High-temperature sintered conductive silver paste and preparation method thereof

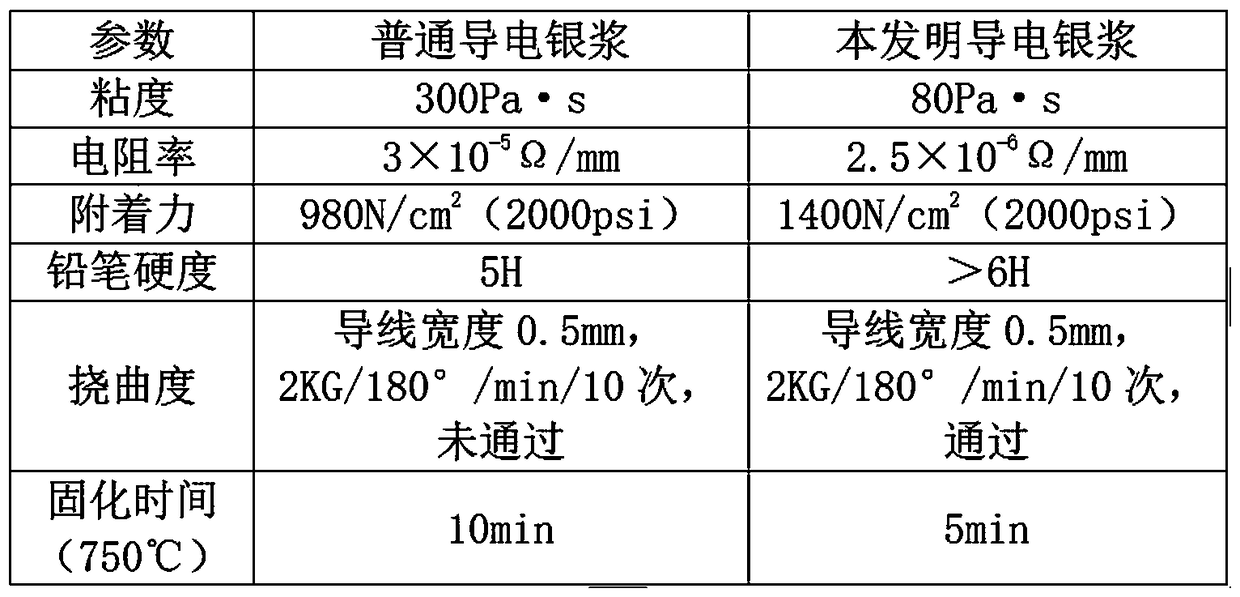

A technology of conductive silver paste and high temperature sintering, which is used in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. Problems such as the adhesion of the silver film to the substrate, to achieve the effect of enhancing capacitance, enhancing conductivity, and increasing connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

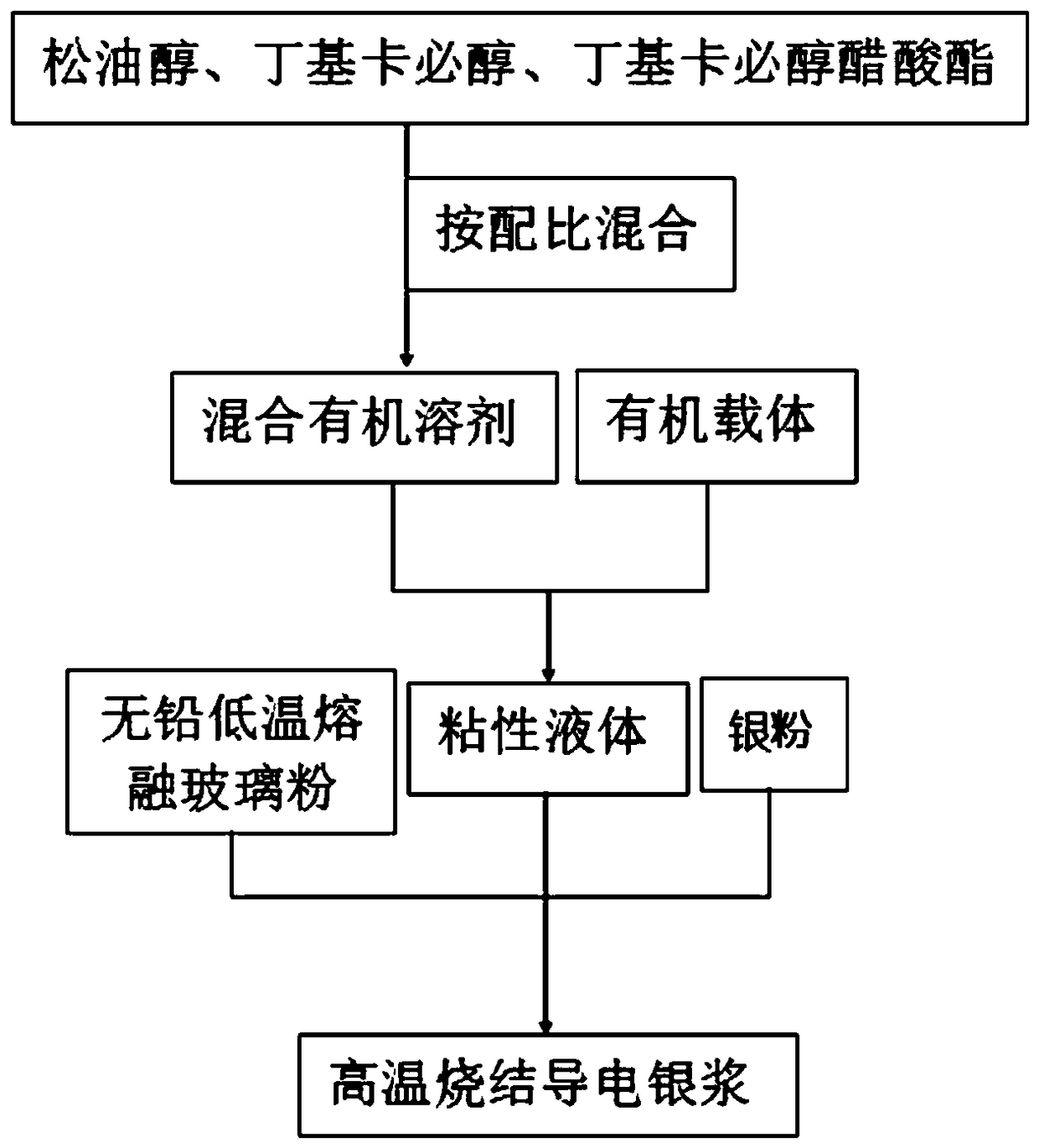

Method used

Image

Examples

Embodiment 1

[0022] Take 68 parts of spherical or flake silver powder with a particle size of 0.1-5 microns, 10 parts of lead-free low-temperature molten glass powder, 8 parts of ethyl cellulose, and 10 parts of organic solvent, of which

[0023] Lead-free low-temperature molten glass powder is composed of the following components: Bi 2 o 3 35%, B 2 o 3 20%, ZnO 10%, SiO 2 22%, Al 2 o 3 2%, CaO 6%, V 2 o 5 5%, choose lead-free low-temperature molten glass powder with a particle size of 4 μm and a softening temperature of 650°C;

[0024] Organic solvents include 6 parts of terpineol, 2.5 parts of butyl carbitol, and 1.5 parts of butyl carbitol acetate;

[0025] S1. Mix organic solvents: 6 parts of terpineol, 2.5 parts of butyl carbitol, and 1.5 parts of butyl carbitol acetate to obtain a mixed organic solvent;

[0026] S2, fully mixing ethyl cellulose with a mixed organic solvent to form a viscous liquid;

[0027] S3. Mixing treatment: fully stir and mix the viscous liquid obtai...

Embodiment 2

[0031] Take 65 parts of spherical or flake silver powder with a particle size of 0.1-5 microns, 6 parts of lead-free low-temperature molten glass powder, 5 parts of ethyl cellulose, and 5 parts of organic solvent, of which

[0032] Lead-free low-temperature molten glass powder is composed of the following components: Bi 2 o 3 35%, B 2 o 3 20%, ZnO 10%, SiO 2 22%, Al 2 o 3 2%, CaO 6%, V 2 o 5 5%, the particle size of lead-free low-temperature molten glass powder is selected as 3 μm, and the softening temperature is 390 ° C;

[0033] Organic solvents include 2.75 parts of terpineol, 1.5 parts of butyl carbitol, and 0.75 parts of butyl carbitol acetate;

[0034] S1. Mix organic solvents: 2.75 parts of terpineol, 1.5 parts of butyl carbitol, and 0.75 parts of butyl carbitol acetate to obtain a mixed organic solvent;

[0035] S2, fully mixing ethyl cellulose with a mixed organic solvent to form a viscous liquid;

[0036] S3. Mixing treatment: fully stir and mix the visc...

Embodiment 3

[0039] Take 70 parts of spherical or flake silver powder with a particle size of 0.1-5 microns, 12 parts of lead-free low-temperature molten glass powder, 10 parts of ethyl cellulose, and 15 parts of organic solvent, of which

[0040] Lead-free low-temperature molten glass powder is composed of the following components: Bi 2 o 3 35%, B 2 o 3 20%, ZnO 10%, SiO 2 22%, Al 2 o 3 2%, CaO 6%, V 2 o 5 5%, choose lead-free low-temperature molten glass powder with a particle size of 5 μm and a softening temperature of 780°C;

[0041] Organic solvents include 9.75 parts of terpineol, 3 parts of butyl carbitol, and 2 parts of butyl carbitol acetate;

[0042] S1. Mix organic solvents: 9.75 parts of terpineol, 3 parts of butyl carbitol, and 2 parts of butyl carbitol acetate to obtain a mixed organic solvent;

[0043] S2, fully mixing ethyl cellulose with a mixed organic solvent to form a viscous liquid;

[0044] S3. Mixing treatment: fully stir and mix the viscous liquid obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com