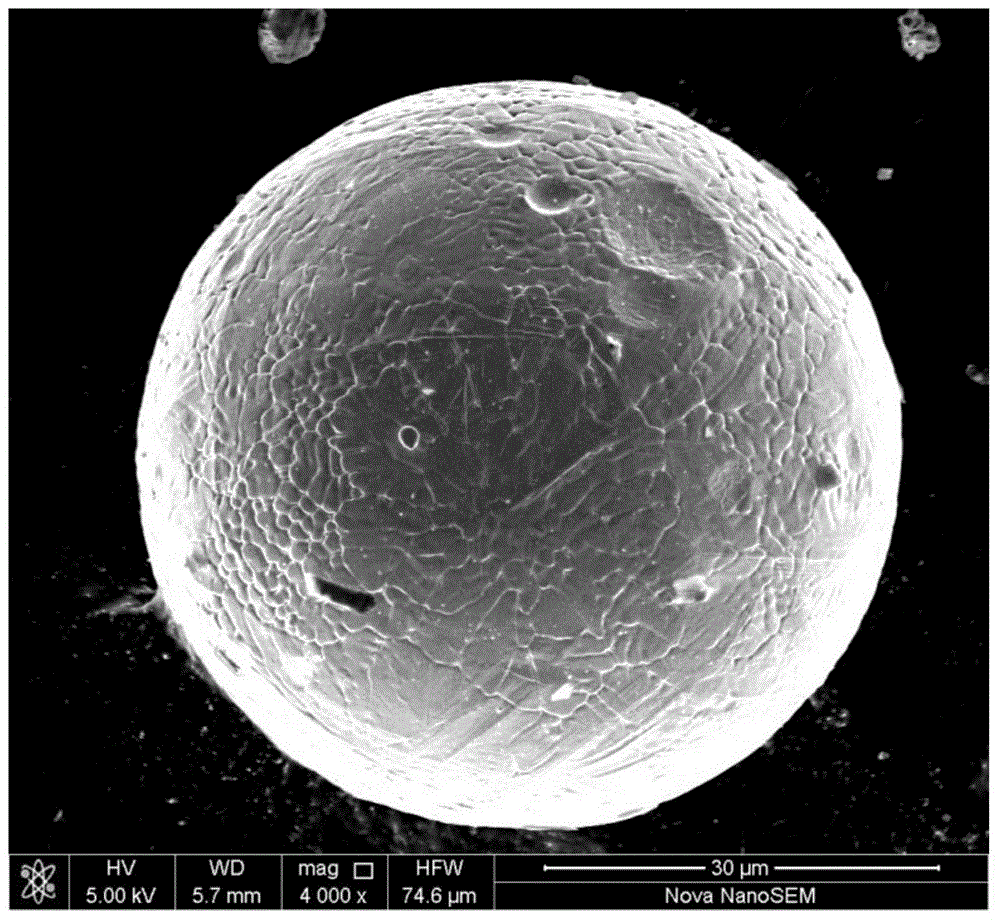

Preparation method and application of polystyrene hollow microspheres

The invention relates to a preparation method and an application of polystyrene hollow microspheres. According to the invention, polystyrene is dissolved into styrene monomer, such that an oil phase is prepared. The viscosity of the oil phase is controlled by controlling the concentration of polystyrene. In a W1 / O / W2 triple emulsion, initiation and polymerization of the styrene monomer, precipitation hardening of polystyrene, and the like are realized, such that the polystyrene hollow microspheres with the hollow structure are formed. The invention also relates to an application of the polystyrene hollow microspheres in drilling fluids and cementing fluids.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-strength electro-conductive copper alloy wire and production method thereof

InactiveCN1804073AImprove heat resistanceThin metal substrateTemperature control deviceMetal rolling arrangementsChemical compositionHigh intensity

The special high-strength Cu alloy cable or wire as the alternate material for Cu-Cd alloy fit to drag, compact, kink and superheat frequently comprises: 0.2-0.6% Mg for solution strengthening, 0.4~0.8% Ni and 0.1~0.2% Si to form Ni2Si intermetallic compound for precipitation hardening, 0.08~0.2% Zr to fine base, promote dispersion, improve thermal resistance and stabilize Mg; and other as Cu, and is manufactured by dissolving, depositing and cold processing.

Owner:JIANGSU UNIV OF SCI & TECH

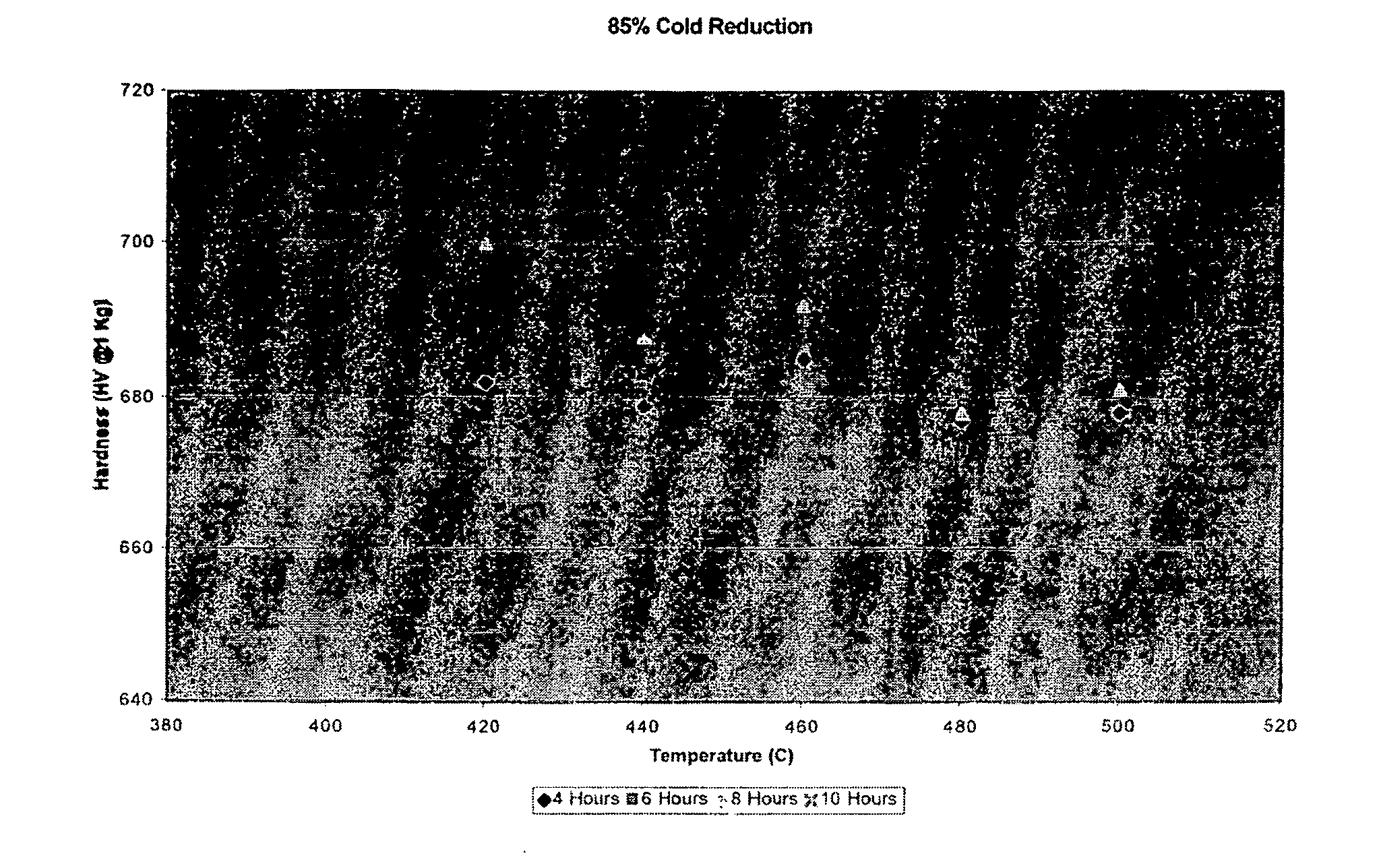

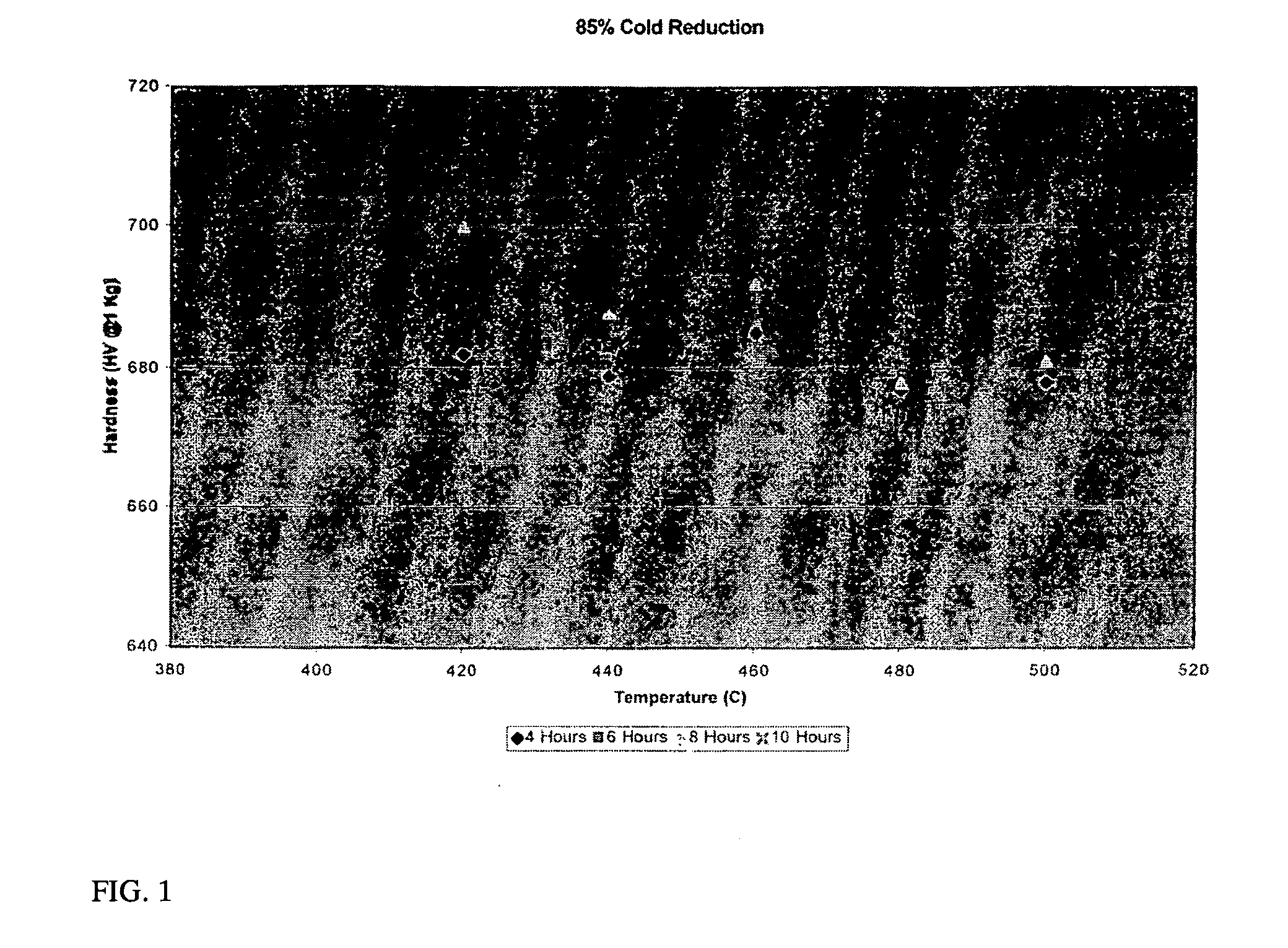

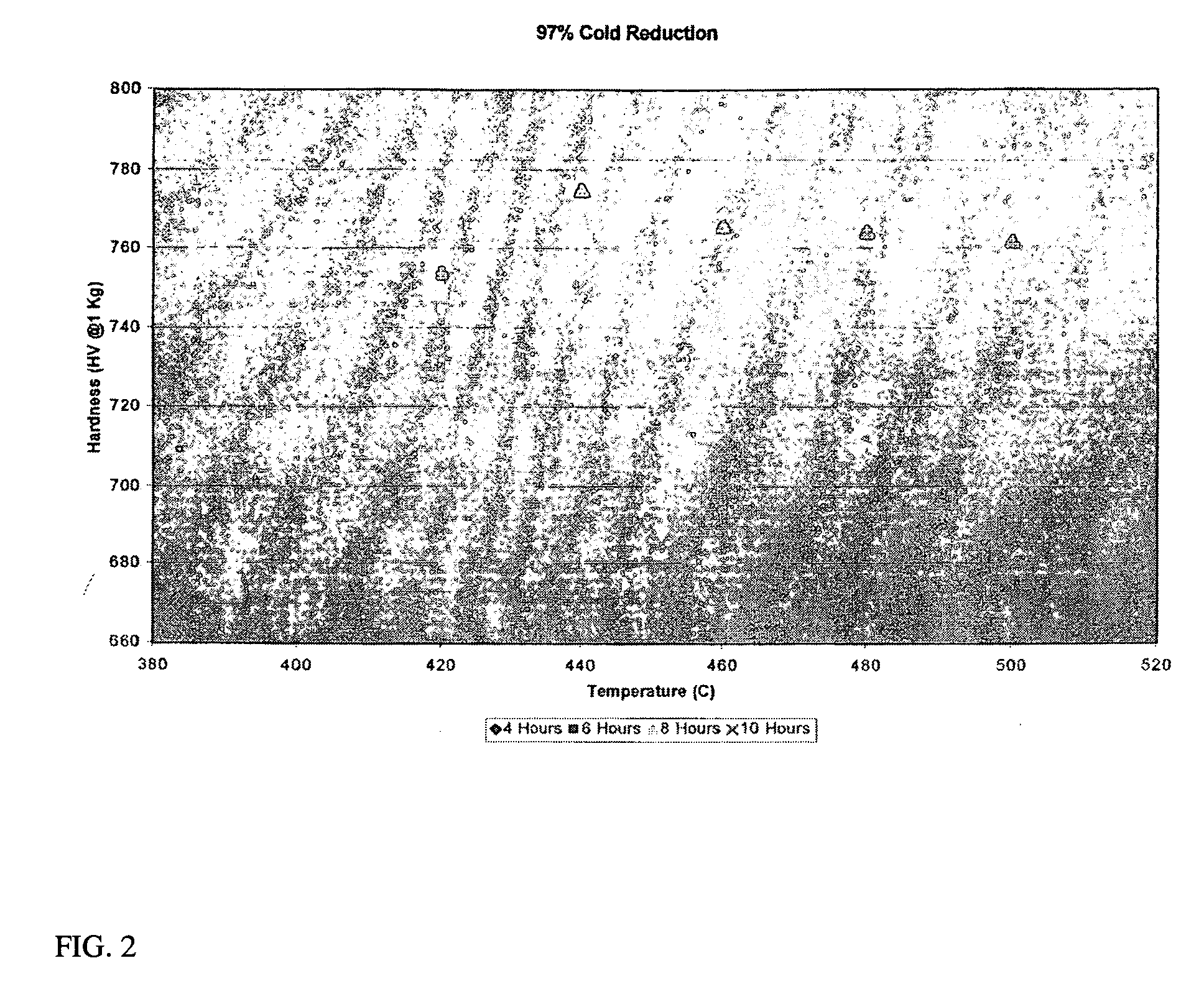

Razor blades and compositions and processes for the production of razor blades

InactiveUS20070137050A1Improve corrosion resistanceFurnace typesMetal working apparatusHardnessMartensite

Razor blades for use in wet shave razors are produced from a precipitation hardenable ferrous composition having an austenitic structure and being supersaturated in certain elements, by a cold rolling process which converts most of the austenite to martensite, followed by a heat treatment process which causes the precipitation of strengthening particles to produce a corrosion resistant material having a hardness in excess of 600 HV.

Owner:EVEREADY BATTERY CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com