Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

111results about How to "Resistant to wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

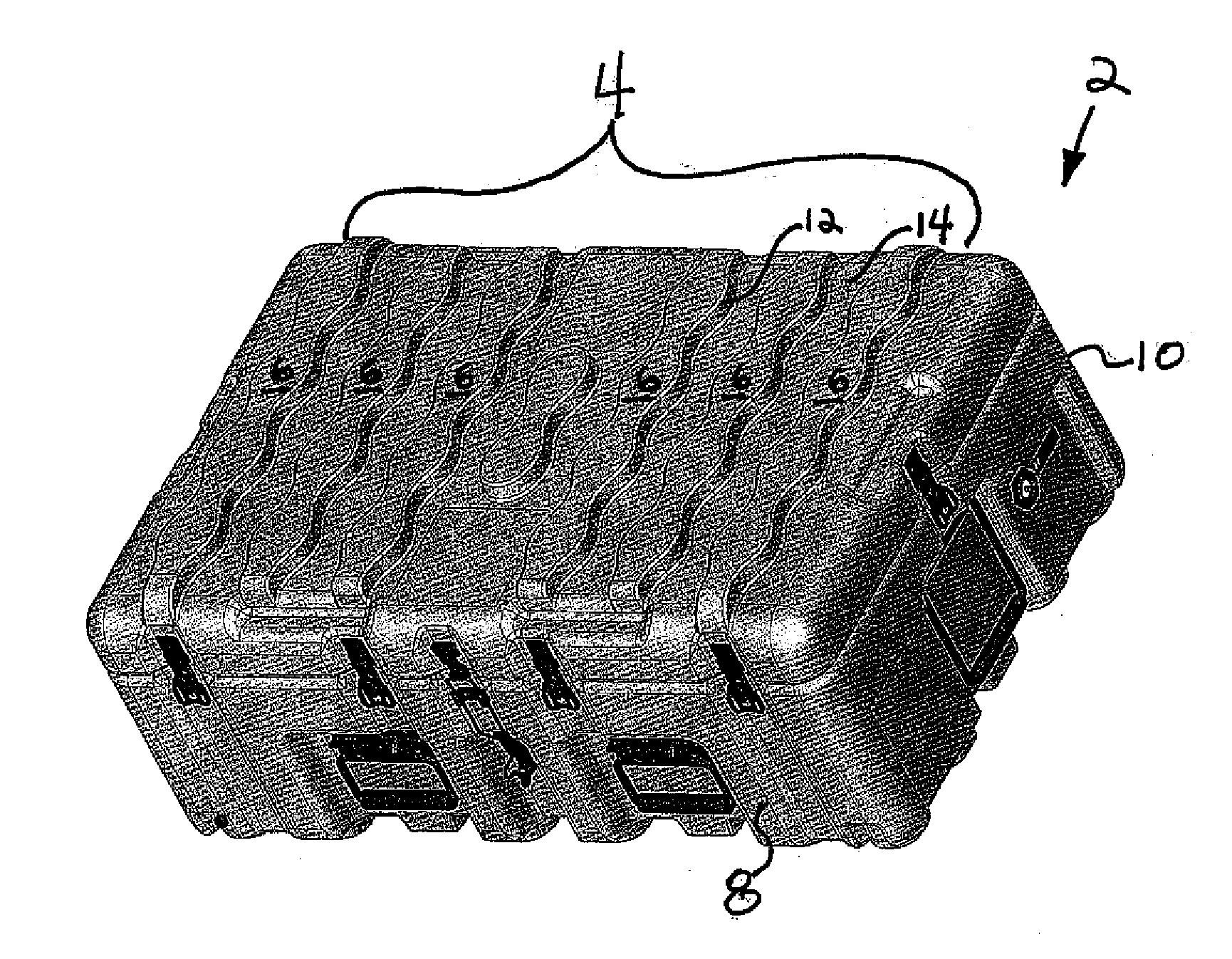

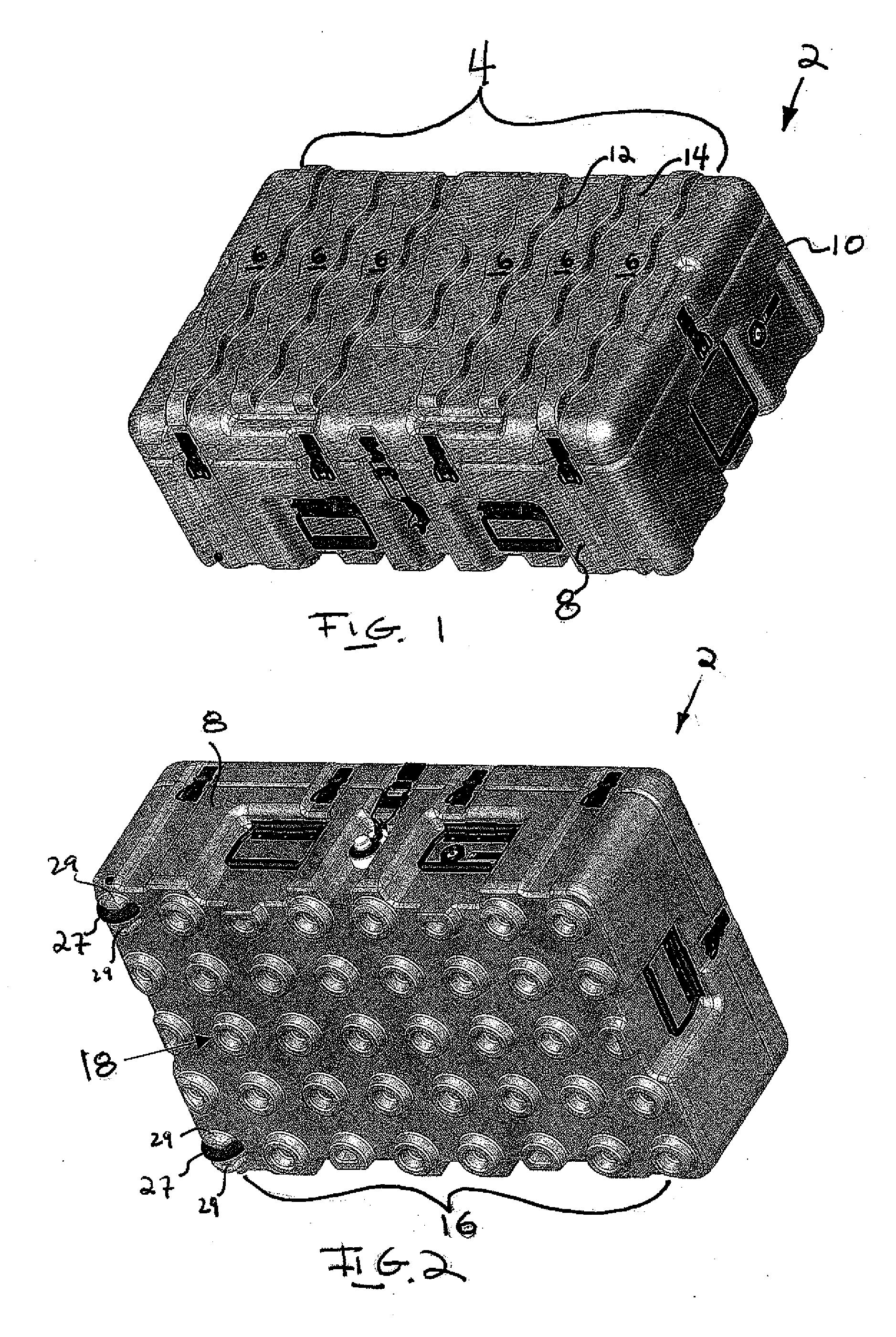

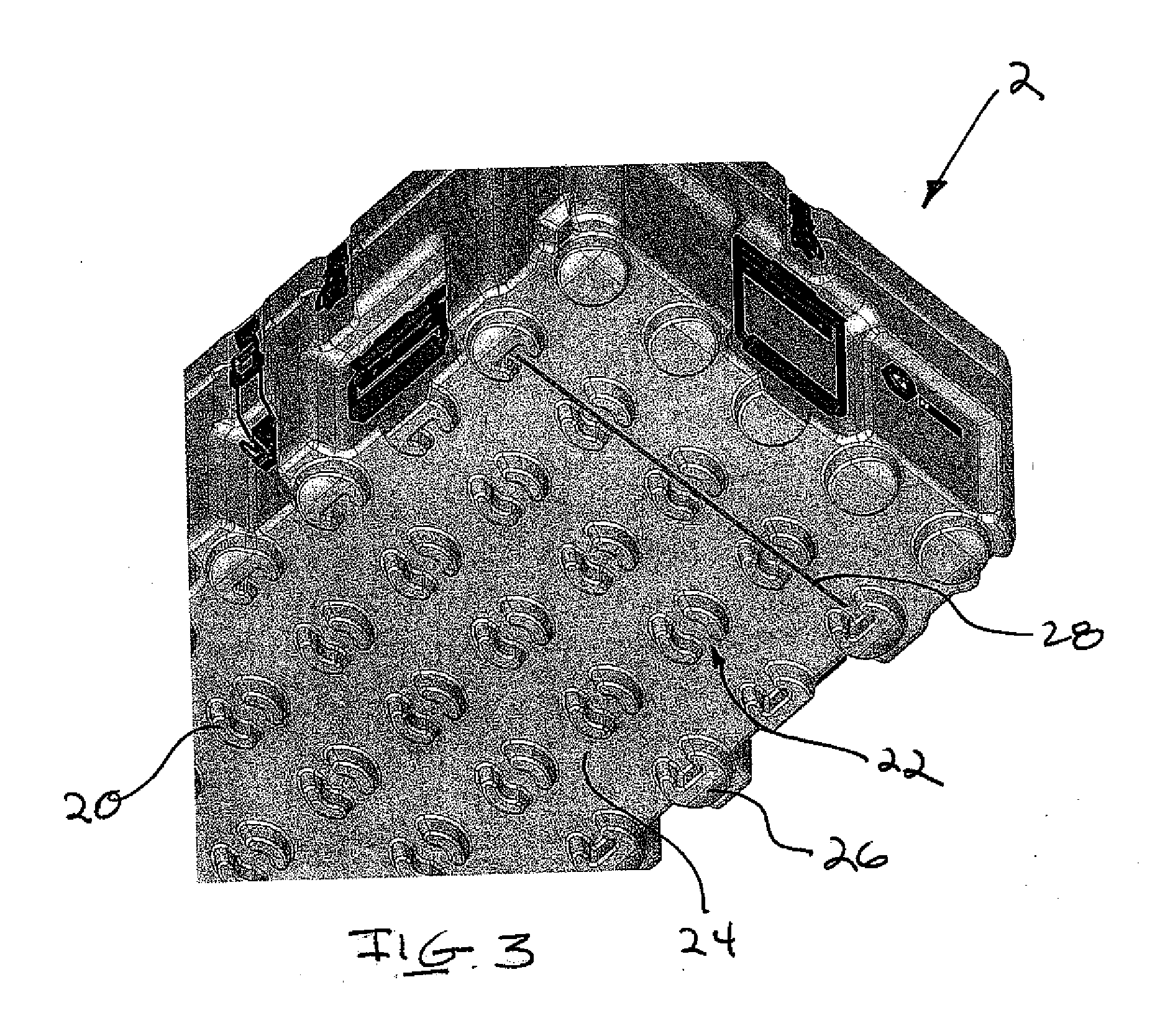

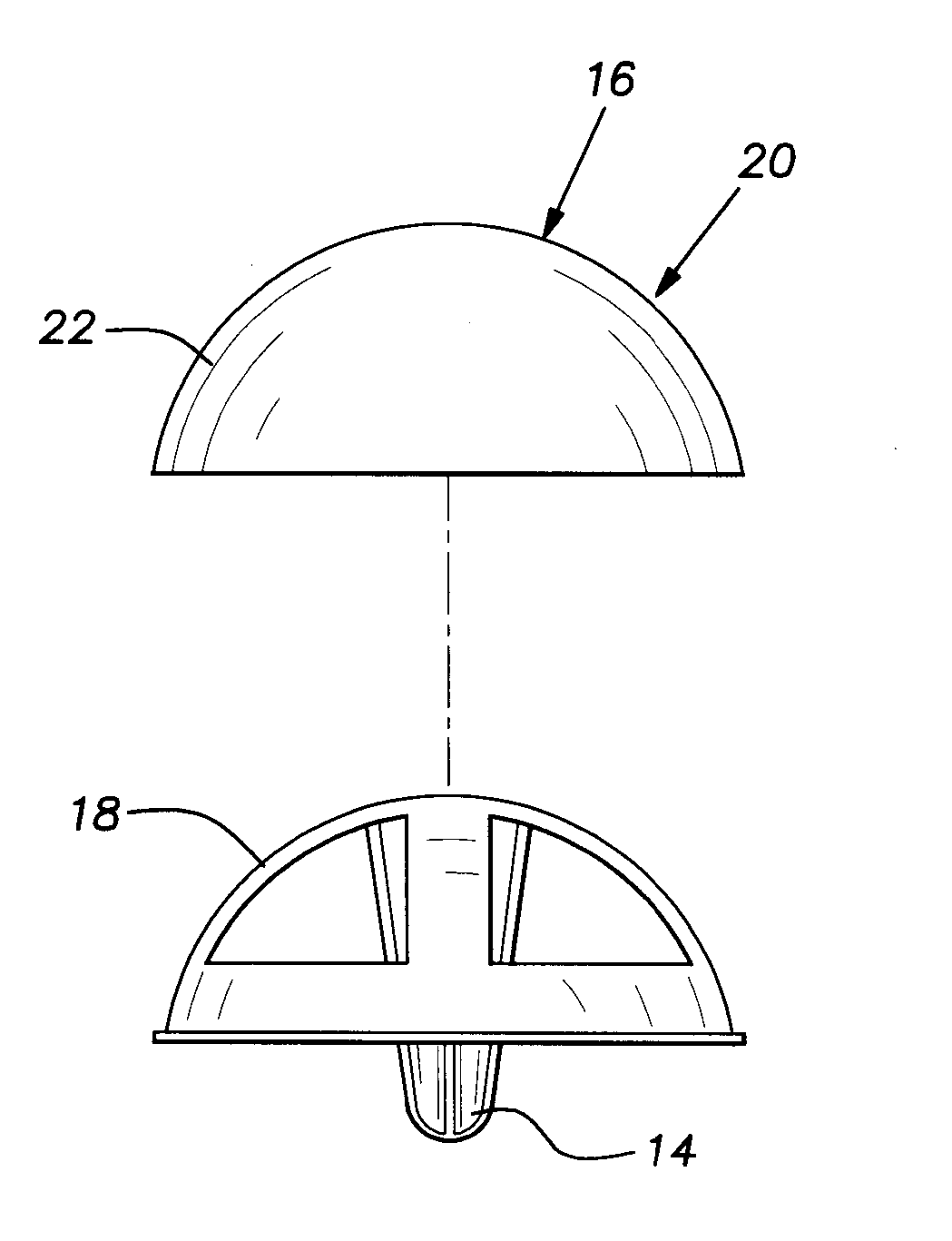

Container assembly

ActiveUS20090178946A1Prevent accessResist damageWing fastenersOther accessoriesEngineeringMechanical engineering

A container assembly for the storage and transport of goods, the assembly including a first portion having an interior with a substantially flat interior bottom surface. The assembly further includes a second portion pivotally connected to the first portion. The first portion has an outer surface that includes a first stacking pattern and the second portion has an outer surface that includes a second stacking pattern which is different from the first stacking pattern and configured to engage the first stacking pattern enabling the container assembly to be bi-directionally stacked on another of the container assemblies.

Owner:CASE-MATE +1

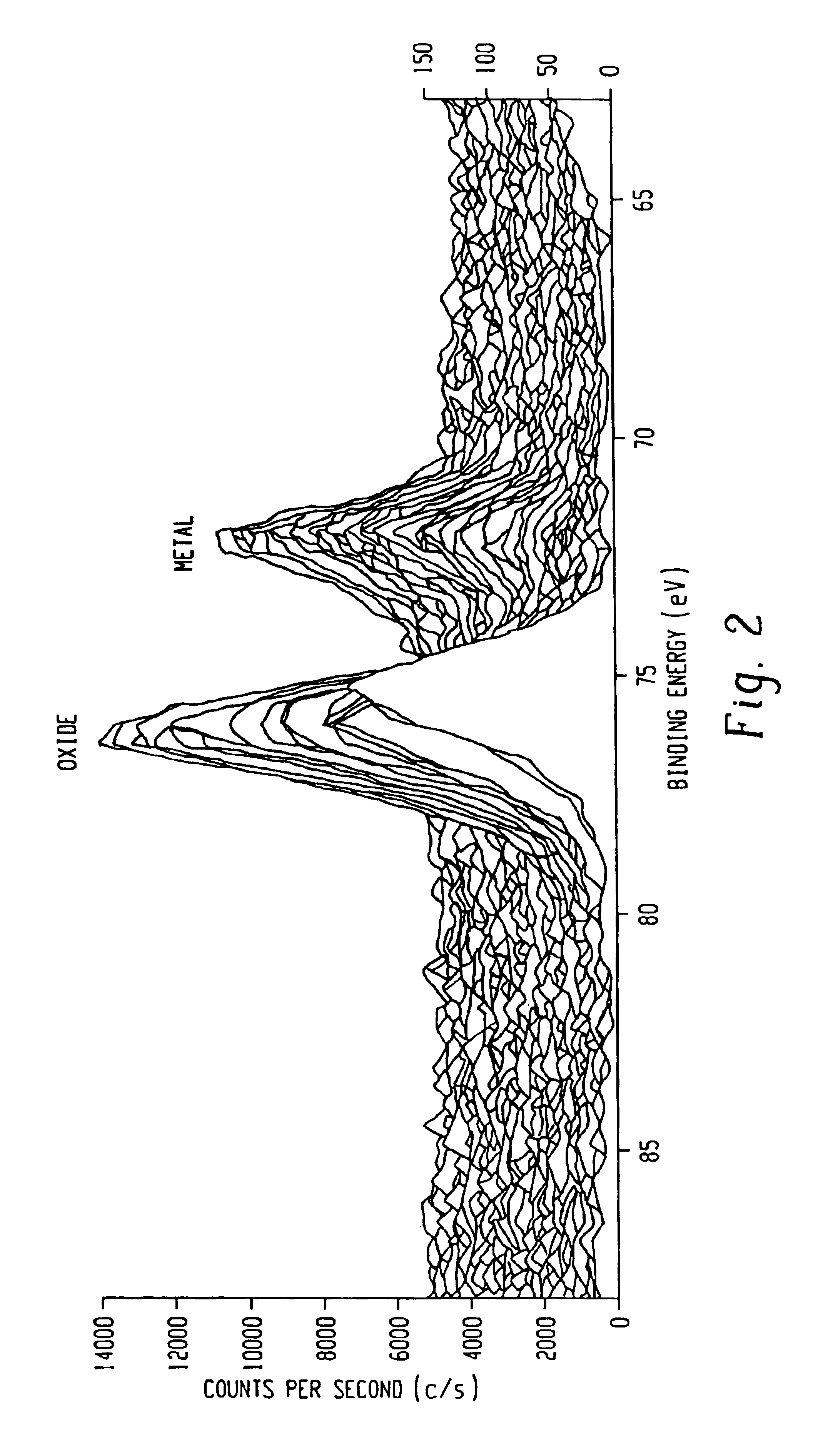

Fine-grained metallic coatings having the coefficient of thermal expansion matched to the one of the substrate

ActiveUS20070281176A1Cost-effective and convenient processIncrease stiffnessMaterial nanotechnologyRodsThermal dilatationMetal coating

Fine-grained (average grain size 1 nm to 1,000 nm) metallic coatings optionally containing solid particulates dispersed therein are disclosed. The fine-grained metallic materials are significantly harder and stronger than conventional coatings of the same chemical composition due to Hall-Petch strengthening and have low linear coefficients of thermal expansion (CTEs). The invention provides means for matching the CTE of the fine-grained metallic coating to the one of the substrate by adjusting the composition of the alloy and / or by varying the chemistry and volume fraction of particulates embedded in the coating. The fine-grained metallic coatings are particularly suited for strong and lightweight articles, precision molds, sporting goods, automotive parts and components exposed to thermal cycling. The low CTEs and the ability to match the CTEs of the fine-grained metallic coatings with the CTEs of the substrate minimize dimensional changes during thermal cycling and prevent premature failure.

Owner:INTEGRAN TECH

Hard-chrome plated layer

InactiveUS6503642B1Improved physical characteristicResistant to wearElectrolytic coatingsReflex reflectorsHexavalent chromiumHard chromium

In an electrodeposited hard-chromium coat, particularly for a piston ring, which is substantially formed of an electrolyte containing hexavalent chromium, wherein there are cracks in the coat and diamond particles are embedded in these cracks, the diamond particles have a size ranging from 0.25 to 0.5 mum.

Owner:FEDERAL MOGUL BURSCHEID

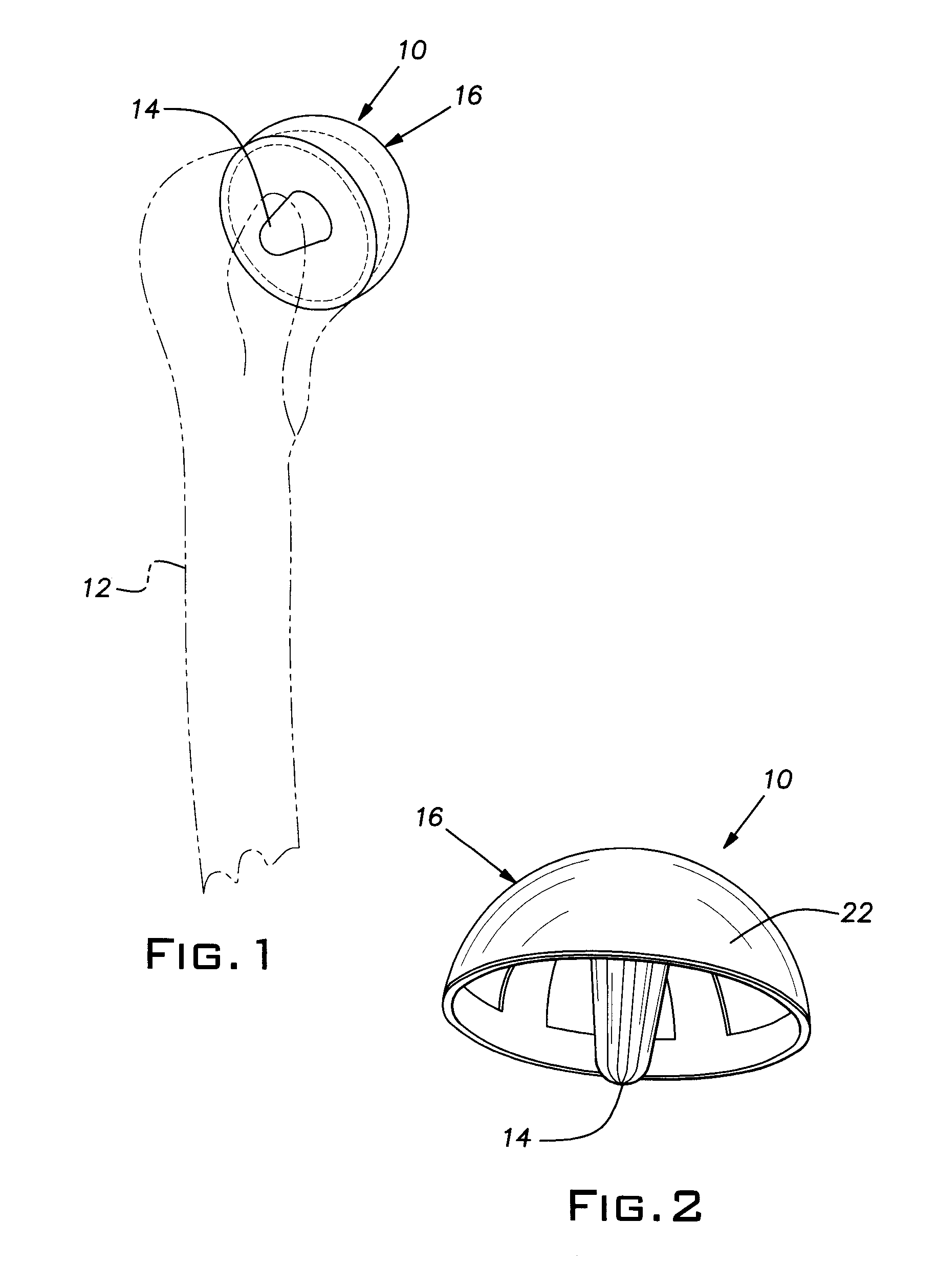

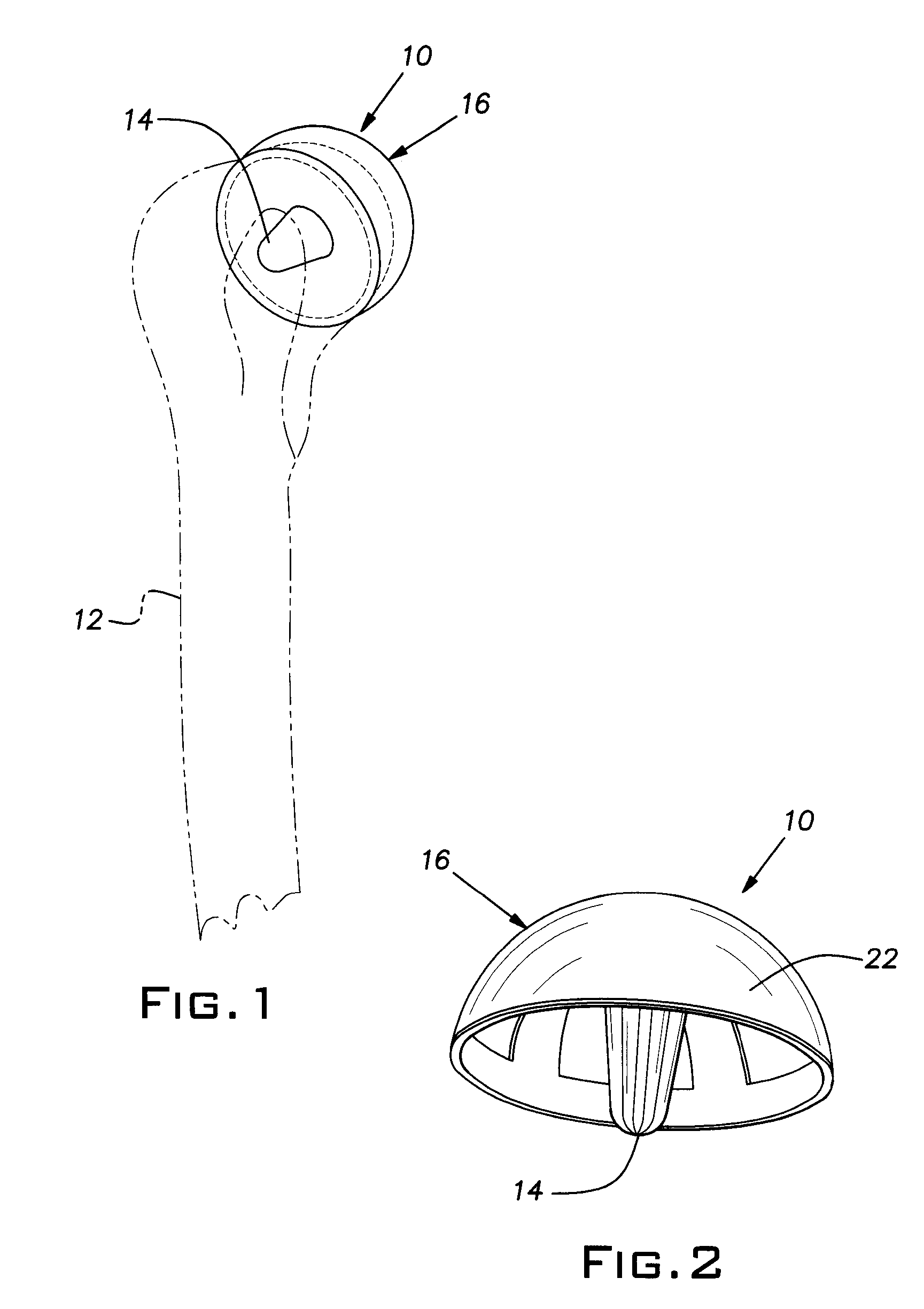

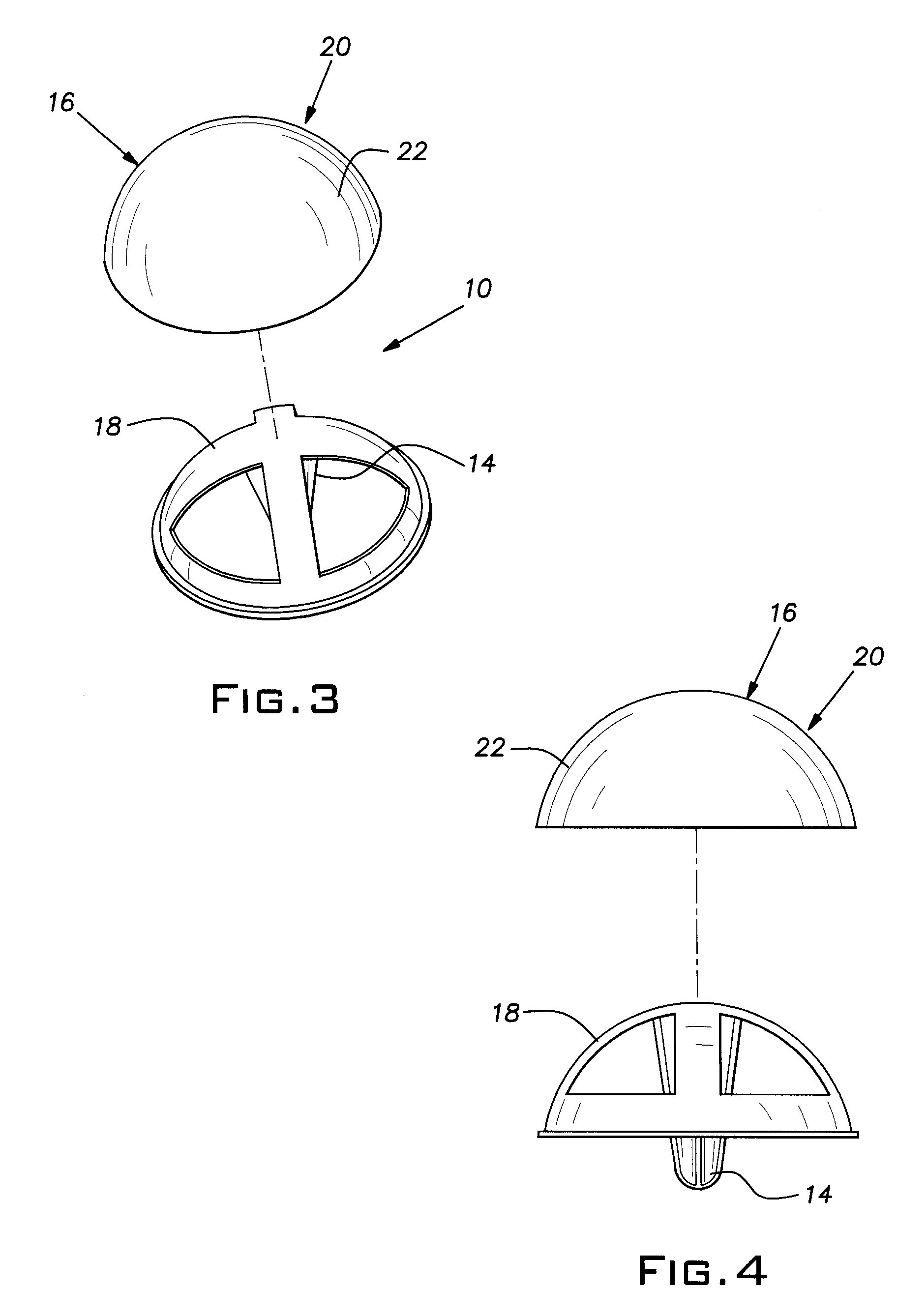

Orthopedic Implants Coated with Pyrolytic Carbon

InactiveUS20070156250A1Resistance to frictionResistant to wearImpression capsBone implantGas phaseTitanium

An orthopedic implant having a metal substrate with an articulating surface includes a coating for the articulating surface made of pyrolytic carbon. Typically, the substrate is made of a metal such as titanium or stainless steel, or alloys thereof. The pyrolytic carbon coating preferably is applied by vapor deposition.

Owner:SEITZ WILLIAM H JR +1

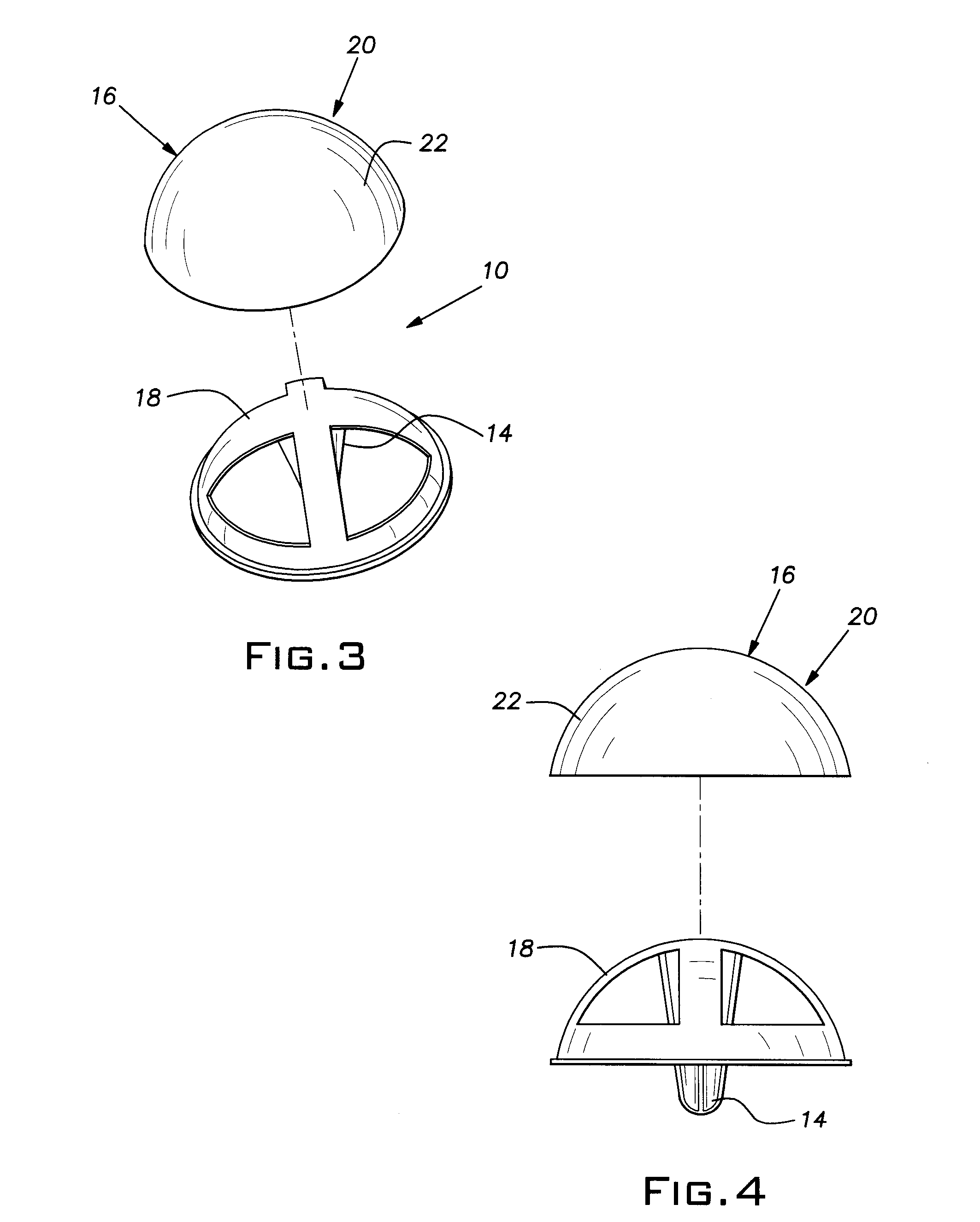

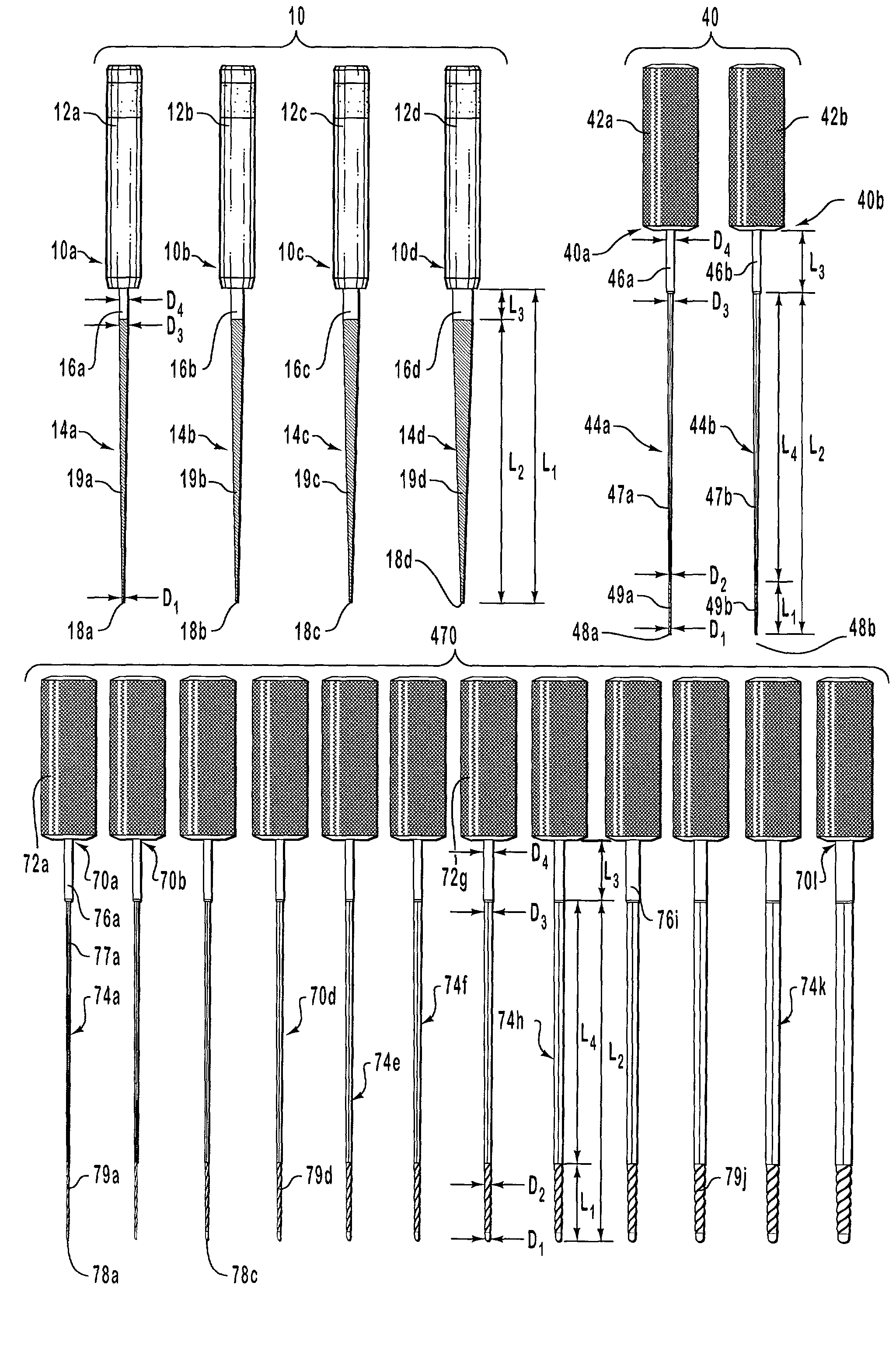

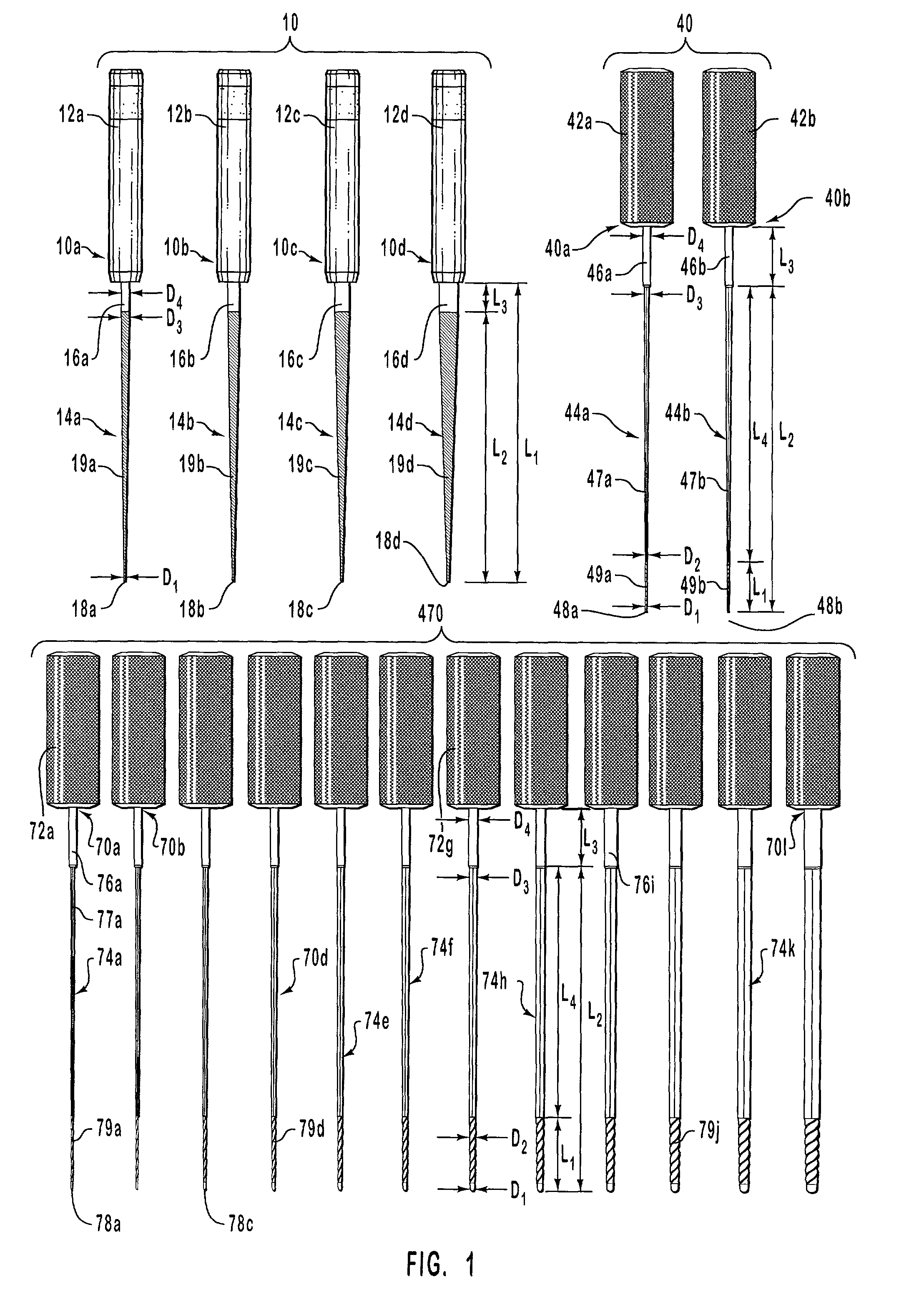

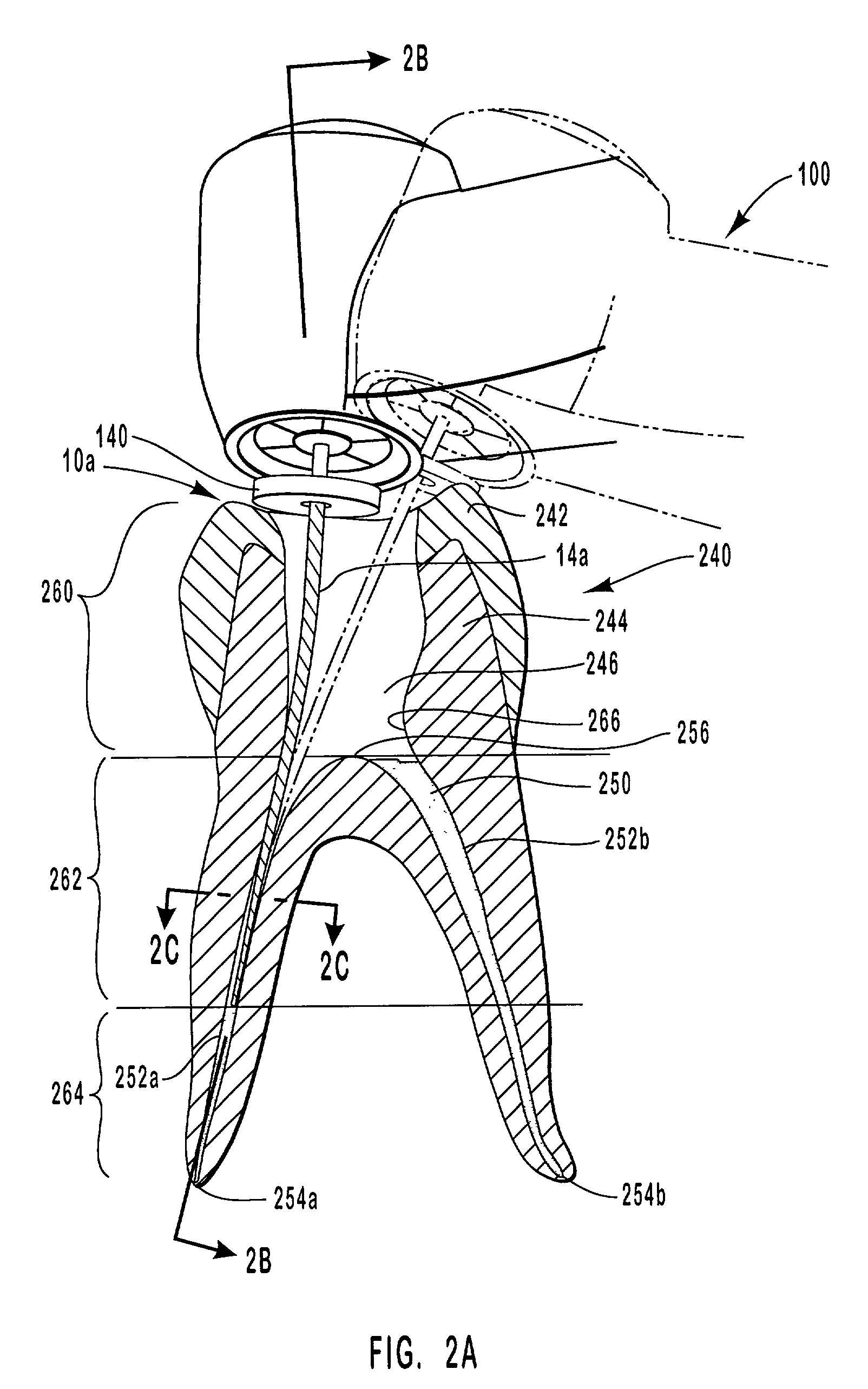

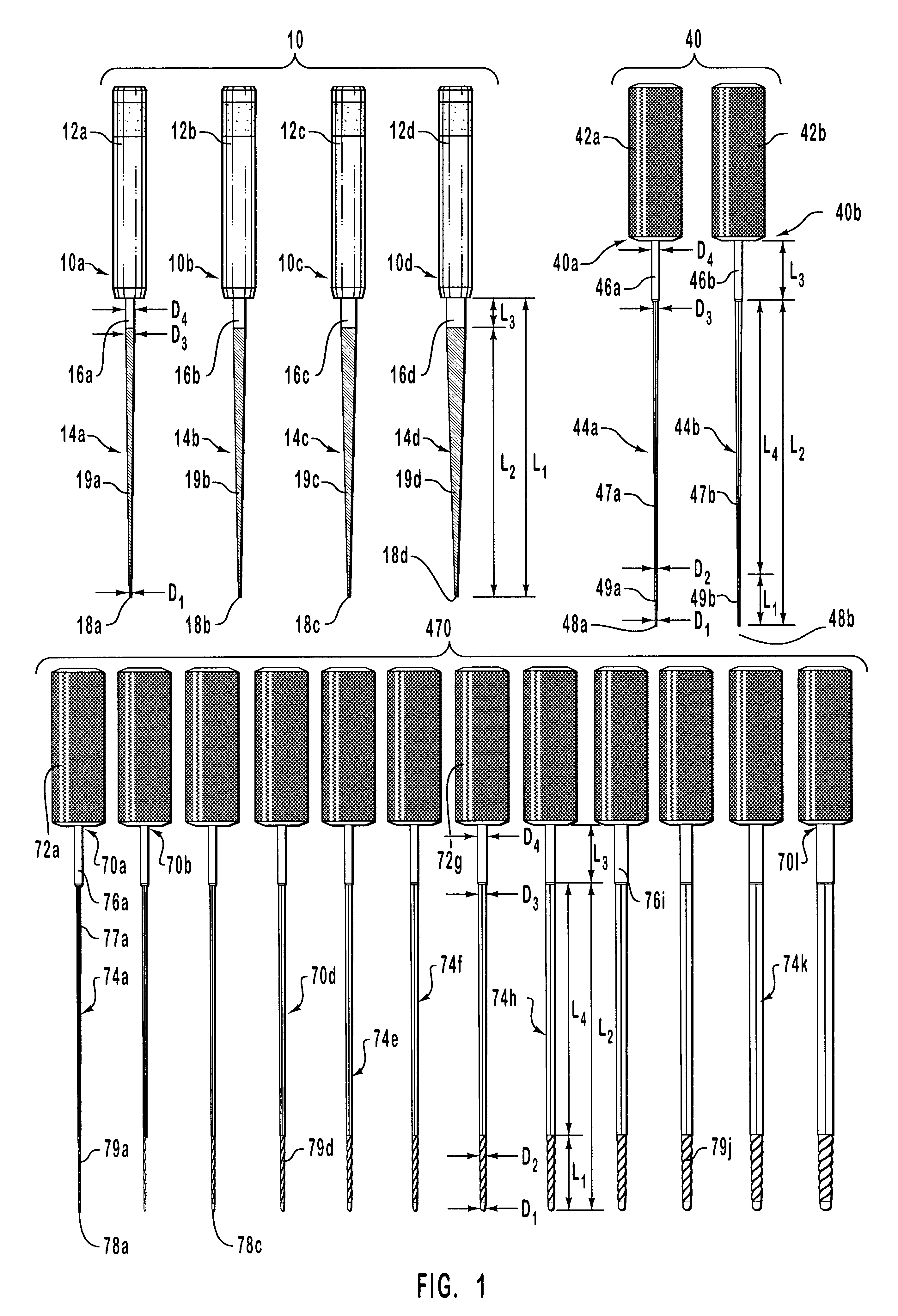

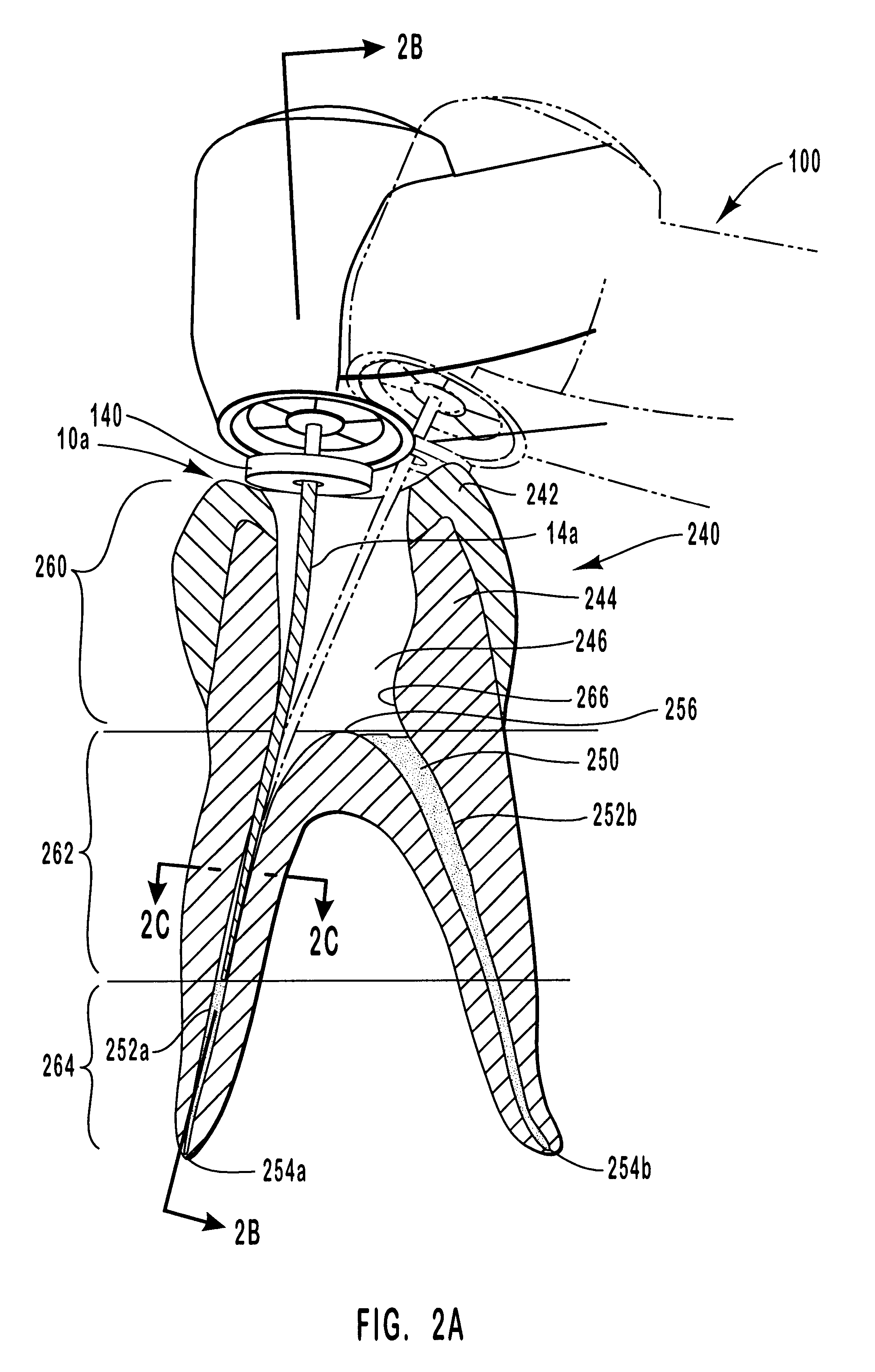

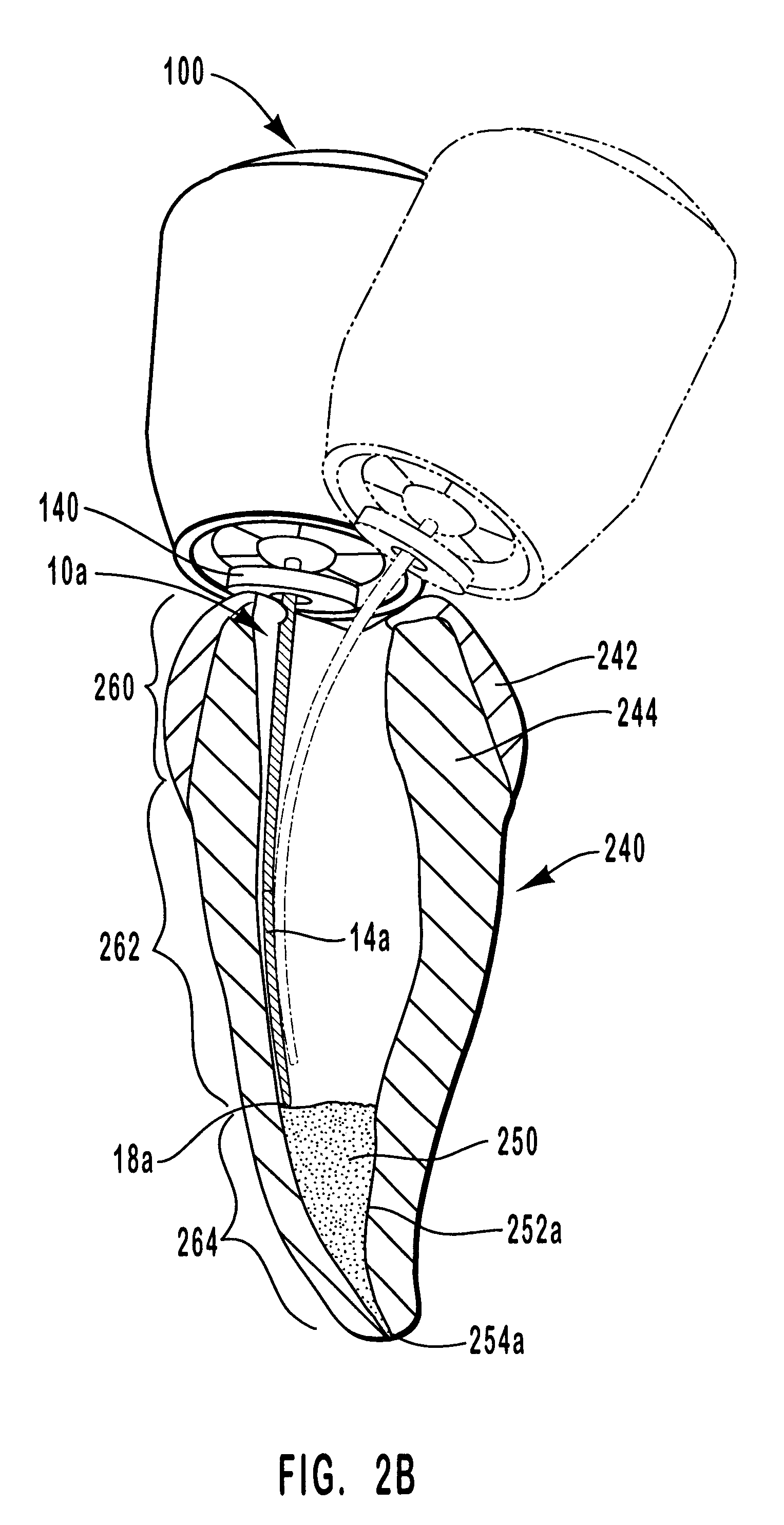

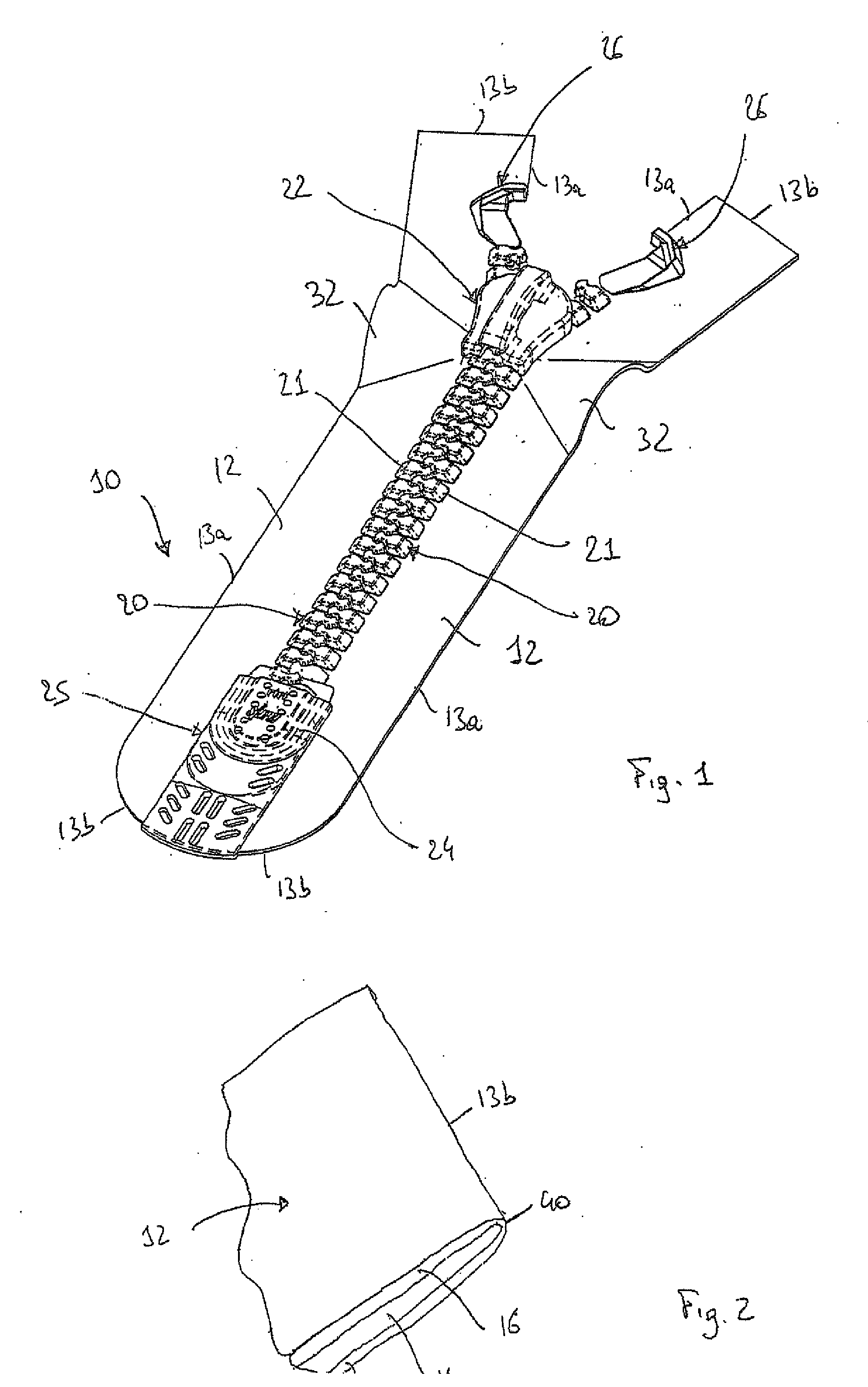

Precipitation hardenable stainless steel endodontic instruments and methods for manufacturing and using the instruments

InactiveUS20030013067A1Improve hardnessExcellent characteristicTeeth cappingTeeth nerve/root treatment implementsEndodontic filesBiocompatibility Testing

Precipitation hardenable stainless steel endodontic files and methods for their manufacture, wherein the most preferred precipitation hardenable stainless steel is 17-4PH and aging is preferably not one of the manufacturing steps. Precipitation hardenable stainless steels used in embodiments of this invention are iron-chromium-nickel grades that have the desired properties of flexibility, strength, hardness, wear resistance, stiffness, resistance to permanent deformation, resistance to variable torque, and biocompatibility for endodontic files.

Owner:ULTRADENT PROD INC

Precipitation hardenable stainless steel endodontic instruments and methods for manufacturing and using the instruments

InactiveUS6514076B1Resistant to wearEasy to useTeeth cappingTeeth nerve/root treatment implementsEndodontic filesChromium nickel

Precipitation hardenable stainless steel endodontic files and methods for their manufacture, wherein the most preferred precipitation hardenable stainless steel is 17-4PH and aging is preferably not one of the manufacturing steps. Precipitation hardenable stainless steels used in embodiments of this invention are iron-chromium-nickel grades that have the desired properties of flexibility, strength, hardness, wear resistance, stiffness, resistance to permanent deformation, resistance to variable torque, and biocompatibility for endodontic files.

Owner:ULTRADENT PROD INC

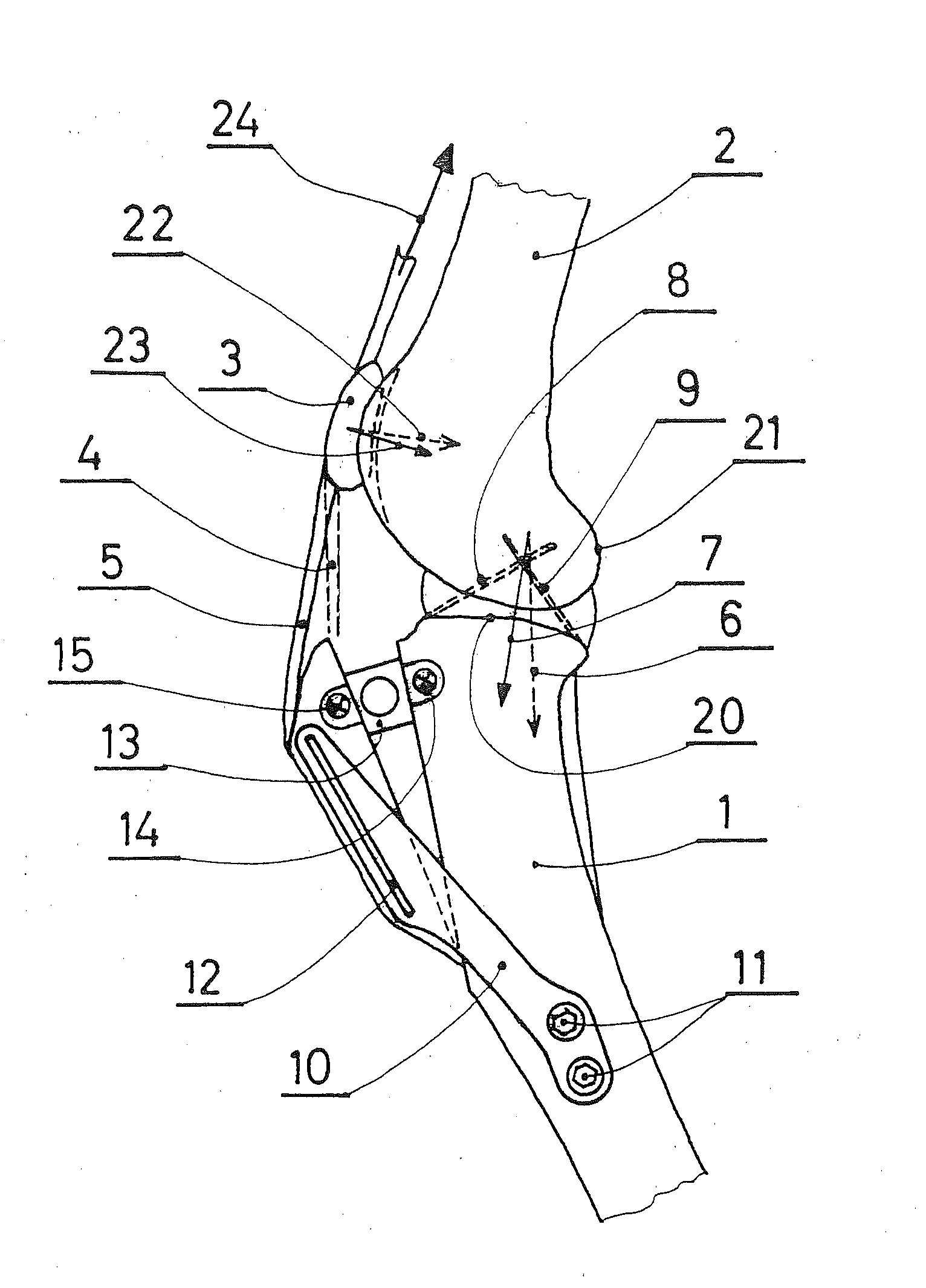

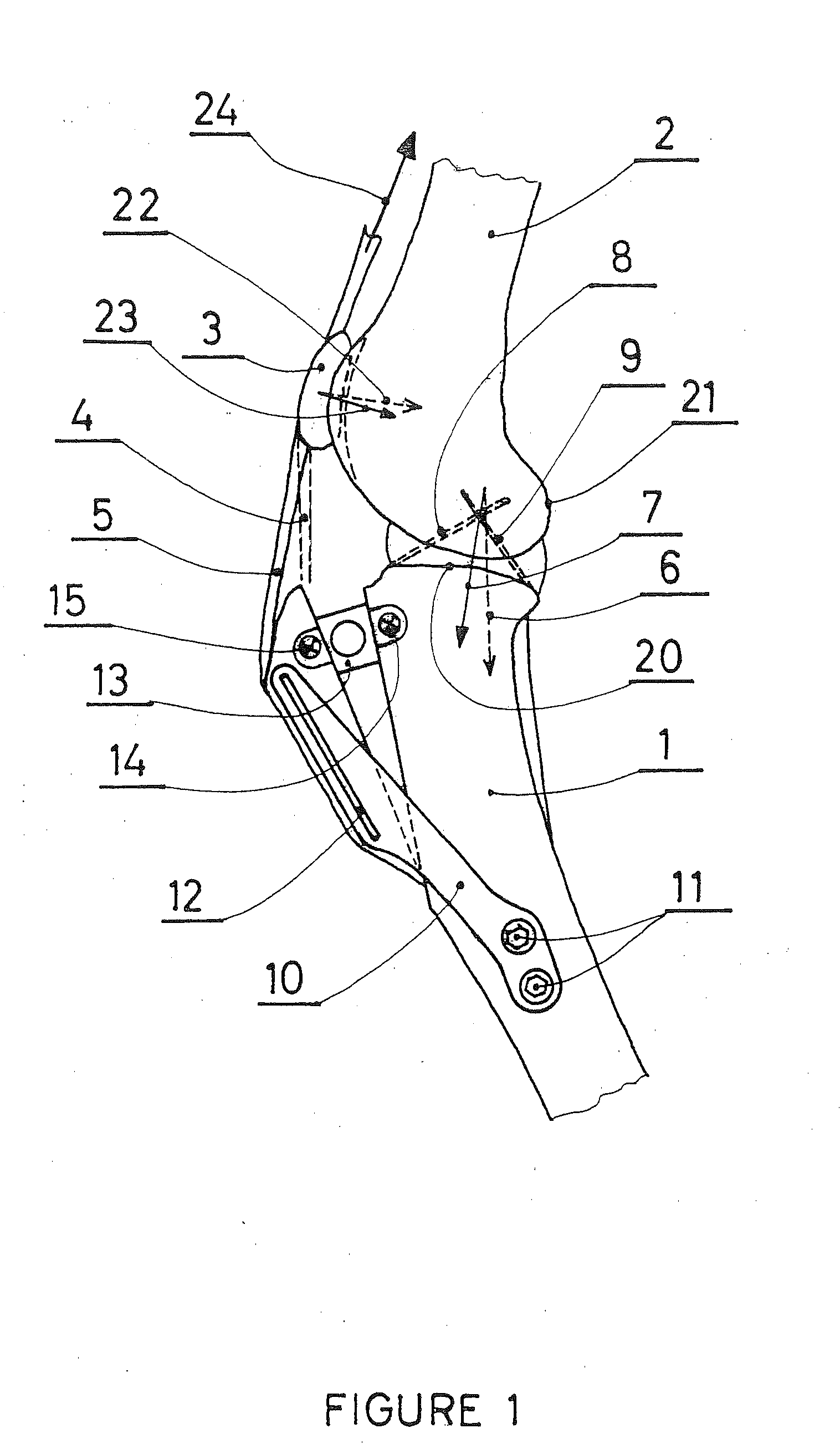

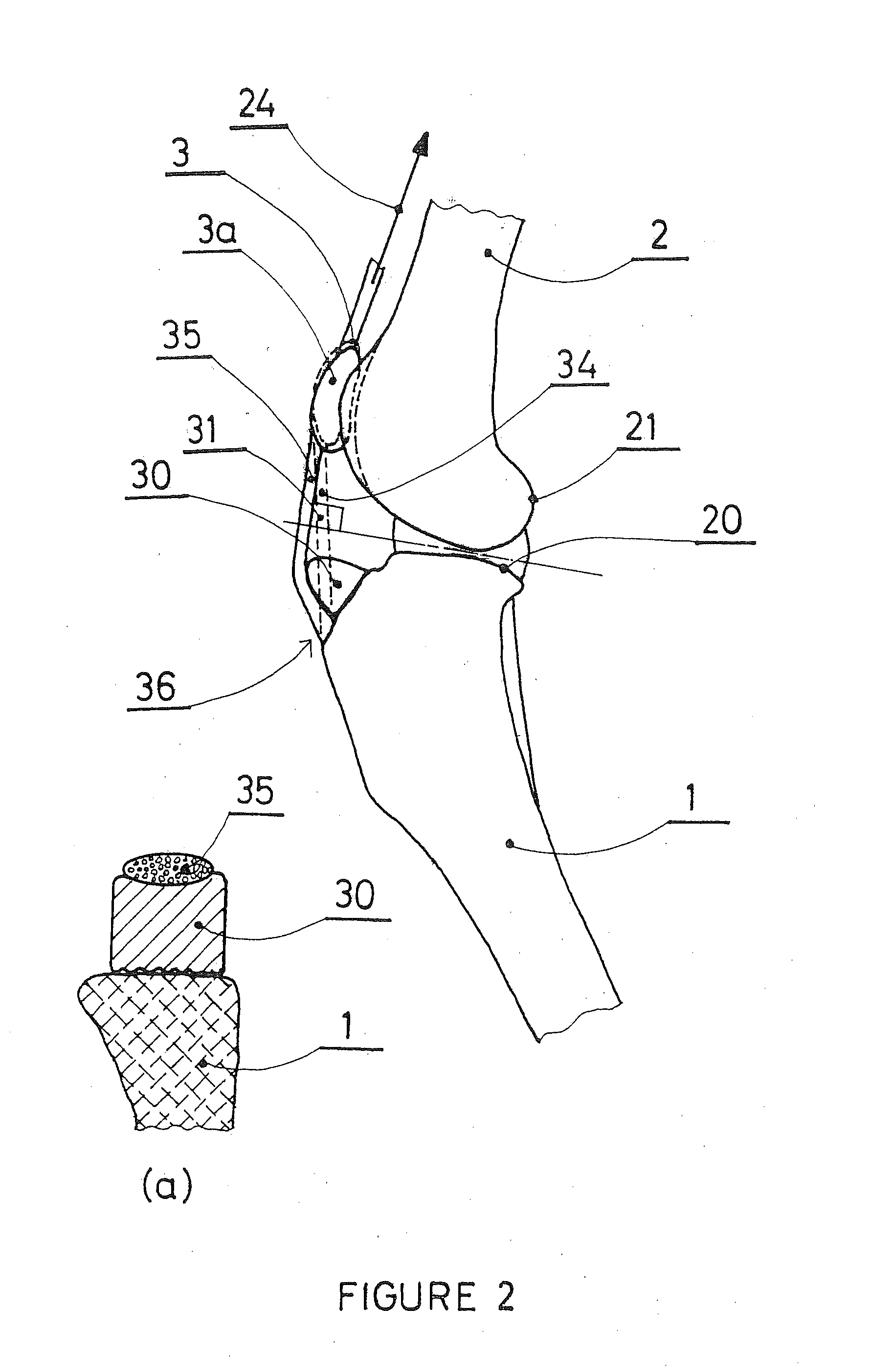

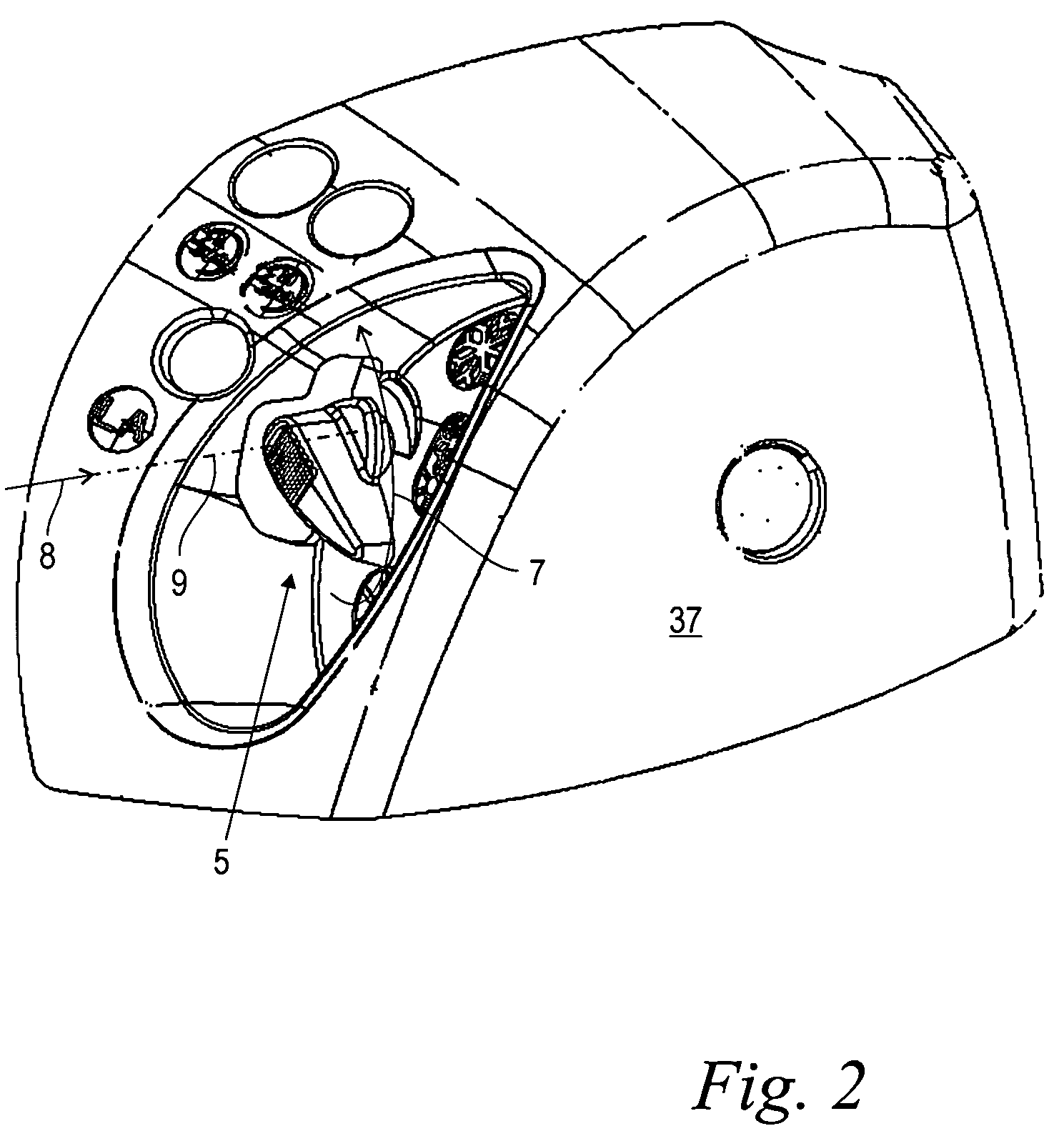

Patellar ligament spacer for acl injuries

ActiveUS20130190886A1Invasive stabilizationReduce frictionSurgeryJoint implantsPosterior cruciate ligamentAnterior Cruciate Ligament Injuries

A method and implant to treat anterior cruciate ligament (ACL) injuries are disclosed. The method involves advancing the insertion of the patellar ligament to the proximal tibia. The implant includes a spacer (30) which is inserted between the patellar ligament and the tibia and fixed to the tibia. The spacer decreases the angle between the patellar ligament and the tibia plateau and consequently modifies the internal joint force, restoring stability to the joint even if the ACL is ruptured. The method and implants are applicable to both human and canine patients.

Owner:KYON

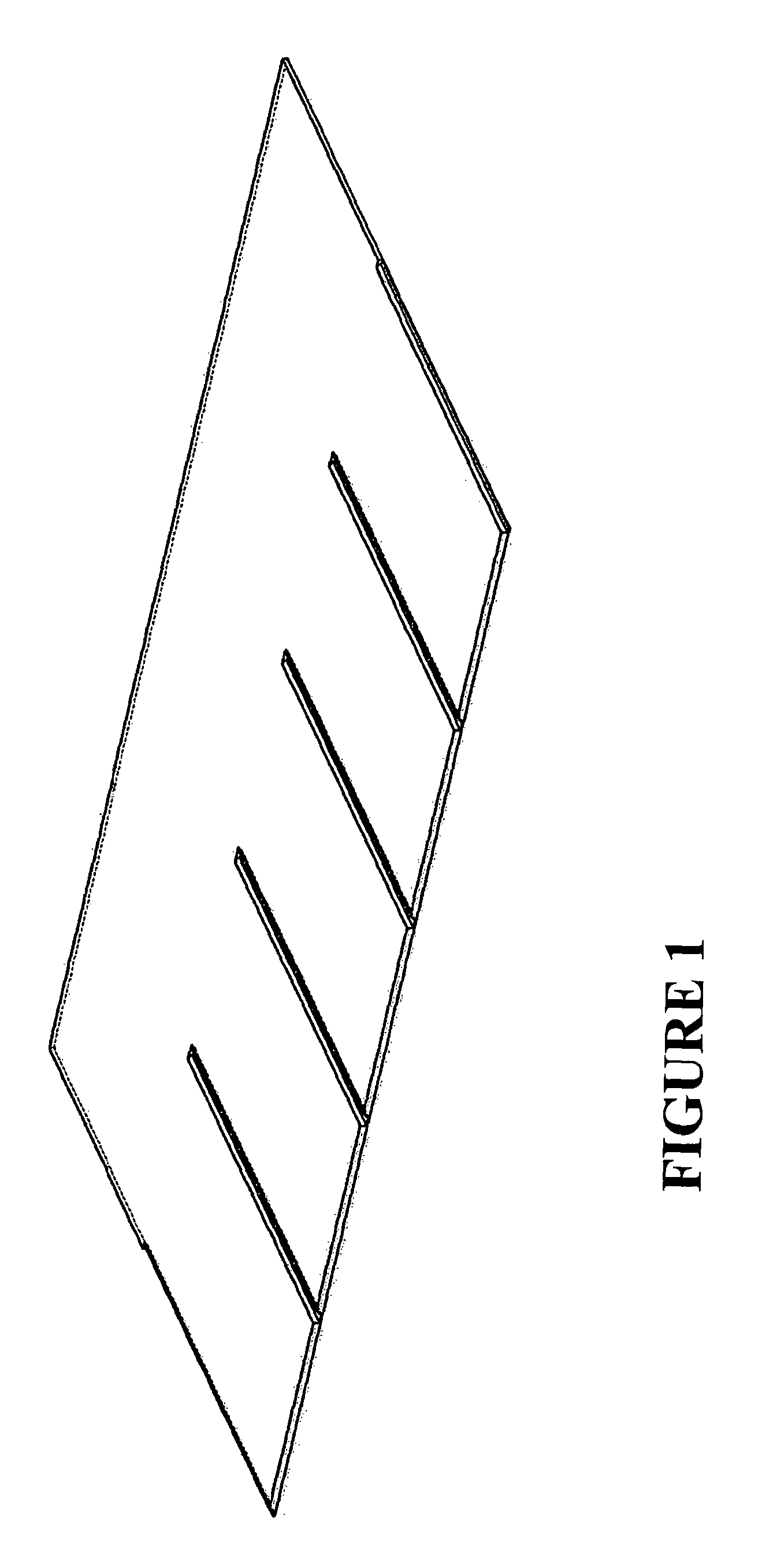

Roofing, cladding or siding product, its manufacture and its use as part of a solar energy recovery system

ActiveUS9518391B2Light weightEasy to installPhotovoltaic supportsSolar heating energyElectrical batteryStructural engineering

This disclosure provides a roofing, cladding or siding product which is light weight, easy to install, durable and resistant to environmental wear. One embodiment relates to a module that can be used to form a weatherproof covering over top of a building surface. Another embodiment is a module which can, in additional to forming a weatherproof covering, be used as part of a thermal energy recovery or removal system. Yet another embodiment is a module which can, in addition to forming a weatherproof covering, and optionally in addition to being useful as part of a thermal energy recovery system, bears an array of solar cells to generate electrical energy. Assemblies, systems, uses, and methods of manufacture are also described.

Owner:ZINNIATEK

Orthopedic Implants Coated with Pyrolytic Carbon

InactiveUS20070225822A1Resistance to frictionResistant to wearImpression capsBone implantGas phaseTitanium

An orthopedic implant having a metal substrate with an articulating surface includes a coating for the articulating surface made of pyrolytic carbon. Typically, the substrate is made of a metal such as titanium or stainless steel, or alloys thereof. The pyrolytic carbon coating preferably is applied by vapor deposition.

Owner:SANTILLI ALBERT N +1

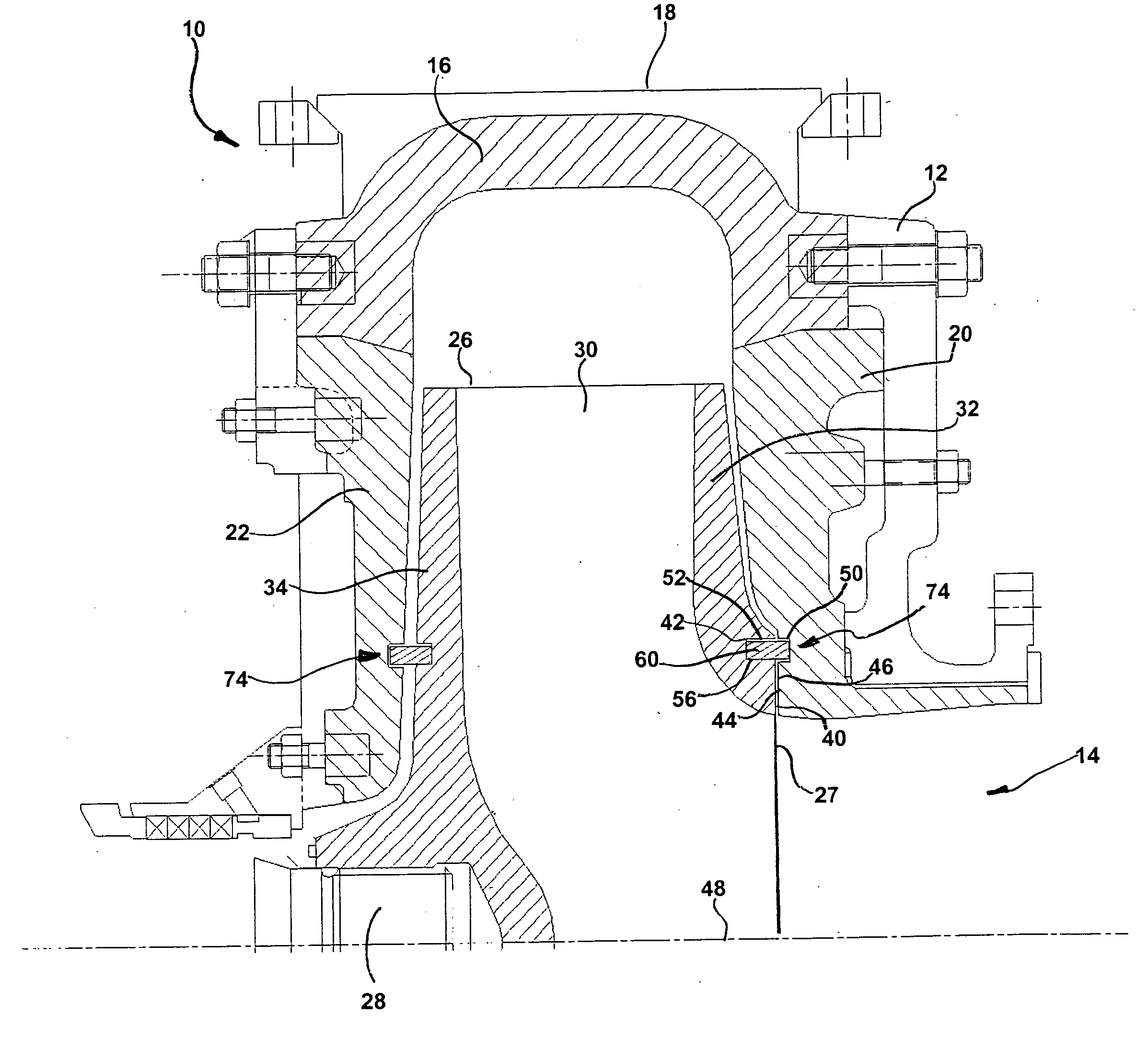

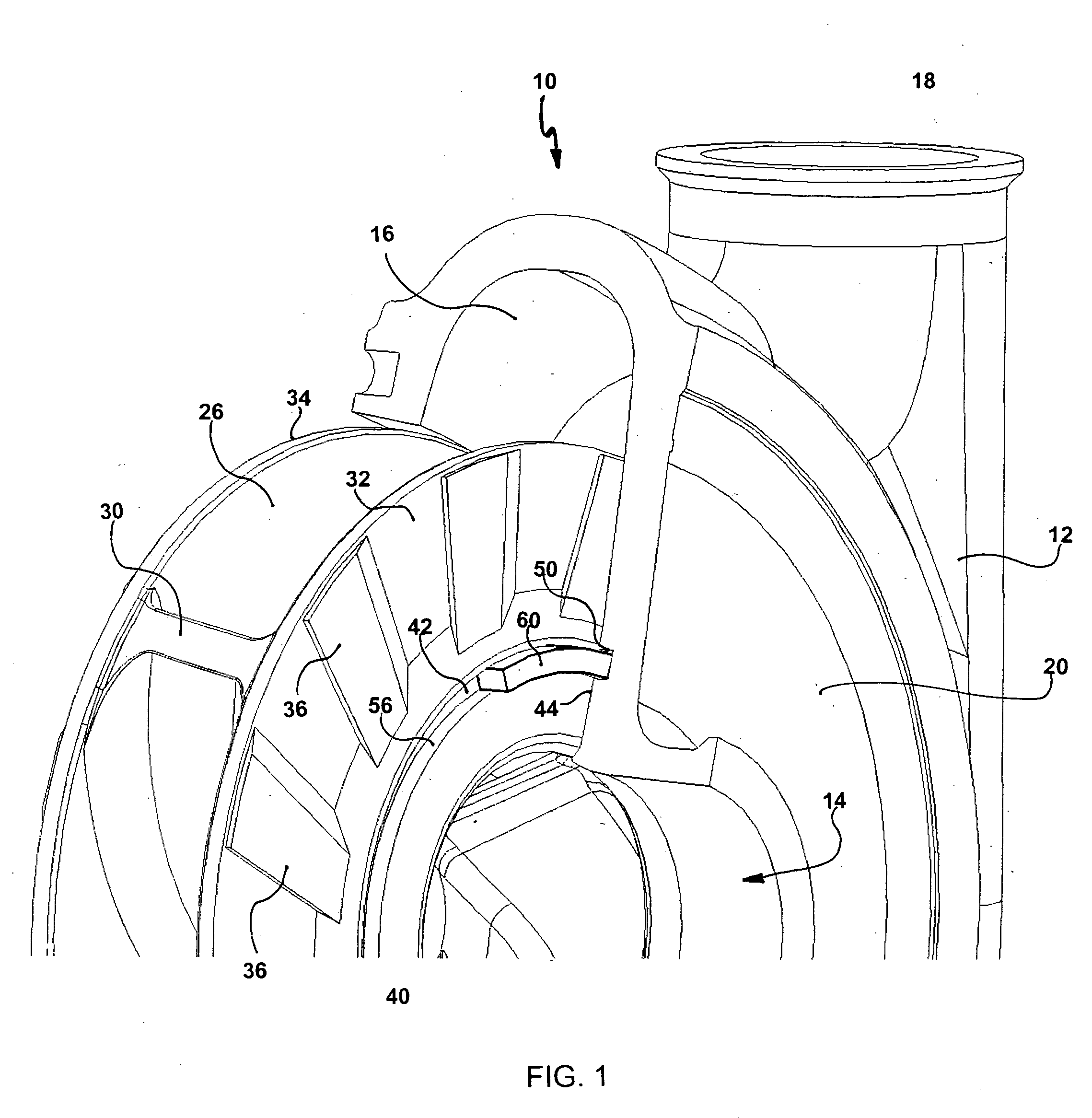

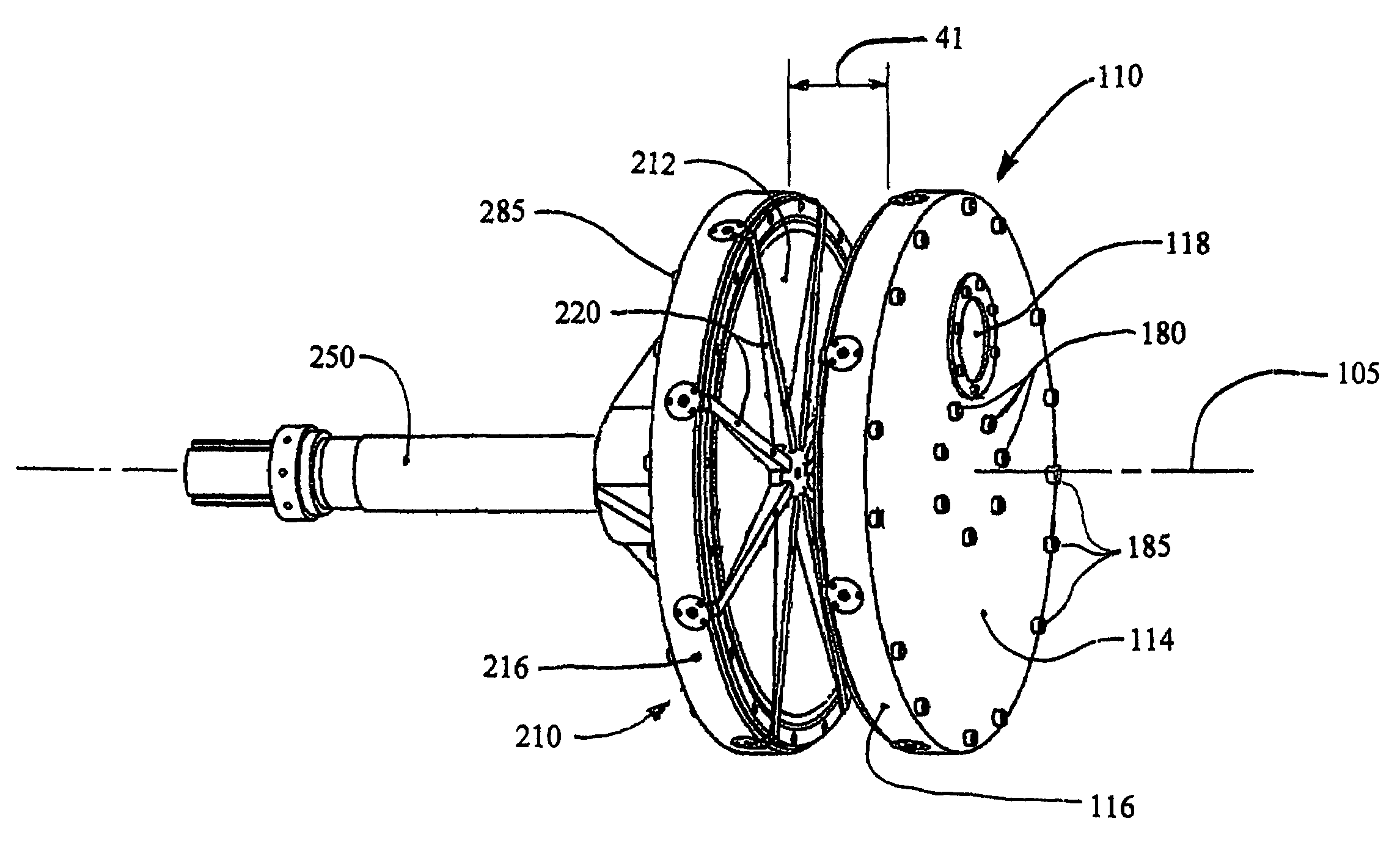

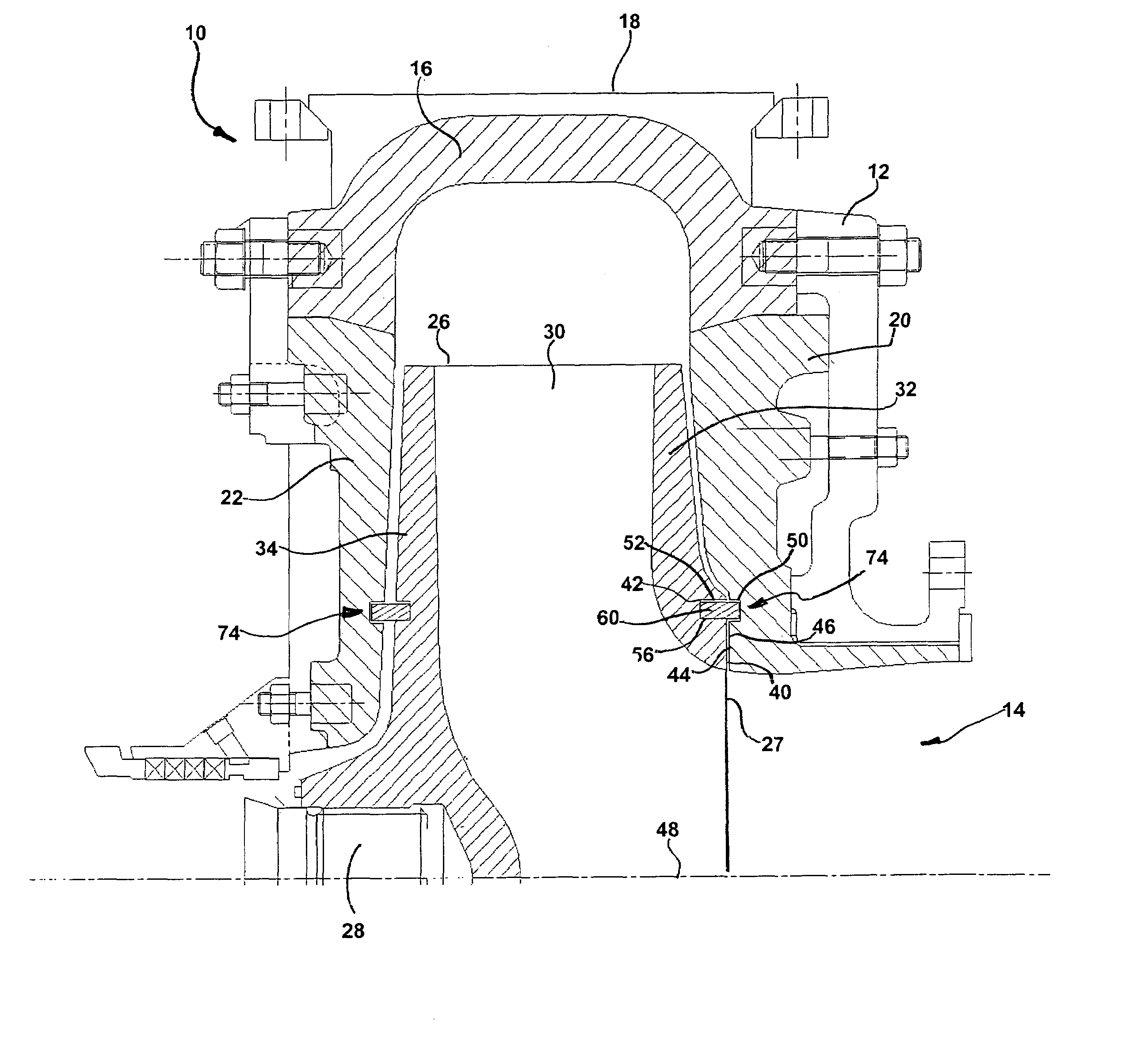

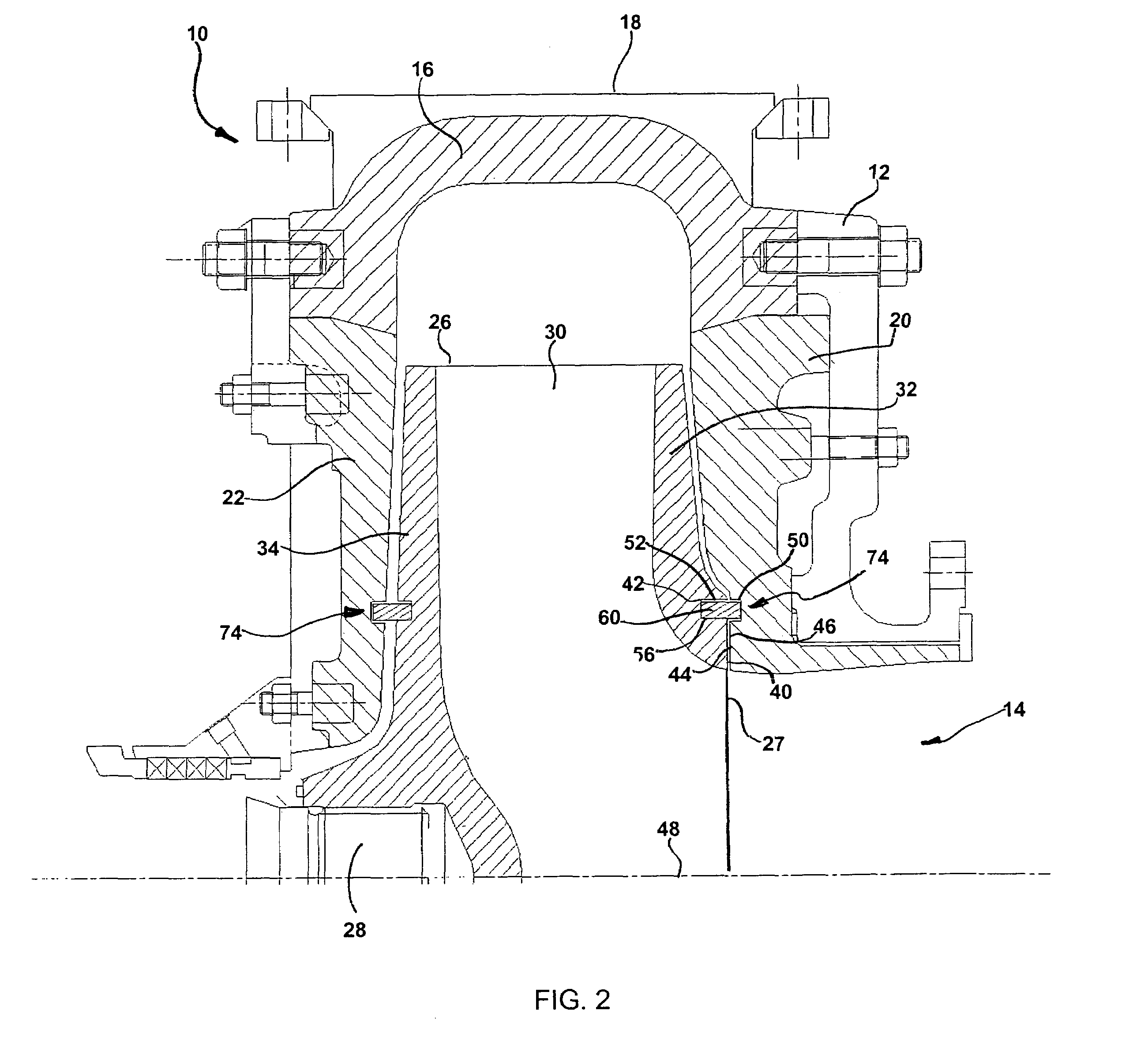

Flexible floating ring seal arrangement for rotodynamic pumps

InactiveUS20070160465A1Effective limitResistant to wearSpecific fluid pumpsPropellersCentrifugal forceRotodynamic pump

A floating ring seal arrangement for rotodynamic pumps comprises a flexible ring that is structured to fit within a circular channel formed by generally concentric grooves in the rotating and non-rotating elements of the pump, the ring further being sized to rest against the inner diameter of the groove of the rotating element when static, and capable of radially expansion under centrifugal forces to cause the flexible ring to float in the circular channel during operation of the pump, or deformation under centrifugal or pressure forces such that gaps between the flexible ring and groove in the non-rotating element are minimized or eliminated.

Owner:WEIR SLURRY GRP INC

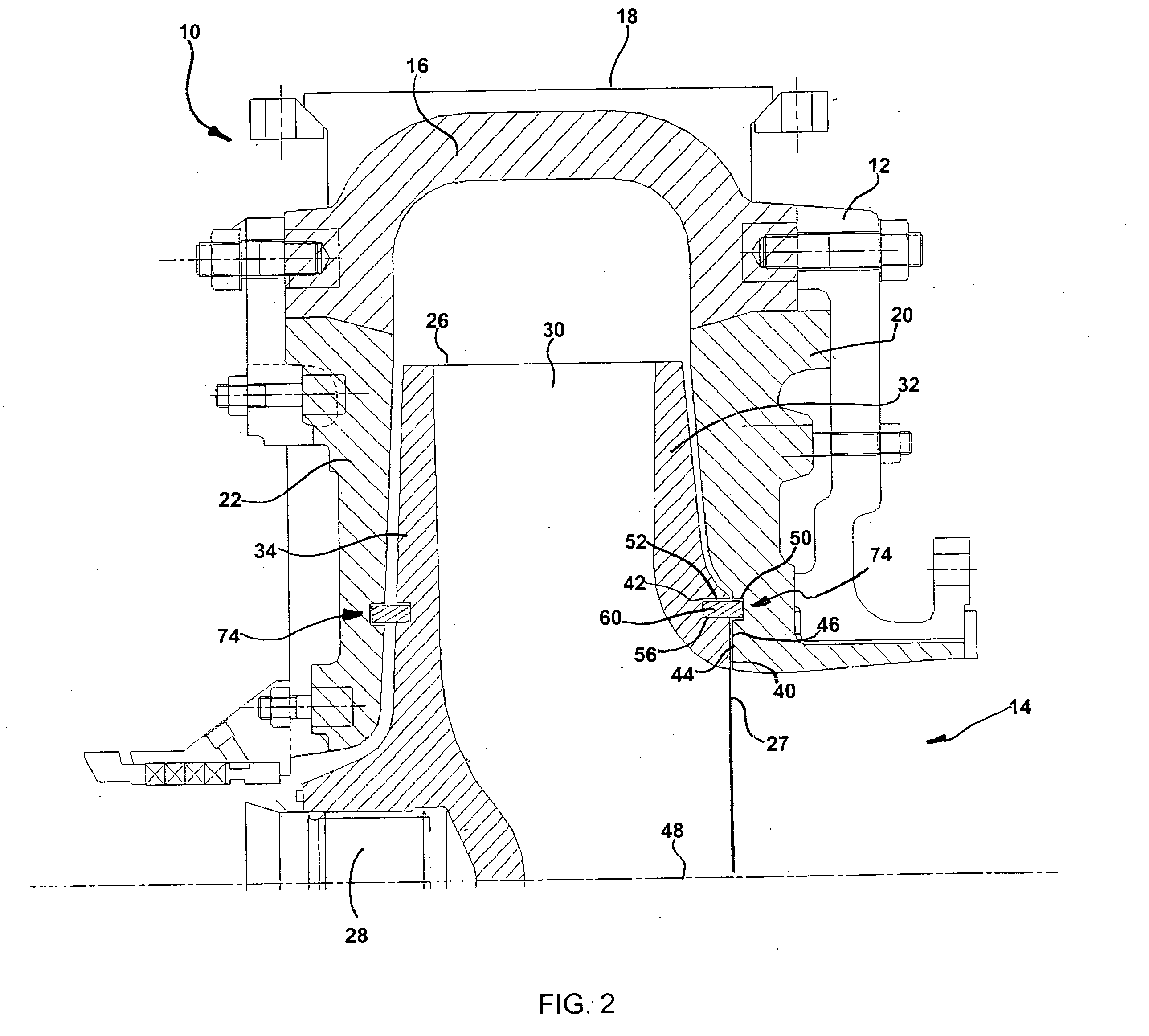

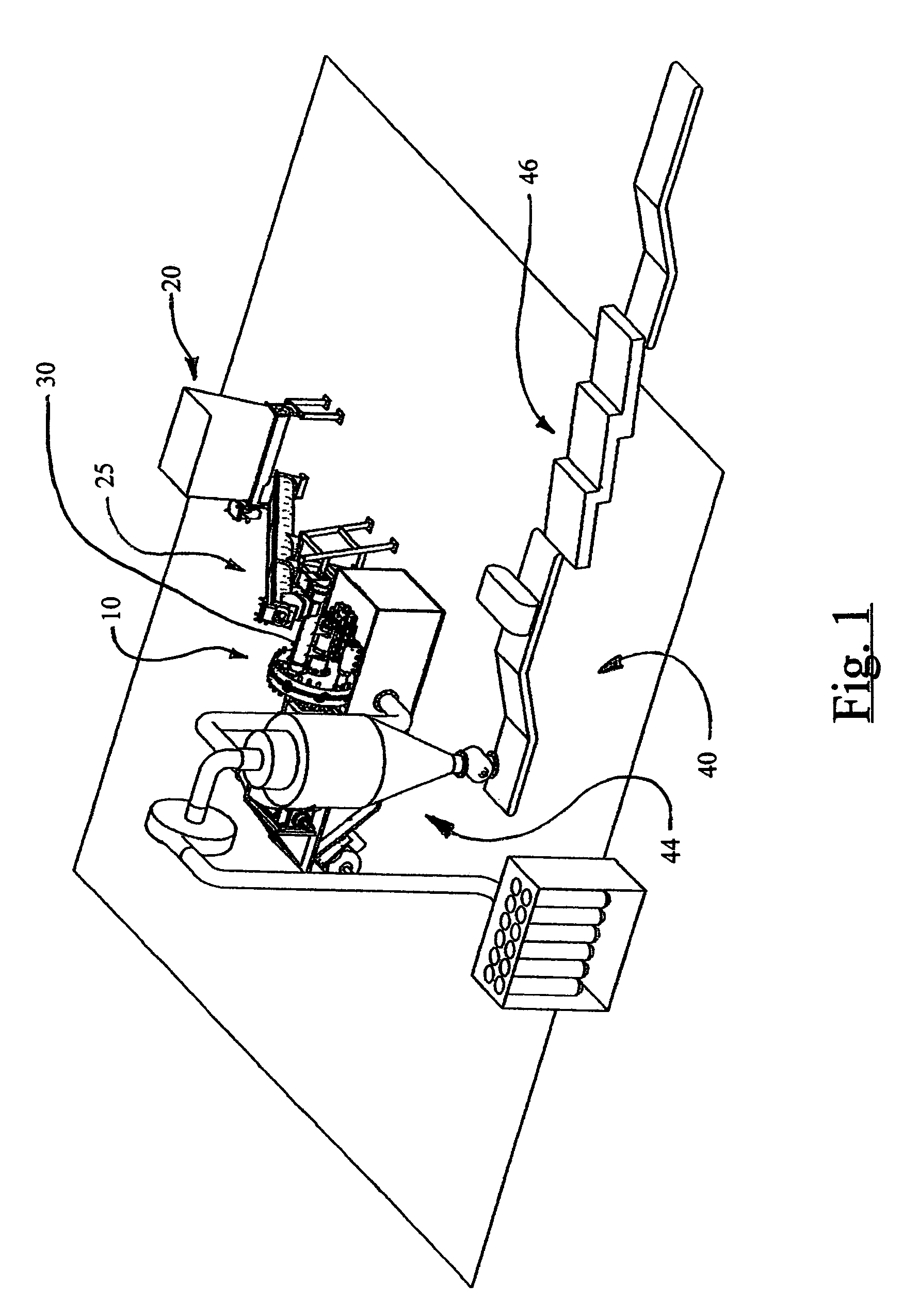

Apparatus for production of fiber-reinforced resin strand

ActiveUS20100224309A1Improve productivityInhibitionLamination ancillary operationsLaminationProduction rateFiber bundle

A manufacturing apparatus of a fiber-reinforced resin strand including spreaders that spread a reinforcing fiber bundle and are provided inside a crosshead to which a molten resin material is supplied continuously from an extruding machine, twisting rollers provided at a downstream position from an exit nozzle of the crosshead and that pultrude a fiber-reinforced resin strand formed of a resin-impregnated fiber bundle from the exit nozzle while imparting twists thereto, and twist retaining rollers provided at a downstream position from the twisting rollers and that retain twists of the fiber-reinforced resin strand. The twisting rollers and the twist retaining rollers are made of metal with asperities being formed on the surface thereof. The manufacturing apparatus can achieve excellent durability and is capable of manufacturing a fiber-reinforced resin strand at a high production rate without causing slipping.

Owner:KOBE STEEL LTD

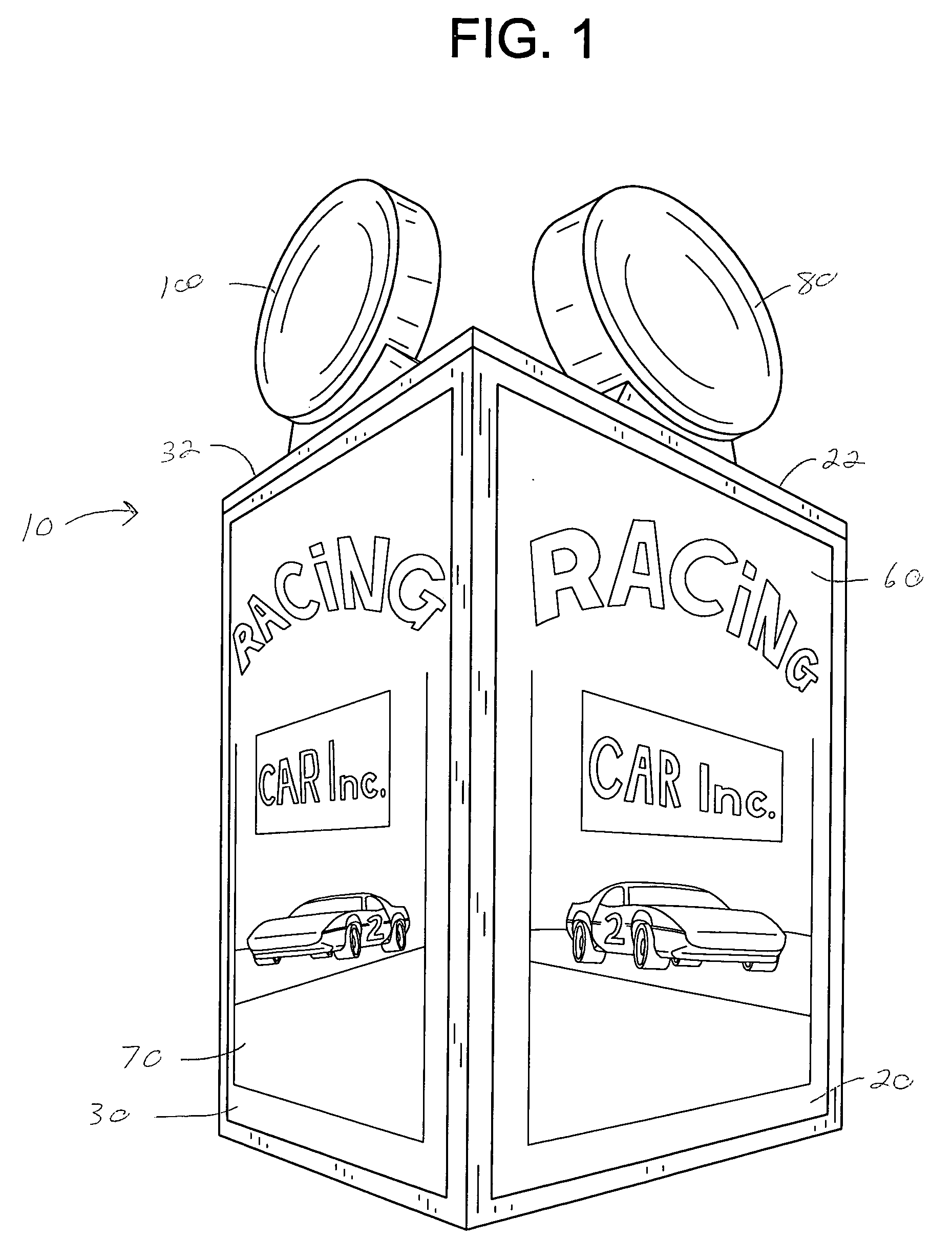

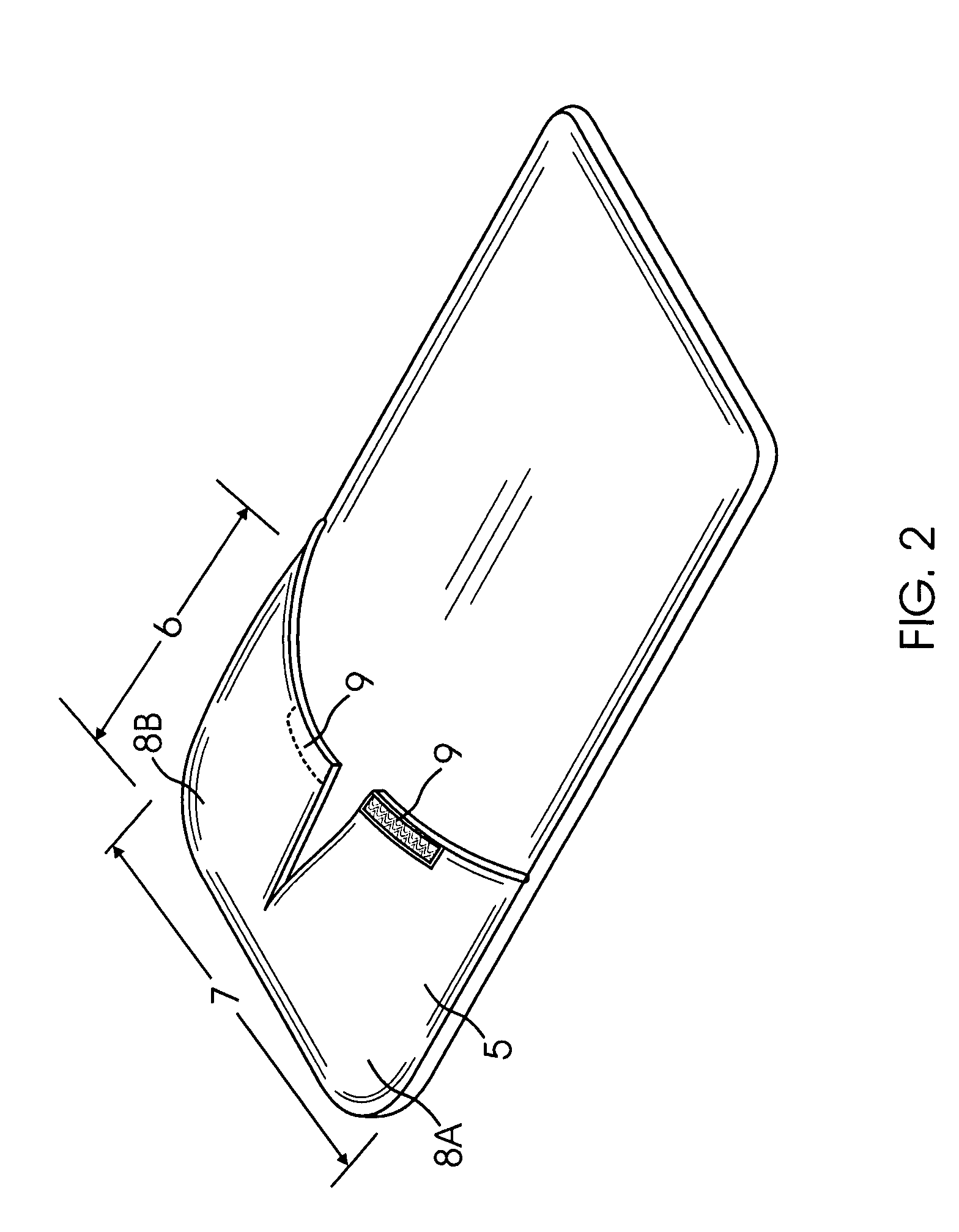

Inflatable projection screen

ActiveUS7114276B2Easily assembleResistant to wearProjectorsIlluminated signsMultimedia deviceComputer science

An inflatable device that includes at least one display panel for displaying an image by a multimedia device positioned in and / or connected to the inflatable device.

Owner:SCHERBA INDS

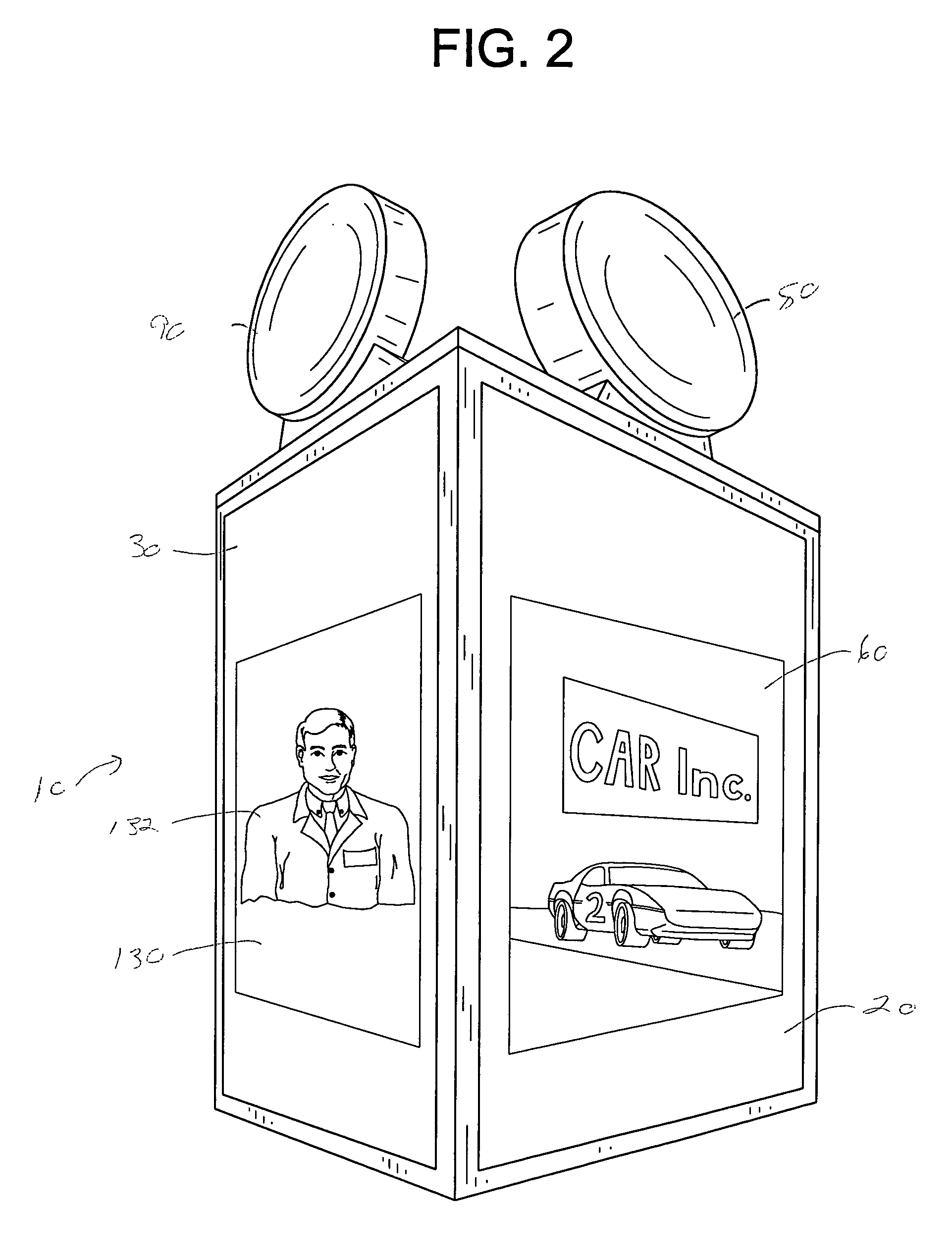

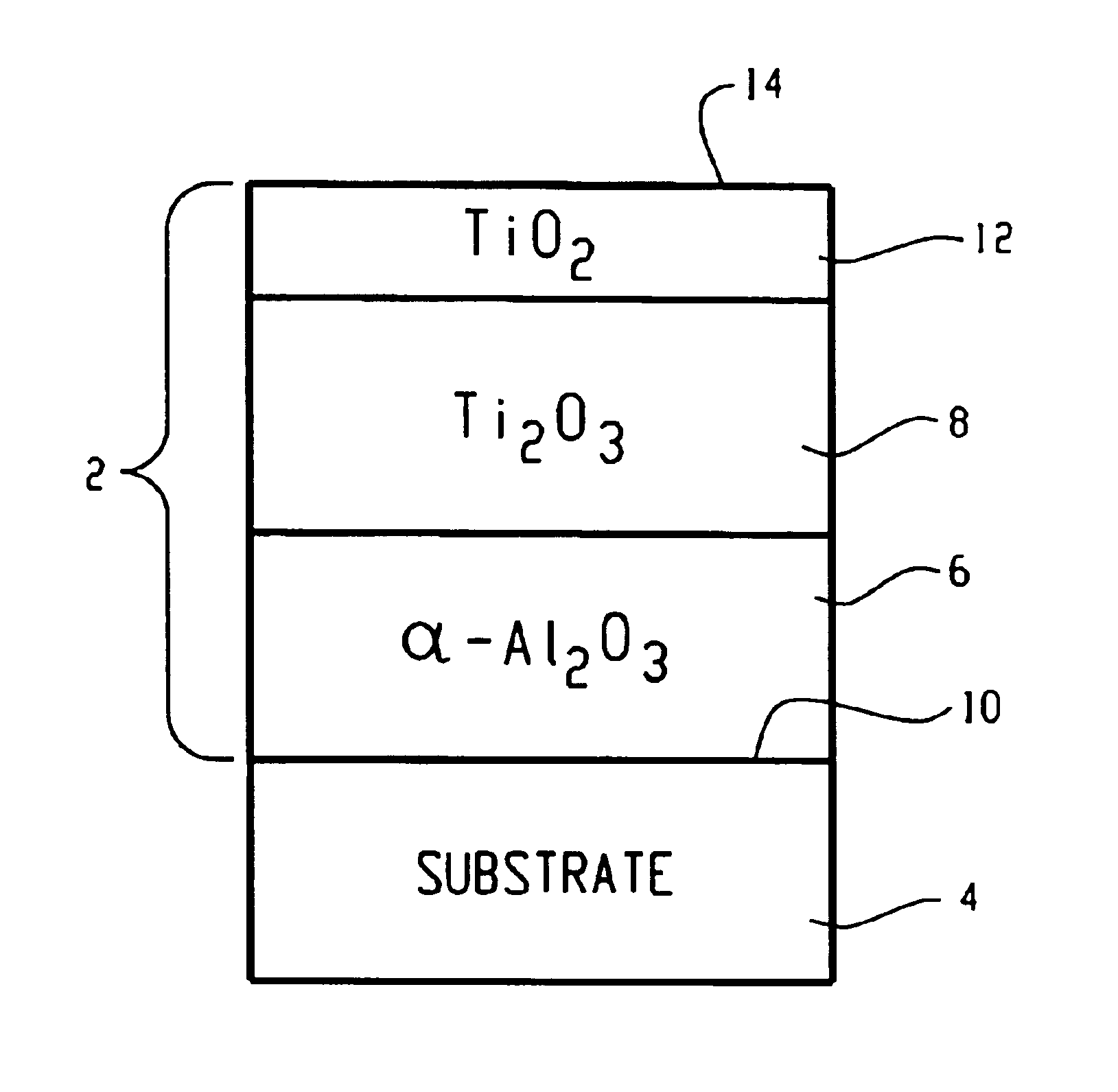

Alpha Al2O3 and Ti2O3 protective coatings on aluminide substrates

InactiveUS6933053B2Permeation resistanceResistant to wearVacuum evaporation coatingSputtering coatingAir atmosphereAluminide

In accordance with one aspect of the present invention, a process for forming a specific reactive element barrier on a titanium and aluminum containing substrate is provided. The process includes creating a dry air atmosphere with a concentration of water vapor below about 750 ppm at a temperature above about 550° C. contiguous to a surface of the substrate on which the barrier layer is to be formed. The temperature is maintained above 550° C. and the water vapor concentration is maintained below about 100 ppm while the water vapor in the dry air atmosphere is reacted with specific reactive elements at the substrate surface. The reaction forms a specific reactive element oxide barrier layer which is strongly bonded to the substrate surface. The barrier layer includes an aluminum oxide layer at the substrate / barrier layer interface and a second oxide layer at a barrier layer / atmosphere interface.

Owner:ALGER DONALD L

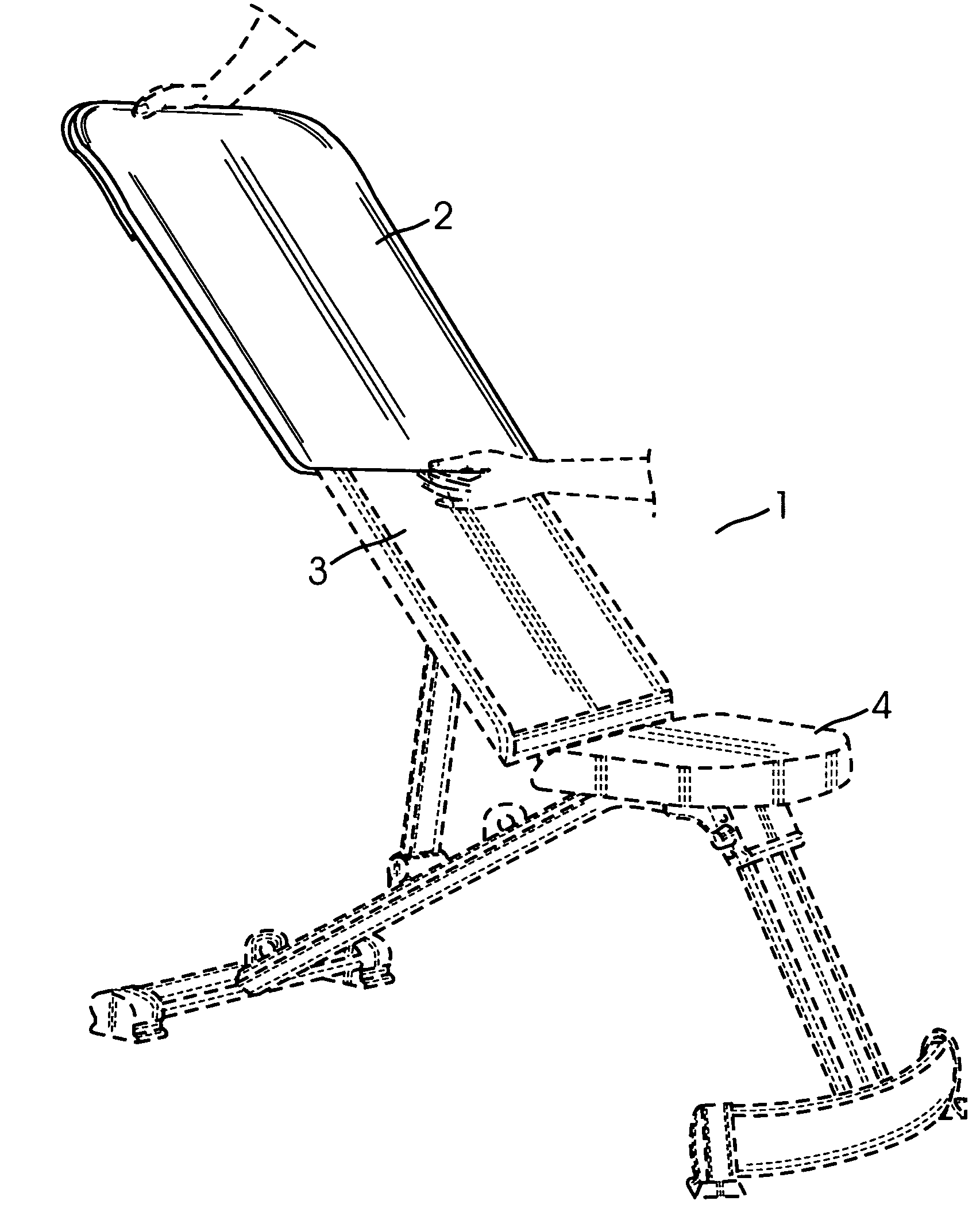

Fitness equipment cover

InactiveUS20080004168A1Extended drying timeConveniently machine-washStuffed mattressesSpring mattressesExercise machineBiomedical engineering

Owner:JACKSON INGRID

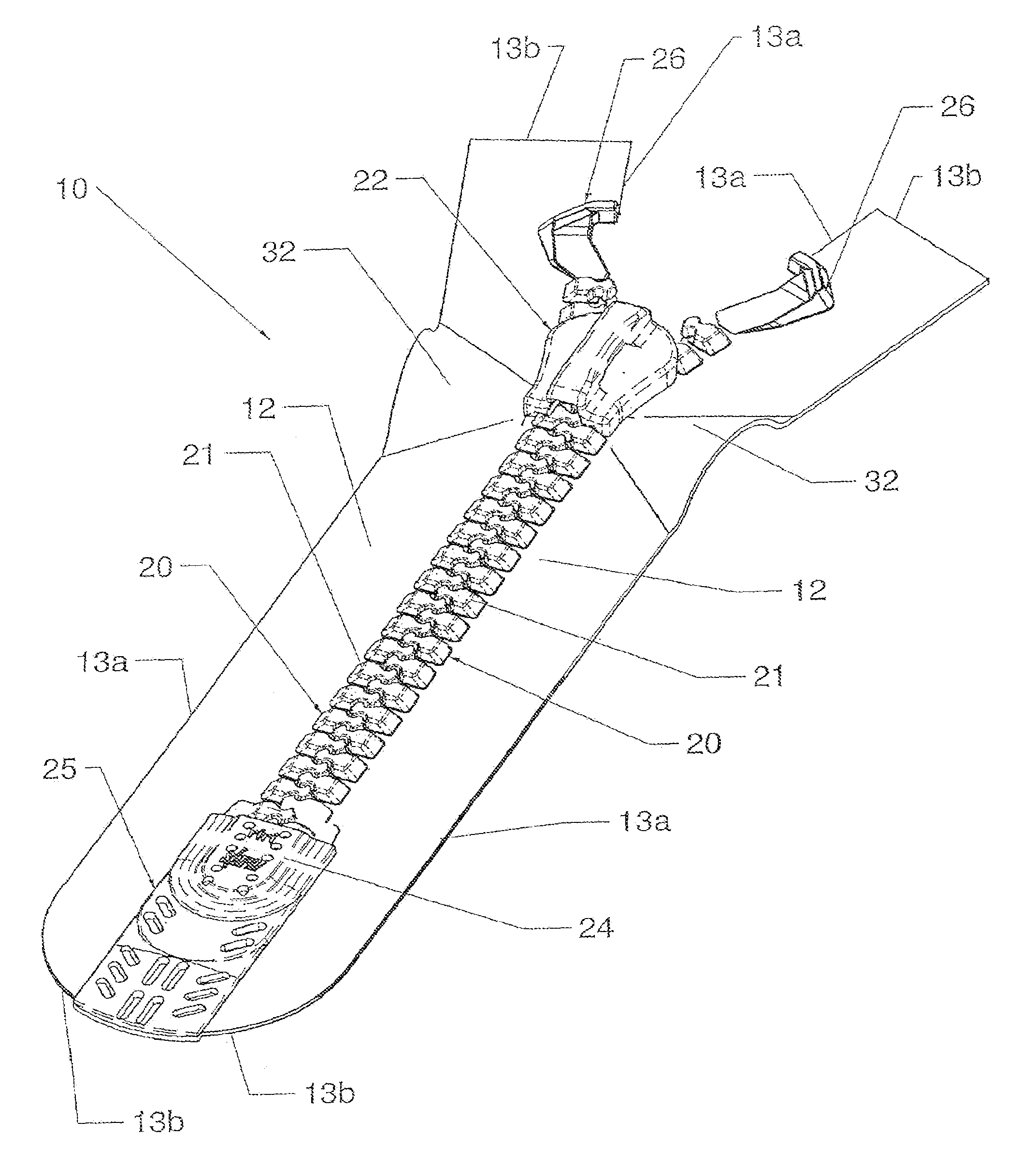

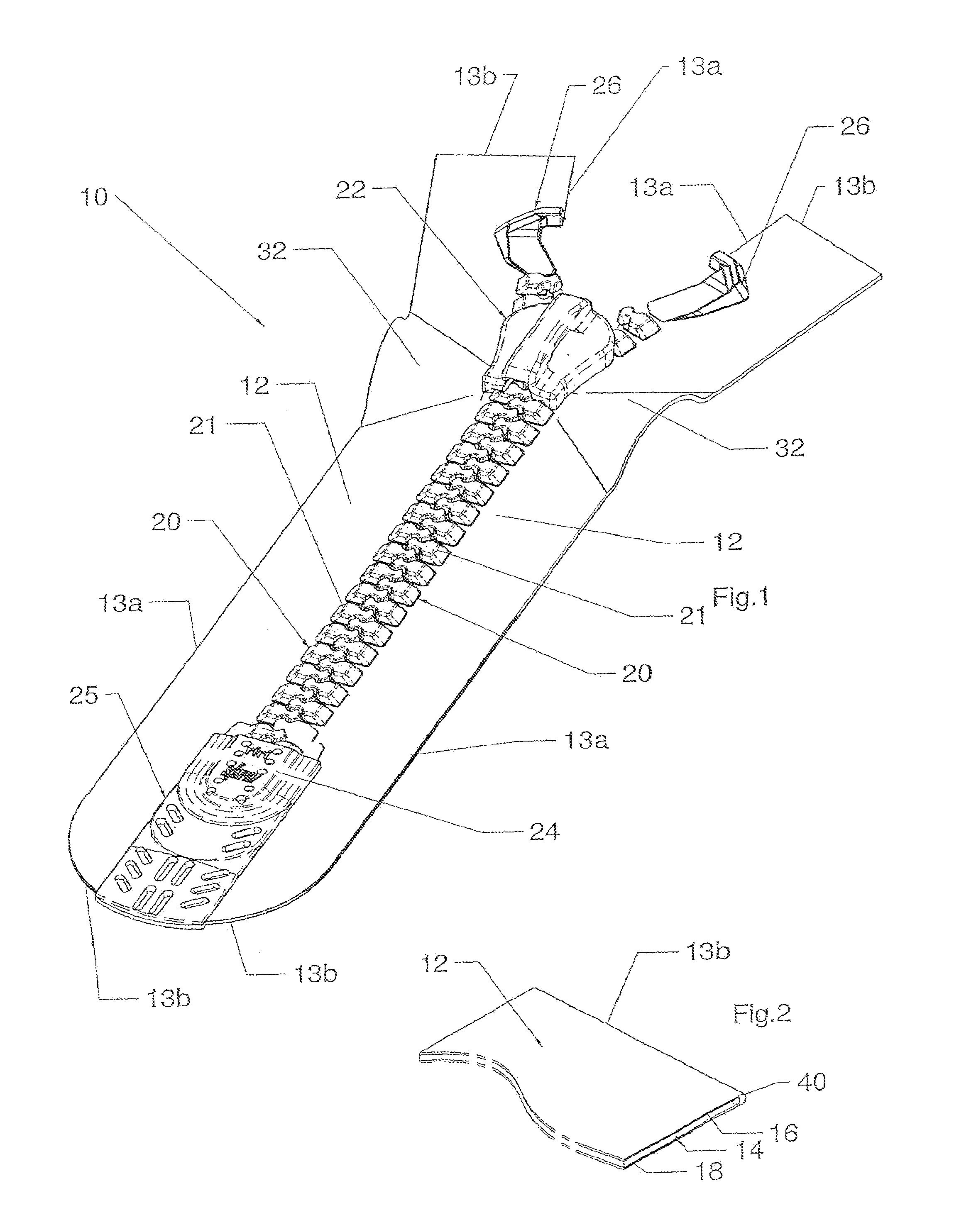

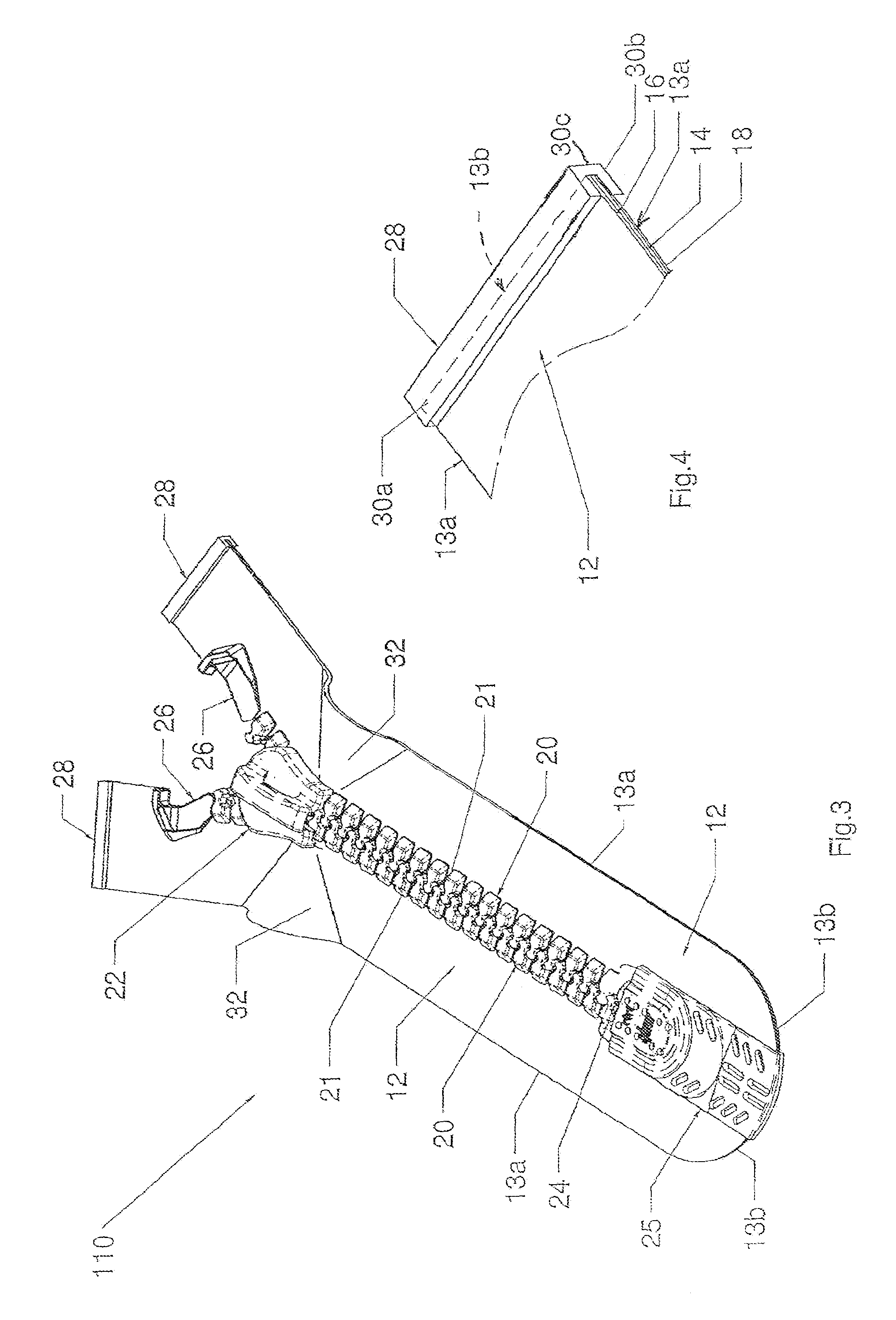

Fluidtight Slide Fastener

InactiveUS20070226965A1Simple and cheap to manufactureGood fluidtight requirementSnap fastenersSlide fastenersEngineeringFastener

A fluidtight slide fastener comprising a pair of tapes both delimited by two opposite long edges and by two opposite short edges, each tape comprising a textile material strip coated with a fluid barrier material layer at least at the opposite faces thereof, the strip remaining uncoated at least one of said short edges of each tape, each tape being equipped with a set of aligned teeth on at least a portion of one of said long sides thereof, the aligned teeth of said sets facing each other and being associated with opposite opening and closing stops, and a slider slidable between said closing stop and said opening stop for engaging in a fluidtight way or disengaging said aligned teeth respectively, wherein the fastener further comprises a coating formed on each tape at said at least one of said uncoated short edges for covering the textile material strip in a fluidtight way at said at least one of said uncoated short edges.

Owner:RIRI GROUP

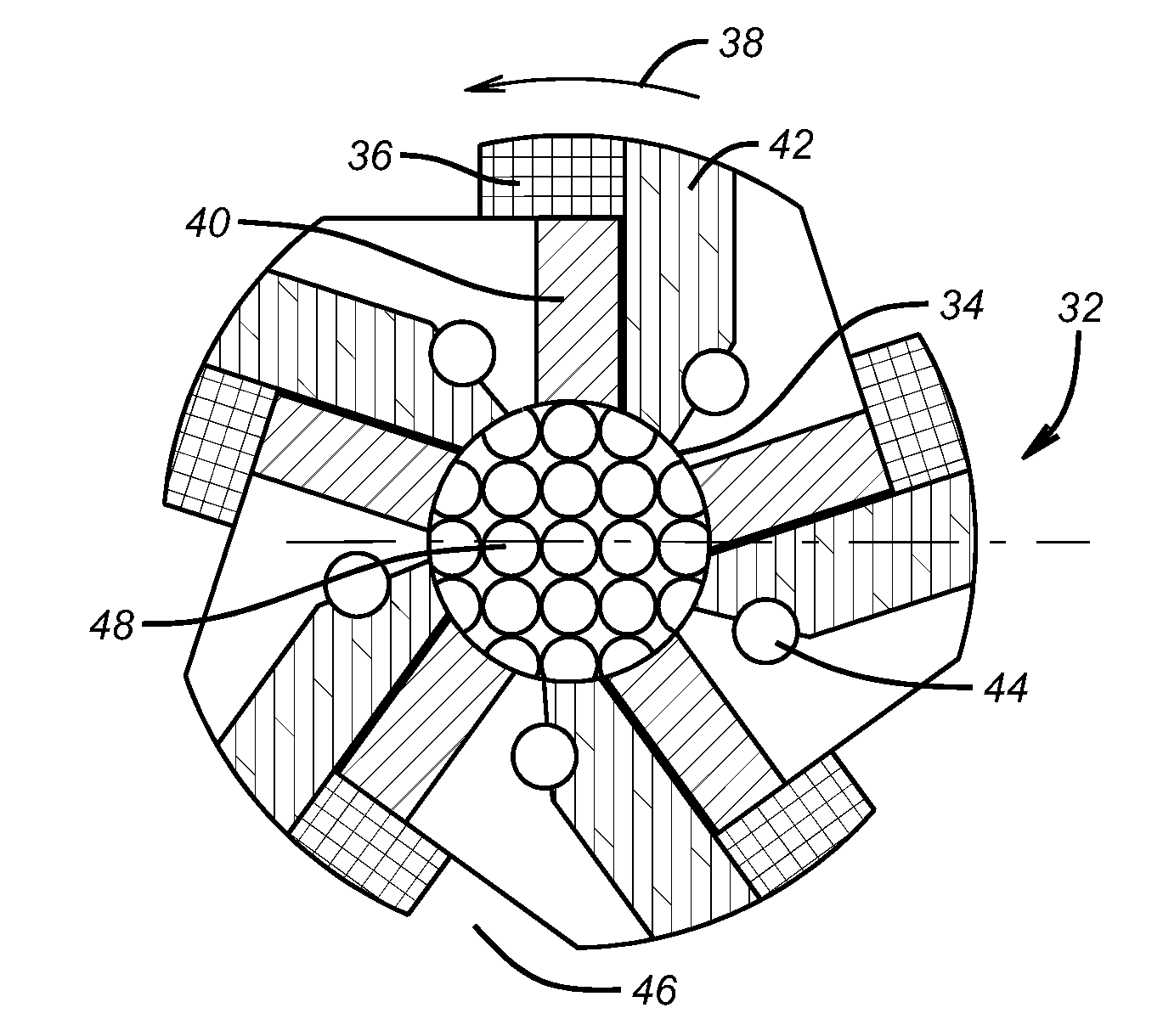

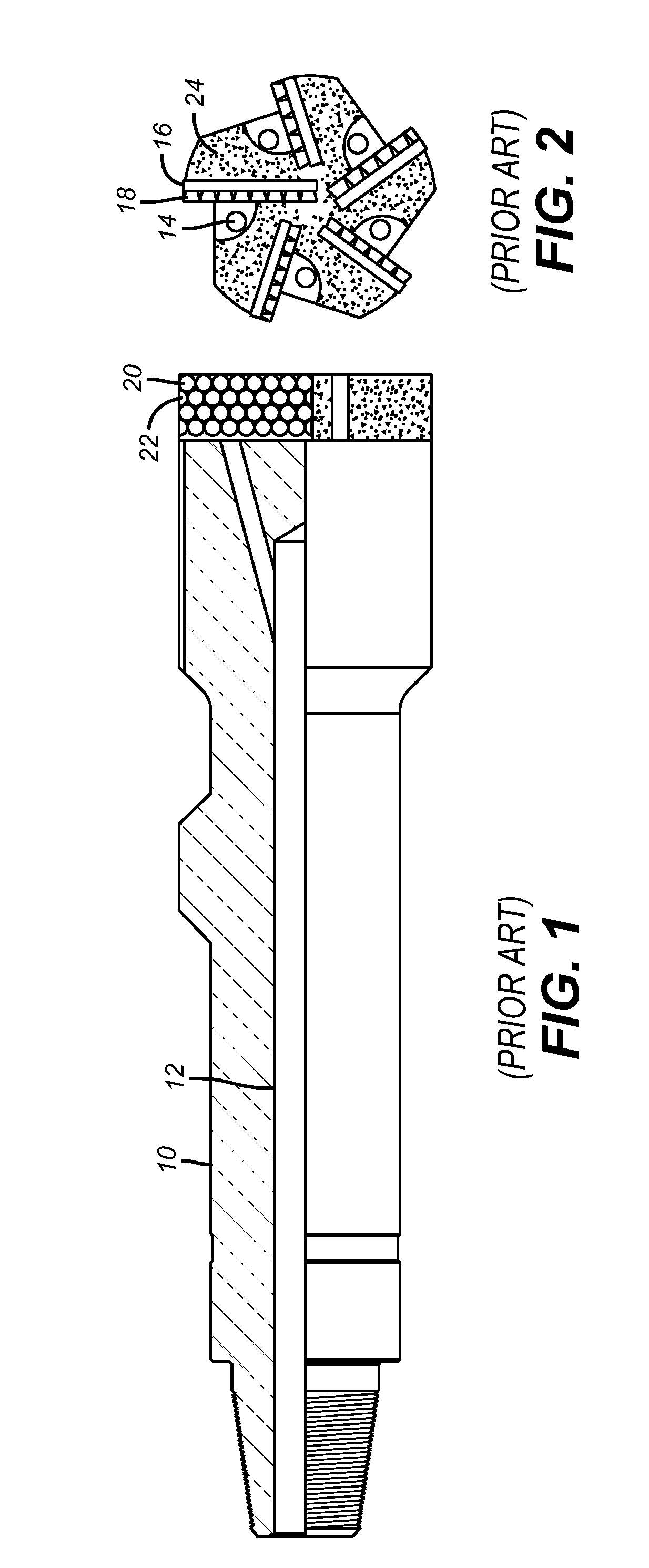

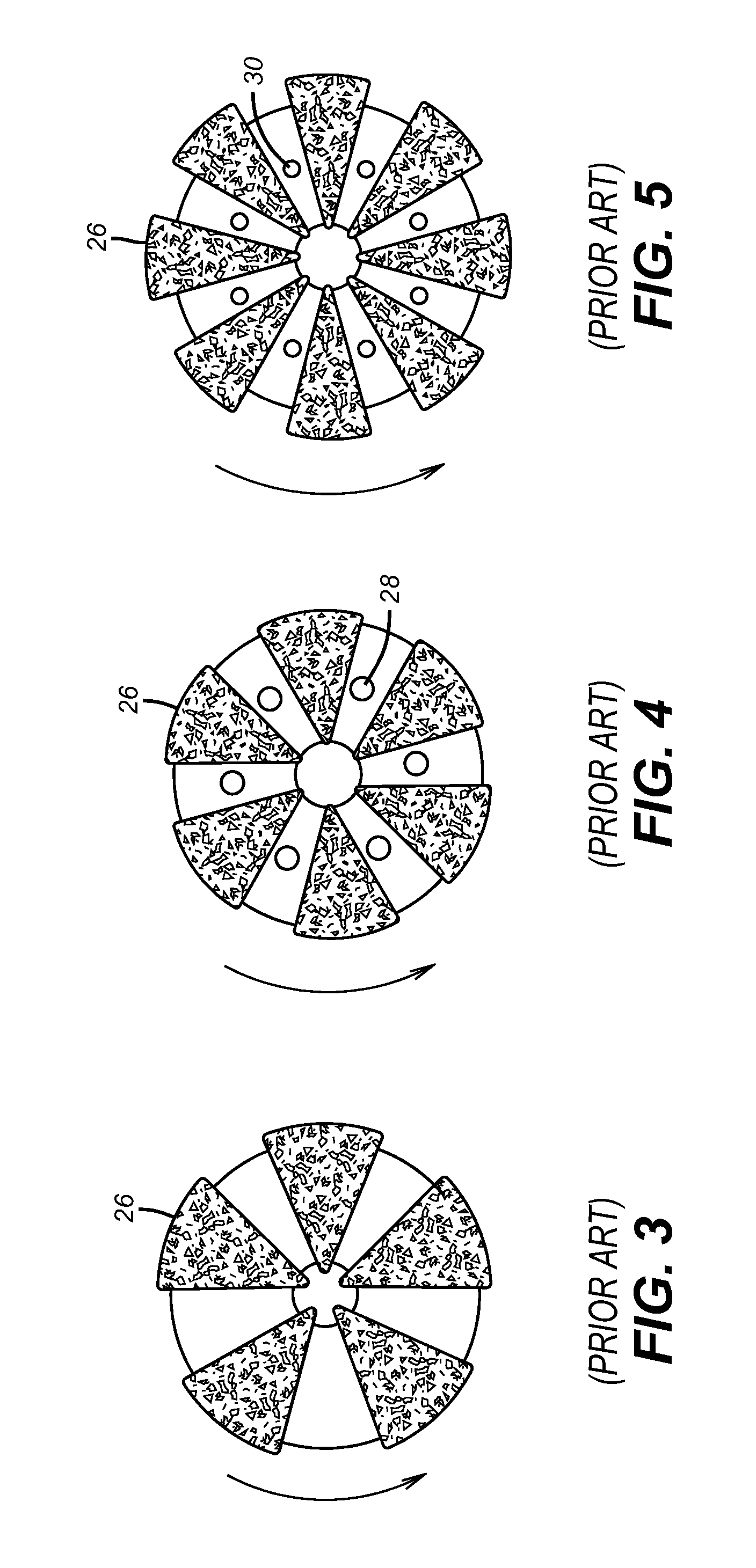

Subterranean Cutting Tool Structure Tailored to Intended Use

ActiveUS20120073880A1Improve wear resistanceGood temperature bond strengthDrill bitsConstructionsWear patternWear resistant

A mill cutting structure is differently configured in three zones. Those zones are the center, the outer edge and in between. At the center has highly wear resistant material that has good temperature bond strength and high impact resistance. The outer periphery can have a material that is highly resistant to wear and impact. In between can be inserts such as used in the Metal Muncher® mills using sintered carbide shapes that resist tracking and create a chipping rather than a grinding action. The shapes should have high edge retention capability and shapes such as a double sided pyramid can be used. The wear patterns of prior designs are addressed to allow longer and faster milling of the fish.

Owner:BAKER HUGHES INC

Sheet metal plate with reliefs for creating industrial flooring over which trucks are to run, engraved cylinder for obtaining such sheet metal plates by rolling

Sheet metal plate for creating flooring, particularly of industrial vehicles, over which trucks are to run, having a plurality of patterns, the maximum height of said reliefs ranging between 0.2 and 1.5 mm, said reliefs having a friction surface which has a mean width of at least 1 mm, in which said reliefs are arranged in a plurality of aligned groups of reliefs all of the same shape, the same orientation, and with their centers of gravity substantially aligned in one and the same given direction (D), the minimum distance, measured in said direction (D), between two adjacent reliefs of one and the same aligned group being less than 6 mm. The direction (D) in which the aligned groups are aligned advantageously coincides with the direction (De) in which the trucks run.

Owner:CONSTELLIUM ISSOIRE

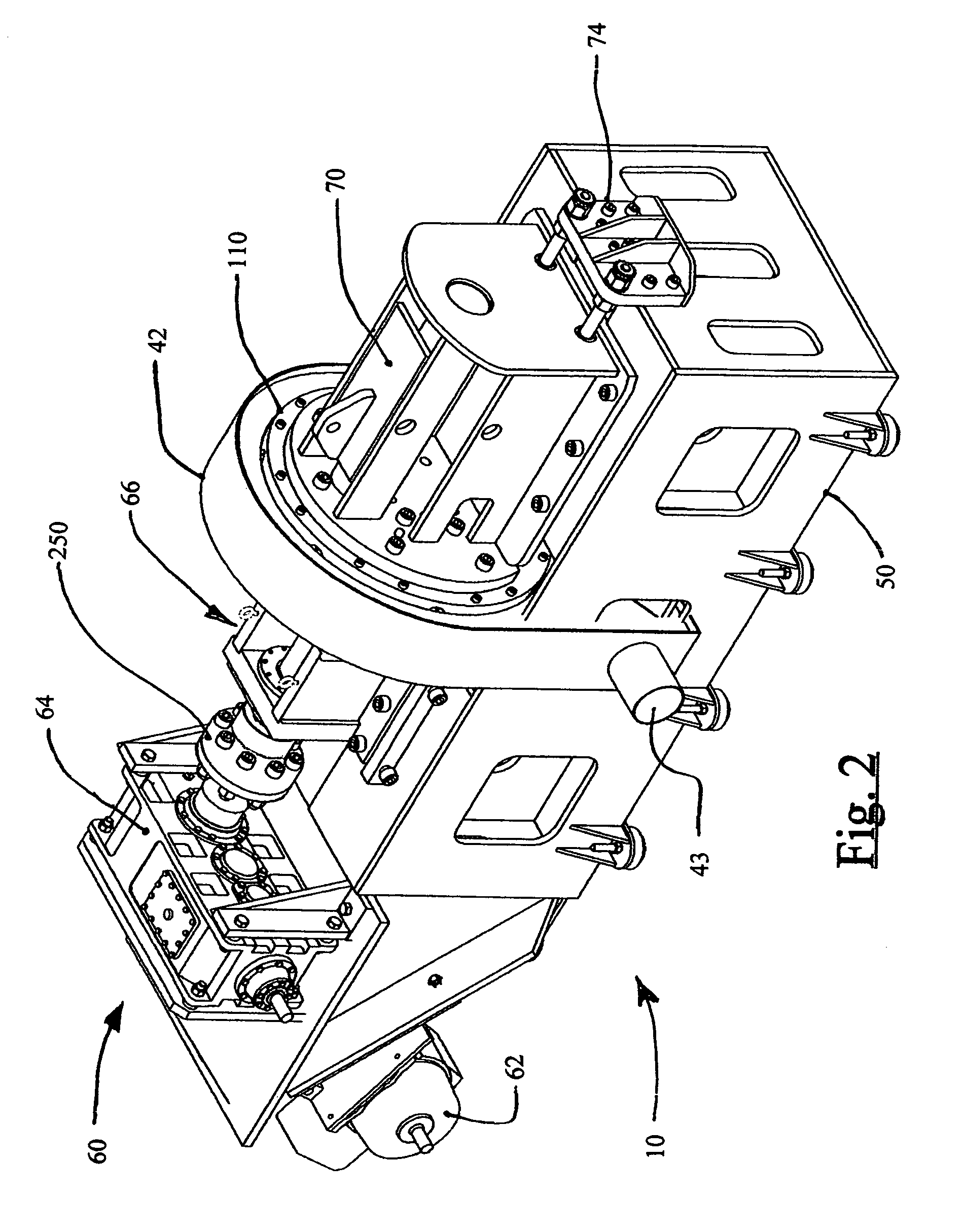

Tire rubber granulator

InactiveUS7182285B1Increased timeResistant to wear and damagePlastic recyclingCocoaMagnetic disksCounter rotation

A comminution apparatus for refining various materials into smaller pieces of a desired size, the apparatus having a pair of generally circular disks disposed on a common axis and arranged generally parallel to one another forming a comminution region there between. Each disk incorporates a plurality of removable cutting bars radially disposed on the disk face, one disk having an even number, the other having an odd number of cutting bars. Process material is fed into the comminution space between the opposing disks and comminuted by counter-rotation of the disks which shears material between opposing cutting bars as they pass. Spacing between the disks is adjustable to suit the input process material. Tapered disk faces control the flow of material during the comminution process, permitting only material that has been sufficiently reduced in size to migrate toward the disk perimeter where a skirt ring structure controls the size of the granulated material output.

Owner:FLINTWOOD METALS

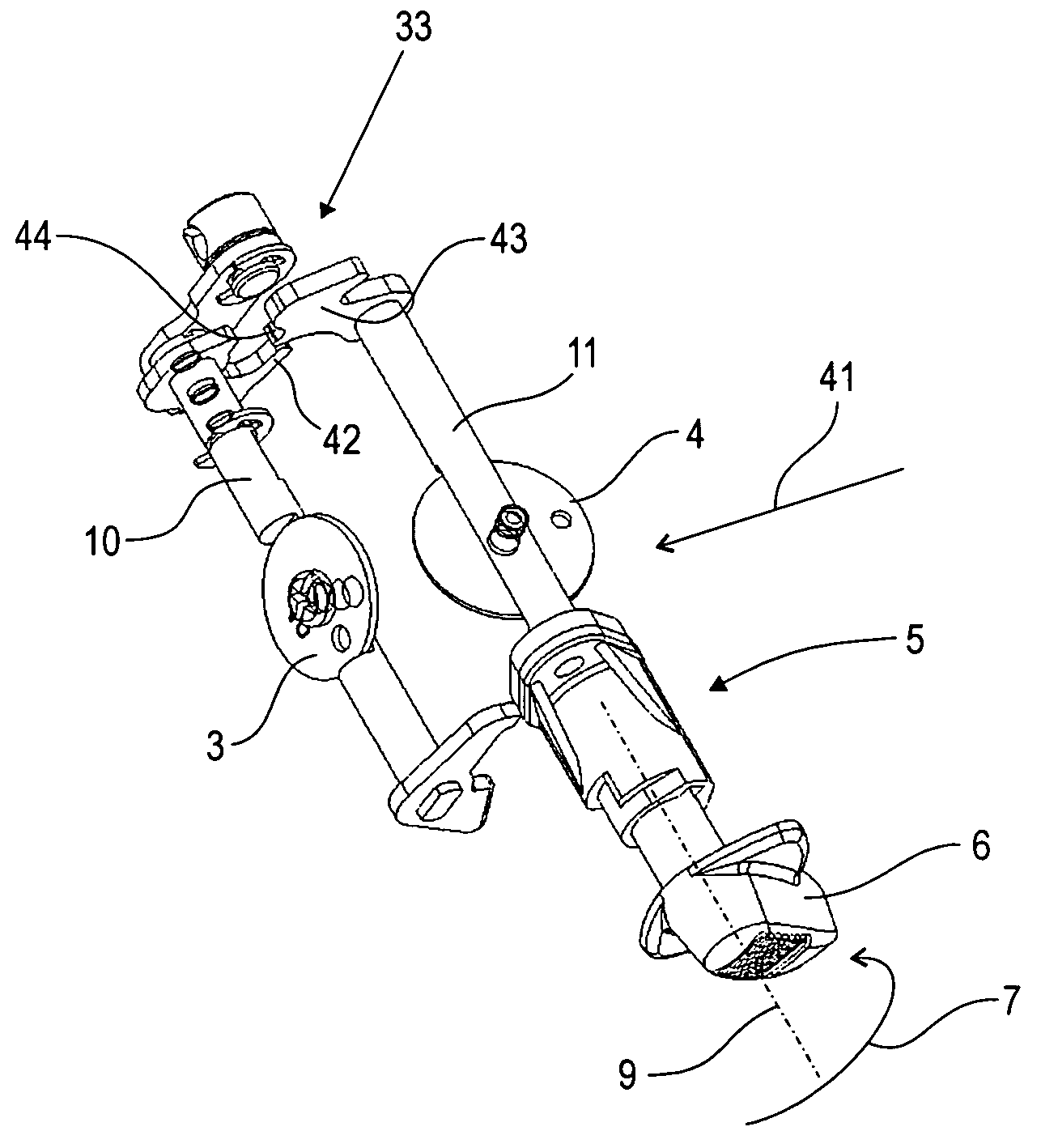

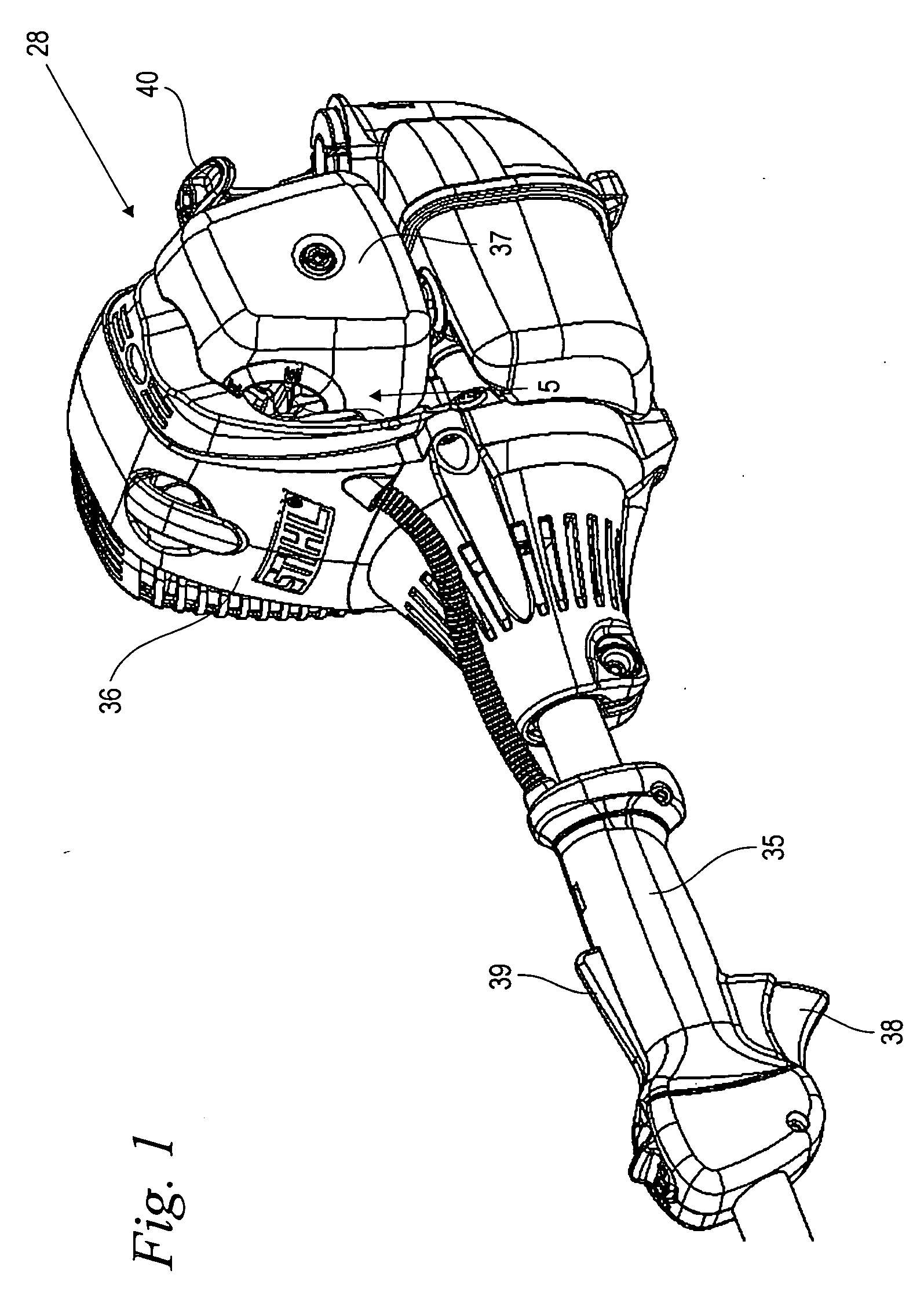

Carburetor arrangement

ActiveUS7404546B2Increase speedAccelerate emissionsLighting and heating apparatusUsing liquid separation agentRest positionExternal combustion engine

A carburetor arrangement for a manually-guided implement operated by an internal combustion engine. A carburetor supplies a fuel / air mixture to the engine, with a butterfly valve being disposed in the intake duct of the carburetor and with a choke valve being disposed upstream of the butterfly valve. A start lever is provided for actuating the carburetor in a start phase, and acts upon the choke valve. The start lever can be shifted in a direction of actuation and in an unlocking direction that is independent of the direction of actuation. The start lever can be locked in a rest position relative to the direction of actuation, and after being shifted out of the rest position in the unlocking direction is shiftable in the direction of actuation.

Owner:ANDREAS STIHL AG & CO KG

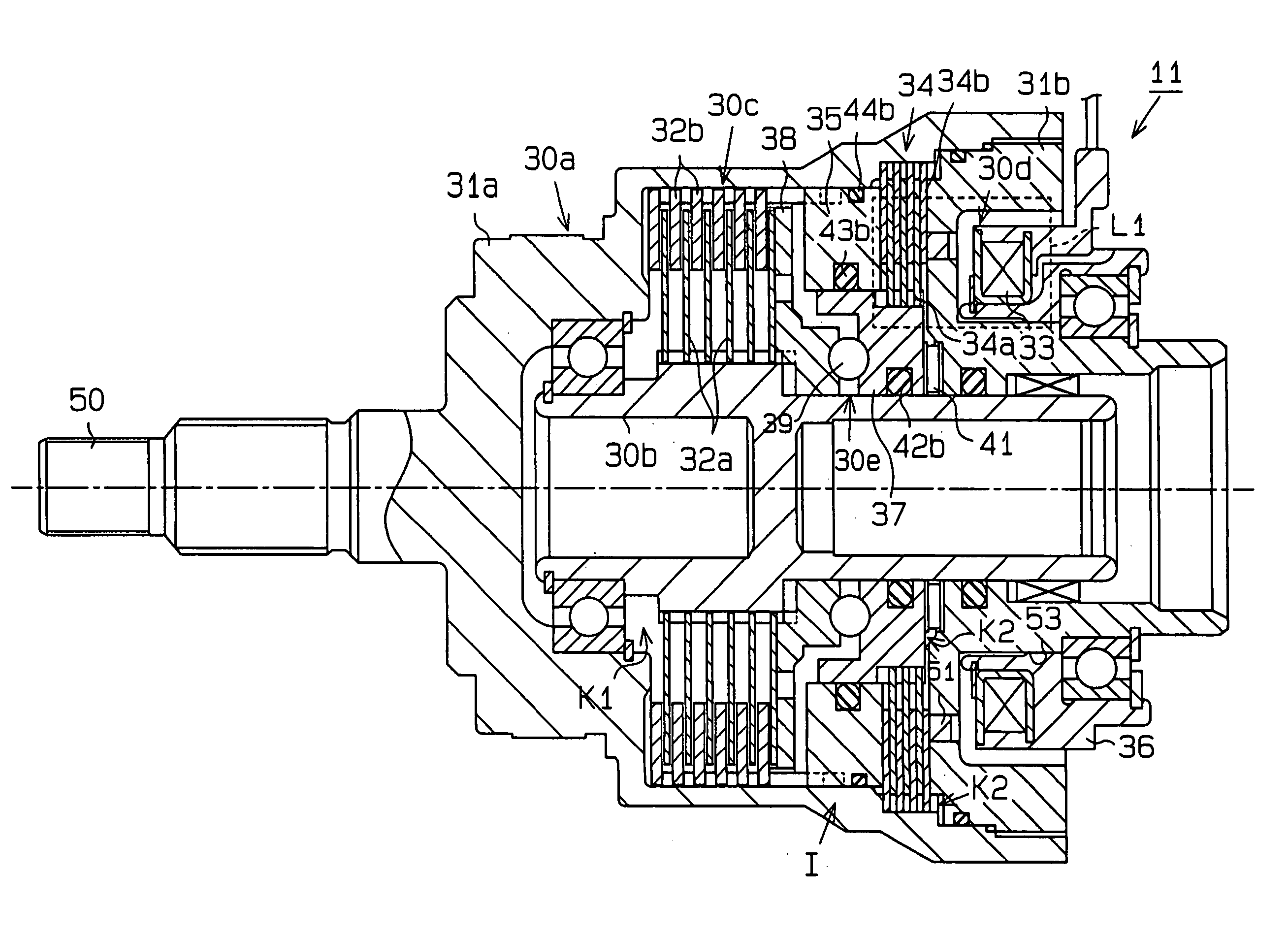

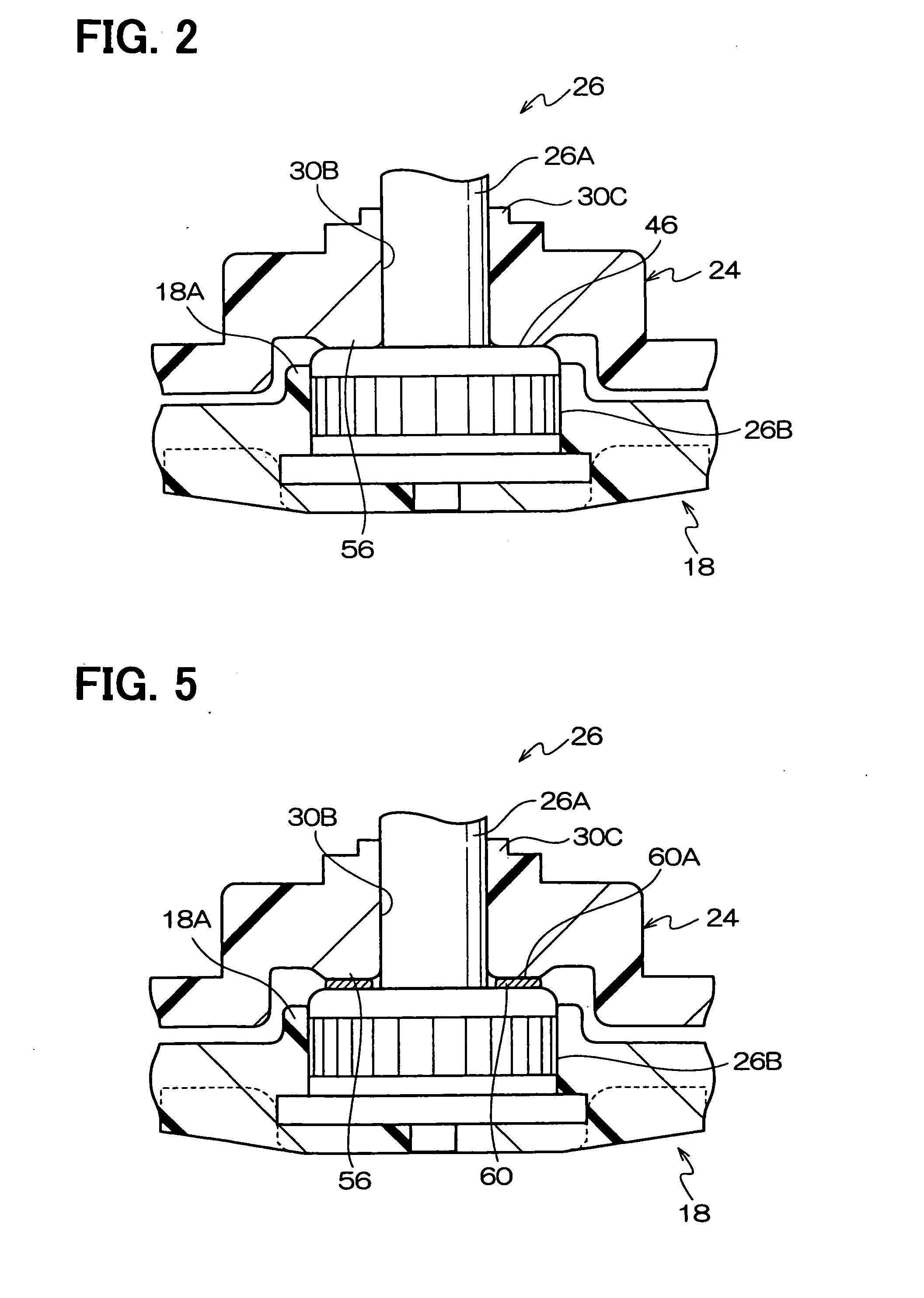

Clutch plate, friction clutch, and coupling device

InactiveUS20050167225A1Resistant to wearIncreased durabilityMagnetically actuated clutchesFriction clutchesCarbon filmGas phase

A friction clutch has a plurality of iron inner clutch plates and a plurality of iron outer clutch plates. Both the clutch plates have sliding surfaces which are friction-engaged each other. A thin carbon film in a diamond form, which functions as a solid lubricant, is formed on each of the sliding surfaces of the outer clutch plates by a known method such as the Chemical Vapor Deposition method. A known nitride treatment or quenching and tempering treatment is applied to the sliding surfaces of the inner clutch plates. A coupling device has a pilot clutch mechanism with the friction clutch and an electromagnetic actuator. As a result, the friction clutch is resistant to wear and the coupling device is excellent in durability.

Owner:JTEKT CORP

Geared electric motor

InactiveUS20090071280A1Resistant to wearLimit wearToothed gearingsPower-operated mechanismEngineeringElectric motor

A housing is made of resin and receives a worm. A worm wheel is made of resin and is received in the housing to mesh with the worm. A support shaft includes a shaft portion and a boss portion. The shaft portion rotatably supports the worm wheel. The boss portion is made of metal and is fixed to the housing. The boss portion holds the shaft portion and includes a slidably engaging surface that slidably engages the worm wheel.

Owner:ASMO CO LTD

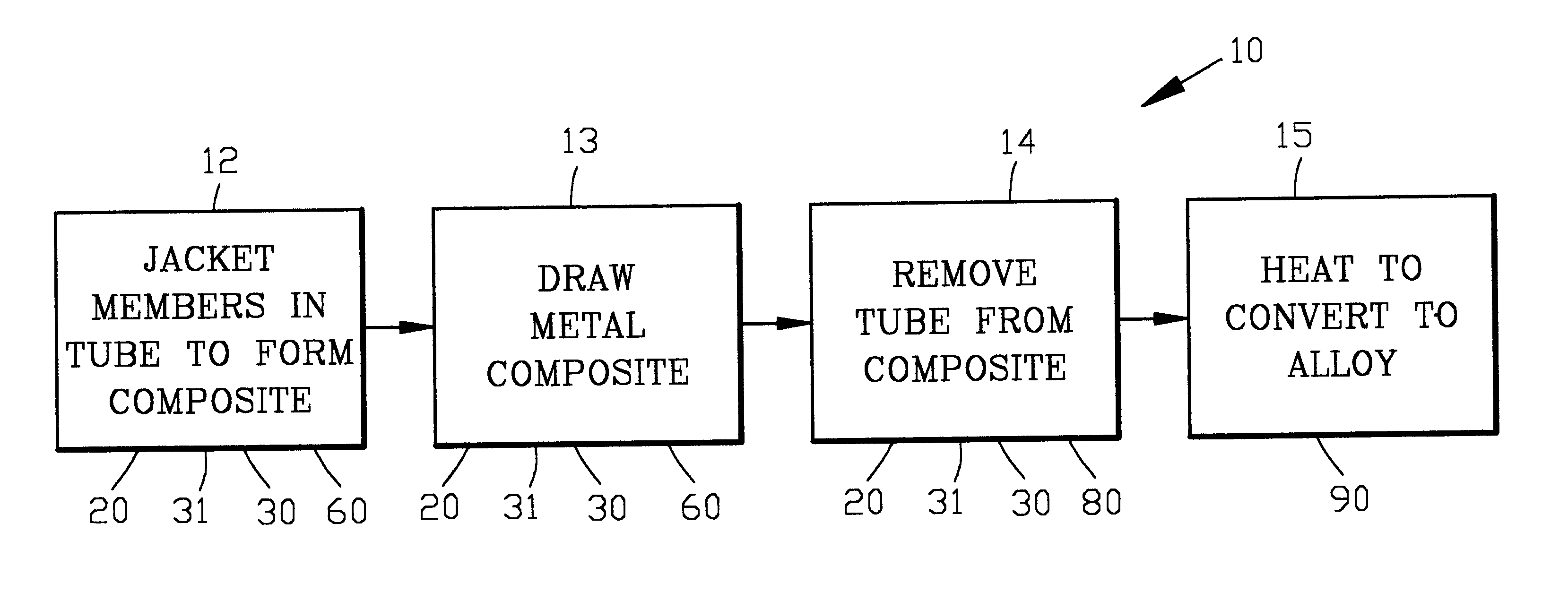

Process for making an alloy

A process is disclosed for making an alloy comprising the steps of cladding with a tube a plurality of metal members including a first and a second metal to form a metal composite. The metal composite is drawn for reducing the diameter thereof. The tube is removed to provide a remainder. The remainder is heated to convert the remainder to alloy. A multiplicity of composites may be processed simultaneously for producing fine alloy fibers.

Owner:USF FILTRATION & SEPARATIONS GROUP

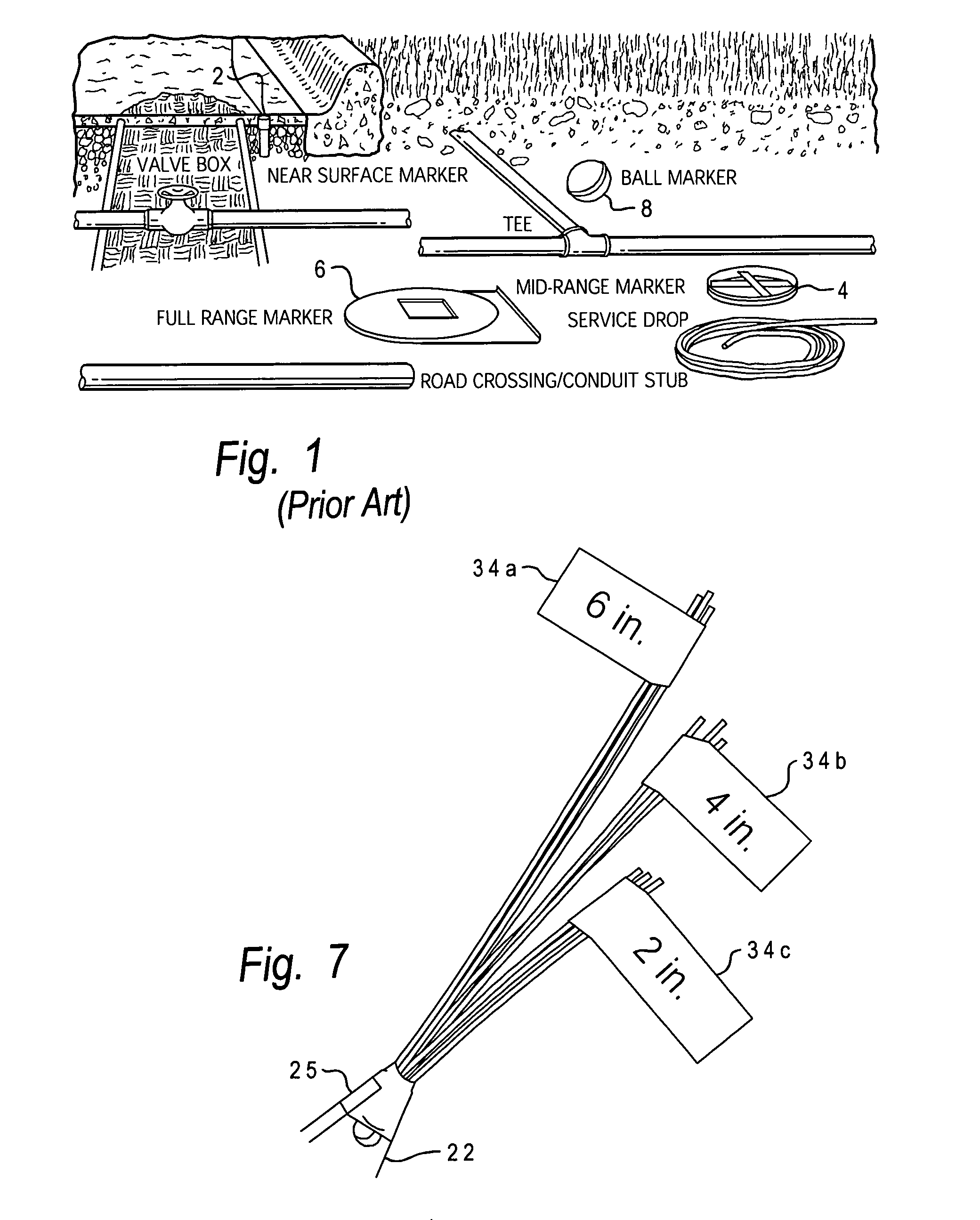

Surface tracker

InactiveUS20050200484A1Long-term locatabilityResistant to wearAnalysis using chemical indicatorsAntenna arraysAbove groundEndurability

A surface tracker includes a tubular marker body having an interior electronic marker and a visual indicator attached to an upper end of the marker body which extends away from the marker body. When deployed, the marker body is mostly underground and the visual indictor extends upwardly from the ground level to provide above-ground visual recognition. The electronic marker may be a passive electronic marker that includes a ferrite core assembly having a longitudinal axis which is generally parallel to a longitudinal axis of the marker body. The visual indicator may be a plurality of resilient filaments which pass through a hole in a tab portion of the marker body at the upper end thereof, the filaments being folded about the tab portion and secured to the tab portion using a heat-shrink tube. In an exemplary embodiment, the filaments extend about six inches from the marker body and are brightly colored. Multiple trackers can be used to mark the path of a buried utility. Due to the resilient and durable nature of the filaments, they are resistant to wear and tear and the elements. The visual indication, along with the ability to electronically detect the marker, provides a tracker with superior locating capability.

Owner:MINAROVIC JOE T

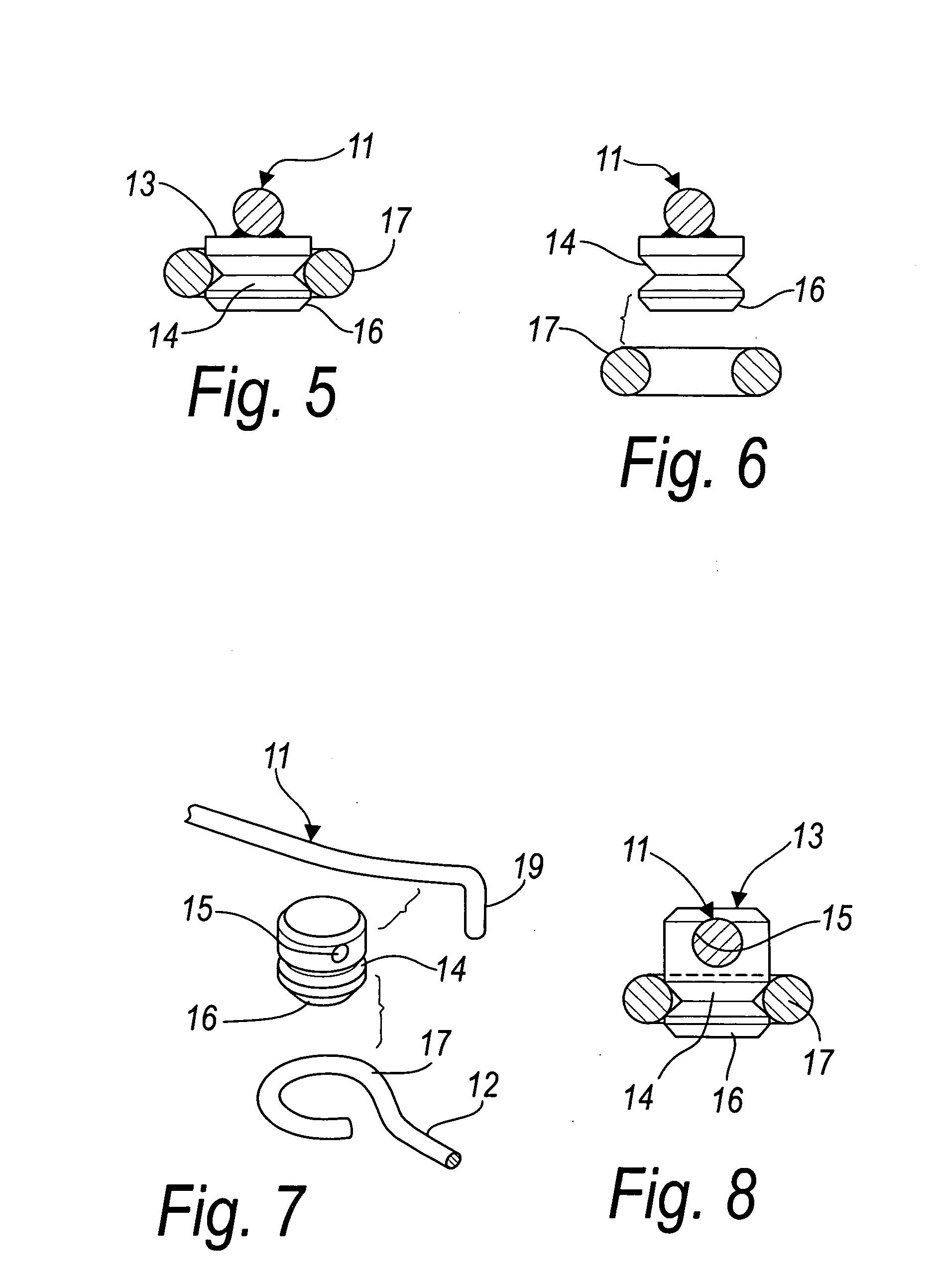

Hinge for eyeglasses, particularly for articulation of the temple to the end piece

A hinge for eyeglasses, particularly for articulation of the temple to the end piece, which comprises a pivot connected to one of the parts that compose the hinge and is provided with a circumferential groove which has a substantially V-shaped profile and a beveled end for insertion in an open ring which is associated with another of the parts that compose the hinge and is deformable radially and elastically for mating with the pivot, engaging the groove thereof.

Owner:ALLISON LTDA

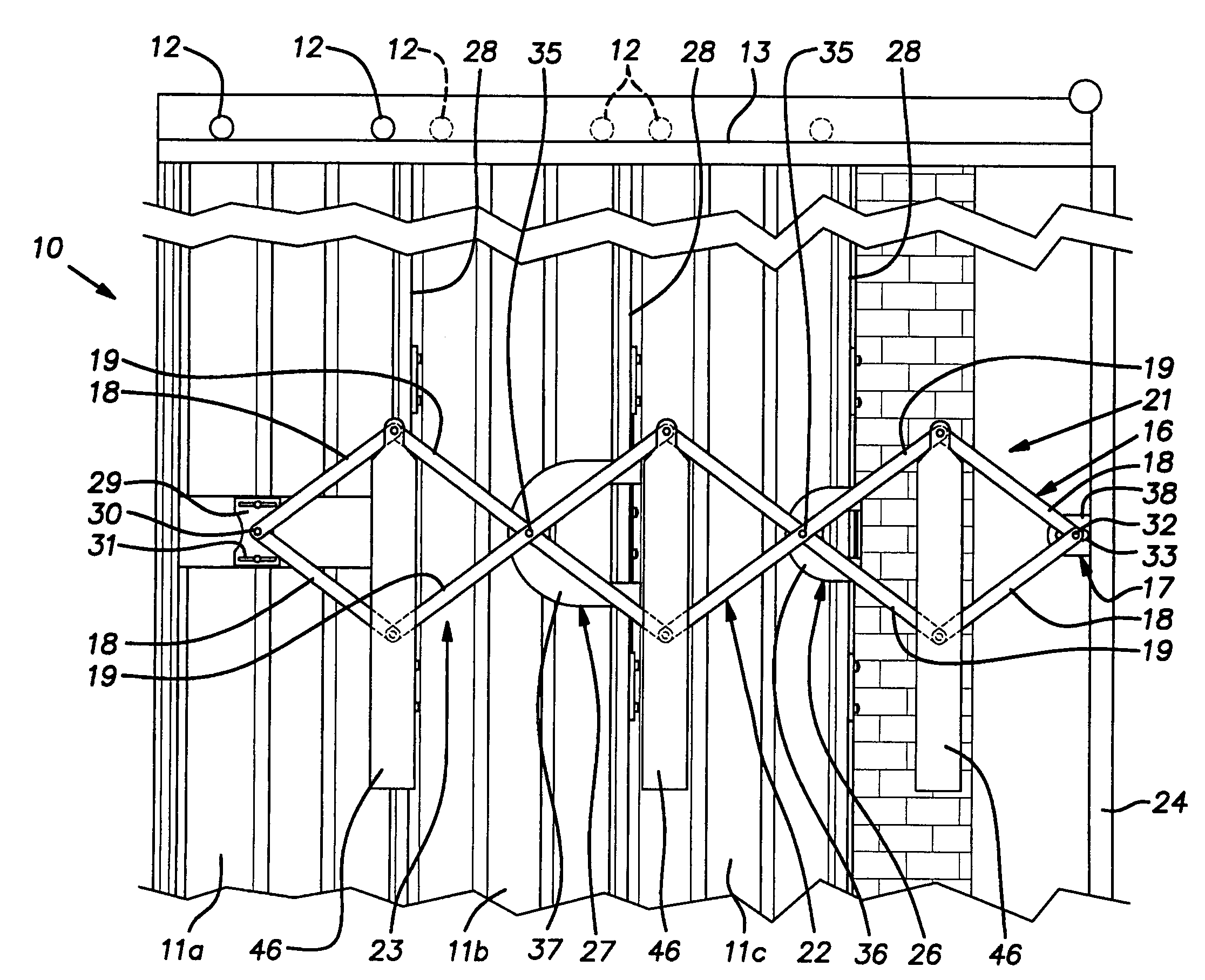

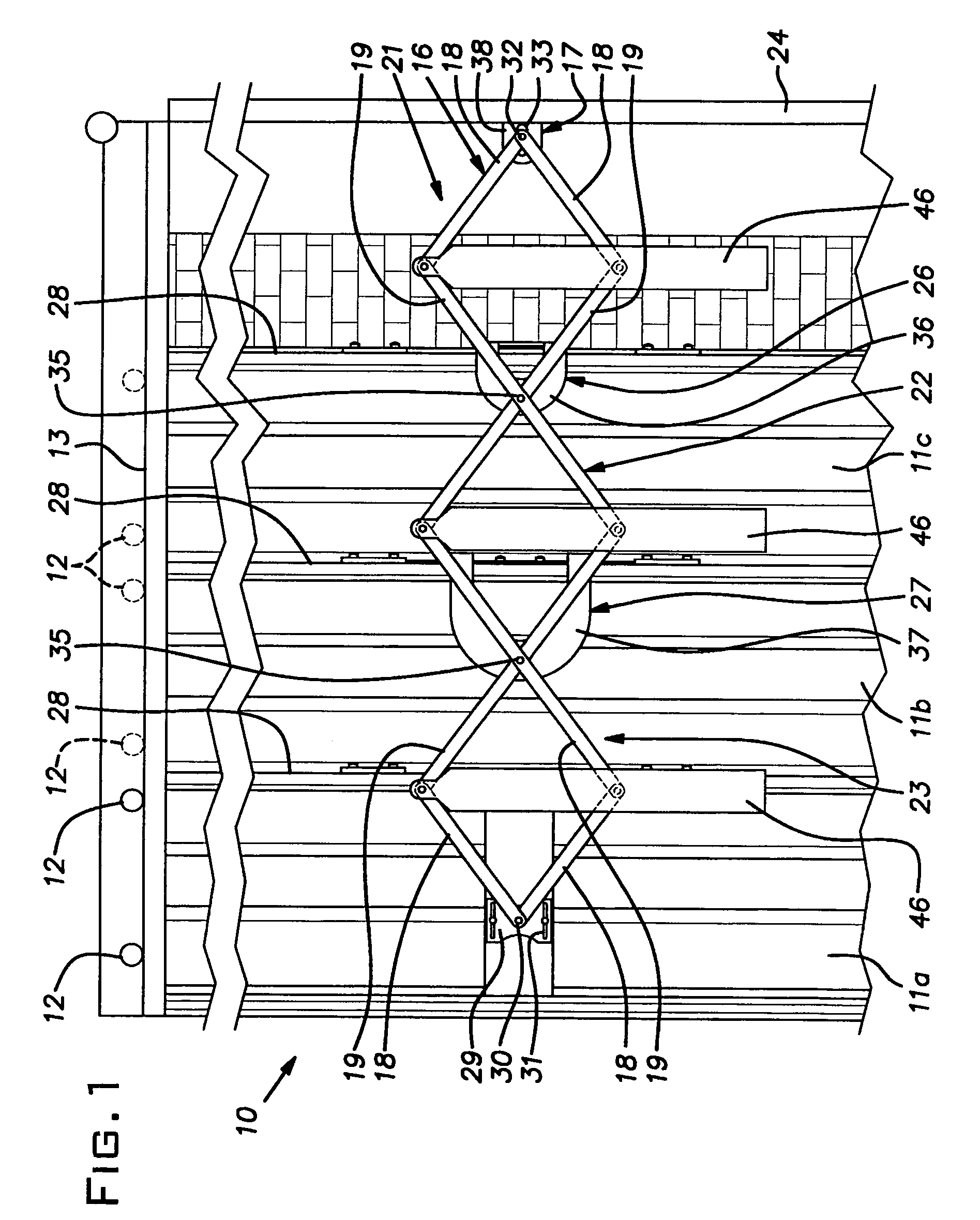

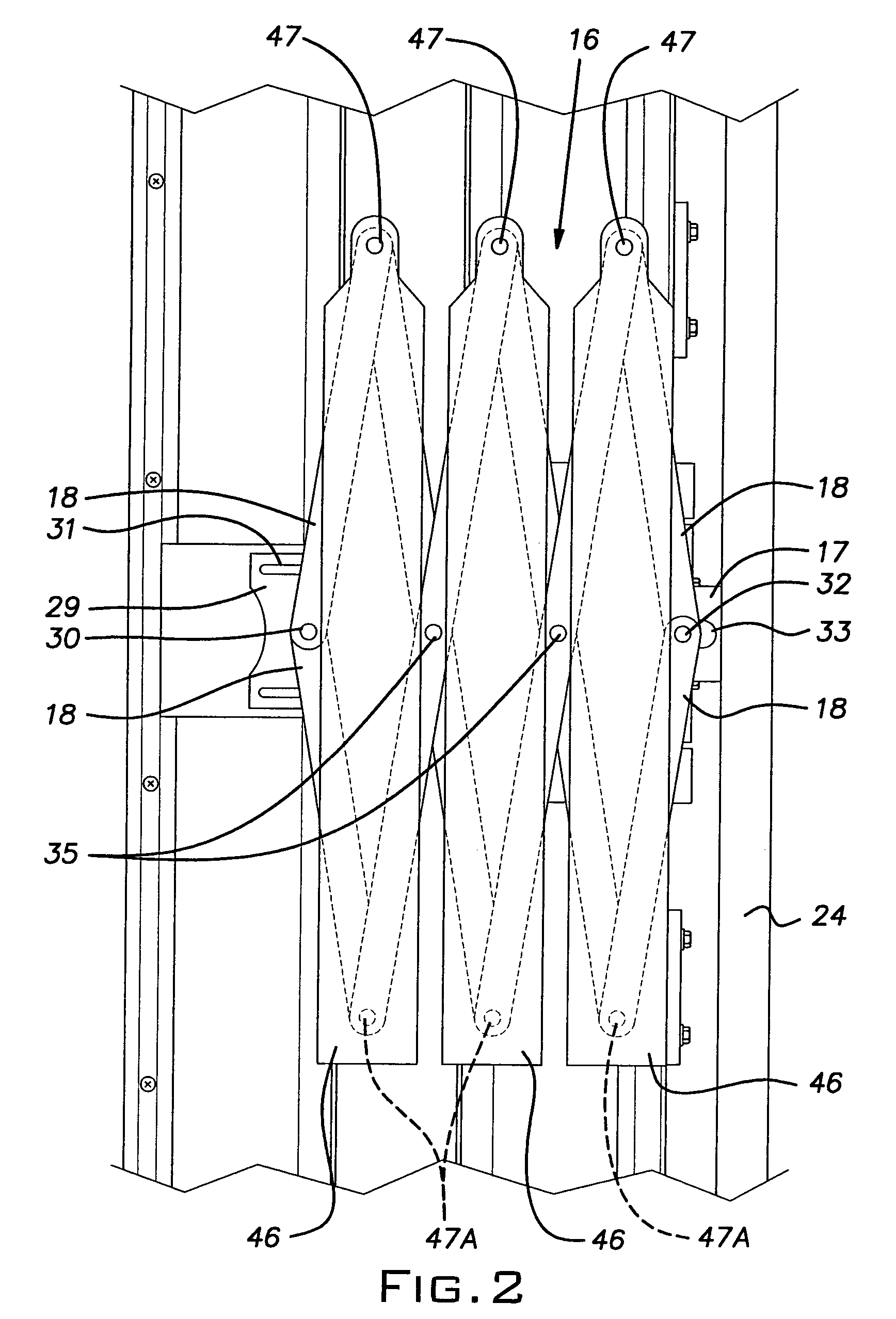

Door interlocking system

InactiveUS7308973B2Simplified linkage arrangementEasy to installExtensible doors/windowsCurtain accessoriesVertical planeEngineering

A door panel position control mechanism for a multiple panel horizontal sliding door assembly of a freight elevator landing. The mechanism comprises a multiple node scissors linkage that is configured to be easily installed and initially adjusted and which has its parts symmetrically balanced about a vertical plane such that excessive eccentric loading on the components is reduced and a long service life is obtained with reduced wear and a reduced need for periodic adjustment.

Owner:PEELLE COMPANY LTD THE

Flexible floating ring seal arrangement for rotodynamic pumps

InactiveUS7429160B2Resistant to wearResistance to recirculationSpecific fluid pumpsPropellersEngineeringCentrifugal force

Owner:WEIR SLURRY GRP INC

Fluidtight slide fastener

A fluidtight slide fastener comprising a pair of tapes comprising a textile material strip coated with a fluid barrier material layer and equipped with a set of aligned teeth, an opening stop and an opposite closing stop, a slider for engaging in a fluidtight way or disengaging said teeth respectively, wherein the fastener comprises a further fluid-tight coating formed on at least one short edge of the tapes.

Owner:RIRI GROUP

Carburetor arrangement

ActiveUS20060138684A1Resistant to wearSensitive to wearLighting and heating apparatusUsing liquid separation agentThe chokesChoke valve

A carburetor arrangement for a manually-guided implement operated by an internal combustion engine. A carburetor supplies a fuel / air mixture to the engine, with a butterfly valve being disposed in the intake duct of the carburetor and with a choke valve being disposed upstream of the butterfly valve. A start lever is provided for actuating the carburetor in a start phase, and acts upon the choke valve. The start lever can be shifted in a direction of actuation and in an unlocking direction that is independent of the direction of actuation. The start lever can be locked in a rest position relative to the direction of actuation, and after being shifted out of the rest position in the unlocking direction is shiftable in the direction of actuation.

Owner:ANDREAS STIHL AG & CO KG

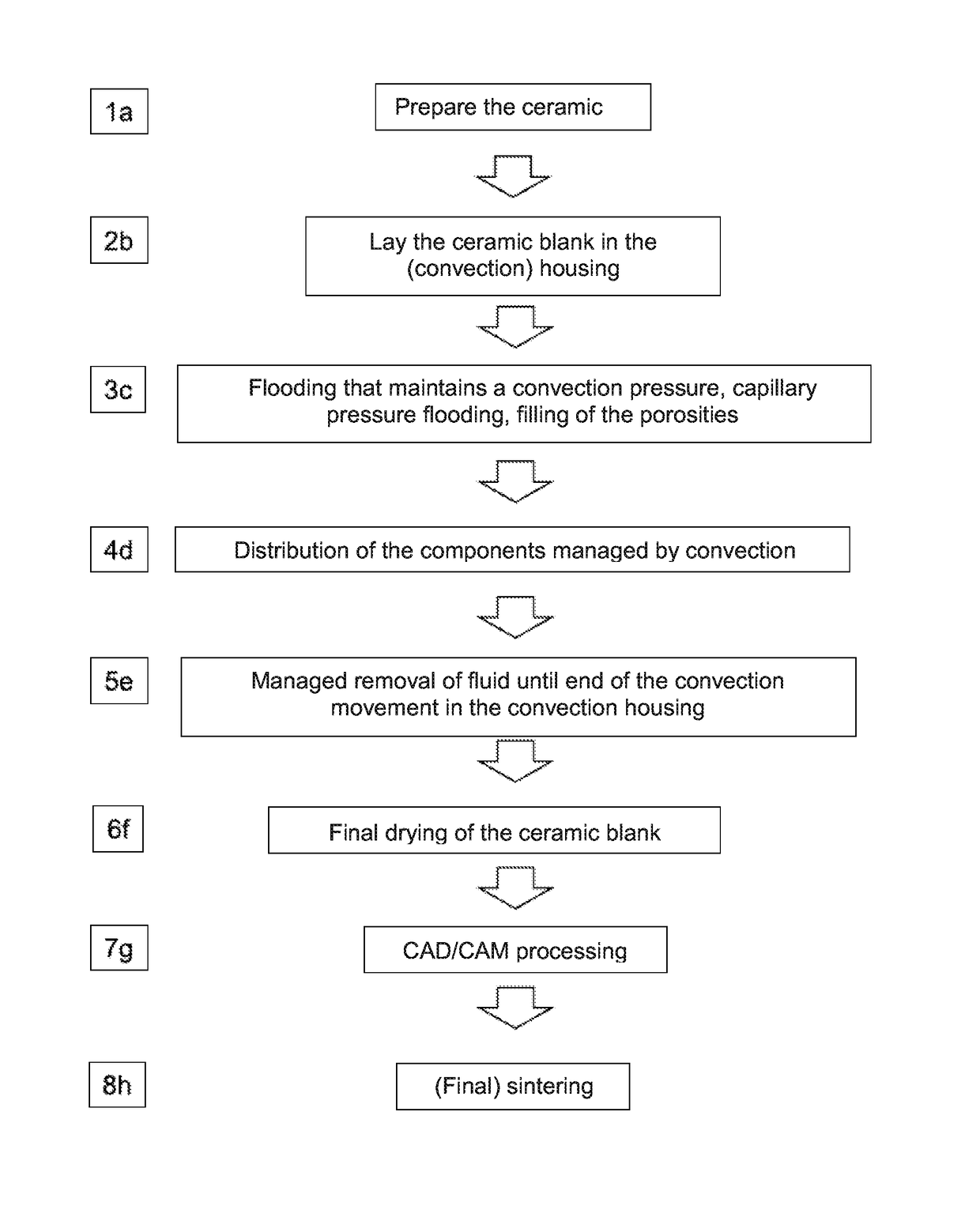

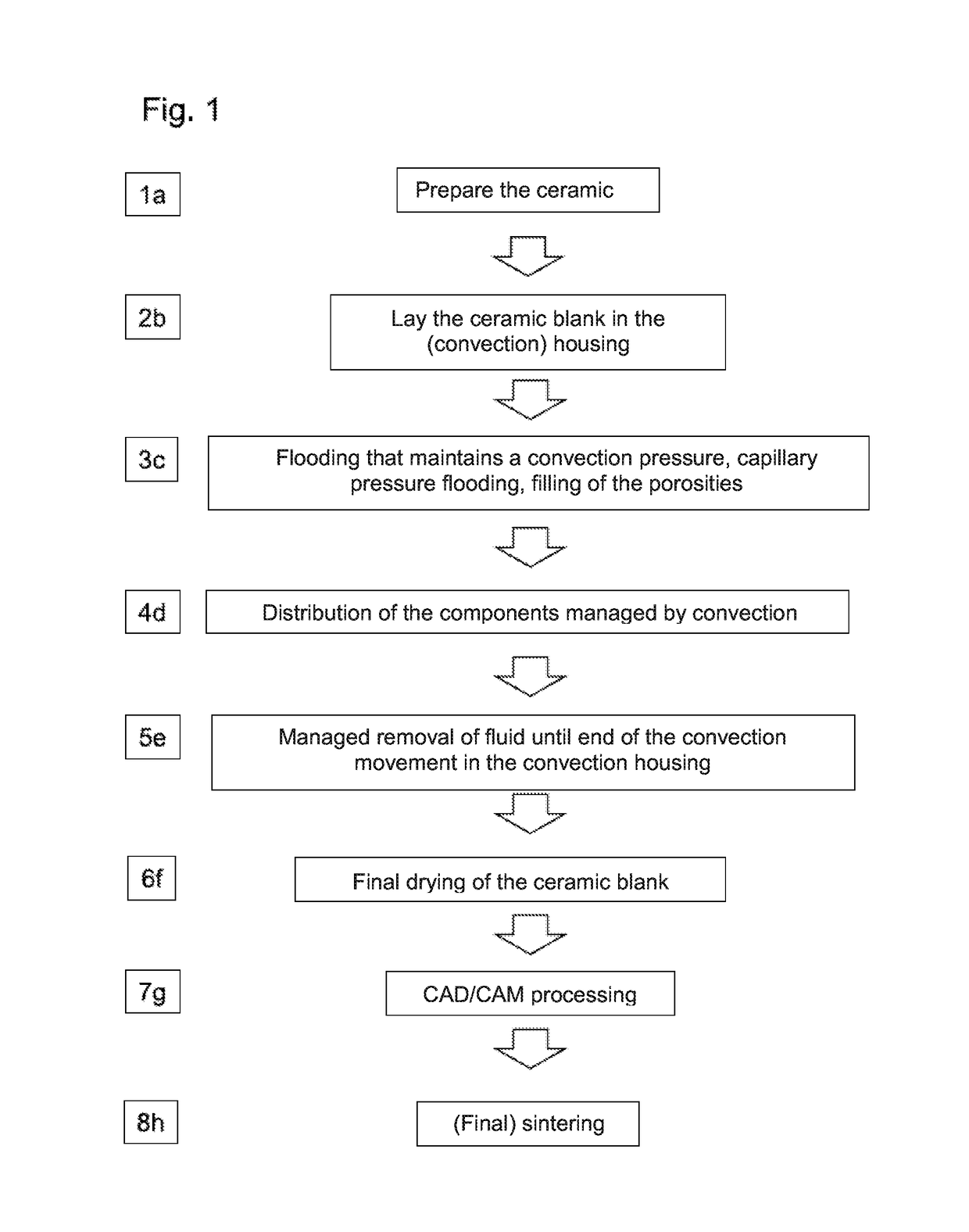

Process For Producing A Polychromic And/Or Spatially Polychromic Or A Monochrome-Colored Ceramic Body And Device For This Purpose

A method for the production of a polychromatic and / or spatially polychromatic or a monochrome colored ceramic body, in particular a dentine ceramic blank, which is dyed in this way, wherein in order to control a targeted distribution of color pigments (101, 102) within a porous ceramic (100), in a first step, which is a loading step (3c), the ceramic (100) is loaded with a color pigment solution (104). In a second step, which is a distribution control step (4d), the distribution of the color pigments (101, 102) within the ceramic (100) is controlled by controlling one or more environmental parameters (106) in an environment (108) and / or the pressure and / or temperature.

Owner:WDT WOLZ DENTAL TECH GMBH

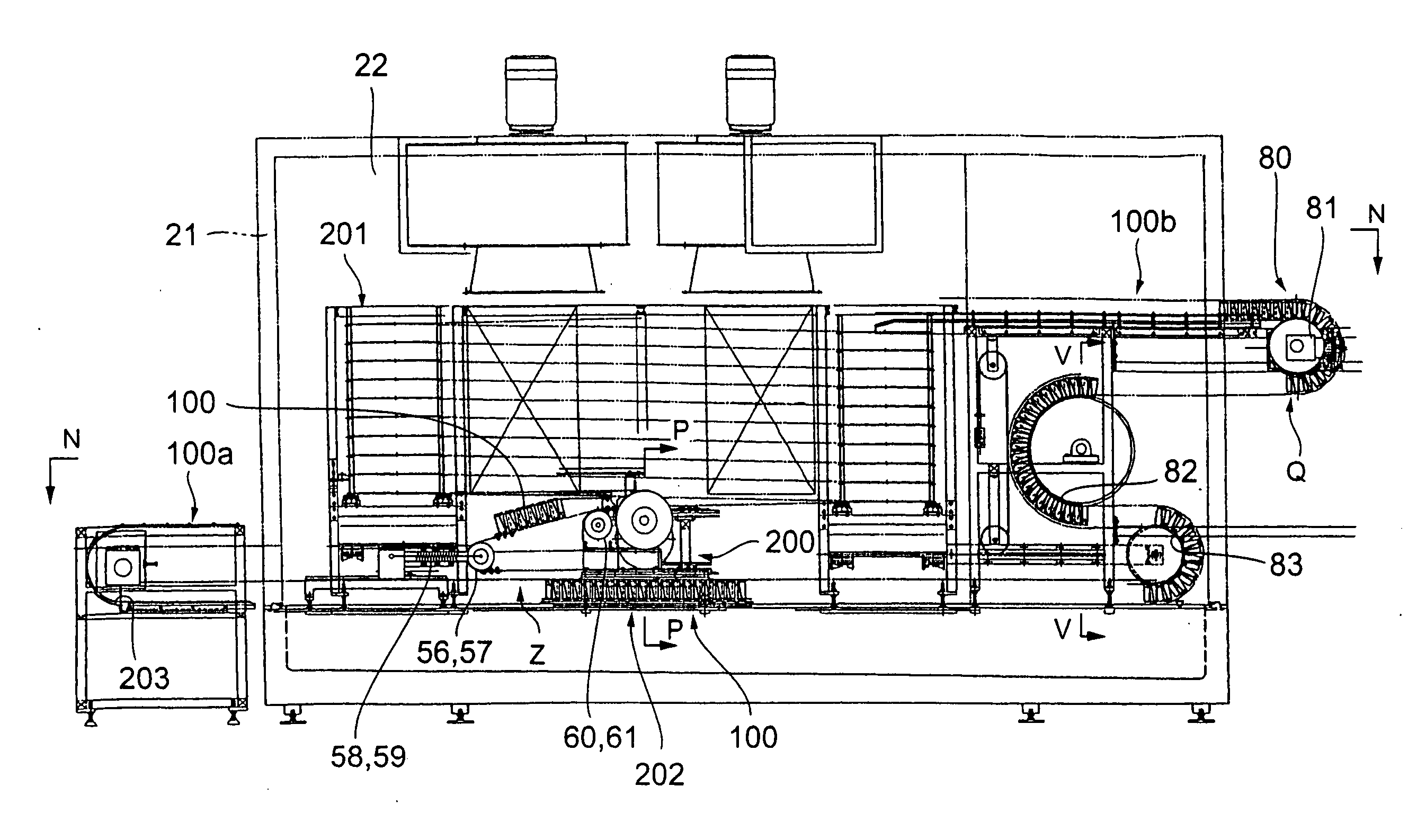

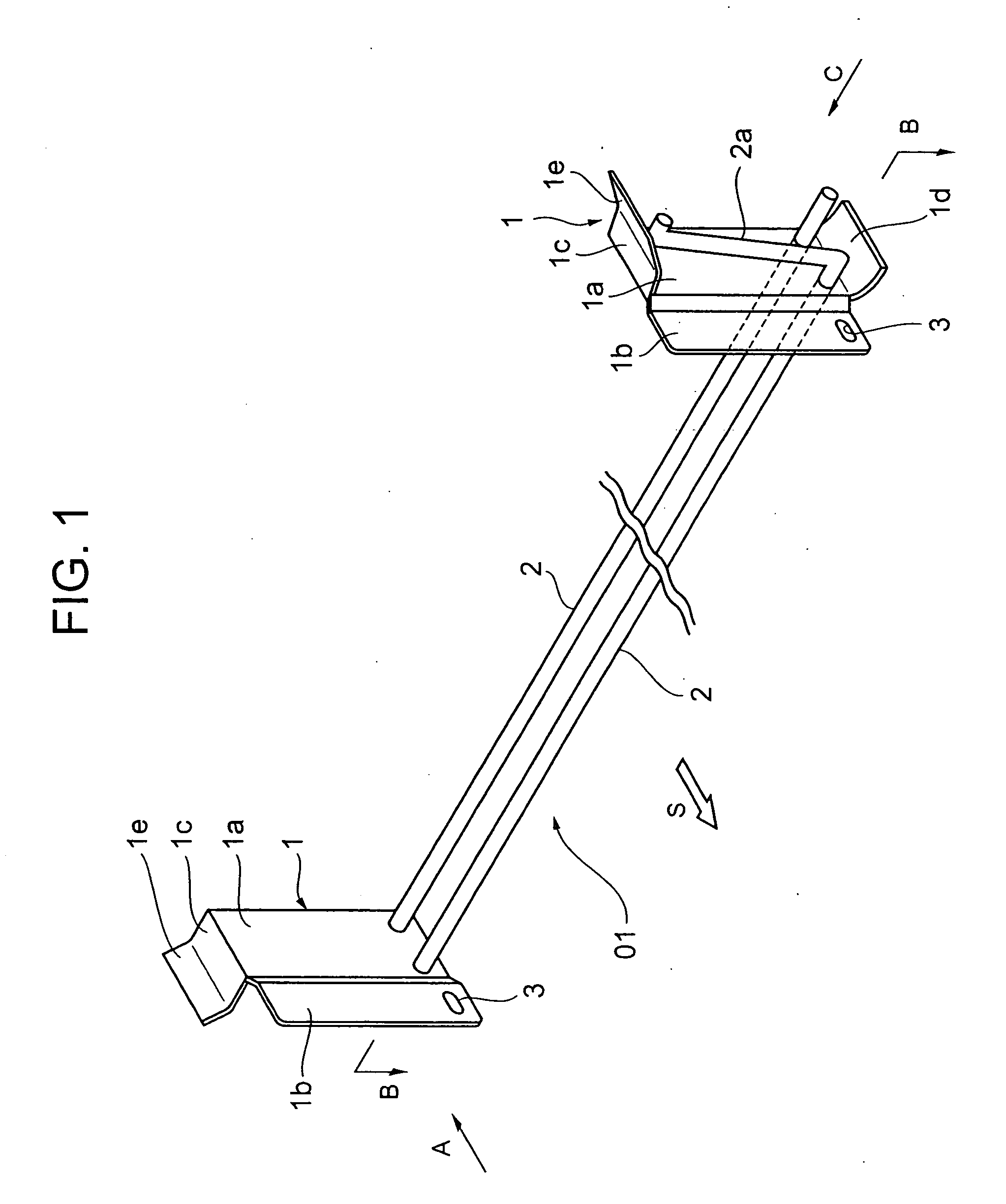

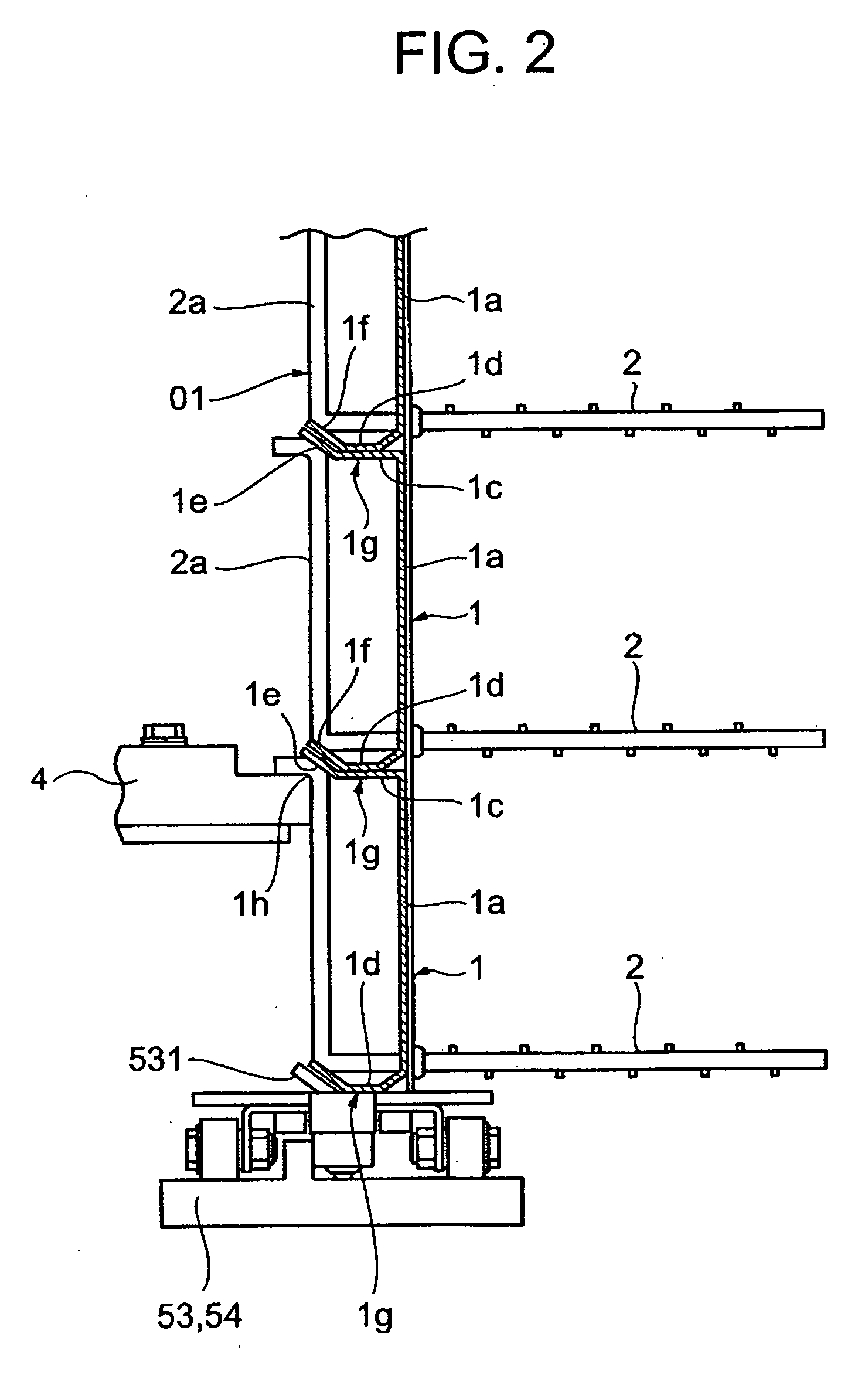

Flexible transfer installation and foodstuff transfer system provided with the flexible transfer installation

InactiveUS20050224316A1Resistant to wearCompact structureConveyorsPackagingTransfer systemEngineering

Owner:MAYEKAWA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com