Membrane-dispersion liquid-phase cycle hydrorefining method

A film-dispersed, liquid-phase technology, applied in hydroprocessing, refining to remove heteroatoms, petroleum industry, etc., can solve the problems of low reaction space velocity, complicated operation process, uneven dispersion, etc., and achieve easy operation and control, The effect of low reaction temperature and high operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

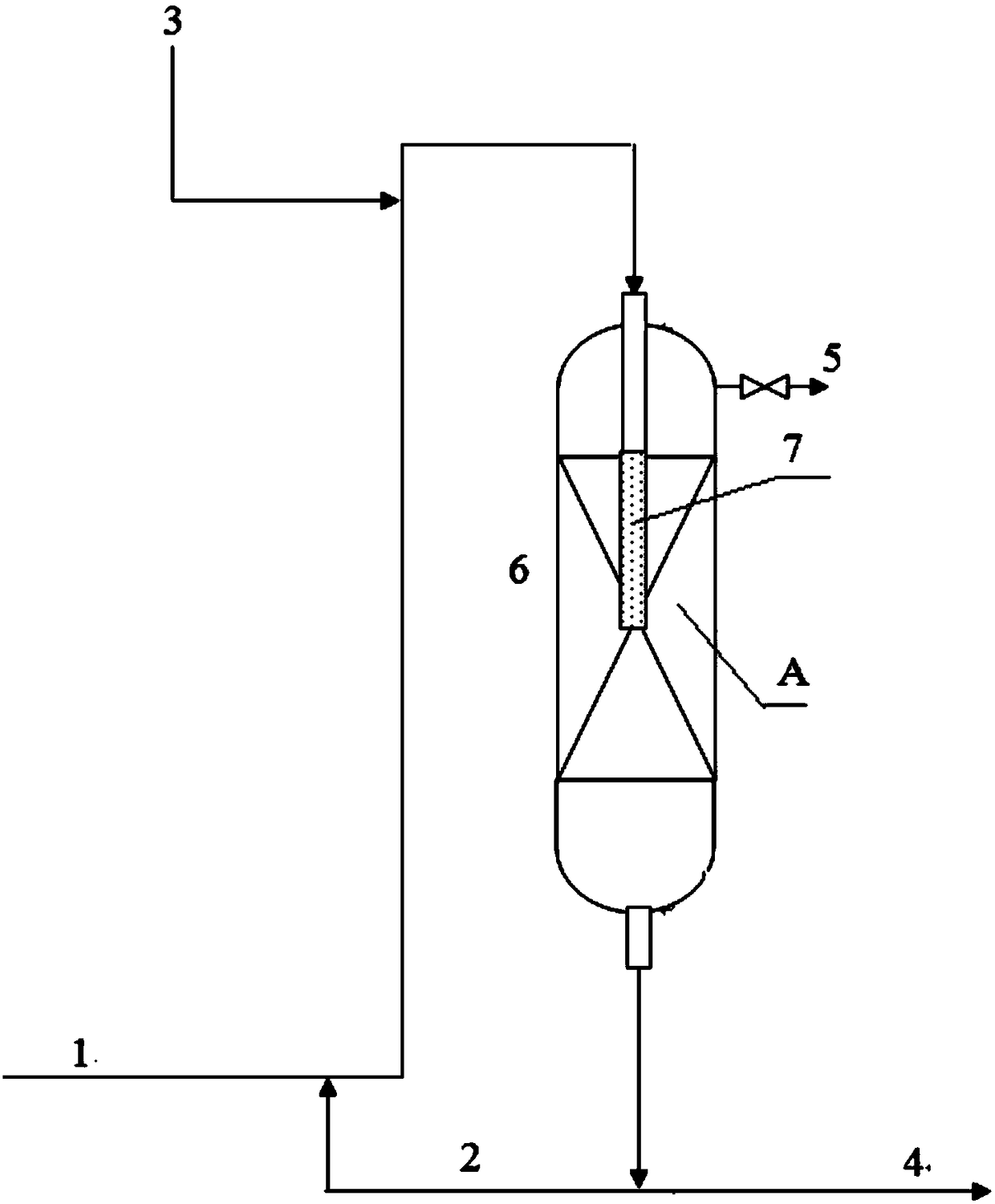

[0035] The production of clean oil products is realized by adopting the membrane-dispersed liquid-phase circulating hydrofining method of the present invention, which only includes the scheme of a single hydrogenation reactor bed, and the schematic diagram of the process flow is as follows figure 1 As shown, in this process, the length of the membrane tube goes deep into 1 / 3 of the catalyst bed. The reaction material used is the bottom feed mode, and some equipment, such as pumps and heat exchangers, are omitted in the figure, but this is well known to those of ordinary skill in the art. Such as figure 1 As shown, the detailed description of the process flow is as follows: After the distillate oil raw material 1 is mixed with the recycled product 2 at the outlet of the hydrogenation reactor 6, it is pre-saturated with hydrogen dissolved in the pipeline with the new hydrogen 3 from the new hydrogen booster. After being saturated with hydrogen, the liquid enters the hydrogenati...

Embodiment 2

[0046] Compared with embodiment 1, used fresh raw material, THDS-I hydrorefining catalyst are the same as embodiment 1. The difference in catalyst loading is that the loading volume of THDS-1 hydrorefining catalyst is 25% of that in Example 1, the hydrogenation process conditions are the same as in Table 1-2 in Example 1, and the properties of the hydrogenation reaction product refined diesel oil are shown in Table 2-1 .

[0047] Table 2-1 Properties of refined oil produced by hydrogenation reaction

[0048] running time, h

Embodiment 3

[0056] The production of clean oil products is realized by adopting the membrane-dispersed liquid-phase circulating hydrofining method of the present invention, which includes the scheme of two hydrogenation reactor beds, and the schematic diagram of the process flow is as follows figure 2 As shown, in this process, the length of the membrane tube in each reactor bed reaches 1 / 3 of the catalyst bed. The reaction material used is the bottom feed mode, and some equipment, such as pumps and heat exchangers, are omitted in the figure, but this is well known to those of ordinary skill in the art. Such as figure 2 As shown, the process flow is described in detail as follows: After the distillate oil raw material 1 is mixed with the recycled product 2 at the outlet of the hydrogenation reactor, it is pre-saturated with hydrogen dissolved in the pipeline with the new hydrogen 3 from the new hydrogen booster. After being saturated with hydrogen, the liquid raw material enters the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com