Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "Improve mixing dispersibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Controllable oxidative-biological degradation plastic master batch and preparation method thereof

The invention relates to a controllable oxidative-biological degradation plastic master batch, comprising an inorganic filling material, a carrier, an oxidative degradation promoter, a biodegradation promoter and a degradation control agent, wherein the degradation control agent is an anti-oxidant. According to the plastic master batch provided by the invention, a bivariate control system of oxidative degradation and biodegradation can be optimized and linked according to an actual environment so as to allow the plastic master batch to have environment targeting performance and degradation controllability. A preparation method for the plastic master batch is simple, is easy and convenient to operate, improves mixing and dispersing capability of the plastic master batch and provides an effective solution to overcome the problems of organic-inorganic interfacial compatibility and uniform dispersibility.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

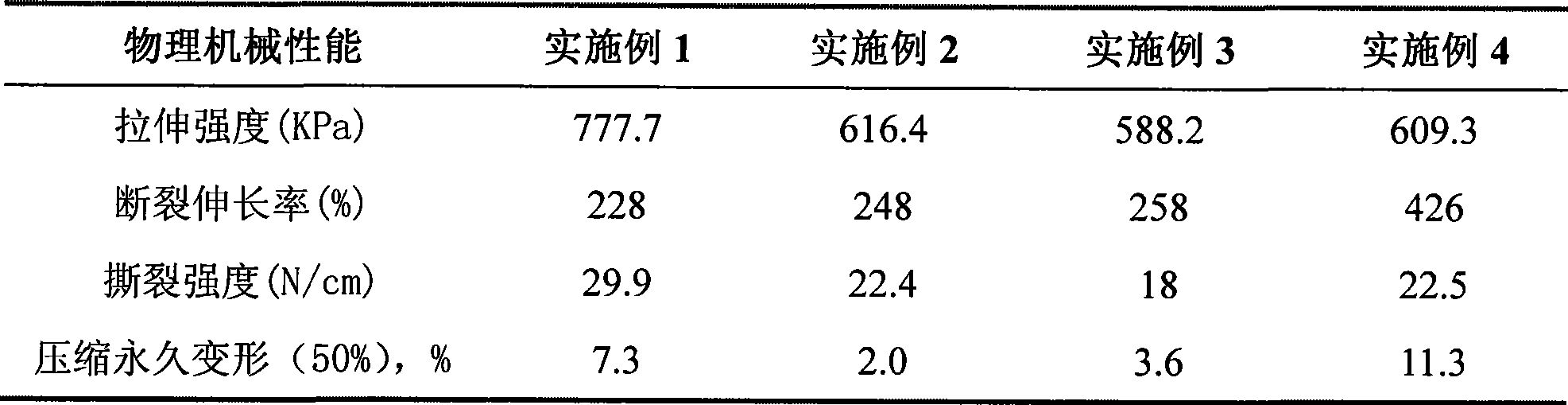

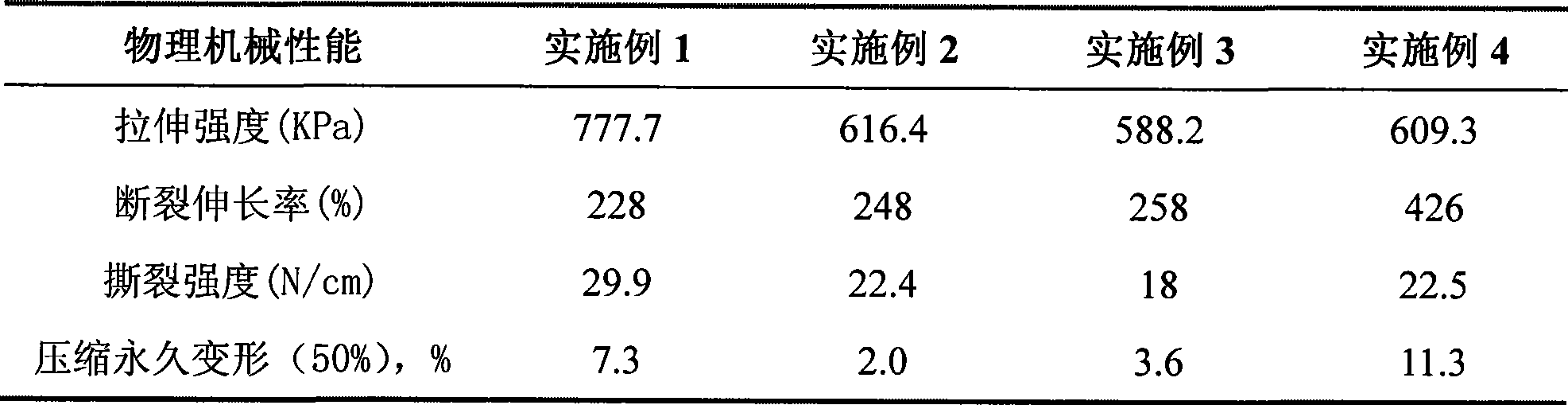

Duprene rubber foamed sheet and preparation method thereof

ActiveCN101392076AImprove flame retardant performanceHigh tensile strengthPolymer sciencePropanoic acid

The invention relates to a neoprene foaming board and a preparation method thereof. The neoprene foaming board is prepared by the following materials according to weight parts: 100 portions of neoprene, 15 portions to 200 portions of kaolin or calcium carbonate, 15 portions to 45 portions of carbon black, 10 portions to 20 portions of a vulcanizing agent, 0 portion to 2 portions of an accelerant, 5 portions to 15 portions of a vesicant, 0 portion to 5 portions of urea resin, 1 portion to 4 portions of olefin, 0 portion to 3 portions of dilauryl thiodipropionate, 0 portion to 2 portions of 2, 2'-methylene-bis(4-methyl-6- tert-butylphenol), 0 portion to 1 portion of nickel dibutyldithiocarbamate, 0 portion to 2 portions of stearic acid, 8 portions to 30 portions of black factice, 0 portion to 4 portions of vaseline, 10 portions to 20 portions of naphthenoid oil, 20 portions to 40 portions of perfume oil, and 1 portion to 4 portions of a dispersant. The preparation method thereof includes the steps of first-time mixing of a pressurizing milling machine, first-time mixing of a mixing mill, second-time mixing of the pressurizing milling machine, second-time mixing of the mixing mill, extrusion of an extruder, first-time foaming vulcanization, second-time foaming vulcanization, cooling and the like. The neoprene foaming board and the preparation method have the advantages of good flame resistance, high tensile strength, high extensibility, good performance of tear resistance, small compression set, good abrasion resistance and skidproof effect, good effect of shock absorption and the like.

Owner:常州美利晟高分子科技有限公司

Negative pole lead paste for lead-carbon super storage battery and preparation method thereof

ActiveCN102074703ALarge specific surface areaImprove mixing dispersibilityLead-acid accumulator electrodesCarbon compositesElectricity

The invention relates to negative pole lead paste for a lead-carbon super storage battery. The lead paste is prepared by mixing solid raw materials consisting of 1 to 93 percent of lead powder and 2 to 95 percent of lead-carbon composite material by using a paste mixing machine via a dry-mixing method and a wet-mixing method. The lead-carbon composite material of the negative pole lead paste for the lead-carbon super storage battery is prepared by the electro-deposition method and contains 25 to 55 weight parts of lead. The negative pole lead paste can increase the porosity and the utilization rate of negative pole active substances, improve the contraction state of a negative polar plate and enhance the bonding force between the lead paste and the polar plate as well as between the lead powder and the active carbon with high specific area, functions like a negative pole lead paste super capacitor under the condition of high carbon-added quantity, and improves the comprehensive performance of the storage battery.

Owner:ZHUZHOU SMELTER GRP +1

Preparation method for high performance butadiene-styrene-isoprene powder polymer

The invention adopts a direct coagulation method for preparation of a high performance butadiene-styrene-isoprene powder polymer. The method comprises the following steps: dispersion of a carbon nanotube: a step of adding the carbon nanotube and water into a high-speed disperser and carrying out stirring to allow the carbon nanotube to be uniformly dispersed; preparation of graft latex: a step of successively adding water, styrene-butadiene latex, an emulsifier and a molecular weight regulator into a polymerization kettle, carrying out nitrogen displacement, adding isoprene, carrying out stirring and heating, adding an initiator and carrying out polymerization to prepare the graft latex; and coagulation for formation of powder: a step of successively adding the graft latex, water and the carbon nanotube into a coagulation kettle, carrying out stirring and heating, adding a release agent, a flocculating agent and a coagulating agent and carrying out curing, washing, dehydration and drying to obtain the powder polymer. The prepared powder polymer has the following performances: a powder particle size of 0.5 to 0.8 mm; isoprene content in PSBIR of 20 to 40%; Mooney viscosity ML(1+4)<100 DEG C> of 50 to 70; 300% stress at definite elongation of 18 to 25 MPa; tensile strength of no less than 27.0 MPa; elongation at break of no less than 560%; antistatic resistance of 106 to 109 omega; and electrization voltage of less than 100V.

Owner:PETROCHINA CO LTD

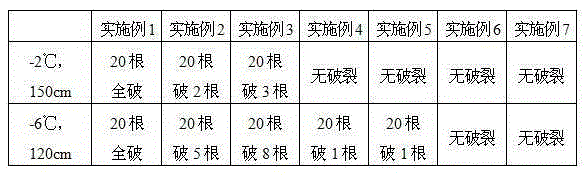

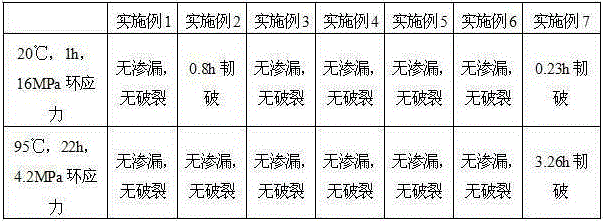

Preparation method for polypropylene-toughened impact-resistant tubular product

The invention relates to a preparation method for a polypropylene-toughened impact-resistant tubular product. The preparation method comprises the following steps: A, weighing raw materials in parts by mass: 100 parts of polypropylene, 5-30 parts of a polyolefin toughening agent, 5-10 parts of inorganic filler, 0.01-1.0 part of an antioxidant and 0.01-1.0 part of an ultraviolet adsorbent; B, drying: drying the raw materials at 60-80 DEG C; C, preparing a premix: after mixing the polypropylene, the polyolefin toughening agent and the inorganic filler in a certain proportion, stirring the raw materials in a low-speed stirrer to be stirred for 10-12 minutes, then adding the antioxidant and the ultraviolet adsorbent, and continuously stirring the mixture for 2-5 minutes; and D, extruding the tubular product: feeding the prepared premix into a single screw extruder, controlling the processing temperature at 160-210 DEG C, controlling the rotating speed of the screw at 60-90 rpm, and extruding the toughened and modified polypropylene tubular product.

Owner:YONGGAO CO LTD

Material for heat insulating nano-material, mixing method of material, heat insulating nano-material and preparation method of heat insulating nano-material

ActiveCN109400011AImprove mixing dispersibilityImprove the effect of mechanical fusionFiberMixed materials

The invention relates to a material for a heat insulating nano-material, a mixing method of the material, the heat insulating nano-material and a preparation method of the heat insulating nano-material. The mixing method includes the steps: uniformly dispersing ceramic fibers by water, drying the uniformly dispersed ceramic fibers to obtain pre-dispersed ceramic fibers; mechanically fusing nano-powder, the pre-dispersed ceramic fibers and auxiliary dispersing agents selected from groups formed by sodium dodecyl benzene sulfonate, methylcellulose, carboxymethylcellulose and polyoxyethylene to obtain nano-heat insulating material. The preparation method of the heat insulating nano-material includes the steps: uniformly mixing 85-100% of materials and 0-15% of additives to obtain a mixed material; performing mold pressing on the mixed material to prepare the nano-heat insulating material. The material is uniformly mixed by the mixing method without destroying fiber shapes and a microstructure of the nano-powder. According to the method, the heat insulating nano-material with low density, low heat conductivity coefficient and excellent mechanical property can be prepared.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Method for toughening and modifying polypropylene

InactiveCN103665546AImprove mixing dispersibilityHigh impact strengthLinear low-density polyethyleneMass ratio

The invention discloses a method for toughening and modifying polypropylene. According to the invention, components, component parts and processing characteristics of the method are as follows: a, stoving polypropylene (PP), polyolyaltha olfin (POE), ultra-high molecular weight polyethylene (UHMWPE) and linear low-density polyethylene (LLDPE) resin at the temperature of 60-80 DEG C, and completing mixing in a high-speed mixer at a mass ratio of PP:POE:UHMWPE:LLDPE=100:(3-25):(2-15):(5-20) to obtain a raw material A; b, adding a stabilizing agent and a lubricant in the raw material A at the mass ratio of polypropylene: stabilizing agent: lubricant=100:0.2:1, and conducting high-speed stirring and mixing to obtain a raw material B; c, conducting twin-screw extrusion on the raw material B, and controlling a processing section temperature within 160-210 DEG C and a screw rotating speed within 120-180 rmp to obtain the toughened and modified polypropylene, wherein the cantilever beam impact strength can be improved by 13 times maximally, and the descend range of the tensile yield strength is no more than 12%.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

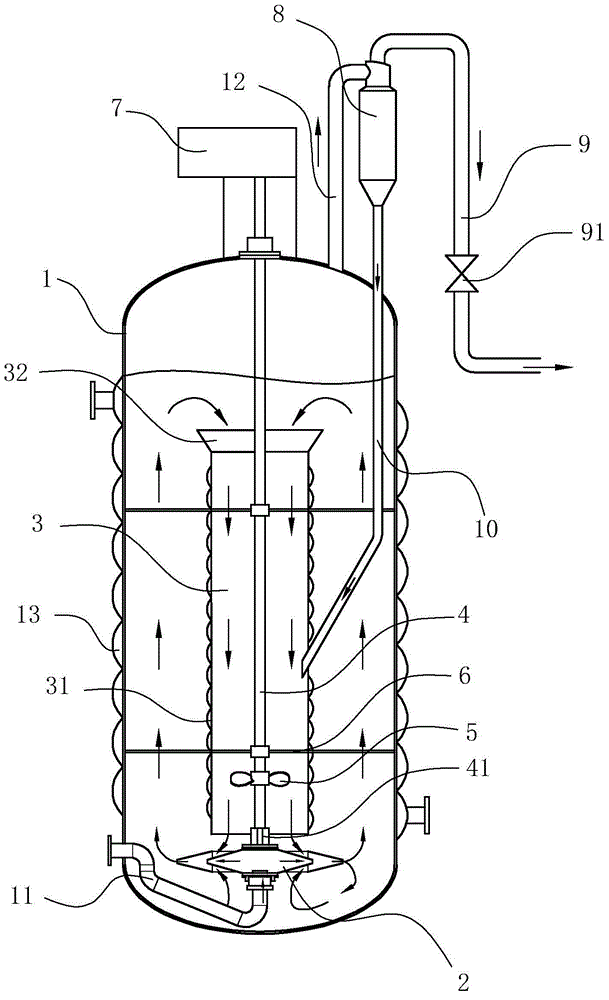

Self-suction airlift fermenting tank

ActiveCN105219618ALow mixing cycle energy consumptionImprove mixing dispersibilityBioreactor/fermenter combinationsBiological substance pretreatmentsCycloneMixing effect

A self-suction airlift fermenting tank comprises a tank body, an intake device, an exhaust device, a flow guide device, and an intake pipe and an exhaust pipe disposed on the tank body. The intake device is a cyclone mixer disposed at the bottom of the tank body and communicated with the intake pipe. The flow guide device is disposed in the tank above the cyclone mixer. The self-suction airlift fermenting tank is characterized in that the flow guide device is a flow guide barrel, the flow guide barrel is vertically disposed on the axis of the tank body, a stirring shaft with a stirrer is disposed on the axis of the tank body, the upper end of the stirring shaft is extended out of the tank body and connected with a motor, the lower end of the stirring shaft is connected with the cyclone mixer, and the stirrer is disposed on the lower portion of the inside of the flow guide barrel. The cyclone mixer rotates with rotating of the stirring shaft, liquid is imparted high kinetic energy by the aid of the rotating cyclone mixer, suction is generated when the liquid leaves, air sucked in may enter the fermenting tank under lower pressure, and air utilization can be increased. The self-suction airlift fermenting tank has the advantages of simple structure, good gas-liquid mixing effect and high fermenting efficiency and has significant comprehensive energy efficiency.

Owner:陆飞浩

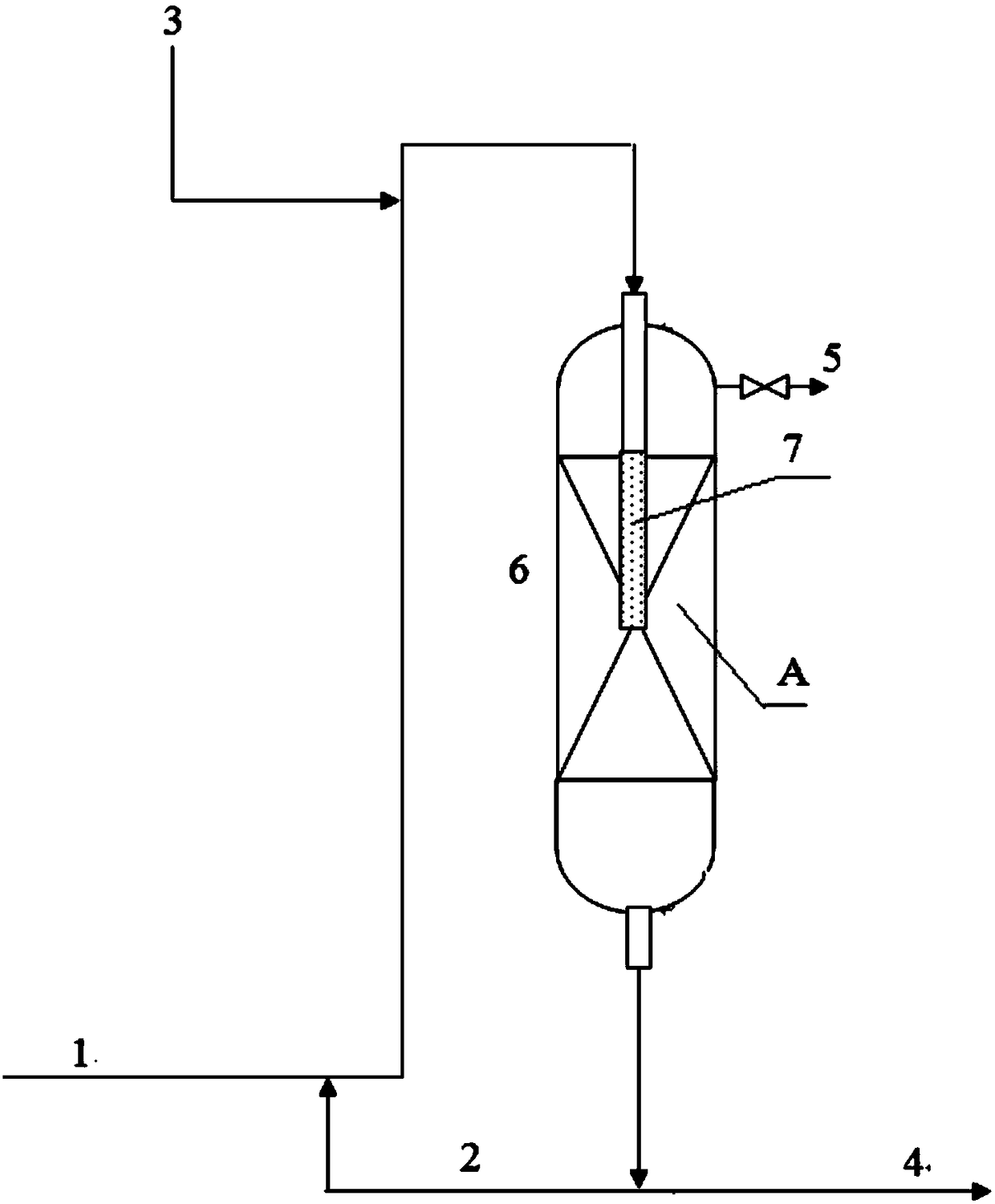

Membrane-dispersion liquid-phase cycle hydrorefining method

ActiveCN108485701AImprove mixing dispersibilityImprove playbackTreatment with hydrotreatment processesRefining to eliminate hetero atomsFixed bedOperating life

The invention discloses a membrane-dispersion liquid-phase cycle hydrorefining method. The membrane-dispersion liquid-phase cycle hydrorefining method comprises the following steps: performing hydrogen saturation on a distillate raw material, hydrogen and a circulating liquid hydrogenation product in a pipeline to form a liquid-phase mixture of distillate raw material / hydrogenation product / hydrogen, enabling the liquid-phase mixture with saturated dissolved hydrogen to enter a porous membrane tube for liquid-phase feed dispersion, which is arranged at an inlet of a fixed-bed hydrogenation reactor, and entering a reactor bed after membrane dispersion, wherein the reactor is filled with a hydrogenation catalyst; dispersing the liquid-phase mixture from the membrane tube, entering a catalystbed zone, performing a hydrogenation reaction, circulating a part of a reaction product from the bottom of the hydrogenation reactor, mixing with a fresh raw material, discharging a part from a reaction system and entering a subsequent product storage unit. By the membrane-dispersion liquid-phase cycle hydrorefining method, the activity of the whole catalyst can be effectively played while hydrogen mixing is achieved, the operating life of the hydrogenation catalyst is prolonged, the hydrogenation reaction efficiency is increased, and the sulfur nitrogen and aromatic hydrocarbon contents of aproduct can be further reduced.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +3

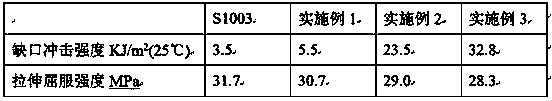

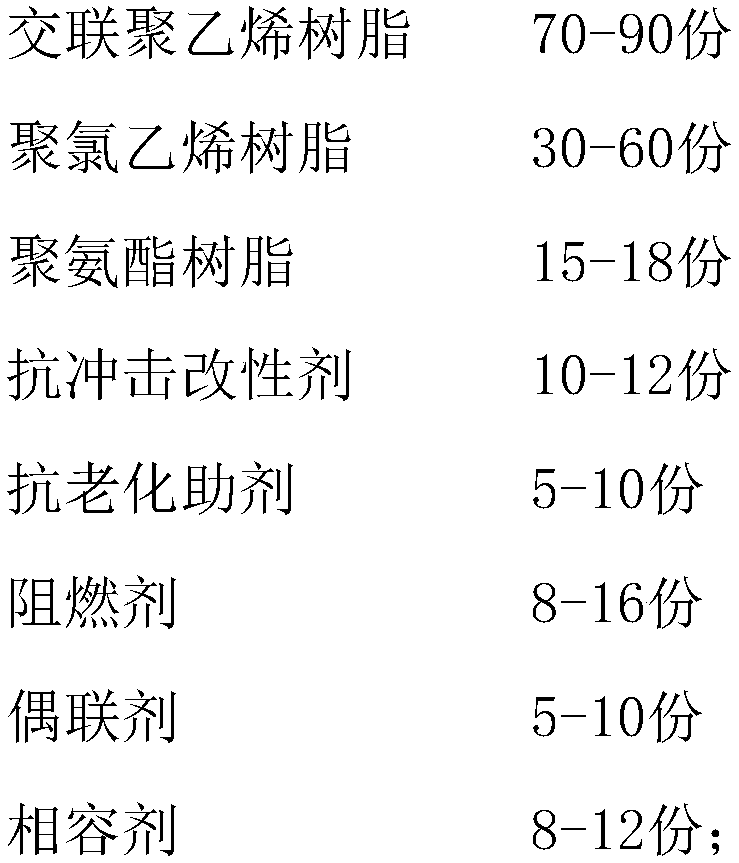

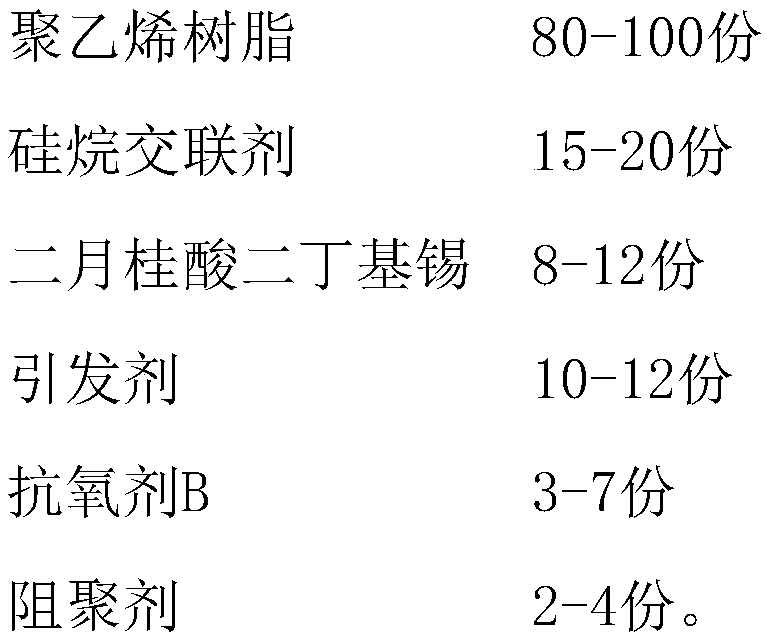

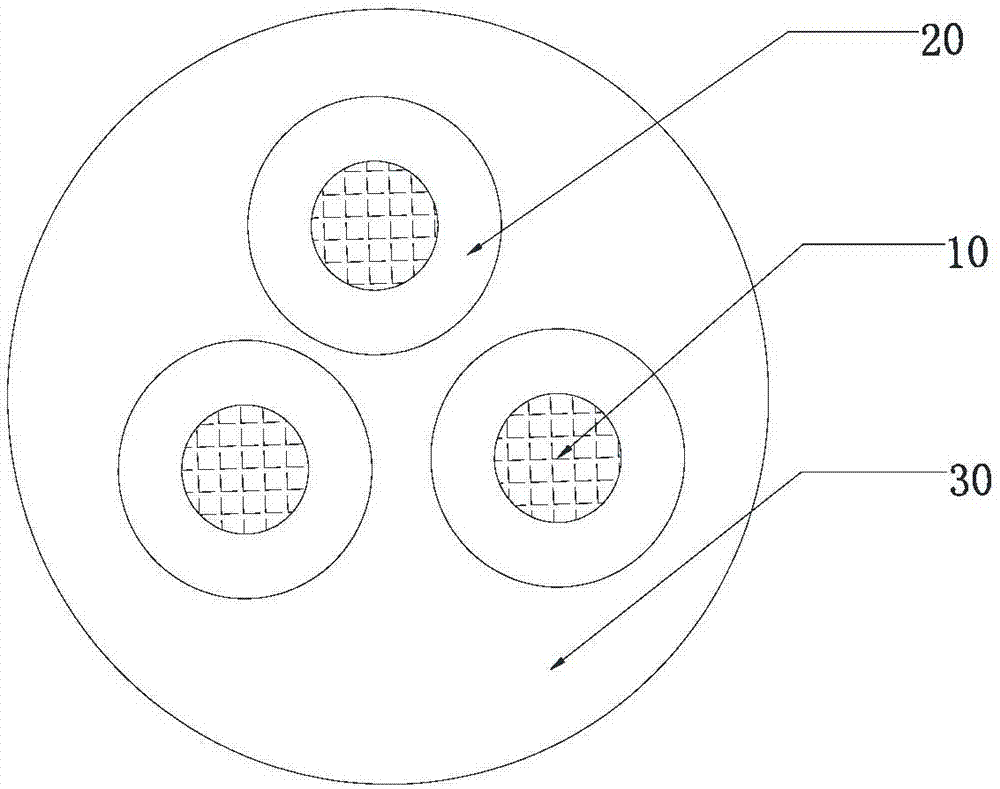

Anti-aging shock resistant material and preparation method thereof as well as cable protection tube prepared from same

The invention relates to the technical field of cable protection tube materials, and specifically relates to an anti-aging shock resistant material and a preparation method thereof as well as a cableprotection tube prepared from the same. The anti-aging shock resistant material comprises the following raw materials in parts by weight: 70 to 90 parts of cross-linking polyethylene resin, 30 to 60parts of polyvinyl chloride resin, 15 to 18 parts of polyurethane resin, 10 to 12 parts of a shock resistant modifier, 5 to 10 parts of an anti-aging accessory ingredient, 8 to 16 parts of a fire retardant, 5 to 10 parts of a coupling agent and 8 to 12 parts of a compatilizer. The anti-aging shock resistant material disclosed by the invention has excellent aging resistance and shock resistance, the shock resistance is 18.65 to 22.96 KJ / m<2>, the tensile strength is 81.8 to 93.4 MPa, the material is high in insulation resistance, strong in loading capacity, excellent in electric insulation performance and insulation effect, the specific insulation resistance is 1.228*10<14> to 1.376*10<15> omega.m, and the comprehensive mechanical property is excellent.

Owner:广东威立瑞科技有限公司

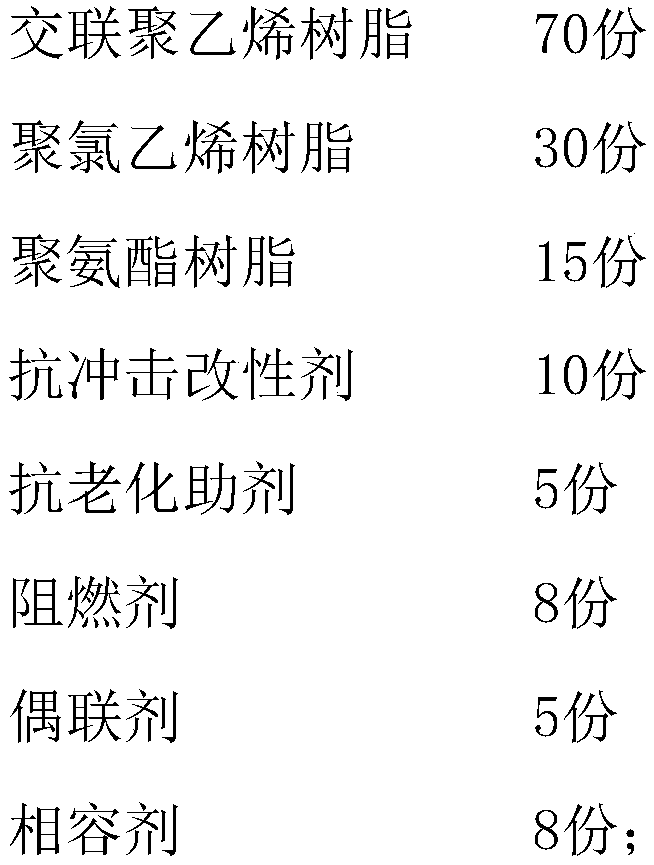

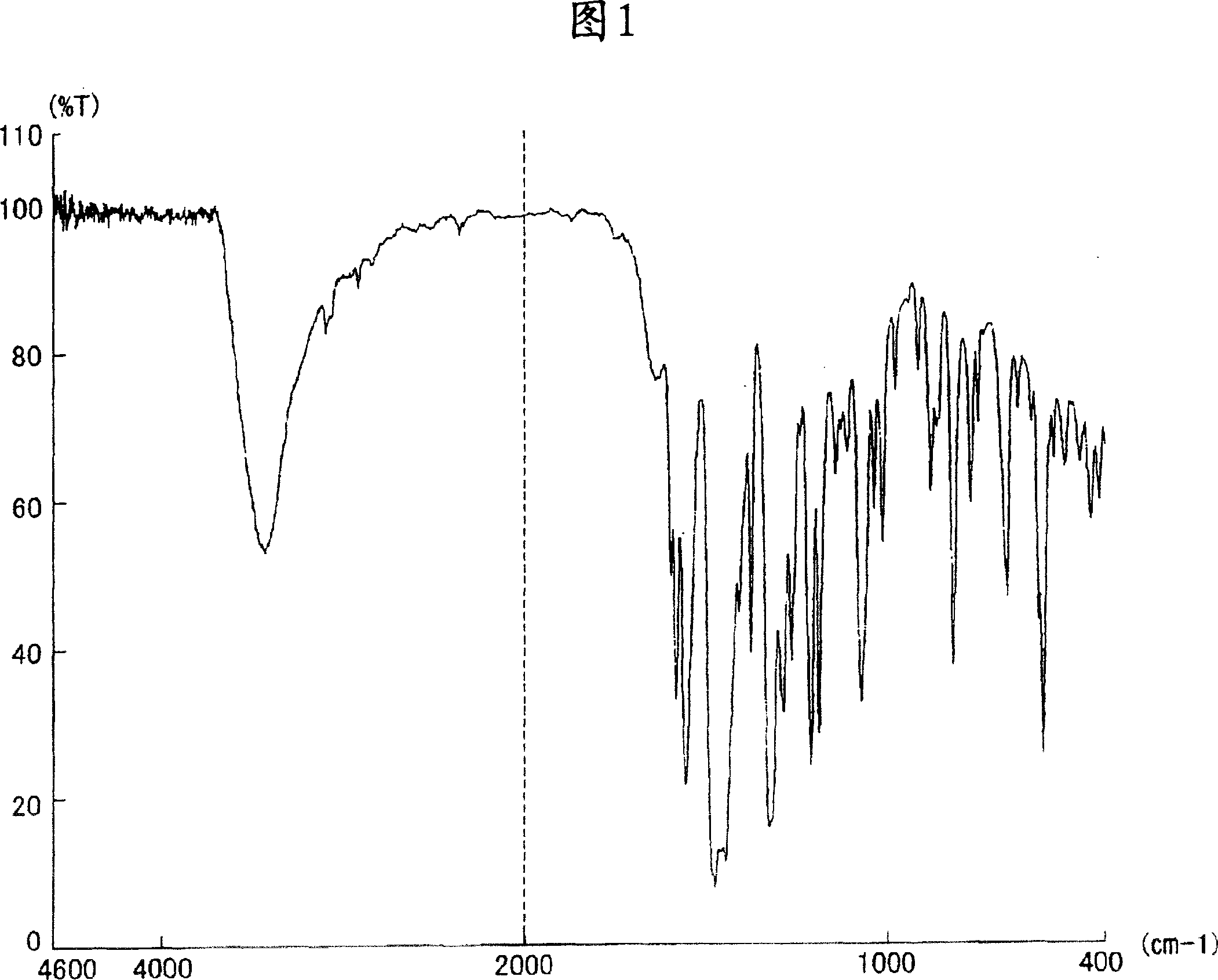

Monoazo/iron complex compound, charge control agent comprising the same, and toner

InactiveCN1938386AHigh chargeHigh electrification enhancementOrganic chemistryDevelopersChemistryHigh rate

An excellent charge control agent which contains no harmful metals, has no fear of readily igniting or exploding, and has a large charge amount and a high rate of initial electrification; and a toner of the negative electrification type. Also provided is a monoazo / iron complex compound represented by the formula [1]. [In the formula (1), J represents H, an alkali metal, ammonium, or alkylammonium or represents a combination of two or more of these].

Owner:HODOGAYA KAGAKU IND

Fireproof aluminium-plastic panel containing nanometer flame retardant and core material special for fireproof aluminium-plastic panel containing nanometer flame retardant

InactiveCN110157072AGood compatibilityGood dispersionSynthetic resin layered productsMetal layered productsDispersityInjection moulding

The invention relates to the technical field of aluminium-plastic panels, in particular to a fireproof aluminium-plastic panel containing a nanometer flame retardant and a core material special for the fireproof aluminium-plastic panel containing the nanometer flame retardant. The core material comprises the following raw materials in parts by weight: 45-55 parts of polyethylene, 25-30 parts of polycarbonate, 15-18 parts of modified enhanced nylon, 2-3 parts of the nanometer flame retardant, 1.5-2.5 parts of modified nanometer cerium oxide, 2-6 parts of a synergist, 3-8 parts of a compatilizerand 1-2 parts of a lubricant. The core material has excellent flame-retardant and fireproof performance, the mobility is high, a core layer can be easily produced through extrusion molding and injection molding, and the core layer produced by using the core material is high in strength and excellent in hardness, resists bending, is not liable to deform, and is excellent in weather resistance; andby adopting the nanometer flame retardant, through combined action of the nanometer flame retardant and the synergist, the core material can have the excellent flame retardant and fireproof performance, and not only can the synergist have an flame-retardant effect, but also a powder state of the synergist can promote the dispersity of materials, so that the rheological property of the core material in the subsequent technologies is improved.

Owner:东莞华尔泰装饰材料有限公司

Hydrophilic coating with high antistatic property and preparation method thereof

ActiveCN107141850AReduce accumulationSolve the pain points of useAlkali metal silicate coatingsElectrically-conductive paintsHydrophilic coatingSolvent

The invention relates to a hydrophilic coating with a high antistatic property and a preparation method thereof. The hydrophilic coating with the high antistatic property is prepared from the following components in parts by weight: 0.3-1.8 parts of conductive filler, 0.5-1.5 parts of conductive auxiliary, 25-50 parts of silicate solution, 10-35 parts of nano sol, 13.4-42 parts of solvent and 0.5-1 part of auxiliary. In preparation, the components are mixed according to a proportion. According to thehydrophilic coating with the high antistatic property and the preparation method thereof provided by the invention, the partial discharge and the dust viscosity caused by poor electrical conductivity of a base material are solved; the hydrophilic coating has the advantages that the hydrophilic property is good, the using experience of a user is improved, the cleaning difficulty is reduced, and the like.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Compound deodorizing, antibacterial and antiviral multifunctional fiber and preparation method thereof

ActiveCN113652766AImprove mixing dispersibilityGood compatibilityBiocideDisinfectantsAnti bacterialAntibacterial agent

The invention belongs to the technical field of functional fiber materials, and discloses compound deodorizing, antibacterial and antiviral multifunctional fiber and a preparation method thereof. PVA and an organosilicon quaternary ammonium salt antibacterial agent are added into a traditional Chinese medicine antiviral extracting solution to obtain a mixed solution, then a catalyst and a sodium silicate or silicate ester compound are added for a condensation reaction, PVA-SiO2 interpenetrating network particles coating a traditional Chinese medicine antiviral component and the organosilicon quaternary ammonium salt antibacterial agent are obtained, and the obtained functional particles and a fiber matrix are subjected to mixed spinning, so that the product is obtained. The PVA is used as a coating agent of the traditional Chinese medicine antiviral component and the organosilicon quaternary ammonium salt antibacterial agent, so that mixing and dispersion of the traditional Chinese medicine antiviral component and the organosilicon quaternary ammonium salt antibacterial agent in the fiber matrix are promoted; and further an interpenetrating network enhanced structure is formed with SiO2. The long-lasting deodorizing, antibacterial and antiviral effects can be achieved and the fiber strength can be enhanced by introducing the multifunctional fiber into the fiber matrix.

Owner:芯安健康科技广东有限公司

Fireproof mineral silicone rubber composition, fireproof mineral silicone rubber material, preparation method thereof and power line containing fireproof mineral silicone rubber material

ActiveCN107011662AInsulate heat transferImprove mixing and dispersing effectRubber insulatorsInsulated cablesPliabilityMineralogy

The invention provides a fireproof mineral silicone rubber composition, a fireproof mineral silicone rubber material, a preparation method thereof and a power line containing the fireproof mineral silicone rubber material. The fireproof mineral silicone rubber composition comprises, by weight, 50-100 parts of methyl vinyl silicone rubber, 30-50 parts of montmorillonite, 5-10 parts of quaternary ammonium salt surface modifier, 10-20 parts of low-melting-point glass powder, 30-50 parts of aluminum hydroxide and 5-10 parts of polyol. A ceramic layer structure formed by the fireproof mineral silicone rubber composition is stable and even in mechanical performance distribution, and the toughness and fireproof performance of the power line is further increased when the ceramic layer structure is used as the sheath of the power line.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Composite fertilizer used for tea trees and capable of improving soil structure

InactiveCN107311793AAvoid damageReduce compactionSuperphosphatesAlkali orthophosphate fertiliserPhosphatePeanut meal

The invention discloses a composite fertilizer used for tea trees and capable of improving soil structure. The composite fertilizer comprises the following raw materials by weight: 20 to 35 parts of urea, 15 to 35 parts of monoammonium phosphate, 4 to 16 parts of double superphosphate, 10 to 20 parts of potassium dihydrogen phosphate, 2 to 8 parts of magnesium-potassium sulfate fertilizer, 2.5 to 4.5 parts of trace elements, 30 to 40 parts of a slow release system, 2 to 6 parts of gelatin, 20 to 30 parts of fermented cottonseed meal, 5 to 15 parts of peat soil, 4 to 18 parts of peanut shell powder, 5 to 15 parts of corn cob powder, 30 to 60 parts of peanut meal and 4 to 12 parts of buckwheat flour. The composite fertilizer provided by the invention realizes reasonable compounding of all the nutrient elements needed in the growth of the tea tree, and has excellent water retention, fertilizer preservation and slow release performance; after the composite fertilizer is applied to soil, available nutrients in the composite fertilizer are slowly released to prolong the duration of fertilizer efficiency; harm to soil caused by inorganic fertilizer components in the composite fertilizer is reduced, and soil hardening is avoided; and the composite fertilizer can improve the physical and chemical properties and fertility of soil.

Owner:天长市翔净蔬菜种植发展有限公司

Compound fertilizer for improving quality of water chestnuts

InactiveCN106810408APromote healthy growthIncrease inputAnimal corpse fertilisersExcrement fertilisersWater ChestnutsPhosphate

The invention discloses a compound fertilizer for improving quality of water chestnuts. The compound fertilizer comprises the following raw materials in parts by weight: 30-50 parts of composted chicken dung, 20-30 parts of mushroom dregs, 10-20 parts of fermented cottonseed cakes, 5-15 parts of fishbone dust, 35-45 parts of bean pulp, 6-12 parts of coal gangue powder, 6-10 parts of diatomite, 6-12 parts of charcoal, 4-8 parts of medical stone powder, 2-5 parts of ferrous sulfate, 2-4 parts of zinc sulfate, 3-7 parts of perlite, 9-15 parts of high gluten flour, 20-40 parts of ammonium nitrate, 20-30 parts of plant ash, 30-40 parts of ground phosphate rock and 80-120 parts of compound urea. The various nutrient elements needed for growth of water chestnuts are reasonably compounded, the fertilizer retaining and slow-release properties are excellent, and healthy growth of the water chestnuts can be obviously promoted, so that the effects of improving the yield, improving the quality and increasing economic benefits are achieved. Meanwhile, the addition amount of the fertilizer can be reduced, and the environmental pollution risk caused by improper fertilization is reduced.

Owner:蚌埠市兵凤赟种植农民专业合作社

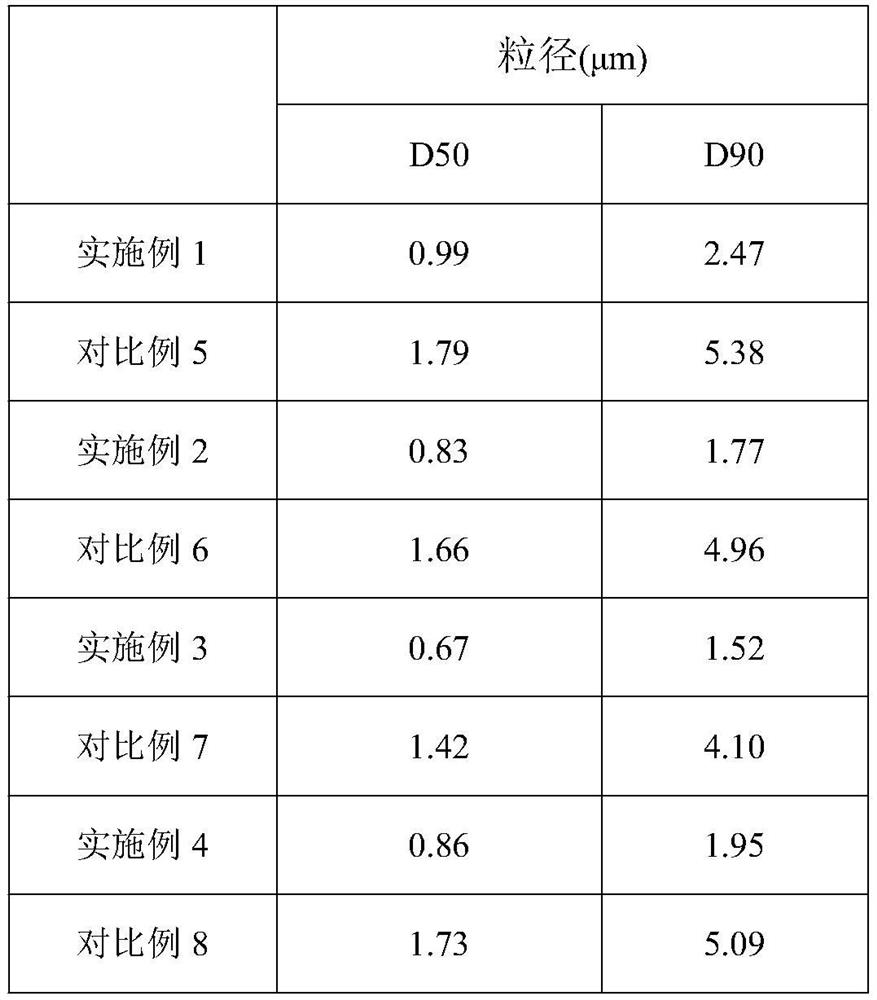

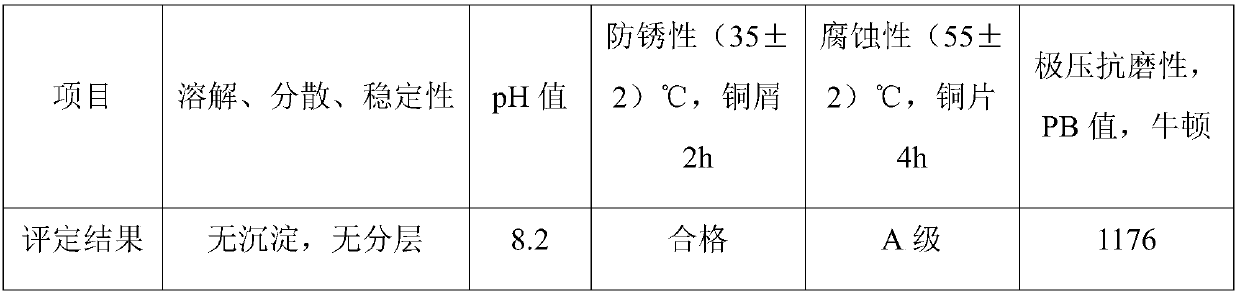

Anti-wear and antioxidant cooling liquid composition used for electric wire and cable copper conductors

InactiveCN107739649AAvoid deformationEffective isolationLubricant compositionCopper conductorPhysical chemistry

The invention discloses an anti-wear and antioxidant cooling liquid composition used for electric wire and cable copper conductors. The anti-wear and antioxidant cooling liquid composition comprises pure water, copper drawing oil and an extreme pressure anti-wear and antioxidant complexing agent, and the mass ratio of pure water to copper drawing oil to the extreme pressure anti-wear and antioxidant complexing agent is (480 to 520): (7 to 13): 1. The cooling liquid composition has preferable corrosion prevention, rust prevention, oxidization resistance and wear resistance, and is low in cost.

Owner:CHINA PETROLEUM & CHEM CORP

Wear-resistant tear-resistant power cable

InactiveCN106633347AImprove tear resistanceAdd lessPlastic/resin/waxes insulatorsPower cablesPolyethylene vinyl acetateElectrical conductor

The invention discloses a wear-resistant tear-resistant power cable which comprises a conductor and a sheath layer coated outside the conductor. The sheath layer is prepared from the following raw materials in parts by weight: 15-25 parts of polytetrafluoroethylene, 40-60 parts of ethylene-vinyl acetate copolymer, 10-18 parts of polyvinyl chloride, 1-2 parts of epoxidized linseed oil, 0.4-1 part of coal tar, 8-12 parts of Turkey red oil composite corn cob, 10-15 parts of zeolite powder, 15-25 parts of white carbon black, 4-8 parts of liquid epoxy resin, 4-8 parts of nano graphene, 3-6 parts of polyethylene vinyl acetate, 3-7 parts of clay, 4-8 parts of kaolin, 2-5 parts of phenolic resin, 2-4 parts of vulcanizing agent TMTD (tetramethyl thiuram disulfide), 1-2 parts of dicumyl peroxide, 0.7-1.1 parts of antioxidant 1076, 0.4-1.2 parts of antioxidant 1035 and 1.5-2.5 parts of antioxidant 1010.

Owner:安徽吉安特种线缆制造有限公司

Tearing-resistant and impact-resistant power cable

InactiveCN106589492AImprove surface activityImprove adsorption capacityRubber insulatorsHalloysiteBetaine

The invention discloses a tearing-resistant and impact-resistant power cable, comprising a conductor and a jacket layer coated at the outer side of the conductor, wherein the jacket layer comprises the following raw materials in parts by weight: 20-40 parts of low-phenyl silicone rubber, 45-85 parts of acrylonitrile-butadiene rubber, 10-20 parts of chlorosulfonated polyethylene, 0.3-0.7 part of antimony dioxide, 1.5-2.5 parts of 2,4-dichlorobenzoyl peroxide, 1.5-2.5 parts of poly-p-nitrosobenzene, 0.3-0.5 part of potassium ammonium dichromate, 1.5-2.5 parts of phenolic resin, 2-4 parts of C5 petroleum resin, 10-16 parts of superfine talc powder, 10-18 parts of lignin, 45-65 parts of sepiolite powder, 4-10 parts of halloysite, 10-20 parts of modified betaine, 2-4 parts of an antioxidant 1076, 0.4-0.8 part of dilauryl thiodipropionate, 2-4 parts of epoxidized soybean oil, and 0.5-1 part of zinc stearate.

Owner:安徽吉安特种线缆制造有限公司

Feed capable of promoting digestion and absorption of pig

InactiveCN107198049APromote growthNutritional diversityAnimal feeding stuffAccessory food factorsBiotechnologyPolyvinyl alcohol

The invention discloses a feed capable of promoting digestion and absorption of a pig. The feed comprises the following raw materials in parts by weight: 4 to 60 parts of sorghum, 20 to 30 parts of buckwheat, 50 to 56 parts of a protein supplement, 4 to 8 parts of vinasse, 10 to 20 parts of rice bran, 10 to 18 parts of folium mori, 4 to 8 parts of fermented straw powder, 0.4 to 0.8 part of radix scutellariae , 1 to 2 parts of fructus crataegi, 0.4 to 0.6 part of fructus jujubae, 0.8 to 1.4 parts of fructus lycii, 0.6 to 1 part of radish seeds, 4 to 8 parts of a digestion promoting agent, and 2 to 5 parts of a chitosan compound. The chitosan compound is prepared by adopting the following processes: stirring chitosan, glacial acetic acid and water; adding guar gum powder and continuing stirring; adding soybean protein; adding sodium hydroxide to regulate the pH of a system to be 9 to 9.6; adding polyving akohol, microcrystalline cellulose and glutaraldehyde, mixing, and grinding by a colloid mill to obtain the chitosan compound.

Owner:宿松县春润食品有限公司

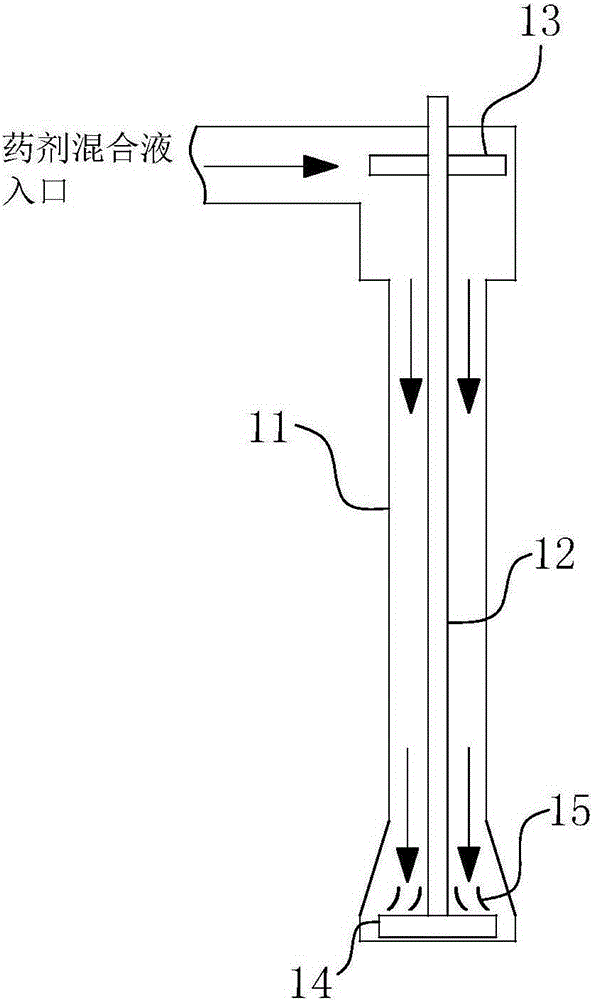

Jet-driven medicament disperse system and pulp mixing modification equipment applying same

ActiveCN105289390AHomogeneous Mix Feed RequirementsImprove impact performanceMixer accessoriesImpellerHybrid system

The invention relates to the field of coal slurry pre-treatment, and in particular relates to a jet-driven medicament disperse system and pulp mixing modification equipment applying the same. The jet-driven medicament disperse system comprises a jet spray nozzle and a liquid flow pipe, wherein the jet spray nozzle comprises an outer pipe body, the outer pipe body is internally and coaxially provided with a rotating shaft in a sleeving manner, and a driving impeller and a driven impeller are coaxially arranged on the rotating shaft; the liquid discharging direction of a pass pipeline, connected with the outer pipe body, of the liquid flow pipe is located in the tangential direction of the driving impeller, and a pipe chamber of the pass pipeline is provided with a pipeline mixer for preliminarily mixing ore pulp and a medicament. The system can effectively realize the uniform mixing feeding requirements of the medicament and the ore pulp in a controllable manner. The pulp mixing modification equipment comprises a mixing box and a graded mixing system, the top of the mixing box is provided with a medicament atomization dispersing system and the bottom is provided with the jet spray nozzle, a liquid outlet of the mixing box is arranged in a way different from the mounting position of the outer pipe body. The equipment is especially suitable for the pulp mixing modification requirement of fine-particle coal difficult to float, the working efficiency of the equipment is high and the pre-treatment process is quick and convenient.

Owner:ANHUI UNIV OF SCI & TECH

Antibacterial polyethylene cable material unlikely to change color

InactiveCN106800694AGood dispersionGood filler tolerancePlastic/resin/waxes insulatorsCarbon fibersMicrocrystalline wax

The invention discloses an antibacterial polyethylene cable material unlikely to change color. The antibacterial polyethylene cable material unlikely to change color comprises the following raw materials in parts by weight: 15-25 parts of an ethylene-vinyl acetate copolymer, 10-20 parts of polyvinyl chloride, 30-40 parts of polyethylene, 6-14 parts of apatite, 5-11 parts of barium metaborate, 4-9 parts of barium titanate, 6-12 parts of polyacrylonitrile-based carbon fibers, 2-8 parts of modified clay, 2-4 parts of disproportionated rosin, 2-6 parts of deacetylated chitosan polysaccharide, 2-4 parts of dioctyl terephthalate, 0.8-1.2 parts of microcrystalline wax, 0.8-1.6 parts of dicumyl peroxide, 0.3-0.9 part of p-phenylenediamine, 0.4-0.8 part of dodeceny succinicanhydride, 0.5-1 part of cerium oxide, 0.2-0.24 part of lanthanum oxide, 0.6-1.2 parts of a polyphenol antioxidant 1076 and 1.5-2.5 parts of an antistatic agent.

Owner:安徽新立电缆材料有限公司

Antibacterial waterproof polyethylene cable material

InactiveCN106750801AGood filler toleranceGood cross-linkabilityPlastic/resin/waxes insulatorsDiethylenetriamineChlorinated paraffins

The invention discloses an antibacterial waterproof polyethylene cable material. The antibacterial waterproof polyethylene cable material is prepared from, by weight, 25-35 parts of polyethylene, 5-12 parts of polytrifluorochloroethylene, 10-18 parts of ethylene-vinyl acetate copolymer, 2-10 parts of polyacrylonitrile-based carbon fiber, 2-8 parts of aluminum oxide, 3-8 parts of aluminum borate whiskers, 2-7 parts of sodium antimonite, 0.2-0.6 part of diethylenetriamine, 0.4-0.8 part of cyanoethylated diethylenetriamine, 0.1-0.6 part of p-phenylenediamine, 1-2 parts of chlorinated polyethylene wax, 0.4-0.9 part of dioctyl adipate, 1-4 parts of modified clay, 1-3 parts of chitosan polysaccharide, 1-2 parts of chlorinated paraffin, 0.1-0.16 part of lanthanum oxide, 0.4-0.9 part of cerium oxide, 0.4-0.8 part of stabilizer and 1-2 parts of color master batch. The antibacterial waterproof polyethylene cable material is good in waterproofness and thermal stability, excellent in mechanical performance and antibacterial performance and not prone to oxidation and discoloring.

Owner:安徽新立电缆材料有限公司

Waterproof compressive deformation low-variable frequency cable material

InactiveCN106957530AGood dispersionImprove waterproof performanceRubber insulatorsBuilding insulationsAntioxidantPotassium

The invention discloses a waterproof compressive deformation low-variable frequency cable material which is prepared from the following raw materials in parts by weight: 20-40 parts of low phenyl siloxane rubber, 11-15 parts of butadiene styrene rubber, 3-9 parts of chloroprene rubber, 24-37 parts of modified graphene oxide, 41-49 parts of medical stone, 11-17 parts of graphite, 5-13 parts of quartz sand, 0.3-0.9 part of ammonium dichromate potassium, 0.2-0.8 part of zinc stearate, 2-4 parts of 2,5-dimethyl-2,5-bi(tert-butyl peroxide) hexane, 0.3-1.2 parts of vaseline, 0.5-2.5 parts of pine tar, 1-2 parts of bi-dodecyl alcohol ester, 0.5-1.3 parts of an antioxidant, 0.5-1.5 parts of an ultraviolet absorber UV-531, 1.2-2.1 parts of diisononyl phthalate, 1-2 parts of epoxidized fatty acid methyl ester and 0.5-2.5 parts of white oil. The waterproof compressive deformation low-variable frequency cable material is small in permanent compression deformation, high in rebound rate and excellent in waterproof performance.

Owner:安徽三鑫电缆材料有限公司

Pig feed with comprehensive nutrition

InactiveCN107373134AMeet the needs of growthPromote growthFood processingAnimal feeding stuffAnimal sciencePhosphate

The invention discloses pig feed with comprehensive nutrition. The pig feed is prepared from raw materials in parts by weight as follows: 15-25 parts of an animal source protein additive, 40-50 parts of sweet potato vine powder, 6-18 parts of alfalfa meal, 10-20 parts of peanut hull flour, 18-26 parts of oat bran, 15-23 parts of corn gluten meal, 10-18 parts of rice bran meal, 6-12 parts of sesame meal, 6-16 parts of an earthworm compound, 4-8 parts of corn starch, 4-8 parts of montmorillonite, 2-4 parts of dicalcium phosphate and 3-5 parts of intestinal bacteria. The pig feed with the comprehensive nutrition has sufficient nutrition, adopts a scientific and reasonable formula, conforms to development laws of the pig intestine and can meet demands of pig growth; appetite of pigs is effectively improved, meat quality and nutritional value of pigs are improved, and growth of the pigs is promoted.

Owner:合肥申仁养殖有限公司

Duprene rubber foamed sheet and preparation method thereof

The invention relates to a neoprene foaming board and a preparation method thereof. The neoprene foaming board is prepared by the following materials according to weight parts: 100 portions of neoprene, 15 portions to 200 portions of kaolin or calcium carbonate, 15 portions to 45 portions of carbon black, 10 portions to 20 portions of a vulcanizing agent, 0 portion to 2 portions of an accelerant,5 portions to 15 portions of a vesicant, 0 portion to 5 portions of urea resin, 1 portion to 4 portions of olefin, 0 portion to 3 portions of dilauryl thiodipropionate, 0 portion to 2 portions of 2, 2'-methylene-bis(4-methyl-6- tert-butylphenol), 0 portion to 1 portion of nickel dibutyldithiocarbamate, 0 portion to 2 portions of stearic acid, 8 portions to 30 portions of black factice, 0 portion to 4 portions of vaseline, 10 portions to 20 portions of naphthenoid oil, 20 portions to 40 portions of perfume oil, and 1 portion to 4 portions of a dispersant. The preparation method thereof includes the steps of first-time mixing of a pressurizing milling machine, first-time mixing of a mixing mill, second-time mixing of the pressurizing milling machine, second-time mixing of the mixing mill, extrusion of an extruder, first-time foaming vulcanization, second-time foaming vulcanization, cooling and the like. The neoprene foaming board and the preparation method have the advantages of good flame resistance, high tensile strength, high extensibility, good performance of tear resistance, small compression set, good abrasion resistance and skidproof effect, good effect of shock absorption and the like.

Owner:常州美利晟高分子科技有限公司

Stable-structure flame-retarding power cable

InactiveCN107602958AExtended service lifeProtection from burnsRubber insulatorsMelamine phosphateEngineering

The invention discloses a stable-structure flame-retarding power cable, which includes a cable core and a protective sheath which coats the outer side of the cable core. The protective sheath includes, by weight, 70-90 parts of nitrile butadiene rubber, 20-40 parts of chloroprene rubber, 20-30 parts of polyurethane rubber, 3-6 parts of a plasticizer, 20-30 parts of modified magnesium hydroxide, 10-20 parts of melamine phosphate, 40-50 parts of expanded graphite, 1-2 parts of a silane coupling agent, 2-4 parts of hydroxyethyl cellulose, 0.5-0.9 parts of chlorinated polyethylene, 1-2 parts of anantioxidant AT-215, 1-3 parts of an ultraviolet absorber UV-327, 1-2 parts of a photostabilizer 744, and 5-9 parts of a crosslinking agent. The stable-structure flame-retarding power cable has high density and high binding force, is further improved in flame-retarding performance, has very excellent mechanical performances, is balanced in flexibility and hardness and is not liable to fracture, and has good structural stability in the protective sheath.

Owner:安徽伙伴电气有限公司

Method for detecting mixing dispersity of original bituminous pavement mixture in on-site heat recovery process

ActiveCN101900719AEnsure successful implementationGood mixing and dispersibilityMaterial testing goodsDispersityRoad surface

Owner:SOUTHEAST UNIV

Flame-retardant and waterproof polyvinyl chloride cable material

InactiveCN106800720AGood dispersionReduce flammabilityPlastic/resin/waxes insulatorsPolyvinyl alcoholPolyvinyl chloride

The invention discloses a flame-retardant and waterproof polyvinyl chloride cable material which is prepared from the following raw materials in parts by weight: 45-65 parts of polyvinyl chloride resin, 4-8 parts of modified kaolin, 9-13 parts of jute fiber, 8-12 parts of sea-foam stone powder, 8-12 parts of oxidized starch, 2-4 parts of isopropyl tri(dioctylpyrophosphate) titanate, 14-18 parts of cornstalks, 4-8 parts of potassium titanate fiber, 10-16 parts of polycaprolactone, 4-6 parts of polyvinyl alcohol, 20-24 parts of ethylene glycol, 2-4 parts of triethanolamine, 1-2 parts of white oil, 2-4 parts of a colorant, 2-4 parts of epoxy tall oil acid butyl ester, 2-6 parts of tung oil, 3-6 parts of disproportionated rosin, 2-4 parts of tertiary butylhydroquinone, 2-4 parts of sodium diacetate and 2-4 parts of an antistatic agent. The flame-retardant and waterproof polyvinyl chloride cable material has excellent heat stability and waterproof property, and also has a gas barrier function and excellent flame resistance.

Owner:ANHUI HUATIAN CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com