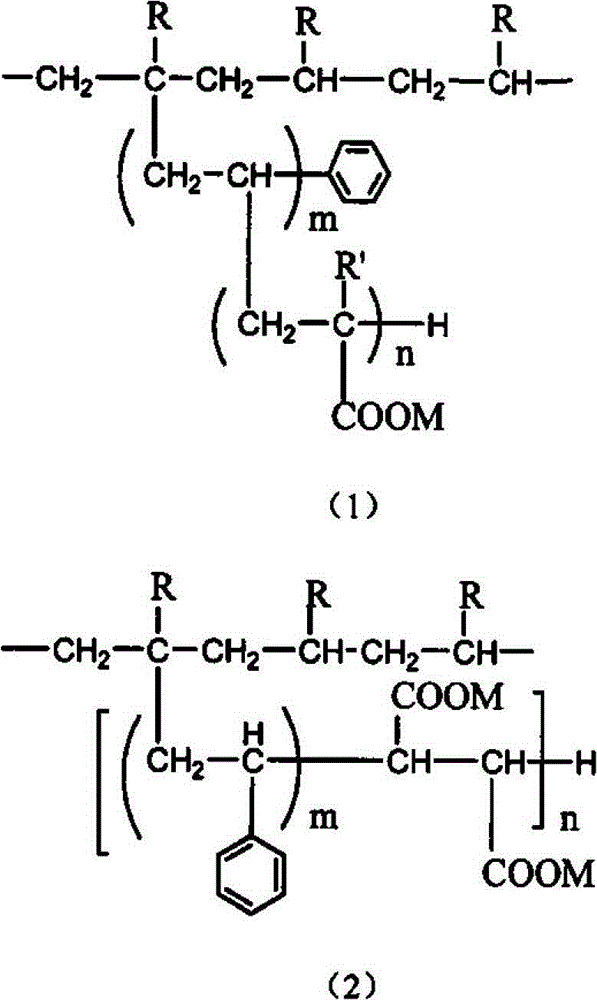

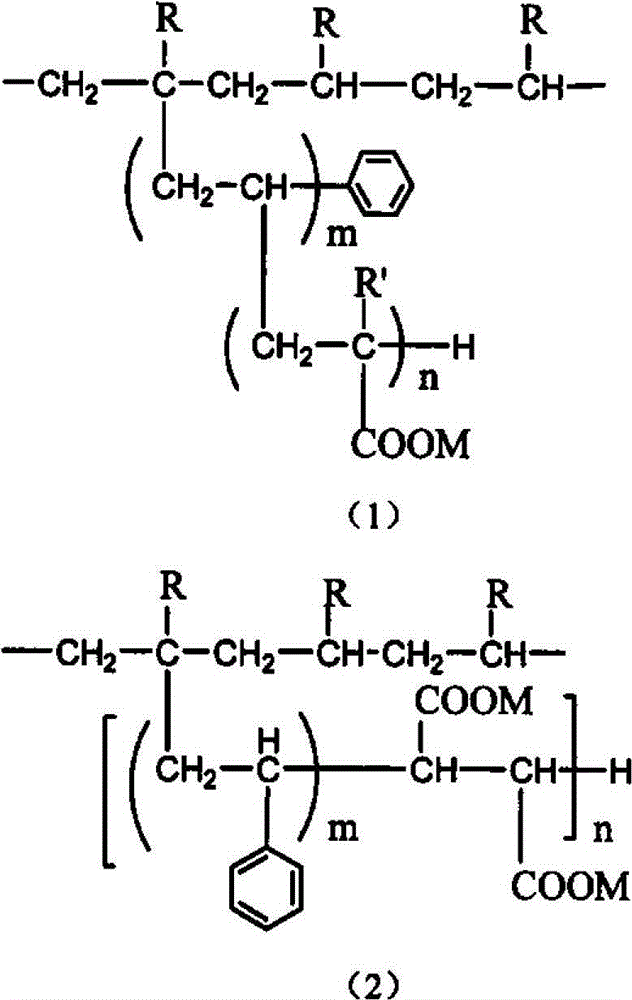

Permanent polyolefin antistatic agent and preparation method thereof

An antistatic agent and polyolefin technology, applied in the field of permanent polyolefin antistatic agent and its preparation, can solve the problem of not involving antistatic agent, etc., and achieve good material color and transparency, good compatibility, good water resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

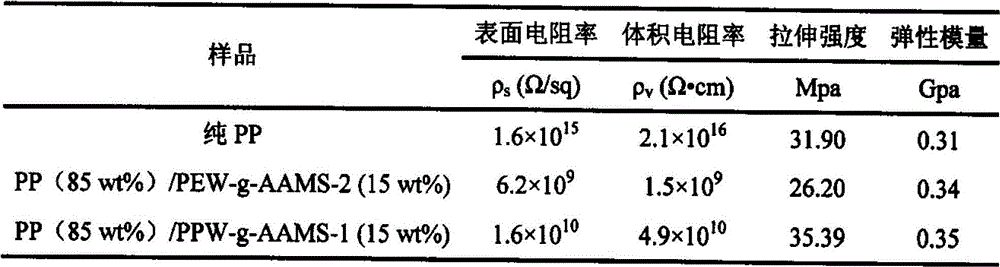

Embodiment 1

[0054] 20 grams of PPW and 100 grams of xylene were added to the reactor, under nitrogen protection, heated to 120°C, and stirred to dissolve the PPW. 7 grams of acrylic acid, 8 grams of styrene and 1 gram of dicumyl peroxide were dissolved in 20 grams of xylene, and were added dropwise into the reactor at a controlled speed for 1 hour. After 3 hours of reaction, a white emulsion was obtained. 4 grams of NaOH was dissolved in 10 grams of ethanol-water (1:1, v / v) solution, added to the above system, after half an hour, the reactant was poured into acetone to dissolve the precipitate, filtered by suction, and washed 3 times with acetone-water solution to obtain The solid was dried under vacuum at 50°C for 10 h to obtain a white product as PPW-g-AAMS-1.

[0055] The grafting rate of acrylic acid was measured to be 17.7% by titration.

Embodiment 2

[0057] 20 grams of PEW and 100 grams of toluene were added to the reactor, under nitrogen protection, heated to 90°C, and stirred to dissolve the PEW. Dissolve 10 grams of methacrylic acid and 1.5 grams of benzoyl peroxide in 20 grams of xylene, drop them into the reactor at a controlled speed for 1 hour, and obtain a white emulsion after 3 hours of reaction. 6 grams of KOH was dissolved in 15 grams of ethanol-water (1:1, v / v) solution and added to the above system. After half an hour, the reactant was poured into acetone to dissolve the precipitate, filtered with suction, and washed 3 times with acetone-water solution. The obtained solid was vacuum-dried at 50° C. for 10 h to obtain a white product as PEW-g-MAAP-1.

Embodiment 3

[0059] Add 40 grams of PEW, 5 grams of Tween-40, and 5 grams of Pan-40 into the reactor and heat it to 120°C, and stir it electrically for 30 minutes to disperse it into a uniform liquid. Quickly add 200 grams of boiling water and form a uniform emulsion under vigorous stirring. The temperature was kept at 100° C., 1 gram of benzoyl peroxide, 7.5 grams of acrylic acid and 7.0 grams of styrene were added, and the same amount of monomers, styrene and initiator were added after 1 hour. After reacting for 3 hours, add 8 grams of NaOH aqueous solution for neutralization, pour the product into an 800mL beaker, let it stand at room temperature for two days, and divide it into two layers, the lower layer is a white emulsion, and the upper layer is a white powder. The upper layer was taken and dried to obtain a white product as PEW-g-AAMS-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com