Method for preparing seamless steel tubes made of martensite precipitation hardening stainless steel

A technology of precipitation hardening and seamless steel pipes, which is applied in the direction of manufacturing tools, metal rolling, heat treatment equipment, etc., can solve the problems of longitudinal cracking on the surface of steel pipes, failure to form batch supply, and failure to produce products, etc., to achieve comprehensive mechanical properties Improvement, surface quality improvement, production efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2

[0025] In this example, 0Cr17Ni4Cu4Nb stainless steel is used, and its chemical composition weight percentage ratio is: C: 0.05, Si: 0.53, Mn: 0.43, S: 0.002, P: 0.022, Cr: 16.12, Cu: 3.28, Ni: 4.37, Nb: 0.26, Mo: 0.09, Ti: 0.01, W: 0.04, As: 0.01, Al: 0.01.

[0026] Heating after peeling and blanking of the tube blank: Φ80 tube blank is peeled to Φ75 through machining, and the specification of the tube blank is determined according to the finished product specification. If the outer diameter of the finished product is less than 60mm, the Φ80 tube blank can be selected; if the finished product outer diameter is greater than 60mm, the specification of the tube blank must be Greater than Φ80; heating temperature 1100°C-1150°C;

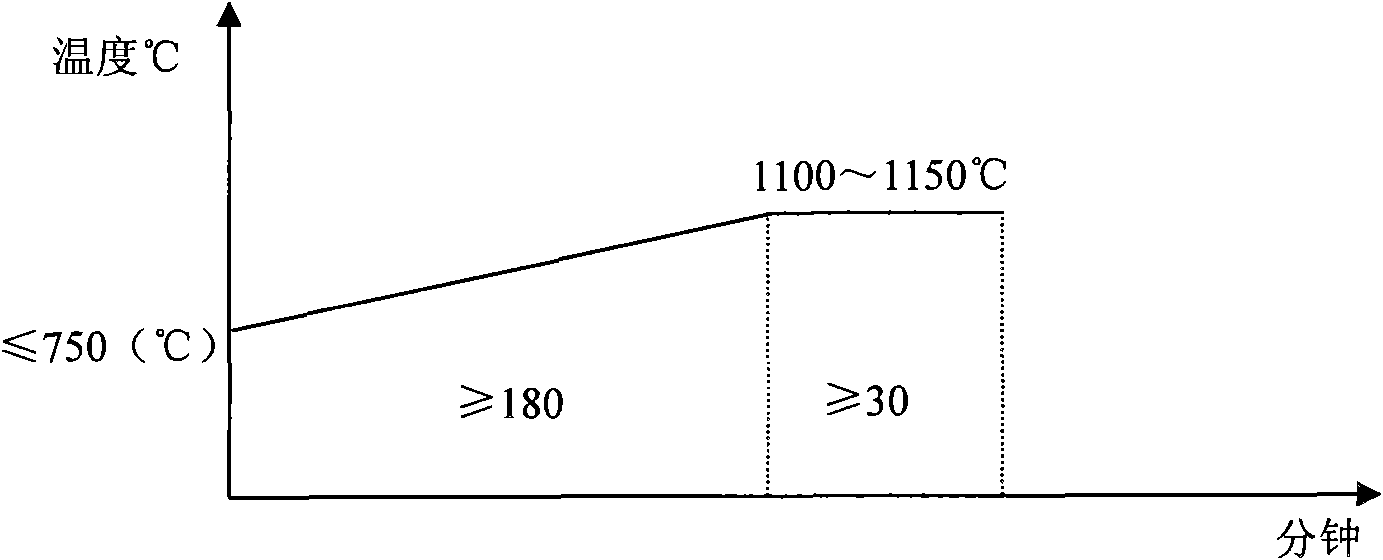

[0027] Hot piercing: tube blank heating process such as figure 1 As shown, the size of the blank tube is Φ80×7mm, the heating temperature is controlled by thermal perforation to 1120°C, and the holding time is greater than 30 minutes;

[0028] Cooling:...

Embodiment 3

[0047] In this example, 0Cr17Ni4Cu4Nb stainless steel is used, and its chemical composition weight percentage ratio is: C: 0.05, Si: 0.53, Mn: 0.43, S: 0.002, P: 0.022, Cr: 16.12, Cu: 3.28, Ni: 4.37, Nb: 0.26, Mo: 0.09, Ti: 0.01, W: 0.04, As: 0.01, Al: 0.01.

[0048] Heating after peeling and blanking of the tube blank: Φ90 tube blank is peeled to Φ85 through machining, and the peeled tube blank is heated in an inclined bottom furnace, and the heating temperature range is 1130°C-1150°C;

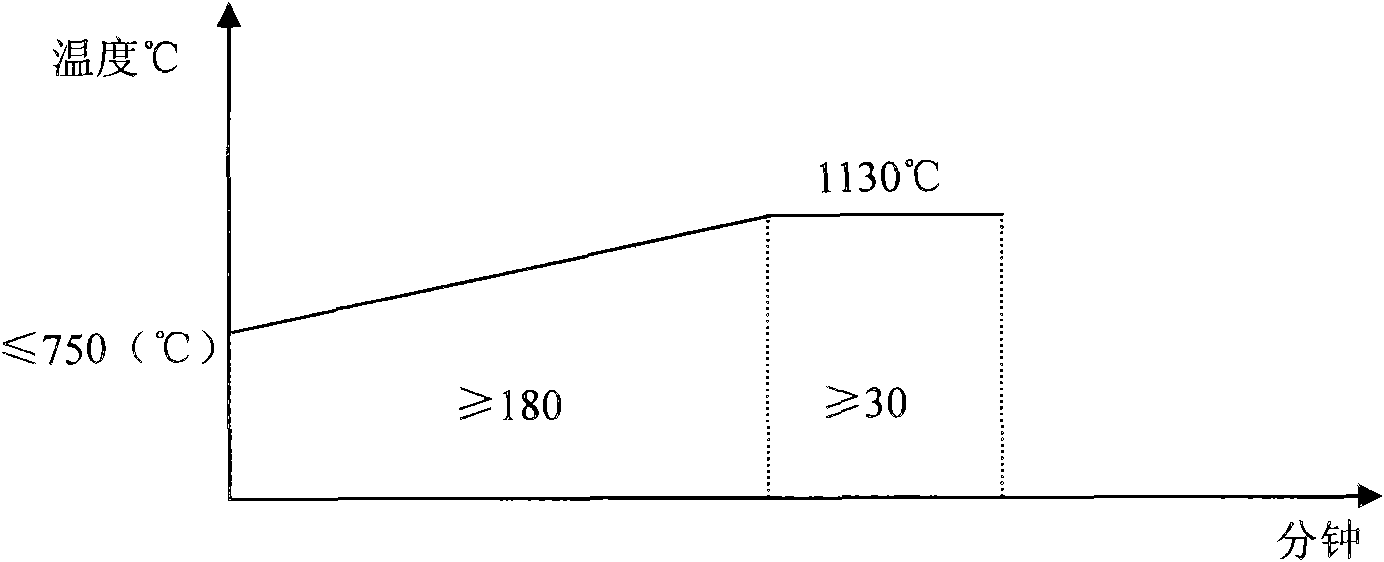

[0049] Hot piercing: tube blank heating process such as figure 2 As shown, the size of the blank tube is Φ90×8mm, the heating temperature is controlled by thermal perforation to 1130°C, and the holding time is greater than 30 minutes;

[0050] Cooling: After thermal perforation, the waste tubes are air-cooled by stacking;

[0051] Surface treatment of waste pipe: including finishing, pickling, lubrication, pickling after flattening the waste pipe, the pickling liquid formula is HF 5-8%, HN...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com