Production process of high-performance ceramic-lined composite steel pipe

A technology of ceramic lining and composite steel pipe, applied in the field of steel pipe, can solve the problems of uneven distribution of ceramic interface, easy agglomeration of raw materials, poor dispersibility, etc., to achieve the effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

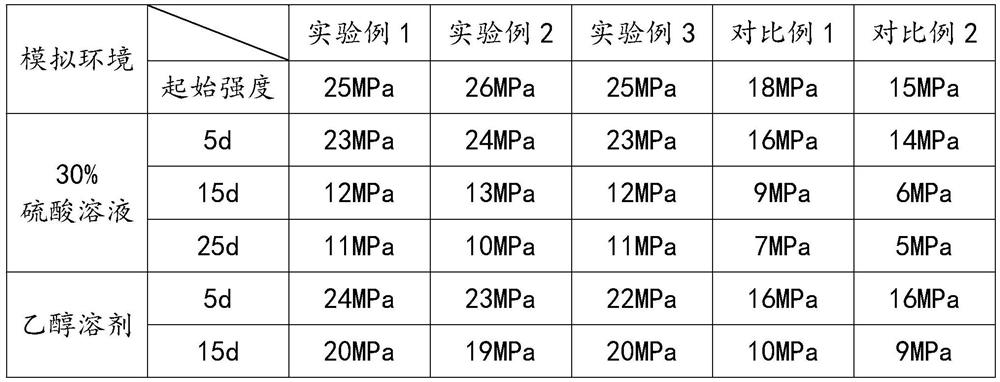

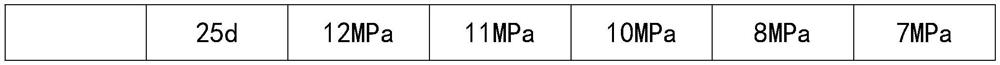

Examples

Embodiment 1

[0032] This embodiment is a production process of high-performance ceramic-lined composite steel pipe, including the following preparation process:

[0033] S1: Pulverize aluminum powder, red iron oxide, iron oxide, mica powder, additive A and additive B, put them into a mixer and stir evenly to obtain a blend;

[0034] S2: Put the steel pipe into the pipe mold of the pipe making machine, and add the blended material into the steel pipe;

[0035] S3: Turn on the pipe making machine and heat the steel pipe, sinter it under centrifugal force, and cool it to room temperature to prepare the high-performance ceramic-lined composite steel pipe;

[0036] Wherein the preparation steps of additive A are as follows:

[0037] S31: Add 2,4-diaminotoluene into a three-necked flask, control the temperature at 5°C, add the solvent N,N-dimethylacetamide, stir under nitrogen protection, add dry pyromellitic dianhydride, and mechanically Stir for 7h to obtain product B;

[0038] S32: SiO 2 an...

Embodiment 2

[0044] This embodiment is a production process of high-performance ceramic-lined composite steel pipe, including the following preparation process:

[0045] S1: Pulverize aluminum powder, red iron oxide, iron oxide, mica powder, additive A and additive B, put them into a mixer and stir evenly to obtain a blend;

[0046] S2: Put the steel pipe into the pipe mold of the pipe making machine, and add the blended material into the steel pipe;

[0047] S3: Turn on the pipe making machine and heat the steel pipe, sinter it under centrifugal force, and cool it to room temperature to prepare the high-performance ceramic-lined composite steel pipe;

[0048] Wherein the preparation steps of additive A are as follows:

[0049] S31: Add 2,4-diaminotoluene into a three-necked flask, control the temperature at 5°C, add the solvent N,N-dimethylacetamide, stir under nitrogen protection, add dry pyromellitic dianhydride, and mechanically Stir for 7h to obtain product B;

[0050] S32: SiO 2 ...

Embodiment 3

[0056] This embodiment is a production process of high-performance ceramic-lined composite steel pipe, including the following preparation process:

[0057] S1: Pulverize aluminum powder, red iron oxide, iron oxide, mica powder, additive A and additive B, put them into a mixer and stir evenly to obtain a blend;

[0058] S2: Put the steel pipe into the pipe mold of the pipe making machine, and add the blended material into the steel pipe;

[0059] S3: Turn on the pipe making machine and heat the steel pipe, sinter it under centrifugal force, and cool it to room temperature to prepare the high-performance ceramic-lined composite steel pipe;

[0060] Wherein the preparation steps of additive A are as follows:

[0061] S31: Add 2,4-diaminotoluene into a three-necked flask, control the temperature at 7°C, add the solvent N,N-dimethylacetamide, stir under nitrogen protection, add dry pyromellitic dianhydride, and mechanically Stir for 8h to obtain product B;

[0062] S32: SiO 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com