Rare earth prealloyed powder and preparation method thereof

A technology of pre-alloyed powder and metal powder, applied in the field of rare-earth pre-alloyed powder and its preparation, can solve the problems of poor diamond holding force, poor quality stability, low degree of alloying, etc. Hard and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

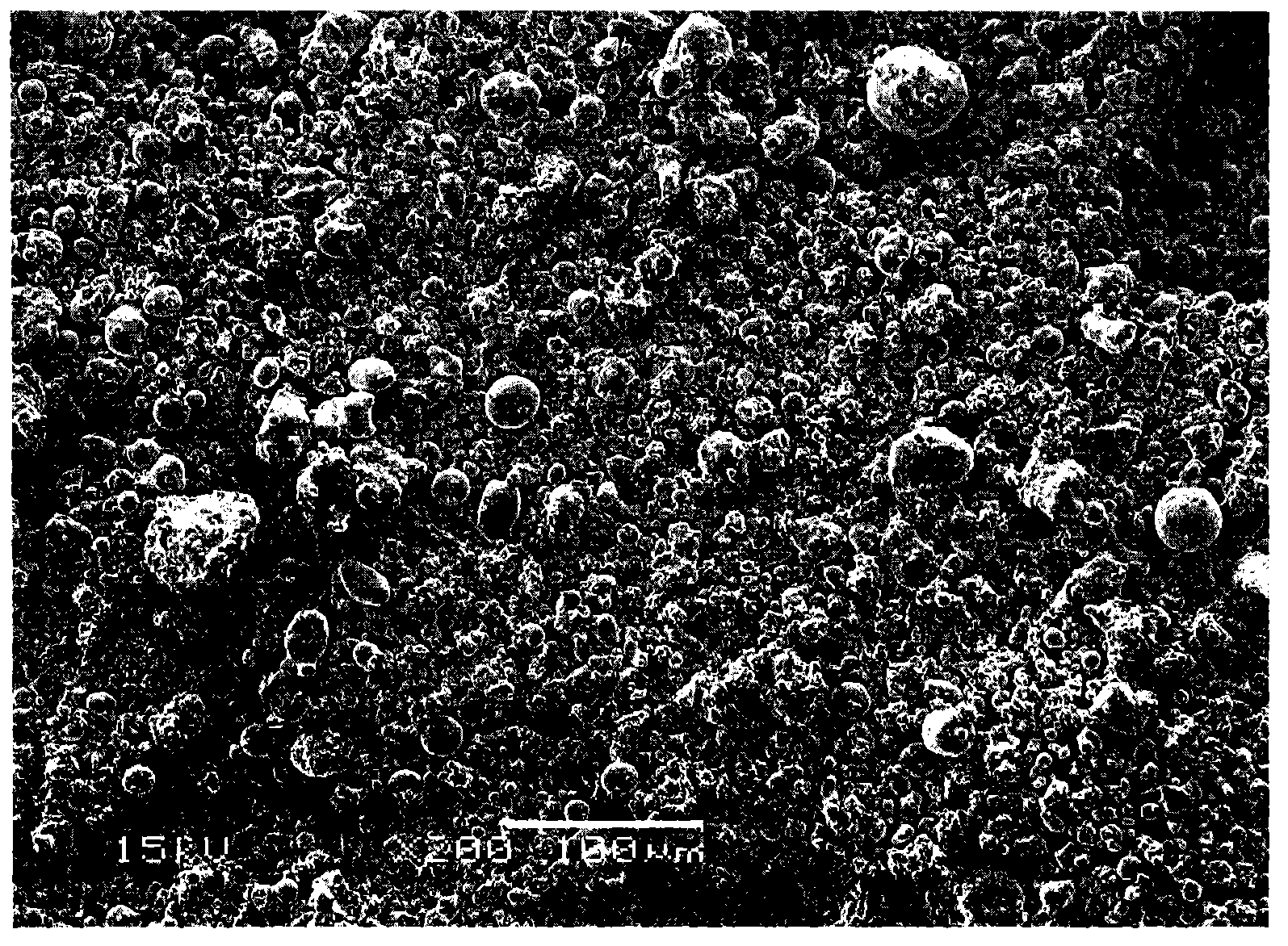

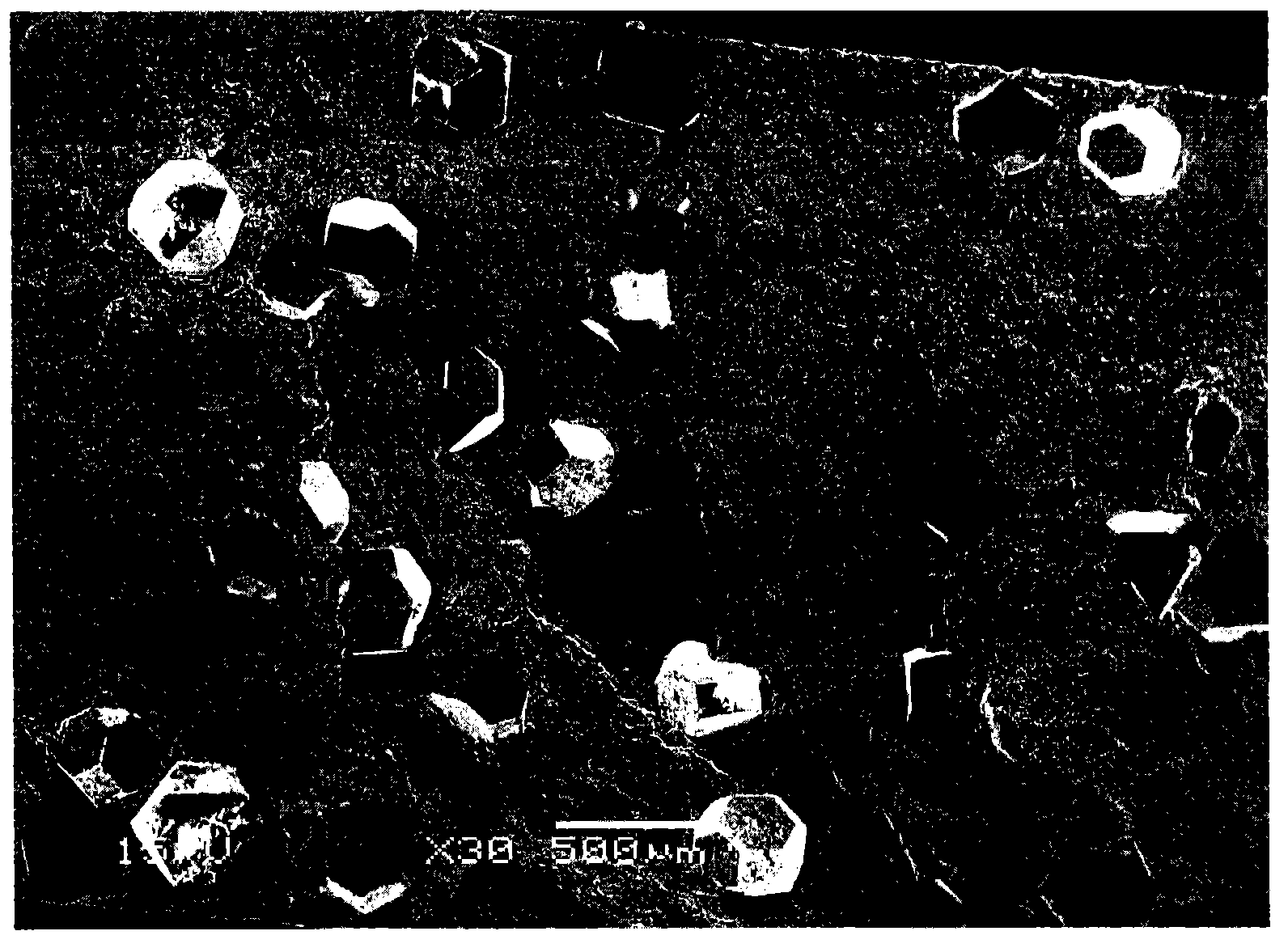

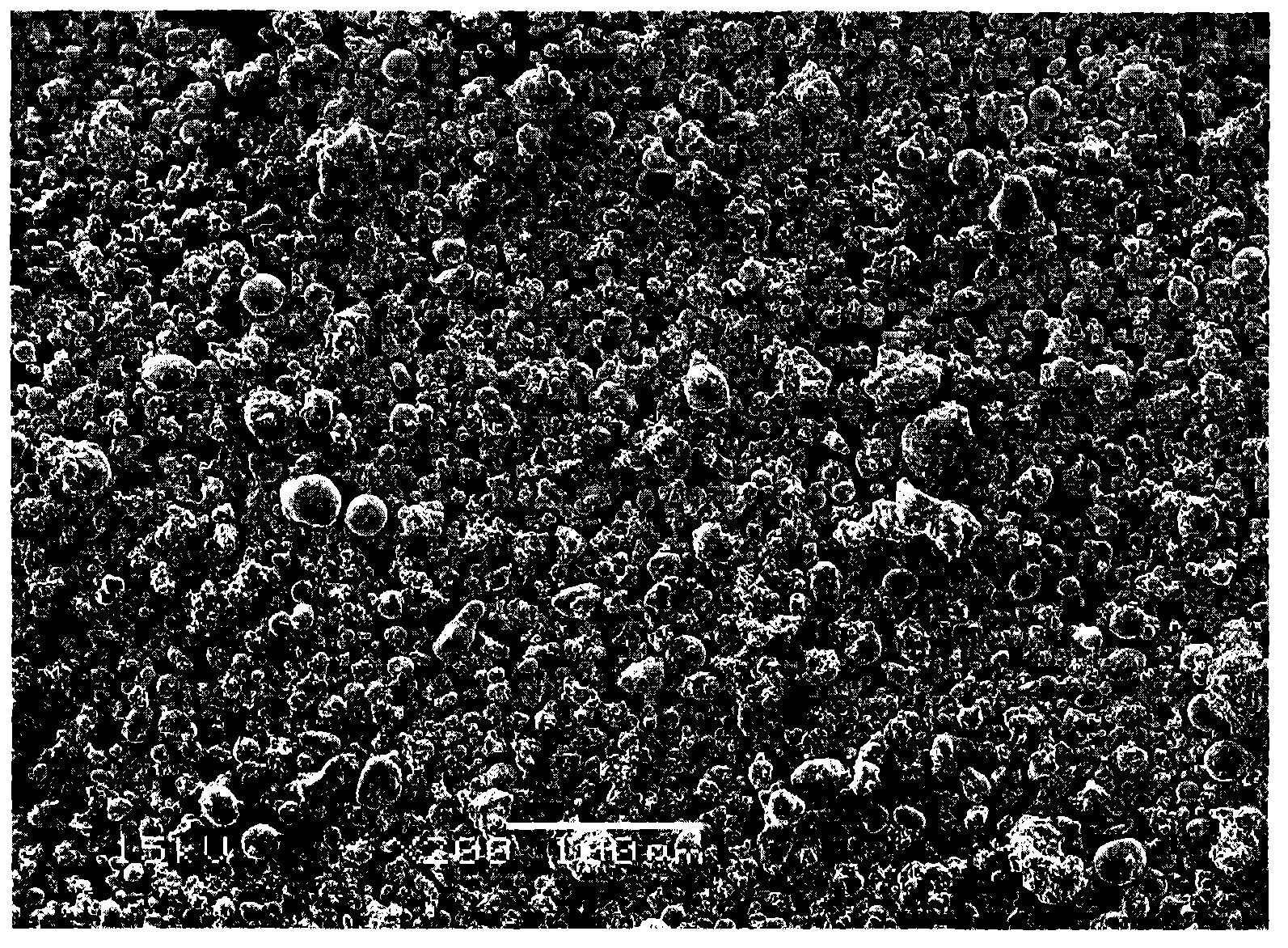

Image

Examples

Embodiment 1

[0037] The rare earth pre-alloyed powder described in this embodiment has the formula of basic constituent elements and their mass percentages: Cu36wt%, Sn5wt%, Ni7wt%, Co10wt%, Ce0.6wt%, and the balance is Fe. Theoretical density: 8.215g / cm 3 ;Sintering temperature 810℃; Density of sintered body: >99%; Bending strength of sintered body: >1100MPa; Hardness of sintered body: HRC28-30.

Embodiment 2

[0039] The rare earth pre-alloyed powder described in this embodiment has the formula of basic constituent elements and their mass percentages: Cu38wt%, Sn7wt%, Ni5wt%, Co8wt%, Ce0.8wt%, and the balance is Fe. Theoretical density: 8.179g / cm 3 ;Sintering temperature 780℃; Density of sintered body: >99%; Bending strength of sintered body: 1060MPa; Hardness of sintered body: HRC27-30.

Embodiment 3

[0041] The rare earth pre-alloyed powder described in this embodiment, its basic constituent elements and its mass percentage formula are: 40wt% Cu, 6wt% Sn, 8wt% Ni, 1.2wt% Ce, 4wt% Si, 8wt% of Co and the balance of Fe. Theoretical density: 8.152g / cm 3 ;Sintering temperature 770℃; Density of sintered body: >99%; Bending strength of sintered body: 1120MPa; Hardness of sintered body: HRC32-35.

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com