Method for enhancing density of SiC/SiC ceramic matrix composite

A composite material and ceramic-based technology, applied in the field of composite materials, can solve the problems of long densification period, failure to meet practical application requirements, and high porosity, and achieve improved densification degree, good chemical compatibility, and short densification time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

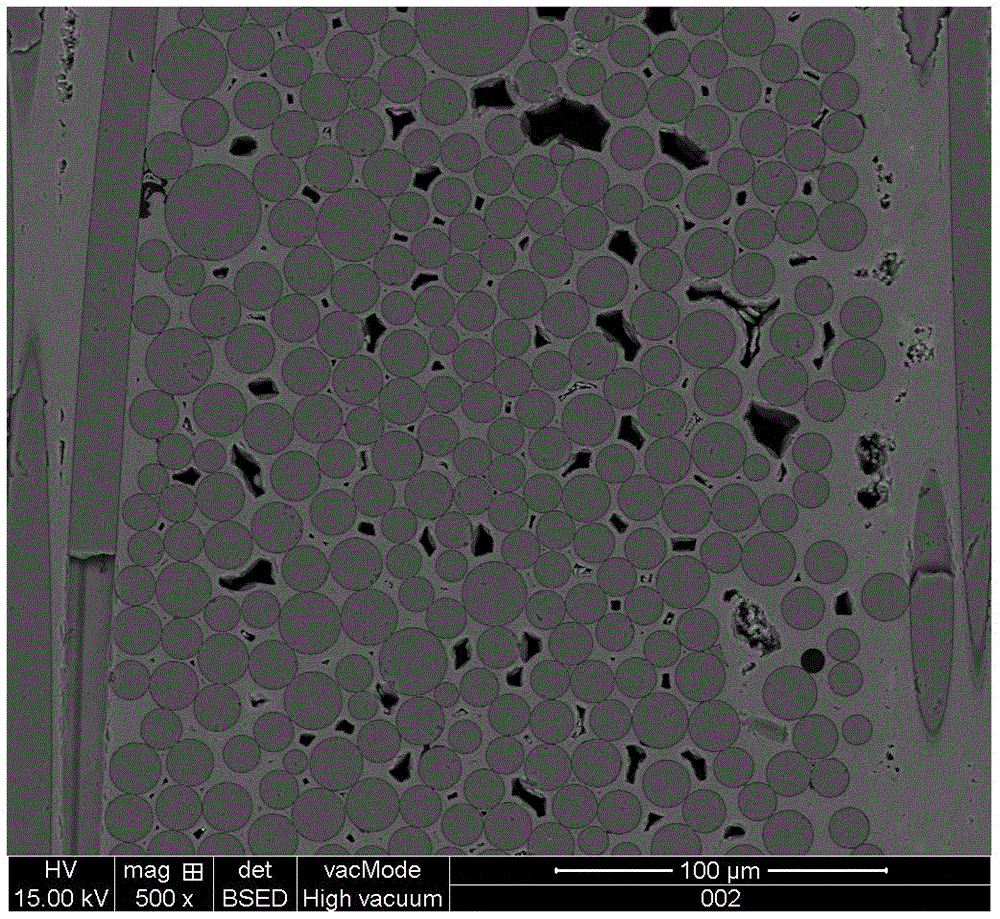

[0050] Embodiment 1: SiC / SiC composite material with porosity 20% (adopt chemical vapor infiltration method to make, SEM picture is as follows figure 1 Shown) Follow the steps below to process:

[0051] (1) Grinding and polishing the surface of the composite material, ultrasonic cleaning 3 times with deionized water, about 40 minutes each time, and then drying;

[0052] (2) Mix polycarbosilane with a molecular weight of 1500-1800 and SiC powder with a particle size of 1.5 μm in a mass ratio of 6:4, and ball mill for 24 hours to make a stable slurry;

[0053] (3) Pour the slurry or organic precursor solution prepared in (2) into the dipping tank, and then put the material treated in step (1) into the dipping tank, keeping the slurry or precursor solution submerged in the material. Seal the impregnation tank, vacuumize it, and impregnate it for 30 minutes at a vacuum degree of 8KPa, so that the slurry penetrates into the internal pores of the composite material;

[0054] (4) P...

Embodiment 2

[0068] Embodiment 2: The SiC / SiC composite material with a porosity of 20% is processed according to the following steps:

[0069] (1) Grinding and polishing the surface of the composite material, ultrasonic cleaning 3 times with deionized water, about 40 minutes each time, and then drying;

[0070] (2) Mix polycarbosilane with a molecular weight of 1500-1800 and SiC powder with a particle size of 1.5 μm in a mass ratio of 6.5:3.5, and ball mill for 24 hours to make a stable slurry;

[0071] (3) Pour the slurry or organic precursor solution prepared in (2) into the dipping tank, and then put the material treated in step (1) into the dipping tank, keeping the slurry or precursor solution submerged in the material. Seal the impregnation tank, vacuumize it, and impregnate it for 30 minutes at a vacuum degree of 8KPa, so that the slurry penetrates into the internal pores of the composite material;

[0072] (4) Put the vacuum-impregnated material into a curing furnace, and raise t...

Embodiment 3

[0077] Embodiment 3: The SiC / SiC composite material with a porosity of 20% is processed according to the following steps:

[0078] (1) Grinding and polishing the surface of the composite material, ultrasonic cleaning 3 times with deionized water, about 40 minutes each time, and then drying;

[0079] (2) Mix polycarbosilane with a molecular weight of 1500-1800 and SiC powder with a particle size of 1.5 μm in a mass ratio of 7:3, and ball mill for 24 hours to make a stable slurry;

[0080](3) Pour the slurry or organic precursor solution prepared in (2) into the dipping tank, and then put the material treated in step (1) into the dipping tank, keeping the slurry or precursor solution submerged in the material. Seal the impregnation tank, vacuumize it, and impregnate it for 30 minutes at a vacuum degree of 8KPa, so that the slurry penetrates into the internal pores of the composite material;

[0081] (4) Put the vacuum-impregnated material into a curing furnace, and raise the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com