Anti-wear and antioxidant cooling liquid composition used for electric wire and cable copper conductors

A wire and cable, anti-oxidation technology, used in lubricating compositions, petroleum industry and other directions, can solve problems such as anti-wear and anti-oxidation effects, and achieve good mixing and dispersing effects, quality assurance, and low prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

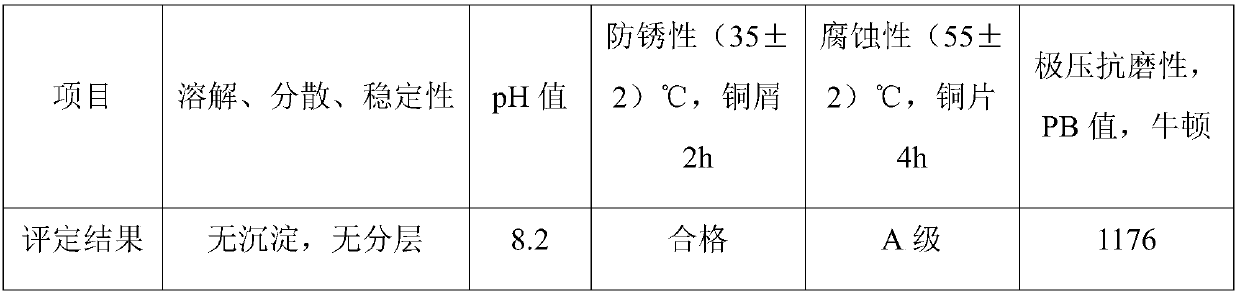

Examples

Embodiment 1

[0021] 480 parts of pure water

[0022] Copper drawing oil 11 parts

[0023] Extreme pressure anti-wear and anti-oxidation complex agent 1 part.

[0024] Composition of extreme pressure anti-wear and anti-oxidation compound: 15% boric acid, 6% potassium hydroxide, 19% No. 120 solvent oil, 43% high alkali value sulfonate extreme pressure agent, 7% bis-succinimide, phosphoric acid Tricresyl ester 7%, benzotriazole 3%.

[0025] Preparation of extreme pressure anti-wear and anti-oxidation composite agent: Add measured boric acid, potassium hydroxide, No. 120 solvent oil and high alkali value sulfonate extreme pressure agent into the blending kettle, heat to 100°C and stir for 2-3 hours After forming borate with good extreme pressure anti-wear and anti-friction properties, oxidation stability and excellent anti-rust and corrosion resistance, non-corrosive to copper at high temperature and non-toxic and tasteless, add bis-succinimide and phosphate and benzotriazole, fully stirred...

Embodiment 2

[0031] 500 parts of pure water

[0032] Copper drawing oil 9 parts

[0033] Extreme pressure anti-wear and anti-oxidation complex agent 1 part.

[0034] Composition of extreme pressure anti-wear and anti-oxidation compound: 19% metaboric acid, 8% sodium hydroxide, 18% jet fuel, 45% high alkali value sodium sulfonate extreme pressure agent, 3% monosuccinimide, triphosphate 5% phenyl ester, 2% benzotriazole.

[0035] Preparation of extreme pressure anti-wear and anti-oxidation composite agent: Add the measured amount of boride, alkali, solvent and high alkali value sulfonate extreme pressure agent into the blending kettle, heat to 100°C and stir for 2-3 hours to form a good Extreme pressure anti-wear and anti-friction properties, oxidation stability and excellent anti-rust and corrosion resistance, non-corrosive to copper at high temperature and non-toxic and tasteless borate, adding dispersant, phosphoric acid ester and benzotriazole, fully Stir to obtain a clear and transpa...

Embodiment 3

[0041] 510 parts of pure water

[0042] Copper drawing oil 13 parts

[0043] Extreme pressure anti-wear and anti-oxidation complex agent 1 part.

[0044] Composition of extreme pressure anti-wear and anti-oxidation compound: 18% boric acid, 8% potassium hydroxide, 20% No. 120 solvent oil, 45% high alkali value calcium sulfonate extreme pressure agent, 3% bis-succinimide, Di-n-butyl phosphate 5%, benzotriazole 1%.

[0045] Preparation of extreme pressure anti-wear and anti-oxidation composite agent: Add the measured amount of boride, alkali, solvent and high alkali value sulfonate extreme pressure agent into the blending kettle, heat to 100°C and stir for 2-3 hours to form a good Extreme pressure anti-wear and anti-friction properties, oxidation stability and excellent anti-rust and corrosion resistance, non-corrosive to copper at high temperature and non-toxic and tasteless borate, adding dispersant, phosphoric acid ester and benzotriazole, fully Stir to obtain a clear and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com