Method for detecting mixing dispersity of original bituminous pavement mixture in on-site heat recovery process

A technology of asphalt mixture and asphalt pavement, applied in the direction of material inspection products, etc., can solve the problems of uneven distribution of original asphalt pavement materials, uneven mixing of new and old materials, poor quality of regenerated pavement, etc., and achieve good promotion and utilization value, test Accurate and reliable data, simple and feasible test method

Active Publication Date: 2010-12-01

SOUTHEAST UNIV

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It can be seen that whether the crushed and mixed original pavement materials can reach a reasonable dispersion state is the primary factor affecting the quality of the recycled mixture. If the old pavement materials cannot be crushed and mixed to achieve a good disp

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

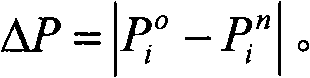

The invention provides a method for detecting mixing dispersity of original bituminous pavement mixture in on-site heat recovery process. The invention is characterized in that the method includes the following steps: step one, pavement material is taken; step two, mixing test is carried out on original bituminous pavement mixture; step three, preheated mineral powder is added and mixing is carried out again; step four, cooling is carried out, and then screening is carried out, so as to obtain unit screening rate Pio; step five, newly mixed bituminous mixture is produced according to bitumen-aggregate ratio and gradation of the original bituminous pavement mixture; step six, preheated mineral powder is added and mixing is carried out again; step seven, cooling is carried out, and then screening is carried out, so as to obtain unit screening rate Pin; step eight, the difference between the unit screening rates of the original bituminous pavement mixture and the newly mixed bituminous pavement mixture at each standard screening level is calculated. The test method provided by the invention can effectively solve the problem that mixing dispersion effect of pavement mixture in the existing bituminous pavement on-site heat recovery process can not be accurately evaluated, thus providing beneficial basis for design and optimization of on-site heat recovery construction technological condition.

Description

technical field [0001] The invention is a method for effectively evaluating the mixing and dispersibility of pavement mixture, especially a method that can easily solve the problem that the mixing and dispersing effect of the original pavement asphalt mixture cannot be accurately evaluated in the current on-site thermal regeneration process of asphalt pavement, and belongs to highway asphalt Pavement regeneration technology field. Background technique [0002] Since Shenyang-Dalian Expressway was completed and opened to traffic in 1988, my country's expressways have developed at an unprecedented speed. By the end of 2008, the mileage of expressways had exceeded 60,000 kilometers, ranking second in the world, of which asphalt pavement accounted for more than 90%. According to the national expressway development plan, my country will build 85,000 kilometers of expressways by the end of 2010, and form a complete national expressway network in 2020. However, compared with the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N33/42

Inventor 马涛赵永利黄晓明俞竞伟

Owner SOUTHEAST UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com