Long-term high-temperature oxidation-resistant multi-element composite ceramic coating for carbon/carbon composite material and preparation and application methods thereof

A carbon composite material, high-temperature oxidation resistance technology, which is applied to carbon/carbon composite material long-term high-temperature oxidation-resistant multi-component composite ceramic coating, preparation and application fields, can solve problems such as easy cracking, and can meet the requirements of long-term use, Combines the effect of strong, superior thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] First, cut the C / C composite material into a block sample of 20×20×5mm, grind the chamfer with 400# sandpaper, then finely grind it with 800# sandpaper, clean it with alcohol, and bake it at 120°C for 1-2 hours before use. ;

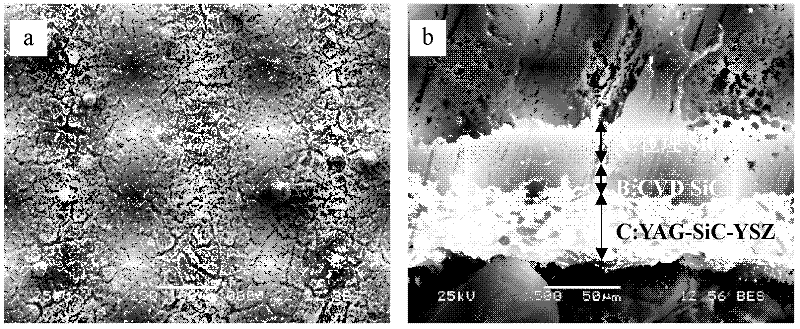

[0036] Next is the embedding process to prepare the SiC connection layer:

[0037] Si powder, SiC powder, C powder, Al 2 o 3 Powder is used as raw material to prepare mixed powder for embedding. The mass ratio of powder is: 50% Si-12% Al 2 o 3 -18%C-20%SiC. Weigh Si powder (over 325 mesh), Al 2 o 3 Powder (over 325 mesh), C powder (over 325 mesh), and SiC powder (over 325 mesh) use ethanol as a dispersant, put them in a planetary ball mill and mix well, take them out and dry them before use. Finally, put the C / C composite material in a graphite crucible and bury it completely with the mixed powder, then put the crucible into a high-temperature furnace, from room temperature to 1100°C, it takes 50min; from 1100°C to 1800°C, it takes 50min ...

Embodiment 2

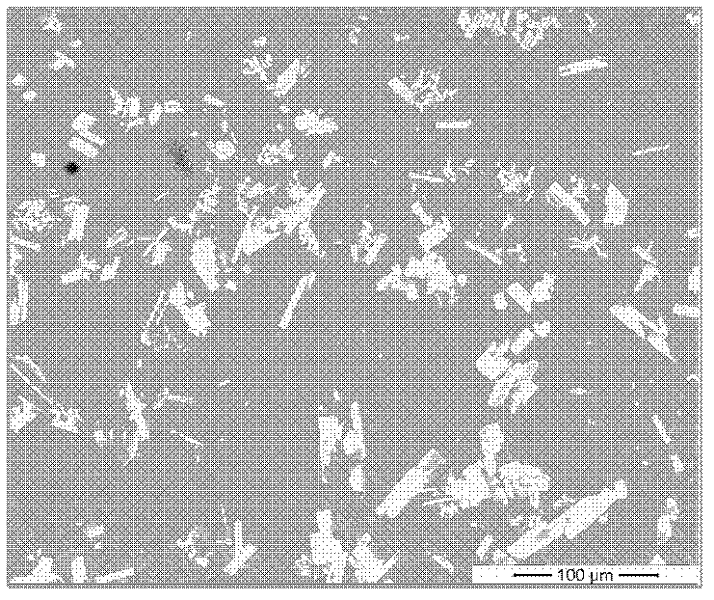

[0044] Using 70%Si-4%Al 2 o 3 -12%C-14%SiC embedding material to prepare SiC connection layer, the parameters used are: H 2 / MTS=10 (molar ratio), Ar flow rate is 200ml min -1 , the deposition pressure is 2 The powder (YSZ) is prepared according to the powder ratio of 60:30:10 to prepare the ceramic outer coating, and the rest of the steps are the same as above. After 150h, 1500°C air oxidation resistance test of the prepared coating sample, the coating remains intact without falling off, the oxidation weight gain rate is 0.35%, and the coating sample strength retention rate is 96.8%.

Embodiment 3

[0046] Using 45%Si-10%Al 2 o 3 -10%C-35%SiC embedding material to prepare SiC connection layer, the parameters used are: H 2 / MTS=12 (molar ratio), Ar flow rate is 180ml min -1 , deposition pressure 2 The powder (YSZ) is prepared according to the powder ratio of 75:25:5 to prepare the ceramic outer coating, and the rest of the steps are the same as above. The prepared coating sample was subjected to the oxidation resistance test in air at 1500°C for 150 hours. The coating remained intact and did not fall off. The oxidation weight gain rate was 0.11%, and the strength retention rate of the coating sample was 95.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com