Al2O3-SiC-C refractory brick for torpedo ladle produced by utilizing waste Al2O3-C and preparation method of Al2O3-SiC-C refractory brick

A technology of refractory bricks and torpedo tanks, which is applied in the field of Al2O3-SiC-C bricks and refractory materials for iron and steel metallurgy, which can solve the problems of discarding, small particle size limit of raw materials, waste of resources, etc., achieve high densification, improve matrix Performance, uniform density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

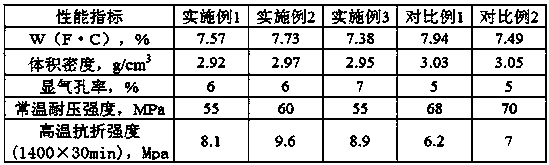

Examples

Embodiment 1

[0024] Use of waste Al 2 o 3- Al used in the production of torpedo tanks with C materials 2 o 3 -SiC-C refractory bricks, the proportion of raw materials by weight percentage is as follows: 30% of super-grade bauxite clinker particles with a particle size of 5-3mm, 15% of super-grade bauxite clinker particles with a particle size of 3-1mm, and 15% of corundum particles with a particle size of 1-0.088mm, 9.5% of corundum fine powder with a particle size of less than 0.088mm, 5% of silicon carbide particles with a particle size of 1-0.088mm, 3% of silicon carbide fine powder with a particle size of less than 0.088mm mm Abandoned long nozzle Al 2 o 3 -C fine powder 10%, alumina powder with particle size less than 0.088mm 5%, bonded clay powder with particle size less than 0.088mm 4%, flake graphite powder with particle size less than 0.088mm 3%, asphalt powder with particle size less than 0.088mm 0.5%, Plus 5% phenolic resin.

[0025] Utilize the abandoned shroud Al 2 o 3...

Embodiment 2

[0037] Use of waste Al 2 o 3 - Al used in the production of torpedo tanks with C materials 2 o 3 -SiC-C refractory bricks, the proportion of raw materials by weight percentage is as follows: 25% of super-grade bauxite clinker particles with a particle size of 5-3mm, 20% of super-grade bauxite clinker particles with a particle size of 3-1mm, and 8.5% of corundum particles with a particle size of 1-0.088mm, 6% of corundum fine powder with a particle size of less than 0.088mm, 3% of silicon carbide particles with a particle size of 1-0.088mm, 3% of silicon carbide fine powder with a particle size of less than 0.088mm, and a particle size of less than 0.088mm mm Discarded submerged nozzle Al 2 o 3 -C fine powder 25%, alumina fine powder less than 0.088mm 5%, bonded clay fine powder less than 0.088mm 3%, flake graphite powder less than 0.088mm 1%, asphalt powder less than 0.088mm 0.5% , plus 4% phenolic resin.

[0038] Utilize the abandoned submerged nozzle Al 2 o 3 - Al us...

Embodiment 3

[0050] Use of waste Al 2 o 3 - Al used in the production of torpedo tanks with C materials 2 o 3 -SiC-C refractory bricks, the proportion of raw materials by weight percentage is as follows: 30% of super-grade bauxite clinker particles with a particle size of 5-3mm, 15% of super-grade bauxite clinker particles with a particle size of 3-1mm, and 10% of corundum particles with a particle size of 1-0.088mm, 13% of corundum fine powder with a particle size of less than 0.088mm, 3% of silicon carbide particles with a particle size of 1-0.088mm, 3% of silicon carbide fine powder with a particle size of less than 0.088mm, and a particle size of less than 0.088mm mm waste integral stopper Al 2 o 3 -C material fine powder 12%, alumina powder with particle size less than 0.088mm 8%, bonded clay fine powder with particle size less than 0.088mm 3%, flake graphite powder with particle size less than 0.088mm 2.5%, asphalt powder with particle size less than 0.088mm 0.5% %, plus 4% phen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com