Surface coating system of fiber reinforced ceramic matrix composite material and preparation method therefor

A composite material and fiber-reinforced technology, which is applied in the field of high-temperature-resistant fiber-reinforced ceramic matrix composite materials, can solve the problems that cannot be directly synthesized, the outer coating cracks or falls off, the density of the mullite coating, and the adhesion are not ideal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

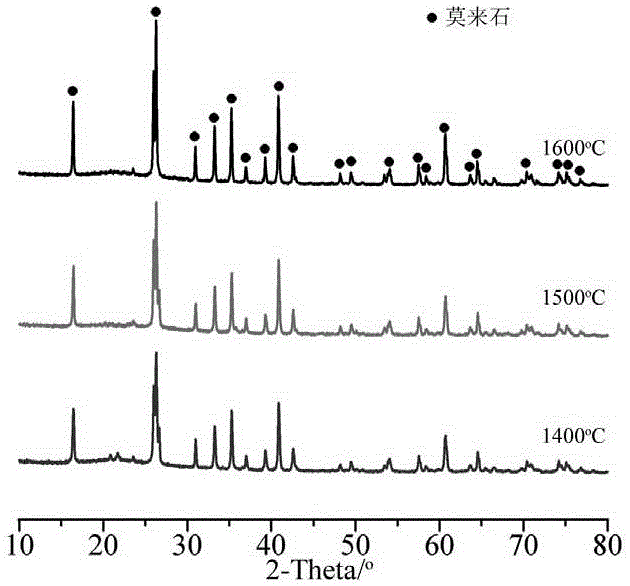

[0072] A high temperature resistant and oxidation resistant surface coating system of the present invention, such as figure 1 Shown. The surface coating system is arranged on the surface of the C / C composite material substrate, and includes a SiC inner coating, a mullite intermediate layer and an yttrium silicate outer coating arranged sequentially from bottom to top.

[0073] In this embodiment, the thickness of the SiC coating is 20 μm; in the chemical composition of the mullite coating, Al 2 O 3 With SiO 2 The mass ratio is 2.13:1, the thickness of the mullite coating is 60μm; the yttrium silicate coating is Y 2 Si 2 O 7 Single-phase coating with a single layer thickness of 80μm.

[0074] A method for preparing the surface coating system of the C / C composite material of this embodiment, including the following steps:

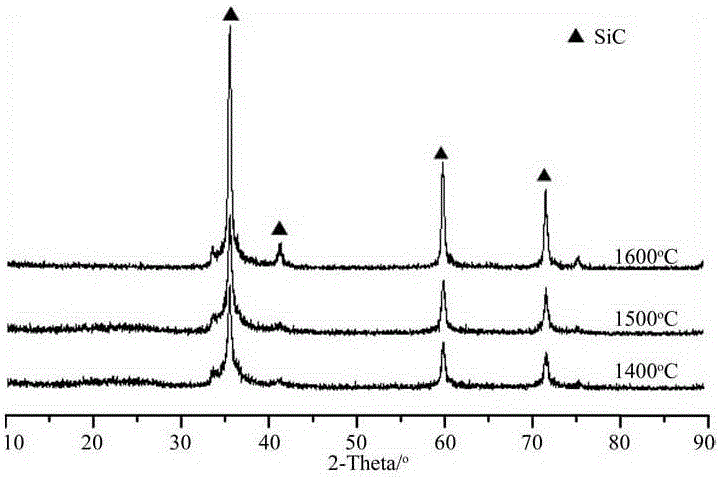

[0075] S1. Preparation of SiC coating slurry raw materials: according to the volume ratio of SiC powder / silicone resin 1:3 (the density of silicone resin used in th...

Embodiment 2

[0095] A high temperature resistant and oxidation resistant surface coating system of the present invention, such as figure 1 Shown. The surface coating system is arranged on the surface of the SiC / SiC composite material substrate, and includes a SiC layer, a mullite coating and an yttrium silicate coating arranged sequentially from bottom to top.

[0096] In this embodiment, the thickness of the SiC coating is 50μm; in the chemical composition of the mullite coating, Al 2 O 3 With SiO 2 The mass ratio is 3.55:1, the thickness of the mullite coating is 50μm; the yttrium silicate coating is Y 2 SiO 5 Single-phase coating with a single layer thickness of 50μm.

[0097] A method for preparing the surface coating system of a composite material of this embodiment described above includes the following steps:

[0098] S1. Slurry material for preparing SiC coating: According to the volume ratio of SiC powder / silicone resin 1:1.5 (the density of silicone resin used in this embodiment is 1.3g...

Embodiment 3

[0118] A high temperature resistant and oxidation resistant surface coating system of the present invention, such as figure 1 Shown. The surface coating system is arranged on the surface of the C / SiC composite material substrate, and includes a SiC inner coating, a mullite intermediate layer and an yttrium silicate outer coating arranged sequentially from bottom to top.

[0119] In this embodiment, the thickness of the SiC coating is 40 μm; in the chemical composition of the mullite coating, Al 2 O 3 With SiO 2 The mass ratio is 2.55:1, the thickness of the mullite coating is 50μm; the yttrium silicate coating is 70wt% Y 2 Si 2 O 7 +30wt%Y 2 SiO 5 Mixed-phase single-layer coating with a single-layer thickness of 100μm.

[0120] A method for preparing the surface coating system of a composite material of this embodiment described above includes the following steps:

[0121] S1. Slurry material for preparing SiC coating: According to the volume ratio of SiC powder / silicone resin 1:9 (t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com