Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

236results about How to "Good chemical compatibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medium-high temperature composite structural heat storage material, preparation method and application thereof

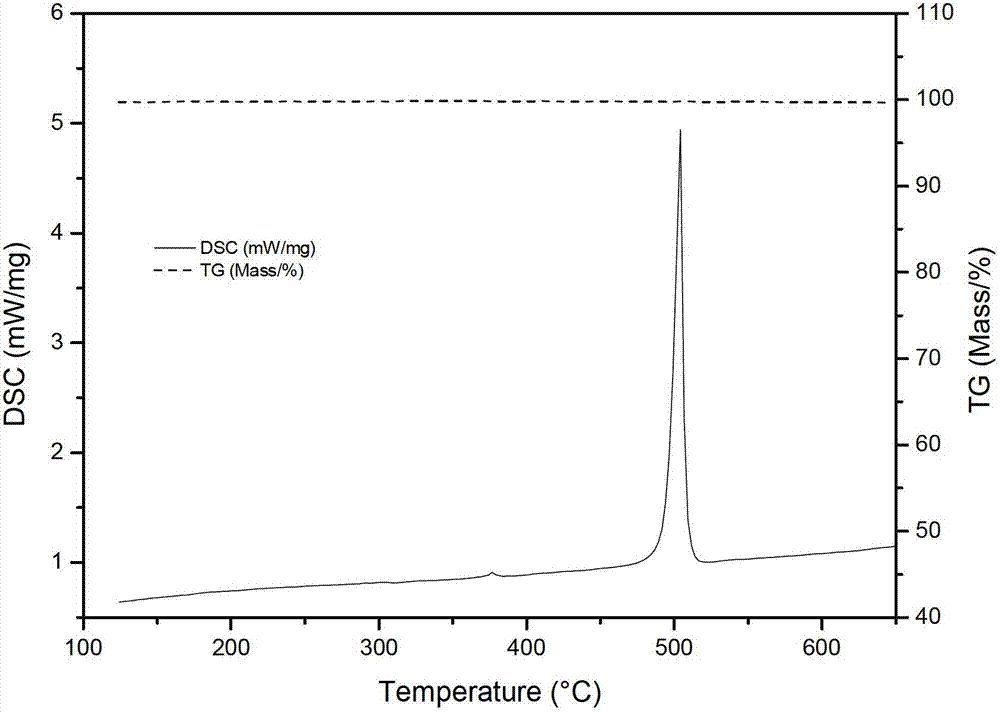

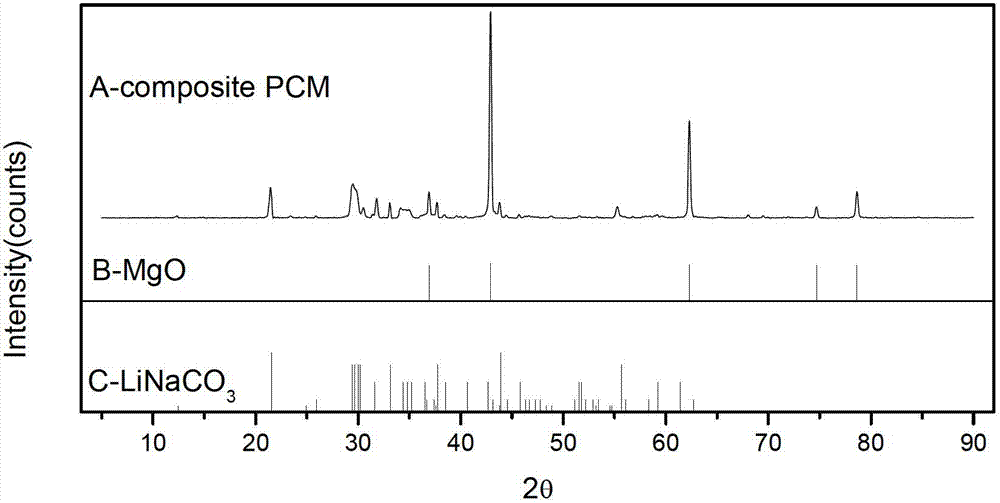

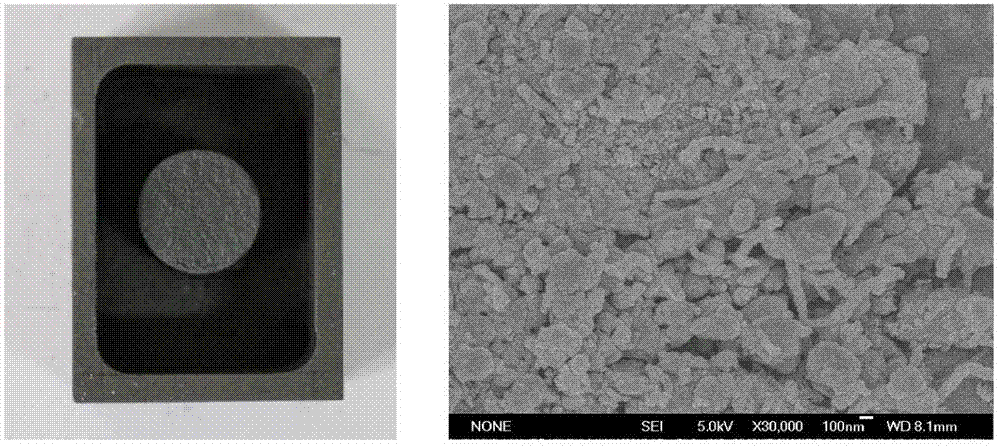

InactiveCN102888209AHigh phase change enthalpyGood chemical compatibilityHeat-exchange elementsMicro nanoMass ratio

The invention relates to a medium-high temperature (120-1000 DEG C or higher) composite structural heat storage material. The medium-high temperature composite structural heat storage material comprises an inorganic salt phase change latent heat material, a sensitive heat storage material and a heat conduction reinforcing material, wherein the mass ratio of the inorganic salt phase change latent heat material to the sensitive heat storage material is of 1: (0.1-10); and the heat conduction reinforcing material is of 0.0001-1kg / (kg heat storage material) based on mass ratio. The preparation method comprises steps as follows: uniformly mixing the inorganic salt phase change latent heat material with the sensitive heat storage material and the heat conduction reinforcing material; pressurizing to form green blank; and then heating and sintering, so as to obtain the medium-high temperature composite structural heat storage material. The medium-high temperature composite structural heat storage material provided by the invention is capable of obviously reducing the corrosion resistance of the sensitive heat storage material; meanwhile, the thermal conductivity of the composite heat storage material is markedly improved by virtue of the micro-nano doping of the heat conduction reinforcing material; and moreover, high heat storage density is achieved, and wide application prospect is provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

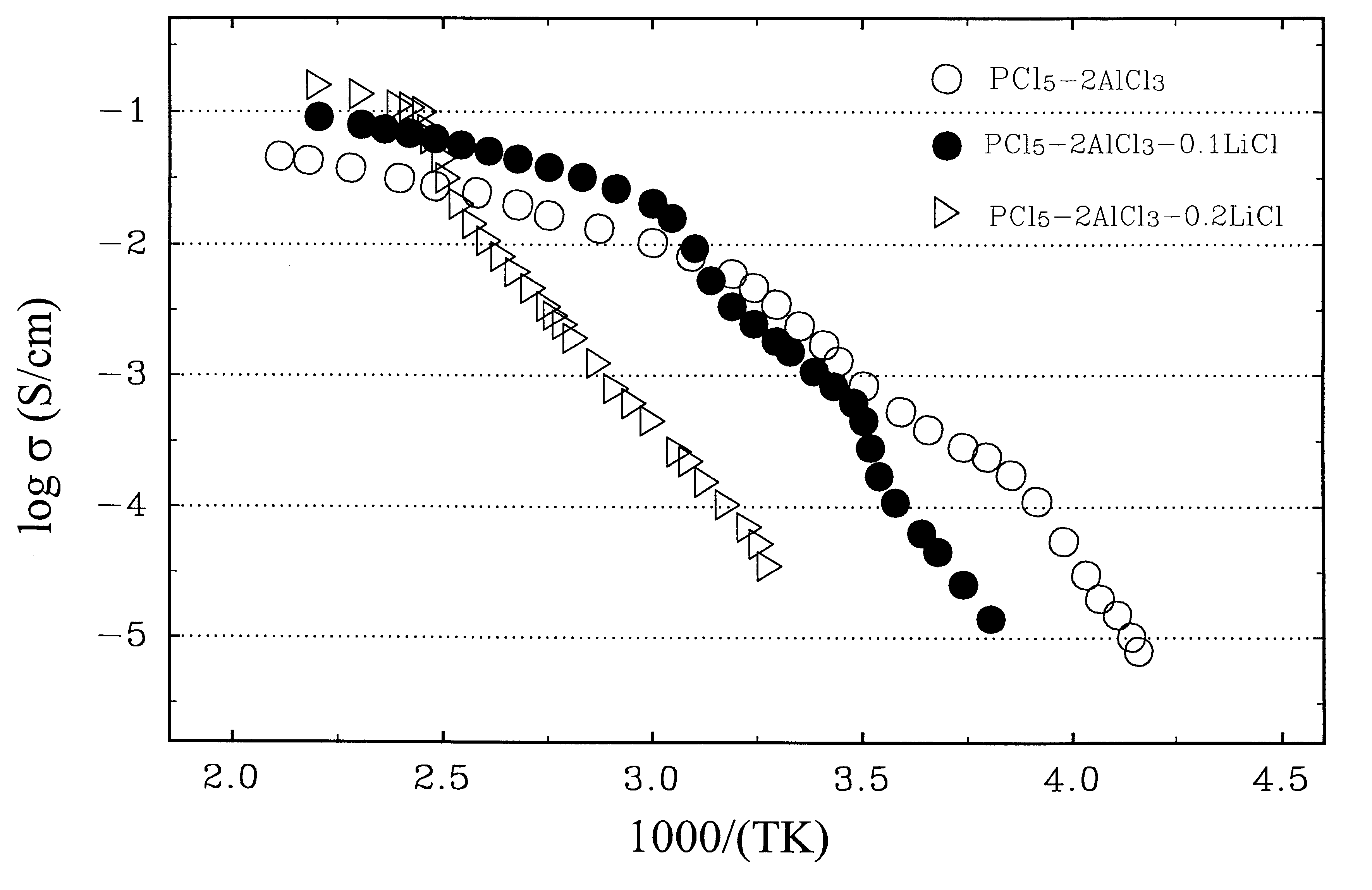

Ambient temperature, rechargeable cells with metal salt-based electrodes and a system of cell component materials for use therein

InactiveUS6187479B1Improve battery performanceImprove performanceLead-acid accumulatorsNon-aqueous electrolyte cellsHalogenRechargeable cell

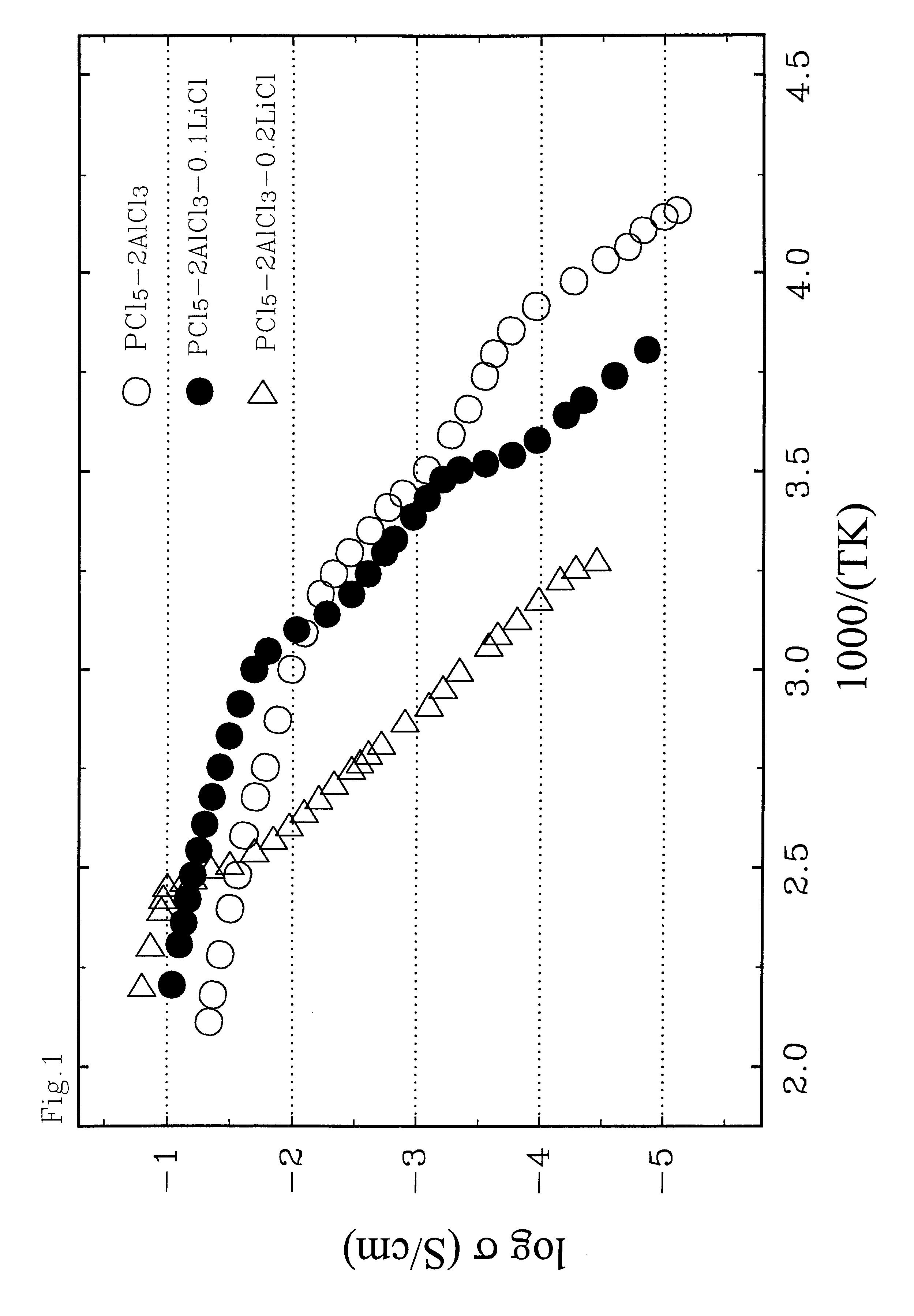

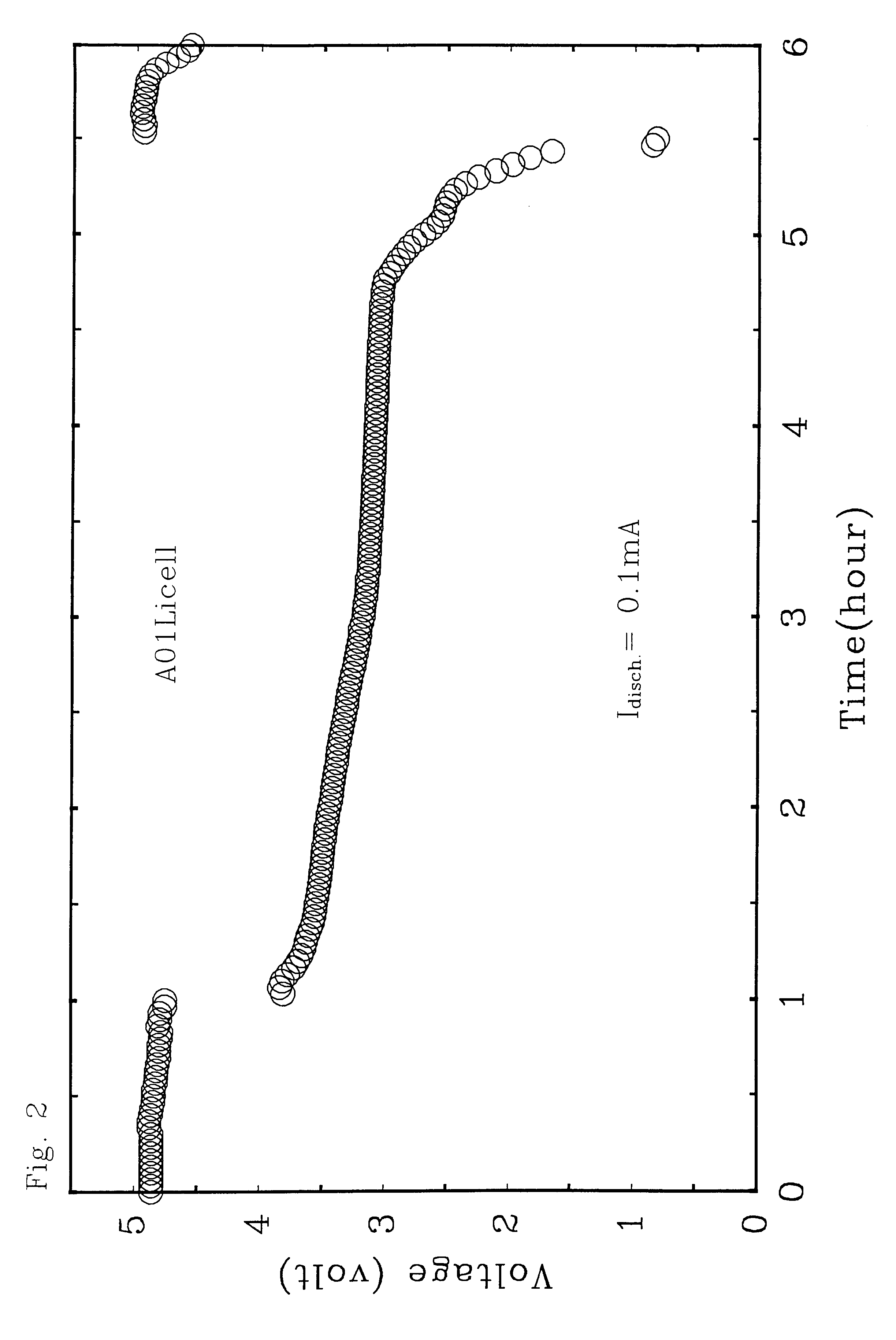

A rechargeable battery or cell is disclosed in which the electrode active material consists of at least one nonmetallic compound or salt of the electropositive species on which the cell is based, and the electrolyte or electrolyte solvent consists predominantly of a halogen-bearing or chalcogen-bearing covalent compound such as SOCl2 or SO2Cl2. Also disclosed are cell component materials which include electrodes that consist primarily of salts of the cell electropositive species and chemically compatible electrolytes. These latter electrolytes include several newly discovered ambient temperature molten salt systems based on the AlCl3-PCl5 binary and the AlCl3-PCl5-PCl3 ternaries.

Owner:LIU CHANGLE

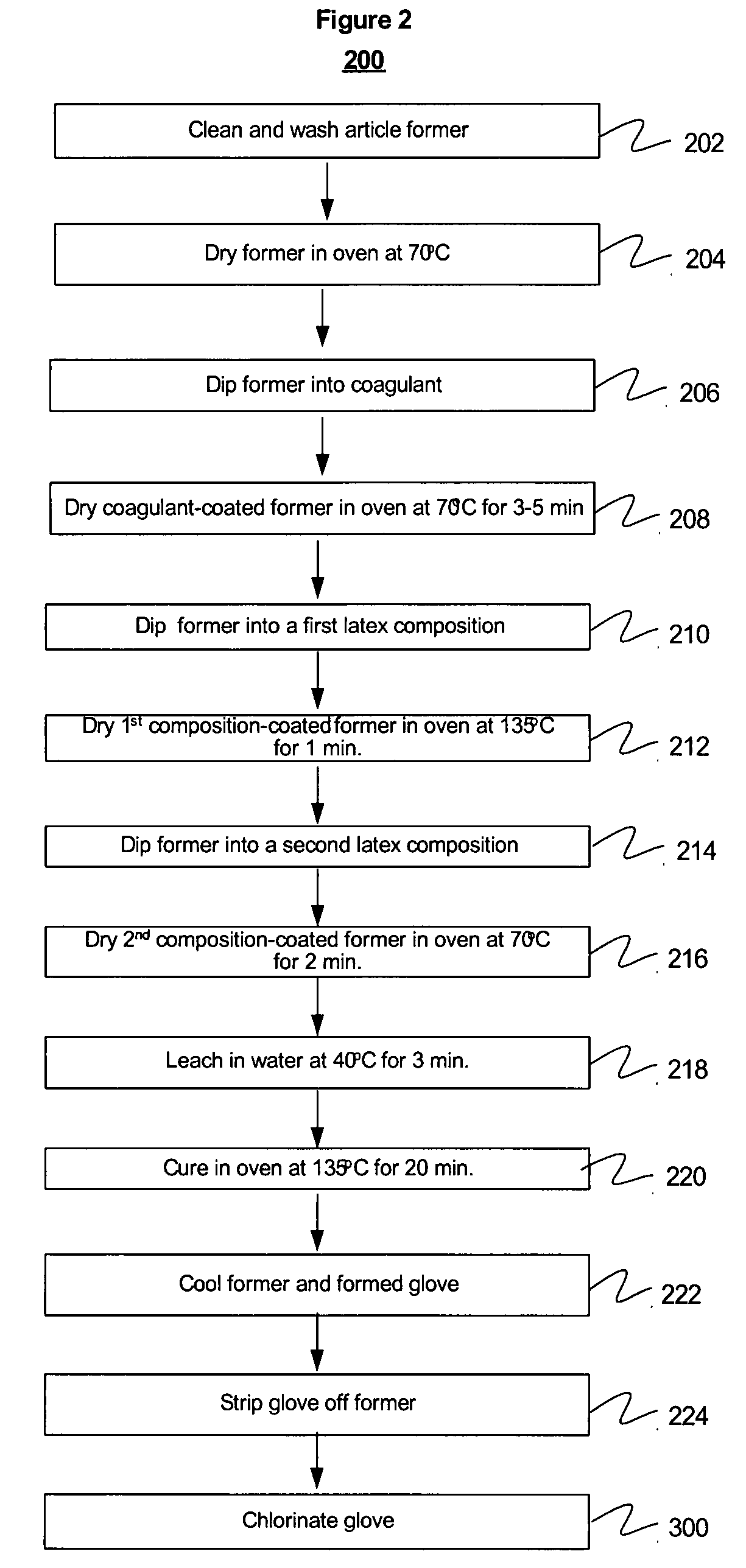

Antistatic gloves and process for making same

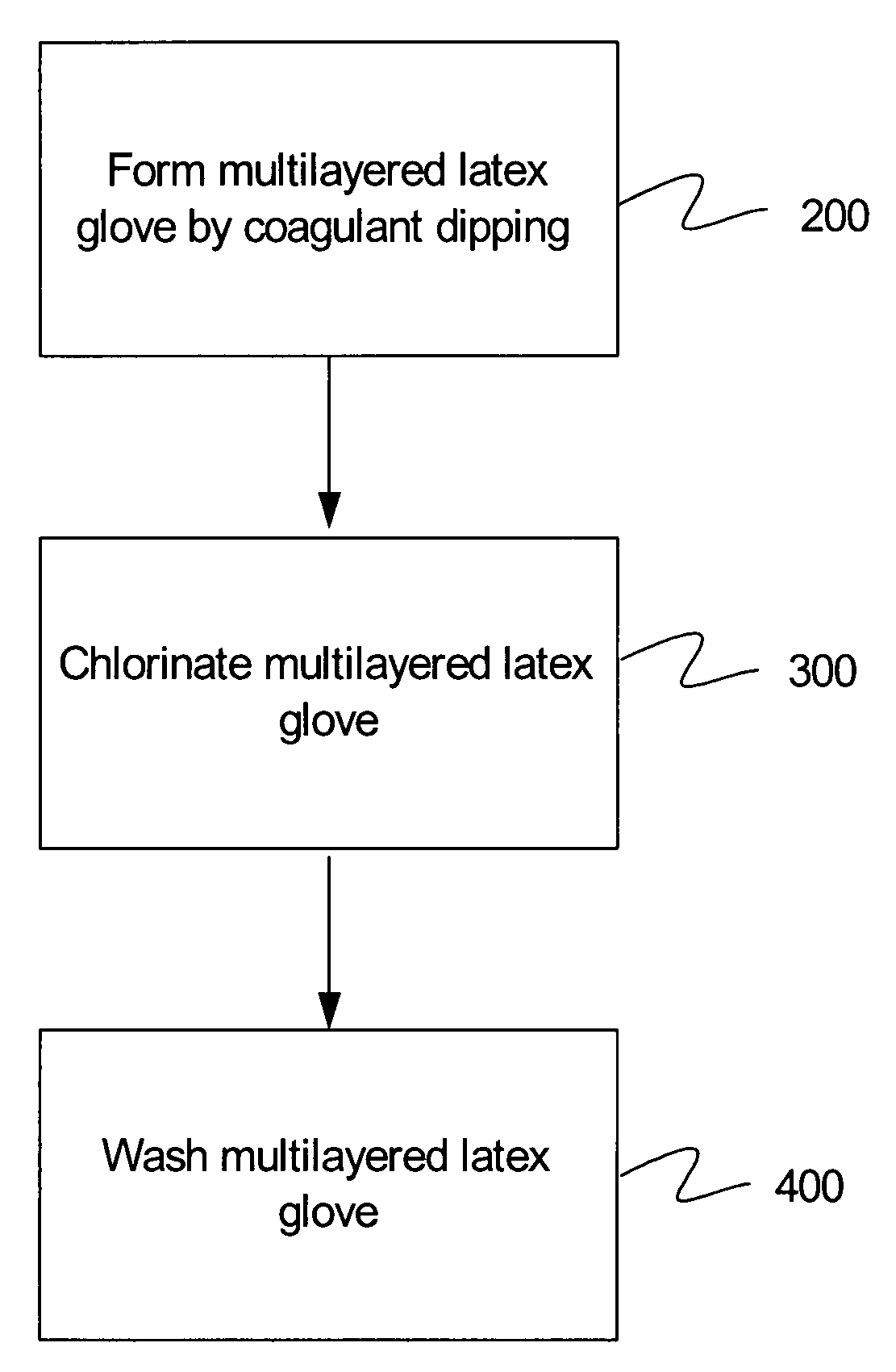

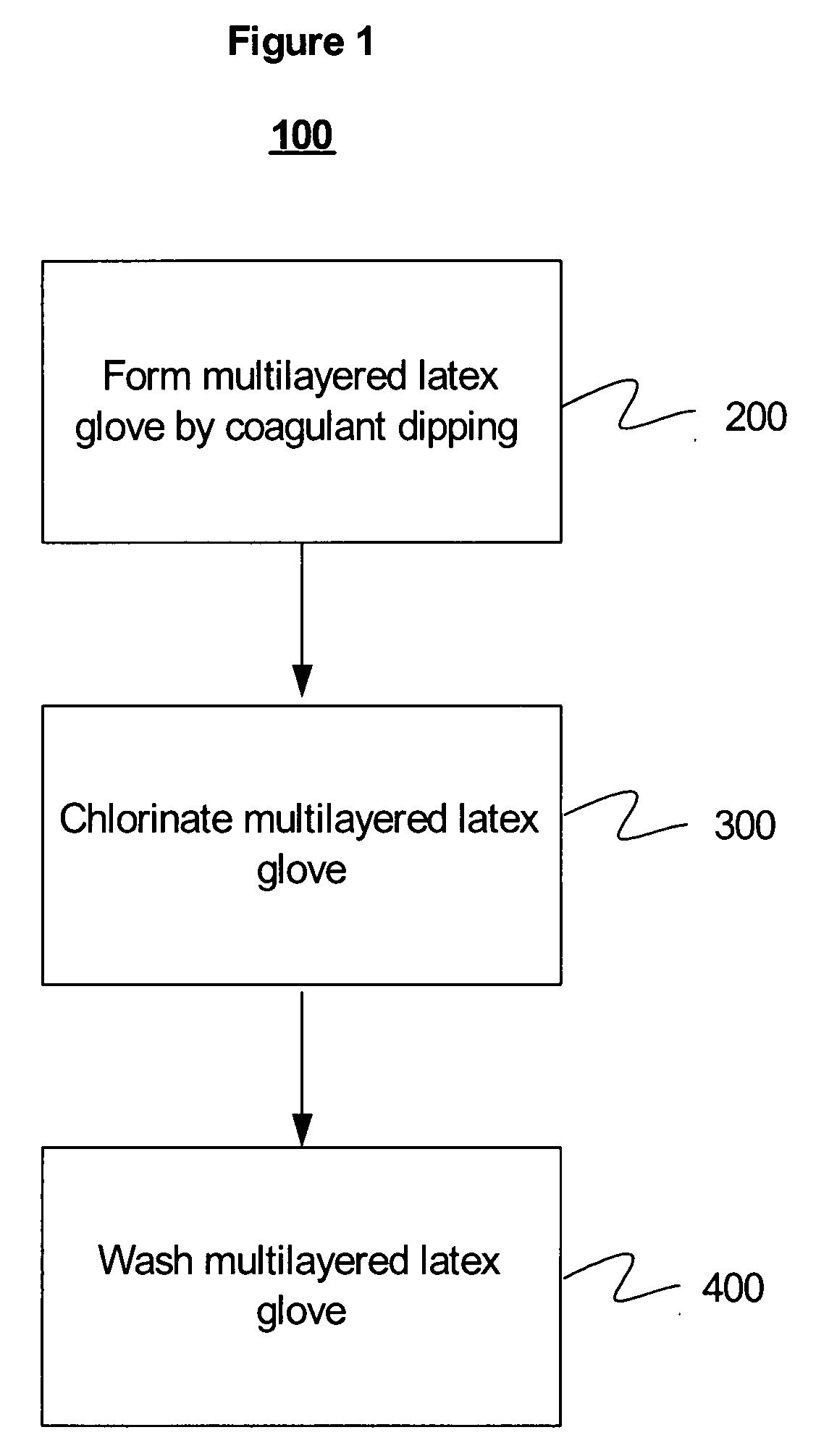

InactiveUS20080306200A1Desirable antistatic propertyDesirable propertyGlovesConjugated diene hydrocarbon coatingsPolymer scienceAntistatic agent

The present invention is directed to antistatic elastomeric articles and methods of making the same. The articles can be single layered or multilayered. The single layered articles possess desirable antistatic properties and desirable properties of comfort and feel. The multilayered articles have an outermost layer / surface that possesses desirable antistatic properties and an innermost layer / surface that exhibits desirable properties of comfort and feel. In preferred embodiments, the elastomeric articles are made form a nitrile / natural rubber blend. Articles of the present invention have antistatic properties measured as having a surface resistivity below about 1014 Ω / sq and a static decay time of less than about 60 seconds.

Owner:ALLEGIANCE CORP

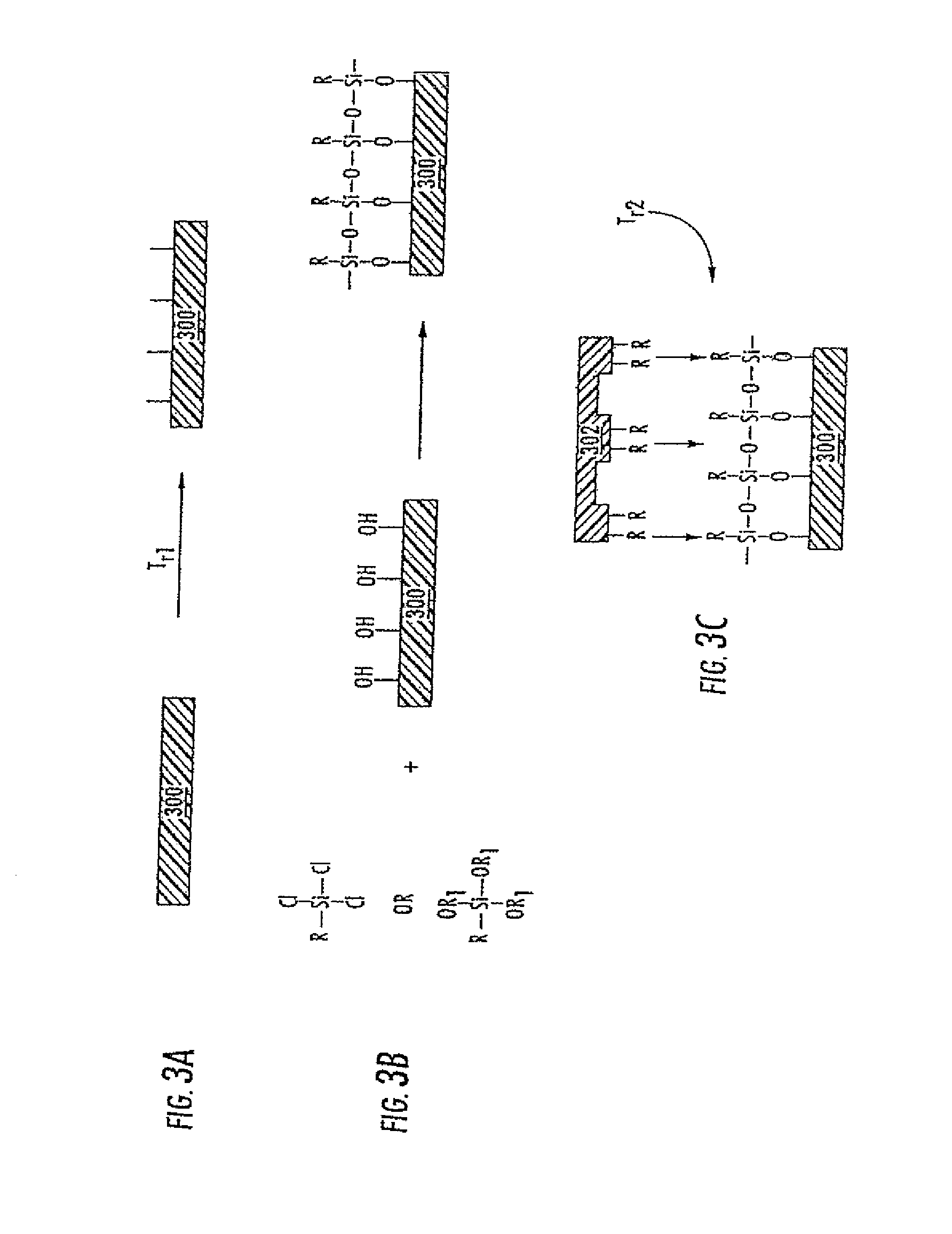

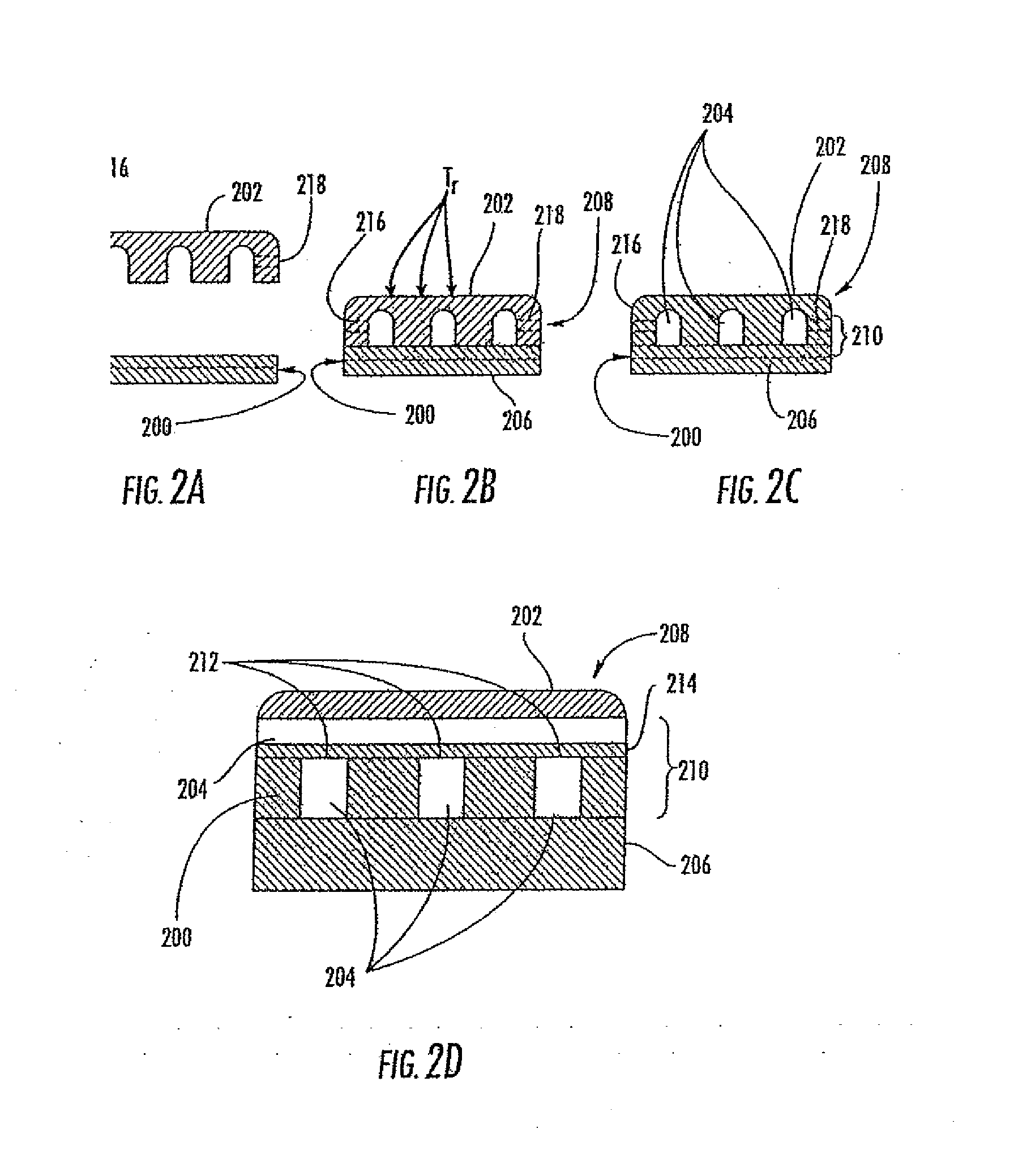

Methods and materials for fabricating microfluidic devices

ActiveUS8444899B2Good chemical compatibilityLaboratory glasswaresPolyether coatingsHydrocarbon solventsDevice material

Materials and Methods are provided for fabricating microfluidic devices. The materials include low surface energy fluoropolymer compositions having multiple cure functional groups. The materials can include multiple photocurable and / or thermal-curable functional groups such that laminate devices can be fabricated. The materials also substantially do not swell in the presence of hydrocarbon solvents.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

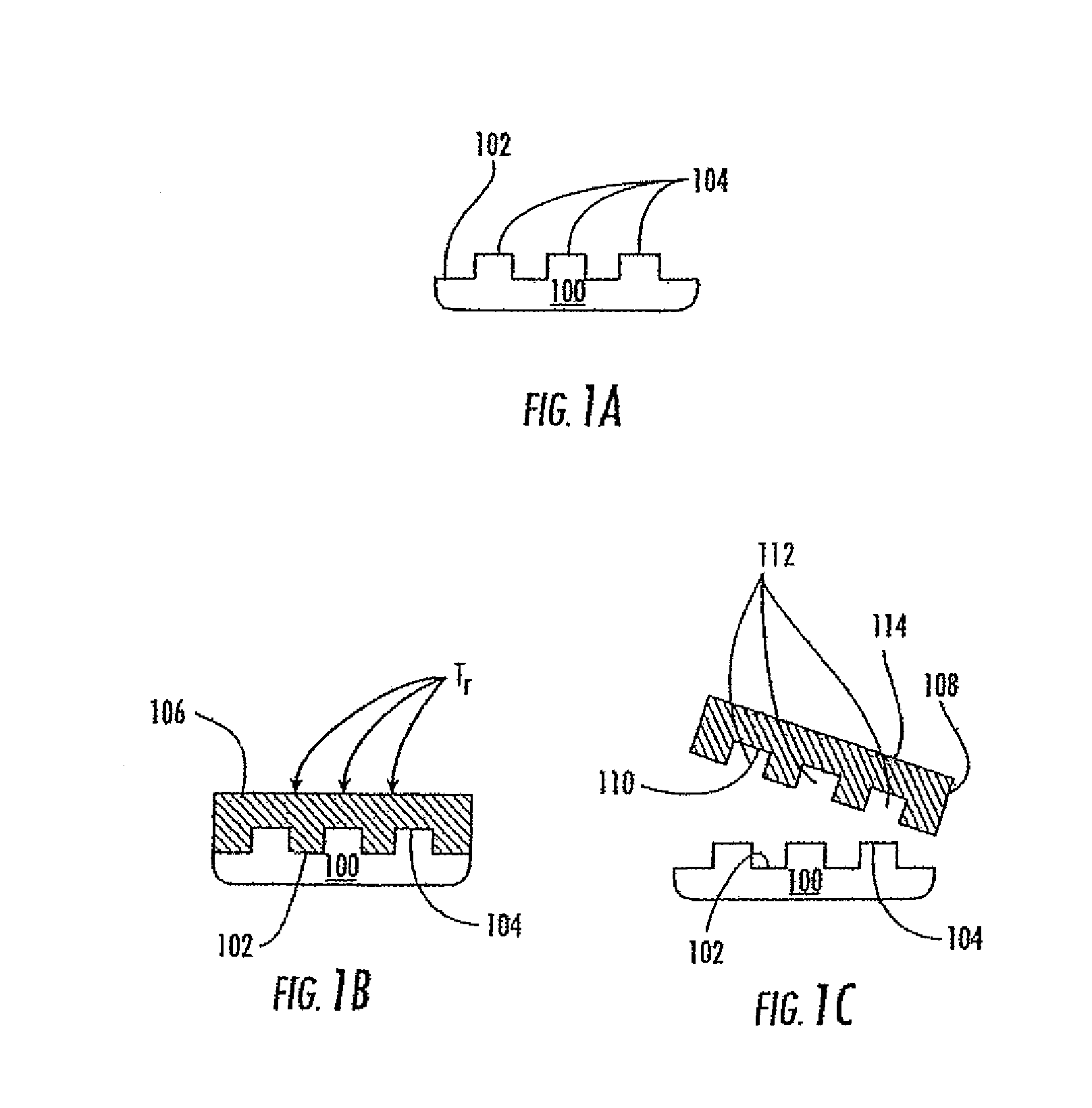

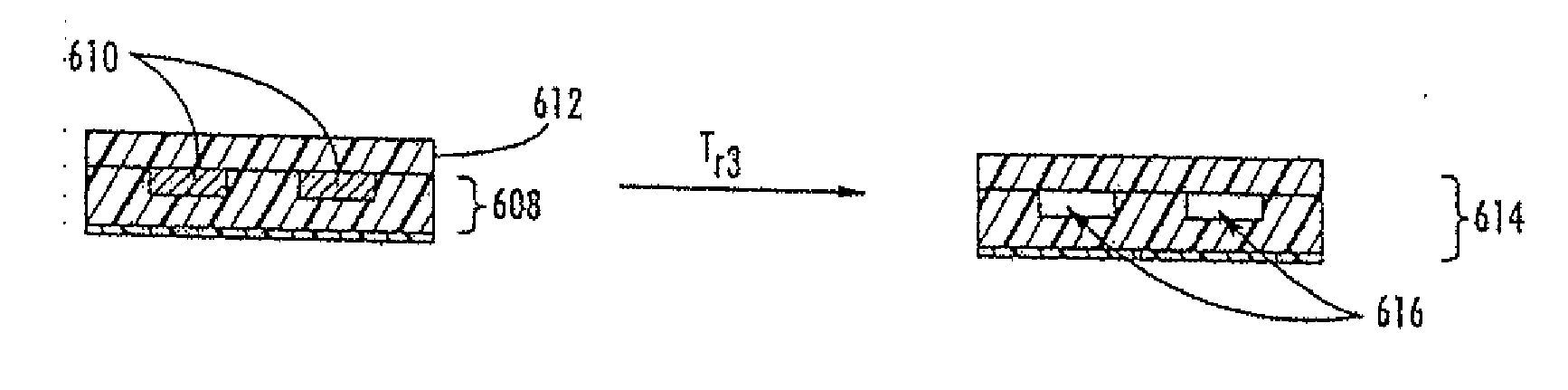

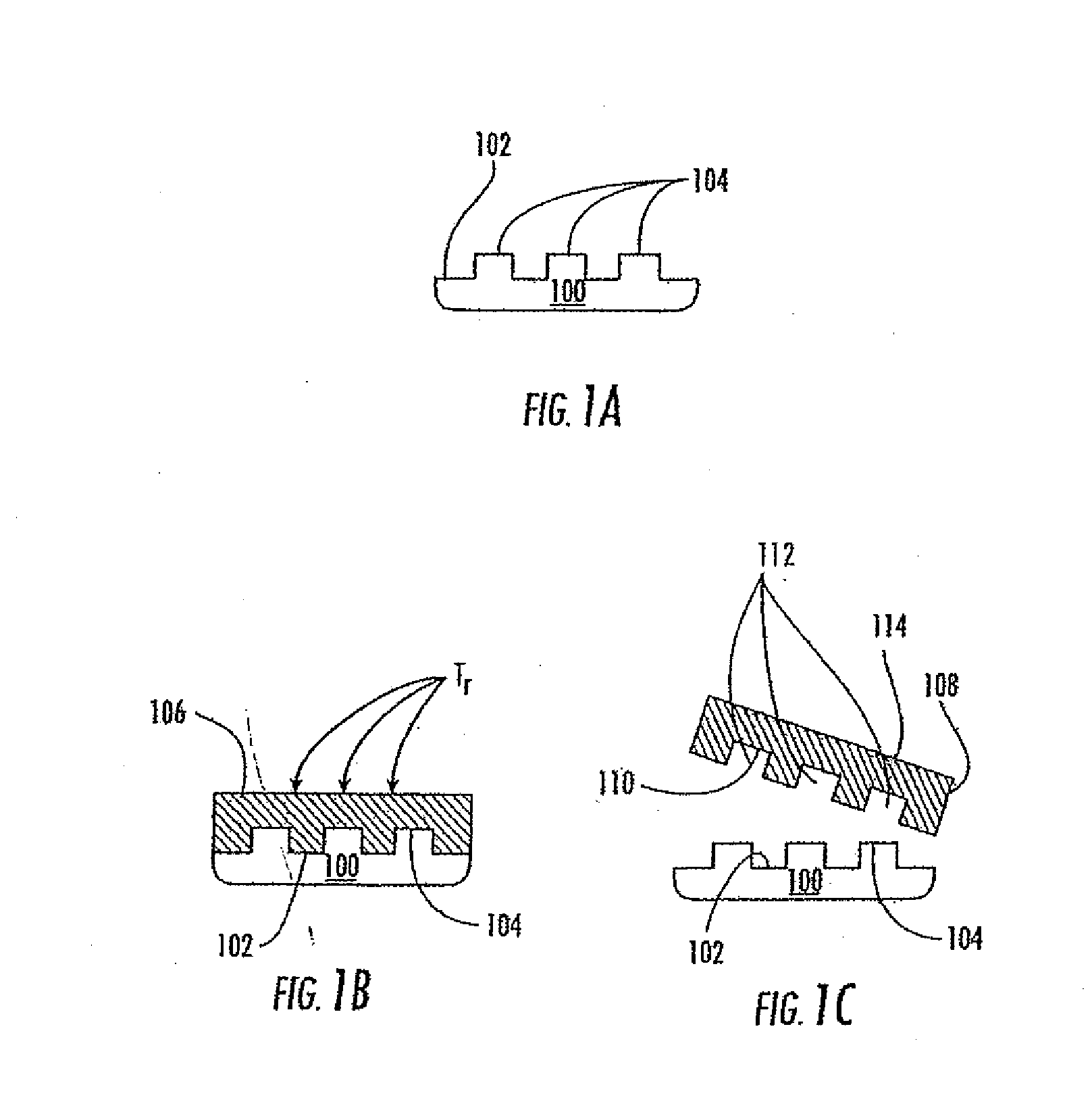

Method of decorating a molded article

InactiveUS6929771B1Prevent seepageEasy adhesionLamination ancillary operationsBristlePolymer scienceShell molding

Owner:HIGH VOLTAGE GRAPHICS

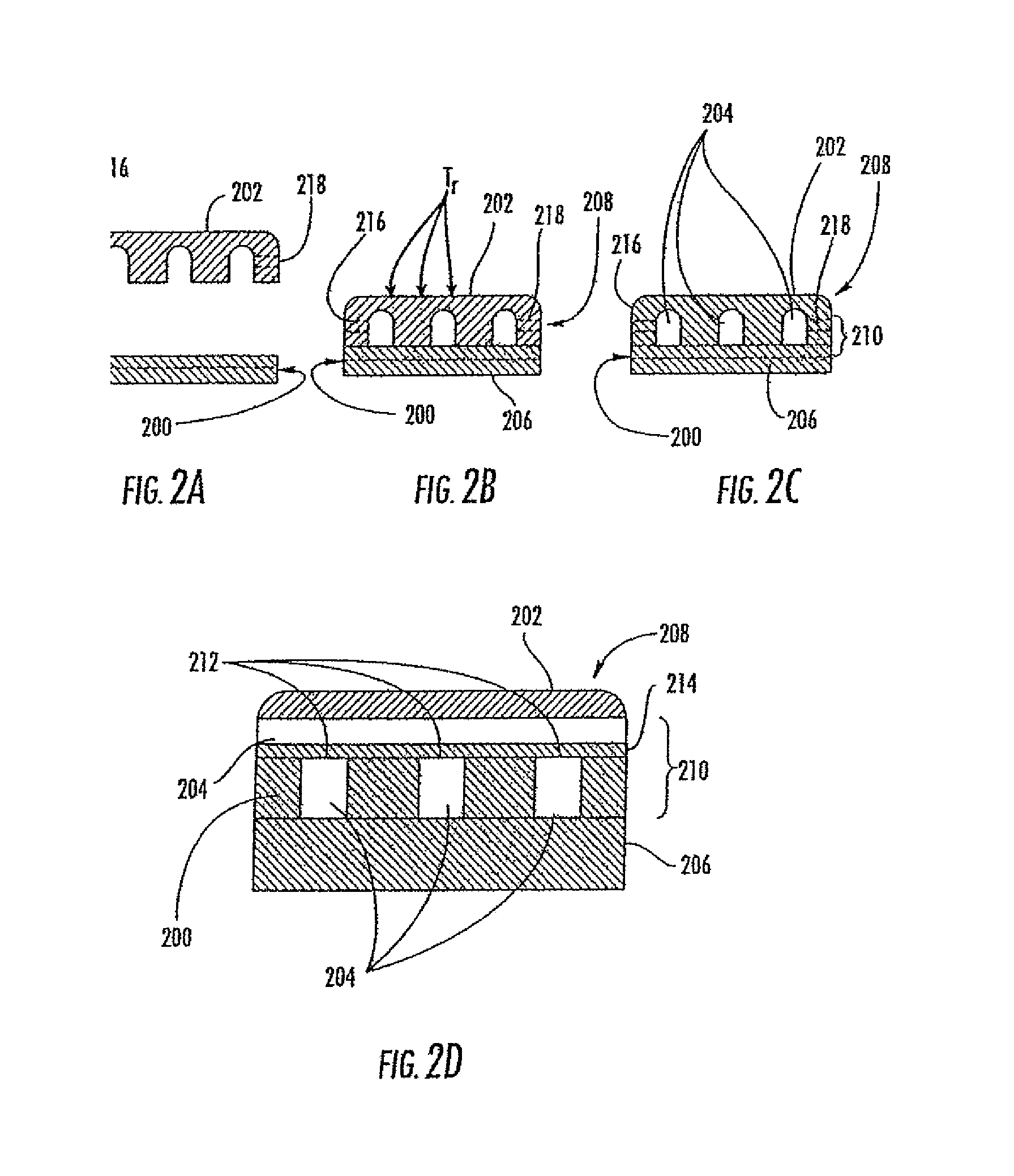

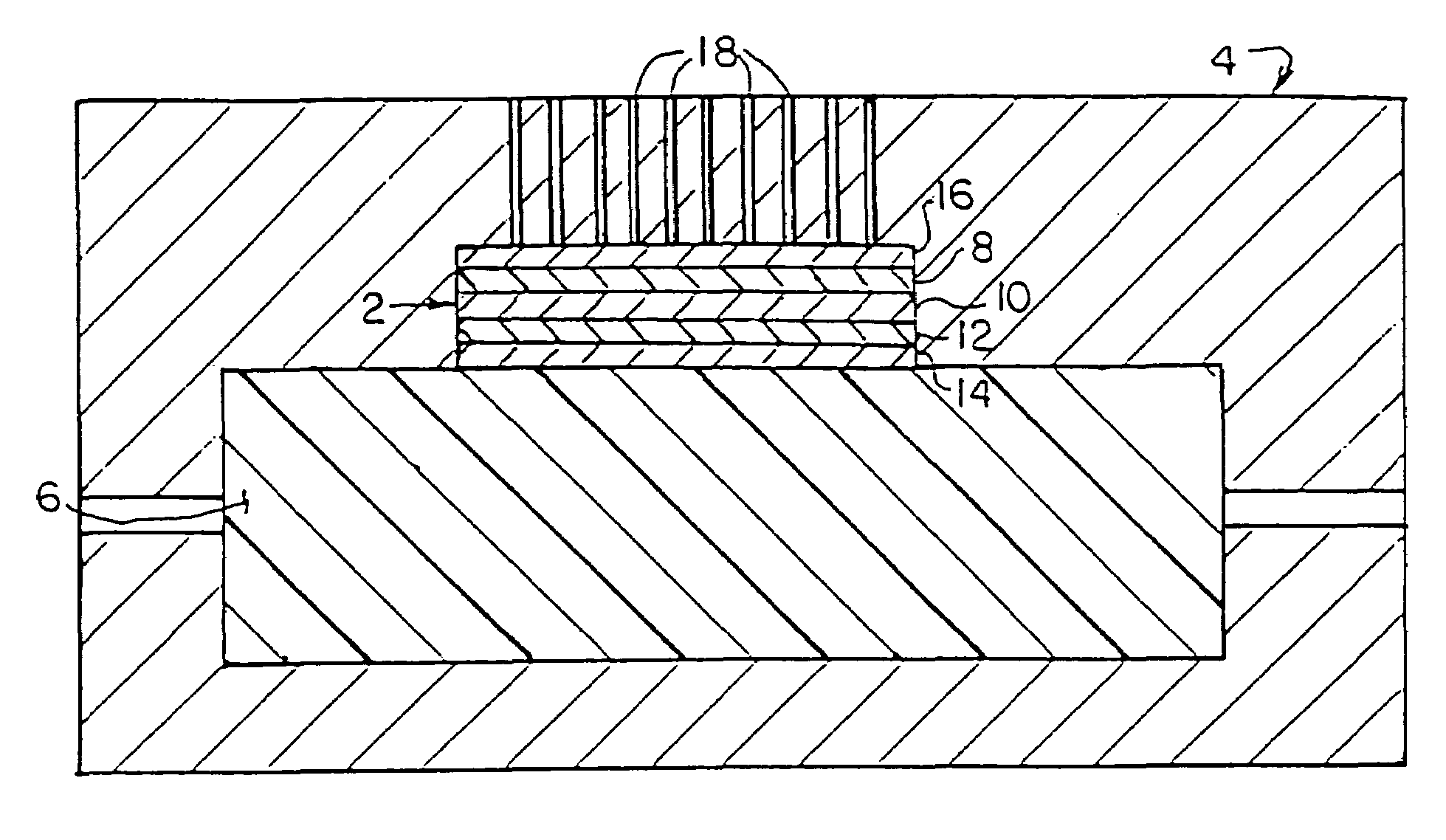

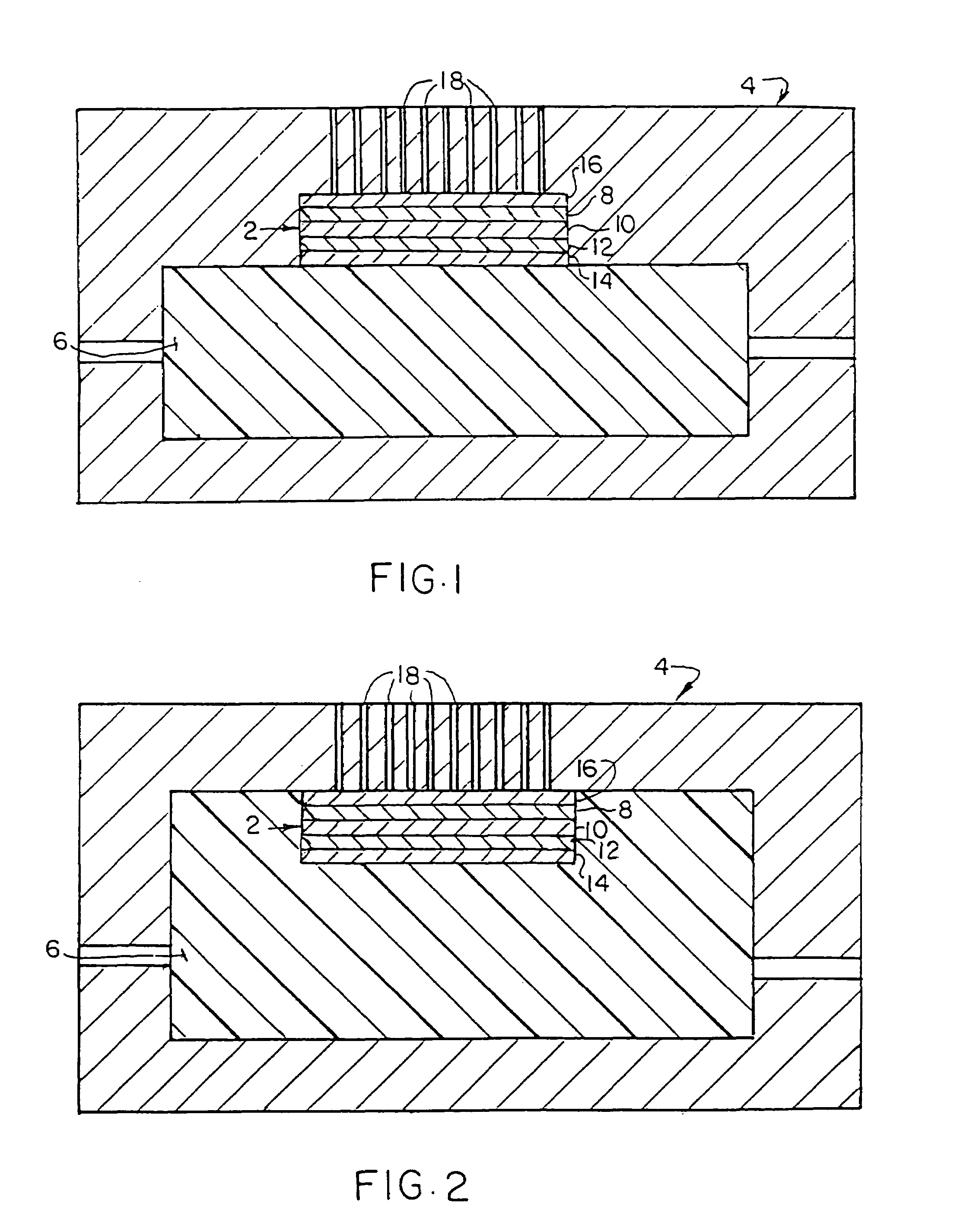

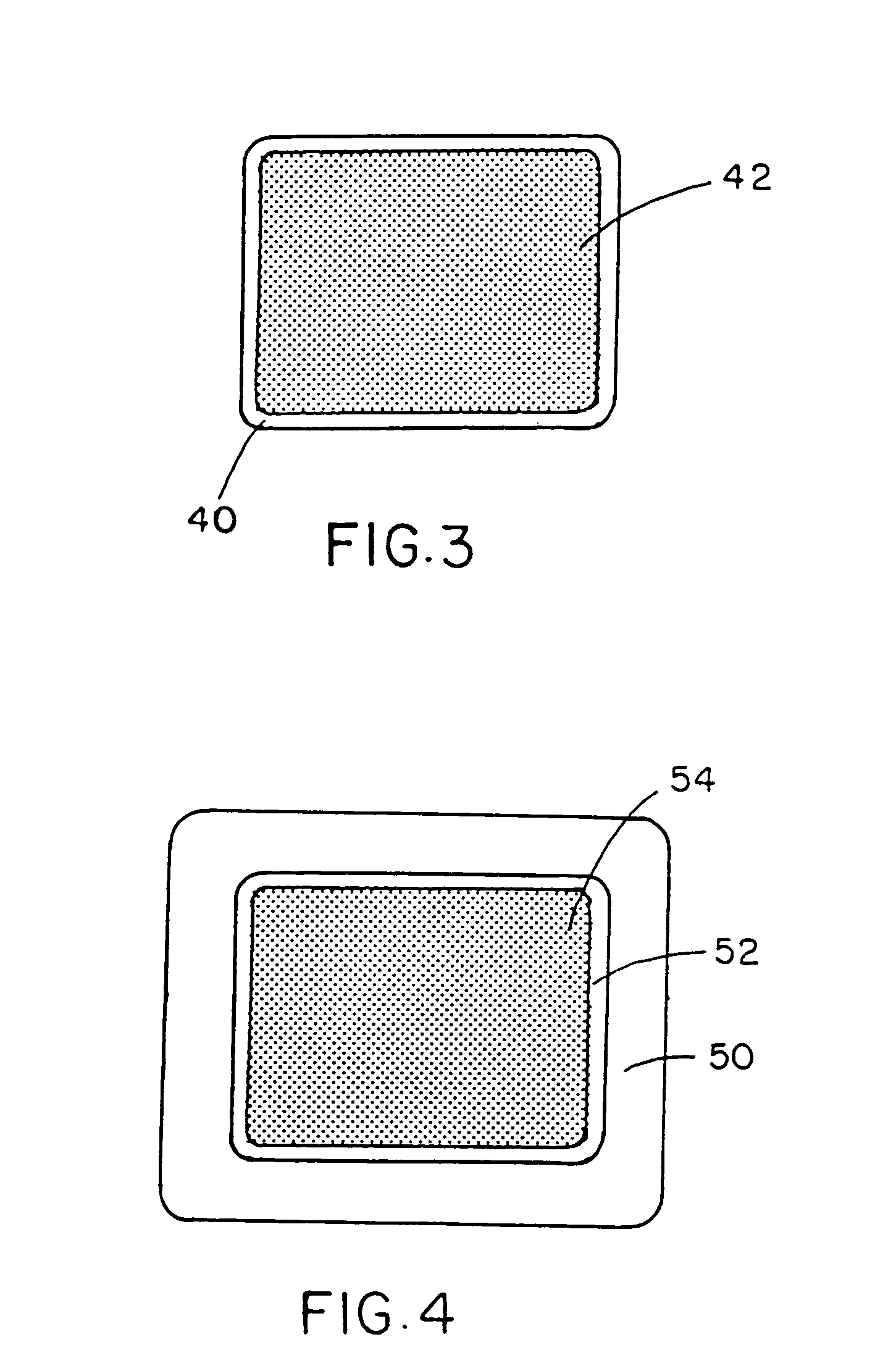

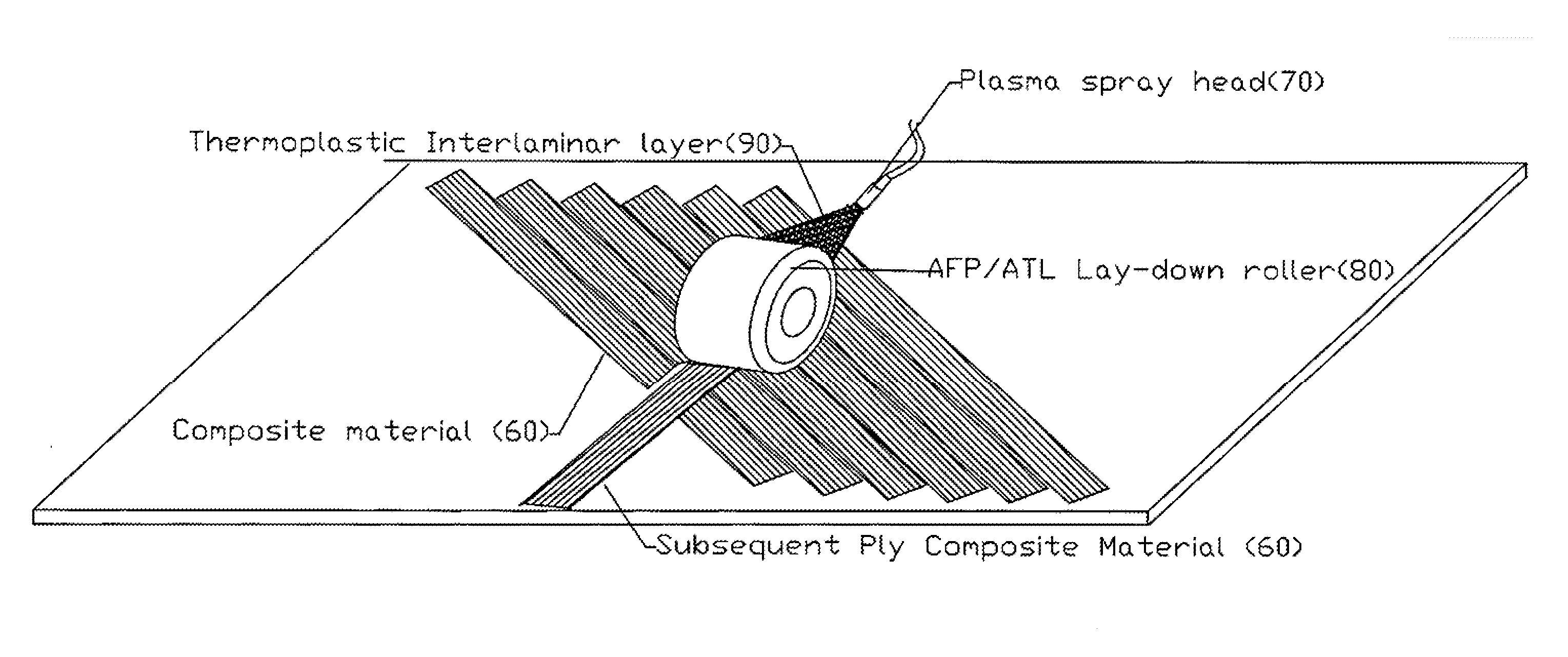

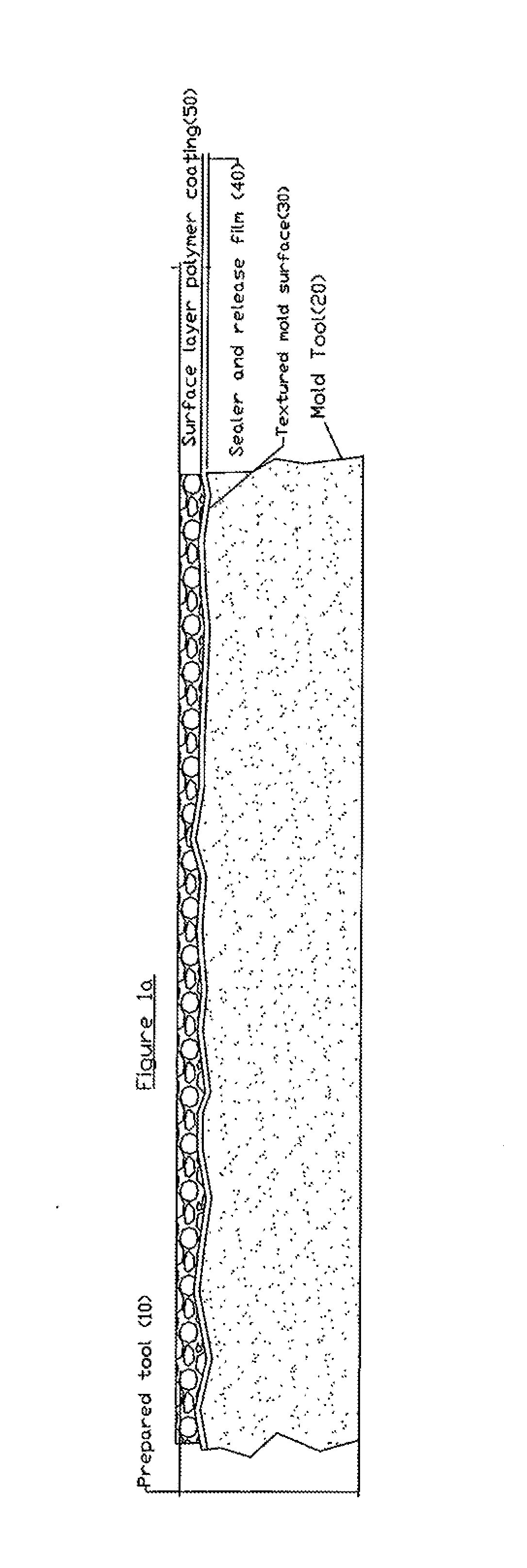

Surface Engineering of Thermoplastic Materials and Tooling

InactiveUS20140110633A1Improve propertiesEasy to separateLiquid surface applicatorsMechanical working/deformationSurface engineeringSurface layer

A prepared mold tool having a thermoplastic surface layer polymer coating on the mold surface of the mold tool or prepared prepreg having a thermoplastic surface layer polymer coating on the surface of the thermoplastic fiber reinforced prepreg are described that enhance first ply laydown of thermoplastic fiber reinforced composite prepregs onto mold tools for prepreg forming or in situ tape placement. Resulting thermoplastic fiber reinforced composite parts from a thermoplastic fiber reinforced thermoplastic composite material having structural reinforcement fibers with one or more high performance polymers, and a thermoplastic surface layer polymer coating which forms a polymer blend with the high performance polymers of the thermoplastic fiber reinforced composite material thereby imparting improved properties, and methods for making and using same, are provided herein.

Owner:CYTEC IND INC

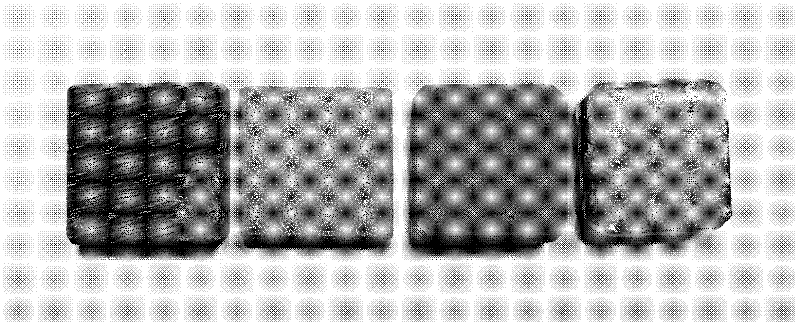

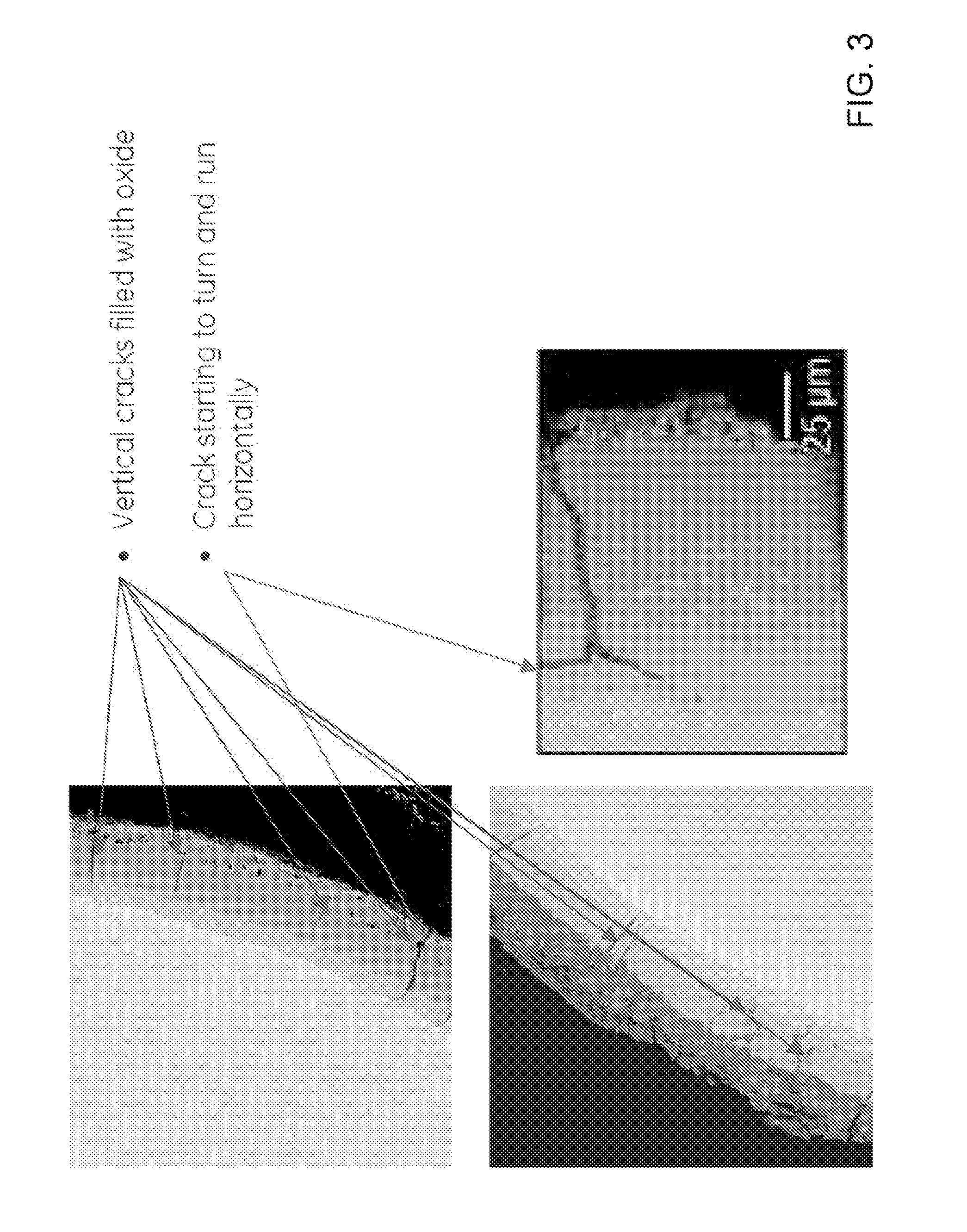

Long-term high-temperature oxidation-resistant multi-element composite ceramic coating for carbon/carbon composite material and preparation and application methods thereof

The invention provides a long-term high-temperature oxidation-resistant multi-element composite ceramic coating for a carbon / carbon composite material and preparation and application methods thereof. The long-term high-temperature oxidation-resistant multi-element composite ceramic coating is a composite coating on the surface of the carbon / carbon composite material and sequentially (from inside to outside) comprises a SiC connection layer prepared with an embedding method, a SiC sealing layer prepared with a chemical vapor deposition method and a SiO2-Y2Si2O7-ZrSiO4-Al2SiO5 ceramic layer prepared with a brush coating method and an in-situ oxidation reaction method, wherein the SiC connection layer is combined with a matrix and exerts the function of connecting the matrix, the SiC sealinglayer exerts the function of filling defects of an inner layer, and the outermost SiO2-Y2Si2O7-ZrSiO4-Al2SiO5 ceramic layer serves as an oxygen blocking layer and exerts the function of self-healing and oxygen blocking. The long-term high-temperature oxidation-resistant multi-element composite ceramic coating has the advantages of firmness in combination with the matrix, no run-through crack, long-term high-temperature oxidation resistance, and capability of being completely applied to the preparation of non-direct-ablation heat-resistant structural members around the head and of the wings ofa hypersonic aircraft and the preparation of a material for the tailpipe chamber of an aircraft engine.

Owner:CENT SOUTH UNIV

Anti-pollution high efficiency isolation liquid and preparing method

The present invention relates to anti-pollution high efficiency isolating liquid for shaft wall cementing operation and its preparation process. The isolating liquid is compounded through adding suspension stabilizer, water reducing agent, tackifier, diluent, viscosity and shearing force increasing agent, weight additive and pH regulator in certain weight proportion into water. One compounding process is a water base process through throwing the said components successively into water in a slurry tank apparatus. One other compounding process is one dry mixture process in a cementing tank apparatus. The isolating liquid has flexible compounding process, high anti-pollution capacity and effective eliminating effect on well wall interface pollutant.

Owner:SOUTHWEST PETROLEUM UNIV

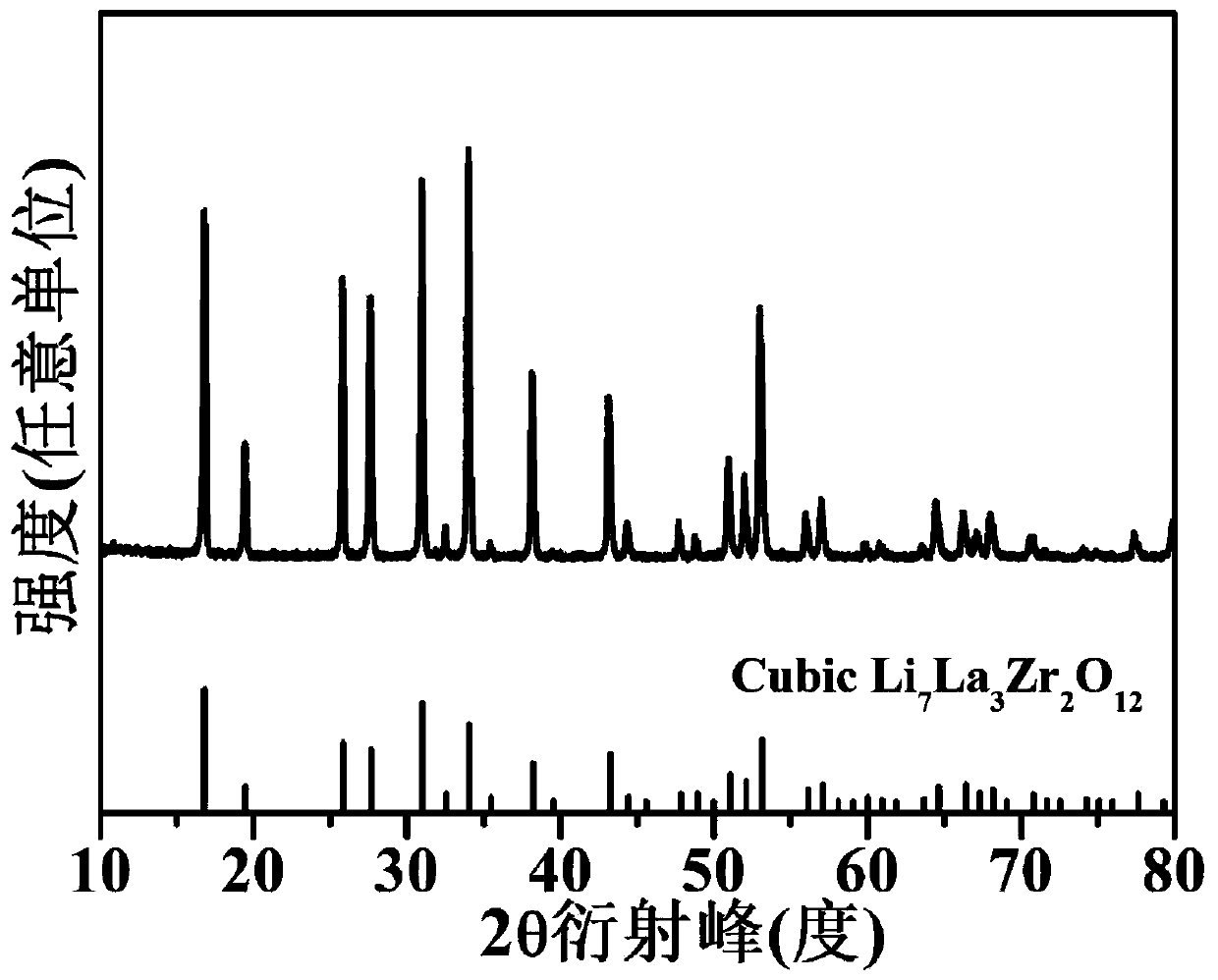

Oxide ceramic composite solid electrolyte and preparation method and application thereof

ActiveCN109755637AIncrease the degree of amorphousnessImproved chemical stability and mechanical strengthFuel and secondary cellsLi-accumulatorsOxidePolymer electrolytes

The invention provides an oxide ceramic composite solid electrolyte and a preparation method and application thereof. The oxide ceramic composite solid electrolyte comprises the following components:20wt.% to 50wt.% tantalum-doped garnet type oxide ceramics, 30wt.% to 60wt.% polymer electrolyte, 10wt.% to 30wt.% lithium salt and 5wt.% to 20wt.% of fluorine-containing imidazole ionic liquid. The preparation method of the oxide ceramic composite solid electrolyte includes a preparation step, a sintering step and a mixing step, wherein the preparation step includes the operations of weighing a lithium source, La2O3, ZrO2 and Ta2O5, and adding the lithium source, La2O3, ZrO2 and Ta2O5 together with isopropanol into a ball milling tank for ball milling; the sintering step includes the operations of removing isopropanol from the material obtained after ball milling, performing pre-sintering, grinding again, and performing secondary sintering to obtain oxide ceramics; and the mixing step includes the operations of adding the tantalum-doped garnet type oxide ceramics, the polymer electrolyte, the lithium salt and the ionic liquid into an organic solvent, uniformly dispersing and pouring into a mold, and then obtaining the oxide ceramic composite electrolyte after the organic solvent is volatilized.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

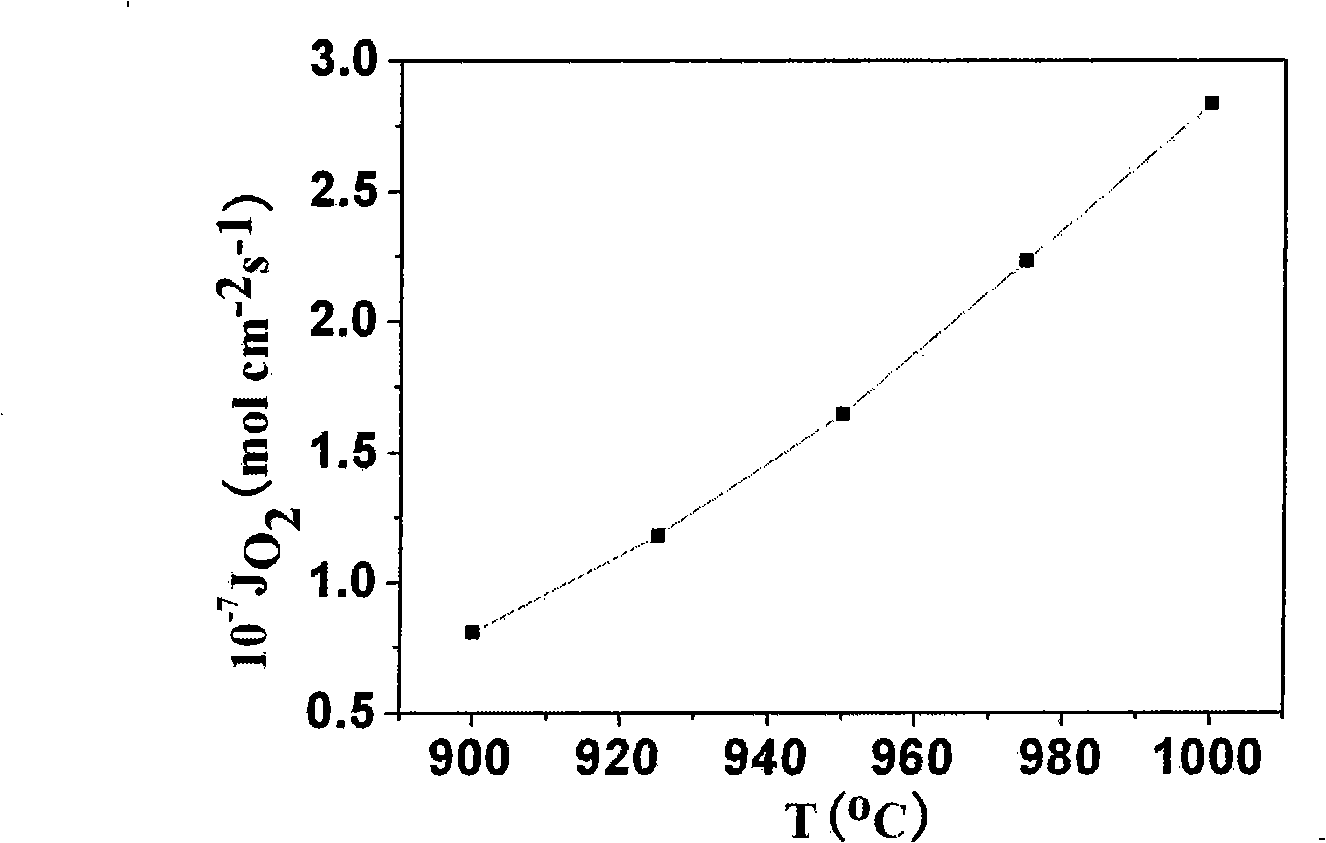

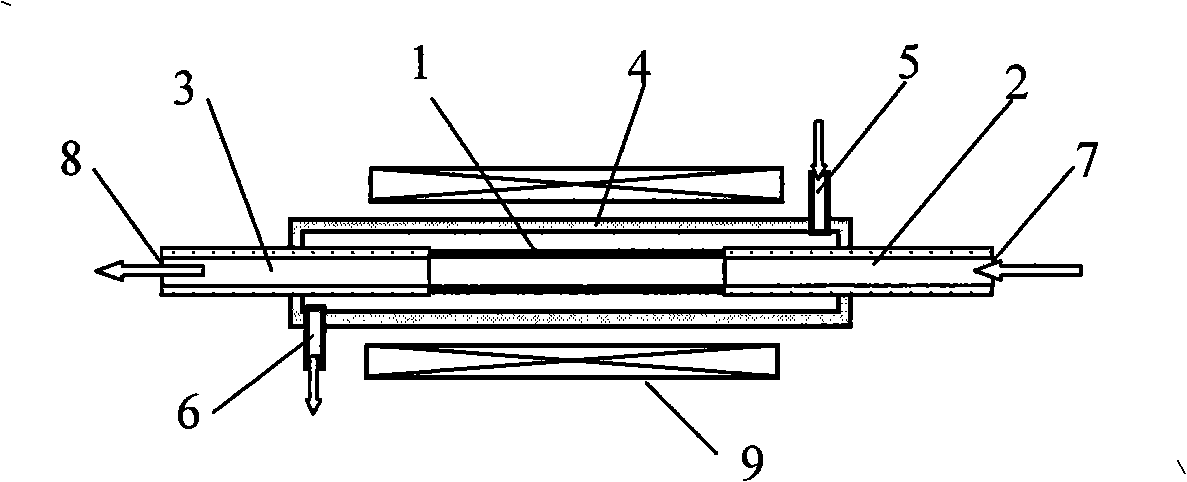

Two-phase composite compact ceramic oxygen permeable membrane and method of preparing the same

InactiveCN101254421ALow costGood chemical stabilitySemi-permeable membranesDispersed particle separationFiberNon toxicity

The invention provides a two-phase composite compact ceramic oxygen-permeable film and production method thereof. The invention is characterized in that: a perovskite-type lanthanum manganate-based composite oxide is mixed with a stabilized fluorite-type zirconium dioxide at a volume ratio of 0.6-1.8:1 to obtain a ceramic blank, the ceramic blank is further sintered to obtain a slab-like or a hollow fiber-like self-support compact ceramic oxygen-permeable film or porous support-loaded compact ceramic oxygen-permeable film with a thickness of 0.001-10 mm; the perovskite-type lanthanum manganate-based composite oxide is Ln1-xAx-yMnO3, wherein Ln is La, Pr, Nb, Ce, Gd, Dy, Sm or a mixture thereof, A is Sr or Ca, x is 0.1-0.4, y is 0-0.10; the stabilized fluorite-type zirconium dioxide is RzZr1-zO2, wherein R is Y, Sc, Yb, Er, Gd, Eu, Dy or a mixture thereof, and z is 0.10-0.26. The oxygen-permeable film is stable and kept in high oxygen permeability during long-term storage in the atmosphere of CO2 and H2O; and has the advantages of rich raw material, low price, non-toxicity and harmfulness, and environmental friendliness.

Owner:UNIV OF SCI & TECH OF CHINA

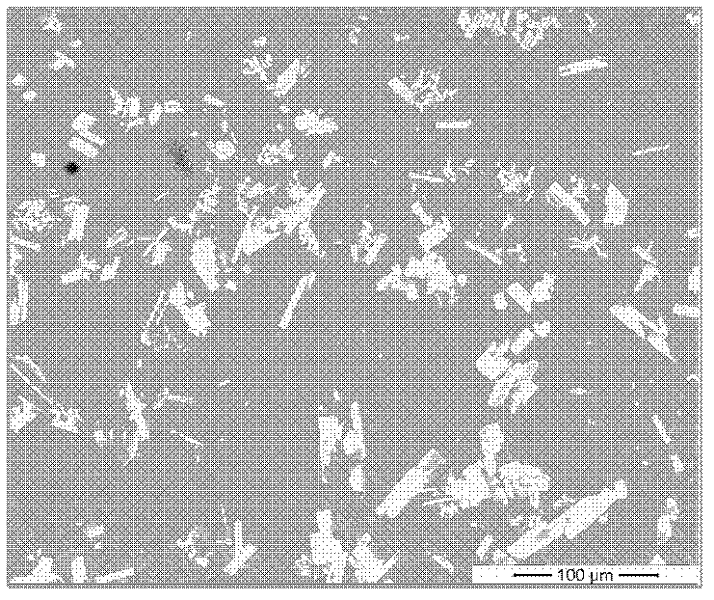

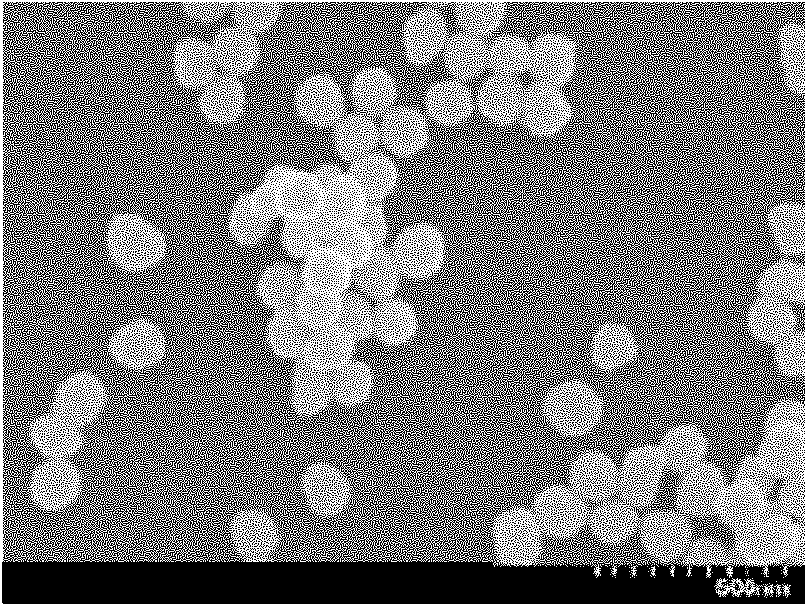

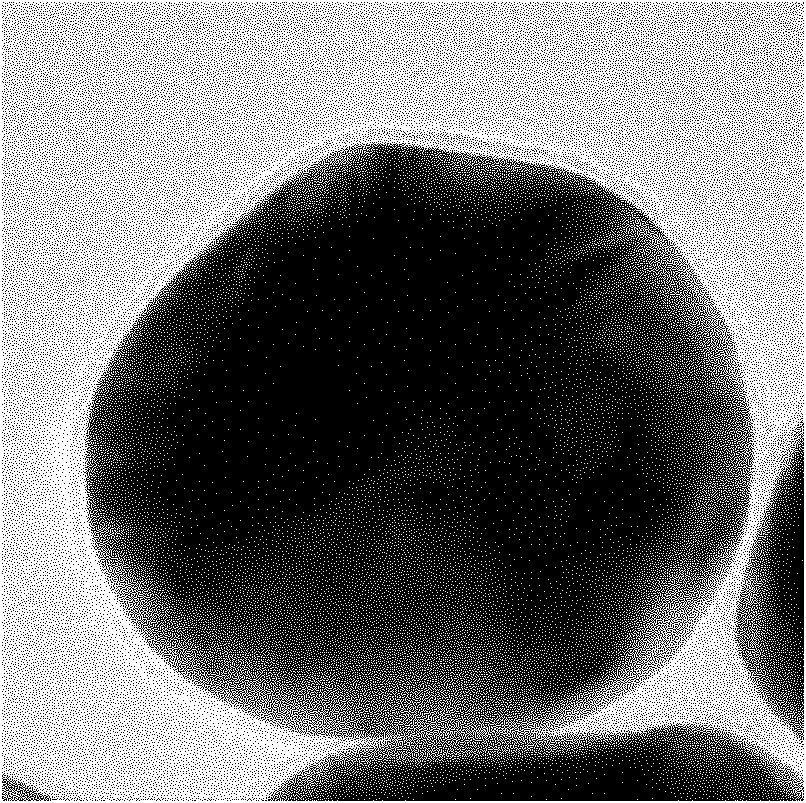

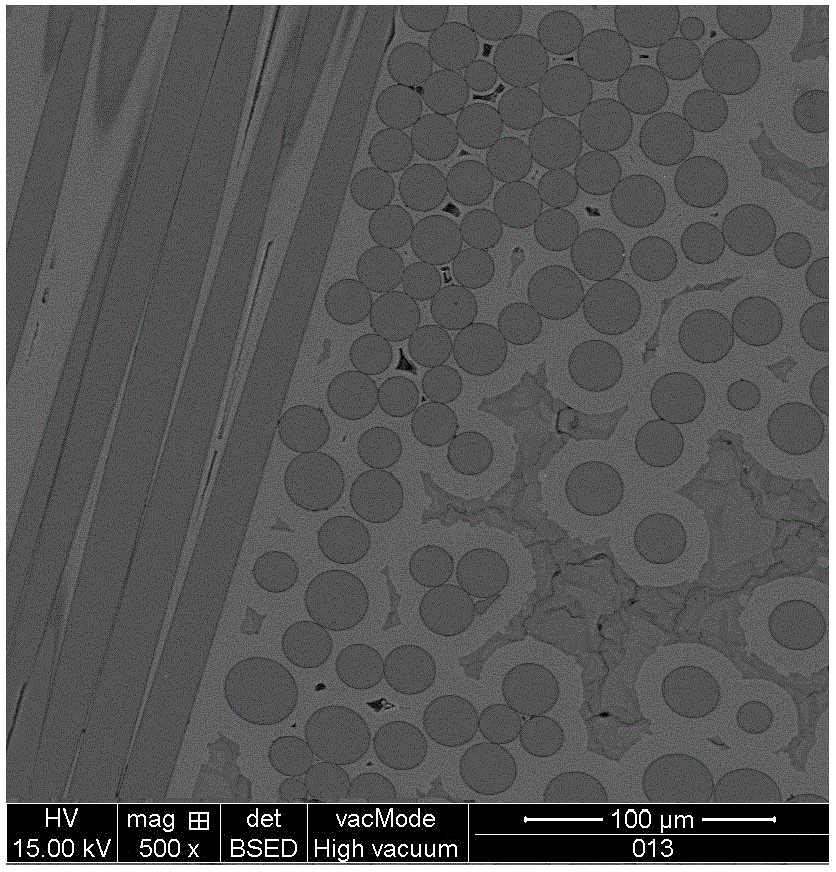

Method for synthesizing macronucleus-silica-coated gold core-shell structure nanoparticles

InactiveCN102078787AUnique physical propertiesGood chemical compatibilityMicroballoon preparationMicrocapsule preparationNanoparticleSilicon dioxide

The invention discloses a method for synthesizing macronucleus-silica-coated gold core-shell structure nanoparticles, relating to core-shell structure nanoparticles. The method has a simple synthesis process, a short period and a high yield, and the prepared core gold nanoparticles have large particle sizes. The cores of the macronucleus-silica-coated gold core-shell structure nanoparticles are gold nanoparticles with a particle size of 80 to 200 nm; an external layer is silica with a particle size of 1 to 20 nm. The method comprises: firstly, synthesizing gold nanoparticles with a particle size of 12 to 60 nm; then using the gold nanoparticles with a particle size of 12 to 60 nm as seeds to synthesize gold nanoparticles with a particle size of 80 to 200 nm; finally, synthesizing silica shell layers with a particle size of 1 to 20 nm on surfaces of the gold nanoparticles with a particle size of 80 to 200 nm. The synthesis method of the invention is widely used in electro-catalysis, bio-sensing, bio-imaging and surface enhanced raman technology.

Owner:XIAMEN UNIV

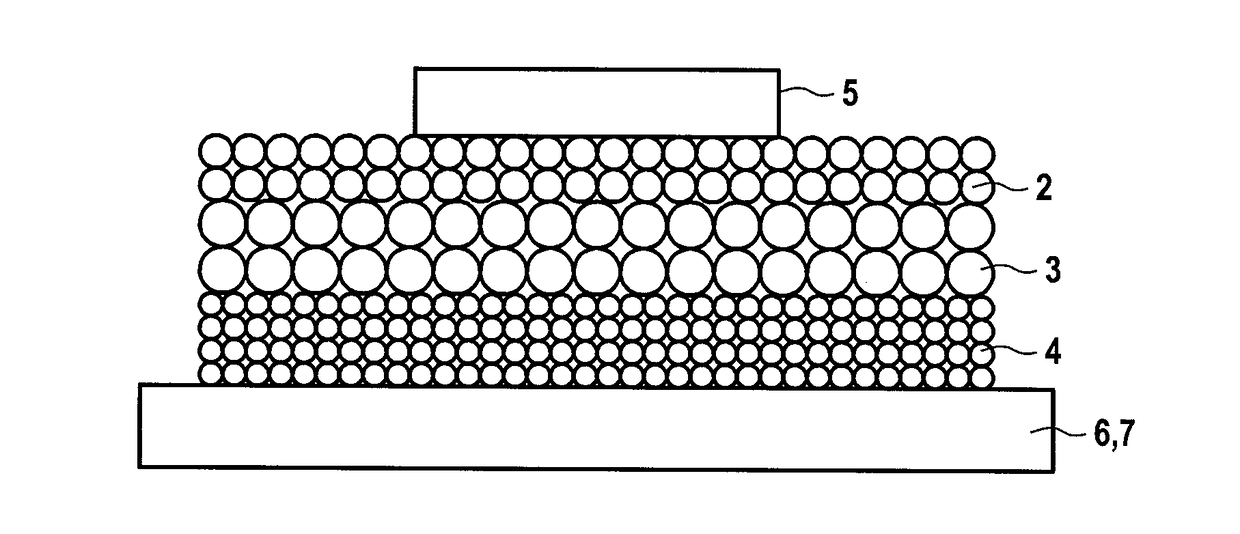

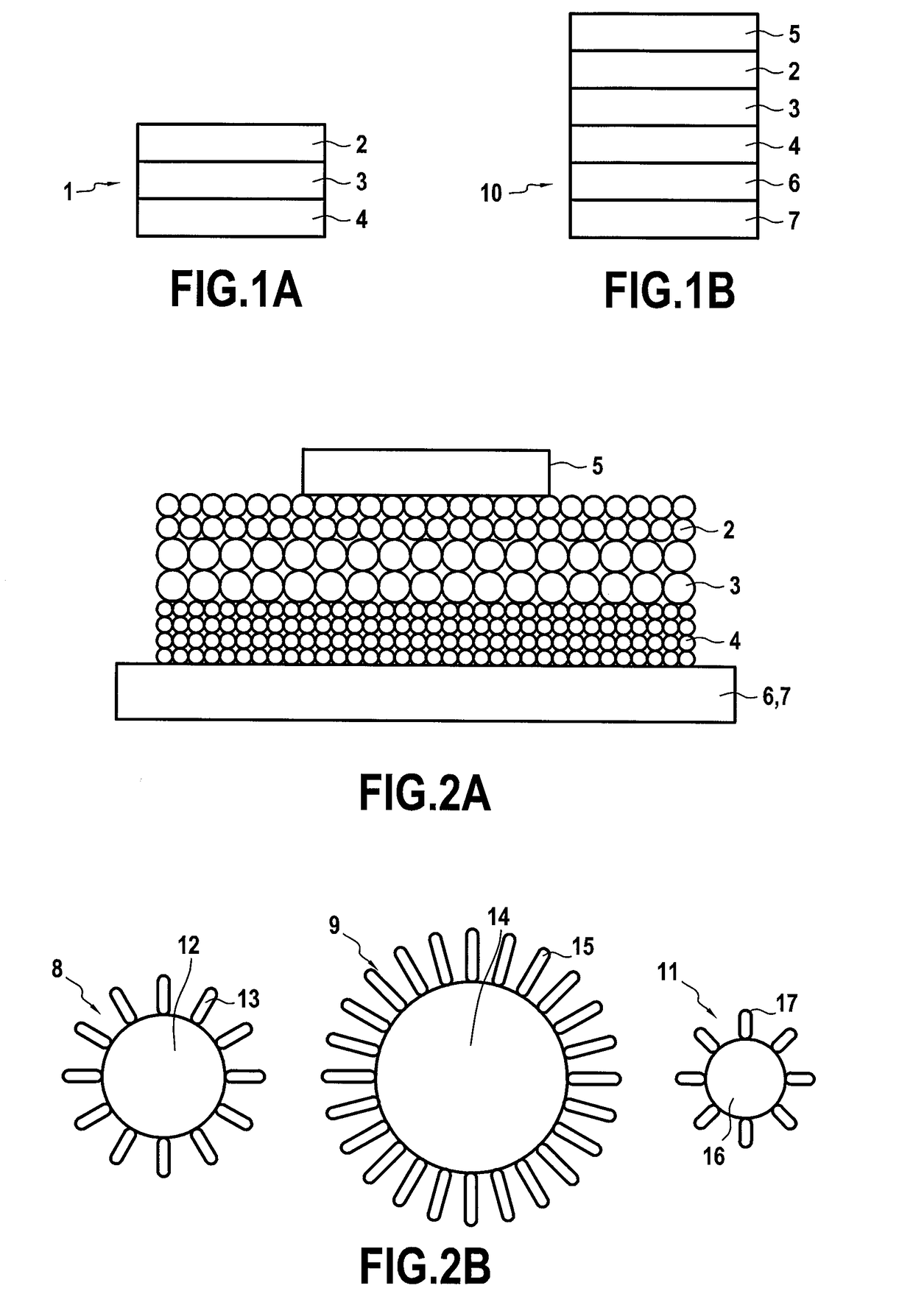

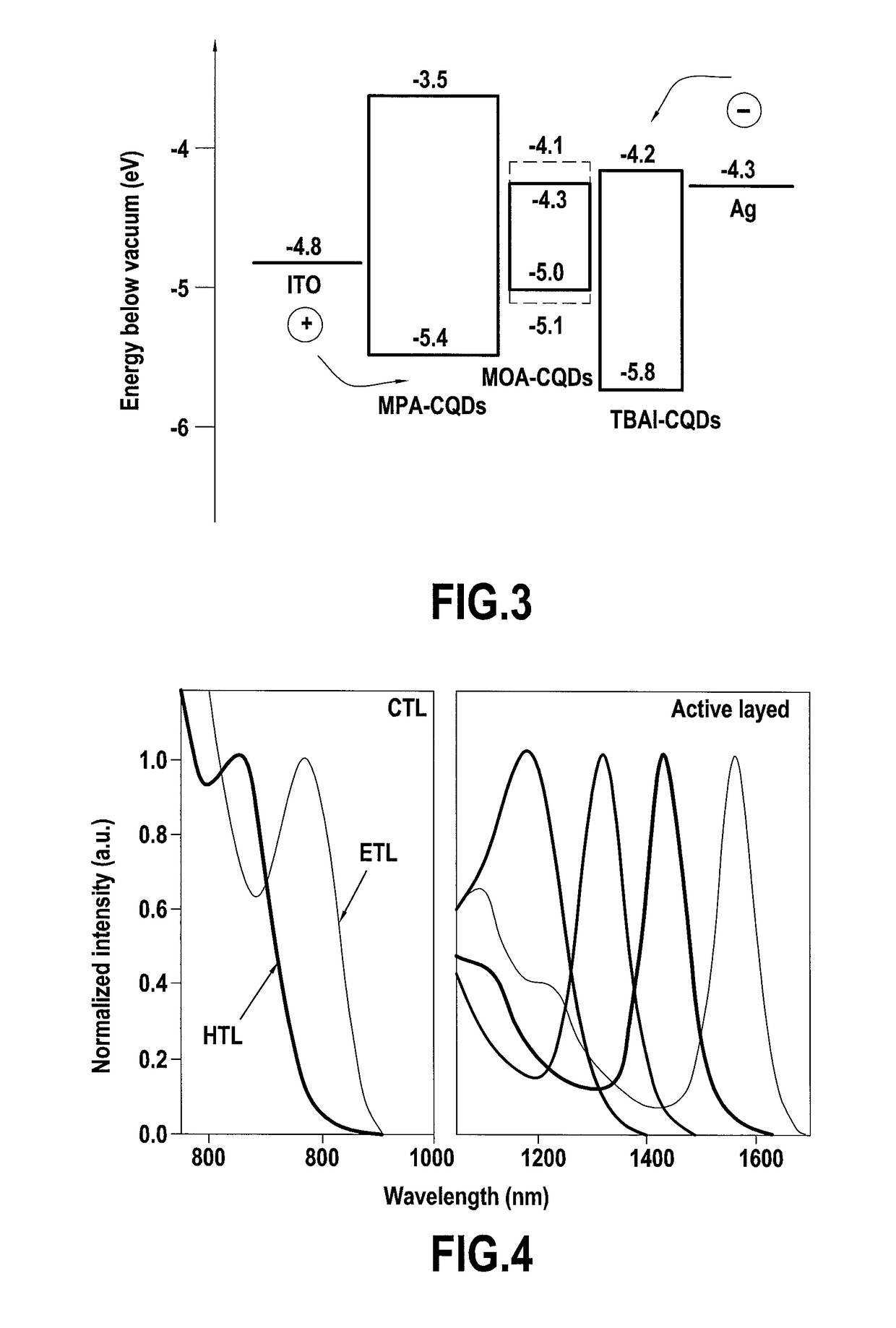

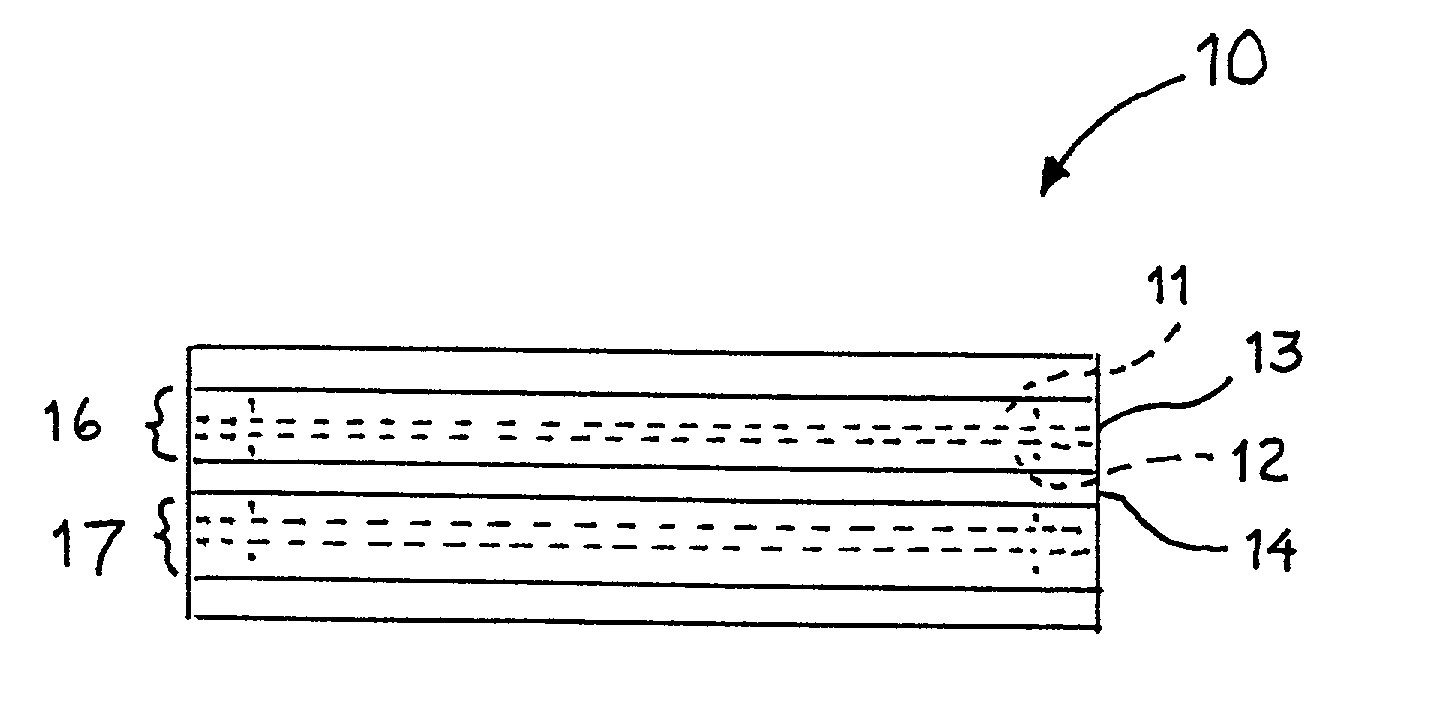

All quantum dot based optoelectronic device

ActiveUS20180254421A1Easily controlChemical compatibilitySolid-state devicesSemiconductor/solid-state device manufacturingQuantum dotMolecular physics

An optoelectronic device has an electron transport layer, an active layer, and a hole transport layer. Each of the electron transport layer, the active layer, and the hole transport layer has quantum dots.

Owner:TOYOTA JIDOSHA KK +1

Laser hard-surface coating process method of titanium alloy vane of gas turbine

InactiveCN101613860AEasy to adjustImprove physicsMetallic material coating processesLaser processingStructural geometry

The invention belongs to a laser processing technology for enhancing the surface hardness, i.e. the wearing resistance of titanium or titanium alloy, in particular to a laser hard-surface coating process method of a titanium alloy vane of a gas turbine. In the invention, corresponding mantle clamping fixture is adopted according to the geometrical shapes of structure of vane apex or damping convex shoulders of the vane, powder is placed in the mantle clamping fixture in advance, a static powder bed is formed by the mantle clamping fixture and the powder added in the mantle clamping fixture, powder is uniformly placed on the vane apex of the vane or the damping convex shoulders of the vane in advance by the static powder bed, and inert gases or N2 is adopted to protect a laser radiation area and carry out laser radiation on the vane. A hard-surface coating with the hardness of 35 to 62 HRC and the thickness of 0.05 to 2.0mm can be formed on the vane apex or the damping convex shoulder of the titanium alloy vane when the invention is adopted. The invention has the advantages that vacuum is not needed; laser cladding can be carried out only under the protection of inert gases of Ar, He, and the like in atmosphere conditions; the operation is convenient; and the formed hard-surface coating and basal body of the vane have good adapter properties in physics and chemistry.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

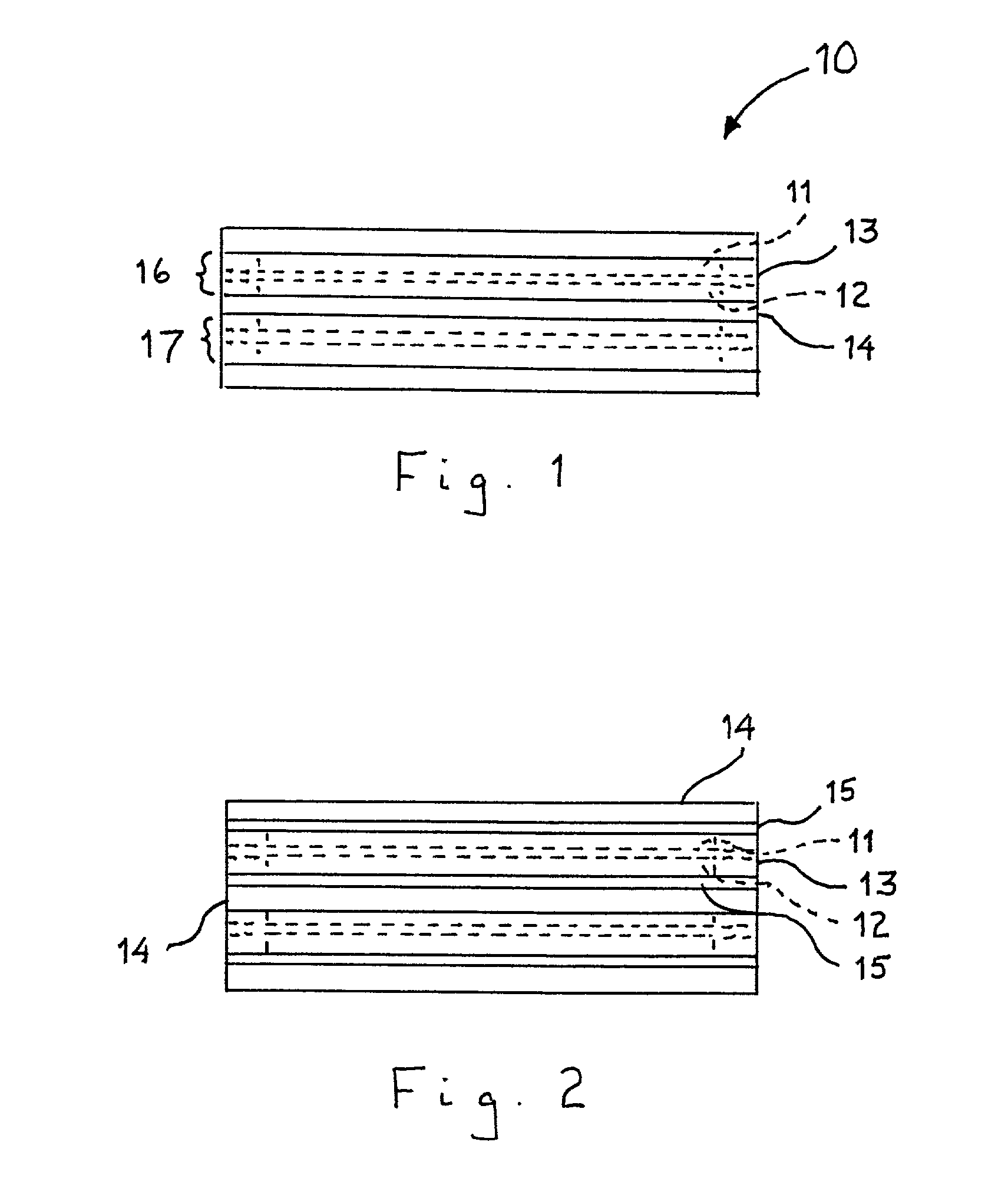

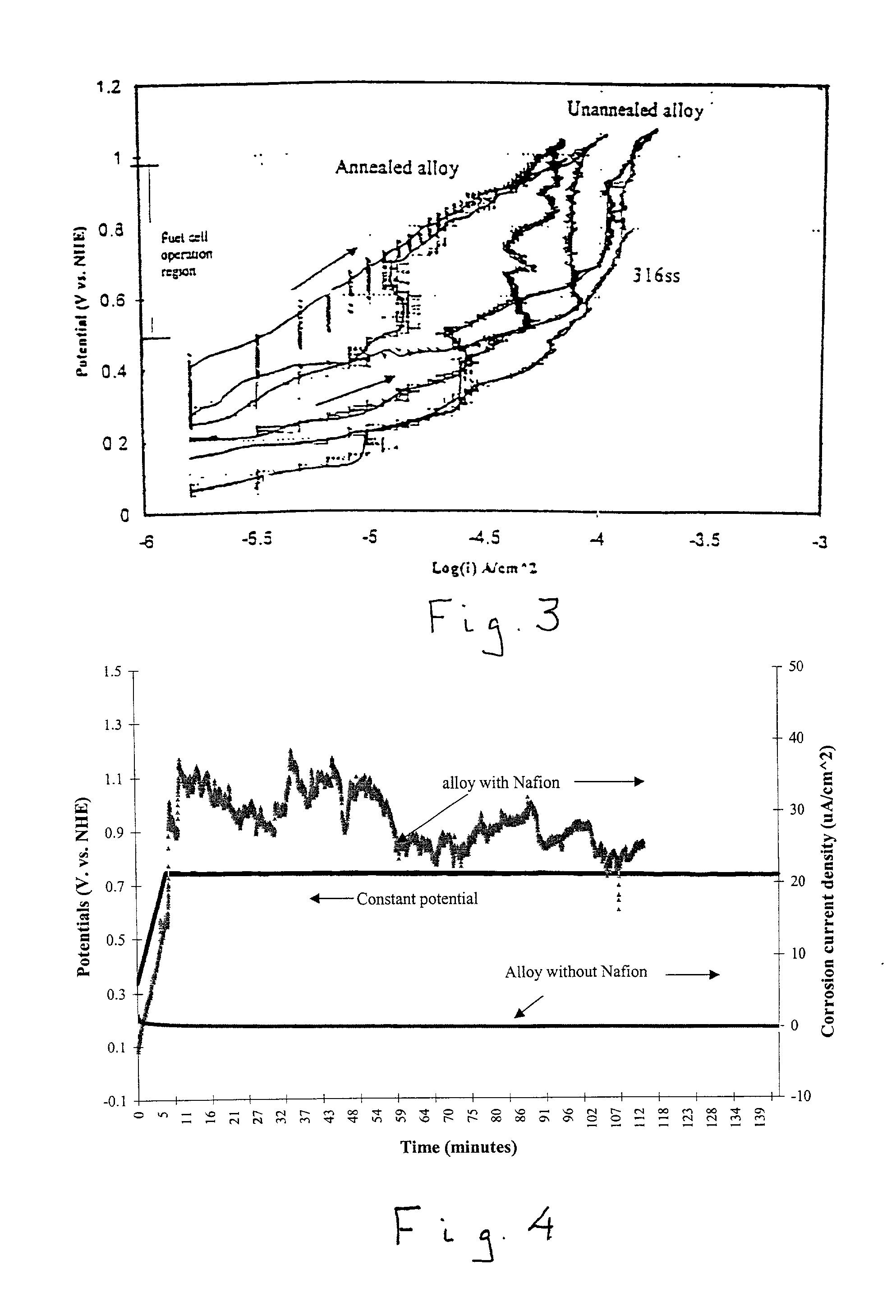

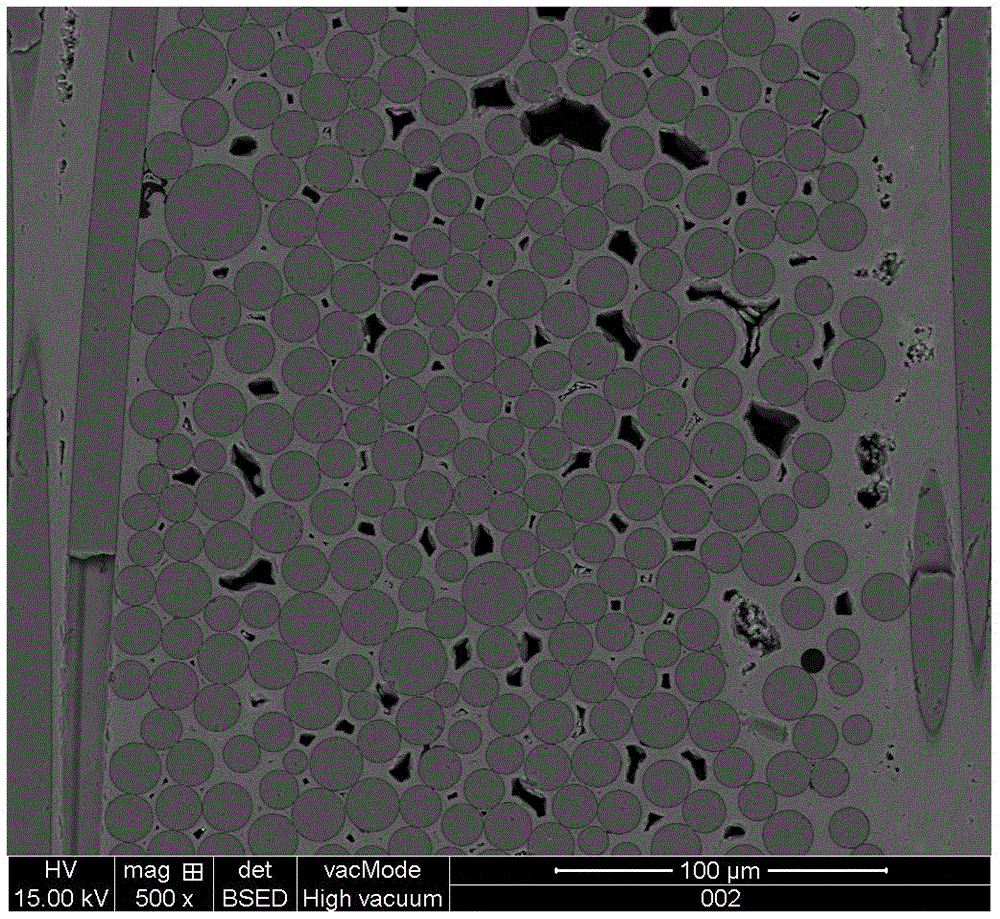

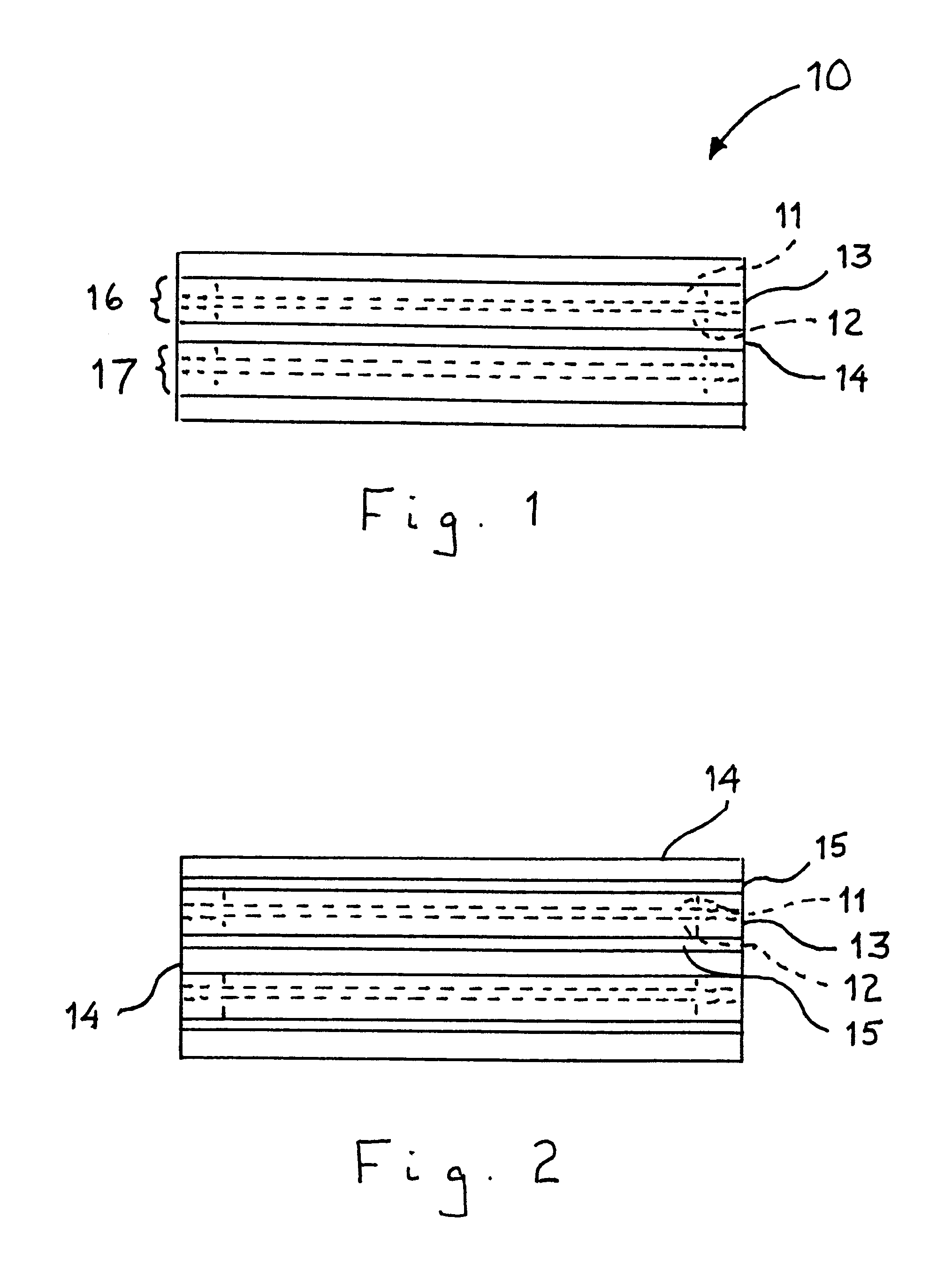

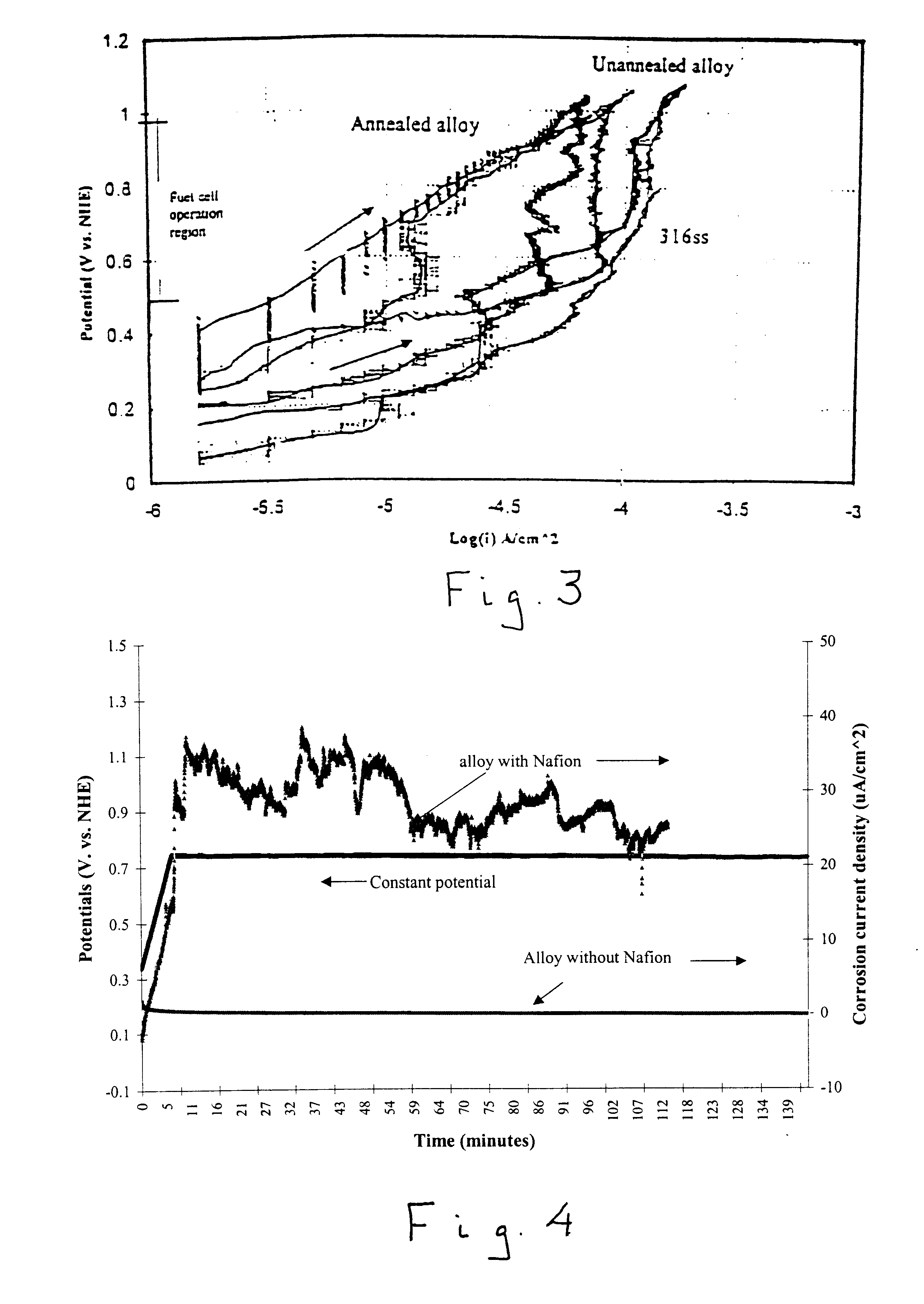

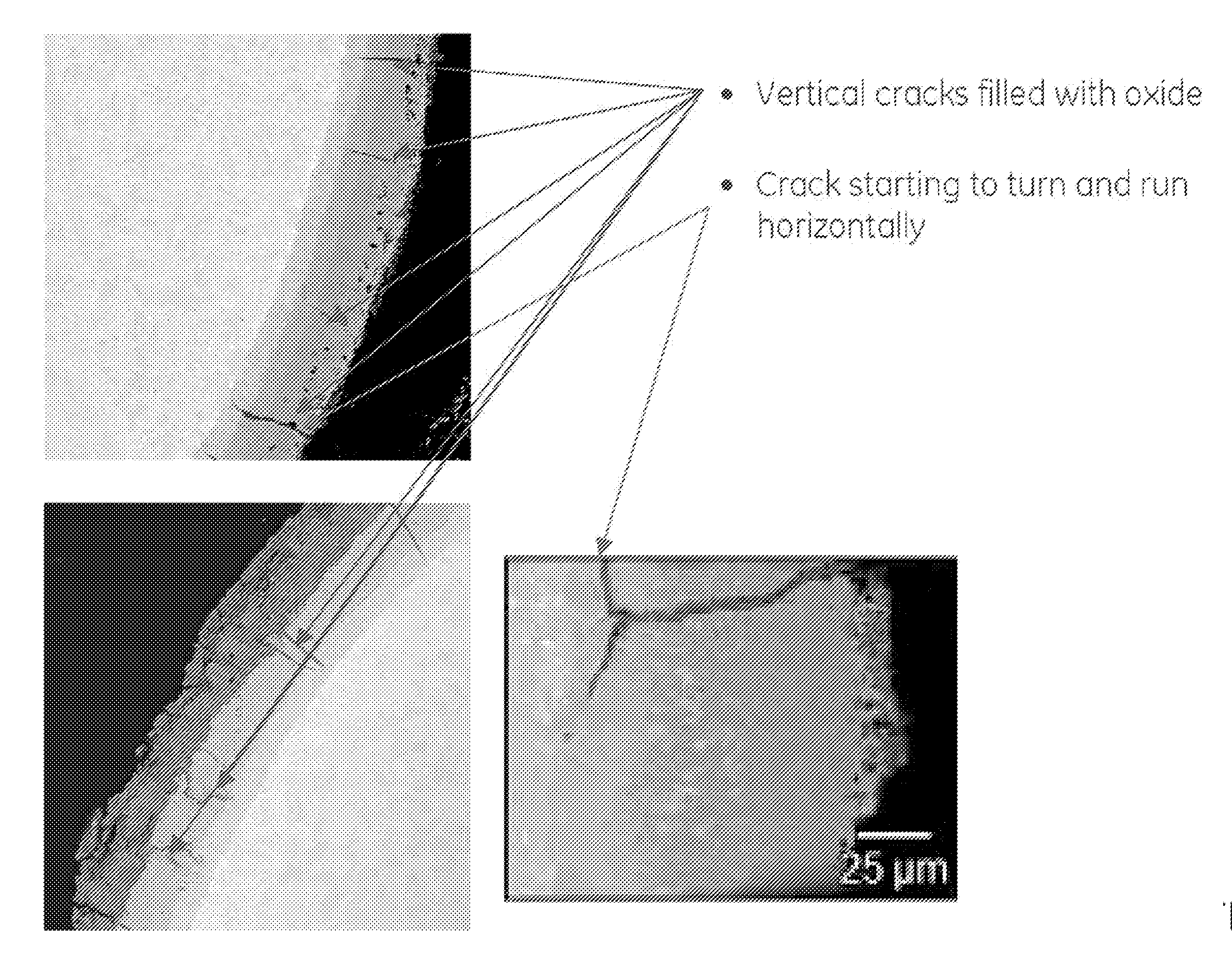

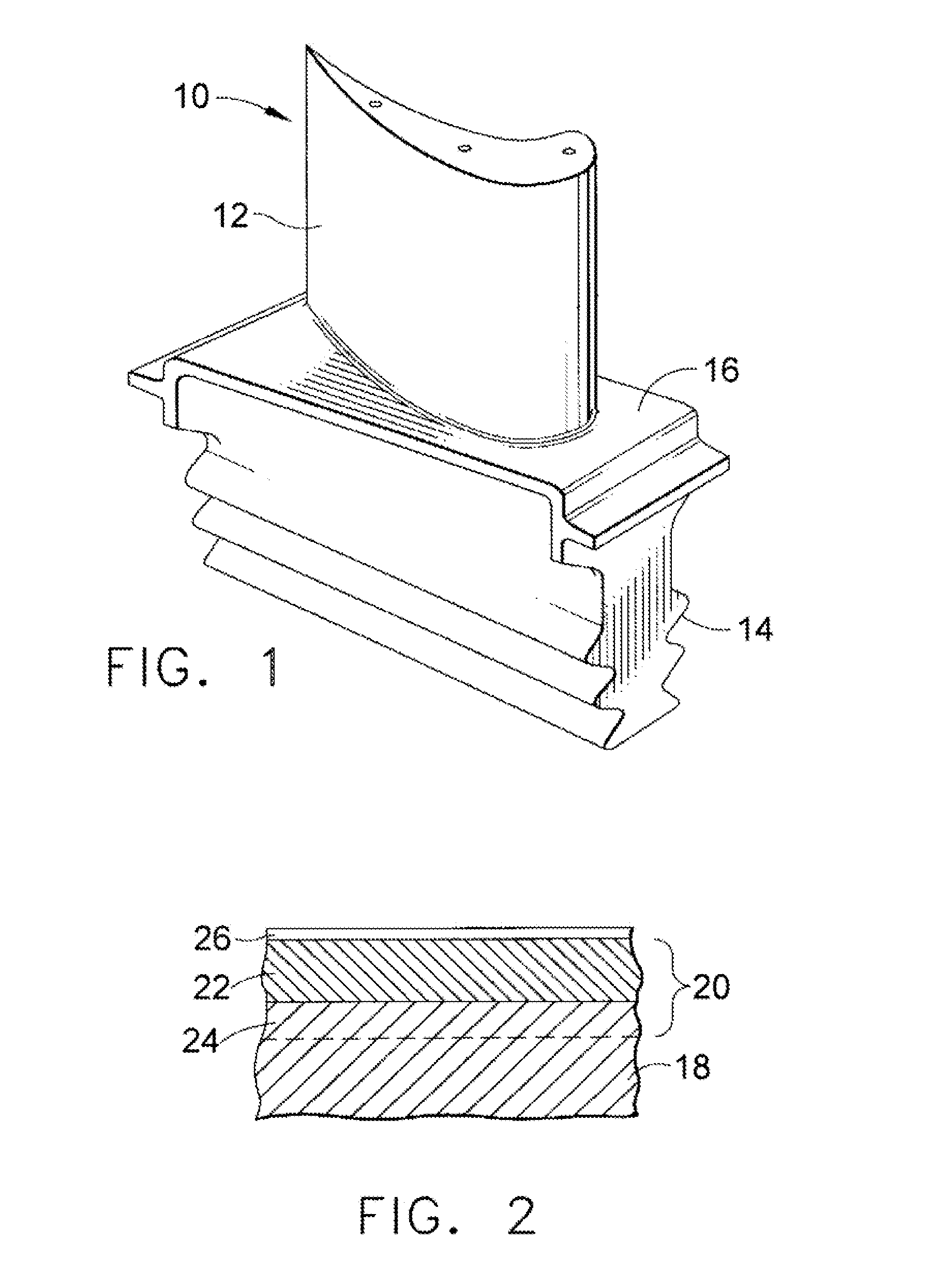

Low cost metal bipolar plates and current collectors for polymer electrolyte membrane fuel cells

InactiveUS20020172849A1Good chemical compatibilityFuel cells groupingCell component detailsCurrent collectorChromium

A polymer electrolyte membrane fuel cell stack having a plurality of substantially planar fuel cell units, each of which comprises an anode electrode, a cathode electrode and a polymer electrolyte membrane disposed between the anode electrode and the cathode electrode. A metal bipolar plate is disposed between the anode electrode of one fuel cell unit and the cathode electrode of an adjacent fuel cell unit. The metal bipolar plate is made of a chromium-nickel austenitic alloy, in which the chromium and the nickel, on a combined basis, make up at least about 50% by weight of the alloy.

Owner:GAS TECH INST

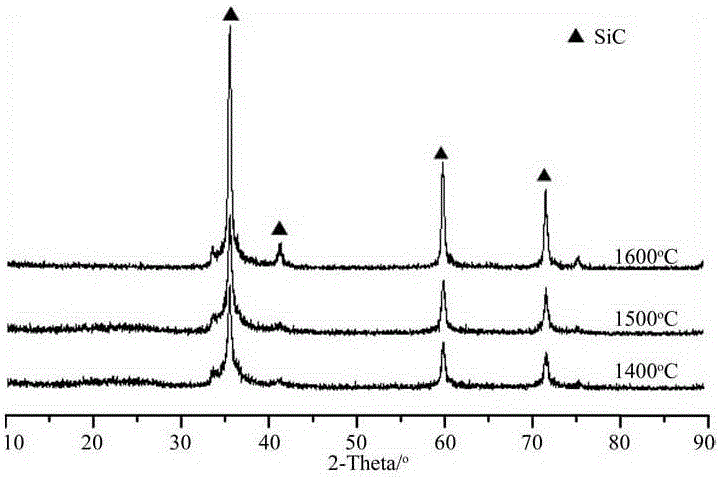

Method for enhancing density of SiC/SiC ceramic matrix composite

The invention relates to a method for enhancing density of a SiC / SiC ceramic matrix composite. The method comprises the following steps: (1) a SiC / SiC ceramic matrix composite with a certain densification degree is immersed in slurry, in which an organic precursor and SiC powder are uniformly dispersed, and impregnation is carried out in an environment of 5-10 KPa vacuum degree for 20-50 min; (2) a material which has undergone vacuum impregnation is dried and the dried material undergoes cross-linking and curing; (3) the cross-linked and cured material undergoes pyrolysis treatment; and (4) the material which has undergone pyrolysis treatment further undergoes densification process in the atmosphere of a gaseous precursor containing Si and C elements by a chemical vapor infiltration technology while infiltration temperature is 850-1100 DEG C, pressure intensity is 10-20 KPa and infiltration time is 4-30 h. The method provided by the invention has advantages of simple operation, short densification time, good repeatability and high densification efficiency and has obvious advantages in the aspect of filling material voids. The method is a method with operability and development prospect.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of high-compaction density 523-type ternary positive electrode material

InactiveCN107799764AIncrease compaction densityLower pHCell electrodesSecondary cellsManganateSingle crystal

The invention provides a preparation method of a high-compaction density 523-type ternary positive electrode material, and belongs to the technical field of preparation of a lithium ion battery positive electrode material. A high-compaction density and low-pH value lithium nickel cobalt manganate NCM523-type ternary positive electrode is in a spherical shape, grain D50 of secondary agglomeration particle is 10-12 micrometers, and the size of primary single-crystal particle is 1.5-3 micrometers. The preparation method of the high-compaction density 523-type ternary positive electrode material comprises the steps of doping 0.1-1.0% of metal oxide into a mixture of lithium carbonate and a ternary precursor LiNi<0.5>Co<0.2>Mn<0.3>(OH)<2>, performing primary sintering, paste washing, secondarysintering, breakage, iron removal, sieving and mixing, and finally, obtaining an NCM523-type ternary positive electrode material. By the method, the compaction density of the NCM523-type ternary positive electrode material is effectively improved, a pH value is reduced, the compaction density of the prepared NCM523-type ternary positive electrode material is larger than 3.7g / cm<3>, and the pH value is smaller than 10.80.

Owner:JINCHUAN GROUP LIMITED +1

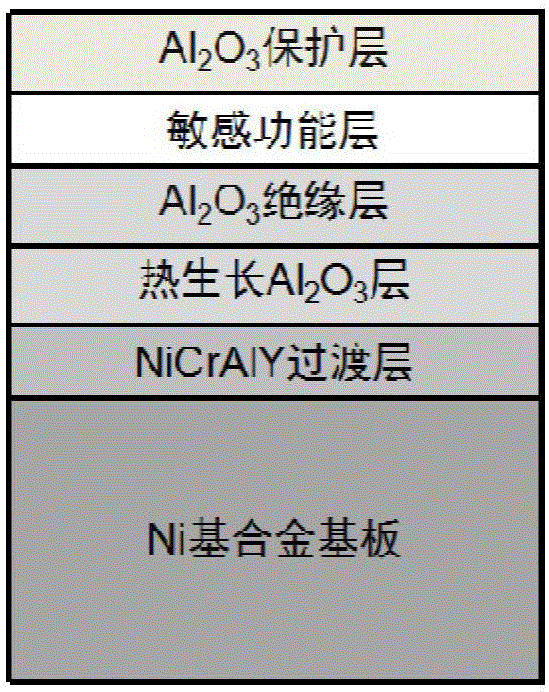

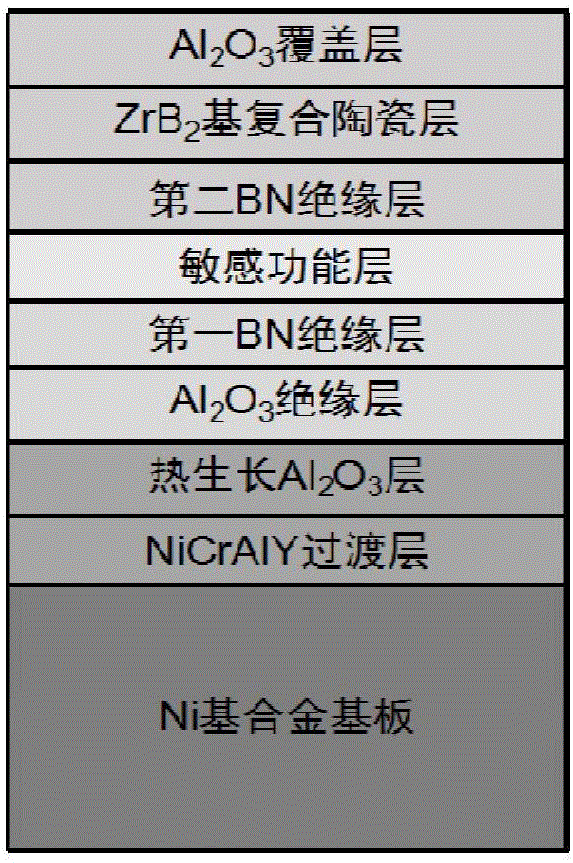

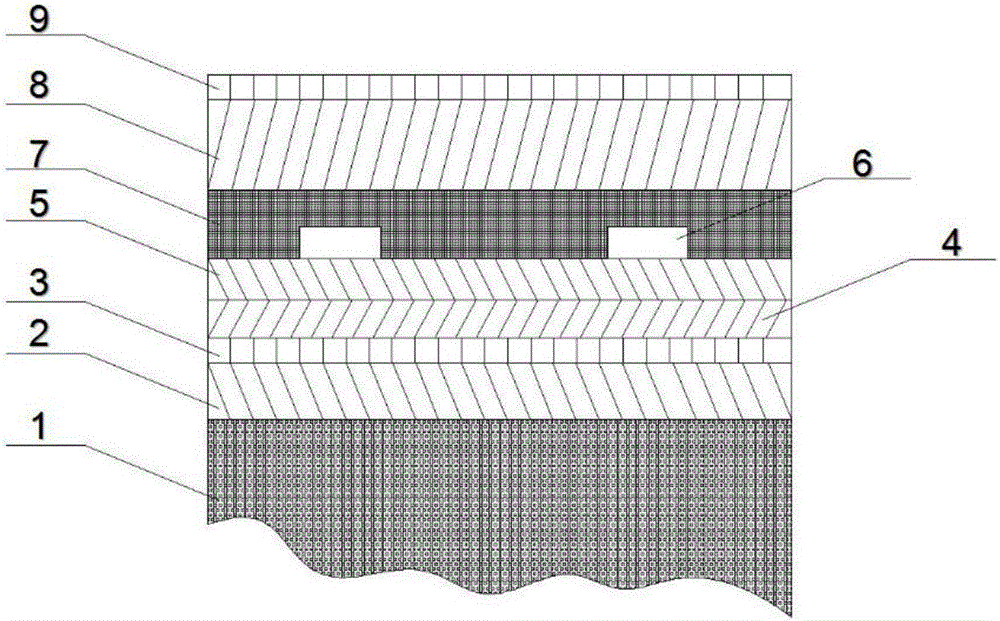

Antioxidant composite protective layer for high-temperature film sensor and manufacturing method of antioxidant composite protective layer

InactiveCN106498355AStrong covalent bond propertiesExcellent high temperature insulation performanceVacuum evaporation coatingSputtering coatingThin film sensorSputtering

The invention discloses an antioxidant composite protective layer for a high-temperature film sensor and a manufacturing method of the antioxidant composite protective layer, and belongs to the technical field of film sensors. The antioxidant composite protective layer sequentially comprises a BN insulation layer, a ZrB2-based composite ceramic layer and a Al2O3 covering layer from bottom to top, wherein the BN insulation layer, the ZrB2-based composite ceramic layer and the Al2O3 covering layer are sequentially deposited on a sensitive function layer of the film sensor in the way of evaporation or sputtering or the like. By means of the antioxidant composite protective layer for the high-temperature film sensor, the antioxidant protective requirements of the aero-engine high-temperature film sensor at the high temperature of 1000-1700 DEG C can be met, the stability and reliability of the film sensor in high-temperature high-pressure severe environment are effectively improved, and the service life of the film sensor in high-temperature high-pressure severe environment is effectively prolonged.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

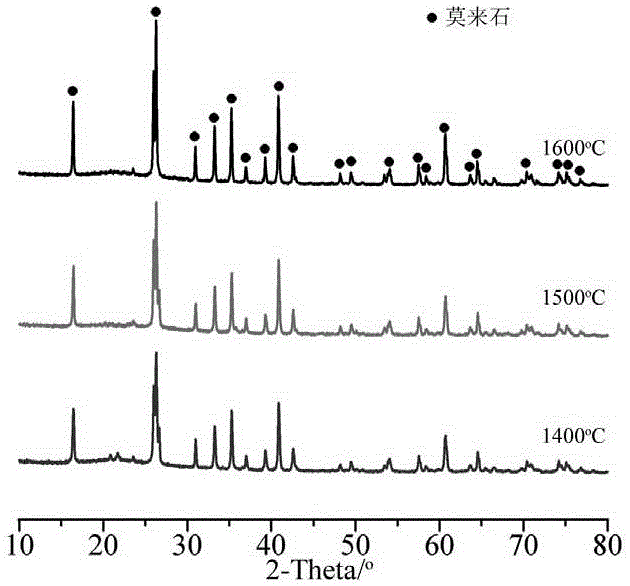

Surface coating system of fiber reinforced ceramic matrix composite material and preparation method therefor

The present invention provides a surface coating system of fiber reinforced ceramic matrix composite material, wherein the surface coating system is arranged on the substrate surface of the fiber reinforced ceramic matrix composite material and comprises a Sic coating layer, a mullite coating layer and a yttrium silicate coating layer laid in order from bottom to top. The preparation method comprises the following steps of preparing sludge raw materials of the Sic coating layer, the mullite coating layer and the yttrium silicate coating layer respectively, and preparing the Sic coating layer, the mullite coating layer and the yttrium silicate coating layer. The present invention is used for the surface coating system of the fiber reinforced ceramic matrix composite material, has the advantages of high density, high temperature resistance and anti-oxidation.

Owner:NAT UNIV OF DEFENSE TECH

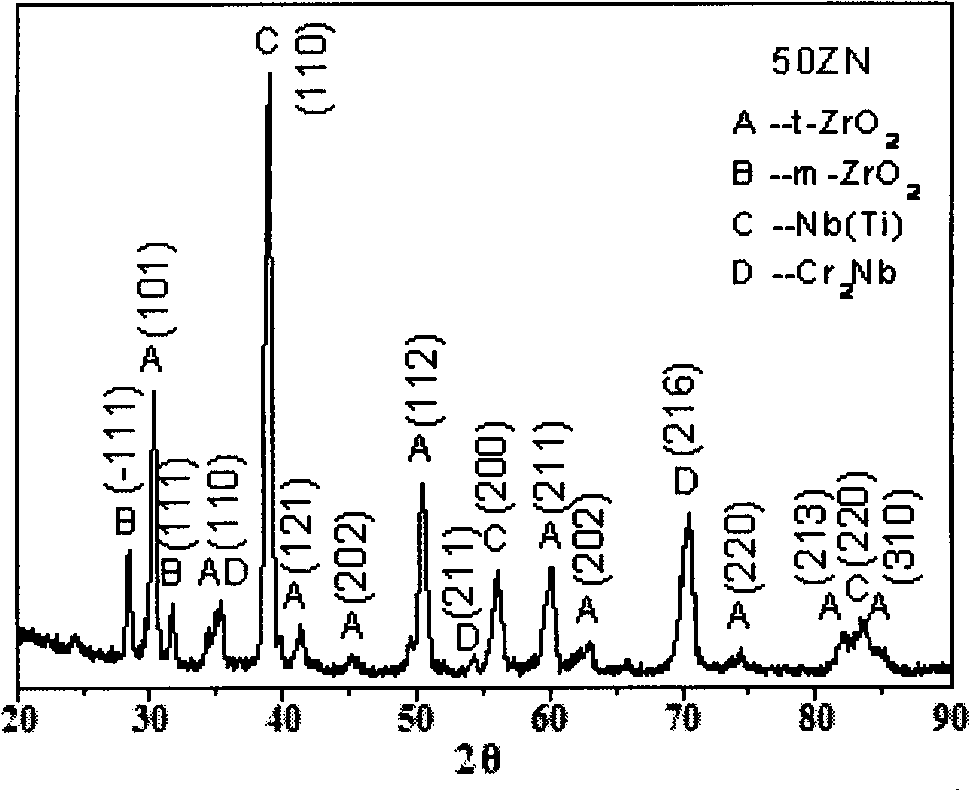

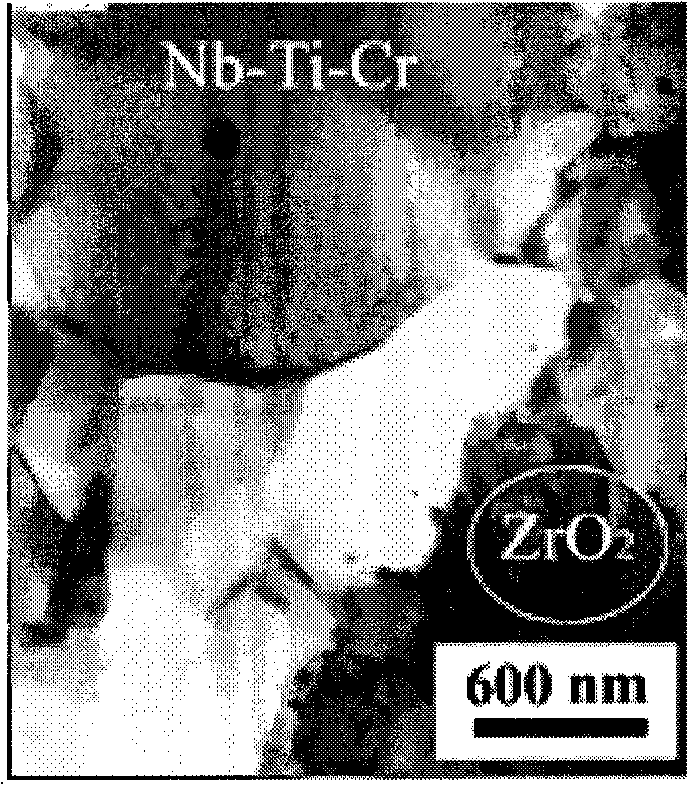

Zirconia ceramic matrix composite and preparation method thereof

InactiveCN101565306AExcellent high temperature mechanicsImprove antioxidant capacityOxidation resistantWhiskers

The invention relates to a zirconia ceramic matrix composite and a preparation method thereof. In the composite, tetragonal zirconia is used as a substrate, and a Nb-Ti-Cr phase is used as a toughening phase, wherein the substrate and the toughening phase account for 20 and 80 volume percent of the total volume of the composite respectively and a sum of the volume percentages of the substrate and the toughening phase is 100 percent. Nb powder, Ti powder and Cr powder are mixed according to the mass ratio of Nb atoms to Ti atoms to Cr atoms of 50:37:23. The preparation method of the zirconia ceramic matrix composite comprises the following steps: ball milling the substrate and the toughening phase and mixing the mixture obtained after ball milling; and preparing the zirconia ceramic matrix composite by hot pressed sintering the mixture under vacuum. The composite of the invention has excellent high-temperature mechanical property and antioxygenic property as well as low cost; and compared with fiber and whisker toughened ceramic, the zirconia ceramic matrix composite has a similar toughening effect, but has simple preparation process, low cost and far more excellent conductivity.

Owner:UNIV OF JINAN

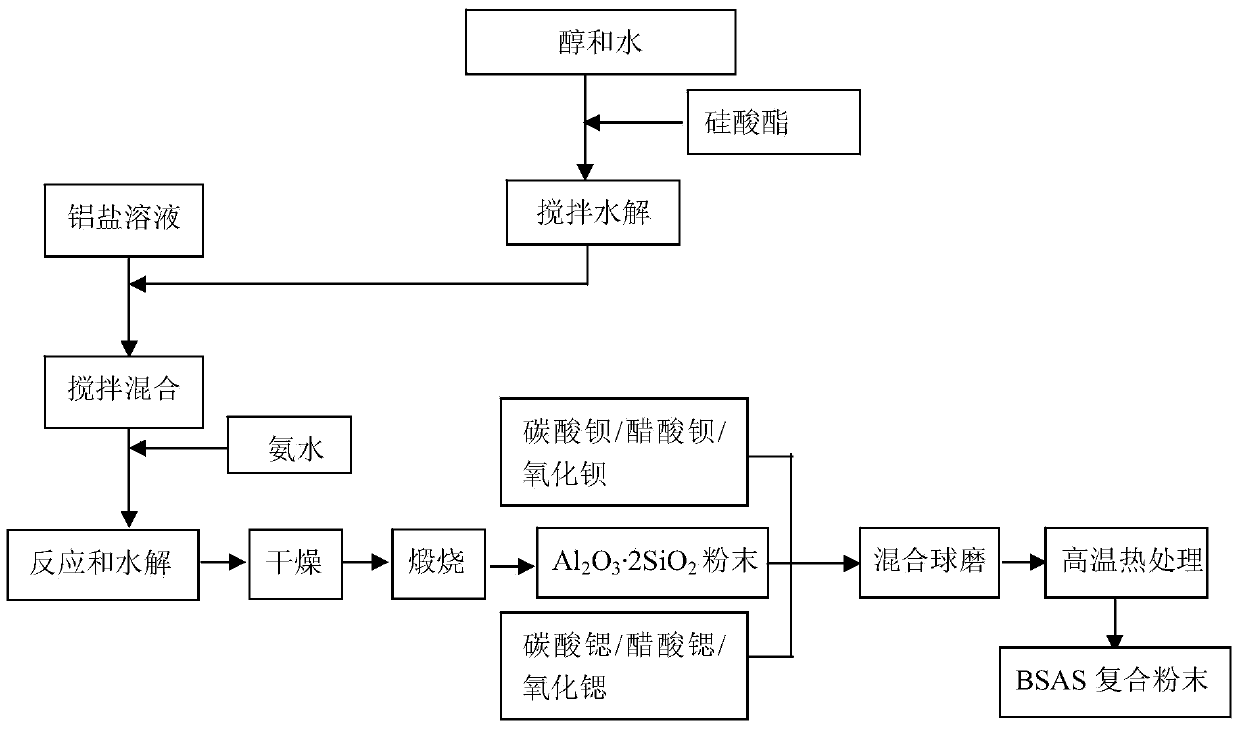

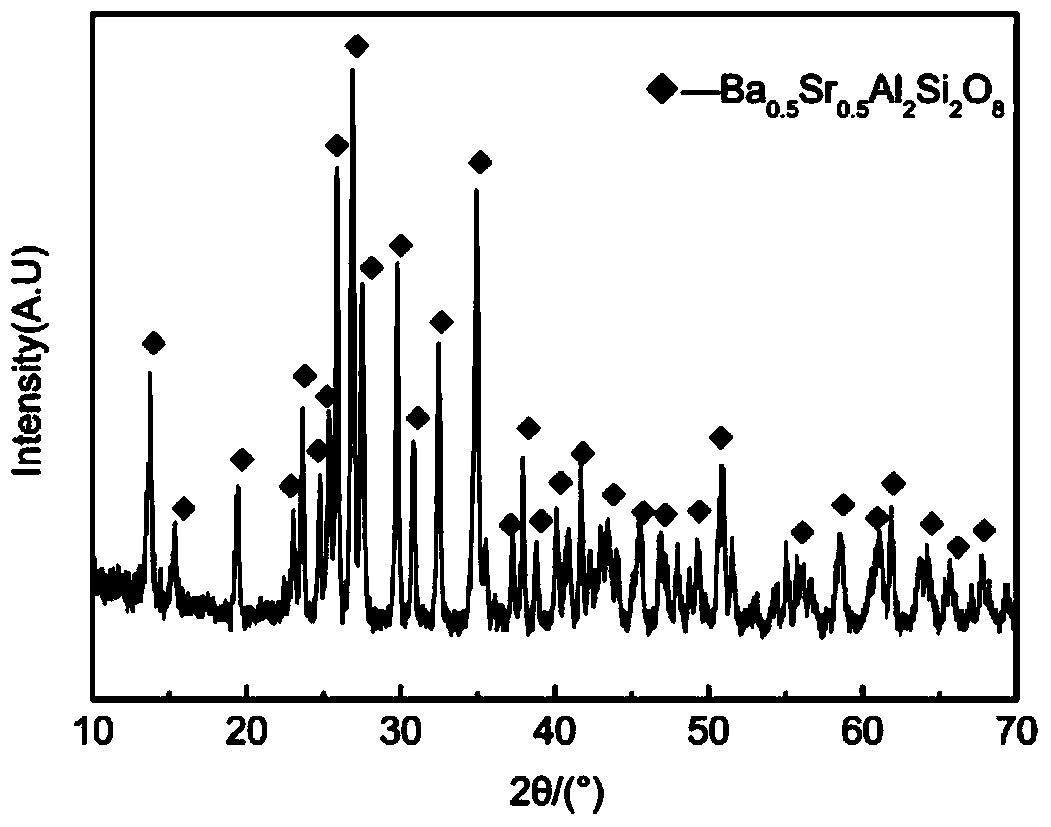

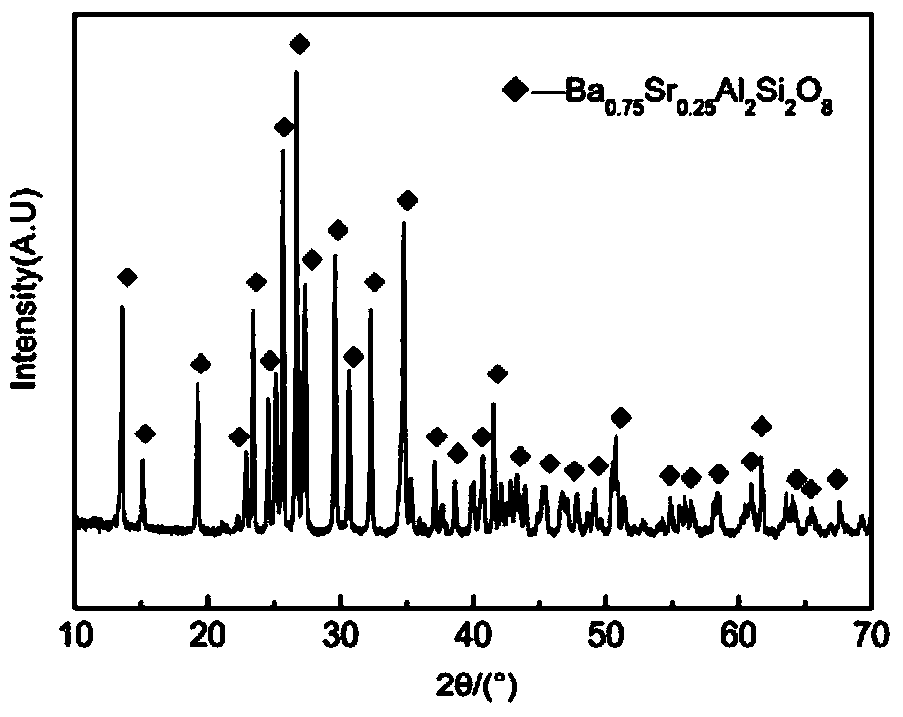

Preparation method of BSAS composite ceramic powder

ActiveCN104003697AProcess raw materials are cheapThe process is simple and easy to controlComposite ceramicCrystallinity

The invention discloses a preparation method of a composite ceramic powder material used for an environmental barrier coating. The composite ceramic powder is composed of single phase BSAS (1-xBaO-xSrO-Al2O3-2SiO2, x is more than 0 and less than 1). The obtained BSAS composite ceramic powder has the advantages of easiness for ingredient control, high purity, high crystallinity and low synthesis temperature. The composite ceramic powder can be used for plasma spraying after being subjected to ball milling, agglomeration, pelletizing and high-temperature heat treatment, so that the environmental barrier coating is prepared on the surface of a C / C-SiC composite material, the coating can be used for effectively improving high-temperature water oxygen corrosion resistance performance of a C / C-SiC matrix, is applicable to surface high-temperature protection of other silicon substrate materials, can be used for solving the problem of high-temperature water oxygen corrosion of a silicon substrate composite material and has an important application value.

Owner:CENT SOUTH UNIV

Stainless steel-TiC nano composite powder and preparation method

The invention relates to a stainless steel-ceramics nanometer composite material. The stainless steel-TiC nanometer composite powder is characterized in that it is obtained by mixing 316 stainless steel powder, Ti powder and C powder and ball milling, in which: 316 stainless steel powder of 70-90 wt%, Ti powder and C powder of 10-30 wt%, wherein, 80 wt% Ti powder and 20 wt% C powder of Ti powder and C powder, with less than 74um of average grading of Ti powder and C powder, and more than 99% of the purity. The composite material produced by the method has good corrosion resistance, good abrasion resistance, high Young's modulus, high chemical stability and long service life with simple process. Fine crystal grain powder metallurgy composite material produced by molding and sintering at high temperature the powder produced by the method has the advantages of corrosion resistance, abrasion resistance, high Young's modulus, high chemical stability and long service life.

Owner:WUHAN UNIV OF TECH

Methods and materials for fabricating microfluidic devices

ActiveUS20120256354A1Lower surface energyGood chemical compatibilityLaboratory glasswaresCeramic shaping apparatusHydrocarbon solventsDevice material

Materials and Methods are provided for fabricating microfluidic devices. The materials include low surface energy fluoropolymer compositions having multiple cure functional groups. The materials can include multiple photocurable and / or thermal-curable functional groups such that laminate devices can be fabricated. The materials also substantially do not swell in the presence of hydrocarbon solvents.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

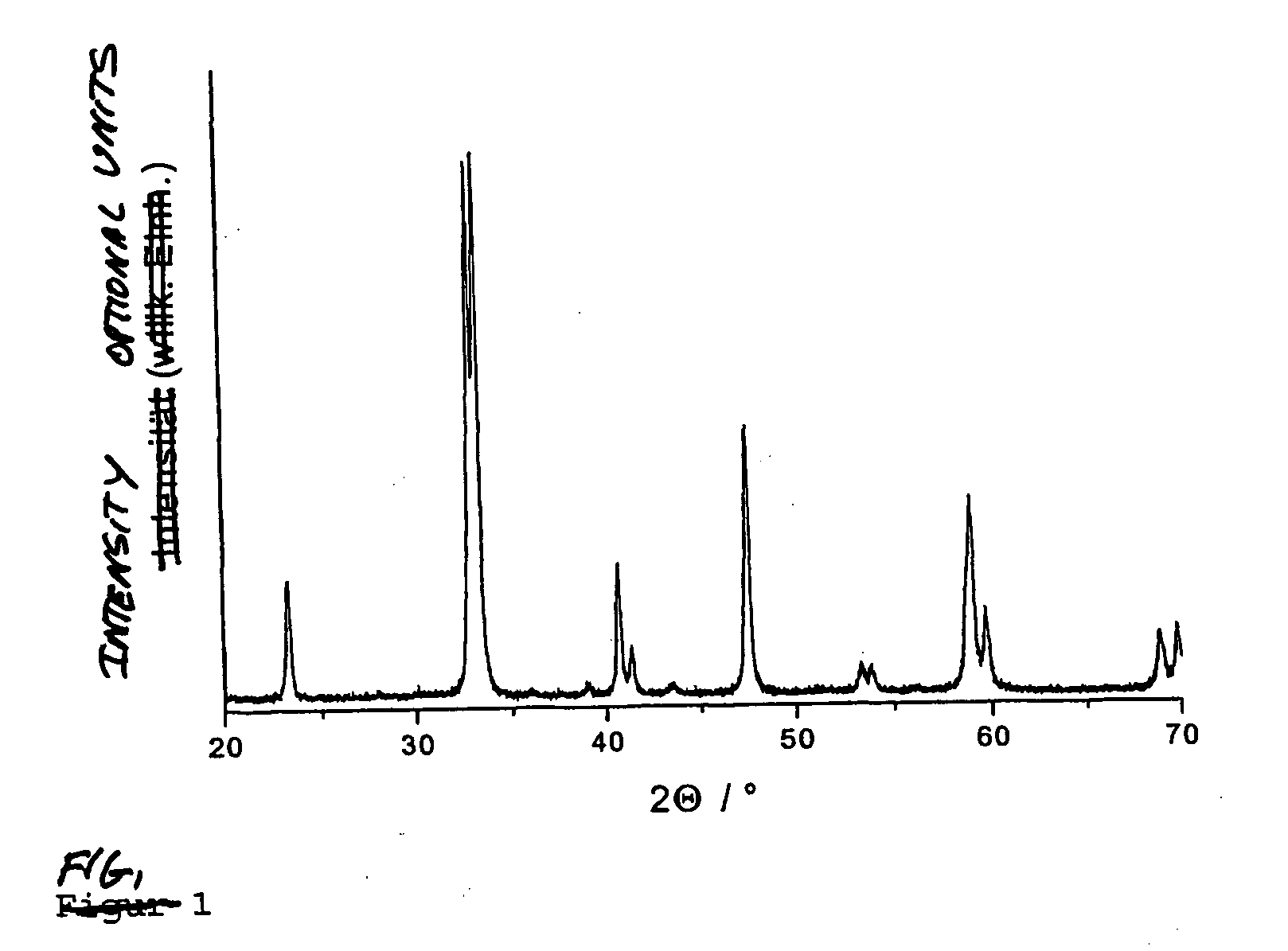

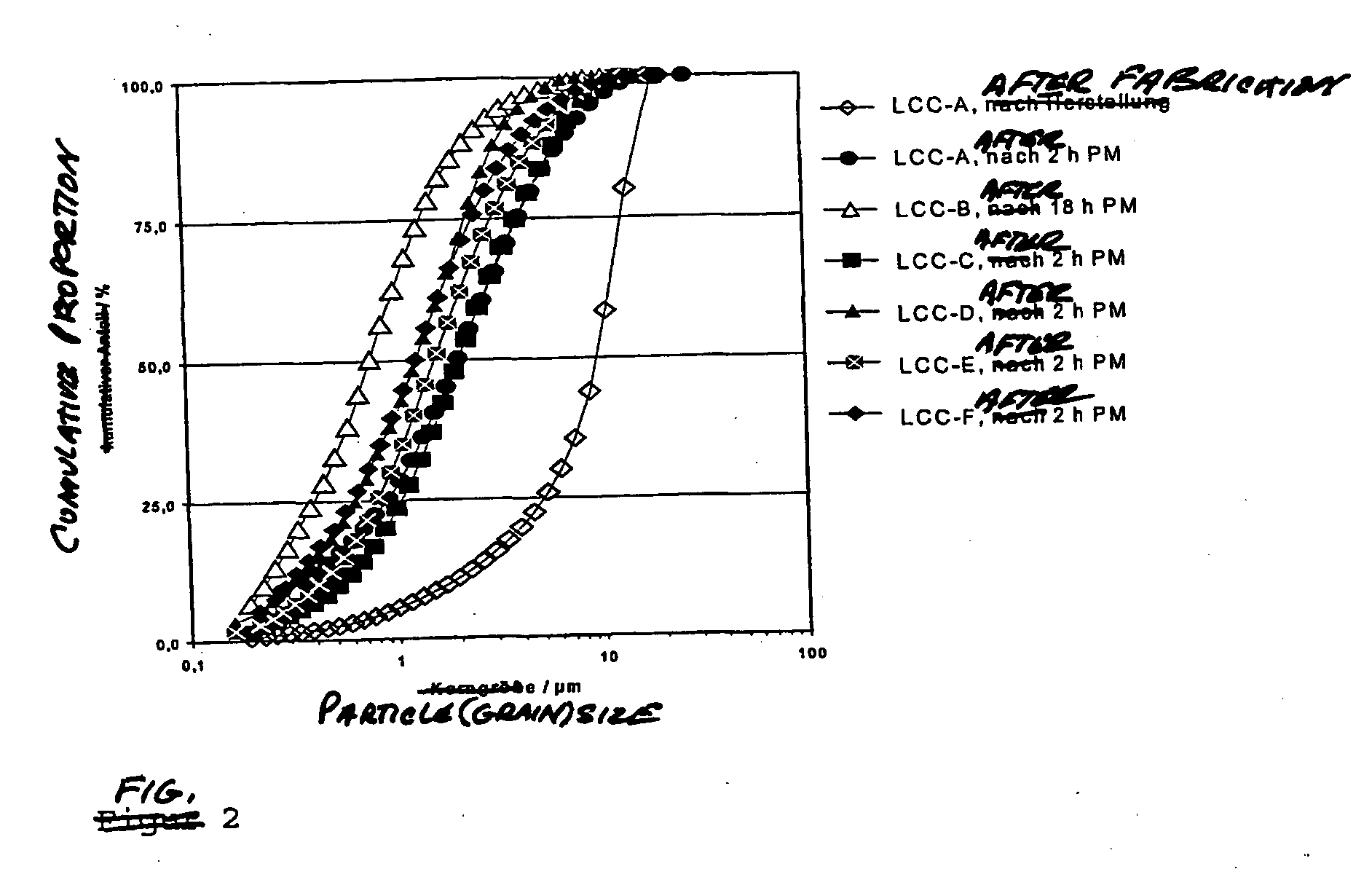

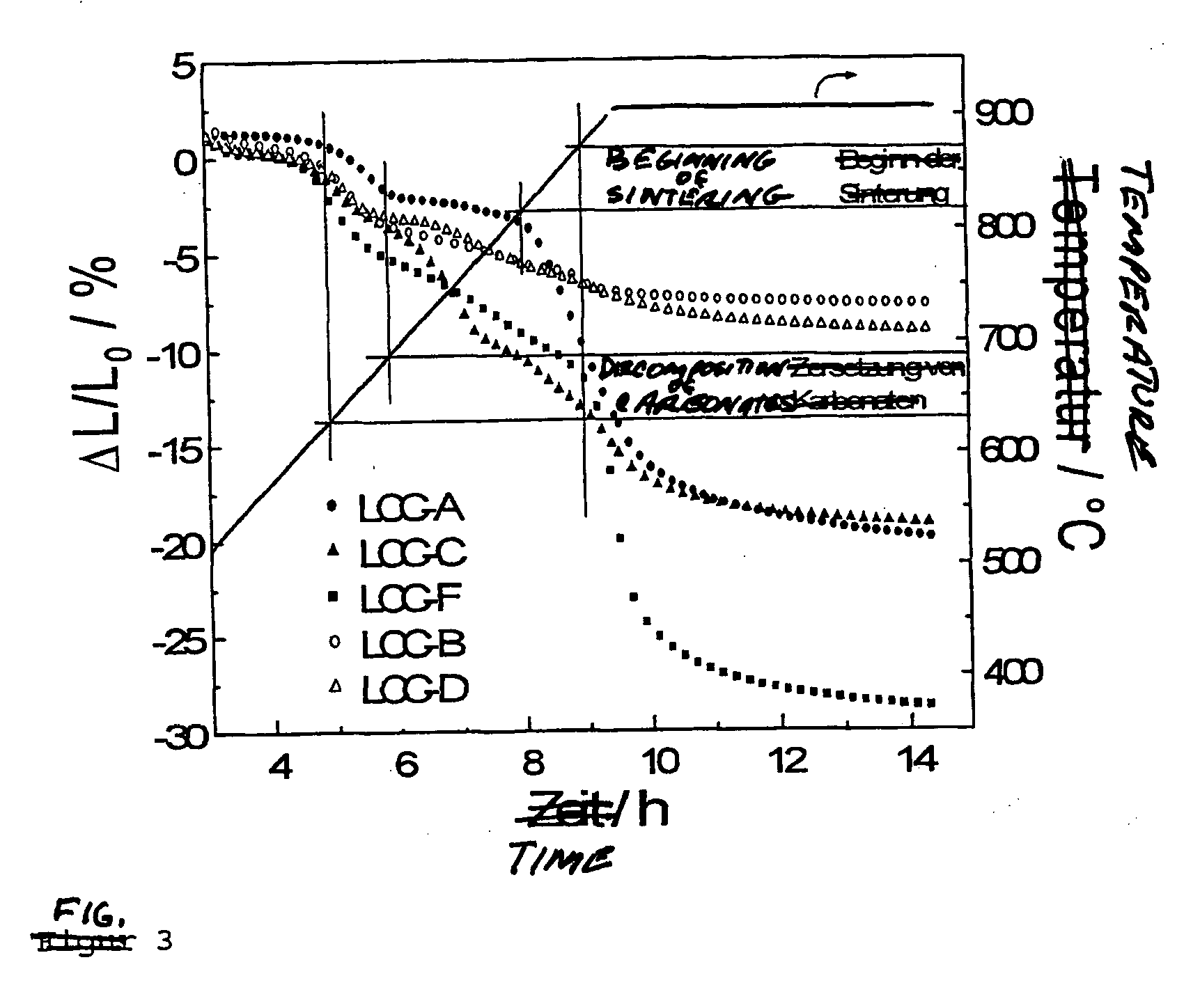

Ceramic material and the production thereof

InactiveUS20040047789A1Small coefficient of thermal expansionConductivity significantlyOxide/hydroxide preparationFinal product manufactureElectricityCeramic sintering

The invention relates to a method for producing ceramics which sinter extremely well and are electrically conductive. As a result of their characteristics, such as low sinter temperatures, an advantageous perovskite structure and a thermal expansion coefficient that can be adjusted in certain areas, said ceramics are particularly suitable for use as electrically conductive connecting elements in high-temperature fuel cells or piezoceramics.

Owner:FORSCHUNGSZENTRUM JILICH GMBH

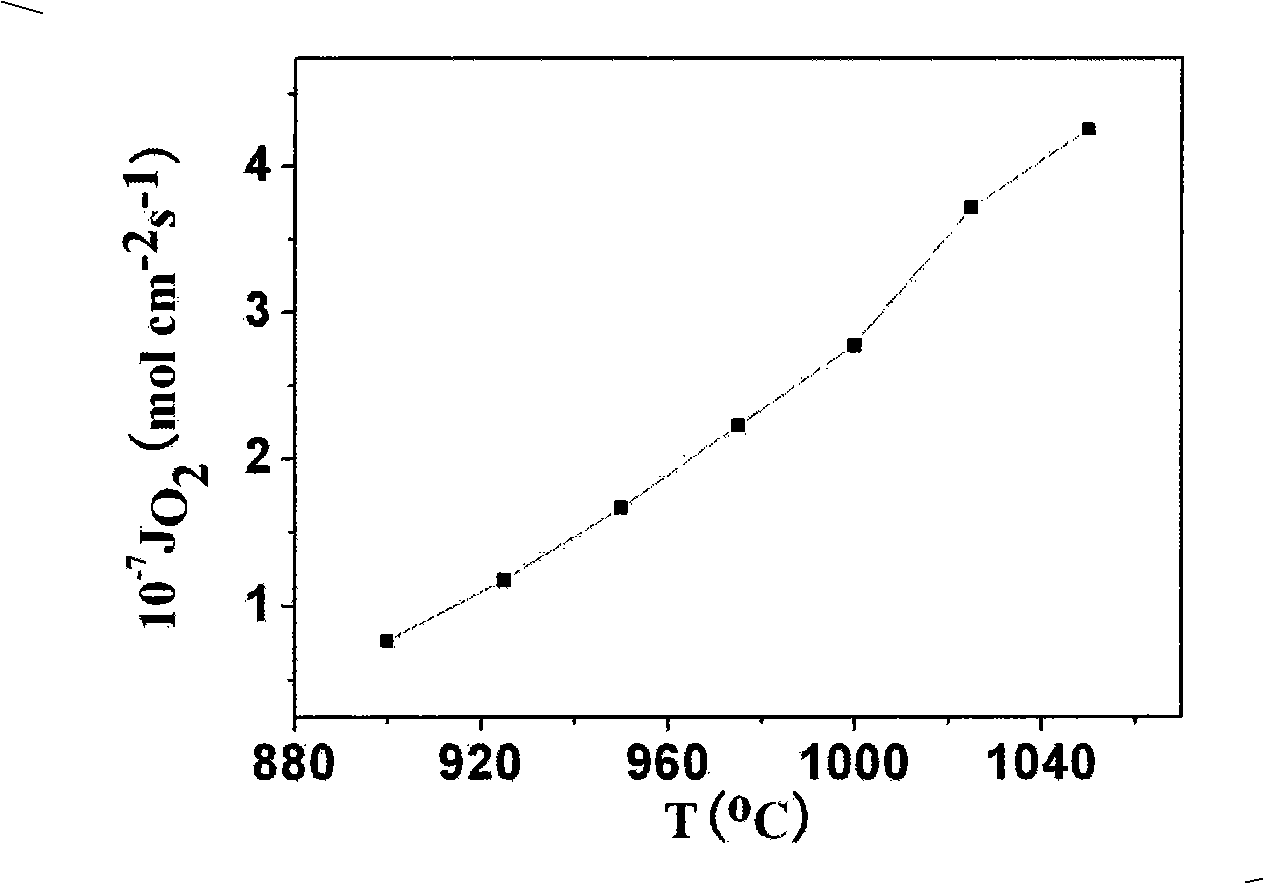

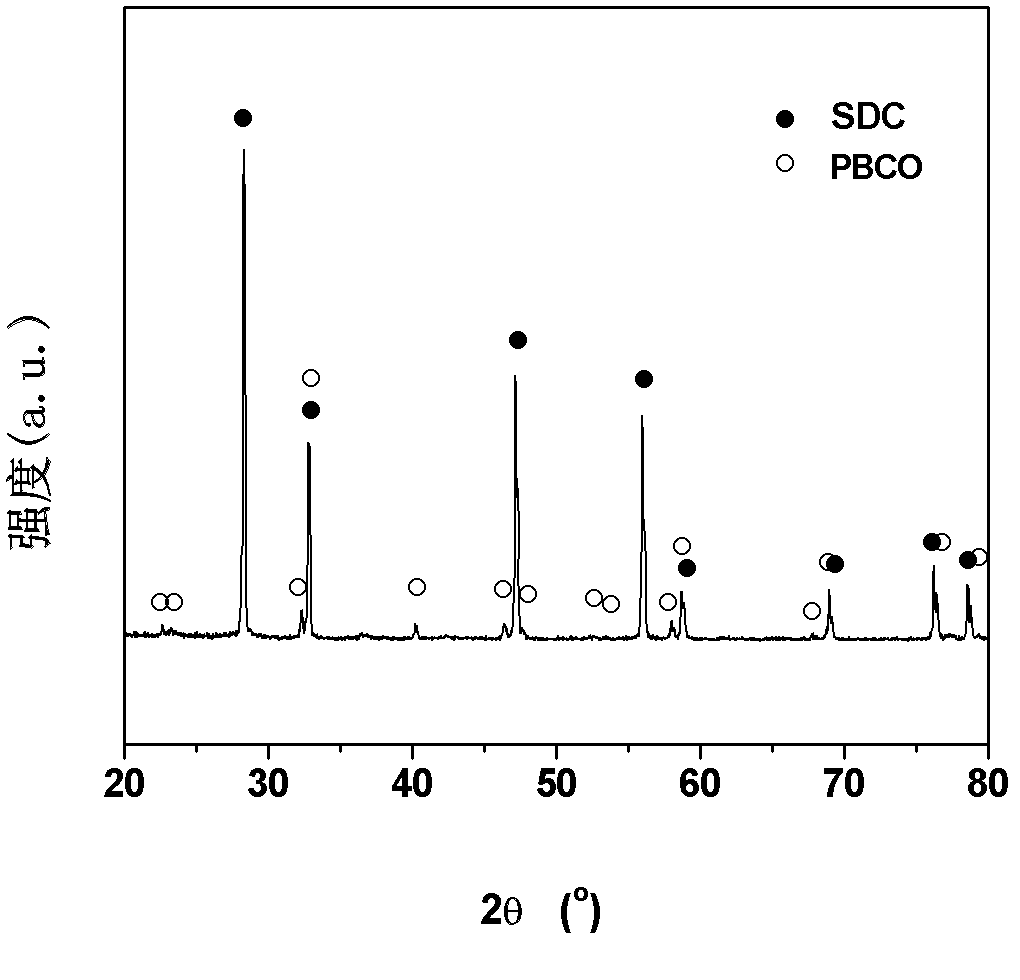

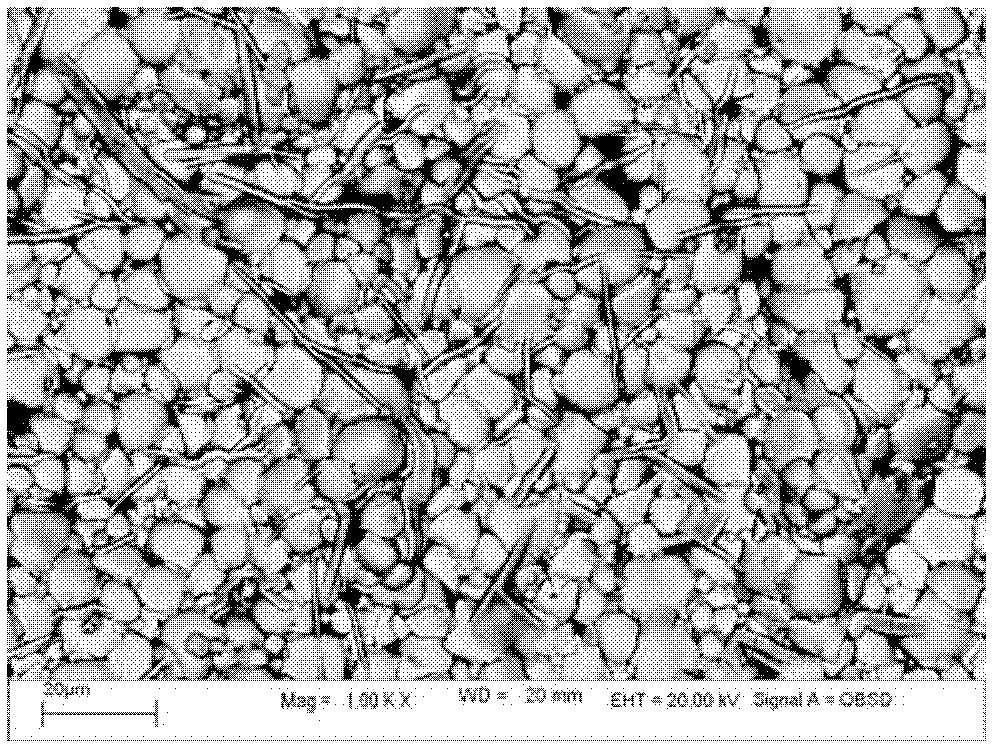

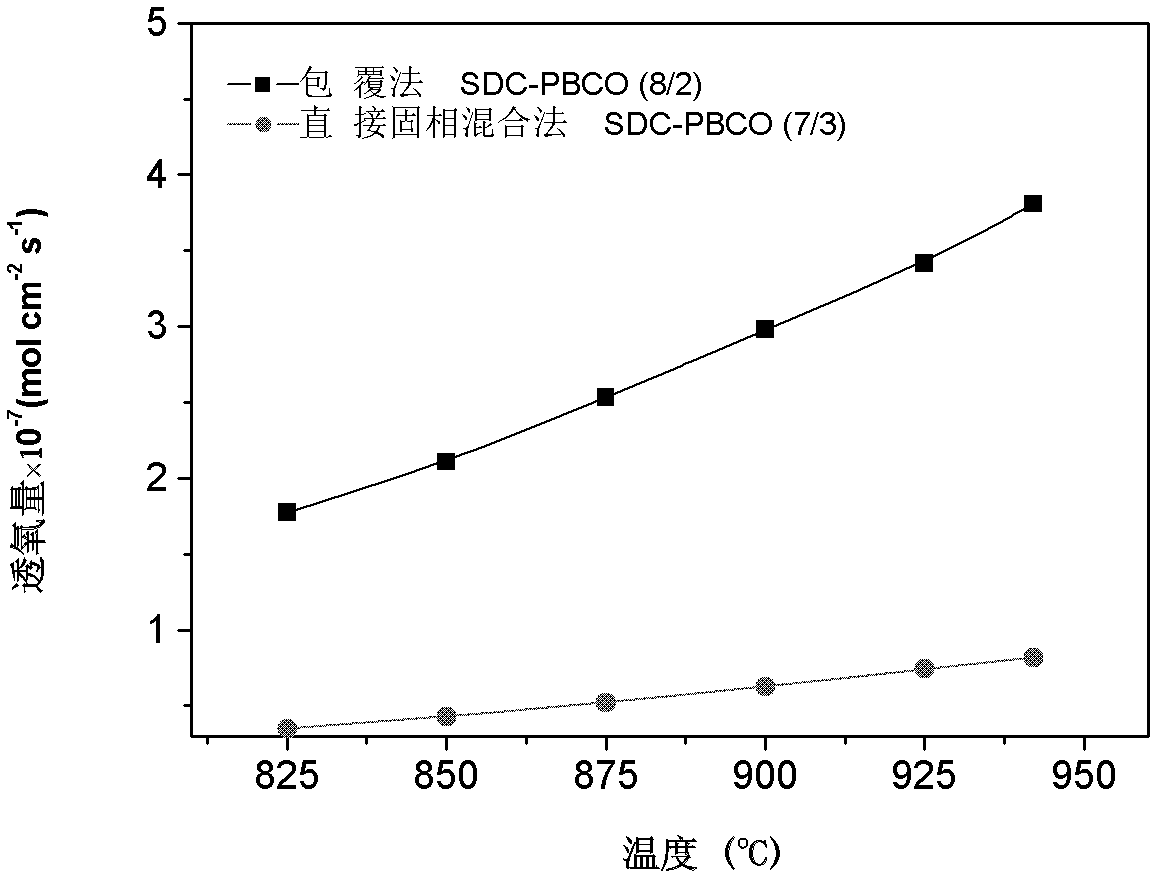

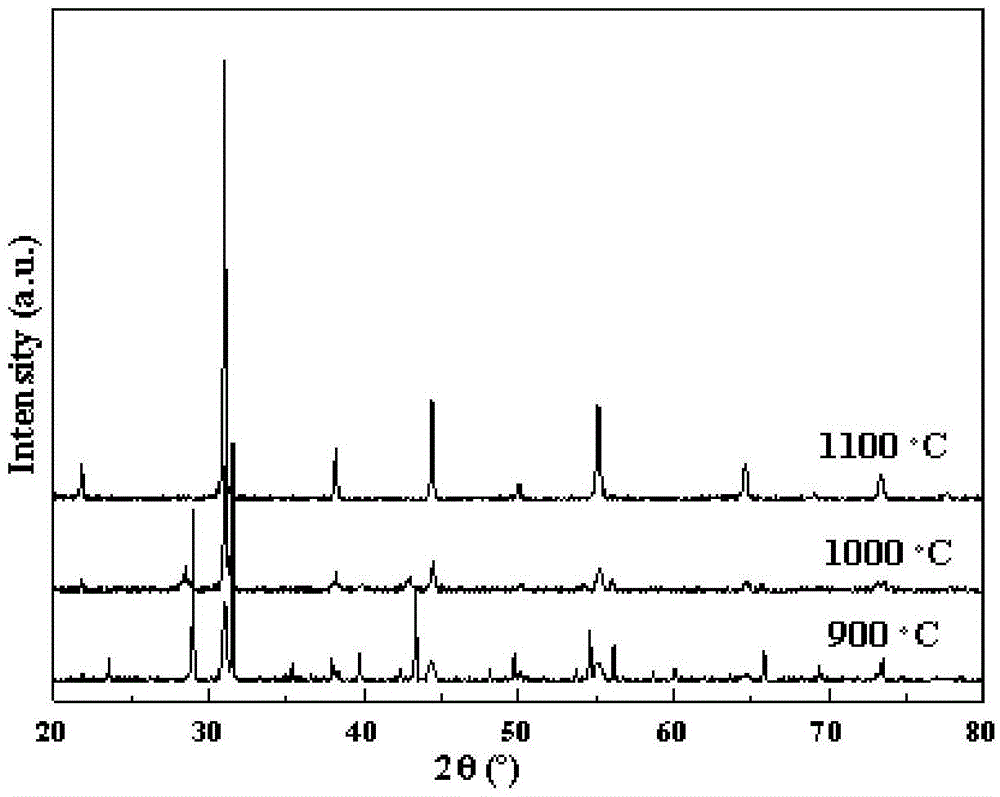

Method for preparing two-phase compact oxygen permeable material with high oxygen permeability

The invention relates to a method for preparing a Ce0.8Sm0.2O2 minus delta and PrBaCo2O5 plus delta two-phase compact oxygen permeable film and belongs to the field of a compact ceramic oxygen permeable film. The method comprises the following steps of: coating an electronic conductive phase PrBaCo2O5 plus delta on the surfaces of an ionic conductive phase, i.e. Ce0.8Sm0.2O2 minus delta particles, by a liquid phase method; and forming a two-phase oxygen permeable material with high ionic conductive phase content by high temperature sintering. Due to the special coating structure, the continuous and through threshold value of a surface to volume ratio of the ionic phase to the electronic phase is improved, which is beneficial for improving the oxygen permeability performance. The material has higher oxygen permeability, chemical stability and mechanical stability and can be used for oxygen separation in the air, a membrane reactor, oxygen enriched combustion and an electrode material of a fuel cell.

Owner:UNIV OF SCI & TECH BEIJING

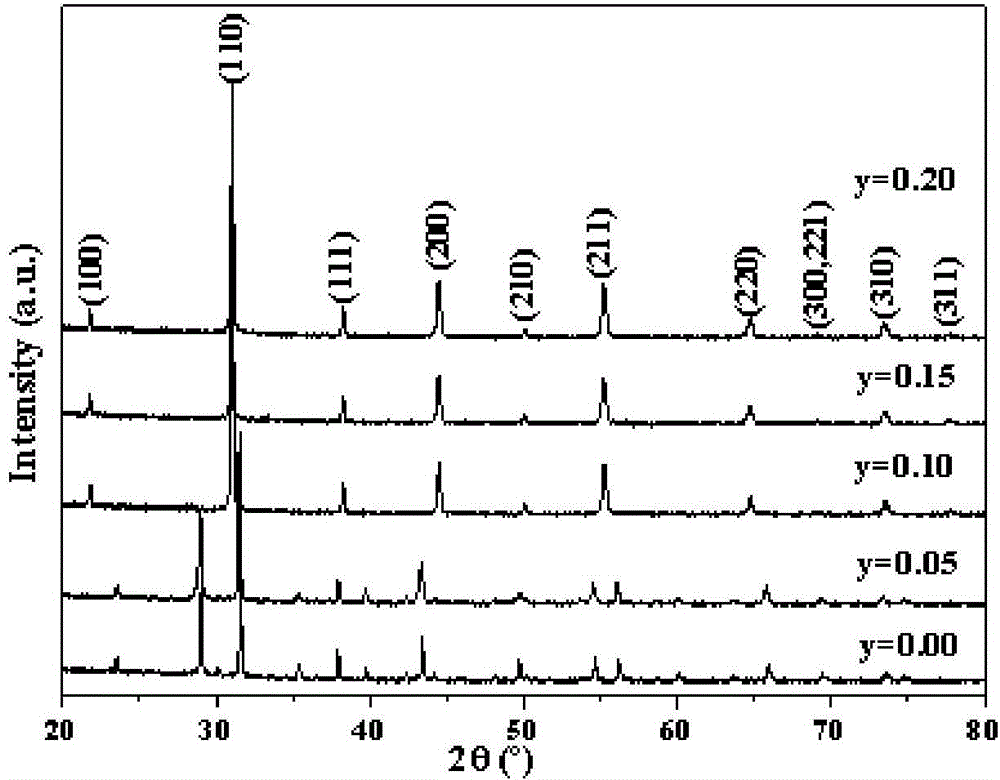

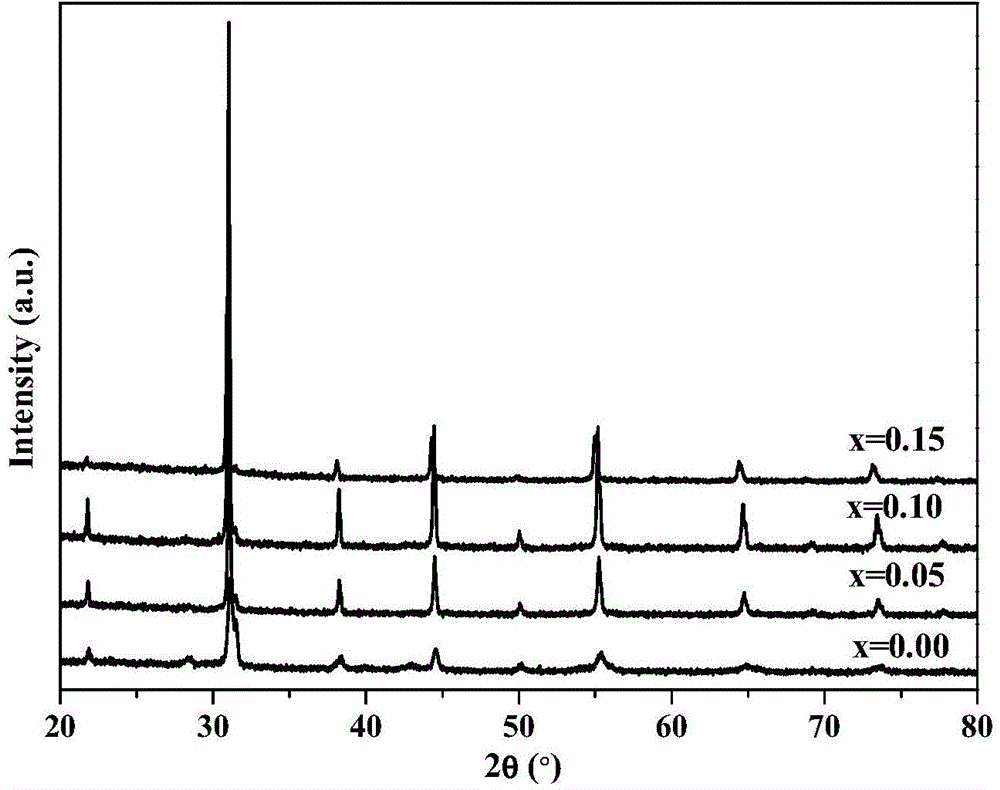

BaCoO3-delta base B-position Bi2O3-Nb2O5 co-doped cathode material of solid oxide fuel cell, preparation method and applications thereof

InactiveCN104409742AImprove structural stabilityCo-doping improvesCell electrodesOxygen ionsChemical compatibility

The invention discloses a BaCoO3-delta base B-position Bi2O3-Nb2O5 co-doped cathode material of solid oxide fuel cell, a preparation method and applications thereof. The provided cathode material has a perovskite type structure and is represented by a chemical formula: BaBi<x>Nb<y>Co<1-x-y>O<3-delta>, wherein the delta represents oxygen excess or oxygen deficiency (-1=<delta=<1), the x represents the doping amount of Bi2O3 (0=<x=<0.15), and the y represents the doping amount of Nb2O5 (0=<y=<0.2). The chemical compatibility between the provided BaBi<x>Nb<y>Co<1-x-y>O<3-delta> cathode material and the conventional electrolyte material such as GDC, and the like is good. In the air the current can be well conducted by the oxygen ions and electrons. In the temperature range of 450 to 850 DEG C, the provided cathode material has a very good oxidation-reduction catalytic activity. The cathode material is suitable for a solid oxide fuel cell used at a mid-low temperature.

Owner:HARBIN INST OF TECH

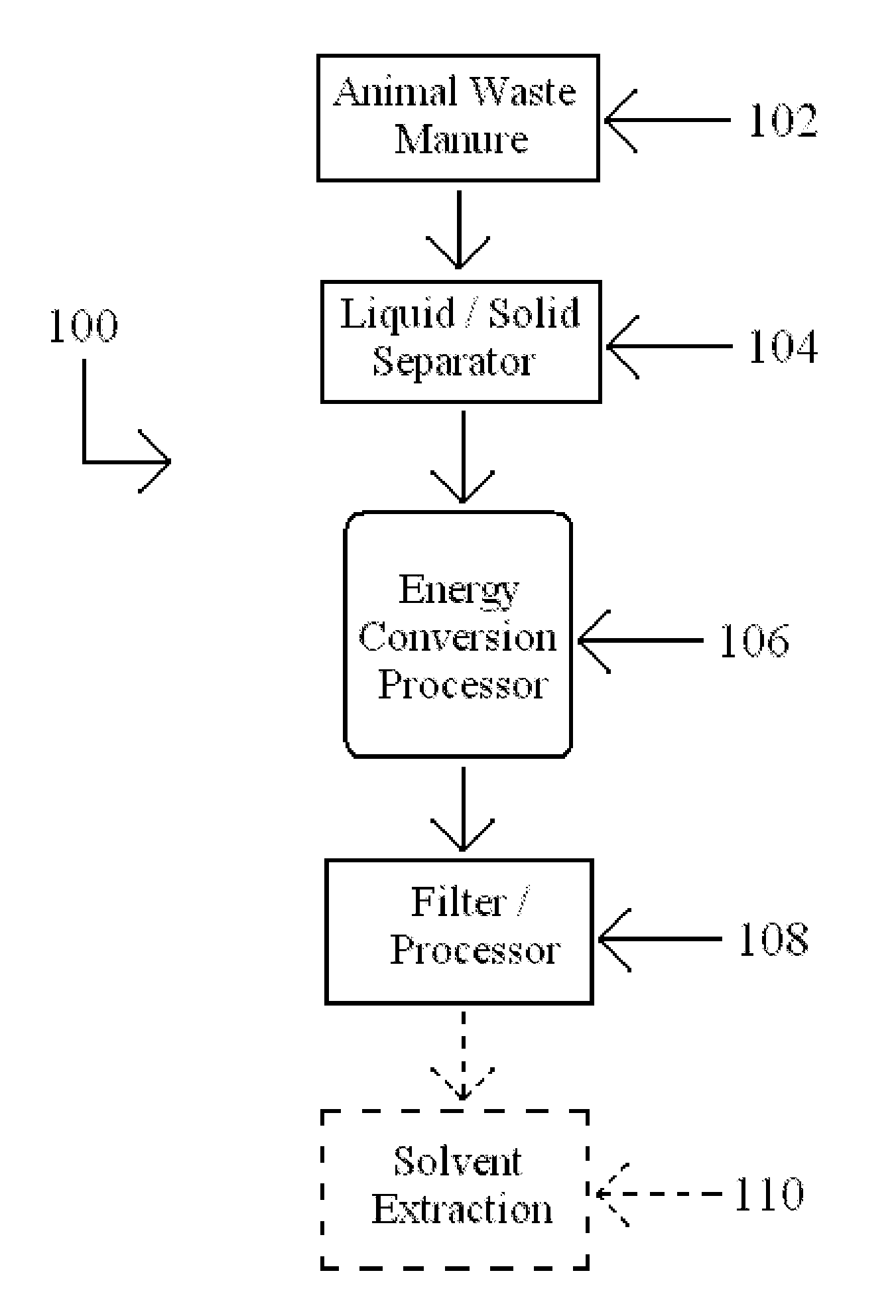

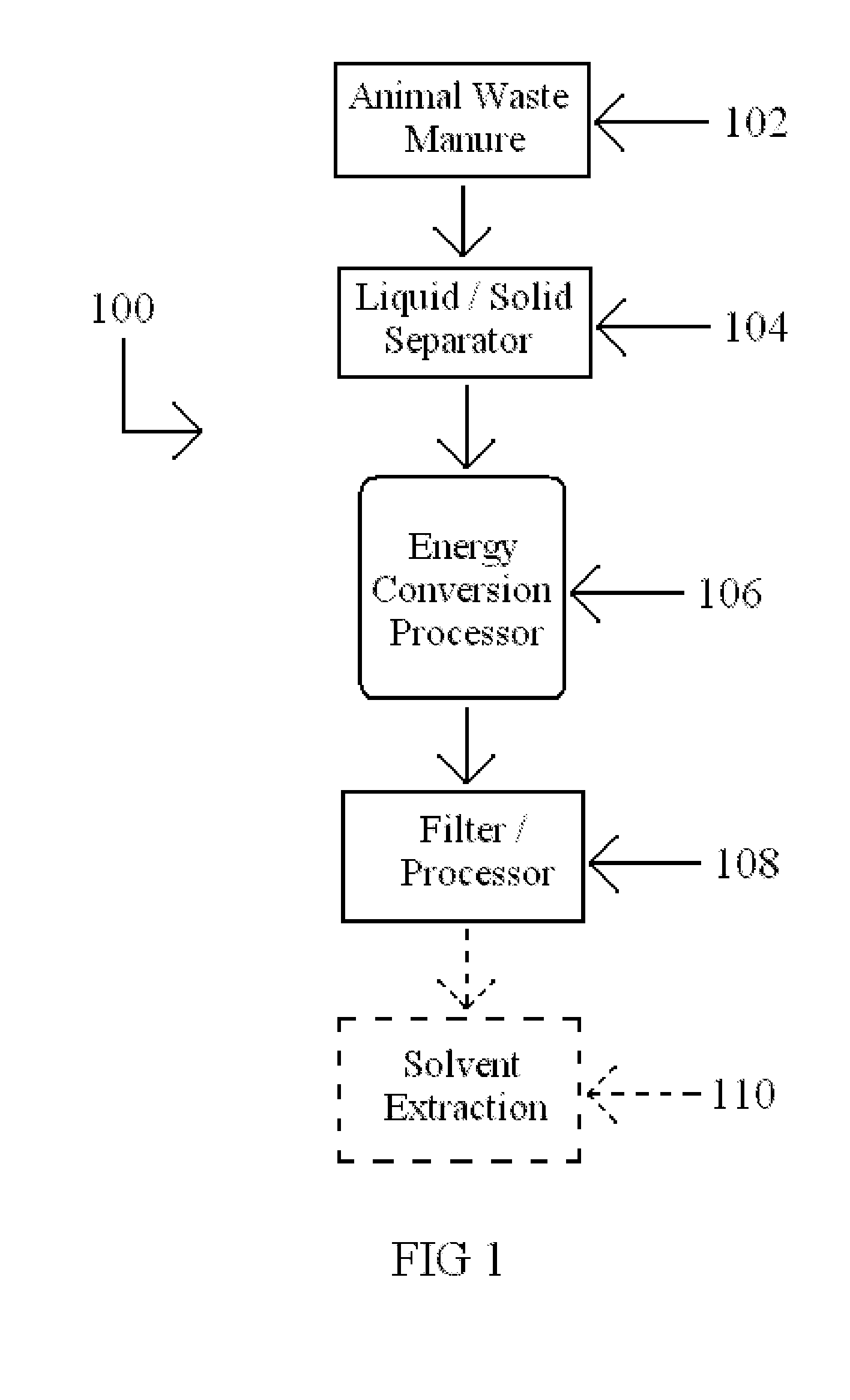

Asphalt compositions with resinous addition derived from animal waste

InactiveUS20130319289A1Good chemical compatibilityFatty acid chemical modificationInksEngineeringChemical compatibility

A bio-resource resin for use as a replacement for a portion of asphalt in asphalt compositions includes a bio-oil derived from animal waste and including hydrocarbons; and a compatibilizing agent. The bio-oil is derived from animal waste by subjecting the animal waste to a conversion process selected from a hydrothermal conversion process and a thermochemical conversion process. This bio-resource resin can be employed as a substitute for a portion of asphalt in common asphalt compositions, and the compatibilizing agent improves the chemical compatibility between the bio-oil and the asphalt.

Owner:IMPERIAL COMMODITIES

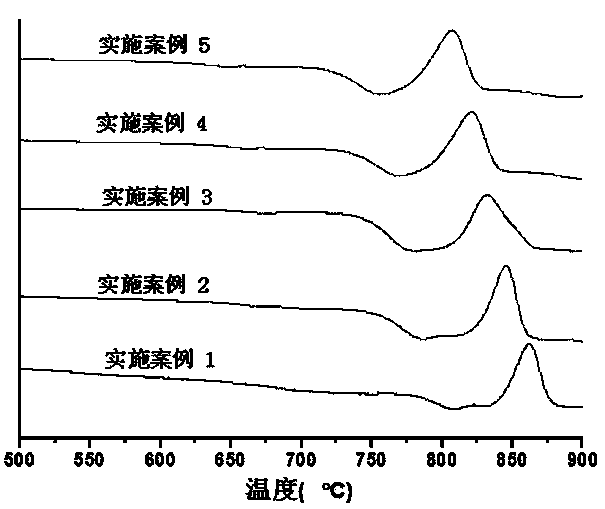

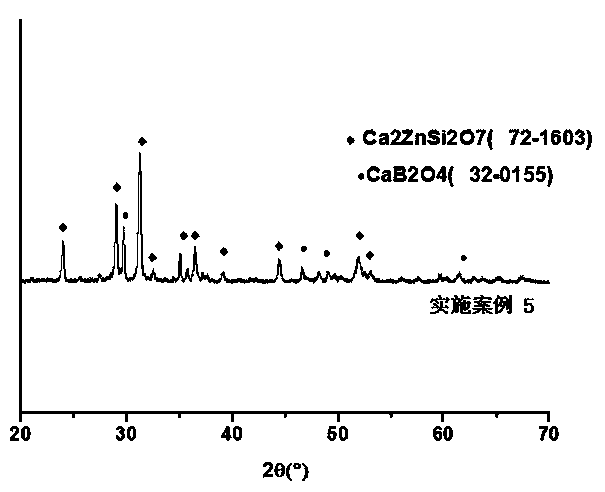

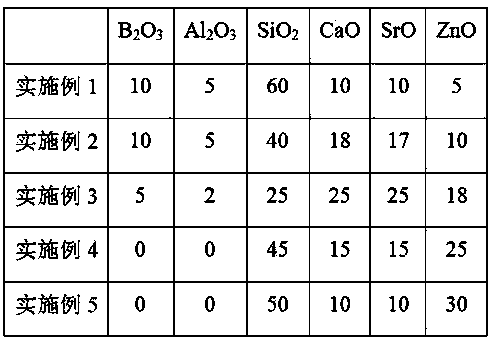

ZnO-containing sealing microcrystalline glass, and preparation and using methods thereof

The invention discloses ZnO-containing sealing microcrystalline glass, and preparation and using methods thereof. The ZnO-containing sealing microcrystalline glass comprises the following raw materials: B2O3, Al2O3, SiO2, MO (one or more of MgO, CaO, SrO and BaO) and ZnO with the molar ratio of (0-10): (0-5): (25-60): (20-50): (5-30). As the ZnO is added, the formation of CaB2O4 crystals in the glass can be promoted, the volatilization of a B-containing substance in the sealing glass in a working environment can be significantly reduced, and the thermal stability of the sealing glass and the chemical compatibility of the sealing glass with a cathode are further improved; and simultaneously, by adding the ZnO, the formation of Ca2ZnSi2O7 crystals in the glass can also be promoted so as to be conductive to improving the thermal expansion coefficient matching degree of the sealing glass with other SOFC (solid oxide fuel cell) components. The ZnO-containing sealing microcrystalline glass disclosed by the invention has the advantages of simple preparation raw materials, easiness in obtainment of the raw materials and stable process, an invert glass grid structure taking SiO2 as a main body is obtained, the cost is low, the process is simple and feasible, and practical and industrial conditions are further achieved.

Owner:FUZHOU UNIV

Low cost metal bipolar plates and current collectors for polymer electrolyte membrane fuel cells

InactiveUS6723462B2Good chemical compatibilityFuel cells groupingCell component detailsPolymer electrolytesFuel cells

A polymer electrolyte membrane fuel cell stack having a plurality of substantially planar fuel cell units, each of which comprises an anode electrode, a cathode electrode and a polymer electrolyte membrane disposed between the anode electrode and the cathode electrode. A metal bipolar plate is disposed between the anode electrode of one fuel cell unit and the cathode electrode of an adjacent fuel cell unit. The metal bipolar plate is made of a chromium-nickel austenitic alloy, in which the chromium and the nickel, on a combined basis, make up at least about 50% by weight of the alloy.

Owner:GAS TECH INST

Oxide-forming protective coatigns for niobium-based materials

ActiveUS20110146848A1Improve antioxidant capacityImprove the immunityEngine fuctionsVacuum evaporation coatingRheniumNiobium

Coatings suitable for use as protective oxide-forming coatings on Nb-based substrates exposed to high temperatures and oxidative environments. The coatings contain chromium and / or molybdenum, preferably contains silicon, and optionally contains niobium, titanium, hafnium, iron, rhenium, tantalum, and / or tungsten, which in combination form multiple intermetallic phases, which in combination form one or more intermetallic phases that promote the formation of a slow-growing oxide scale. Depending on the particular coating composition, the intermetallic phases may be: a silicon-modified Cr2Nb Laves phase and optionally a chromium solid solution phase, a CrNbSi intermetallic phase, and / or an M3Si intermetallic phase where M is niobium, titanium, and / or chromium; or M5Si3, MSi2 and / or M3Si2 where M is molybdenum, niobium, titanium, chromium, hafnium, iron, rhenium, tantalum, and / or tungsten.

Owner:GENERAL ELECTRIC CO

Method for transferring heat

InactiveUS20130168049A1Reducing and even eliminating riskImprove efficiencyIndirect heat exchangersHeat-exchange elementsCarbon fibersPerfluoropolyether

A process for transferring heat comprising the following steps:(1) transferring heat from a body to a first heat transfer system by means of a secondary loop passageway comprising a heat transfer fluid and, optionally,(2) transferring heat from a second heat transfer system to said body by means of said secondary loop passageway comprising said heat transfer fluid,wherein: said second heat transfer system being the same as or different from said first heat transfer system, said secondary loop passageway comprises at least one polymer sealant selected from a rubber seal and a plastic pipe; and said heat transfer fluid comprises one or more linear perfluoropolyethers having formula RF—(OCF2)n(OCF2CF2)m(OCF2(CF2)zCF2)p—ORF (I), wherein RF, equal or different at each occurrence, is a C1-C3 perfluoroalkyl group, m, n and p, equal to or different from each other, are integers comprised between 0 and 100, the sum m+n being higher than 0, and z is equal to 1 or 2, and wherein said heat transfer fluid is circulated through said secondary loop passageway in step (1) for transferring said heat from said body to said first heat transfer system and, optionally, in step (2) for transferring said heat from said second heat transfer system to said body.

Owner:SOLVAY SOLEXIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com