Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about How to "Avoid volume shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

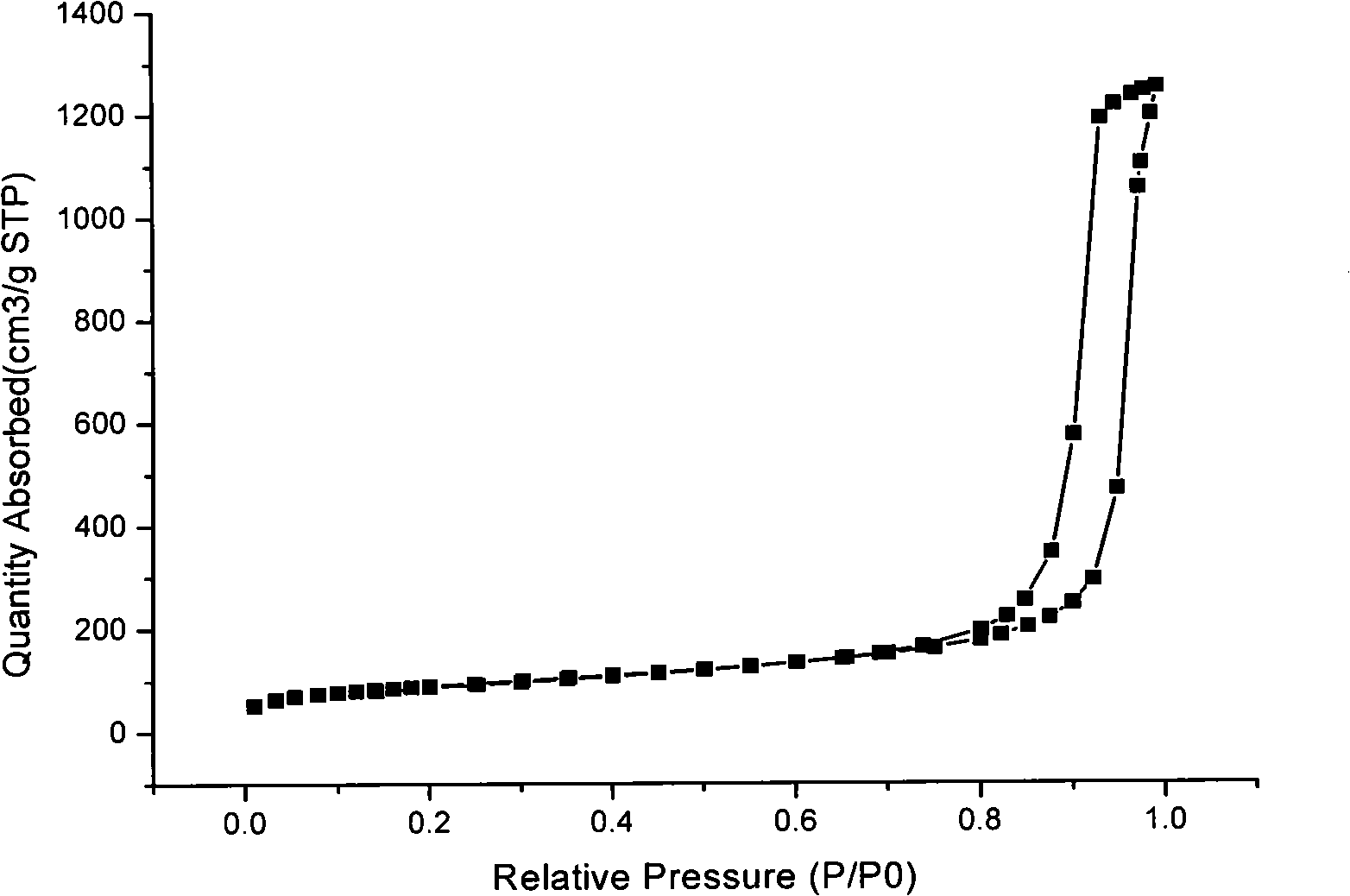

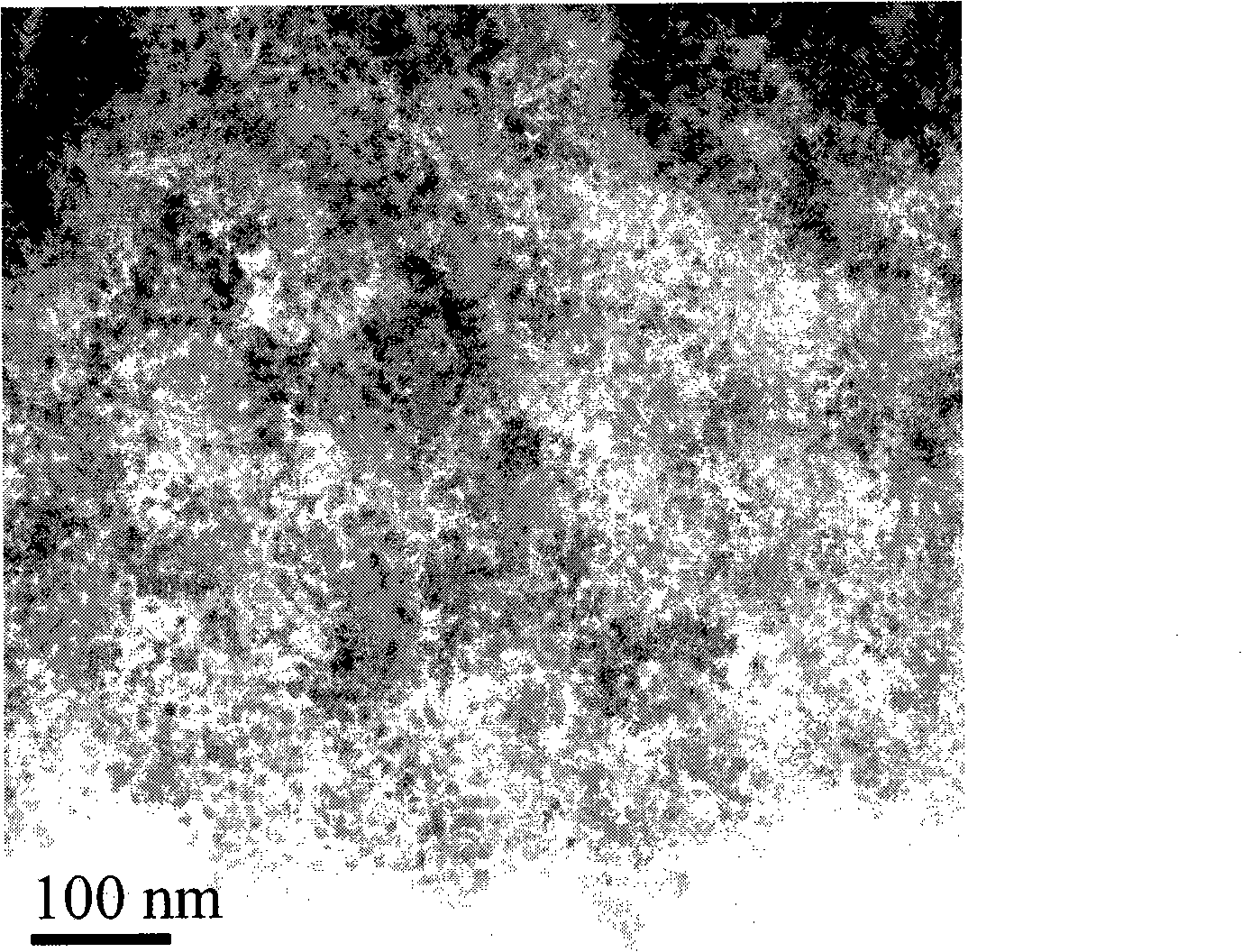

Preparation method of carbon-silicon compound aerogel

InactiveCN101288837APrevent collapseLarge specific surface areaMicroballoon preparationMicrocapsule preparationCarbonizationAlkaline catalyst

The invention relates to a preparation method for carbon-silicon composite aerogel with low density, high ratio surface area and high pore volume. The method takes silicone gel grains as a framework structure, takes resorcinol and formaldehyde as reactant and prepares the hydrogels by the sol-gel reaction under the catalysis of alkaline catalyst. After the hydrogels are dried, high-temperature carbonization is carried out on the hydrogels under the protection of inert gases, so as to gain the carbon-silicon composite aerogel. The carbon-silicon composite aerogel prepared by the method of the invention has the characteristics of high ratio surface area, large pore volume and low density.

Owner:EAST CHINA UNIV OF SCI & TECH

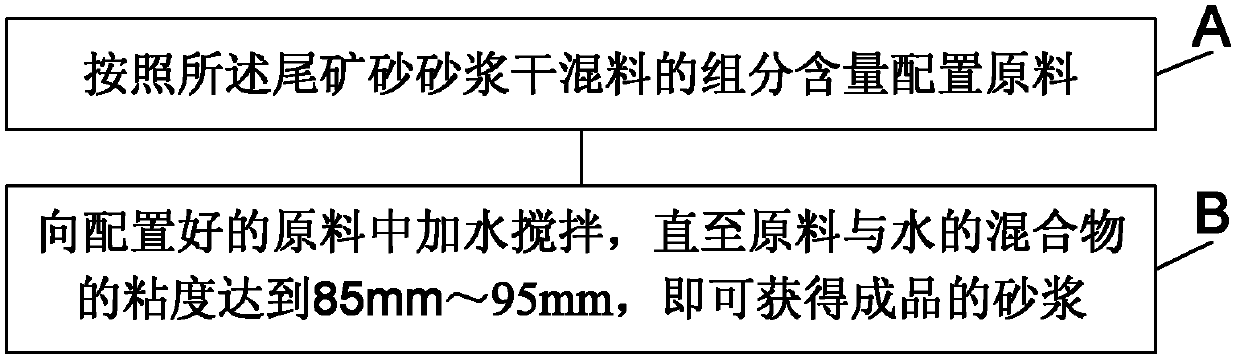

Tailing sand mortar dry blend and mortar preparation method thereby

InactiveCN102603248ARealize the rational application of resourcesImprove water retentionCellulosePortland cement

The invention discloses a tailing sand mortar dry blend and a mortar preparation method thereby. The tailing sand mortar dry blend comprises the following raw materials of common portland cement, sand, cellulose ether, naphthalene formaldehyde water reducer and re-dispersible latex powder, wherein the mass ratio of the common portland cement to the sand is 1:2-1:4; the mass of the cellulose ether accounts for 0.02-0.1% of the total mass of the common portland cement and the sand; the mass of the naphthalene formaldehyde water reducer accounts for 0.5-1.2% of total mass of the common portland cement and the sand; the mass of the re-dispersible latex powder is 0.05-0.4% of the total mass of the common portland cement and the sand; and the sand comprises 60-80wt% of tailing sand and the balance of natural sand. According to the embodiment of the tailing sand mortar dry blend, the use amount of the natural sand in the mortar is reduced, and the problem that the natural sand is in shortage is alleviated. In addition, the recycling reasonable application of the tailing sand is realized, and the preparation cost of the mortar is lowered.

Owner:北京建筑工程学院

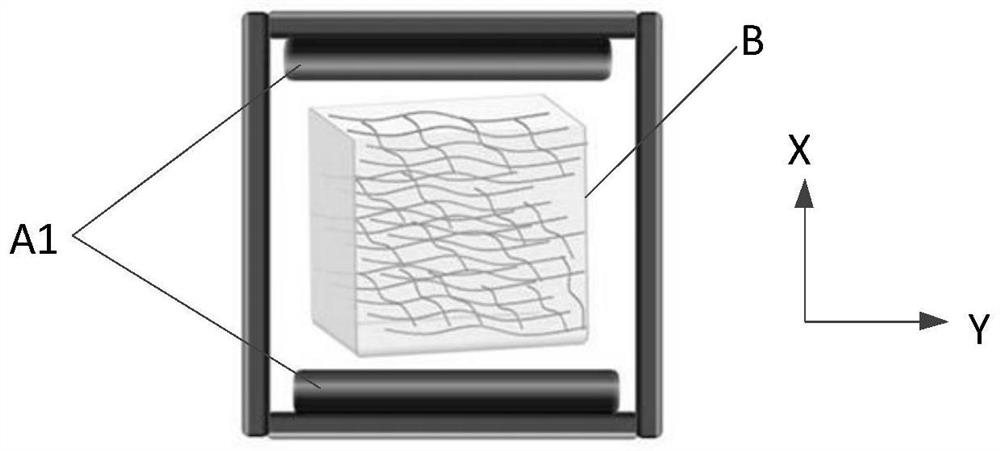

Method for enhancing density of SiC/SiC ceramic matrix composite

The invention relates to a method for enhancing density of a SiC / SiC ceramic matrix composite. The method comprises the following steps: (1) a SiC / SiC ceramic matrix composite with a certain densification degree is immersed in slurry, in which an organic precursor and SiC powder are uniformly dispersed, and impregnation is carried out in an environment of 5-10 KPa vacuum degree for 20-50 min; (2) a material which has undergone vacuum impregnation is dried and the dried material undergoes cross-linking and curing; (3) the cross-linked and cured material undergoes pyrolysis treatment; and (4) the material which has undergone pyrolysis treatment further undergoes densification process in the atmosphere of a gaseous precursor containing Si and C elements by a chemical vapor infiltration technology while infiltration temperature is 850-1100 DEG C, pressure intensity is 10-20 KPa and infiltration time is 4-30 h. The method provided by the invention has advantages of simple operation, short densification time, good repeatability and high densification efficiency and has obvious advantages in the aspect of filling material voids. The method is a method with operability and development prospect.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Negative pole lead paste for lead-carbon super storage battery and preparation method thereof

ActiveCN102074703ALarge specific surface areaImprove mixing dispersibilityLead-acid accumulator electrodesCarbon compositesElectricity

The invention relates to negative pole lead paste for a lead-carbon super storage battery. The lead paste is prepared by mixing solid raw materials consisting of 1 to 93 percent of lead powder and 2 to 95 percent of lead-carbon composite material by using a paste mixing machine via a dry-mixing method and a wet-mixing method. The lead-carbon composite material of the negative pole lead paste for the lead-carbon super storage battery is prepared by the electro-deposition method and contains 25 to 55 weight parts of lead. The negative pole lead paste can increase the porosity and the utilization rate of negative pole active substances, improve the contraction state of a negative polar plate and enhance the bonding force between the lead paste and the polar plate as well as between the lead powder and the active carbon with high specific area, functions like a negative pole lead paste super capacitor under the condition of high carbon-added quantity, and improves the comprehensive performance of the storage battery.

Owner:ZHUZHOU SMELTER GRP +1

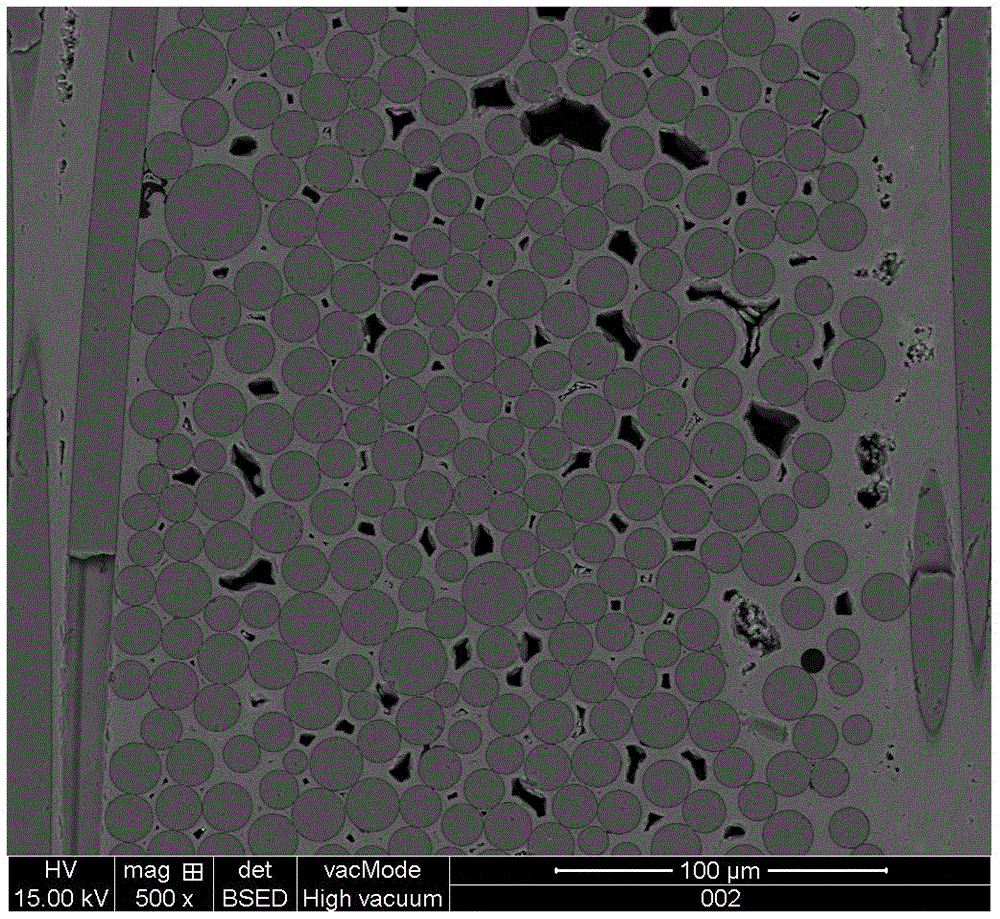

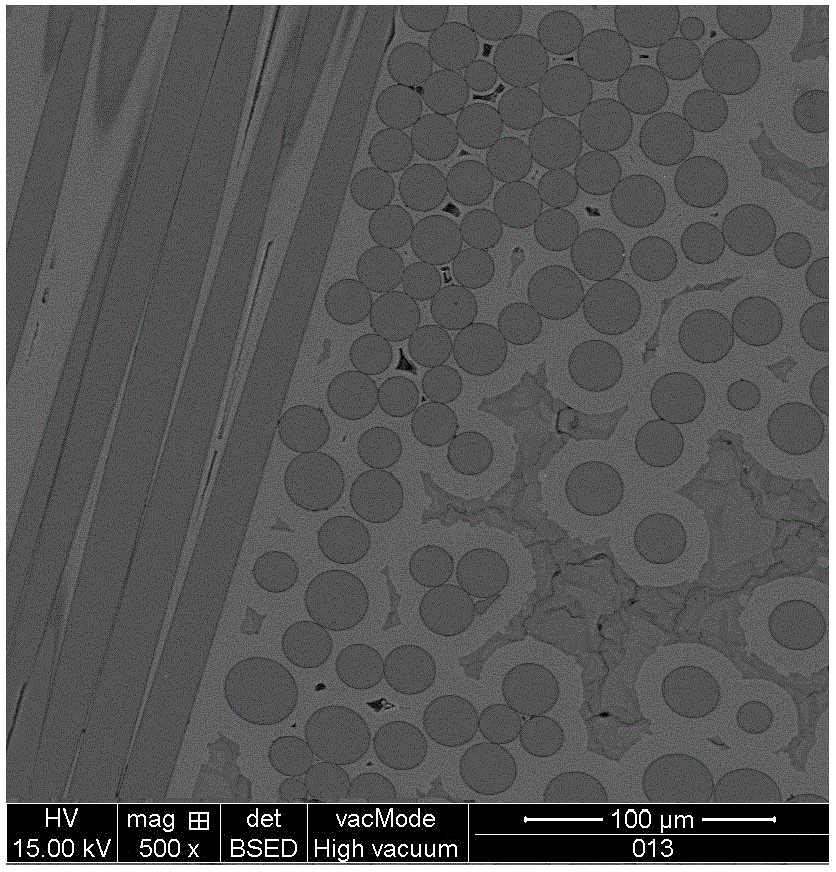

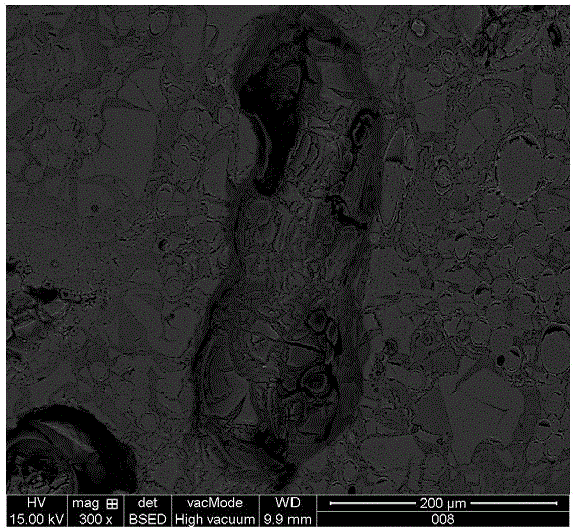

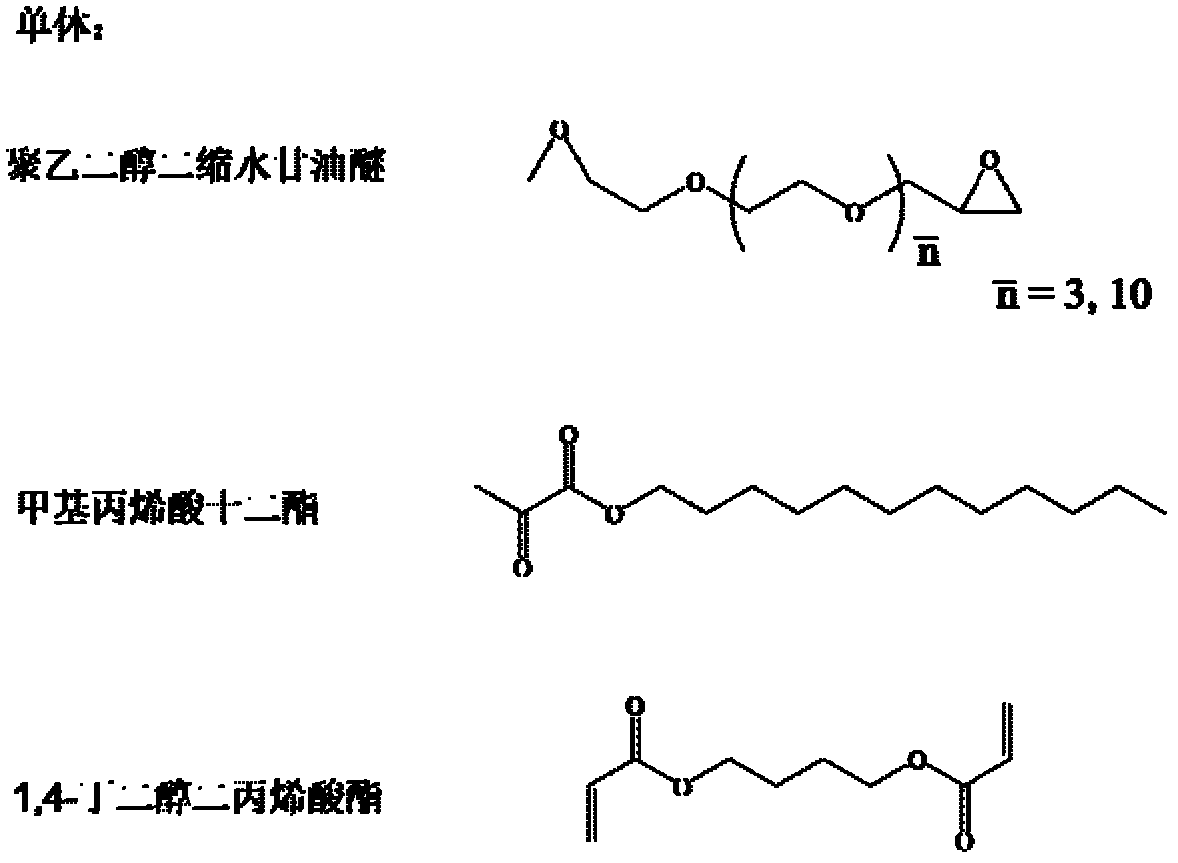

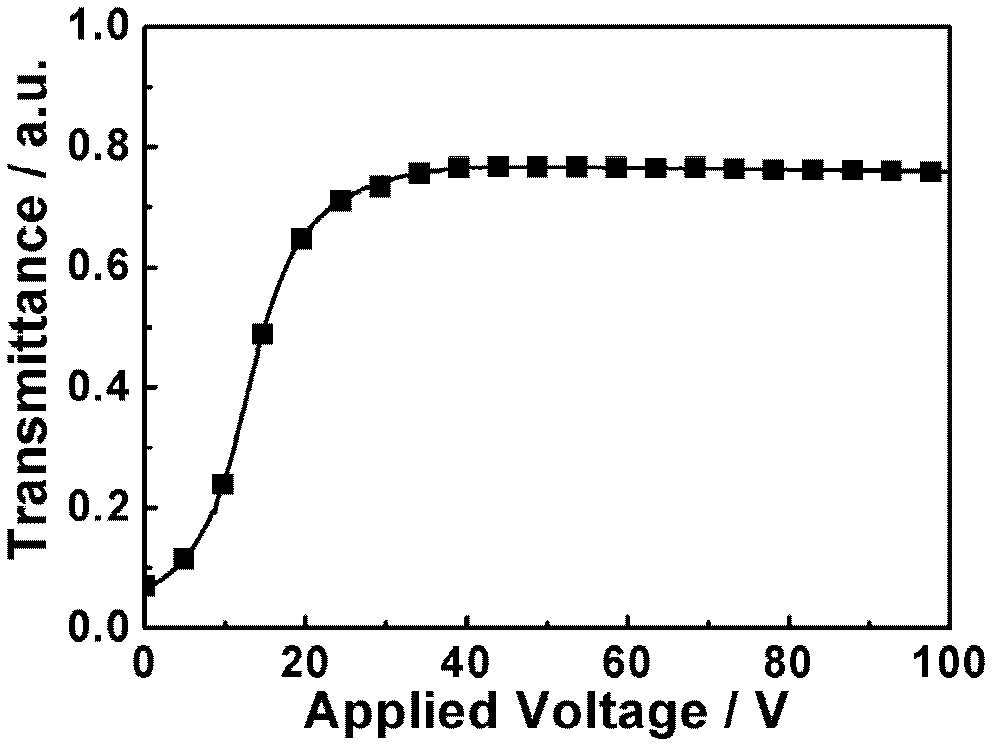

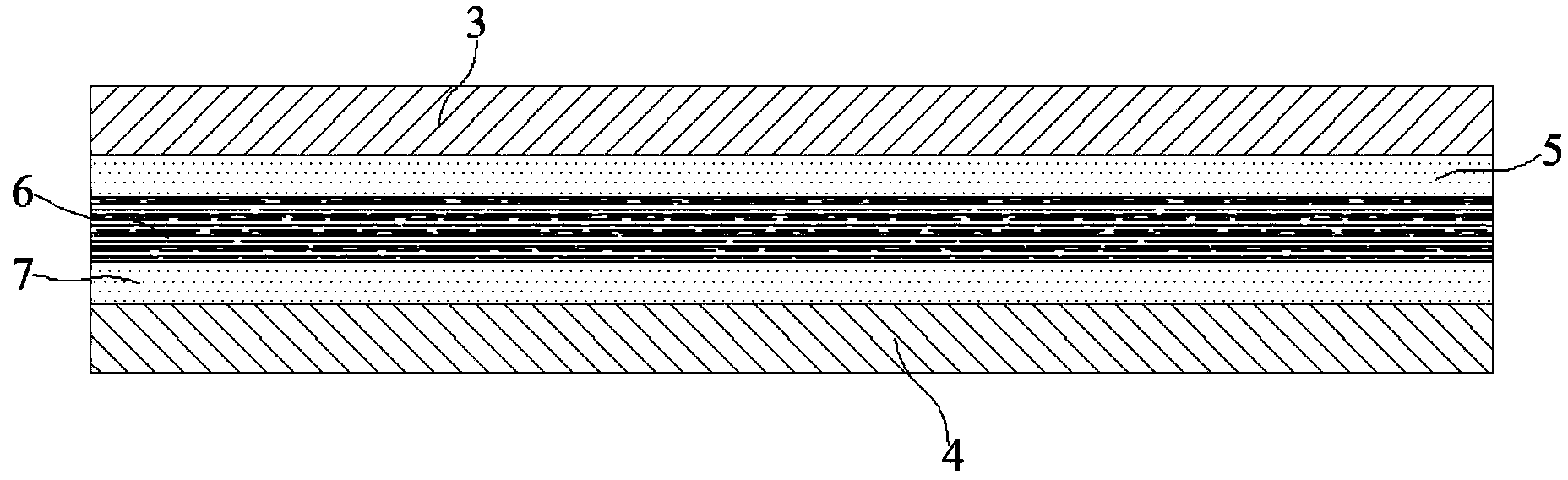

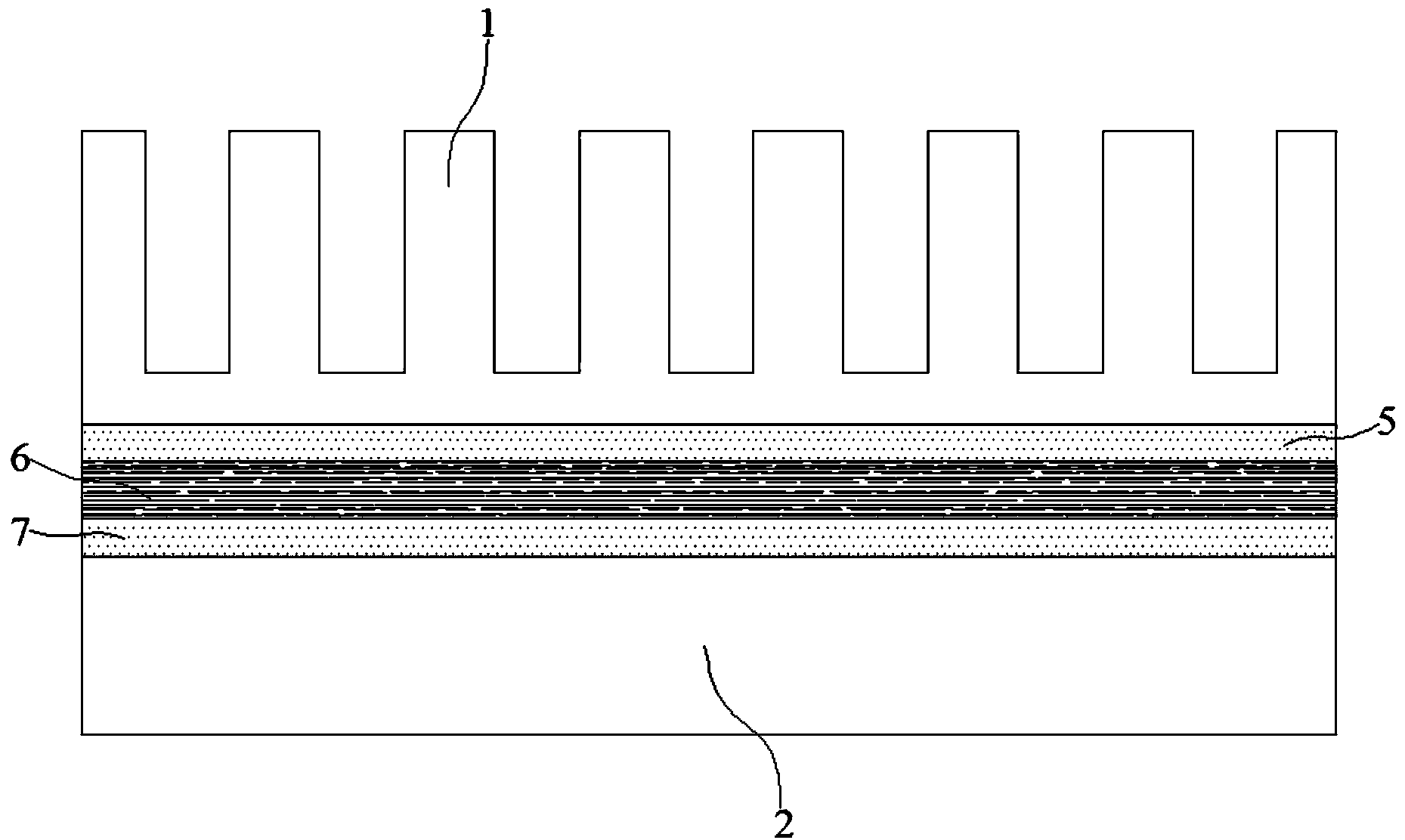

Preparation method of polymer mixed network-based polymer dispersed liquid crystal (PDLC) film material

The invention belongs to the technical field of liquid crystal application and especially relates to a preparation method of a polymer mixed network-based polymer dispersed liquid crystal (PDLC) film material. The preparation method of the polymer mixed network-based PDLC film material is characterized in that one or more ultraviolet light polymerisable epoxy monomers, an ultraviolet light polymerisable acrylate (or methacrylate) monomer, nematic liquid crystals, a cationic photoinitiator, a free radical photoinitiator and glass beads are uniformly mixed according to a certain mass ratio; the mixture is coated between two transparent indium tin oxid (ITO) conductive plastic films and then is pressed into films having different thickness values; and the films are irradiated by ultraviolet lights having wavelength of 365nm to be cured into the polymer mixed network-based PDLC film material. The polymer mixed network-based PDLC film material obtained by the preparation method has the advantages belonging to an acrylate or methacrylate network-based PDLC film and an epoxy resin network-based PDLC film. The preparation method improves the cohesion between a polymer network and an ITO plastic film interface, and improves the stability of the polymer mixed network-based PDLC film material.

Owner:UNIV OF SCI & TECH BEIJING

Denitrification and VOC removing catalyst

ActiveCN106238067ALarge specific surface areaHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationInterference resistanceActive component

The invention relates to a denitrification and VOC removing catalyst, and belongs to the field of environmental protection catalysts. According to the present invention, the Mo-V-W / TiO2-Al2O3 system is formed among various components of the catalyst, such that the functions of denitrification and VOC removing can be concurrently achieved under the effect of the active components such as Mo, V and W and the carrier TiO2-Al2O3, the structure of the tail gas filtration discharging equipment can be effectively simplified, and the environmental protection cost can be reduced; and the denitrification and VOC removing catalyst has the high dust interference resistance, and can provide the maximum filtration performance on the basis of no requirement of the frequent stopping-dust cleaning, such that the catalyst has advantages of uniform aging speed, strong filtration ability, and long service life.

Owner:山东海润环保科技有限公司

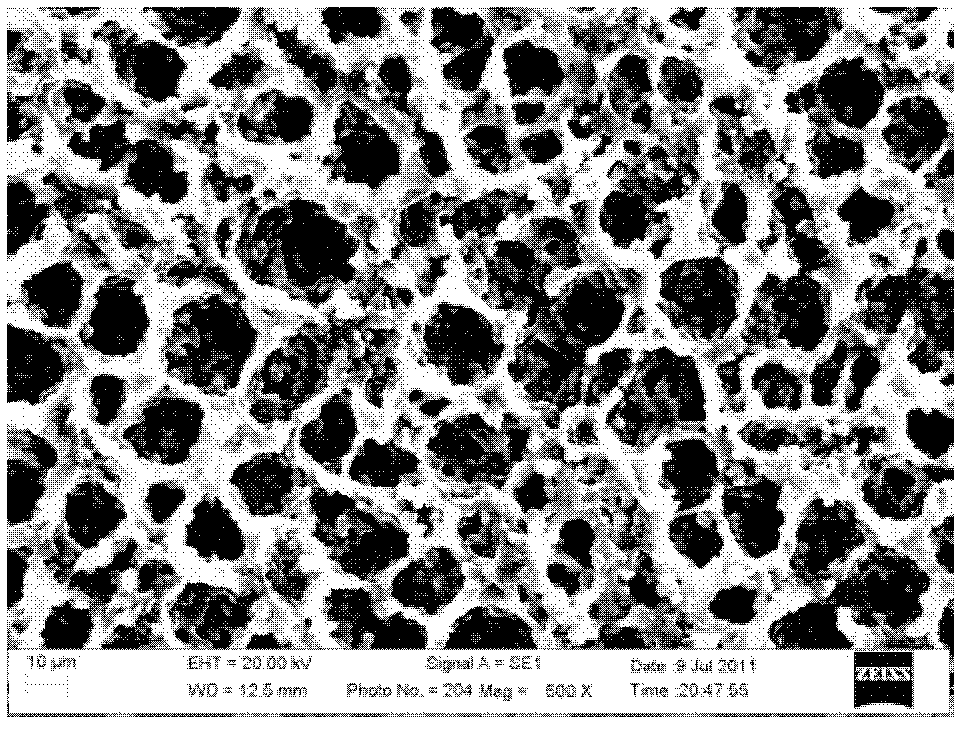

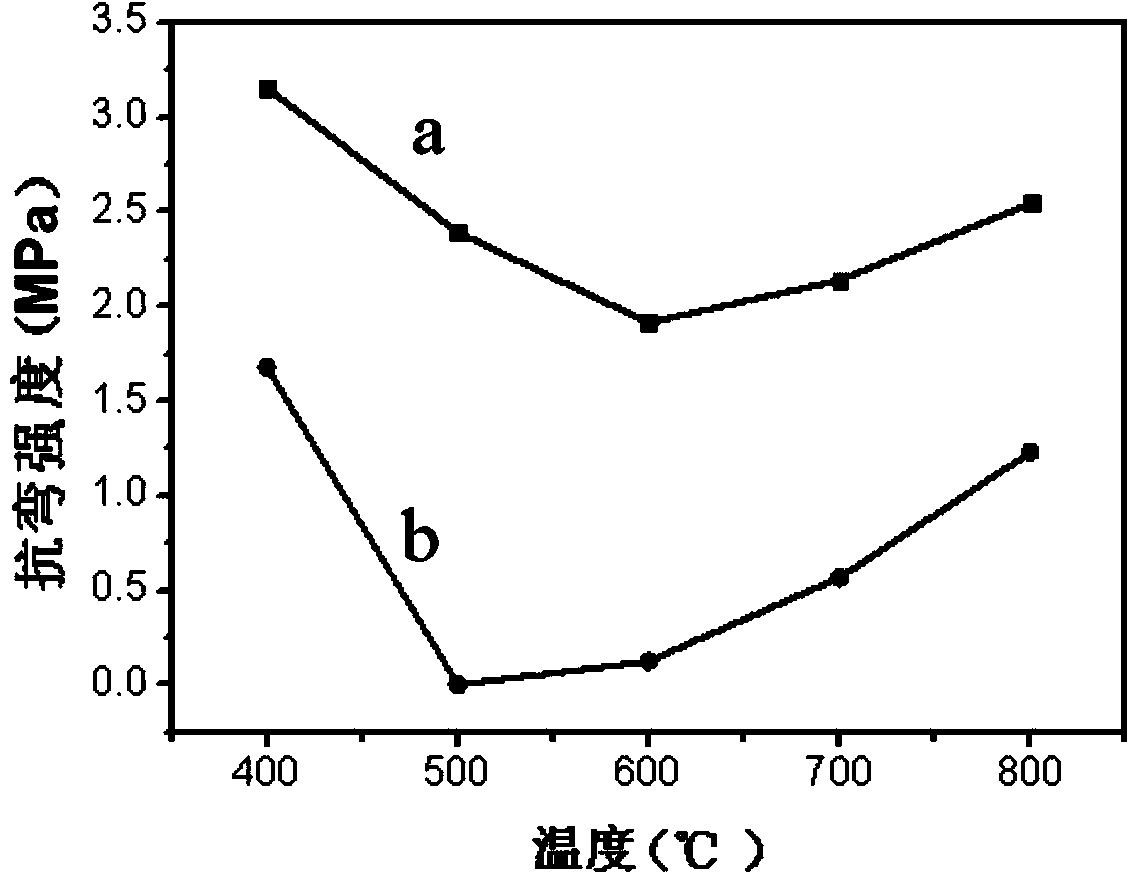

Method for controlling medium-temperature strength of gel-cast ceramic parts

The invention discloses a method for controlling the medium-temperature strength of gel-cast ceramic parts. The method comprises the steps of firstly, adding organic monomers, a cross-linking agent and a dispersant sodium polyacrylate into diluted silica sol, so as to obtain a premix, then, adding polysiloxane, ceramic powder and polyimide, and carrying out ball milling, so as to obtain ceramic slurry, carrying out in-situ curing, then, carrying out freeze drying, and carrying out degreased pre-sintering, impregnation aftertreatment and final-sintering, thereby obtaining the ceramic parts. According to the method, polyimide has adhesion property due to the high-temperature resistance of polyimide, a reticular structure is formed due to the low-temperature cross-linking of polysiloxane, a role in adhering ceramic granules is played, after freeze drying, silica sol is dehydrated, so as to form a silicon-oxygen bond three-dimensional reticular structure, and the medium-temperature strength of ceramic blanks at a degreasing stage can be remarkably improved due to the synergism of polyimide, polysiloxane and silica sol; the method can be applied to the preparation of the gel-cast ceramic parts, and the medium-temperature strength of the ceramic blanks at the degreasing stage is effectively controlled, so that the integrity of the ceramic parts can be guaranteed.

Owner:XI AN JIAOTONG UNIV

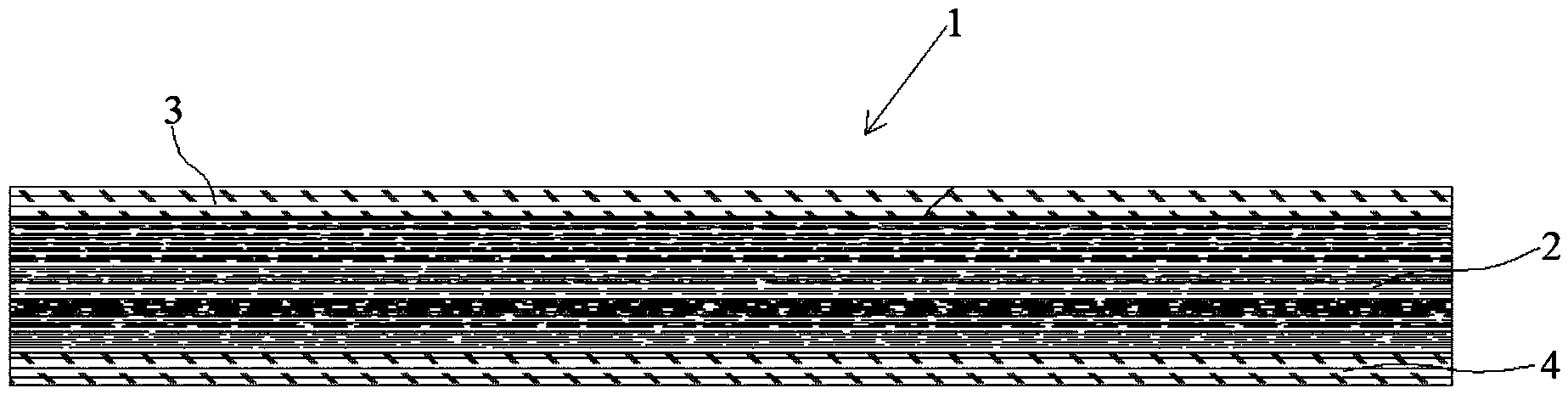

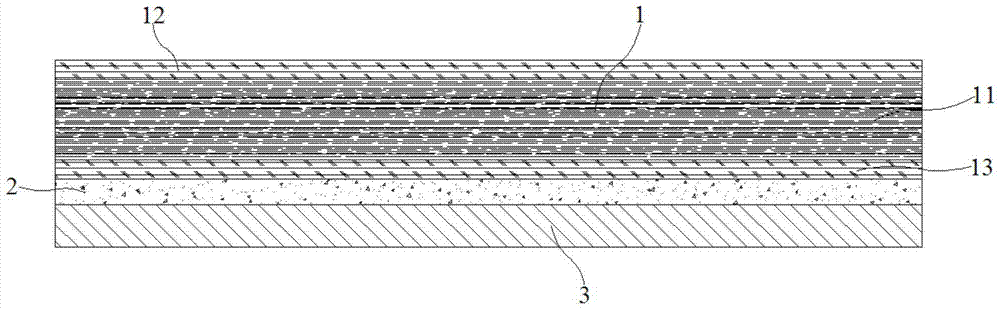

Heat conduction graphite sheet and manufacturing method thereof

ActiveCN103770415AImprove thermal conductivityAvoid local overheatingCarbon compoundsFilm/foil adhesivesDimethyl formamidePolyimide

The invention discloses a heat conduction graphite sheet and a manufacturing method thereof. The heat conduction graphite sheet consists of a polyimide film, a first coating layer and a second coating layer, wherein the first coating layer and the second coating layer are positioned on the upper and lower surfaces of the polyimide film respectively and are formed by sintering graphite modifiers respectively; each graphite modifier consists of the following components in parts by weight: 20-25 parts of benzophenonetetracarboxylic dianhydride, 14-16 parts of benzenetetracarboxylic anhydride, 22-26 parts of diaminodiphenylmethane, 20-25 parts of dimethyl formamide, 8-10 parts of N-methyl pyrrolidinone, 1.8-2.5 parts of ethylene glycol and 2.5-3 parts of polydimethylsiloxane. The heat conduction performance of the heat conduction graphite sheet is improved in the vertical direction and the horizontal direction, local overheating is avoided, the uniformity of the heat conduction performance is realized, and meanwhile, the stability and reliability of the heat dissipation performance of a product are improved; the cost of the product is greatly reduced.

Owner:斯迪克新型材料(江苏)有限公司

Honeycomb type SCR denitration catalyst and preparation method thereof

ActiveCN104971780AHigh cost of solutionLow costOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationMolecular sievePtru catalyst

The present invention relates to a honeycomb type SCR denitration catalyst and a preparation method thereof, and belongs to the field of denitration catalysts. According to the present invention, diatomite and a molecular sieve are used to replace a large number of titanium dioxide as the carrier, such that the high cost problem of the existing catalyst is easily solved, and advantages of good chemical stability, good thermal stability, high activity, low cost, high anti-poisoning property, long service life and the like are provided; the rare earth oxide is added, such that the heat resistance of the catalyst can be improved, and the double effect of lattice structure stabilizing and volume shrinkage preventing can be provided; polyferrocene is the polymer reducing agent so as to easily improve the denitration rate of the denitration catalyst, wherein the denitration efficiency achieves more than or equal to 91%; and the honeycomb type SCR denitration catalyst preparation method has characteristics of simpleness, easy performing, and high production efficiency.

Owner:山东海润环保科技有限公司

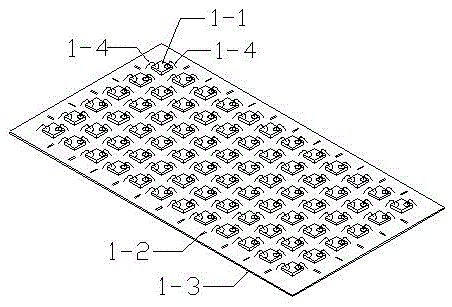

A kind of LED molding sealing device and sealing method thereof

InactiveCN104210064BEasy to implementReduce manufacturing costCoatingsSemiconductor devicesThermodynamicsAdhesive glue

The invention discloses an LED molding sealing device and a sealing method thereof. The device comprises an upper mold, a lower mold and a glue channel partition structure. The upper part of the upper mold is provided with a glue injection port, the upper part of the lower mold is provided with a cavity, and the glue injection port The cavity is connected to the mold cavity through the glue channel set on the lower part of the upper mold and the upper part of the lower mold. The upper mold and the lower mold are locked by the locking parts. It also includes the glue channel partition structure set in the glue channel. The glue channel partition structure is shifted to connect the rubber channel. When the glue injection is completed, the glue thrust disappears, and the glue channel partition structure is reset to automatically isolate the glue channel. The present invention is applicable to the LED sealing field. The present invention not only has a simple structure and is convenient to use, but also can well maintain the pressure of the glue in the mold cavity when the sealing is completed, avoiding volume shrinkage during the heat curing process of the sealing glue, and ensuring the sealing effect. The colloid of the finished product is complete, increasing the yield of the molded product.

Owner:GUANGDONG VTRON TECH CO LTD

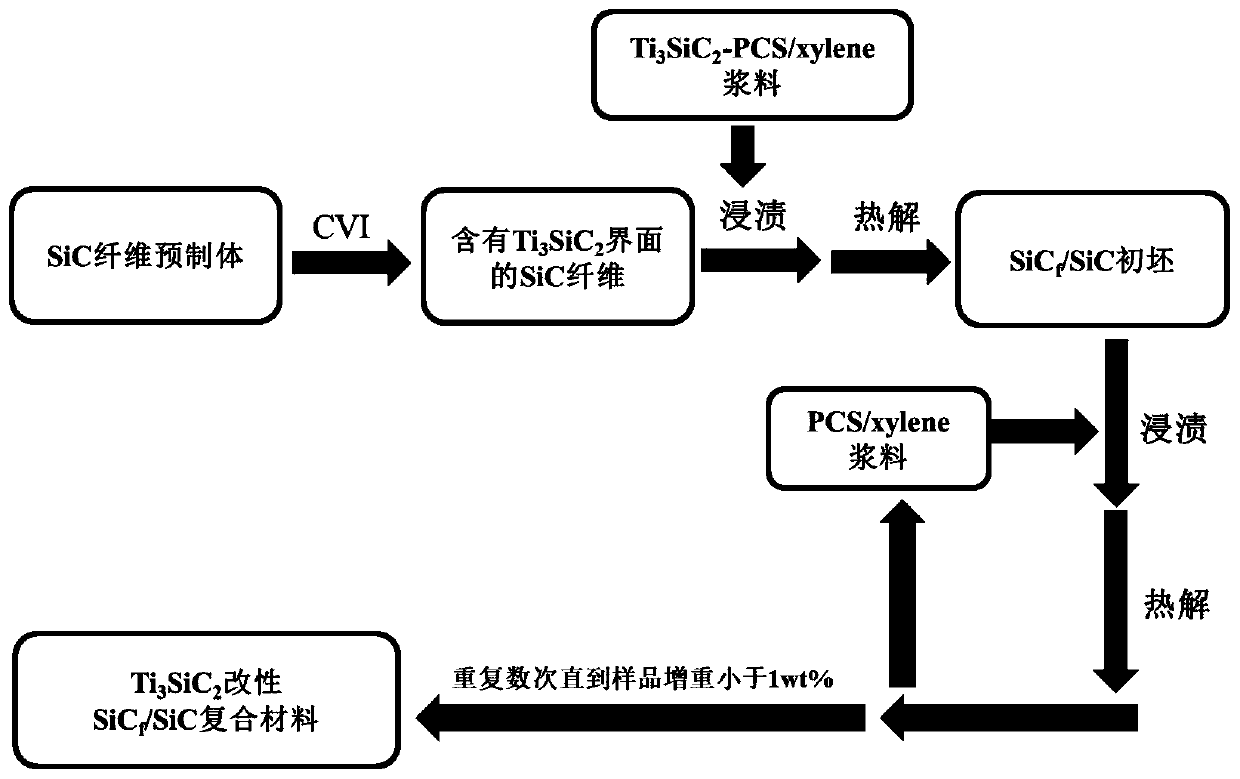

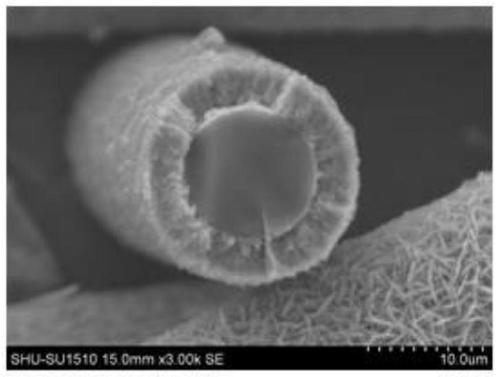

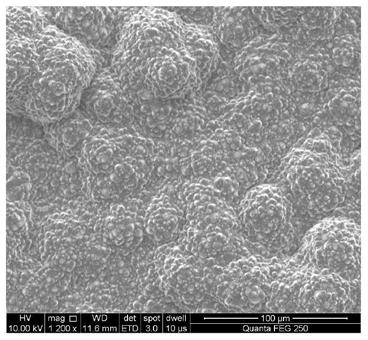

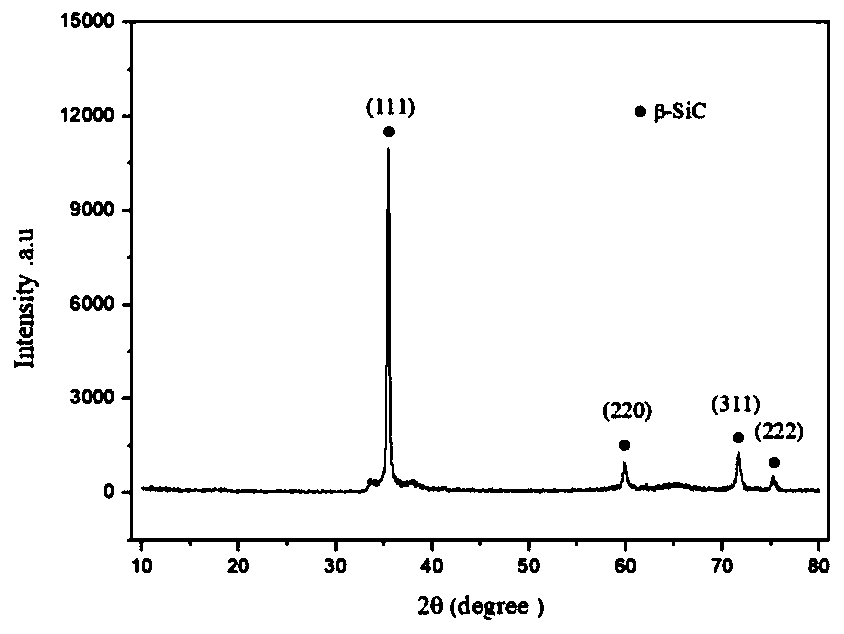

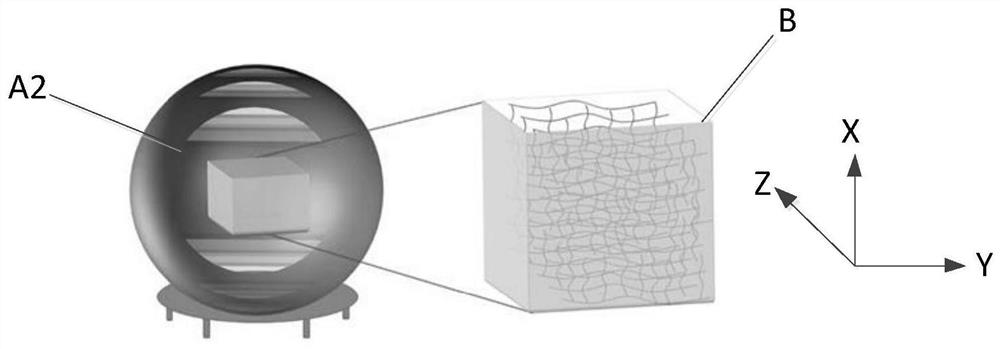

Titanium-silicon-carbon interface modified SiCf/SiC wave-absorbing composite material and preparation method thereof

ActiveCN111592371AReduce particle agglomerationReduce clumpingMagnetic/electric field screeningCarbide siliconSic fiber

The invention discloses a titanium-silicon-carbon interface modified SiCf / SiC wave-absorbing composite material and a preparation method thereof. The preparation method comprises the steps: putting asilicon carbide fiber prefabricated body in a constant-temperature area of a CVD furnace, and depositing a titanium-silicon-carbon interface layer on the surface of silicon carbide fibers through a chemical vapor infiltration method within a proper temperature range; and soaking in slurry containing polycarbosilane and titanium silicon carbon to be impregnated; and preparing the ceramic matrix composite material through a precursor impregnation pyrolysis method (PIP). The SiCf / SiC composite material containing the Ti3SiC2 interface is prepared, the process is simple, the cost is low, the dielectric constant of the wave-absorbing composite material is effectively regulated and controlled, and a good wave-absorbing effect is achieved.

Owner:SHANGHAI UNIV +1

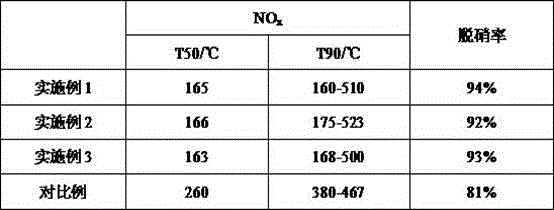

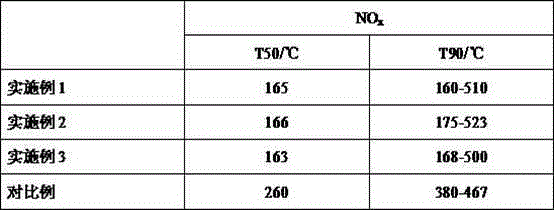

Rare-earth modified SCR denitrification catalyst and preparation method therefor

ActiveCN104998684ALarge specific surface areaHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationPtru catalystAluminium oxides

The invention relates to a rare-earth modified SCR denitrification catalyst and a preparation method therefor, and belongs to the field of denitrification catalysts. The rare-earth modified SCR denitrification catalyst takes aluminum oxide and nano titanium dioxide as carriers and takes rare-earth oxide and cross-linked chitosan resin as active centers; and the prepared catalyst is low in price, good in chemical and thermal stability, relatively high in activity, high in anti-poisoning performance and long in service life. The preparation method for the rare-earth modified low-temperature SCR denitrification catalyst is simple, feasible and high in production efficiency; and raw materials are easily available.

Owner:北京晨晰环保工程有限公司

Heat conduction graphite patch for microelectronic device

ActiveCN103763892AImprove biaxial tensile propertiesAvoid local overheatingLamination ancillary operationsSynthetic resin layered productsAdhesiveCarbonization

The invention discloses a heat conduction graphite patch for a microelectronic device. The heat conduction graphite patch comprises a first heat conduction adhesive layer, a graphite layer and a second heat conduction adhesive layer, the graphite layer is obtained through the following technique, and the technique comprises the following steps that the upper surface and the lower surface of a polyimide film after the first step are coated with graphite modifiers to obtain the processed polyimide film; the processed polyimide film is heated to 800 DEG C, heat preservation is carried out, and then the film is heated to 1200 DEG C to obtain a pre-burned carbonization film; a calender is adopted to calender the pre-burned carbonization film in the fourth step; the carbonization film is heated to 2400 DEG C, heat preservation is carried out, then the film is heated to 2900 DEG C, and therefore a mainly-burnt graphite film is obtained; the mainly-burnt graphite film obtained in the fifth step is calendered to obtain the graphite layer. The method avoids local overheating of adhesive tape, uniformity of heat conduction performance of the adhesive tape is achieved, the stability and reliability of heat dissipation performance of the patch are improved, and the cost of the patch is greatly reduced.

Owner:斯迪克新型材料(江苏)有限公司

Pouring sealant for filling gap between warhead charge and shell

InactiveCN103205229AEasy pottingAvoid volume shrinkageNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesHydroxyl-terminated polybutadieneChemistry

The invention discloses a pouring sealant for filling a gap between a charge and a shell of a warhead. The pouring sealant comprises hydroxyl-terminated polybutadiene, a curing agent, a plasticizer and a curing catalyst, wherein mol ratio of R=[NCO] in the curing agent to [OH] in the hydroxyl-terminated polybutadiene is 0.8-1.2, content of the plasticizer is 0-1.5 times that of the hydroxyl-terminated polybutadiene, and the content of the curing catalyst is 0-0.01wt% that of the hydroxyl-terminated polybutadiene. The pouring sealant disclosed by the invention can be used for effectively solving the problem of an inherent gap between the charge and the shell of the warhead of the conventional weapon, so that use safety performance of the warhead and penetration stability to a target are greatly improved; and by adopting the pouring sealant disclosed by the invention, fabricated charging can be carried out without prefabricating a grain, so that the warheads in various sizes and shapes are directly poured and moulded, the mass production capability is greatly improved and the charging process cost is greatly reduced.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

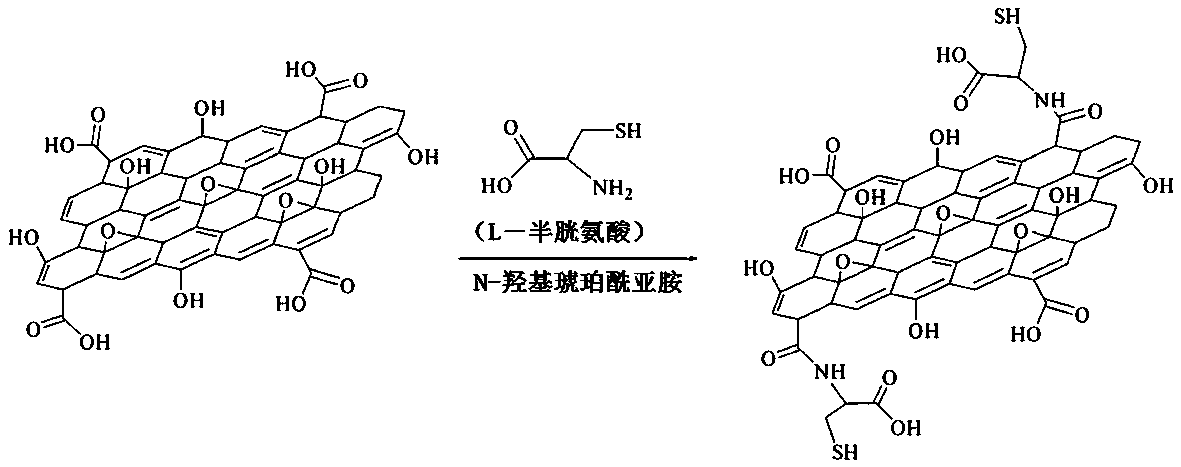

Modified graphene oxide concrete crack repairing material and preparation method thereof

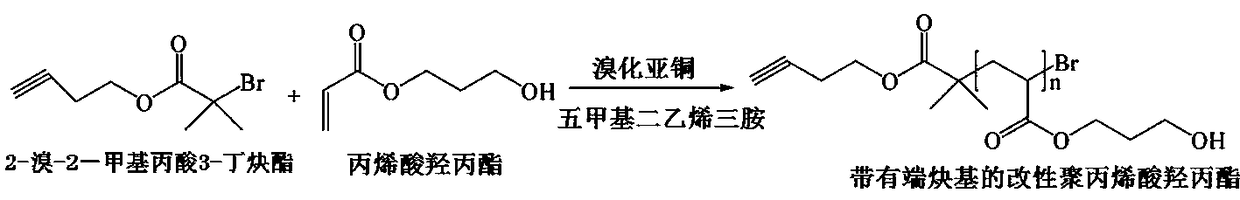

The invention relates to a modified graphene oxide concrete crack repairing material and a preparation method thereof. According to the invention, a sulfydryl-terminated modified graphene oxide dispersion and alkynyl-terminated poly(hydroxypropyl acrylate) are firstly prepared; a large-sized monolithic graphene oxide dispersion is obtained through a clicking reaction of a sulfydryl group and an alkynyl group; and a concrete crack repairing material is prepared by mixing the large-sized monolithic graphene oxide dispersion with concrete components. According to the invention, the uniform large-sized monolithic graphene oxide dispersion is doped into the concrete crack repairing material to promote formation of a regular and uniform hydration product which is aggregated to form an intertwined and cross-linked compact structure, so the best repairing effect to concrete cracks is achieved; meanwhile, a functional waterborne polymer is introduced, so product performances are optimized; andthe modified graphene oxide concrete crack repairing material provided by the invention has the advantages of low cost, simple generation and repairing processes, good social benefits and economic benefits, and practicality.

Owner:SHAANXI UNIV OF SCI & TECH

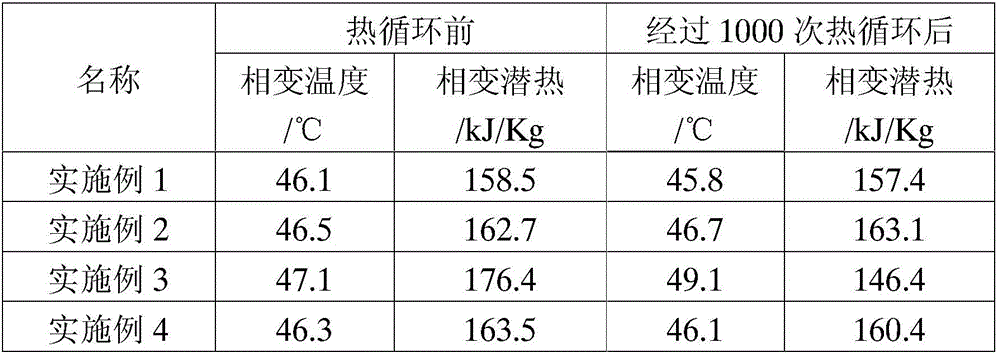

Composite phase change energy storage material containing ionic liquid and preparation method thereof

InactiveCN105754556AOvercome stabilityOvercome phase separationHeat-exchange elementsMass ratioPhosphate

The invention discloses a composite phase change energy storage material containing ionic liquid and a preparation method thereof and belongs to the technical field of phase change energy storage materials.The composite phase change material is formed by compounding a phase change energy storage material and a supporting material.The phase change energy storage material is formed by mixing one or two of 1-methyl imidazole dihydric phosphate and the propylamine formate ionic liquid and one or two of formate diethanolisopropanolamine, twain-80, polyethylene glycol 400 and fatty alcohol-polyoxyethylene ether WA, wherein the mass ratio of the ionic liquid is 90-95%.The supporting material is expanded graphite.The mass ratio of the phase change energy storage material to the expanded graphite is (6-10):1, and the phase change energy storage material is evenly adsorbed in holes of the expanded graphite.According to the composite phase change energy storage material containing the ionic liquid, the phase change temperature is about 46+ / -2.0 DEG C, the phase change latent heat is large (150-180 KJ / Kg), the volume slightly expands, the preparation method is simple, cost is low, no volatility exists, emissions of waste water, waste gas and waste residues are avoided, and large-scale application and popularization are promoted.

Owner:MAANSHAN NBWAVE HEAT ENERGY SCI

Preparation method of high-performance bamboo steel composite material

InactiveCN112356196ARemove completelyRetain natural colorWood compressionWood treatment detailsEpoxyFreeze-drying

The invention discloses a preparation method of a novel bamboo steel composite material, and belongs to the technical field of bamboo artificial boards and bamboo engineering materials. The method comprises the following steps: (1) removing lignin and hemicellulose in the bamboo wood by a two-step method, (2) breaking through a pore structure in the bamboo wood by using a freeze-drying process, (3) carrying out vacuum impregnation epoxy resin treatment on an obtained bamboo wood framework, and (4) carrying out hot-pressing curing to realize densification of the bamboo wood, thereby obtaining the bamboo-steel composite material with high fiber content. The bamboo steel material provided by the invention has the advantages of high bamboo utilization rate, excellent mechanical properties, high dimensional stability, low thermal conductivity and the like, and is expected to be applied to the fields of energy-saving buildings, bridges, transportation, aerospace and the like.

Owner:CHONGQING UNIV

Heat conduction graphite paster for adhesive tape and preparing method of heat conduction graphite paster

ActiveCN103796493AAvoid local overheatingAchieve uniformityLamination ancillary operationsSynthetic resin layered productsAdhesiveDimethyl siloxane

The invention discloses a heat conduction graphite paster for adhesive tape and a preparing method of the heat conduction graphite paster. The surface of the heat conduction graphite paster is coated with a heat conduction adhesive layer, the heat conduction graphite paster is composed of a polyimide film, a first coating layer and a second coating layer, and the first coating layer and the second coating layer are located on the upper surface and the lower surface of the polyimide film respectively. The first coating layer and the second coating layer respectively comprise, by weight, 20-25 parts of benzophenone tetracid dianhydride, 12-18 parts of pyromellitic acid dianhydride, 20-28 parts of diaminodiphenylmethane, 20-25 parts of dimethyl formamide, 8-10 parts of N-methyl pyrrolidone, 1.5-2.5 parts of ethylene glycol, 2-3 parts of dimethyl silicone polymer and 0.8-1.5 parts of phthalic acid dibutyl ester. According to the heat conduction graphite paster, local overheating is avoided, the evenness of the heat conduction performance is achieved, the stability and reliability of the heat dissipation performance of the heat conduction graphite paster are improved, and the cost of the heat conduction graphite paster is reduced.

Owner:JIANGSU SIDIKE NEW MATERIALS SCI & TECH CO LTD

Mesoporous nano-crystal tungsten trioxide electrochromic energy-storing film and preparation method thereof

The invention discloses a mesoporous nano-crystal tungsten trioxide electrochromic energy-storing film and a preparation method thereof. The method comprises the following steps: dissolving tungsten hexachloride and F127 into absolute ethanol, stirring and ageing to form a dip-coating solution; vertically inserting a conductive substrate into the dip-coating solution, and lifting at constant speeduntil the substrate completely departs from the solution to obtain a conductive substrate covered with a sol film; transferring the sol film to a drying oven to dry to form a gel film; performing high-temperature heat treatment on the gel film and removing a template agent F127 to obtain the mesoporous nano-crystal tungsten trioxide electrochromic energy-storing film. The film prepared by the preparation method has excellent electrochromic property and energy storage property and high cycling stability, can realize large-area preparation and can realize industrialized production easily.

Owner:ZHEJIANG UNIV

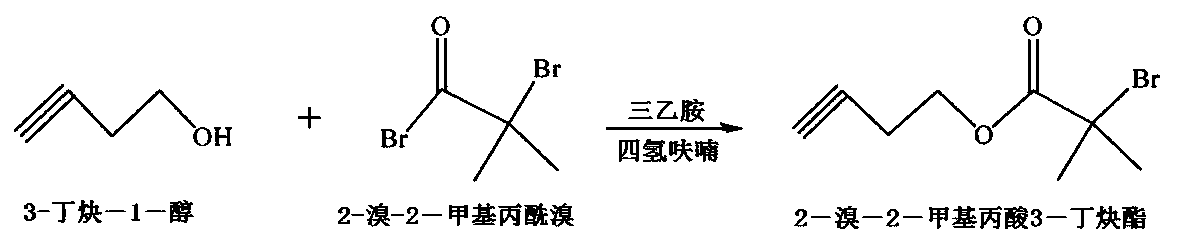

UV-PU dual-curing 3D printing resin and preparation method and application thereof

ActiveCN109320666AImprove shrinkageImprove mechanical propertiesAdditive manufacturing apparatusPolyureas/polyurethane adhesivesPolymer scienceUltraviolet

The invention provides a preparation method of ultraviolet-polyurethane (UV-PU) dual-curing rein for 3D printing. The dual-curing resin contains pre-polymers with the structural formula as shown in the formula 1, the formula 2, the formula 3 and the formula 4, wherein R1 represents methyl or hydrogen, R2 and R3 represent alkylene, cycloalkylene and arylidene, R2 and R3 can be the same or different, and R4 is arylidene, alkylene and cycloalkylene. (The formulas are shown in the description). A low-viscosity polyurethane curing agent added into a UV-PU dual-curing system is equivalent to a diluent in the 3D printing process, and serves as a curing agent in the post-curing process, the polyurethane curing agent reacts with hydroxy in the low polymer for further curing, the connection strengthamong the layers of a printout is improved, and meanwhile, the mechanical performance and the thermal stability of the printout are enhanced. The dual-curing 3D printing resin has the advantages of high tensile strength, high breaking elongation, low shrinkage rate and low viscosity.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Functional admixture for improving durability of concrete and cement products and preparation method of functional admixture

InactiveCN104310833AAvoid volume shrinkageReduce manufacturing costSolid waste managementFreeze thawingPortland cement

The invention relates to functional admixture for improving durability of concrete and cement products. The admixture is prepared by mixing a certain number of volume expansion carbonatite powder with alkali-aggregate reaction and an activator, namely grinding the volume expansion carbonatite powder with alkali-aggregate reaction into cement fineness, uniformly stirring with alkali-containing salt, and doping according to the mass of portland cement when the concrete and cement products are prepared. Tests prove that the functional admixture has the effects of reducing volume shrinkage of the concrete and cement products, reducing production cost of the concrete and cement products, effectively improving the compact degree and volume stability of the concrete and cement products, remarkably improving the durable performance of the concrete and cement products, improving the freeze thawing resistance, permeation resistance, carbonization resistance and other durable performances of the concrete and cement products, and prolonging the service lives of the concrete and cement products.

Owner:JILIN JIANZHU UNIVERSITY

Method for preparing ceramic coating by precursor conversion method

The invention relates to a method for preparing a ceramic coating by a precursor conversion method. In the invention, an ultraviolet-curable organic silicon polymer is used as a ceramic precursor, and a slurry is prepared by adding a certain amount of solid BaO·Al2O3·SiO2 powder Brush on the surface of the composite material, and obtain a dense and uniform ceramic coating after UV curing and high temperature treatment. The invention effectively solves the problem of cracking cracks in the ceramic coating prepared by the traditional precursor conversion method, and has the characteristics of short preparation period, simple process and good repeatability. It has been verified that the coating system prepared by the invention can effectively improve the oxidation resistance of the composite material.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

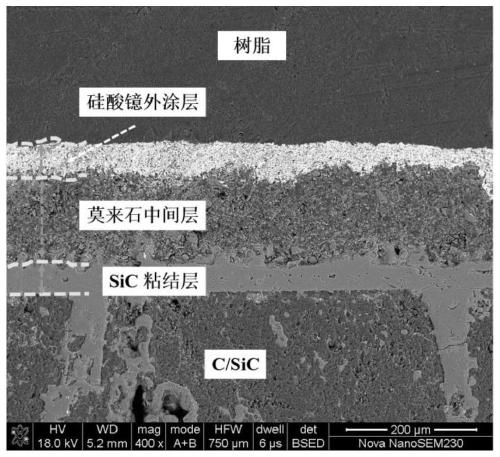

Environmental barrier coating as well as preparation method and application thereof

The invention provides an environmental barrier coating. The environmental barrier coating is composed of a SiC bonding layer, a mullite middle layer and an ytterbium silicate outer coating, which coat a C / SiC composite material and are sequentially arranged from inside to outside. The C / SiC composite material coated by a SiC coating is prepared by a secondary chemical vapor deposition (CVD) method; the mullite middle layer is prepared by combining a sol-gel method with an air spraying technology, and the ytterbium silicate outer coating is prepared by combining a solid phase sintering technology with an air spraying technology. Through a smart EBC coating system and a preparation process, the ytterbium silicate outer coating is prepared by combining a solid phase sintering technology withan air spraying technology for the first time, the mullite middle layer and the ytterbium silicate outer coating are tightly combined, and the coating is compact and free of cracks. The traditional sol-gel process is improved to a great extent, the defects of cracking, peeling and poor binding force in the sintering process of a coating prepared through a traditional sol-gel method are maximallyovercome, and the use requirements of large components and special-shaped parts can be met.

Owner:CENT SOUTH UNIV

Manufacturing process of heat-conductive film used for cell phones

The invention discloses a manufacturing process of a heat-conductive film used for cell phones. The manufacturing process mainly includes the steps of: 1) pre-treating a thin film; 2) smearing a graphite modifier on the thin film; 3) pre-sintering the thin film; 4) calendering: calendering the pre-sintered carbonized film in the step 3) on a calender machine until the thickness of the film is 0.3-0.8 mm; 5) main sintering: heating the calendered polyimide thin film in the step 4) to 800-900 DEG C and maintaining the temperature for 30-60 min, and increasing the temperature to 900-1100 DEG C and maintaining the temperature for 10-30 min, and cooling the film to normal temperature to obtain the heat-conductive film. The manufacturing process is easy to carry out and is low in cost. The heat-conductive film is high in scraping strength and is high in heat conductivity. By uniformly smearing a layer of graphite modifier on both surfaces of the polyimide thin film, the heat conductive property in the vertical and horizontal directions is improved, so that heat dissipation uniformity of the film is achieved.

Owner:HEFEI DONGHENGRUI ELECTRONICS TECH CO LTD

Denitration and demercuration catalyst

ActiveCN106362732AHigh activityImprove anti-poisoning performanceGas treatmentHeterogenous catalyst chemical elementsEngineeringActive components

The invention relates to a denitration and demercuration catalyst and belongs to the field of environment-friendly catalysts. Components of the catalyst form a Mo-V-W / TiO2-Al2O3 system, the functions of denitration and demercuration are achieved at the same time under the effect of the active components Mo, V and W and the carrier TiO2-Al2O3, the structure of tail gas filtering and exhausting equipment can be effectively simplified, and environmental protection cost is reduced. In addition, the catalyst has high dust interference resisting capacity, and still can exert maximum filtering performance on the basis that no frequent halt is needed for removal of accumulated dust, and the catalyst is uniform in aging speed, high in filtering-out capacity and long in service life.

Owner:山东海润环保科技有限公司

Preparation method of special unsaturated resin for car putty ash

The invention discloses a preparation method of special unsaturated resin for car putty ash, which belongs to the technical field of car coatings. The preparation method comprises the following steps:pretreating graphene oxide, surfactant and water to obtain pretreated graphene oxide, and then preparing modified carbon fibers by virtue of carbon fibers and silane coupling agent ethanol solution;preparing nano calcium carbonate dispersion by virtue of nano calcium carbonate, linoleic acid and Carbomer; heating and refluxing phthalic anhydride, diethylene glycol, ethylene glycol, propanediol,cottonseed oil, pretreated graphene oxide, modified carbon fibers and nano calcium carbonate dispersion, performing reaction, then adding fumaric acid and maleic anhydride, continuously heating and refluxing reacting, cooling, vacuumizing, adding styrene, stirring, mixing, naturally cooling, and discharging, thus obtaining the special unsaturated resin for the car putty ash. The special unsaturated resin for the car putty ash prepared by the technical scheme of the invention has the characteristic of significantly improving the mechanical performance, flexibility and impact resistance of the car putty ash.

Owner:吴迪

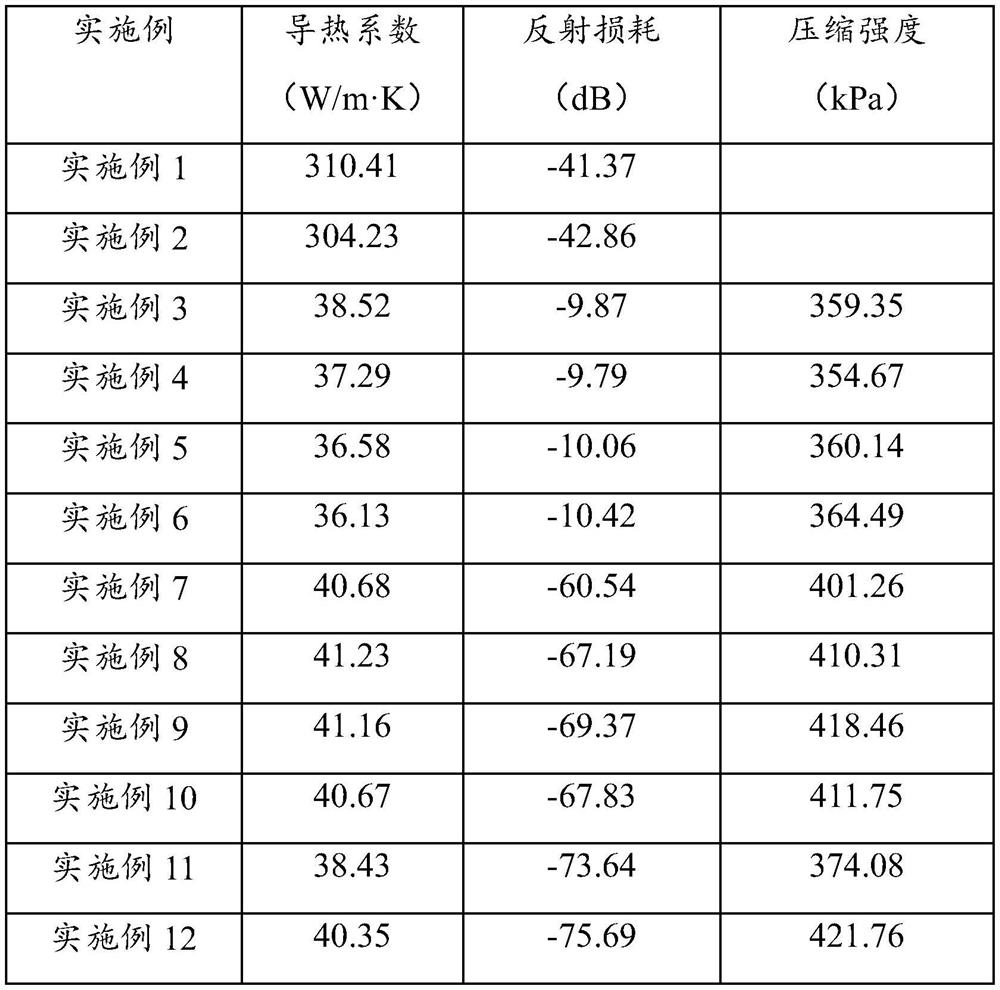

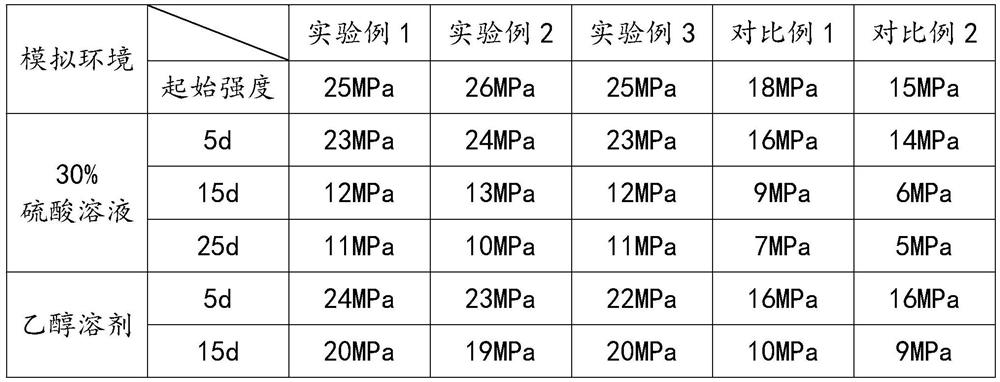

Preparation method of heat-conducting and wave-absorbing composite aerogel and heat-conducting and wave-absorbing composite aerogel

ActiveCN114832741AStrong cross-linked structureAvoid volume shrinkageMagnetic/electric field screeningChemical industryHydration reactionFreeze-drying

The embodiment of the invention discloses a preparation method of heat-conducting and wave-absorbing composite aerogel and the heat-conducting and wave-absorbing composite aerogel. The method comprises the following steps: step 1, coating multi-walled carbon nanotubes (MWCNTs) with silicon dioxide (SiO2) to prepare a SiO2 (at) MWCNTs nano composite material, and carrying out surface modification on the SiO2 (at) MWCNTs nano composite material; step 2, weighing polyvinylpyrrolidone, ethylene glycol and ferric chloride hexahydrate, mixing to obtain a Fe < 3 + > precursor solution, then adding the surface-modified SiO2 (at) MWCNTs nano composite material to obtain a mixed solution, then transferring the mixed solution into a reaction kettle for reaction, and drying to obtain a Fe3O4 (at) SiO2 (at) MWCNTs ternary nano composite material; 3, carrying out surface modification on the Fe3O4 (at) SiO2 (at) MWCNTs ternary nano composite material, then adding into water, and carrying out ultrasonic dispersion to prepare a suspension; step 4, adding phytic acid PA and alginate into the suspension while stirring, and then adding glucolactone to obtain a composite gel solution; and 5, introducing the composite gel solution into a mold, and freeze-drying to obtain the composite aerogel.

Owner:彗晶新材料科技(杭州)有限公司

Production process of high-performance ceramic-lined composite steel pipe

The invention discloses a production process of a high-performance ceramic-lined composite steel pipe, and relates to the field of steel pipes. The production process comprises the following steps: adding 2, 4-diaminotoluene into a three-neck flask, adding dried pyromellitic dianhydride to obtain a product B, uniformly mixing SiO2 and B4C, adding a silane coupling agent, carrying out ultrasonic dispersion to obtain a product C, and adding the product C into the product B to obtain an additive A. The problems that an existing ceramic steel material cannot meet the high-temperature-resistant requirement, cracks are likely to be generated in the impact and vibration process, raw materials are likely to be agglomerated, and the dispersity is poor are solved. When the ceramic steel pipe is impacted, SiO2 dispersed in a matrix can absorb impact energy of microcracks in the matrix and prevent the cracks from expanding, so that the mechanical property of a system is enhanced, B203 in a molten state can flow to the cracks of a ceramic interface to inhibit crack diffusion, and the ceramic interface is denser, therefore, the ceramic steel pipe is resistant to high temperature and not prone to cracks.

Owner:扬州金鑫管业有限公司

Red mud-based cementing material activator and red mud-based goaf filling material

The invention discloses a red mud-based cementing material activator and a red mud-based goaf filling material. The red mud-based cementing material activator comprises the following components: desulfurization gypsum, fly ash, sodium carbonate, mirabilite, sodium silicate, sodium dihydrogen phosphate and bauxite. The red mud-based goaf filling material comprises a red mud-based cementing material activator, red mud, steel slag, cement, basalt fiber chopped yarns and sericite reinforced polypropylene master batches. According to the invention, red mud can be effectively excited by adopting the composite exciting agent disclosed by the invention, a filling material with stable structure and performance is formed, and the filling material has good flowability and compressive strength and can meet the filling requirements of a mine goaf; and compared with a traditional cementing material with cement as a main component, the red mud-based goaf filling material provided by the invention also has expansibility, can inhibit volume shrinkage in a cement hardening process, and can solve the problem of void in a current filling area.

Owner:WUHAN UNIV OF TECH

Preparation method of heat stable type insulation binder

InactiveCN109054704AExcellent bonding strength and high temperature resistanceNot easy to pyrolysisNon-macromolecular adhesive additivesOil/fat/wax adhesivesEpoxidized soybean oilOxide

The invention relates to the technical field of binder preparation, in particular to a preparation method of a heat stable type insulation binder. Epoxidized soybean oil can play a role in promoting the curing cross-linking of a high-temperature binder, the heat resistance of the binder is improved through adding the cross-linking degree, and meanwhile, the high-temperature binder keeps appropriate cohesion strength. Phosphoric acid is added into a raw material prepared from a phenolic resin, so that the volume shrinkage after high-temperature heat treatment is inhibited, a binding performanceis improved, and favorable thermal shock resistance is realized; through heating reaction, transition metal molybdenum is bonded into a phenolic resin molecule main chain so as to form an O-Mo-O structure connected with a benzene ring in a phenolic resin, so that the thermal decomposition temperature of the insulation binder is improved. Metallic oxide and metal salt are adopted as modified additives, and the voltage impact resistance of the insulation binder can be improved, so that the insulation binder has excellent heat stability and has a wide application prospect.

Owner:FOSHAN TENGLI NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com