Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

133 results about "Protective oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

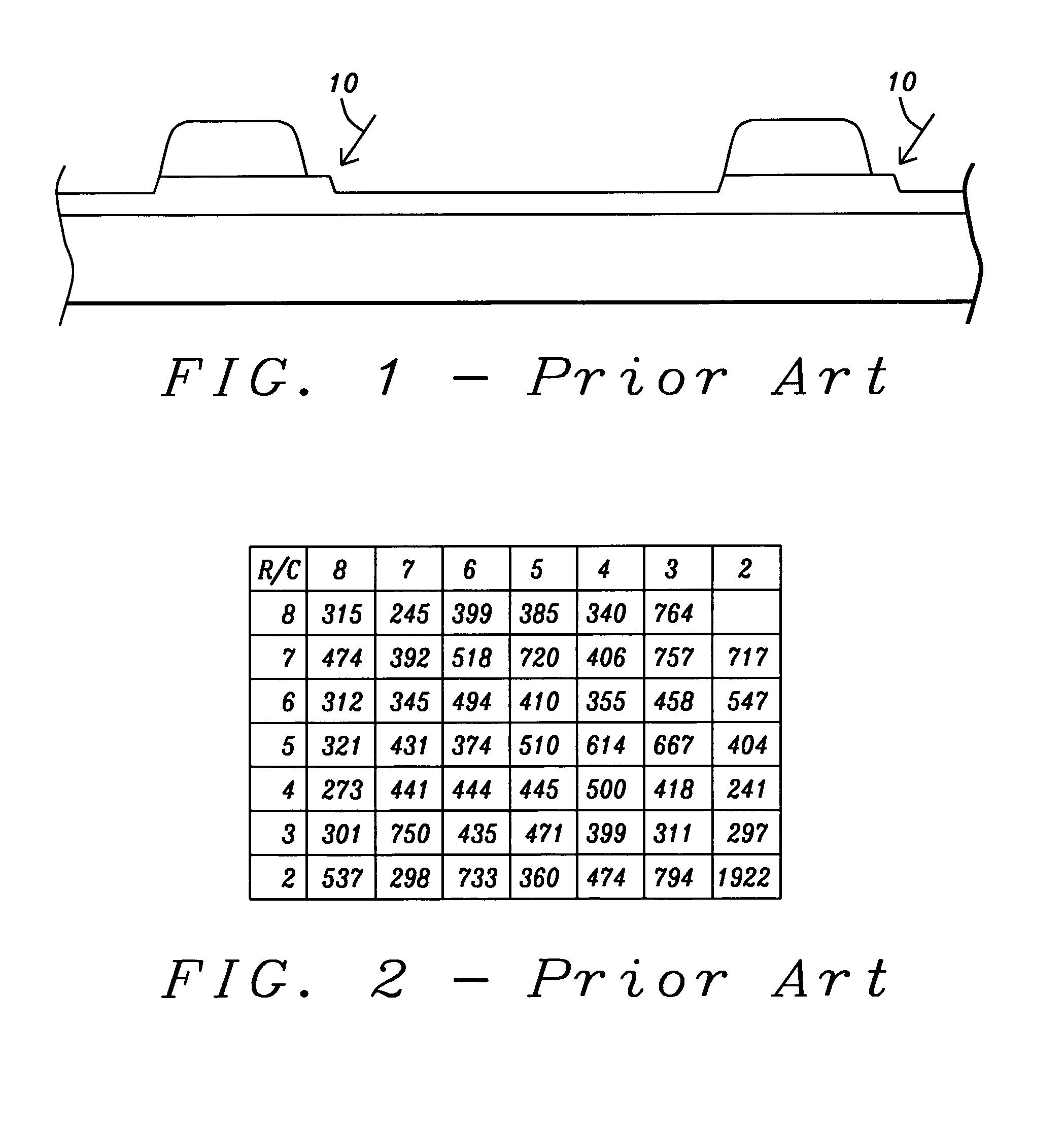

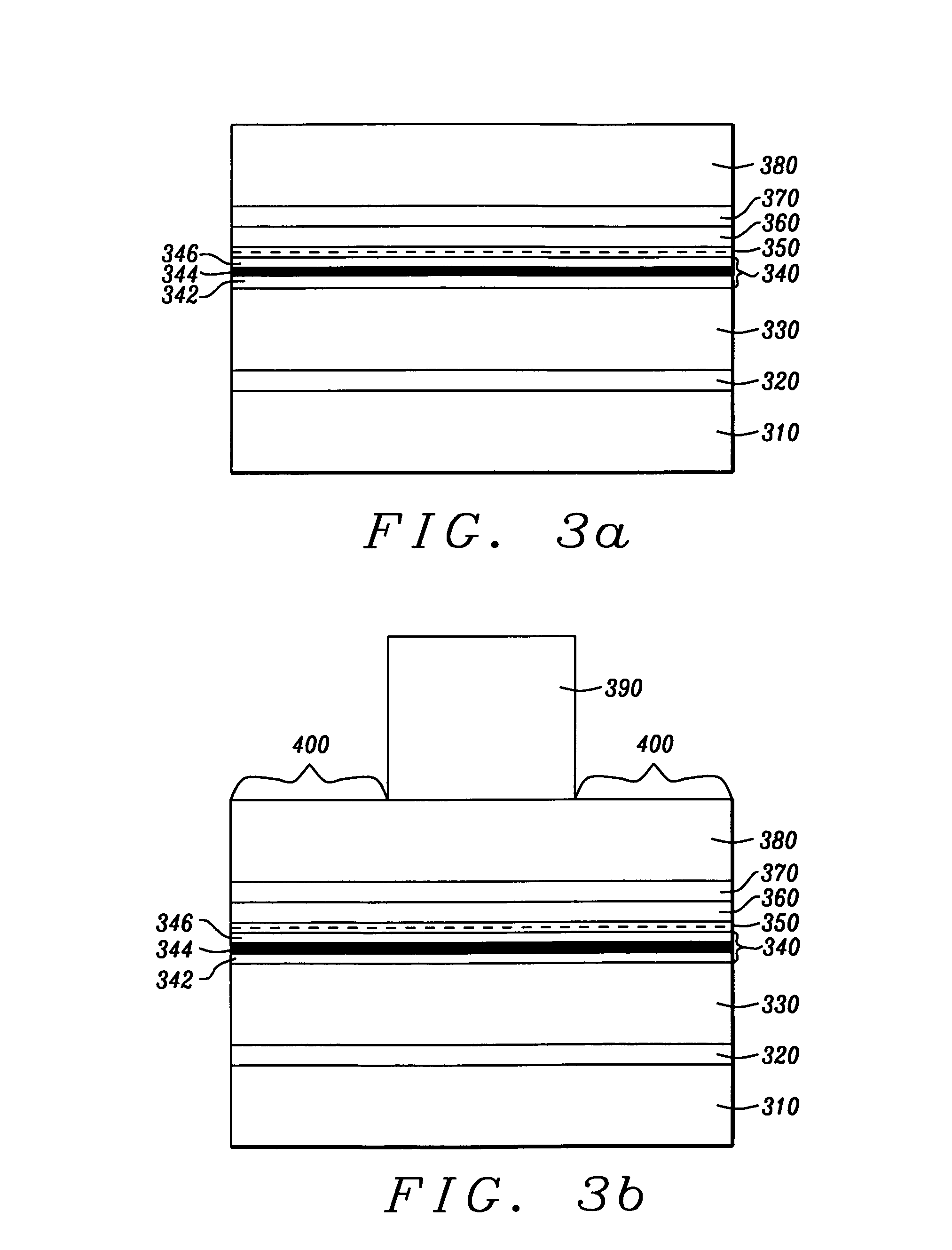

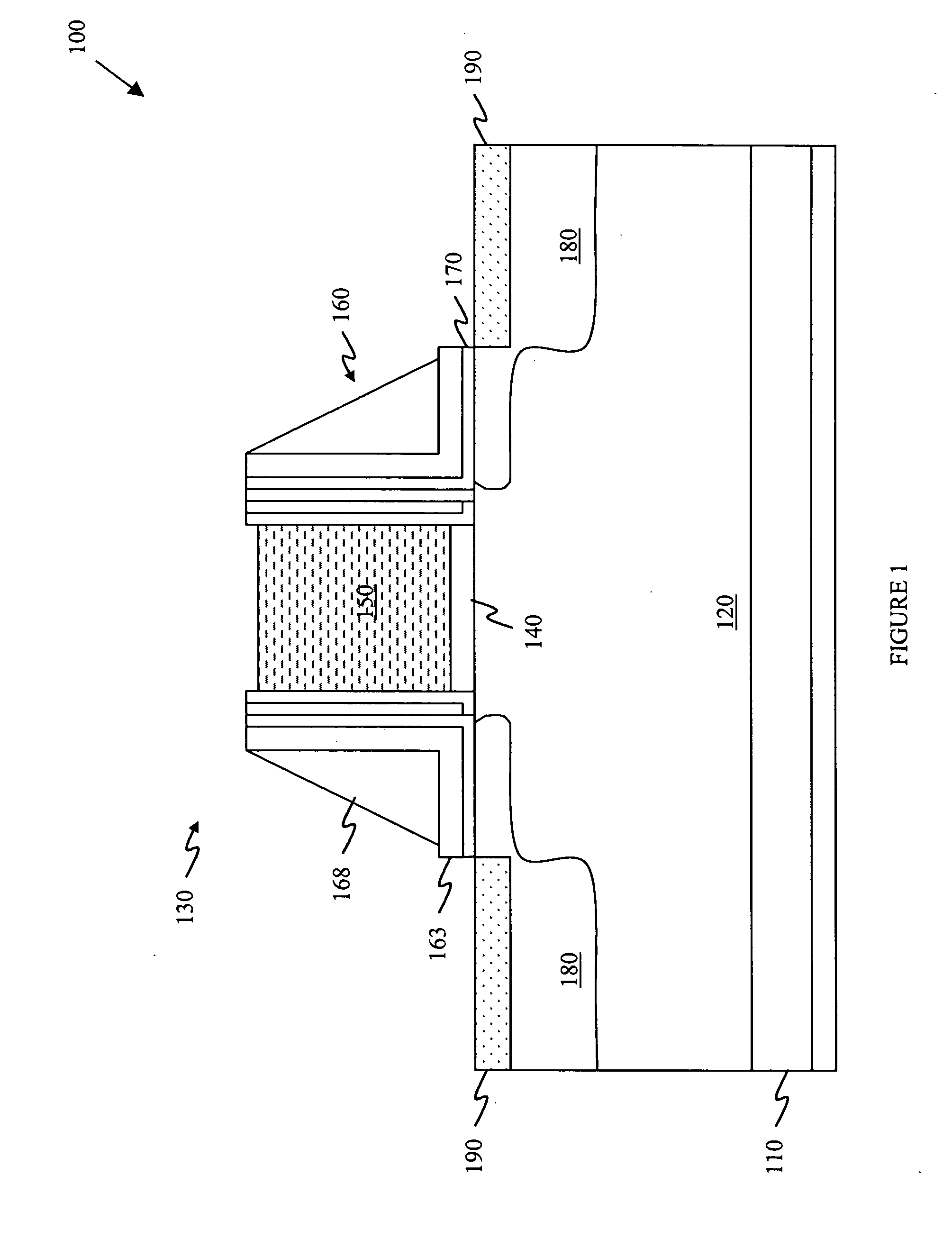

Method of MRAM fabrication with zero electrical shorting

ActiveUS7936027B2Reduces and eliminates electrical shortingLarge deviationMagnetic-field-controlled resistorsSemiconductor/solid-state device manufacturingElectricityHydrogen

Owner:TAIWAN SEMICON MFG CO LTD

Austenitic stainless steel

ActiveUS20080107559A1Careful analysisAvoid dissociationHeat exchange apparatusMetallurgyProtective oxide

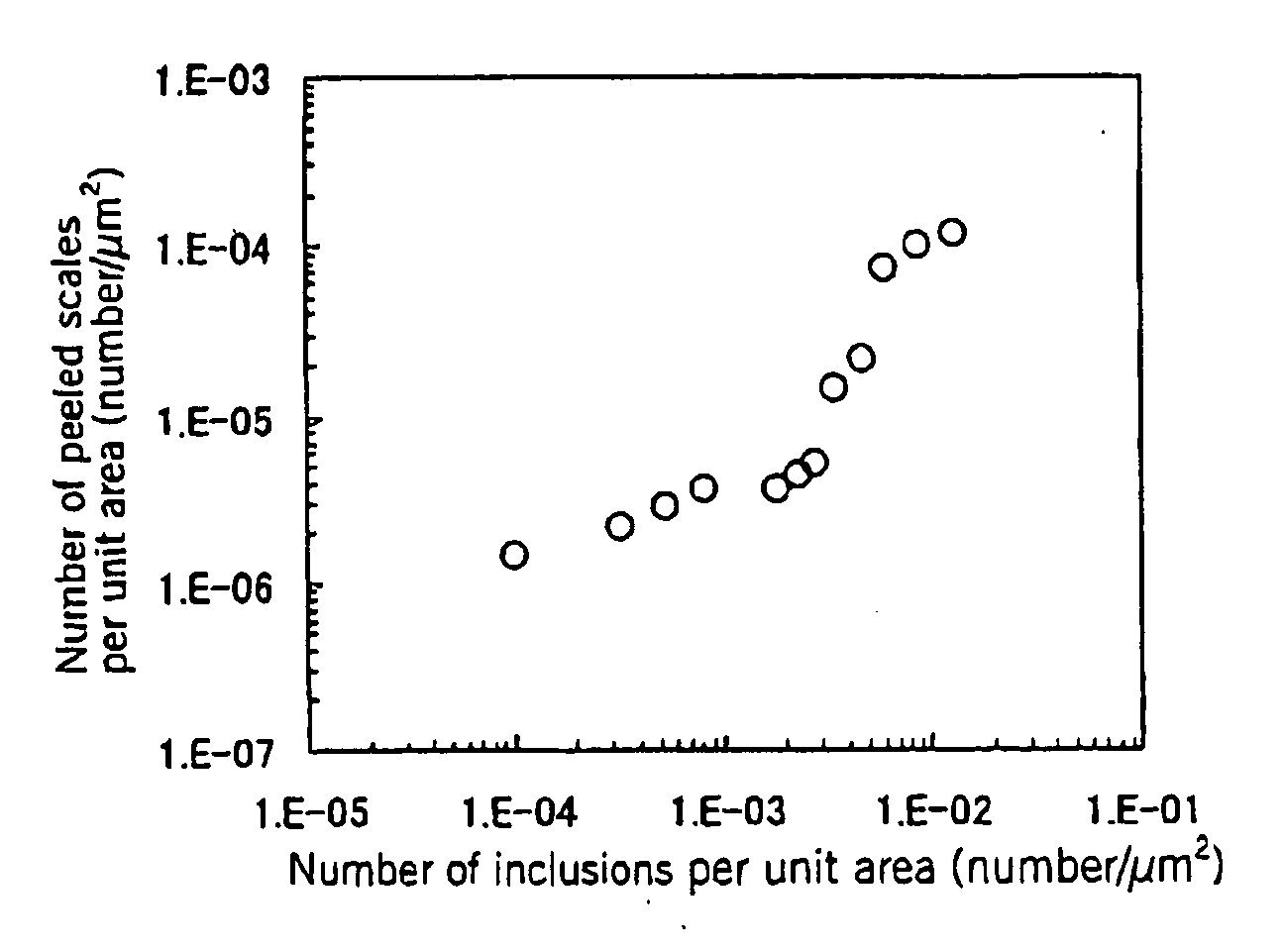

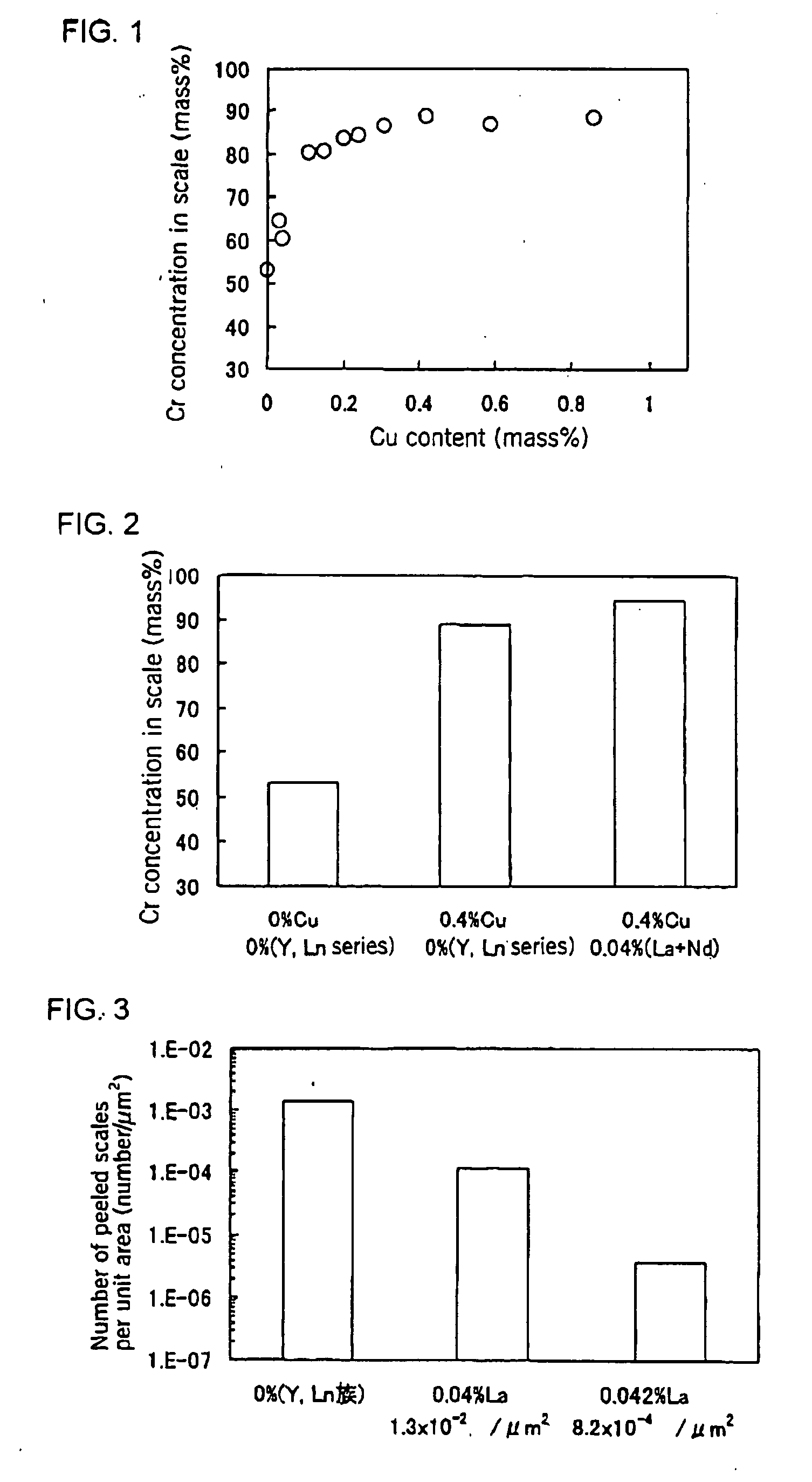

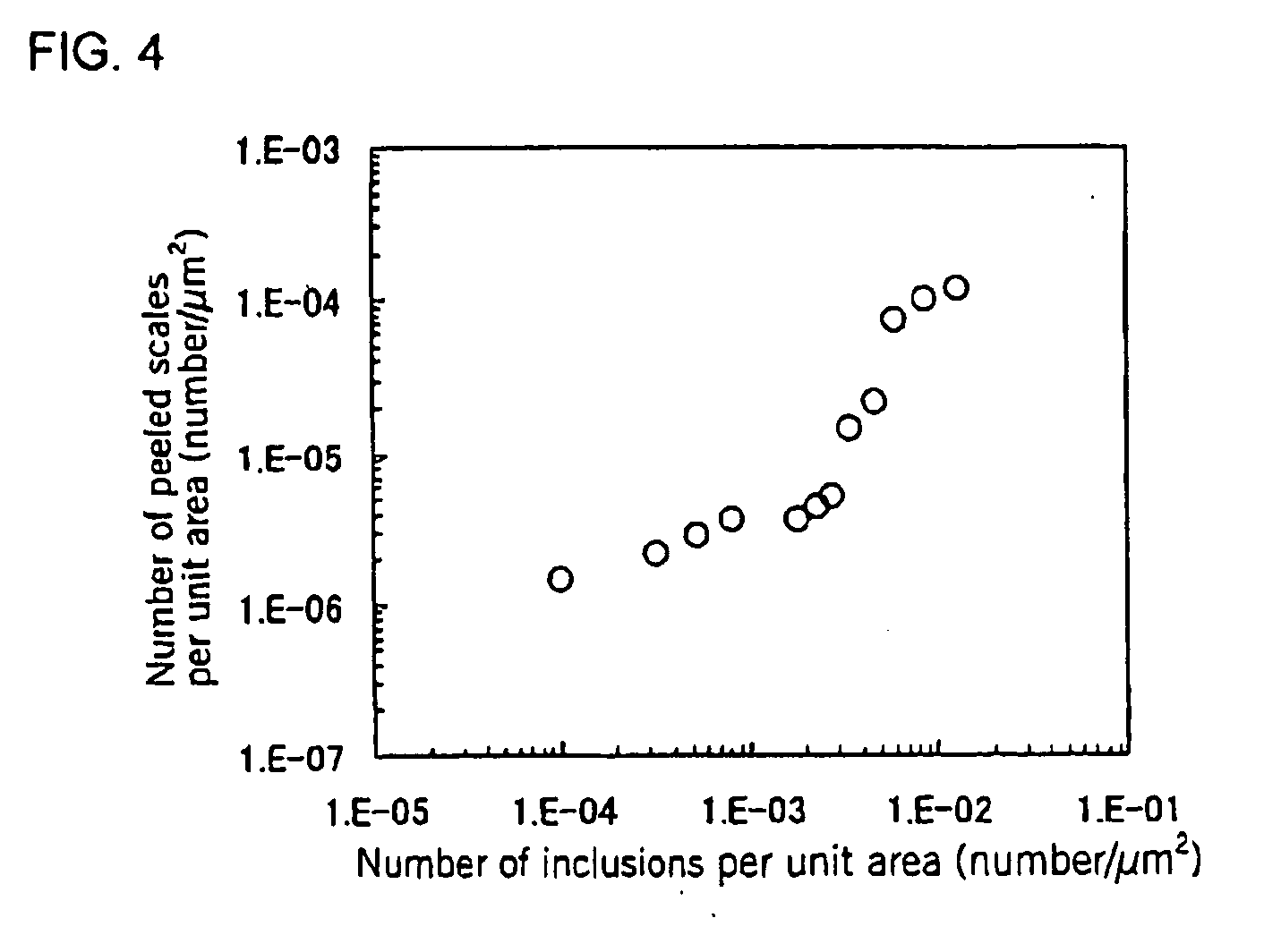

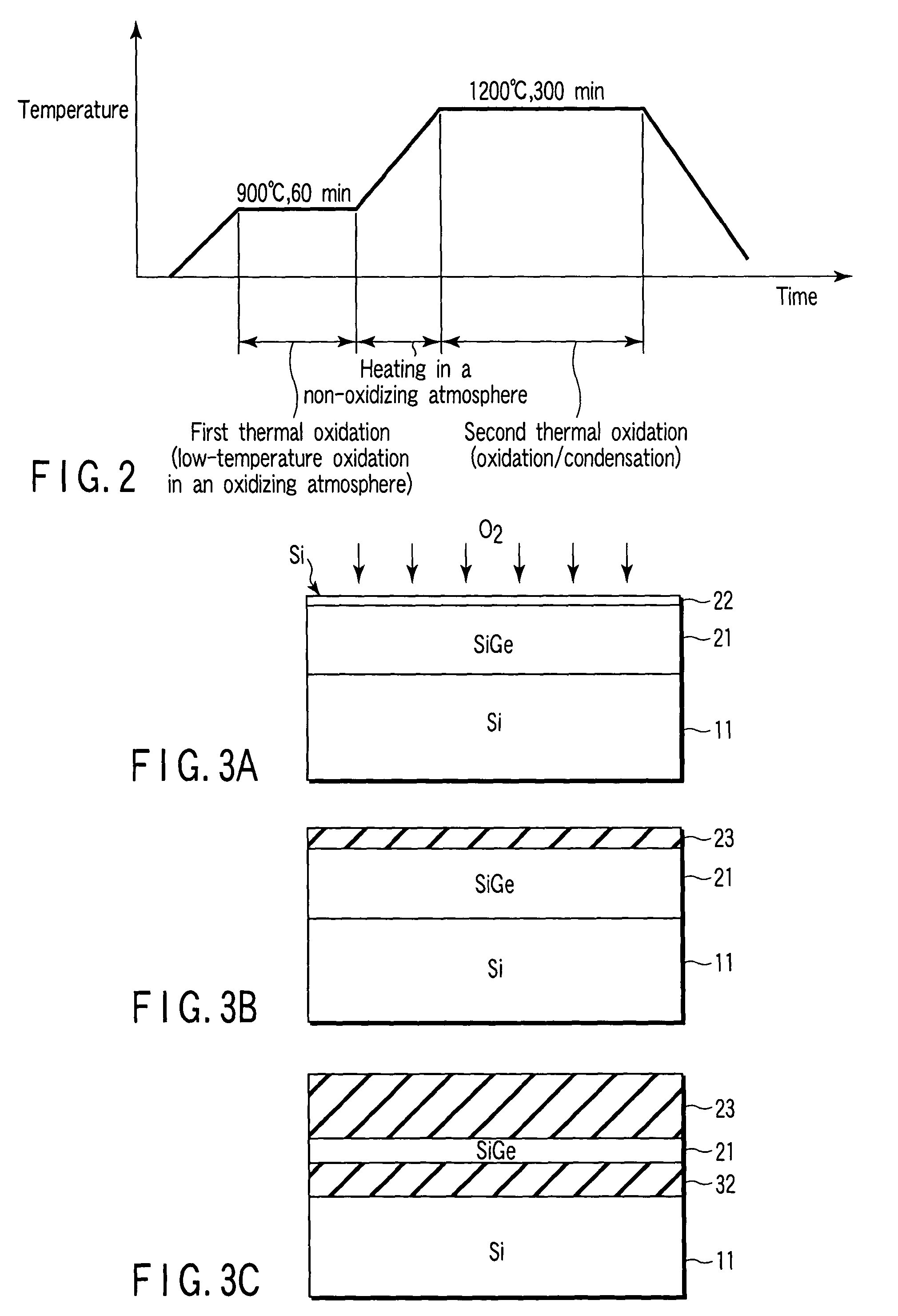

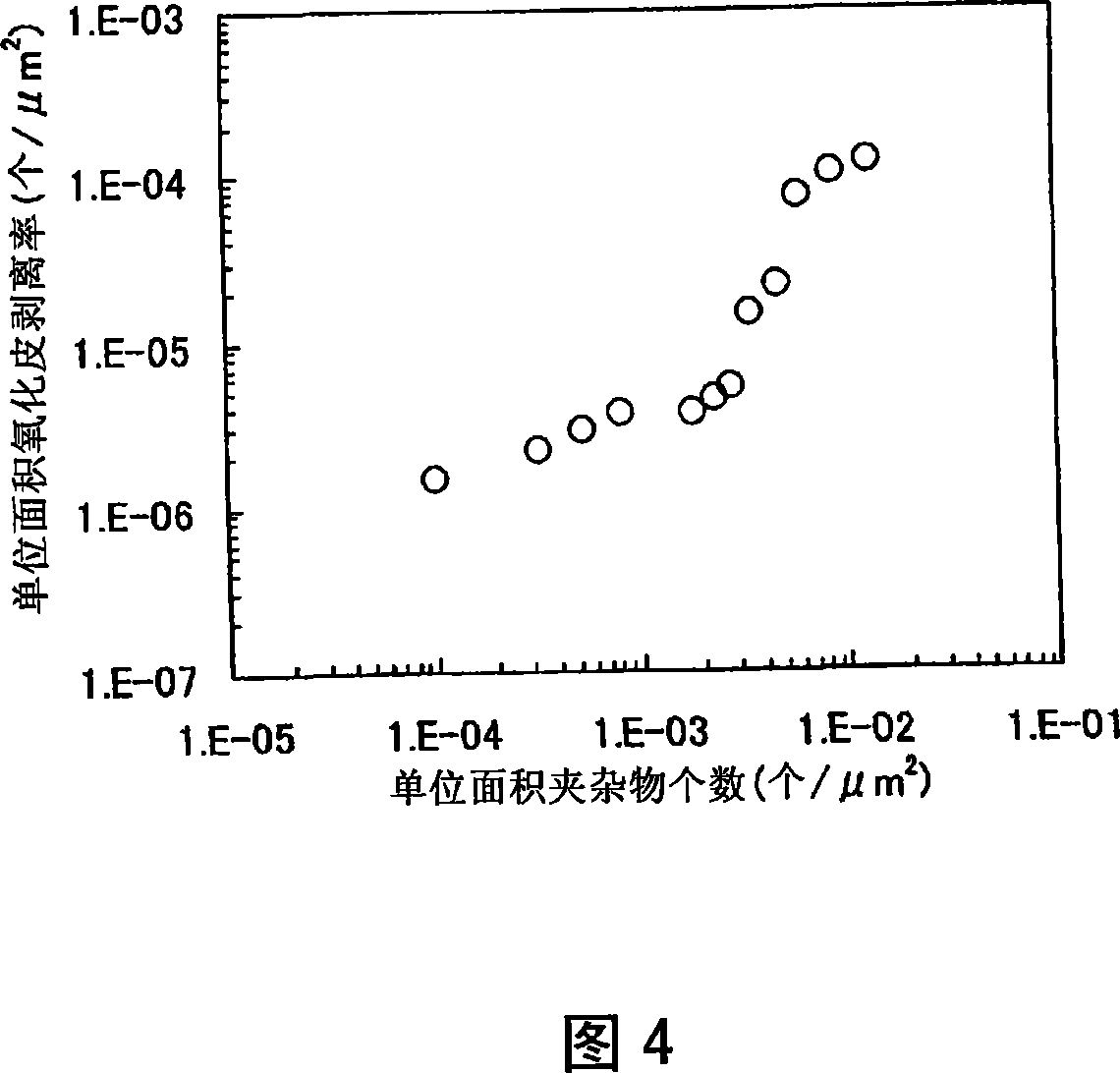

An austenitic stainless steel having excellent resistance to scale peeling which can suppress peeling of a protective oxide scale which is formed on the steel surface even when the steel undergoes repeated cycles of high temperature heating and cooling and which is suitable for use in a high temperature, humidified gas environment at a high temperature and particularly at 1023 K or above has a steel composition consisting essentially of C: 0.01-0.15%, Si: 0.01-3%, Mn: 0.01-2%, Cu: 0.1-2.5%, Cr: 23-30%, Ni: 16-25%, Al: 0.005-0.20%, N: 0.001-0.40%, P: at most 0.04%, S: at most 0.01%, at least one of Y and Ln series elements: a total of 0.005-0.1%, and a balance of Fe and unavoidable impurities, with the number of inclusions containing Y and Ln series elements in the steel surface being at most 5×10−3 / μm2.

Owner:NIPPON STEEL CORP

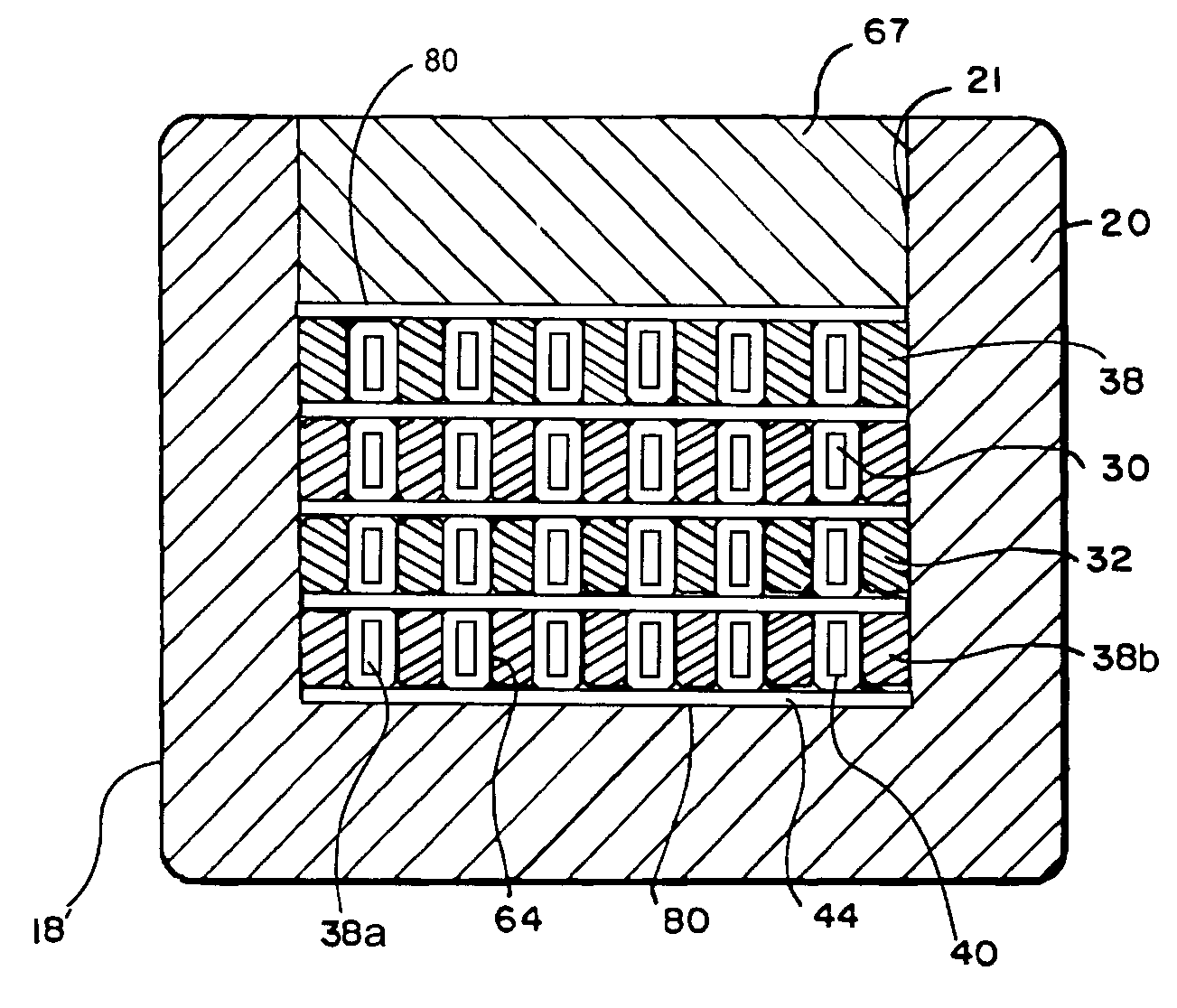

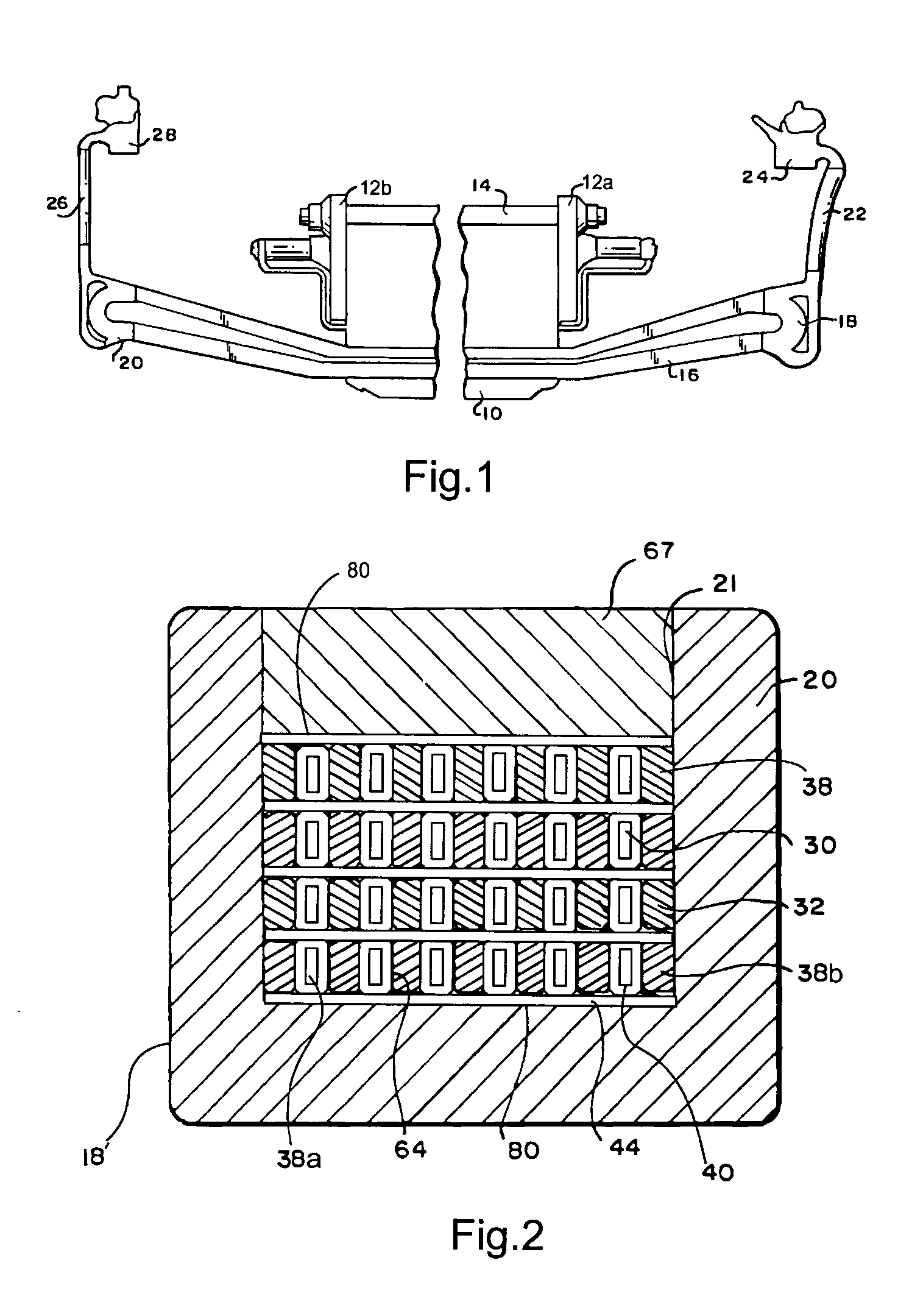

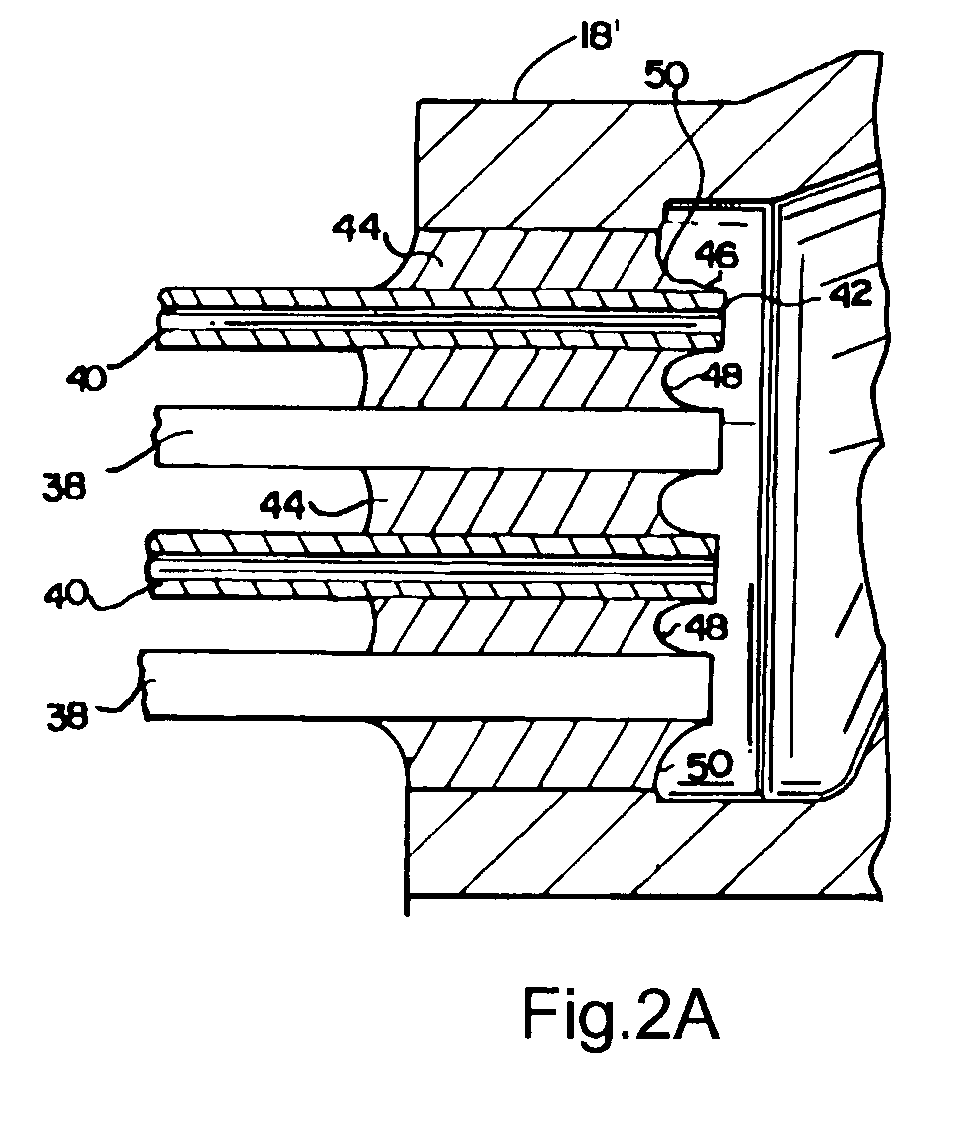

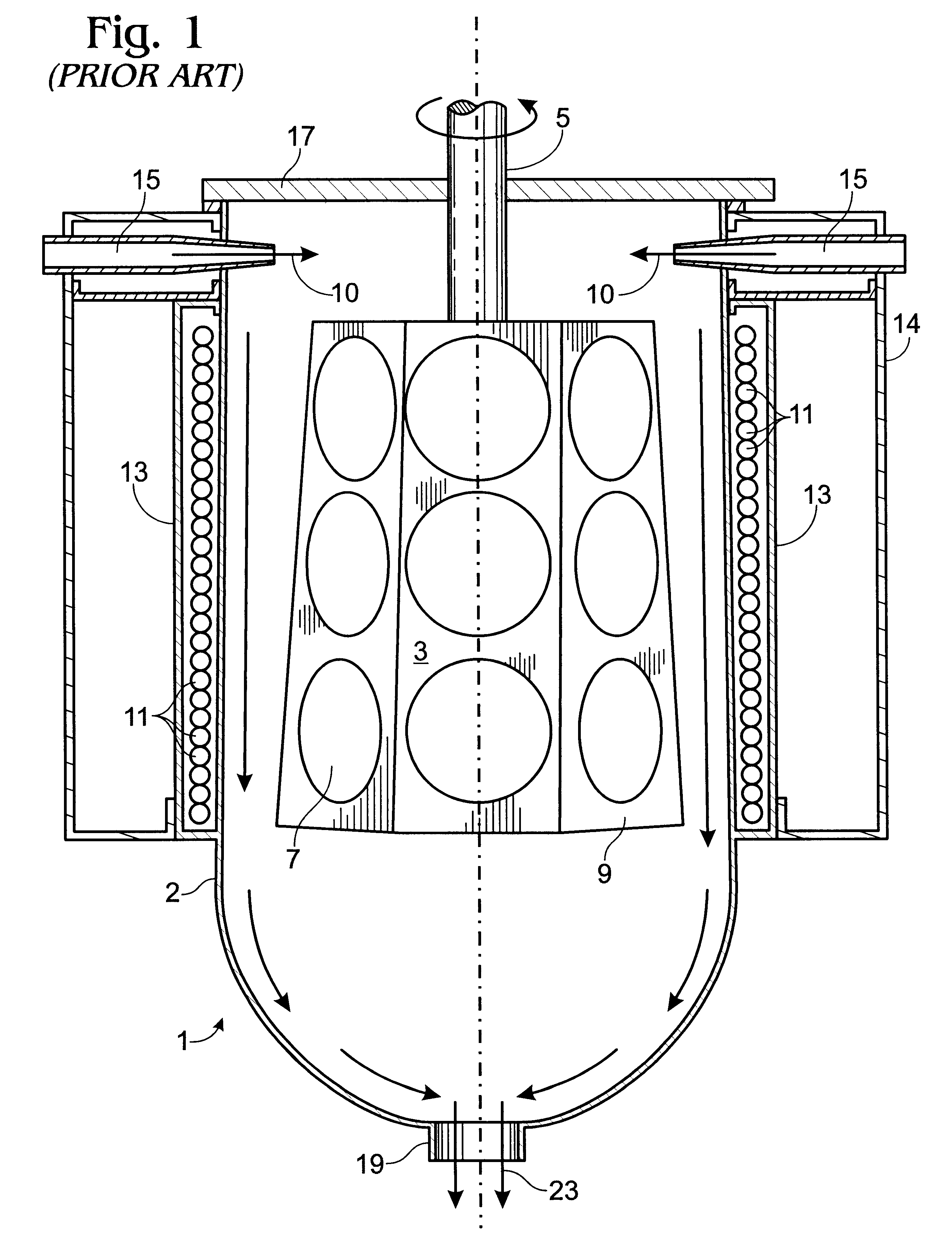

Method for a controlled bottle trench for a dram storage node

InactiveUS6190988B1Solid-state devicesSemiconductor/solid-state device manufacturingDopantElectrical conductor

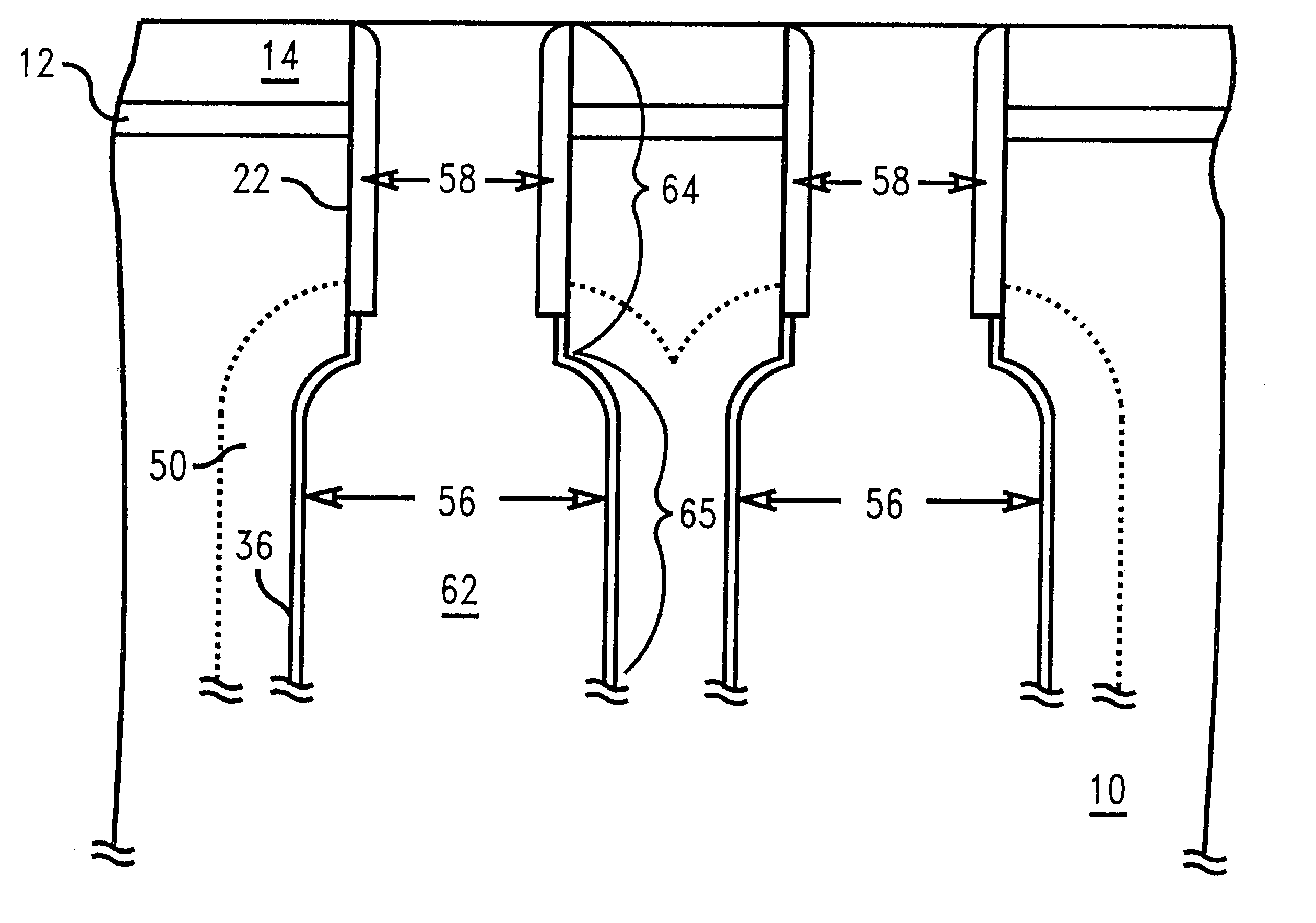

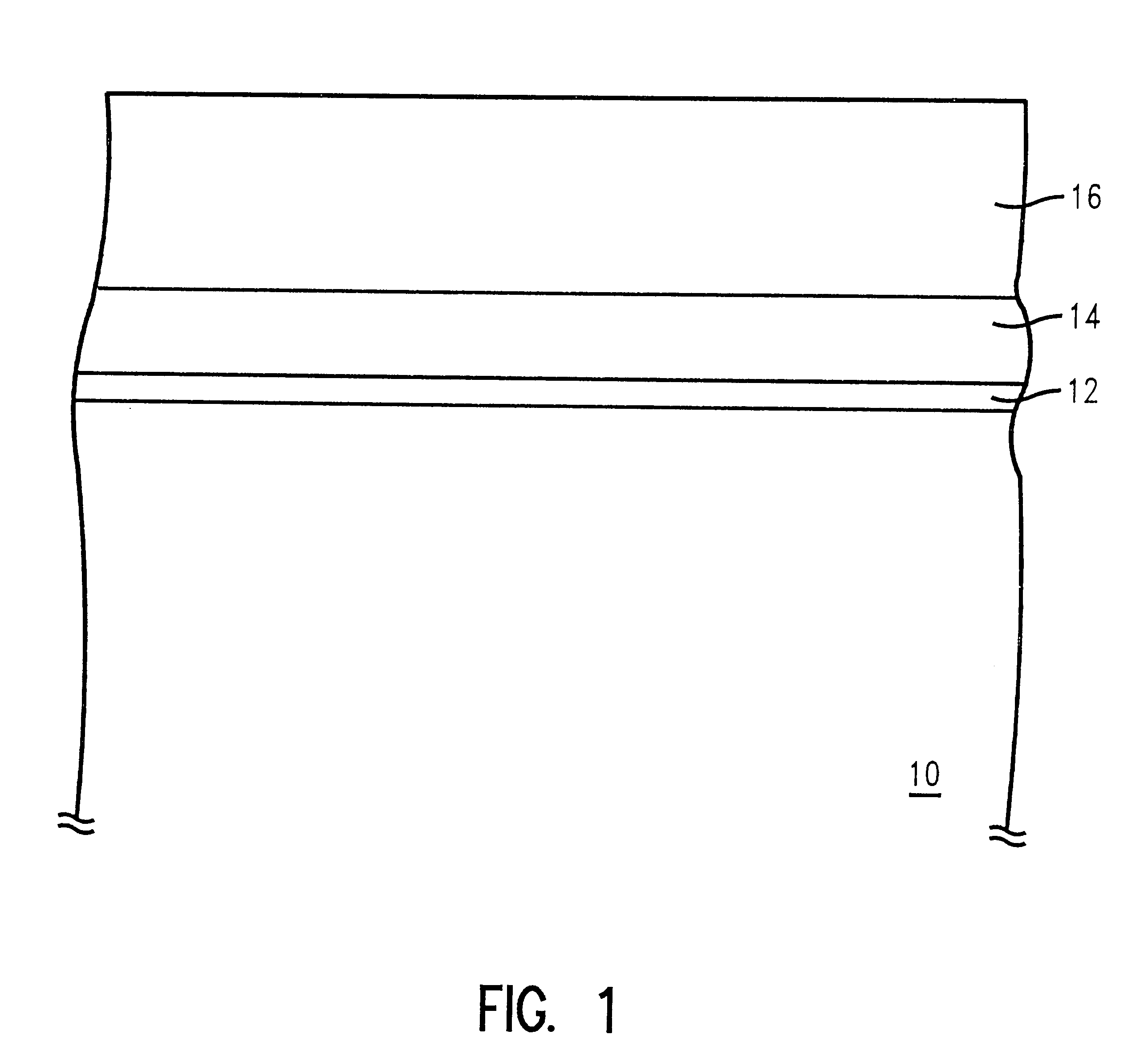

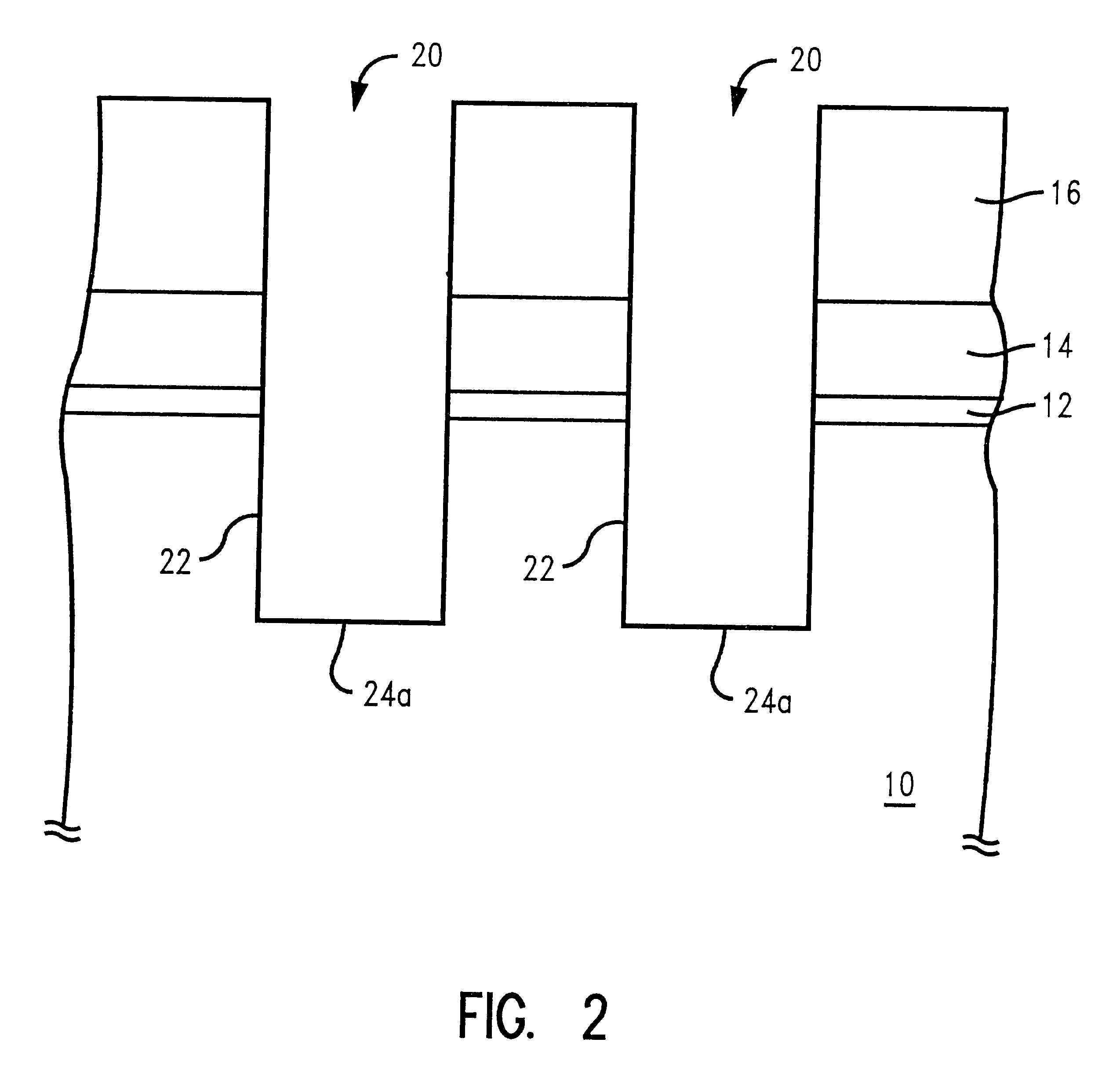

A bottle-shaped trench capacitor with a buried plate is formed in a controlled etch process. The bottle-shape is fabricated by etching deep trenches from a layered substrate, using the layers as a mask, and covering the side walls of the substrate with protective oxide and nitride layers. With the side walls covered, deep trench etching is then resumed, and a lower trench portion, below the protective layers of the side wall are formed. By diffusing a first dopant in the lower portion of the deep trench region, using the side wall protective layers as a mask, an etch stop is established for a wet etch process at the p / n junction established by the first dopant. The width of the lower trench portion is regulated by the time and temperature of the diffusion. Removing the doped material and applying a second dopant to the lower trench portion establishes a continuous buried plate region between trenches. A capacitor is formed by applying an insulating layer to the trench and filling with a conductor.

Owner:IBM CORP

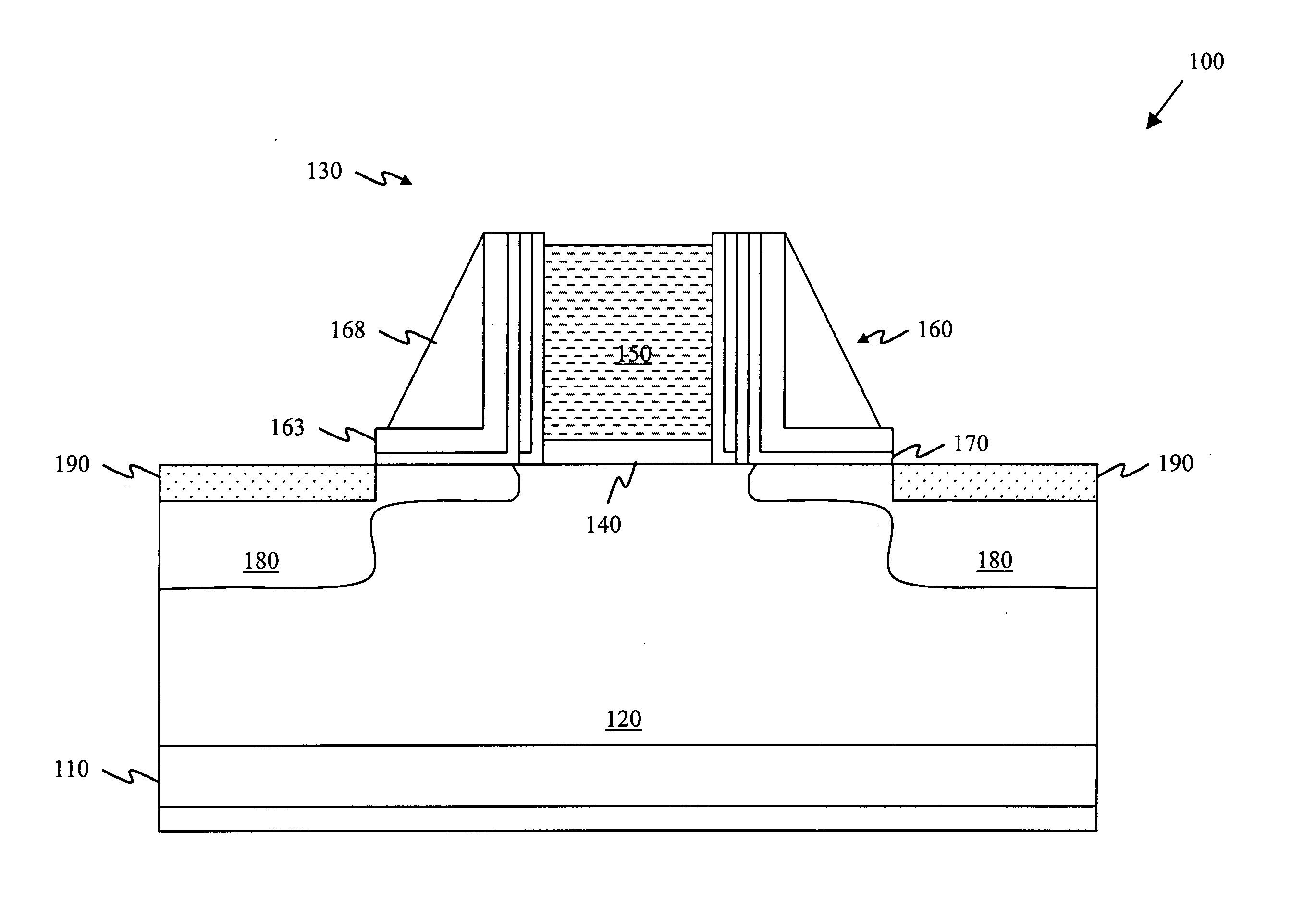

Method of MRAM fabrication with zero electrical shorting

ActiveUS20090173977A1Reduces and eliminates electrical shortingLarge deviationMagnetic-field-controlled resistorsSolid-state devicesHydrogenEngineering

An MTJ cell without footings and free from electrical short-circuits across a tunneling barrier layer is formed by using a Ta hard mask layer and a combination of etches. A first etch patterns the Ta hard mask, while a second etch uses O2 applied in a single high power process at two successive different power levels. A first power level of between approximately 200 W and 500 W removes BARC, photoresist and Ta residue from the first etch, the second power level, between approximately 400 W and 600 W continues an etch of the stack layers and forms a protective oxide around the etched sides of the stack. Finally, an etch using a carbon, hydrogen and oxygen gas completes the etch while the oxide layer protects the cell from short-circuits across the lateral edges of the barrier layer.

Owner:TAIWAN SEMICON MFG CO LTD

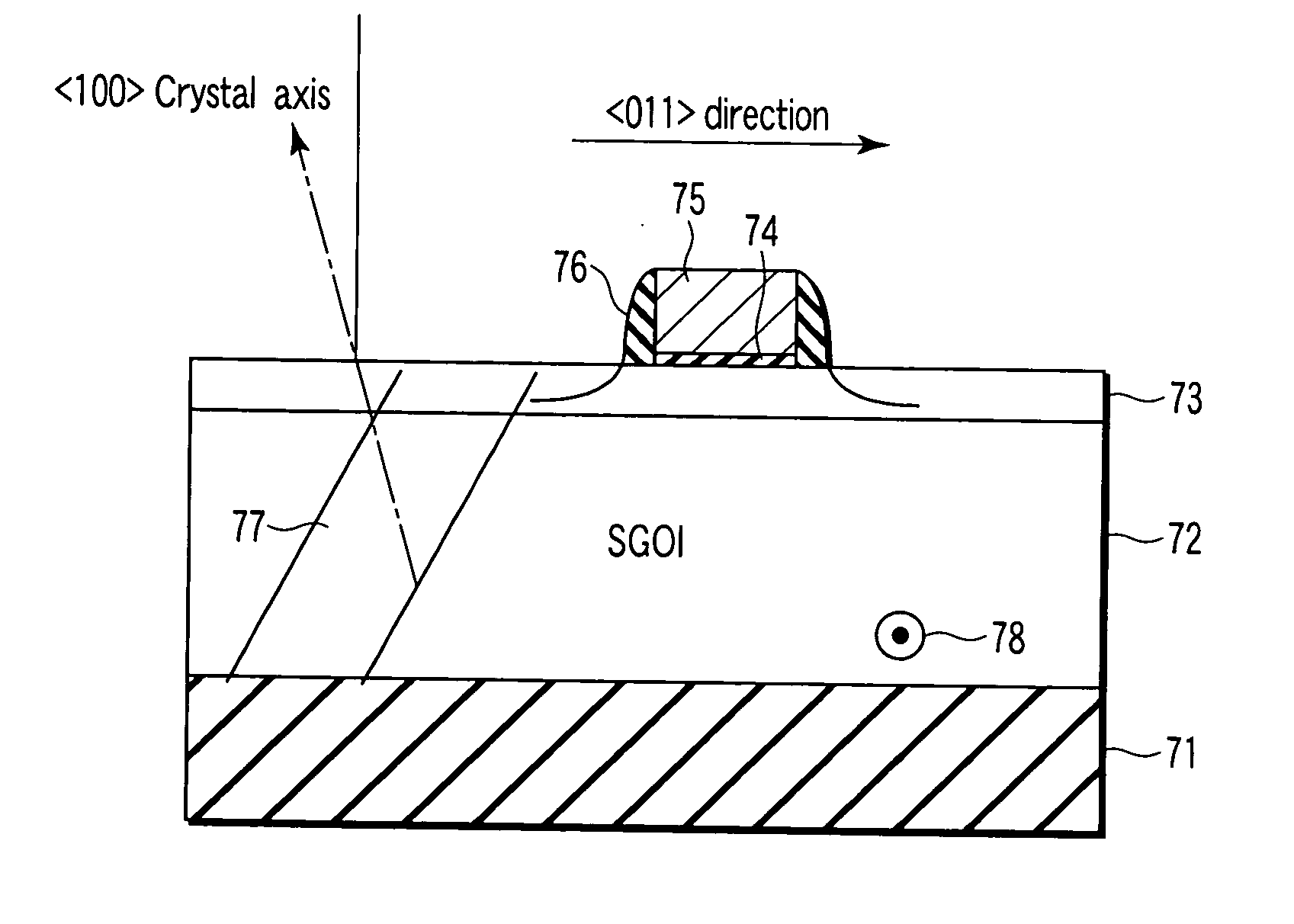

Semiconductor device and method of manufacturing the same

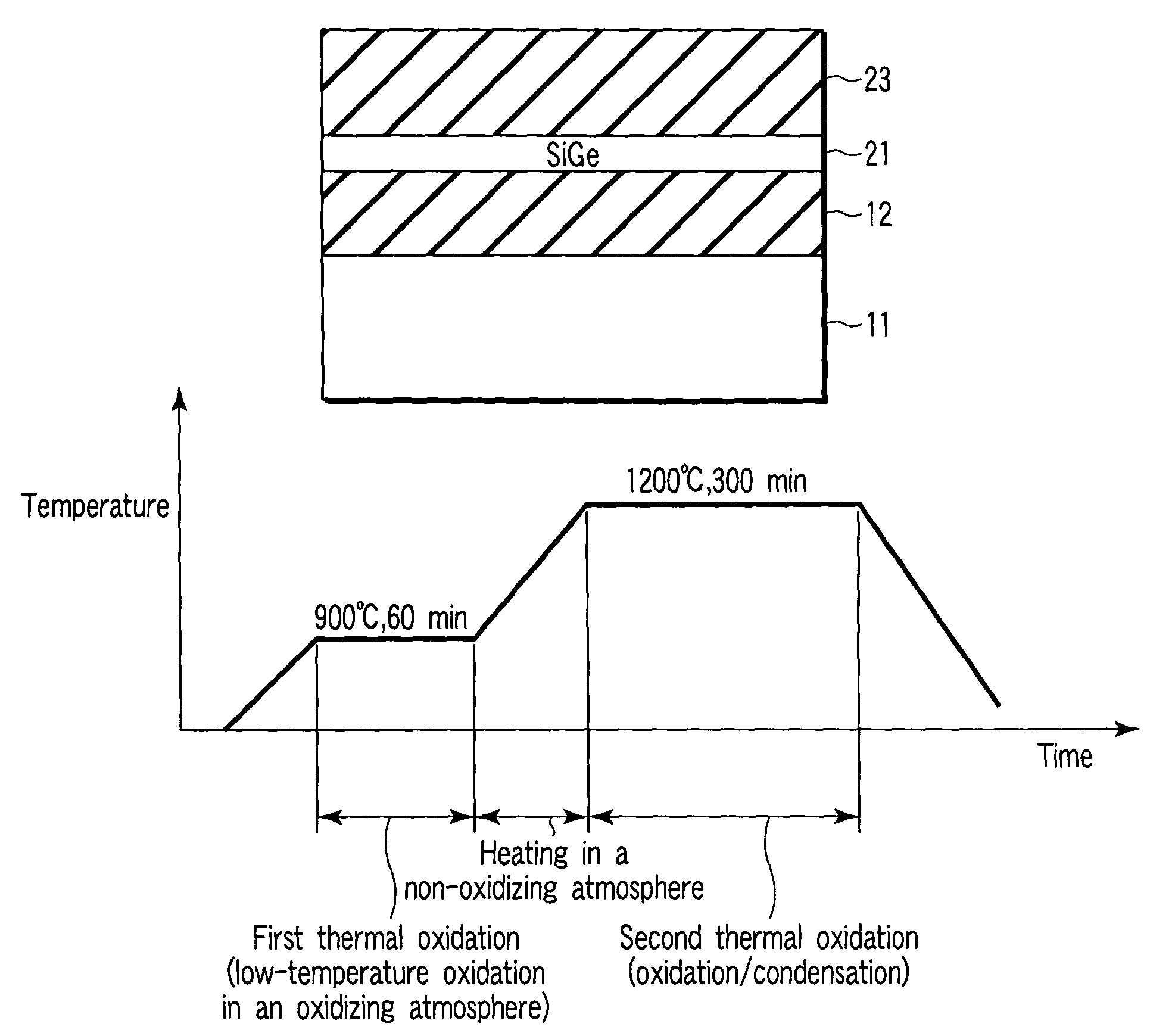

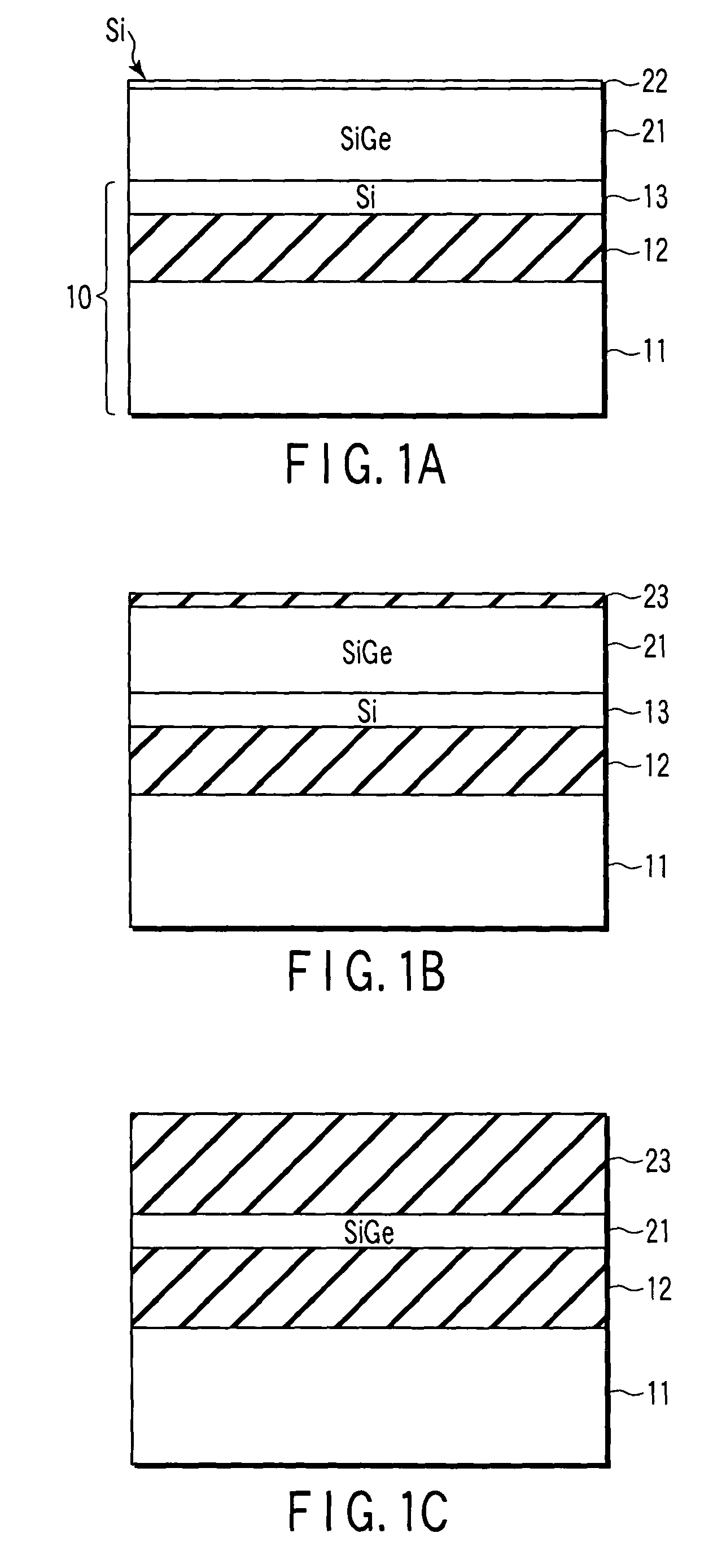

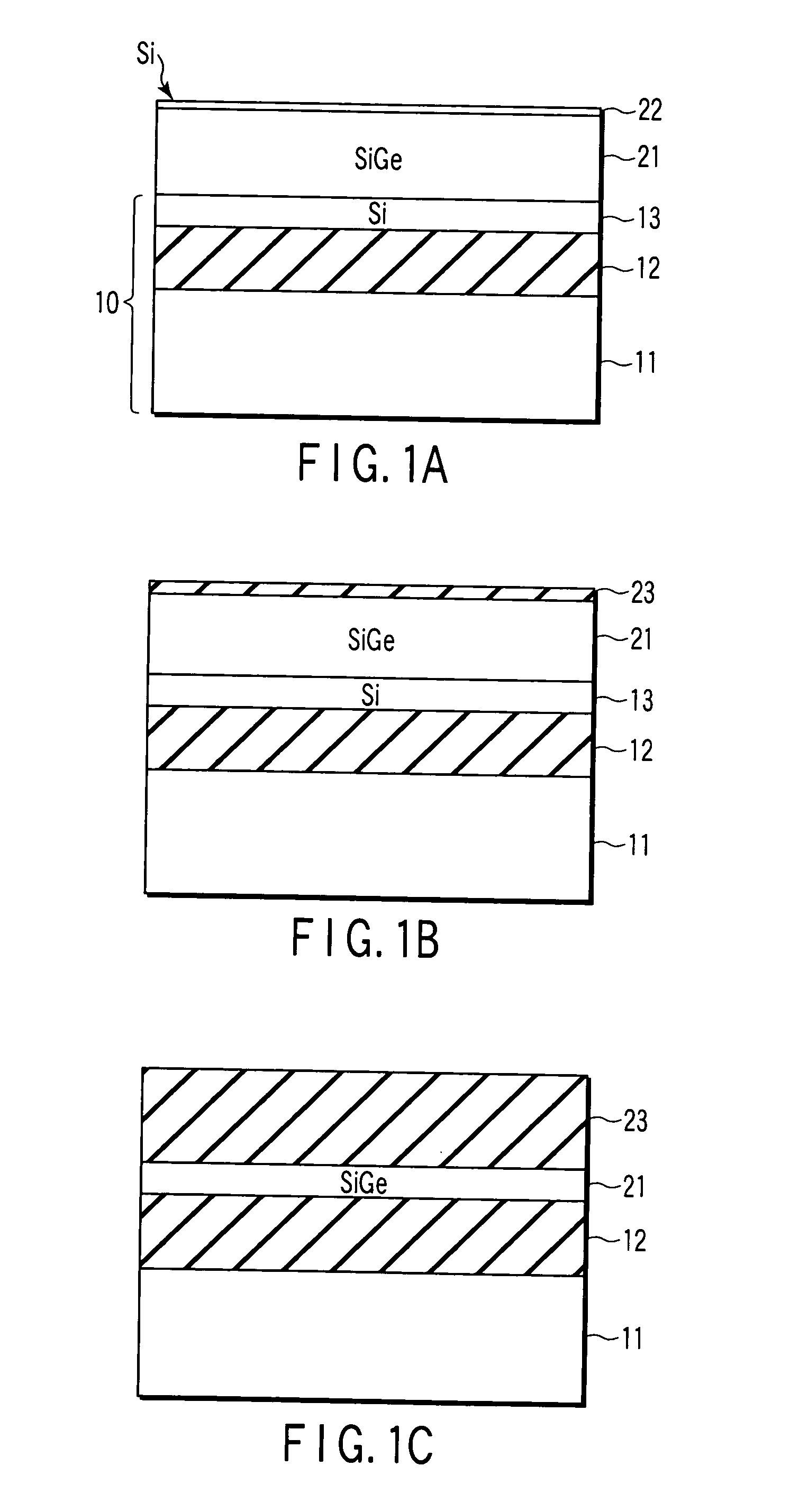

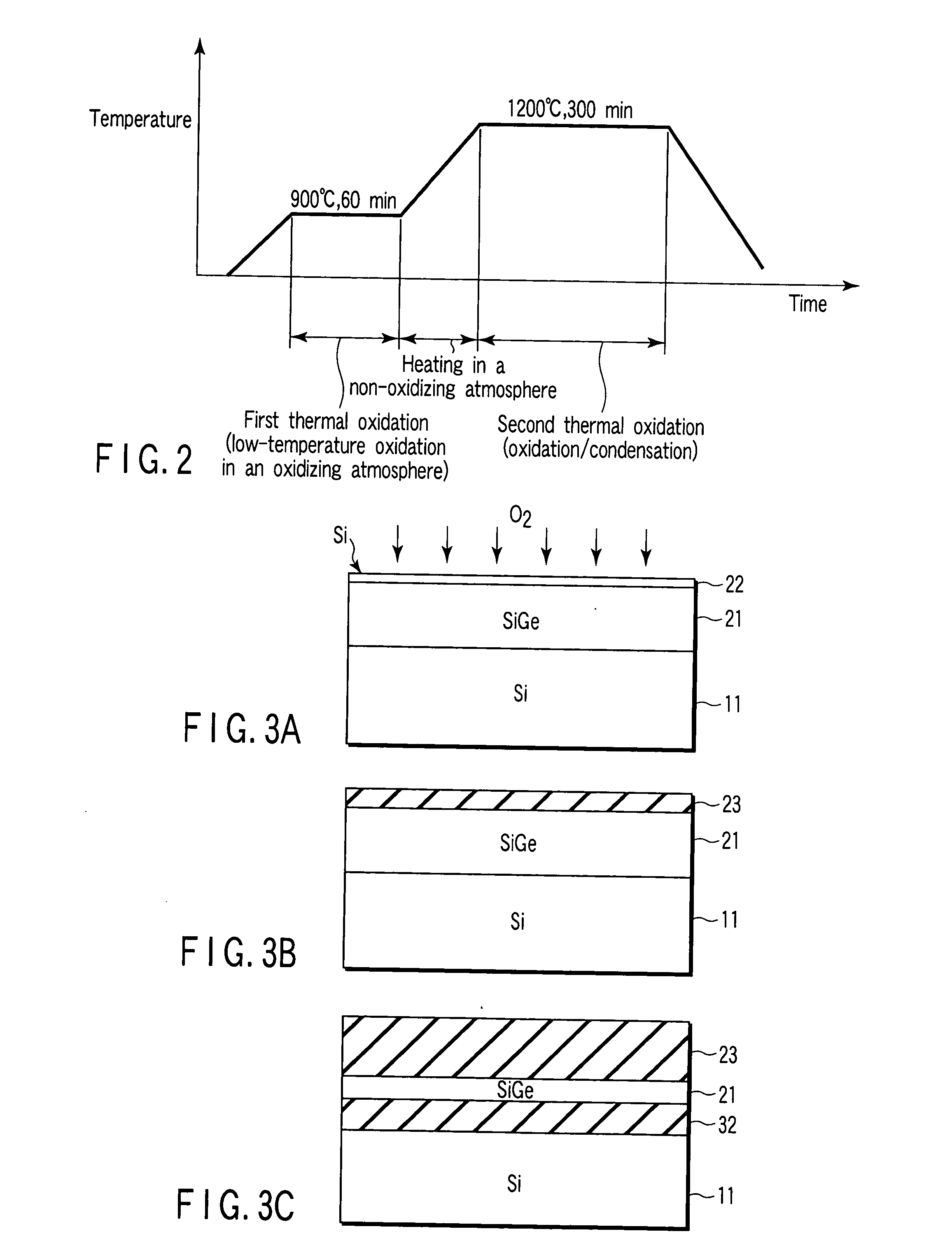

A method of manufacturing a semiconductor device. In the method, a substrate is prepared, which includes a buried oxide film and a SiGe layer formed on the buried oxide film. Then, heat treatment is performed on the substrate at a temperature equal to or lower than a first temperature, to form a protective oxide film on a surface of the SiGe layer. Next, the substrate having the protective oxide film is heated in a non-oxidizing atmosphere to a second temperature higher than the first temperature. Further, heat treatment is performed on the substrate thus heated, in an oxidizing atmosphere at a temperature equal to or higher than the second temperature, to form oxide the SiGe layer, make the SiGe layer thinner and increasing Ge concentration in the SiGe layer, thus forming a SiGe layer having the increased Ge concentration.

Owner:LAPIS SEMICON CO LTD +1

Austenitic stainless steel

ActiveCN101194037APrevent peelingIncreased durabilityHeat exchange apparatusRare-earth elementSS - Stainless steel

Even after repeated high-temperature heating-cooling cycles, it still has excellent scale peeling resistance that can inhibit the peeling of protective oxide scales formed on the steel surface, and can be used in high temperature, especially high temperature humidified gas environments above 1023K. System stainless steel with the following steel composition: C: 0.01-0.15%, Si: 0.01-3%, Mn: 0.01-2%, Cu: 0.1-2.5%, Cr: 23-30%, Ni: 16-25% , Al: 0.005 to 0.20%, N: 0.001 to 0.40%, P: 0.04% or less, S: 0.01% or less, and one or more rare earth elements selected from the Y and Ln groups: total 0.005 to 0.1%, the balance is substantially composed of Fe and unavoidable impurities, and the inclusions containing Y and Ln group elements on the steel surface are 5×10-3 / μm2 or less.

Owner:NIPPON STEEL CORP

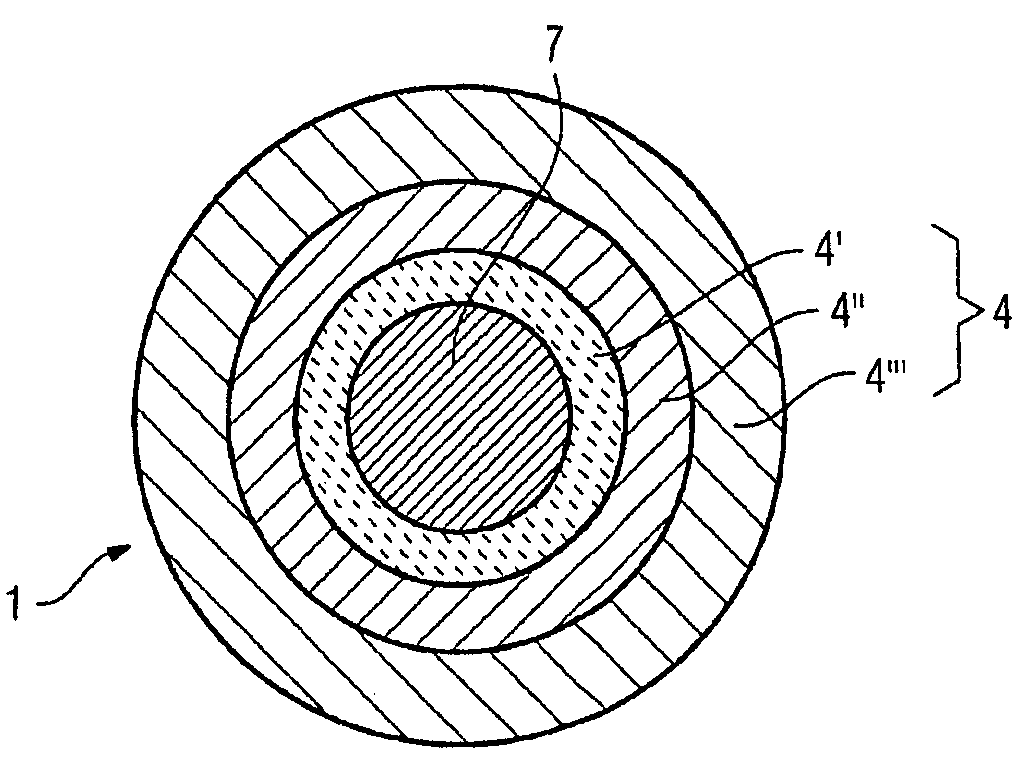

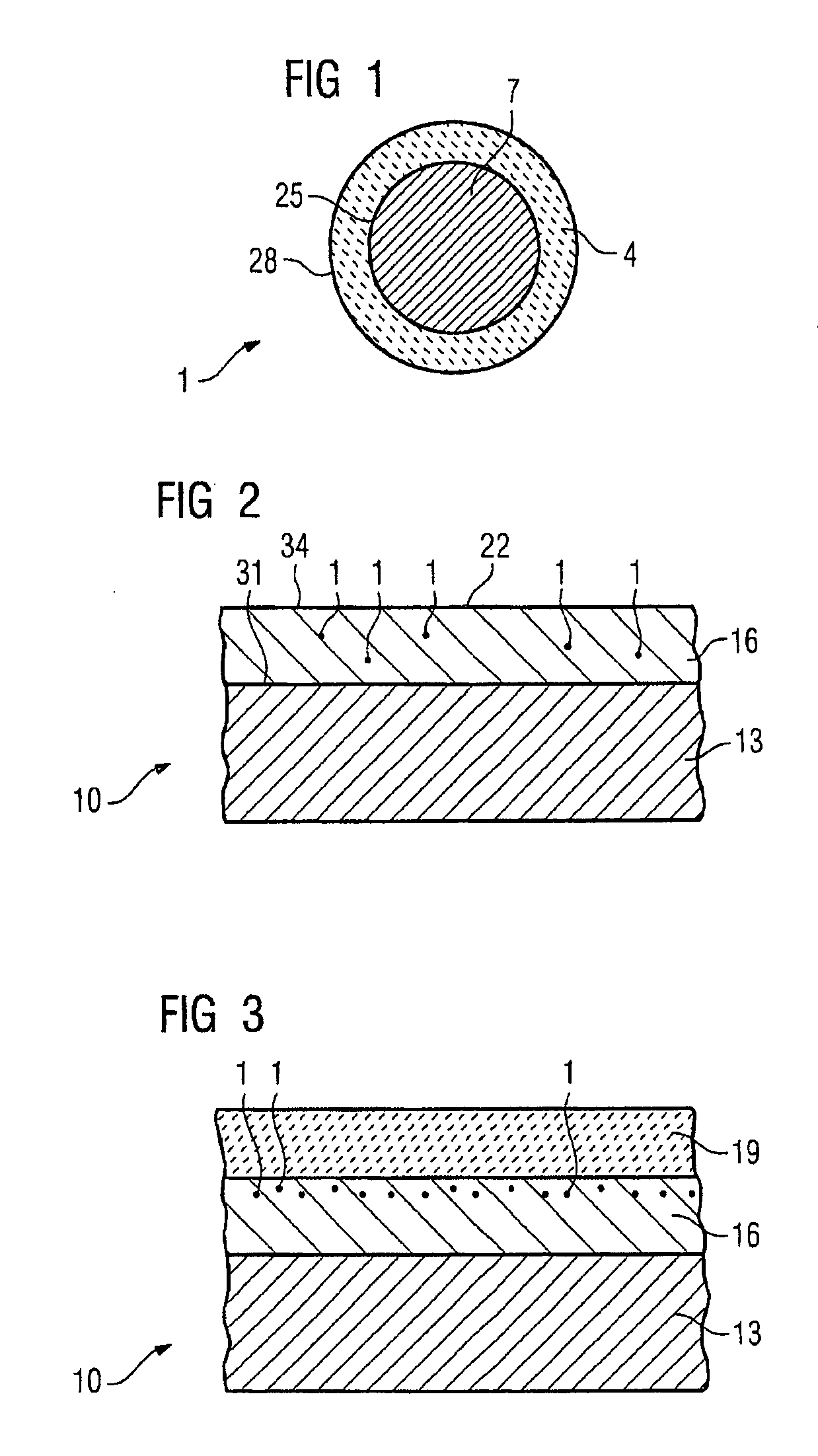

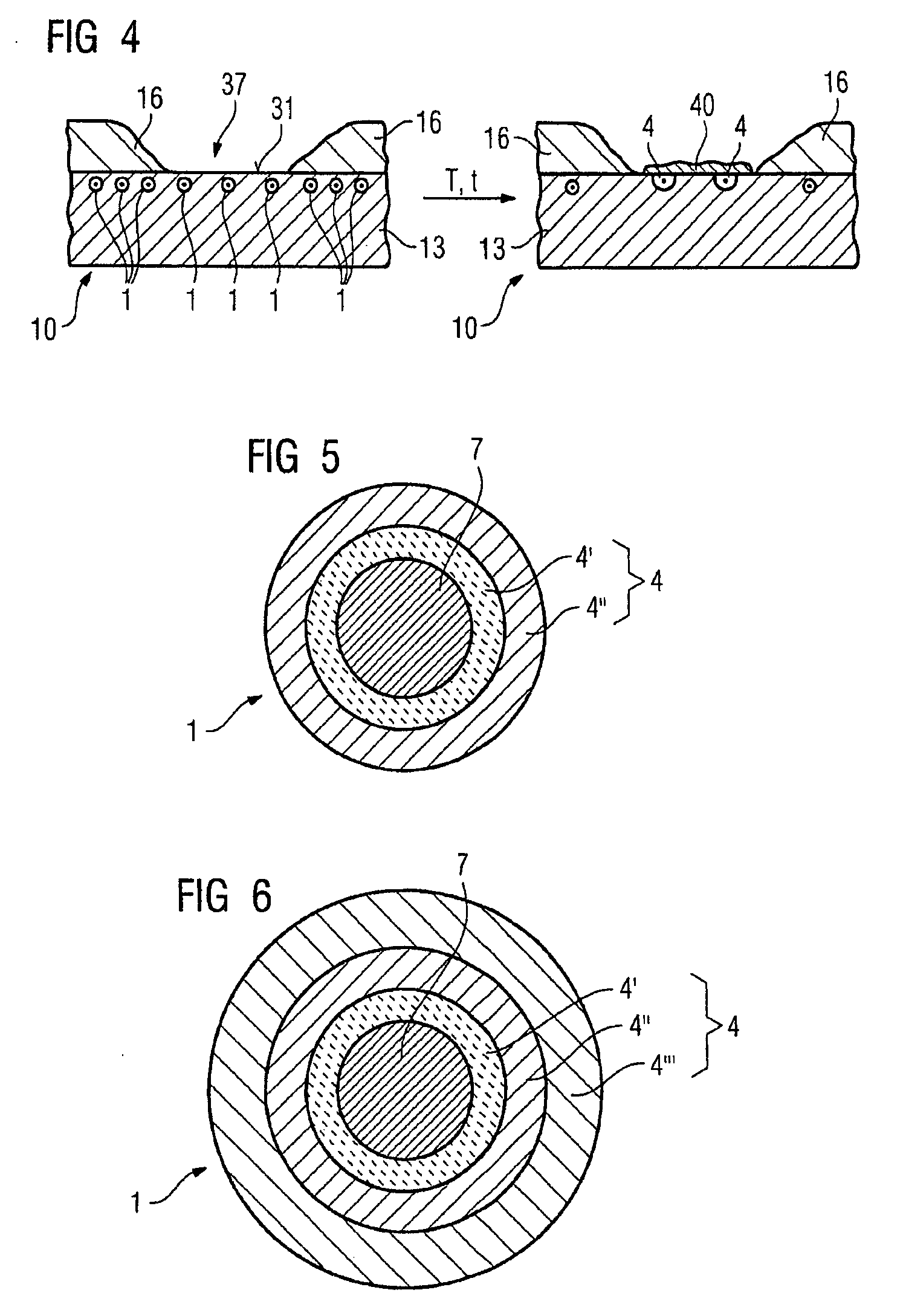

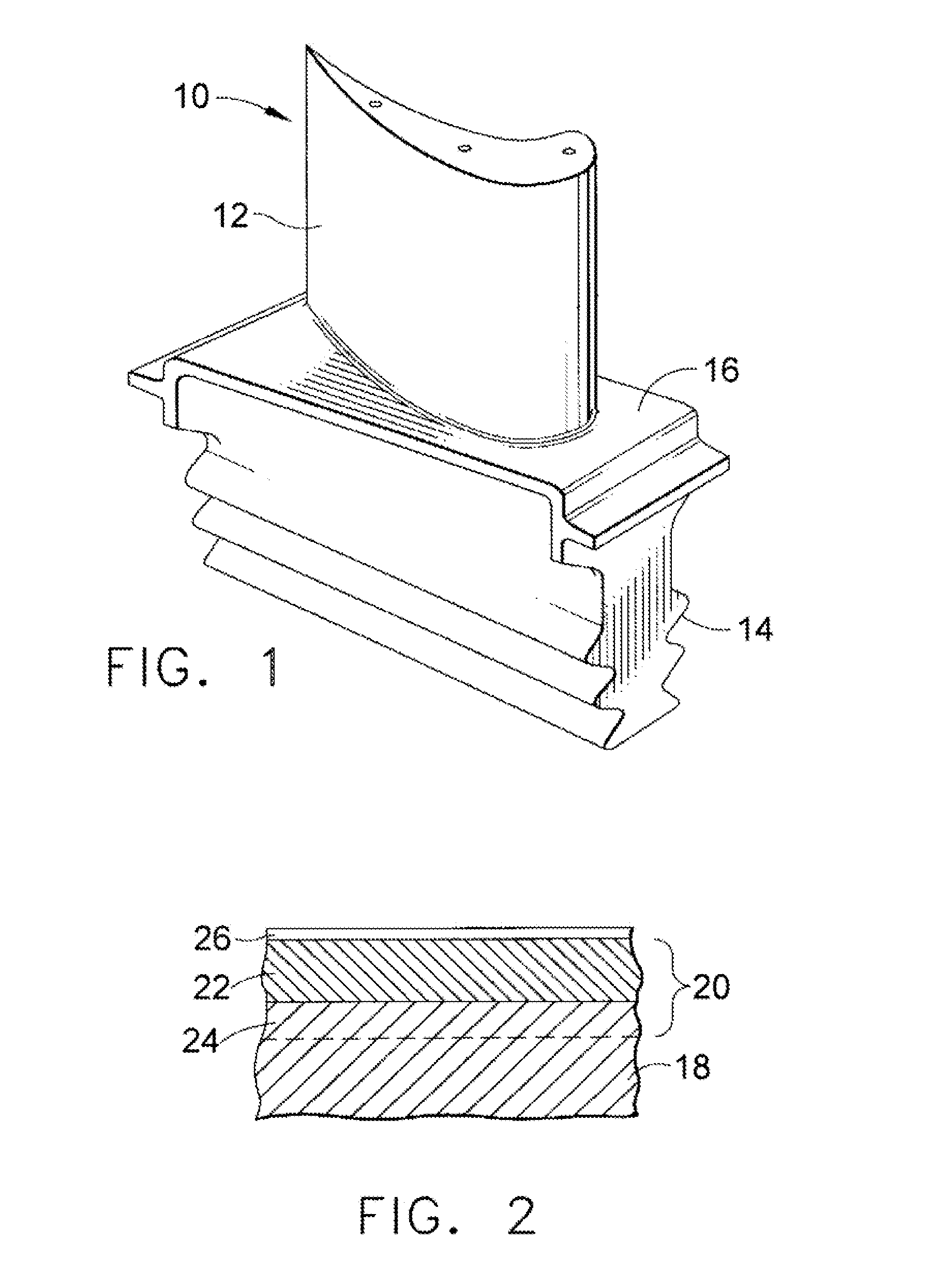

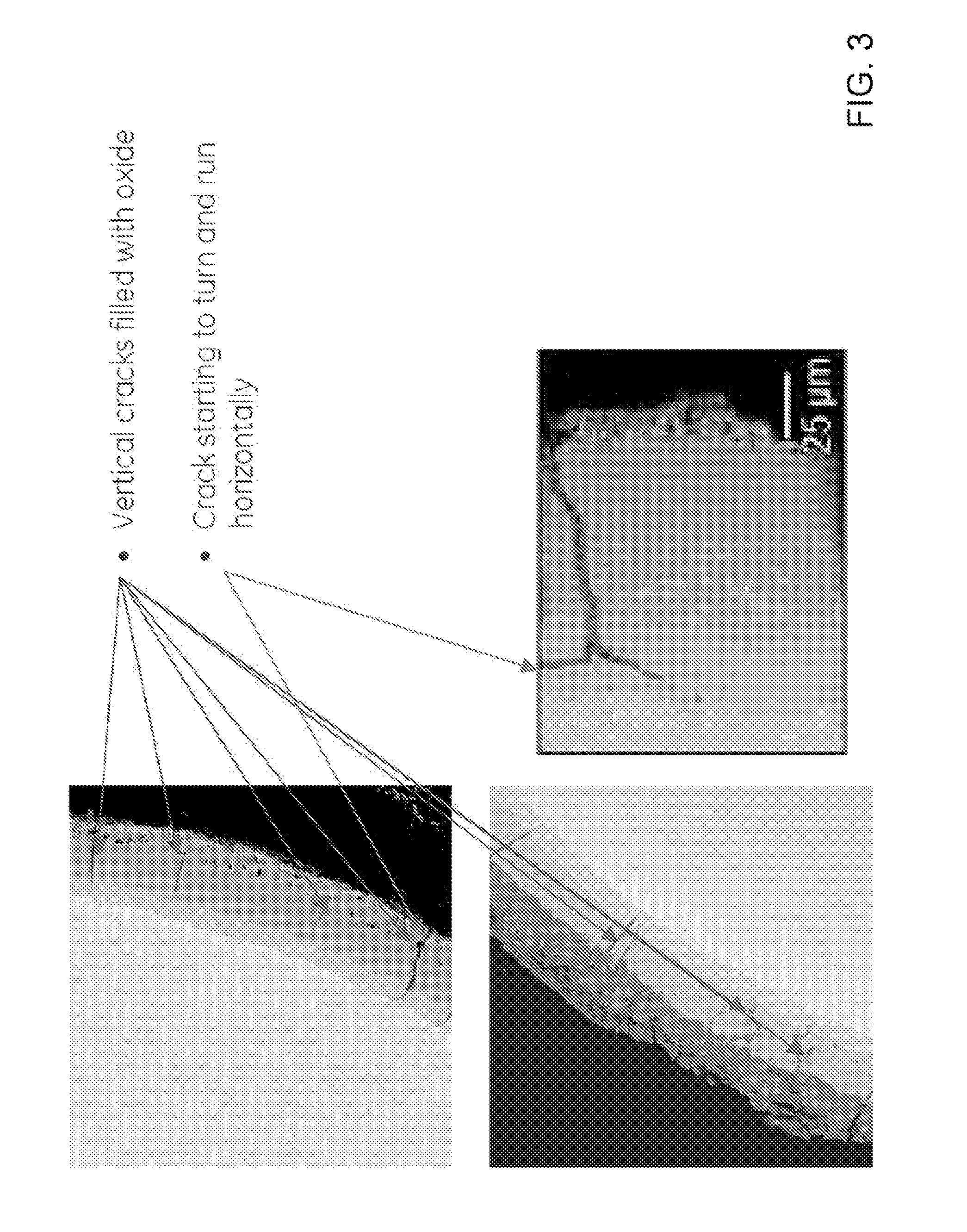

Matrix and Layer System

InactiveUS20090202814A1Longer protective effectPropellersReaction enginesProtective oxideMaterials science

Prior art protective layers can exercise their protecting function because they are depleted in a specific element which forms a protective oxide, or which is used as sacrificial material. When said material has been consumed, the protecting function can no longer be provided. The invention is characterized in that it consists in using powder particles comprising a reserve of the consumed material, which is delivered in delayed manner. Therefor, the material is enclosed in an envelope.

Owner:SIEMENS AG

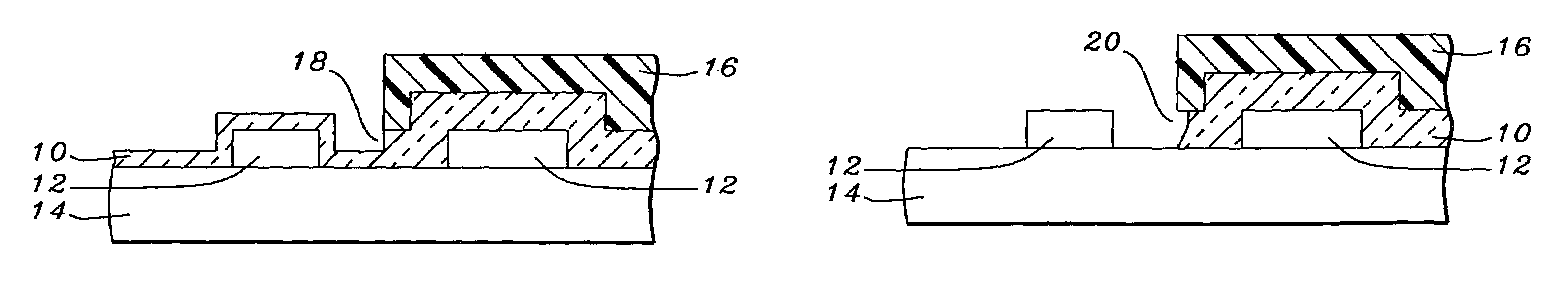

Method to improve etching of resist protective oxide (RPO) to prevent photo-resist peeling

InactiveUS7015089B2Prevent peelingSolid-state devicesSemiconductor/solid-state device manufacturingResistTwo step

An improved method of patterning resist protective dielectric layer and preferably protective silicon dioxide layer is described. The method consists of two sequential etching steps, the first one being a timed plasma etching process and the second one being a timed wet etching process. Plasma etching is used to remove approximately 70%–90% of the RPO film thickness and wet etching is used to remove the remaining 10%–30% of the film thickness. The two-step etching process achieves superior dimensional control, a non-undercut profile under the resist mask and prevents resist mask peeling from failure of adhesion at the mask / RPO film interface. The improved method has wide applications wherever and whenever RPO film is used in the process flow for fabricating semiconductor devices.

Owner:TSMC CHINA COMPANY

Semiconductor device and method of manufacturing the same

ActiveUS20060281234A1Increased Ge concentrationIncrease Ge concentrationFrom gel statePolycrystalline material growthDevice materialProtective oxide

A method of manufacturing a semiconductor device. In the method, a substrate is prepared, which includes a buried oxide film and a SiGe layer formed on the buried oxide film. Then, heat treatment is performed on the substrate at a temperature equal to or lower than a first temperature, to form a protective oxide film on a surface of the SiGe layer. Next, the substrate having the protective oxide film is heated in a non-oxidizing atmosphere to a second temperature higher than the first temperature. Further, heat treatment is performed on the substrate thus heated, in an oxidizing atmosphere at a temperature equal to or higher than the second temperature, to form oxide the SiGe layer, make the SiGe layer thinner and increasing Ge concentration in the SiGe layer, thus forming a SiGe layer having the increased Ge concentration.

Owner:LAPIS SEMICON CO LTD +1

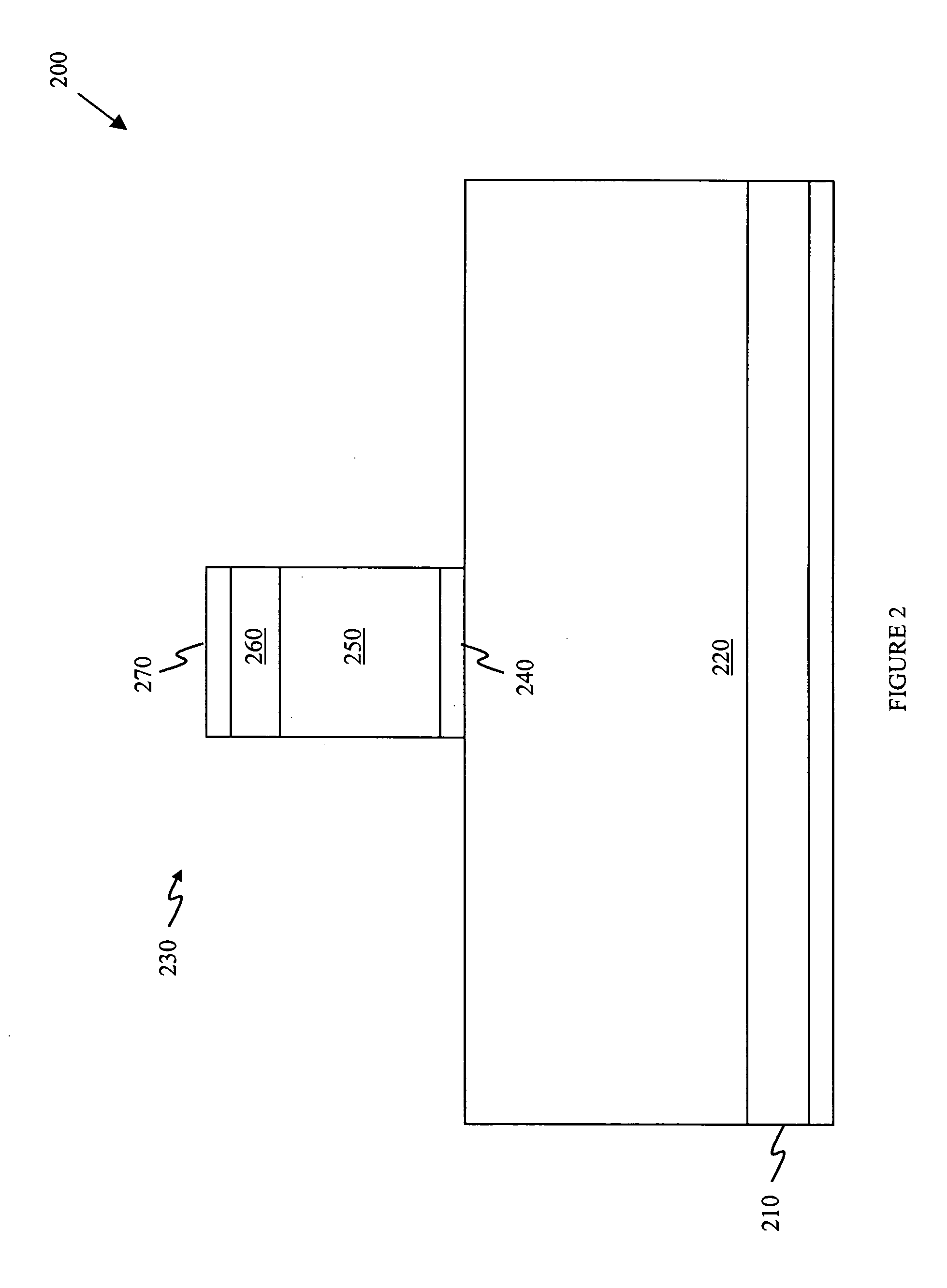

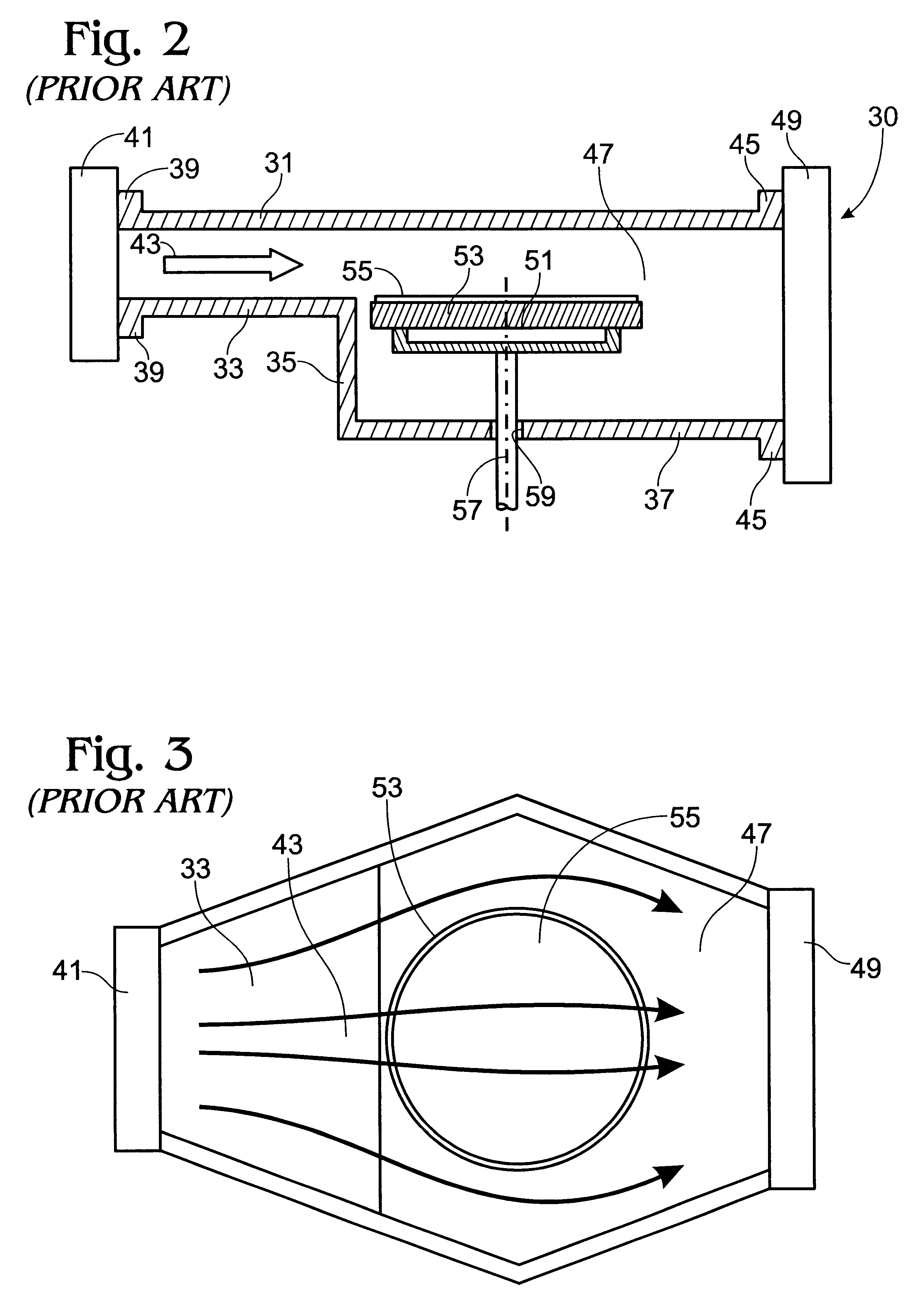

Method for using a wet etch to manufacturing a semiconductor device having a silicided gate electrode and a method for manufacturing an integrated circuit including the same

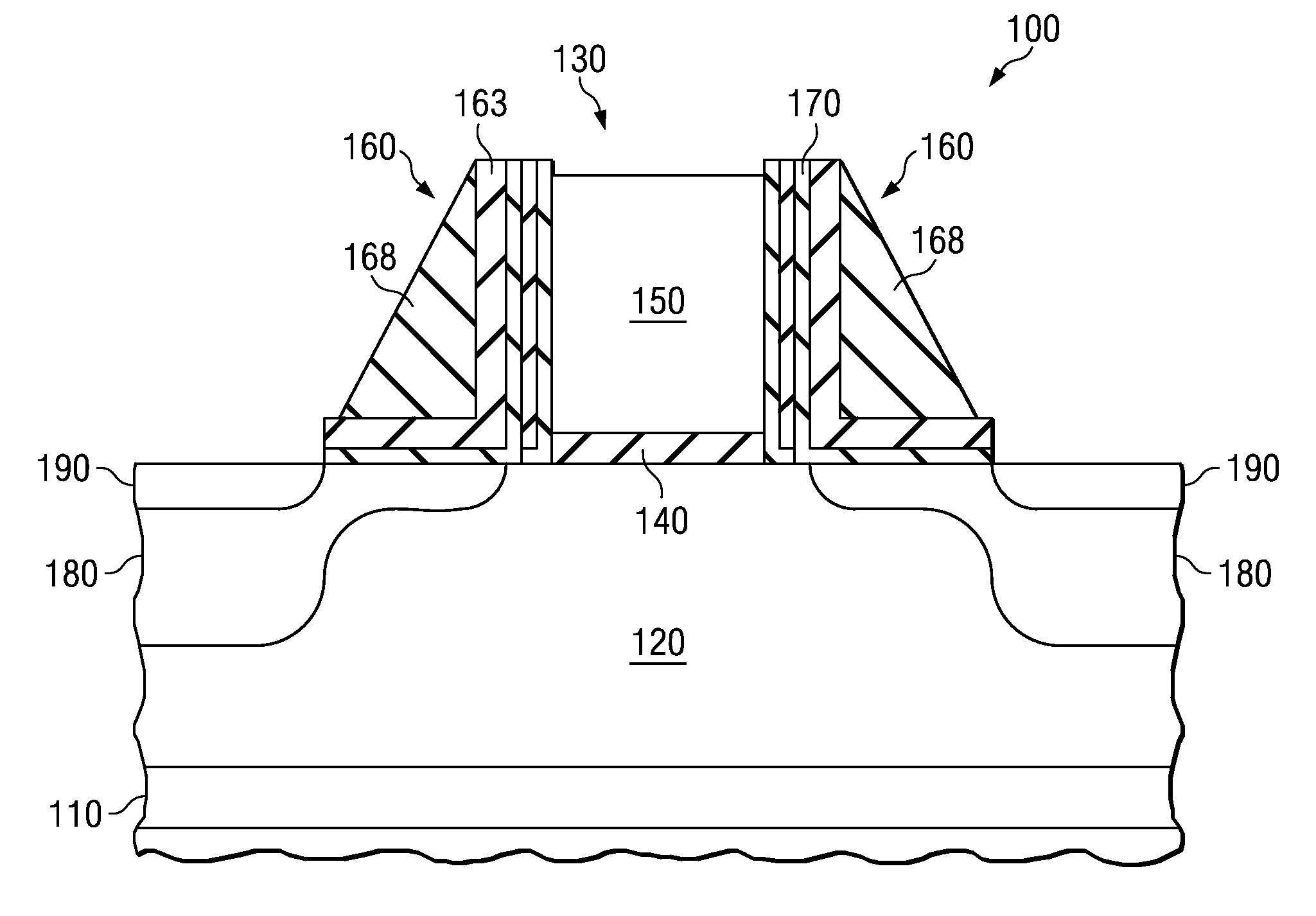

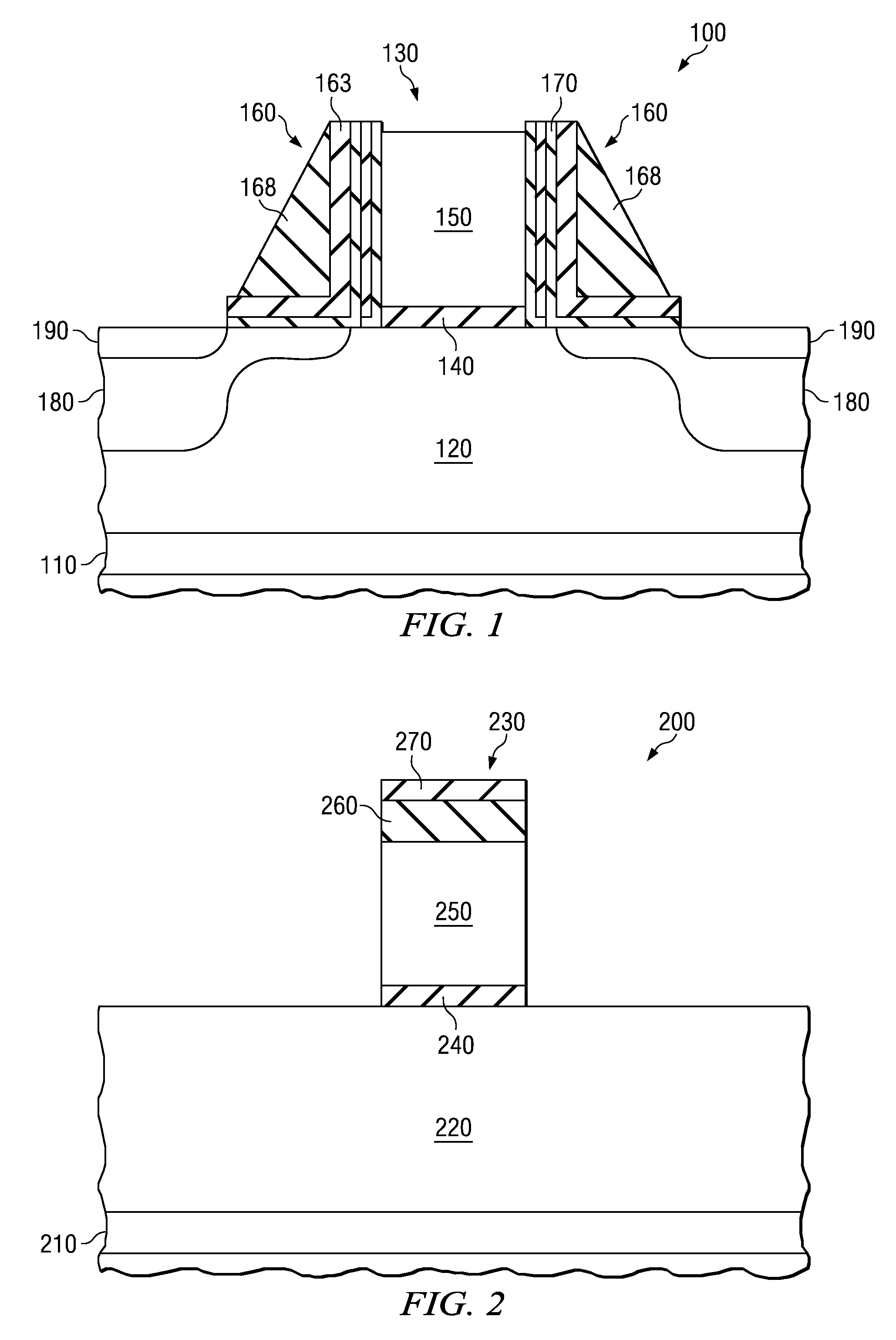

ActiveUS7157358B2TransistorSemiconductor/solid-state device manufacturingProtective oxideProtection layer

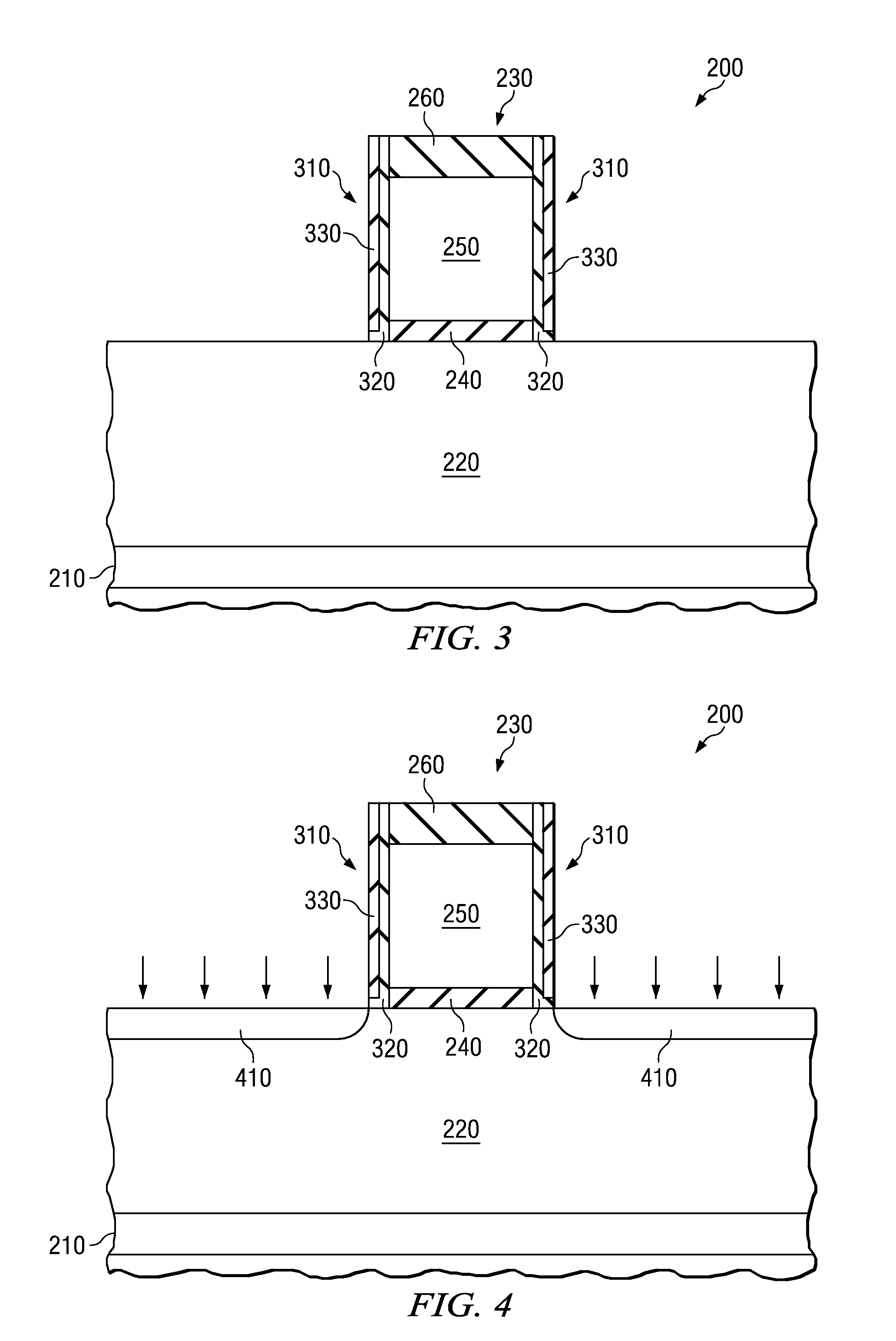

The present invention provides a method for manufacturing a semiconductor device and a method for manufacturing an integrated circuit including the semiconductor device. The method for manufacturing the semiconductor device, among other possible steps, forming a polysilicon gate electrode (250) over a substrate (210) and forming a protective layer (260) over the polysilicon gate electrode (250) to provide a capped polysilicon gate electrode (230). The method further includes forming a protective oxide (510) on a surface proximate the polysilicon gate electrode (250), and removing the protective oxide (510) using a wet etch, the wet etch not having a substantial impact on the protective layer (260).

Owner:TEXAS INSTR INC

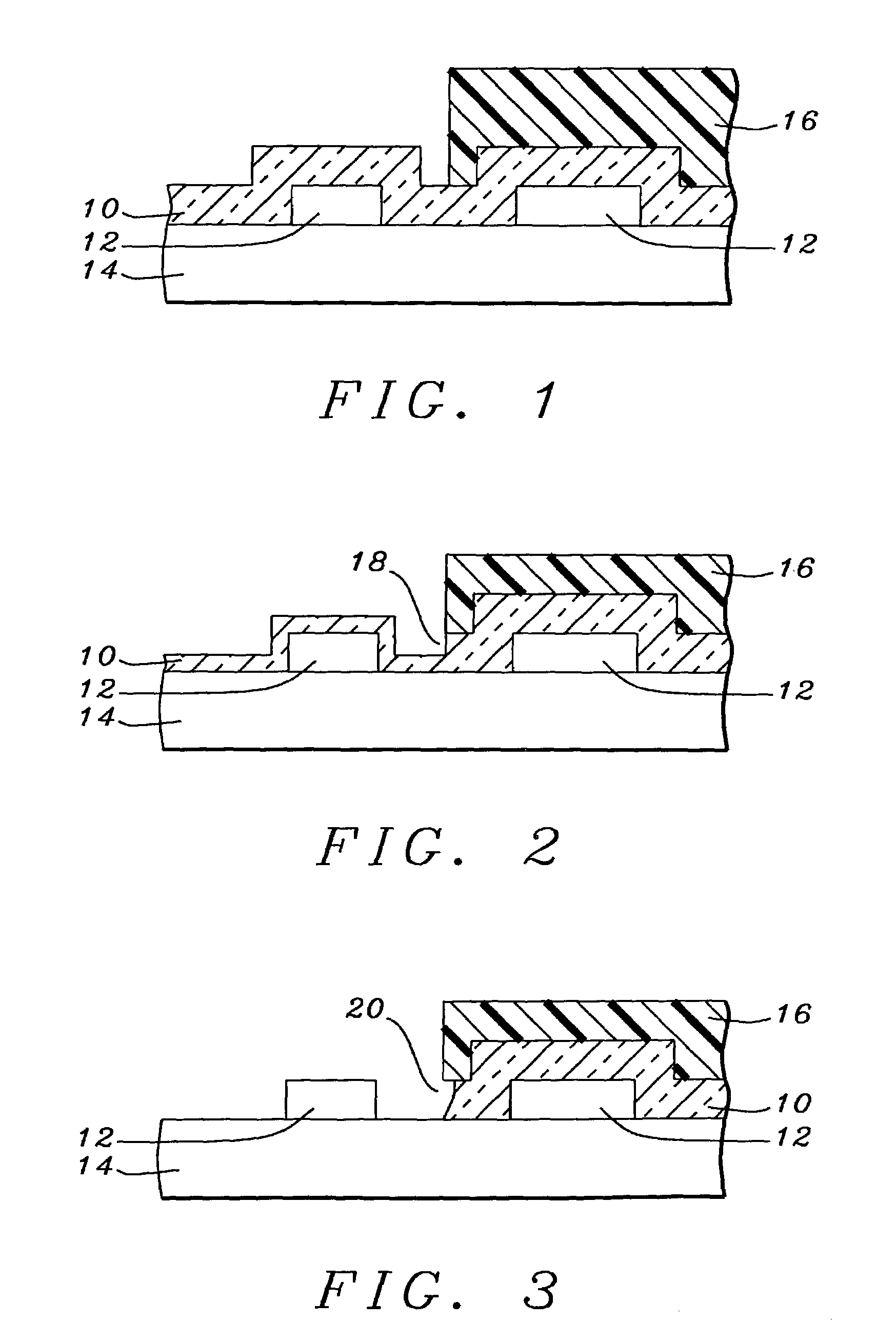

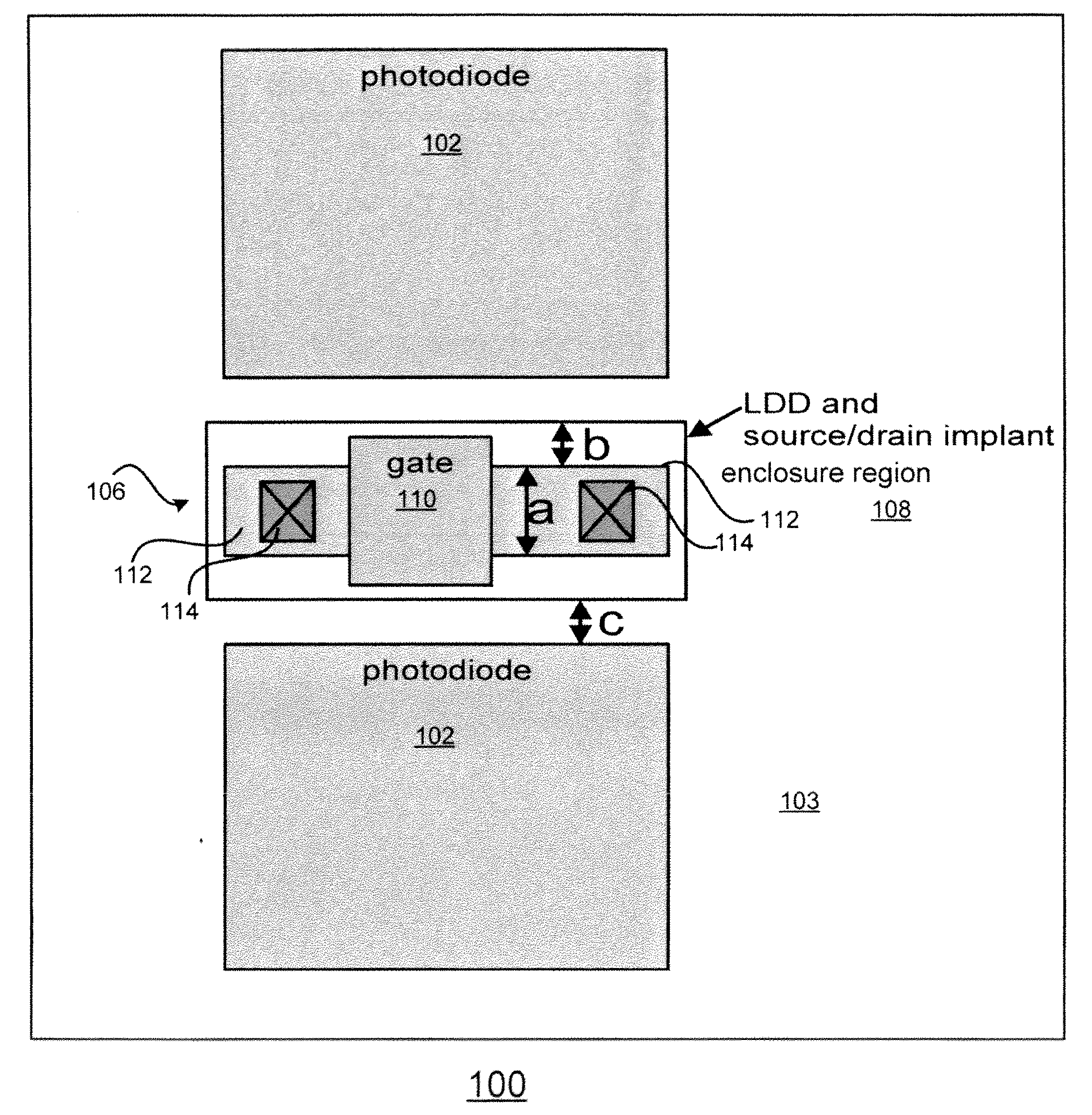

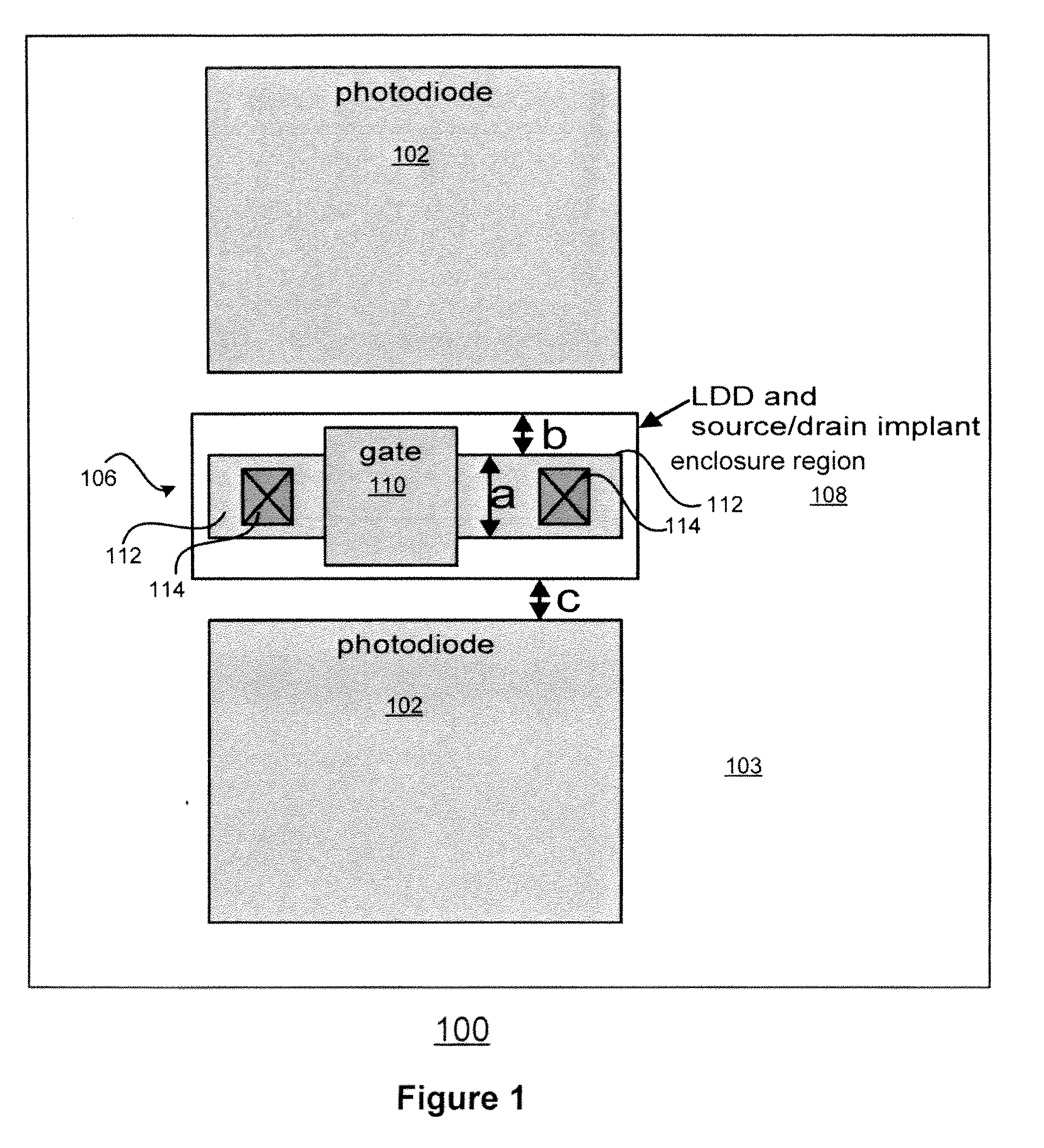

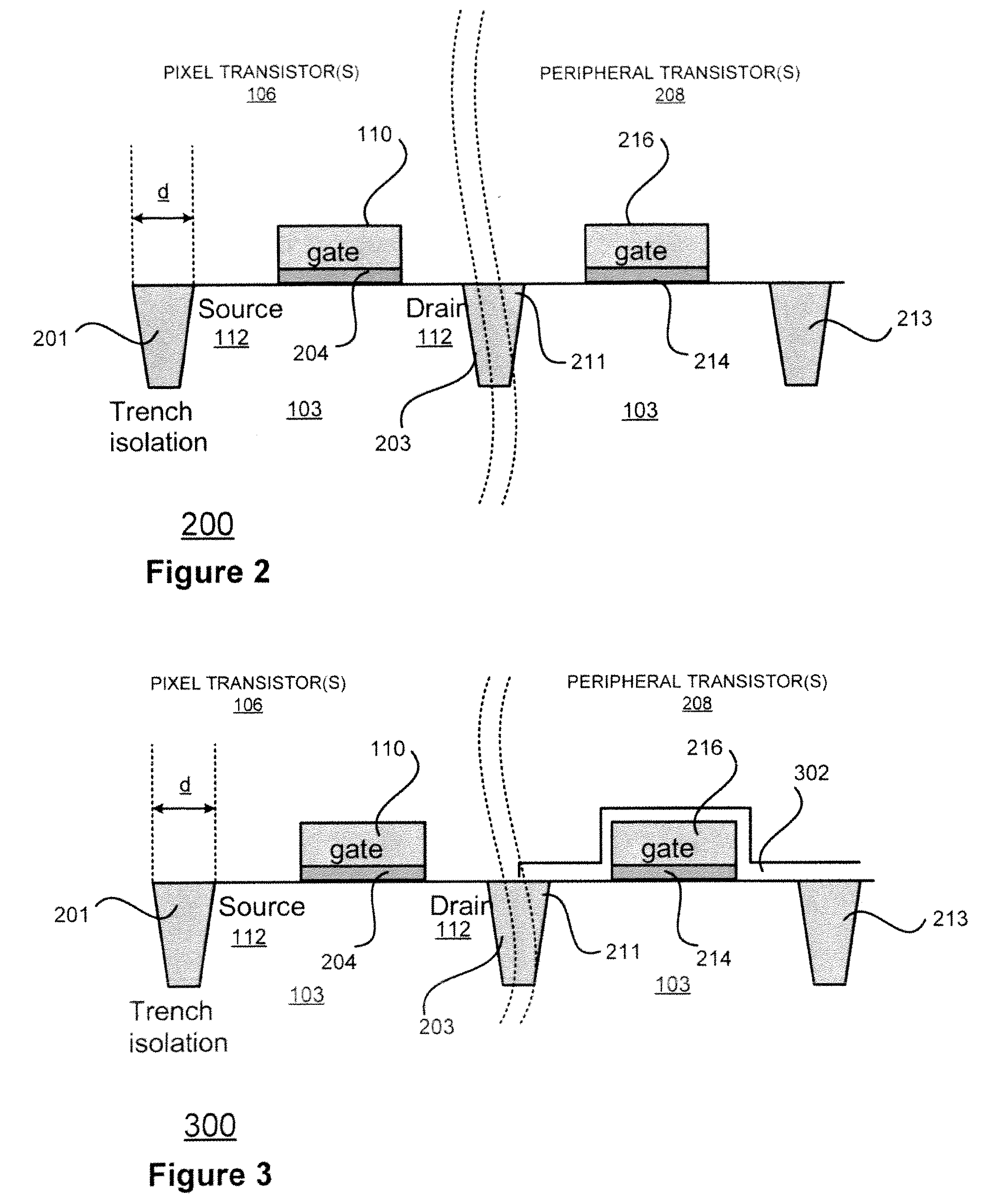

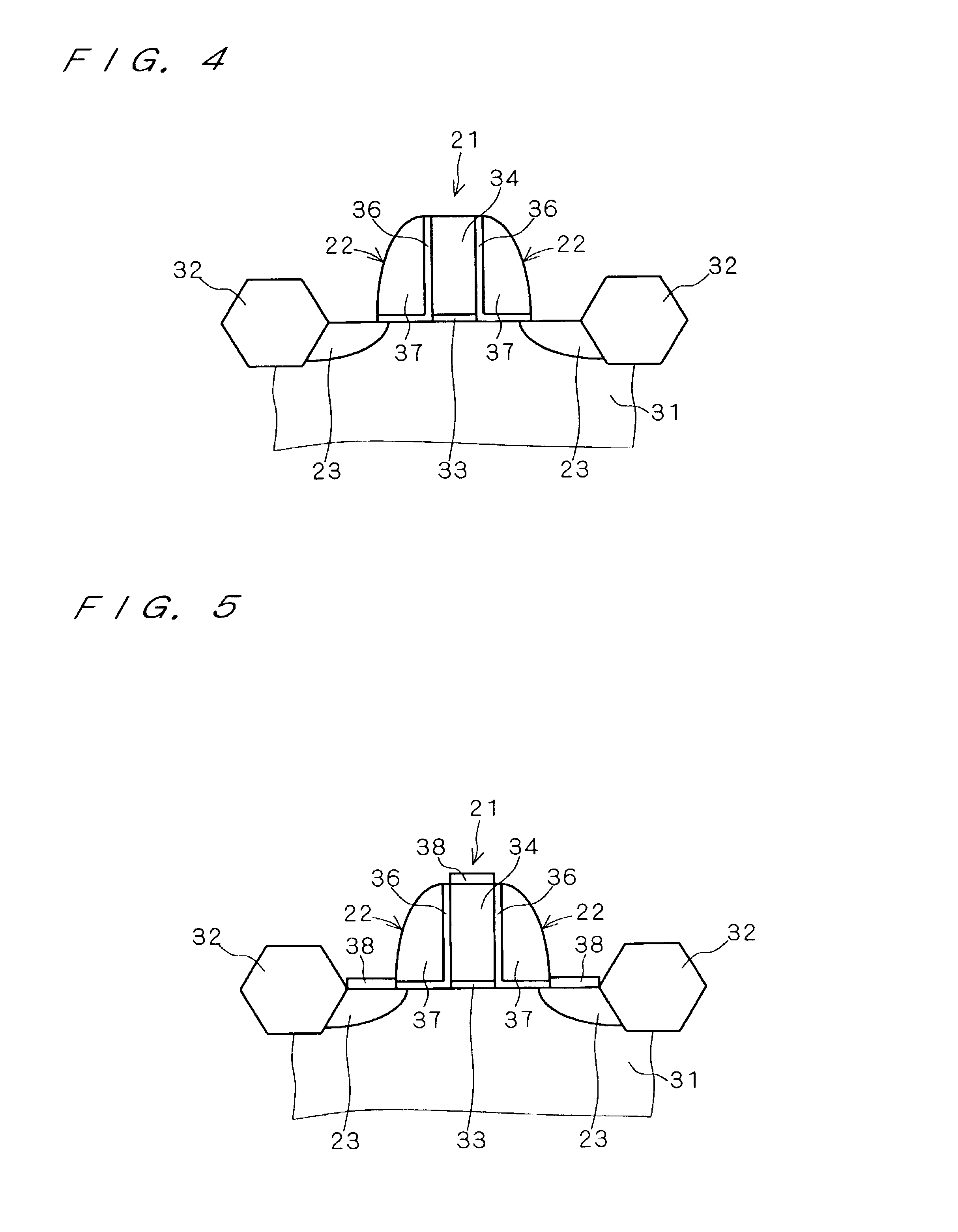

Lightly-doped drains (LDD) of image sensor transistors using selective epitaxy

Embodiments of the present invention are directed to an image sensor having pixel transistors and peripheral transistors disposed in a silicon substrate. For some embodiments, a protective coating is disposed on the peripheral transistors and doped silicon is epitaxially grown on the substrate to form lightly-doped drain (LDD) areas for the pixel transistors. The protective oxide may be used to prevent epitaxial growth of silicon on the peripheral transistors during formation of the LDD areas of the pixel transistors.

Owner:OMNIVISION TECH INC

Oxidation and wear resistant rhenium metal matrix composites

An alloy and metal matrix composite (MMC) based on a refractory metal such as rhenium resists oxidation by the inclusion of alloying substances with affinity for oxygen or other oxidizing substances. Rhenium enjoys excellent high temperature strength but oxidizes at a much lower temperature. This reduces its desirability for hot, stressed environments. The addition of substances, such as soluble metals, that attract oxygen may form a protective oxide layer over the remaining portion of the rhenium-alloy part or piece. Such soluble alloying constituents may include chromium, cobalt, nickel, titanium, thorium, aluminum, hafnium, vanadium, silicon, aluminum, and yttrium. The addition of second phase fiber or particulates such as carbides of silicon, tungsten, titanium and / or boron provides additional wear resistance in the formation of a resulting metal matrix composite (MMC).

Owner:HONEYWELL INT INC

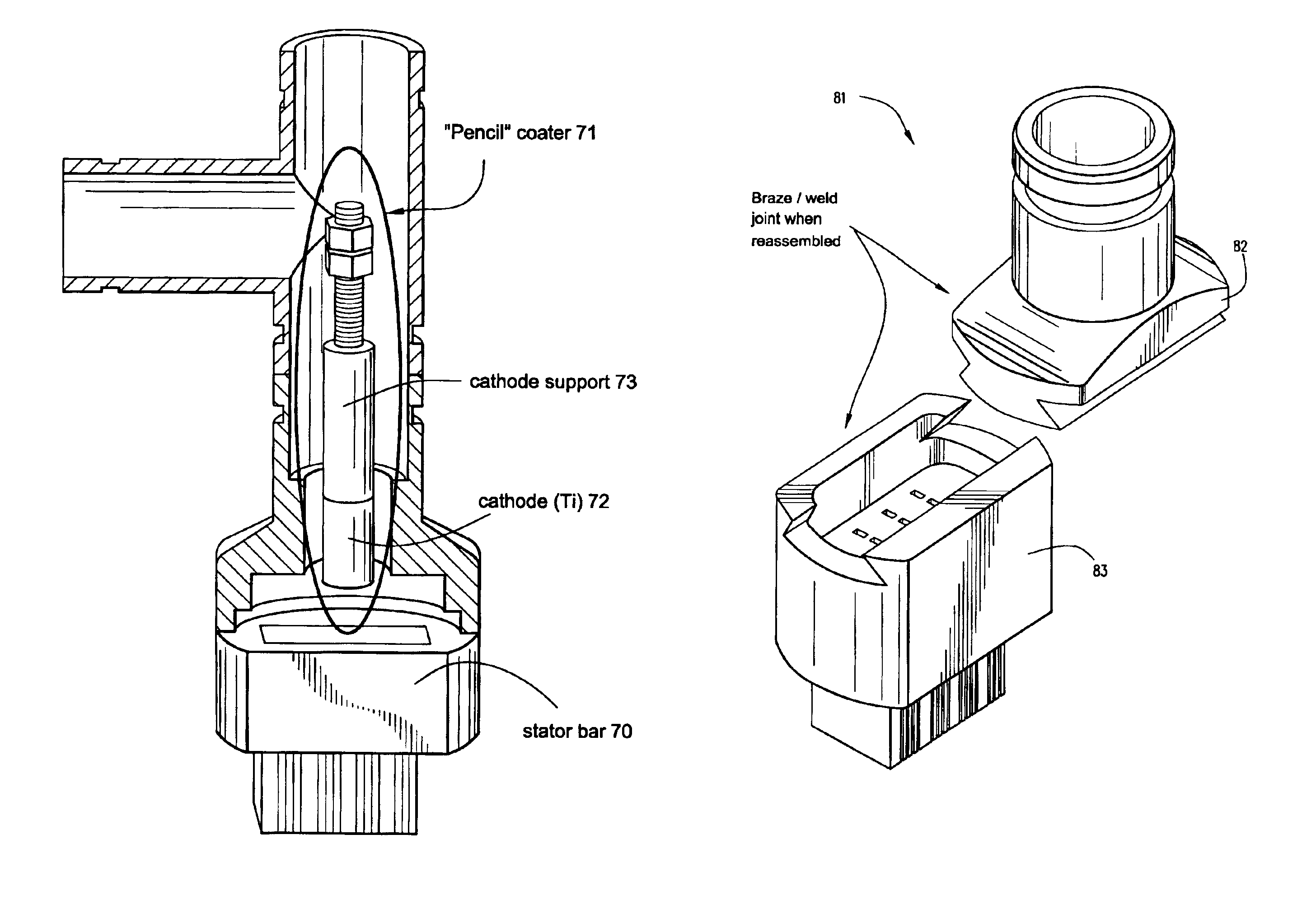

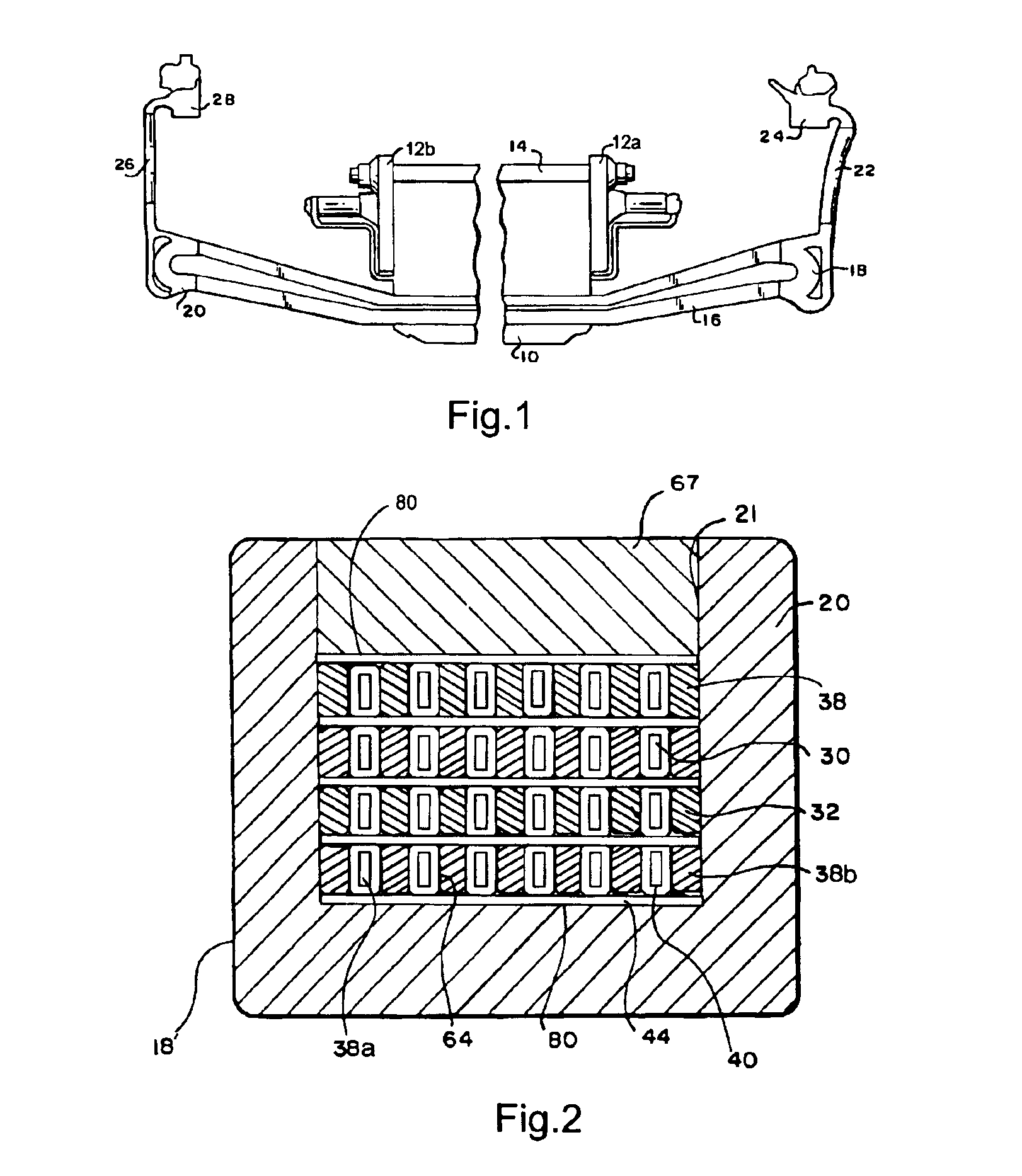

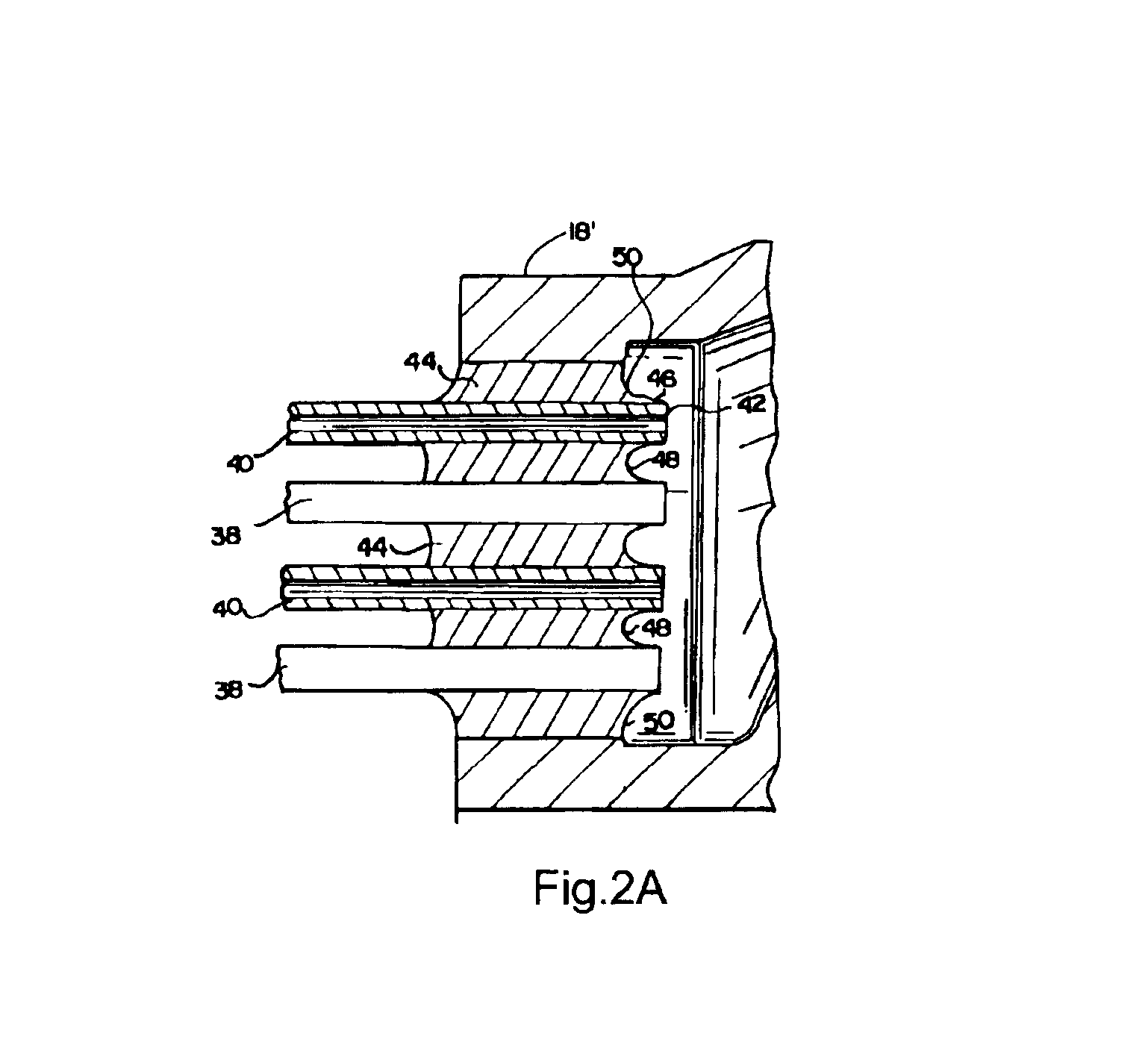

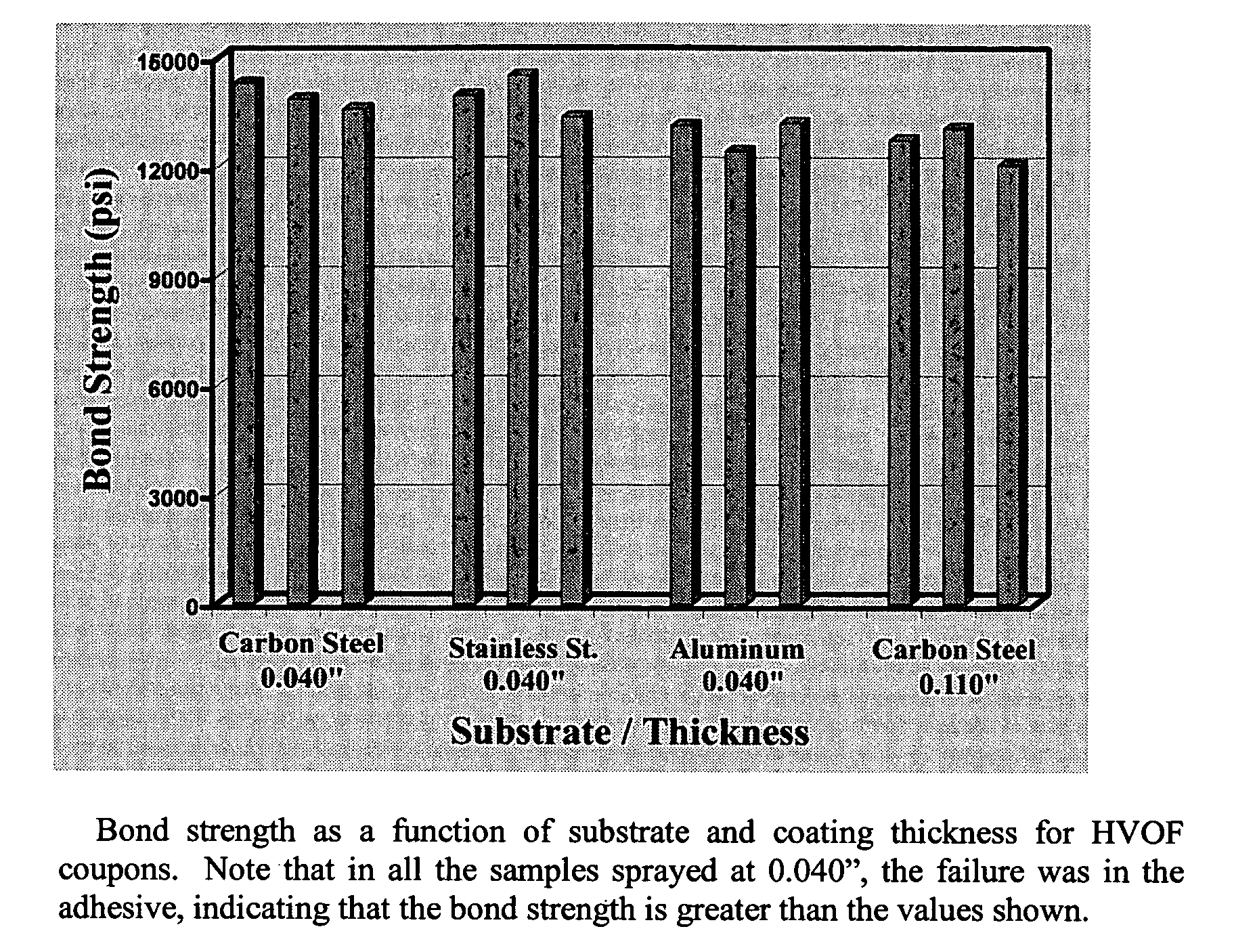

Application of corrosion protective coating for extending the lifetime of water cooled stator bar clips

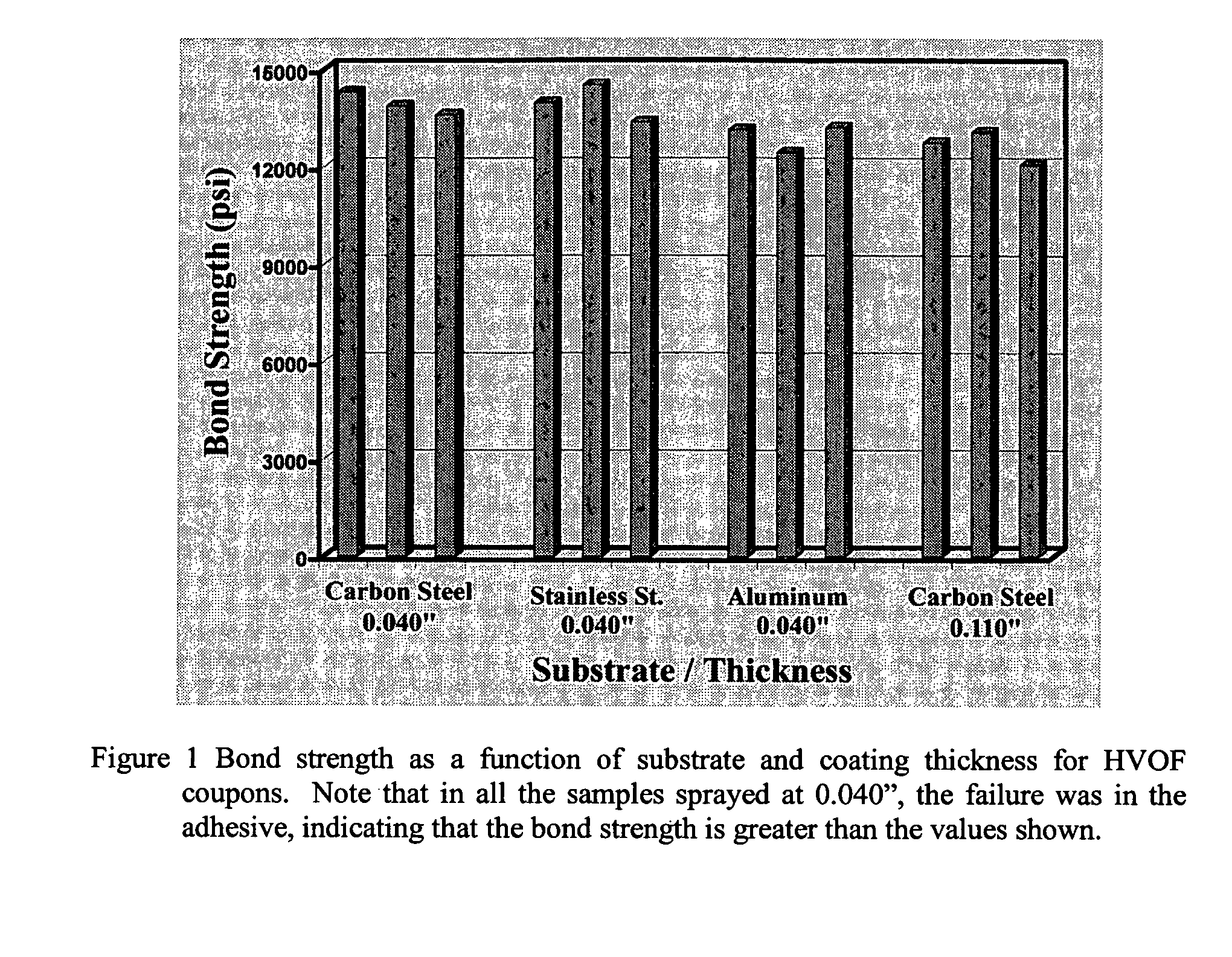

InactiveUS6969932B2Extends projected lifetimeImprove reliabilitySynchronous machinesAsynchronous induction motorsPlasma depositionChemical vapor deposition

A water-cooled stator bar clip for electrical generators and a method for applying a corrosion-resistant protective coating, preferably Sc, Ti, Cr, Zr, Nb, Mo, Hf, Ta, W, Ni, and Al, and their alloys or oxides to existing stator bar end fittings in order to significantly reduce the possibility of leaks through the brazed connections of the copper stator bar end connections. The coatings can be applied locally using various known physical vapor deposition (“PVD”), chemical vapor deposition (“CVD”) or other direct coating techniques known in the art. For example, the coatings can be applied using ion plasma deposition, sputtering or wire arc techniques (all PVD processes) or by using electroplating, high velocity oxygen free (“HVOF”) deposition, DC arc or electroless plating. Preferably, the coatings are applied either to new stator bar clips or to existing clips in the field using a known pencil coater technique. After being deposited, the metallic coatings form a protective oxide layers over the existing copper brazed joint after being exposed to a water environment, thereby protecting the chemical and structural integrity of the underlying copper brazed joint.

Owner:GENERAL ELECTRIC CO

Highly active liquid melts used to form coatings

ActiveUS8070894B2Reduce layeringHot-dipping/immersion processesLiquid surface applicatorsProtective oxideUltimate tensile strength

An alloy suitable for coating metal surfaces is provided in which the alloy provides a liquid melt which contains a fraction of dissolved oxide forming additives as deoxidizers. The alloyed combination of elements in the liquid melt resists compound formation thus preserving the chemical activity of the individual elements. In a coating application, the alloy may form a coating that can interact with and remove the oxide or residual oxide coating of the base metal to be coated, i.e., scrub the surface of the metal clean. This results in increased coating bond strength and the ability to bond effectively to normally difficult alloys such as stainless steel, refractory metals (W, Ti, Ta etc.), or aluminum alloys which form protective oxide layers.

Owner:THE NANO CO INC +1

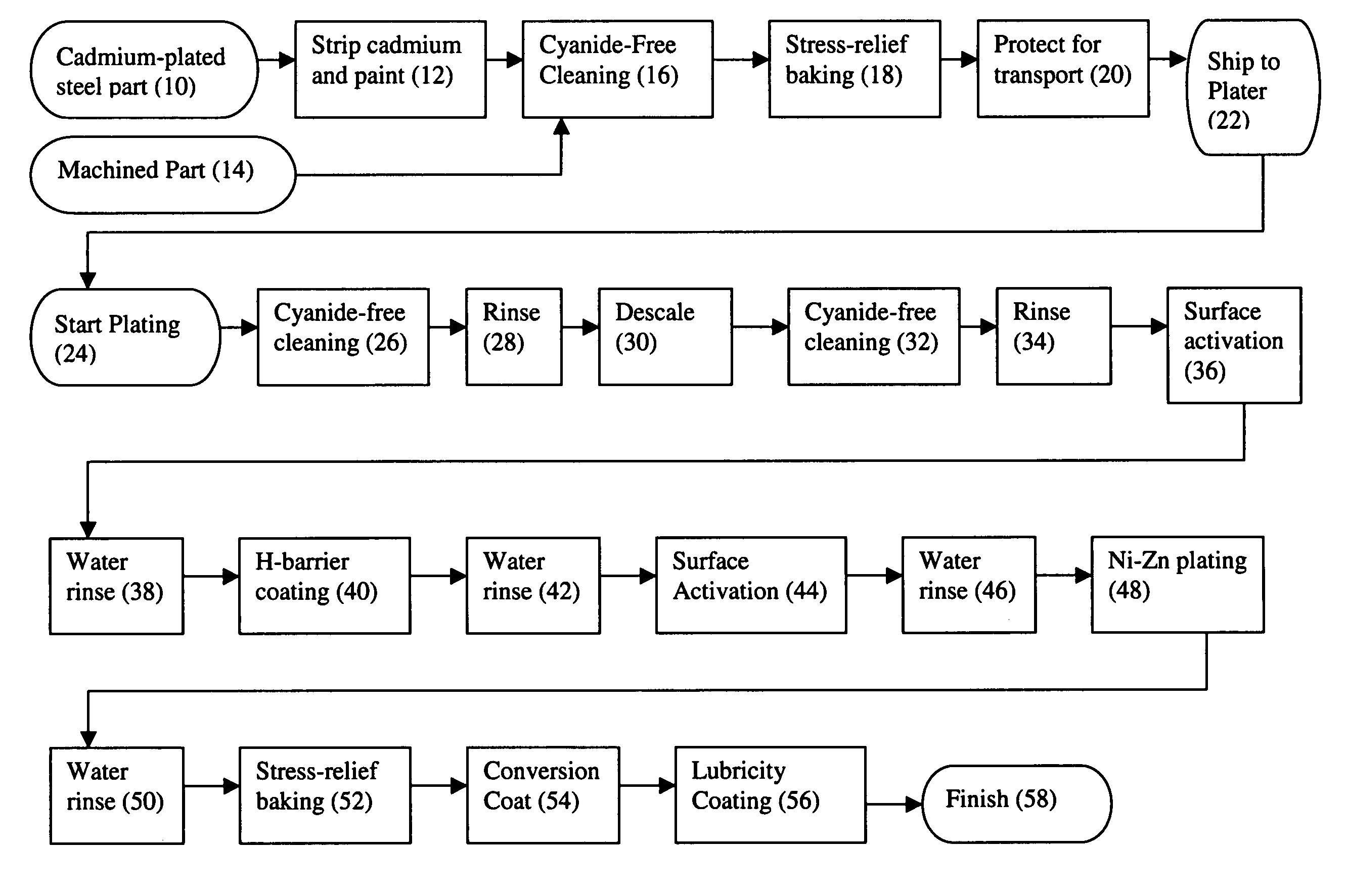

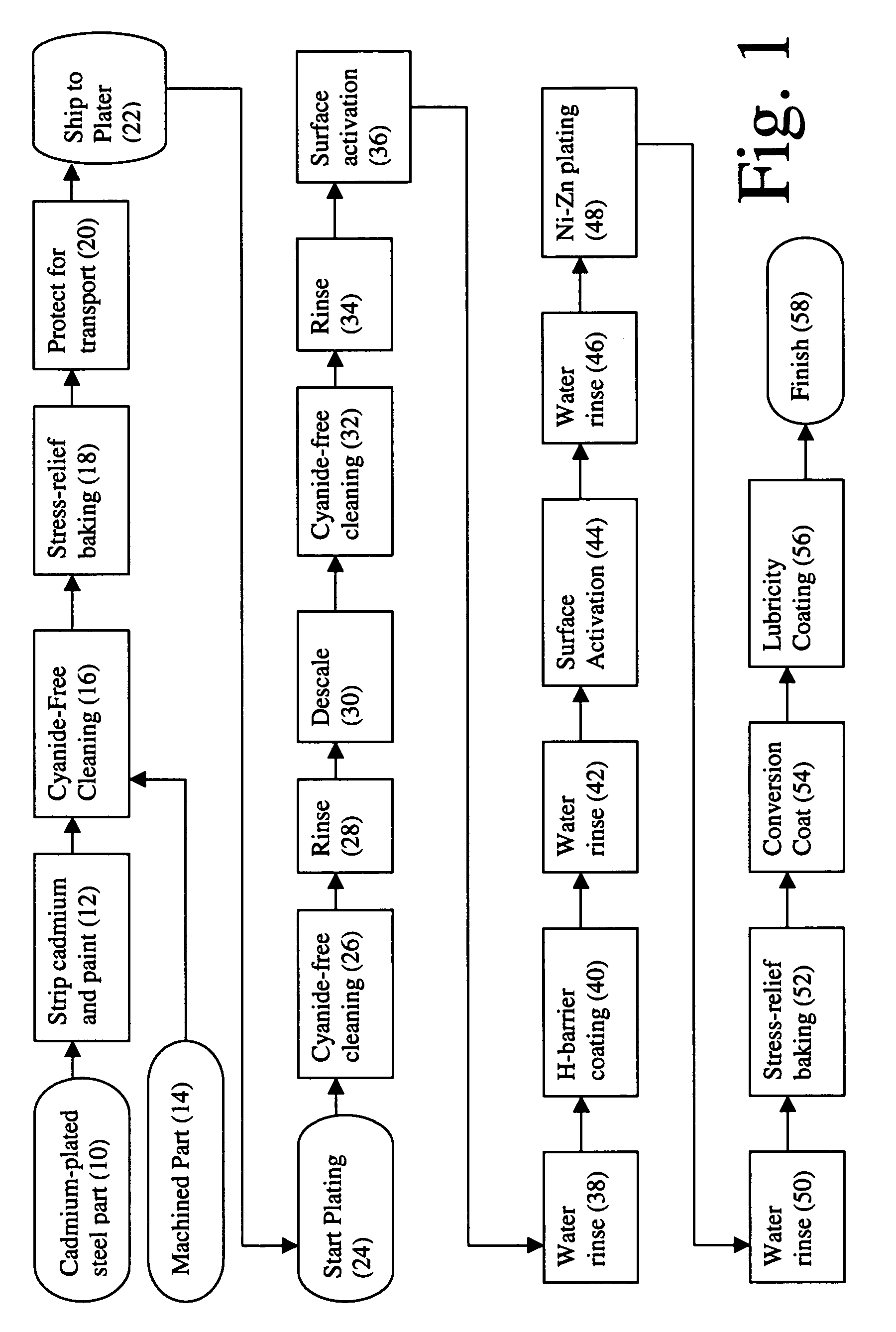

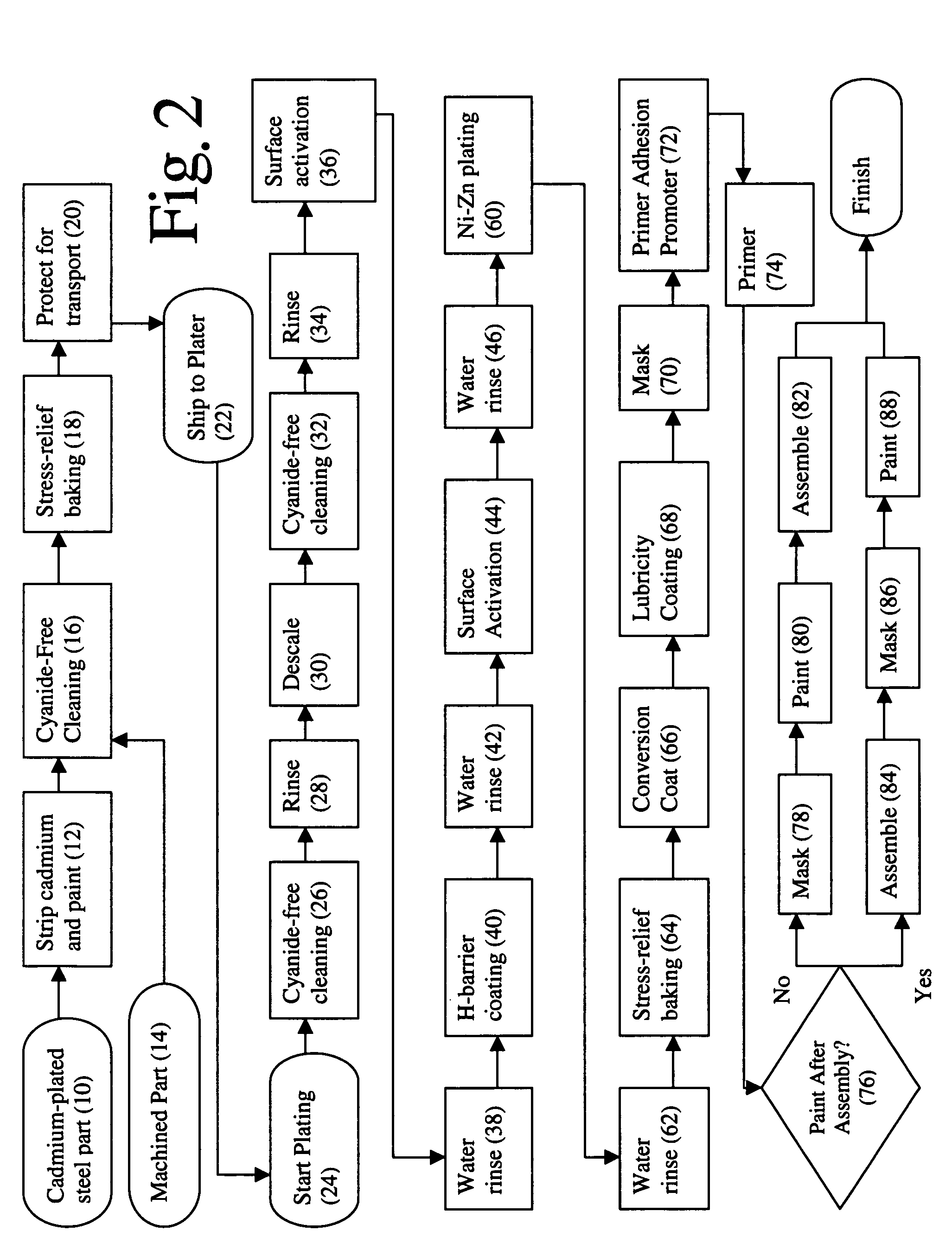

Method for deposition of steel protective coating

InactiveUS7514153B1Improve protectionLow toxicitySuperimposed coating processThin material handlingNickel alloyCadmium Cation

A method is provided for coating a steel surface of a workpiece. According to an aspect of the invention, a steel workpiece is subjected to a first embrittlement-relief baking operation to form a protective oxide layer on the steel surface. The protective oxide layer is de-scaled, and the steel surface is activated. A hydrogen barrier coating is deposited on the activated steel surface, and activated. A zinc-nickel alloy is plated on the barrier coating, and subjected to a second embrittlement-relief baking operation. The porous plating is sealed with a conversion coat. The method is especially useful in making low to no hydrogen embrittlement cadmium-replacement steel parts. Also provided is a corrosion resistant coated steel workpiece.

Owner:SEC OF THE NAVY UNITED STATES OF AMERICA AS REPRESENTED BY THE THE

Application of corrosion protective coating for extending the lifetime of water cooled stator bar clips

ActiveUS20050012408A1Extends projected lifetimeImprove reliabilitySynchronous machinesAsynchronous induction motorsGas phasePlasma deposition

A water-cooled stator bar clip for electrical generators and a method for applying a corrosion-resistant protective coating, preferably Sc, Ti, Cr, Zr, Nb, Mo, Hf, Ta, W, Ni, and Al, and their alloys or oxides to existing stator bar end fittings in order to significantly reduce the possibility of leaks through the brazed connections of the copper stator bar end connections. The coatings can be applied locally using various known physical vapor deposition (“PVD”), chemical vapor deposition (“CVD”) or other direct coating techniques known in the art. For example, the coatings can be applied using ion plasma deposition, sputtering or wire arc techniques (all PVD processes) or by using electroplating, high velocity oxygen free (“HVOF”) deposition, DC arc or electroless plating. Preferably, the coatings are applied either to new stator bar clips or to existing clips in the field using a known pencil coater technique. After being deposited, the metallic coatings form a protective oxide layers over the existing copper brazed joint after being exposed to a water environment, thereby protecting the chemical and structural integrity of the underlying copper brazed joint.

Owner:GENERAL ELECTRIC CO

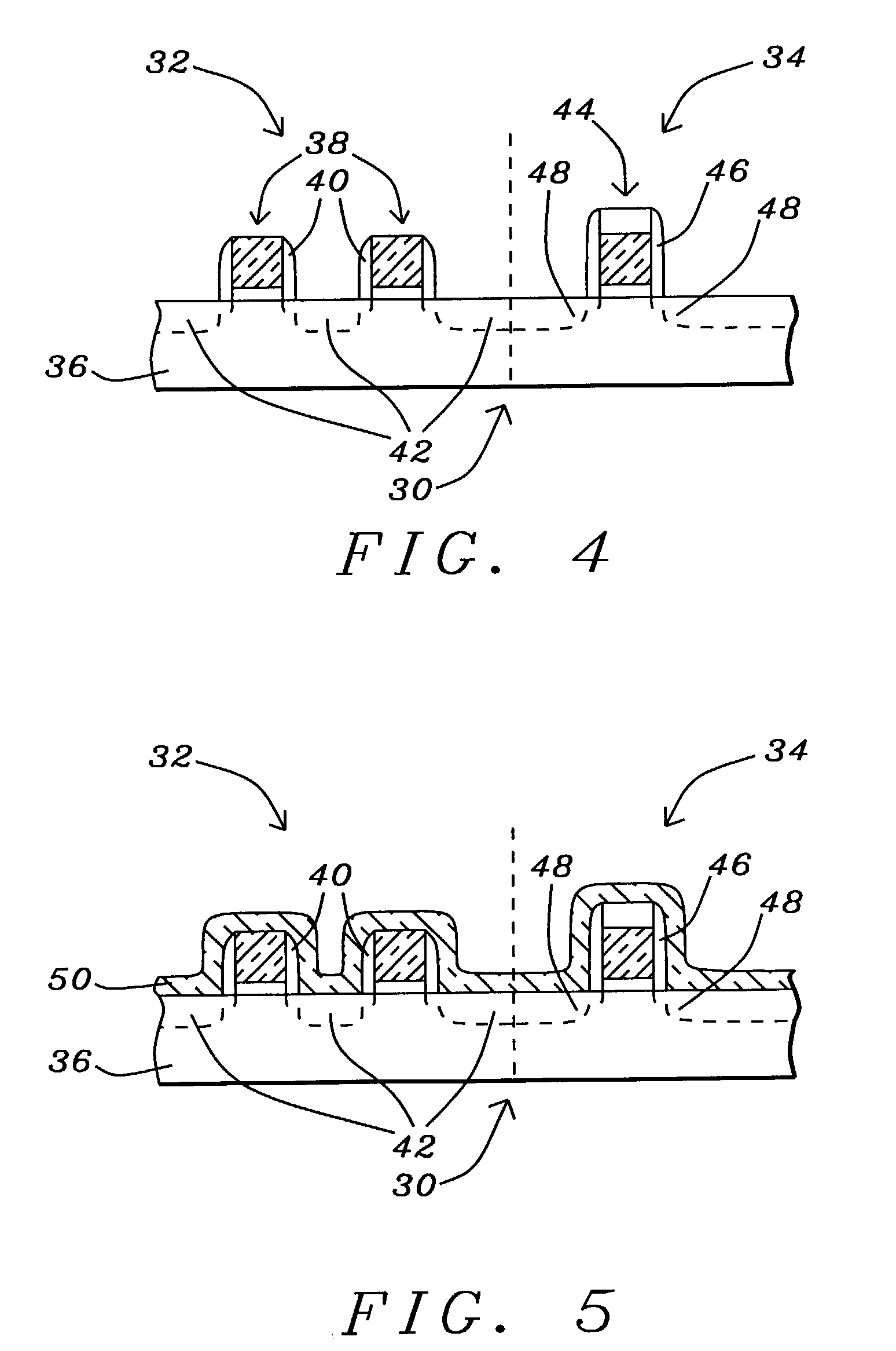

Method for using a wet etch to manufacturing a semiconductor device having a silicided gate electrode and a method for manufacturing an integrated circuit including the same

ActiveUS20050215038A1TransistorSemiconductor/solid-state device manufacturingDevice materialProtective oxide

The present invention provides a method for manufacturing a semiconductor device and a method for manufacturing an integrated circuit including the semiconductor device. The method for manufacturing the semiconductor device, among other possible steps, forming a polysilicon gate electrode (250) over a substrate (210) and forming a protective layer (260) over the polysilicon gate electrode (250) to provide a capped polysilicon gate electrode (230). The method further includes forming a protective oxide (510) on a surface proximate the polysilicon gate electrode (250), and removing the protective oxide (510) using a wet etch, the wet etch not having a substantial impact on the protective layer (260).

Owner:TEXAS INSTR INC

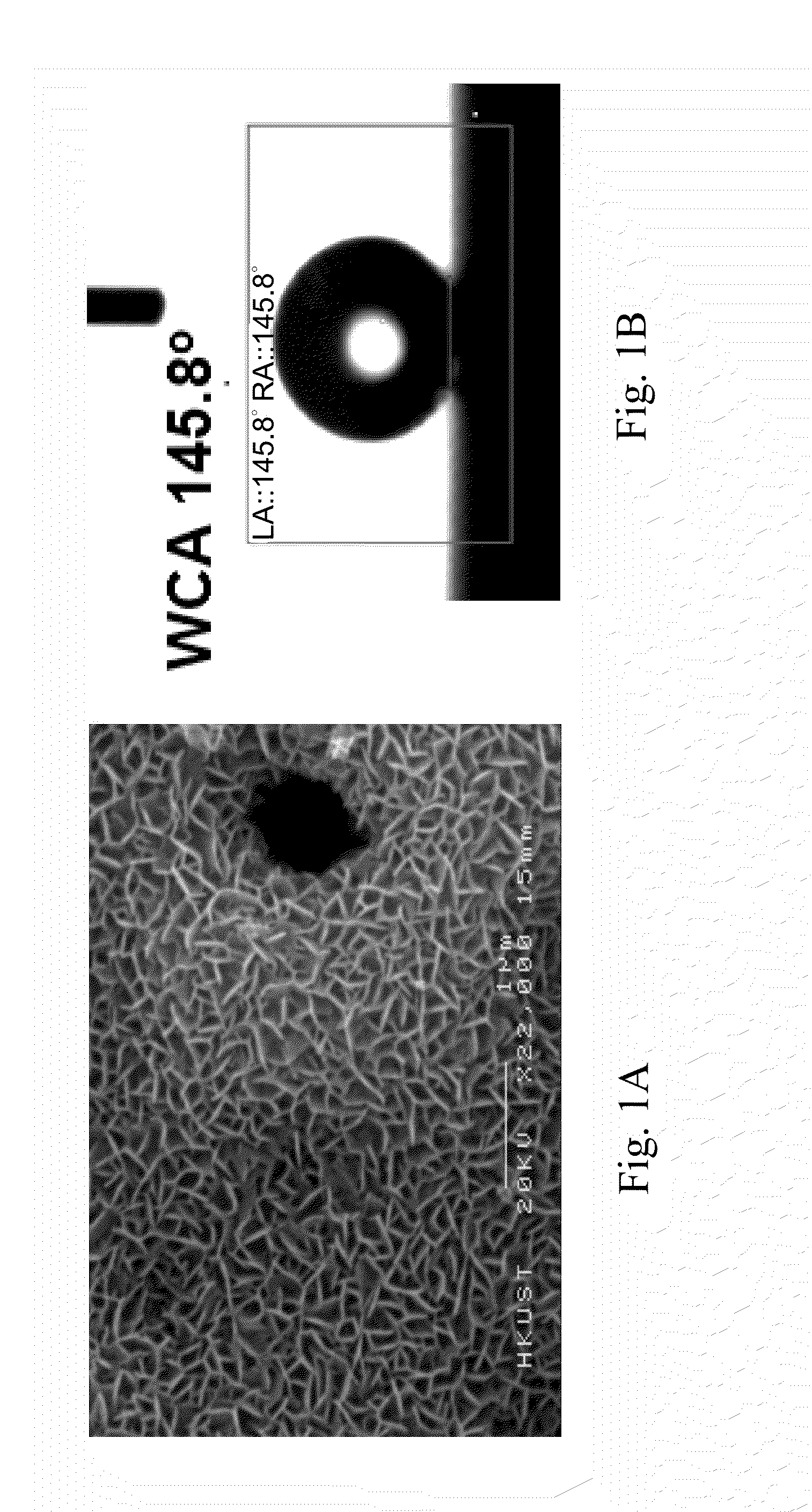

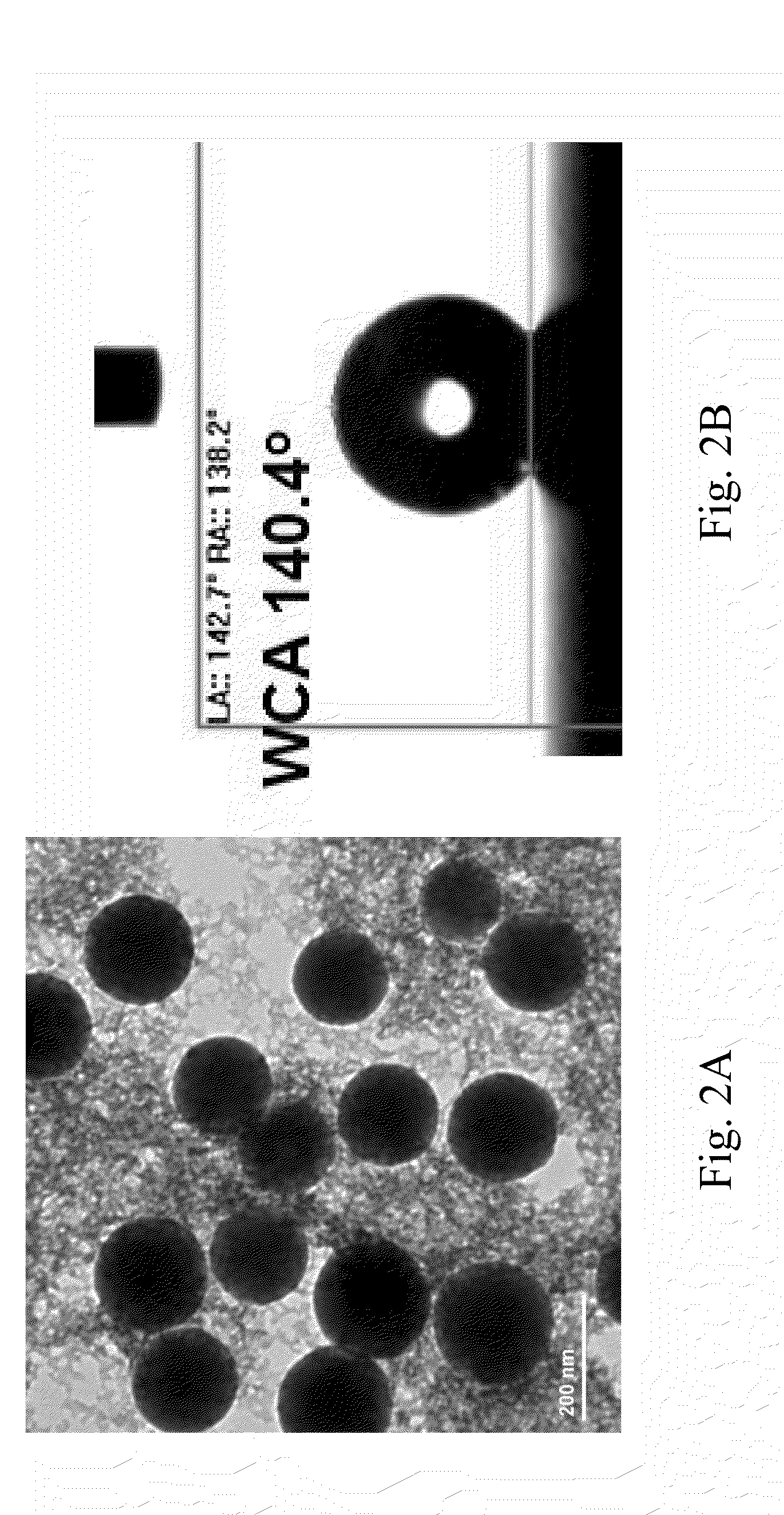

Surface treatment method on Micro-arc Oxidation treated Mg alloys

InactiveUS20150140314A1Improve conductivityAnodisationDecorative surface effectsMicro structureElectricity

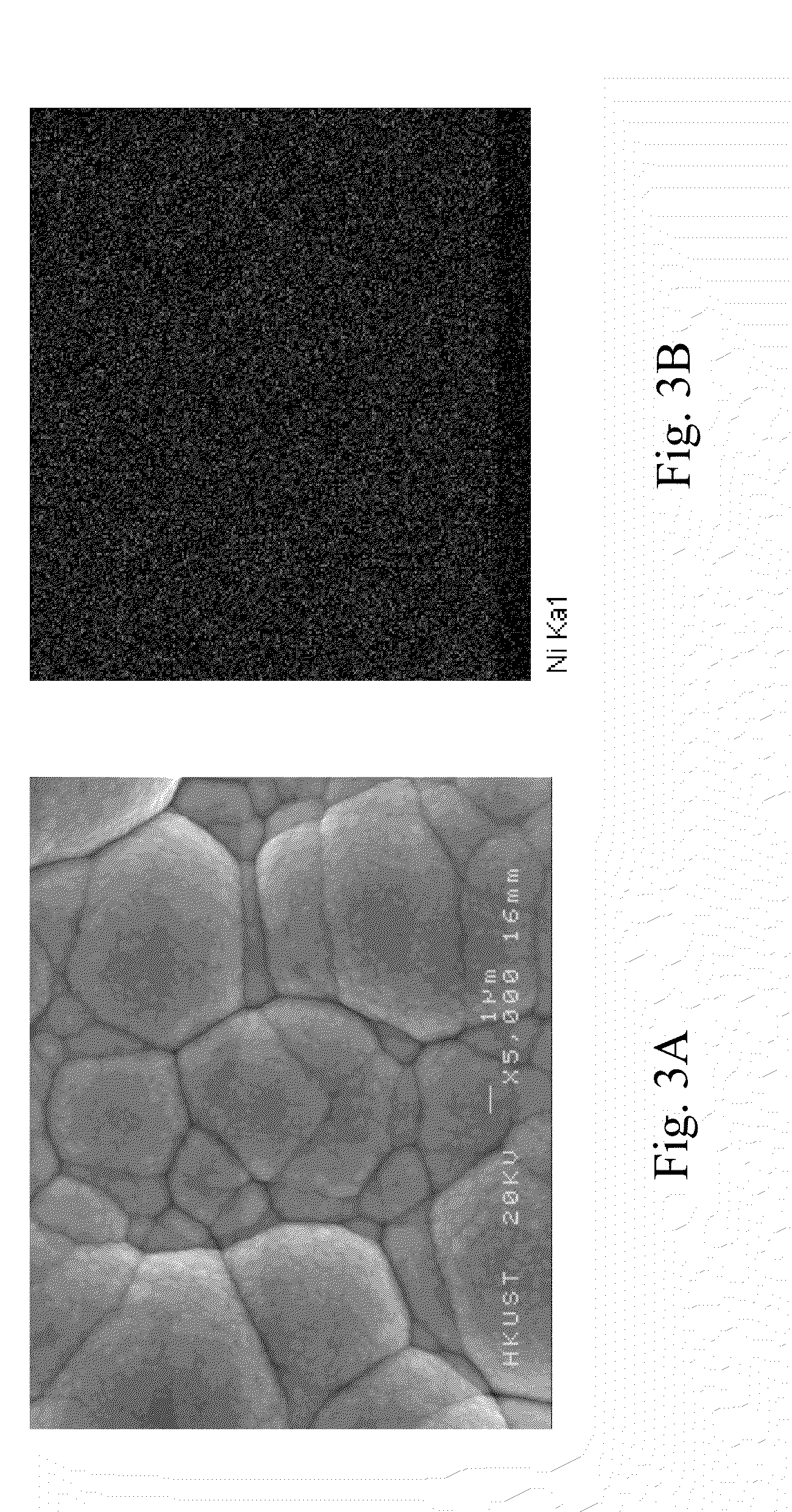

Chemically and mechanically protective oxide film was formed on Mg alloys using micro-arc oxidation (MAO) methods. Further modification of the obtained MAO surfaces was made in various aspects and the processes thereof were described. Firstly, the protection is enhanced by forming super-hydrophobic surfaces, with water contact angle higher than 140°, attributed to hierarchical nano-micro structures. Secondly, the electrical property of the MAO surfaces is modified. A film with sheet resistance as low as 0.05 Ω / sq is achieved by electro-less Ni deposition on MAO surfaces. Thirdly, black colors are achieved by the sol-gel process on MAO samples.

Owner:NANO & ADVANCED MATERIALS INST

Oxidation and wear resistant rhenium metal matrix composites

InactiveUS20030206824A1Avoid attackEasy to wearBearing componentsSliding contact bearingsFiberRhenium

An alloy and metal matrix composite (MMC) based on a refractory metal such as rhenium resists oxidation by the inclusion of alloying substances with affinity for oxygen or other oxidizing substances. Rhenium enjoys excellent high temperature strength but oxidizes at a much lower temperature. This reduces its desirability for hot, stressed environments. The addition of substances, such as soluble metals, that attract oxygen may form a protective oxide layer over the remaining portion of the rhenium-alloy part or piece. Such soluble alloying constituents may include chromium, cobalt, nickel, titanium, thorium, aluminum, hafnium, vanadium, silicon, aluminum, and yttrium. The addition of second phase fiber or particulates such as carbides of silicon, tungsten, titanium and / or boron provides additional wear resistance in the formation of a resulting metal matrix composite (MMC).

Owner:HONEYWELL INT INC

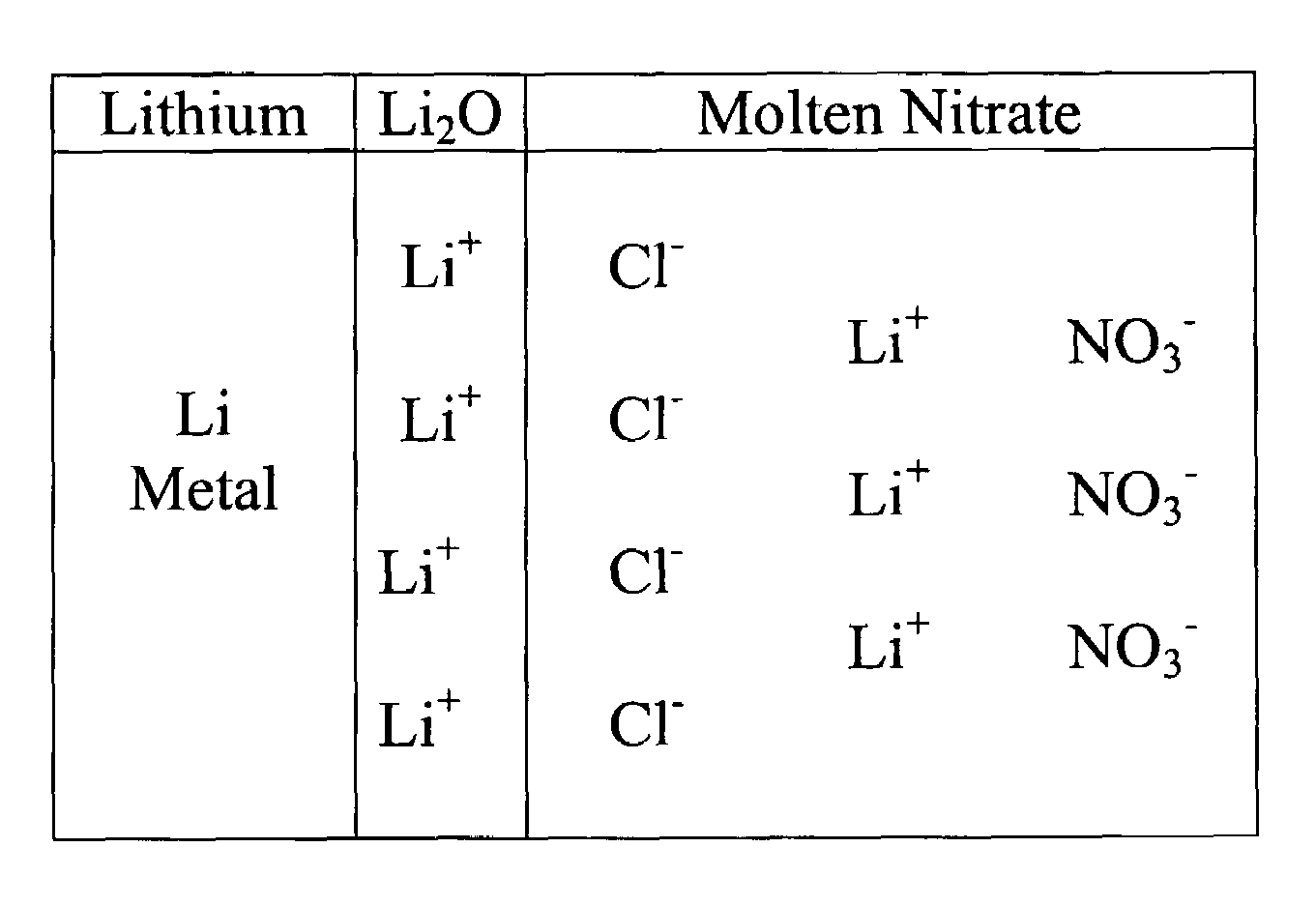

Chloride-free thermal batteries using molten nitrate electrolytes

ActiveUS20090047573A1Shorten activation timeReduce weightDeferred-action cellsCell electrodesHigh cellDecomposition

Thermal batteries using molten nitrate electrolytes offer significantly higher cell voltages and marked improvements in energy and power densities over present thermal batteries. However, a major problem is gas-evolution reactions involving the molten nitrate electrolytes. This gassing problem has blocked the advantages offered by thermal batteries using molten nitrates. The solution to this problem is the use of chloride-free molten nitrate electrolytes. Most important is the avoidance of potassium perchlorate (KClO4) or any other chlorine-containing substances that can decompose to produce chloride ions in any thermal battery component. The Fe+KClO4 pyrotechnic used to activate thermal batteries is a key example. The decomposition of such substances into chloride ions (Cl−) results in passivating-film breakdown and gas-producing reactions with the molten nitrate electrolyte. These reactions largely involve the lithium-component of the anode used in thermal batteries such as Li—Fe (LAN), Li—Si, and Li—Al. The introduction of chloride ions into the nitrate melt via the pyrotechnic materials produces a rapid breakdown of the protective oxide film on lithium-based anodes and leads to gas-producing reactions.

Owner:AXIENT LLC

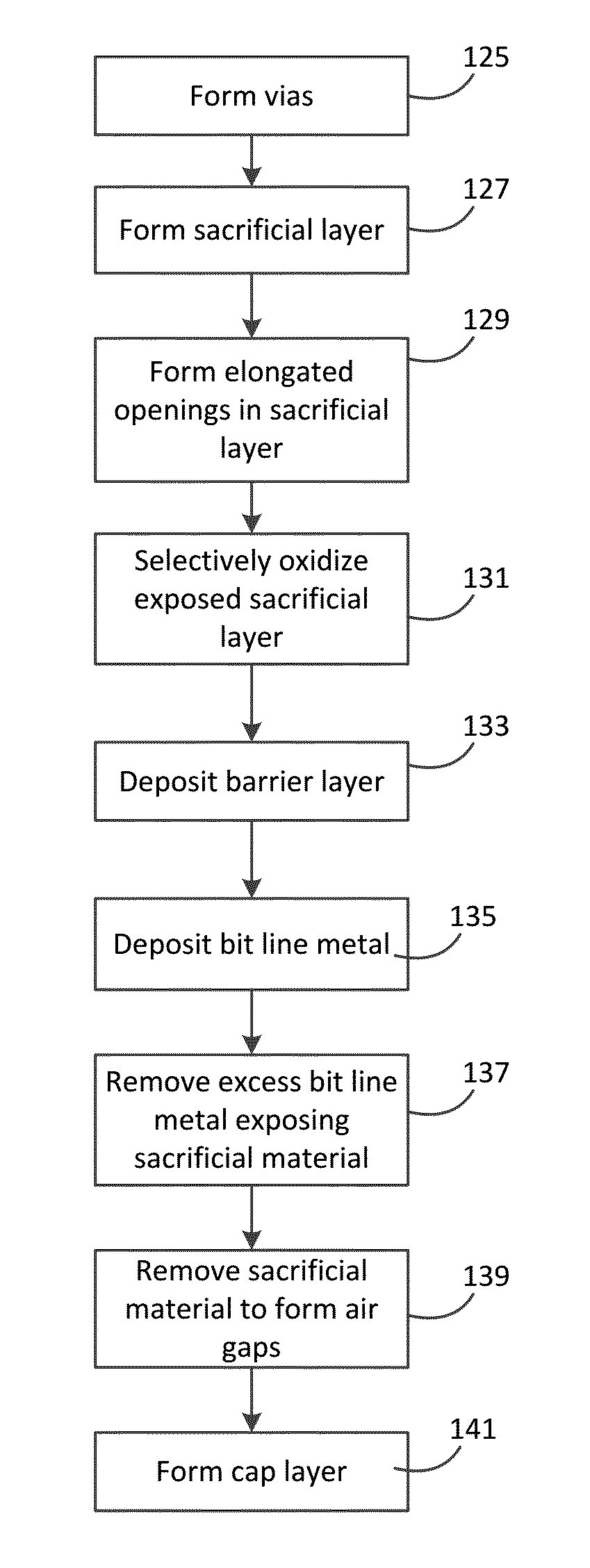

Air Gap Formation Between Bit Lines with Side Protection

ActiveUS20150228582A1Reduce bit line-to-bit line capacitanceReducing and eliminating etch damageSemiconductor/solid-state device detailsSolid-state devicesBit lineEngineering

Air gaps are formed between bit lines by etching to remove sacrificial material from between bit lines. Bit lines are protected from etch damage. Sacrificial material may be selectively oxidized prior to deposition of bit line metal so that protective oxide lies along sides of bit lines during etch. Portions of protective material may be selectively formed on tops of bit lines prior to etching sacrificial material.

Owner:SANDISK TECH LLC

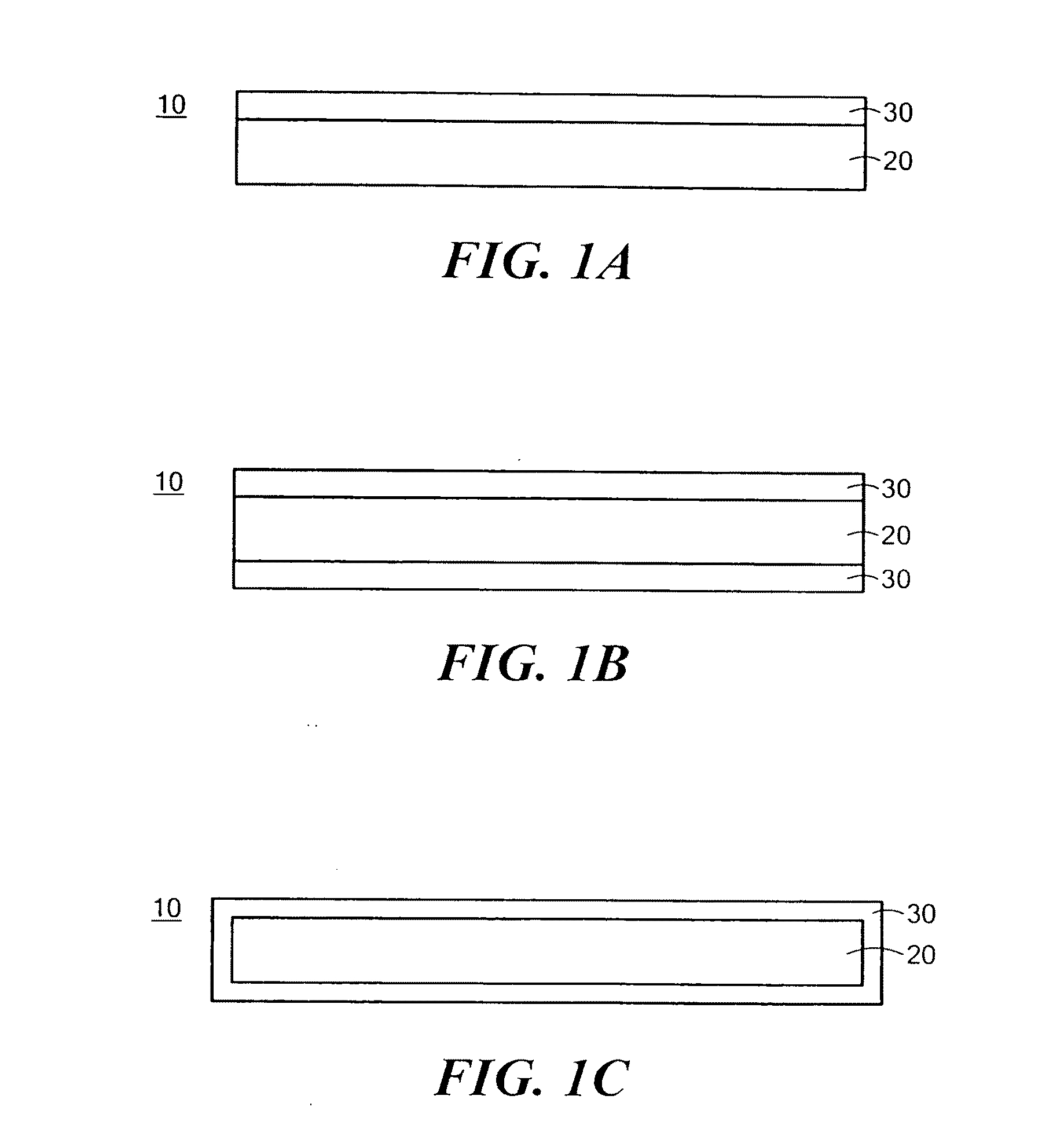

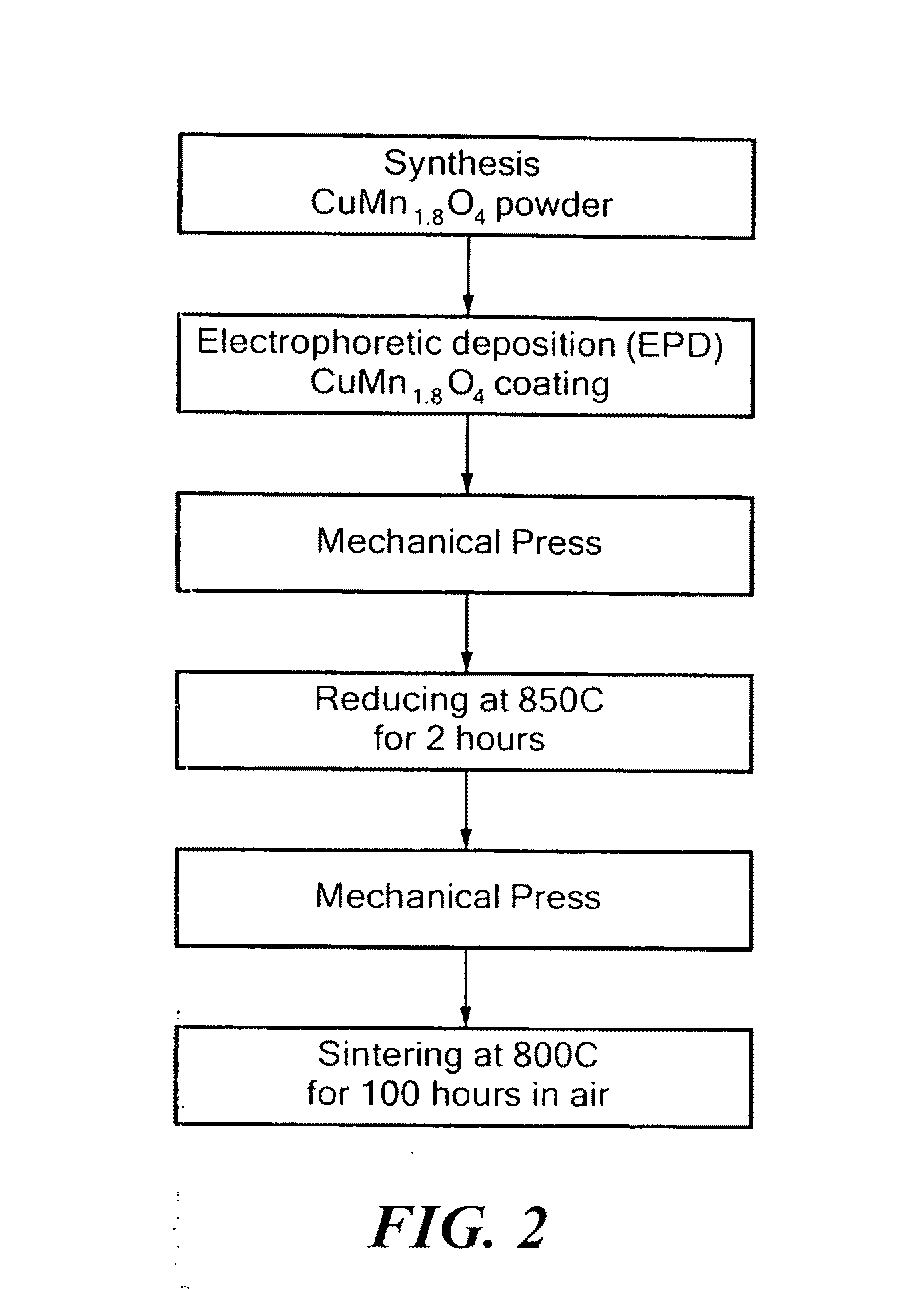

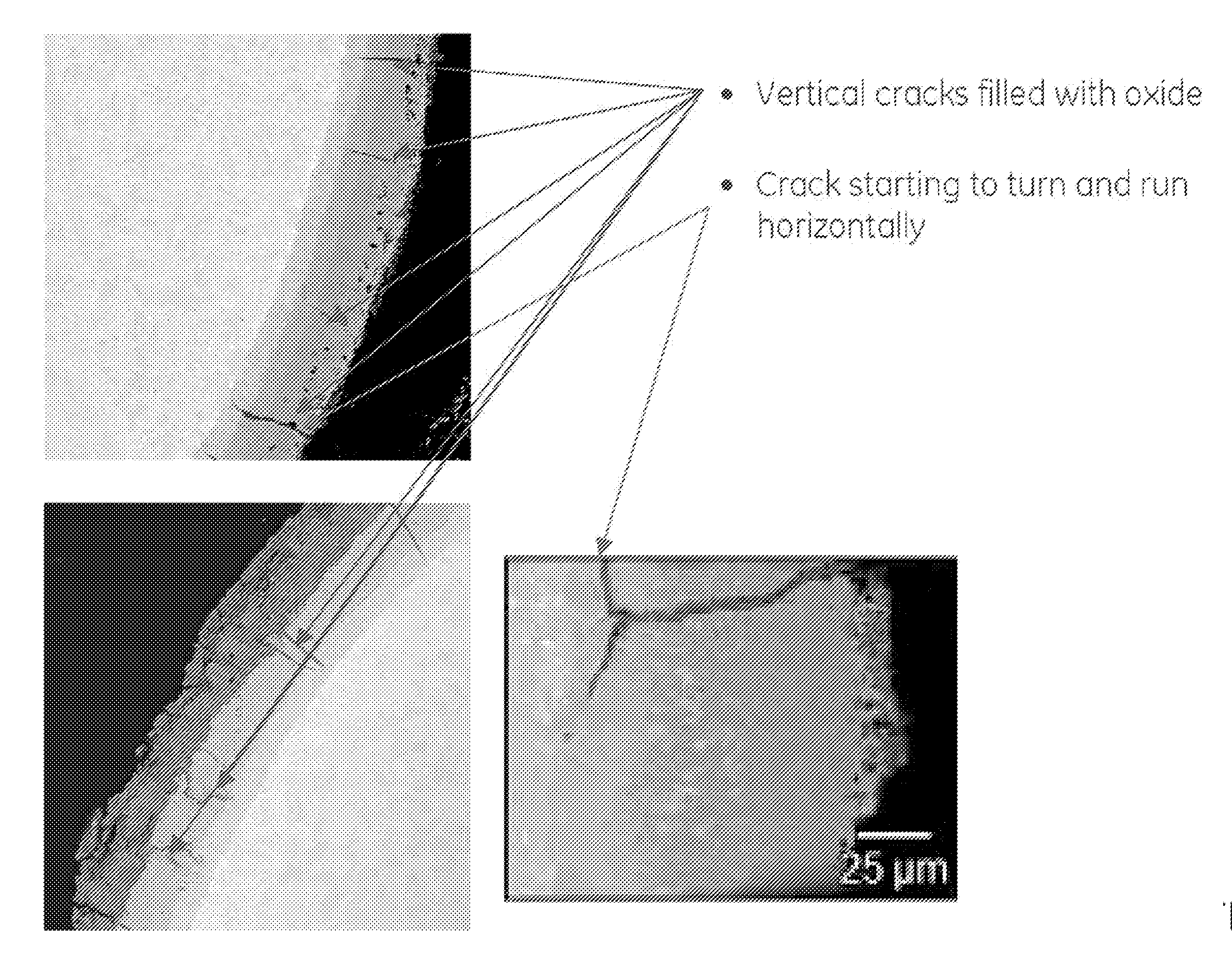

Protective oxide coatings for SOFC interconnections

A dense and well adhered spinel coating such as CuMn1.8O4, when deposited on a stainless steel substrate by electrophoretic deposition, significantly reduces the oxidation rate of the steel compared to the uncoated steel at elevated temperature. The protective oxide spinel coating is useful for preparing solid oxide fuel cell interconnects having long term stability at 800° C.

Owner:TRUSTEES OF BOSTON UNIV

Oxide-forming protective coatigns for niobium-based materials

ActiveUS20110146848A1Improve antioxidant capacityImprove the immunityEngine fuctionsVacuum evaporation coatingRheniumNiobium

Coatings suitable for use as protective oxide-forming coatings on Nb-based substrates exposed to high temperatures and oxidative environments. The coatings contain chromium and / or molybdenum, preferably contains silicon, and optionally contains niobium, titanium, hafnium, iron, rhenium, tantalum, and / or tungsten, which in combination form multiple intermetallic phases, which in combination form one or more intermetallic phases that promote the formation of a slow-growing oxide scale. Depending on the particular coating composition, the intermetallic phases may be: a silicon-modified Cr2Nb Laves phase and optionally a chromium solid solution phase, a CrNbSi intermetallic phase, and / or an M3Si intermetallic phase where M is niobium, titanium, and / or chromium; or M5Si3, MSi2 and / or M3Si2 where M is molybdenum, niobium, titanium, chromium, hafnium, iron, rhenium, tantalum, and / or tungsten.

Owner:GENERAL ELECTRIC CO

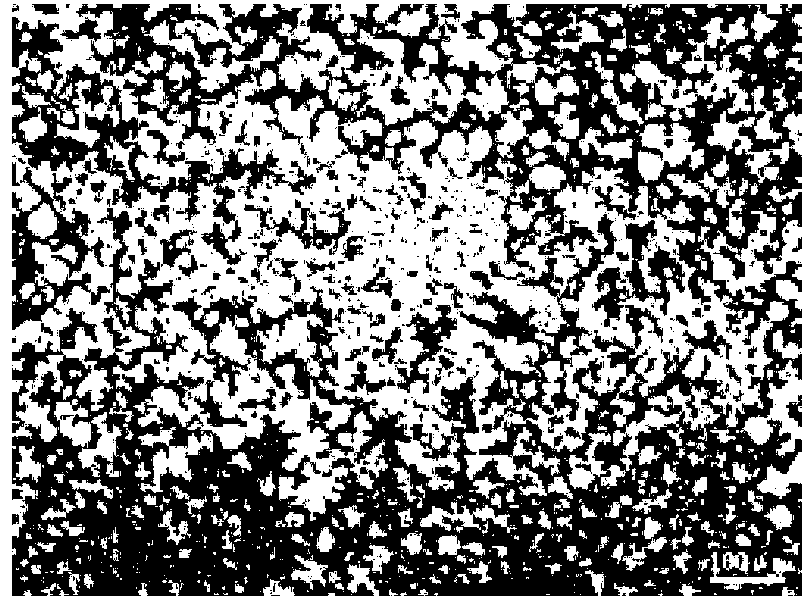

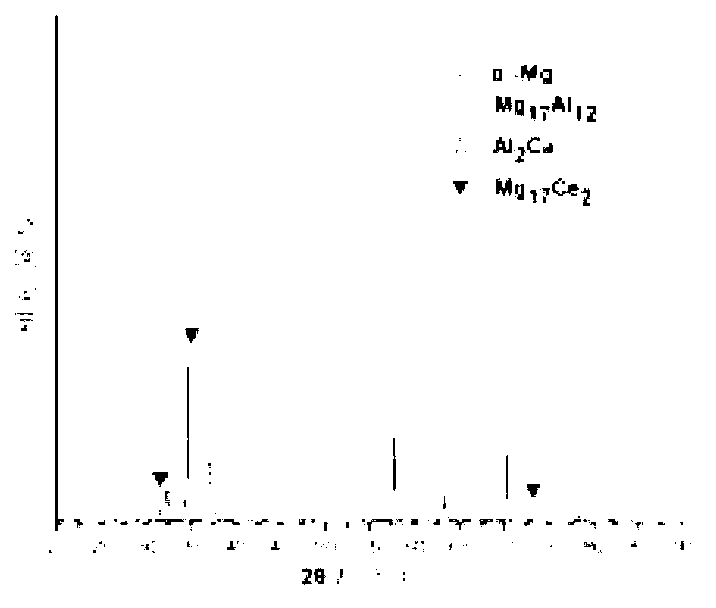

Calcium and cerium added flame-retardant magnesium alloy and preparation method thereof

The invention discloses a calcium and cerium added flame-retardant magnesium alloy and a preparation method thereof. The flame-retardant magnesium alloy comprises the following elements in percentage by mass: 85.90-88.03% of Mg, 8.18-9.15% of Al, 0.43-0.87% of Zn, 0.16-0.38% of Mn, 2.20-2.50% of Ca, 1.00-1.20% of Ce. The preparation method of the alloy is implemented through compositely adding Mg (29.9wt% of Ca)-Mg (30.8wt% of Ce) intermediate alloy into an AZ91D magnesium alloy melt, so that a dense protective oxide film is generated on the surface of the magnesium alloy melt, thereby preventing the alloying approach of magnesium alloy burning; the magnesium alloy can be smelted under the condition of no fusing agent or gas protection measures. Through carrying out an appropriate heat treatment process on a magnesium alloy sample, the cast magnesium alloy disclosed by the invention both has good flame retardant properties and good mechanical properties.

Owner:HEBEI UNIV OF TECH

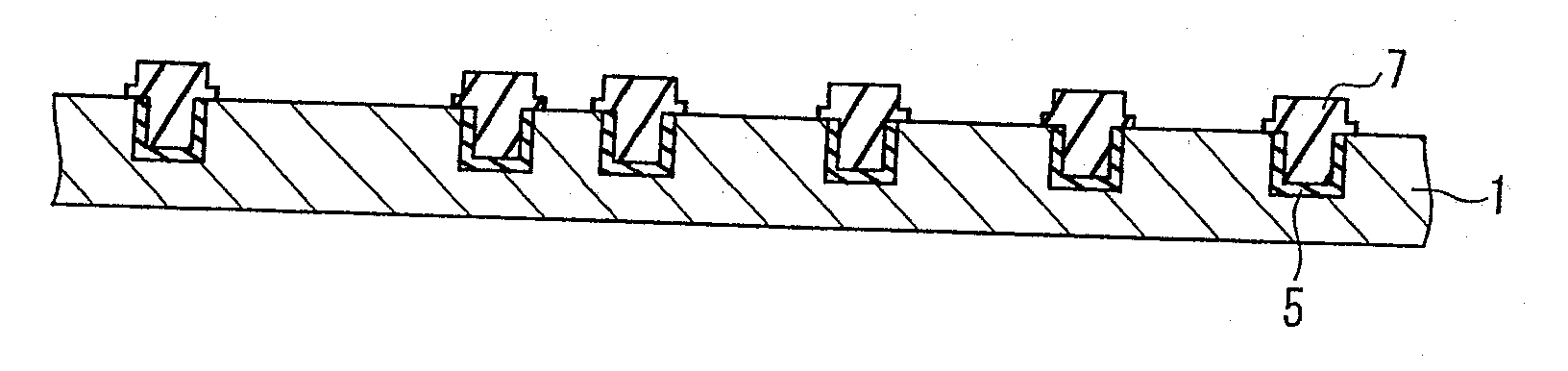

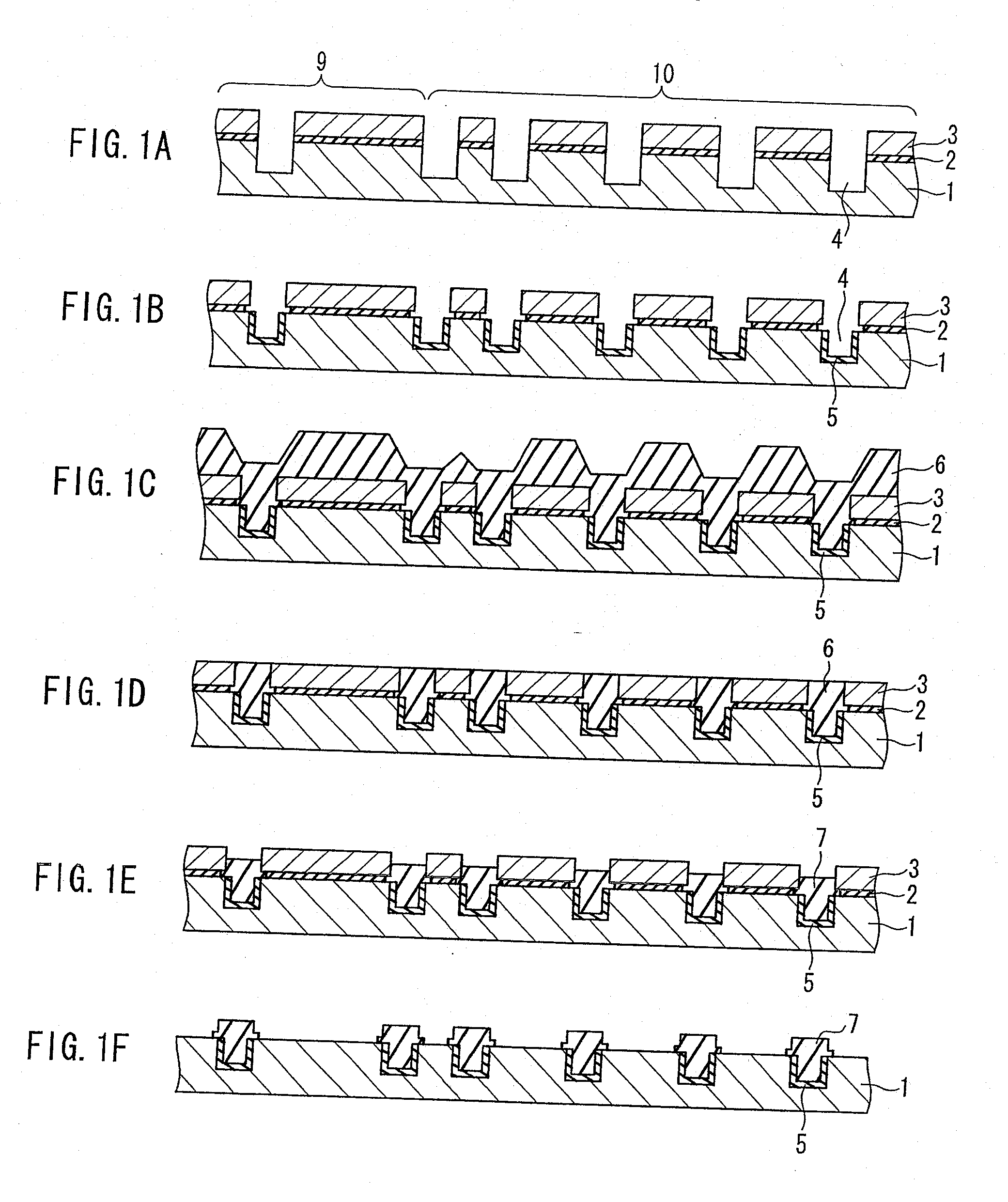

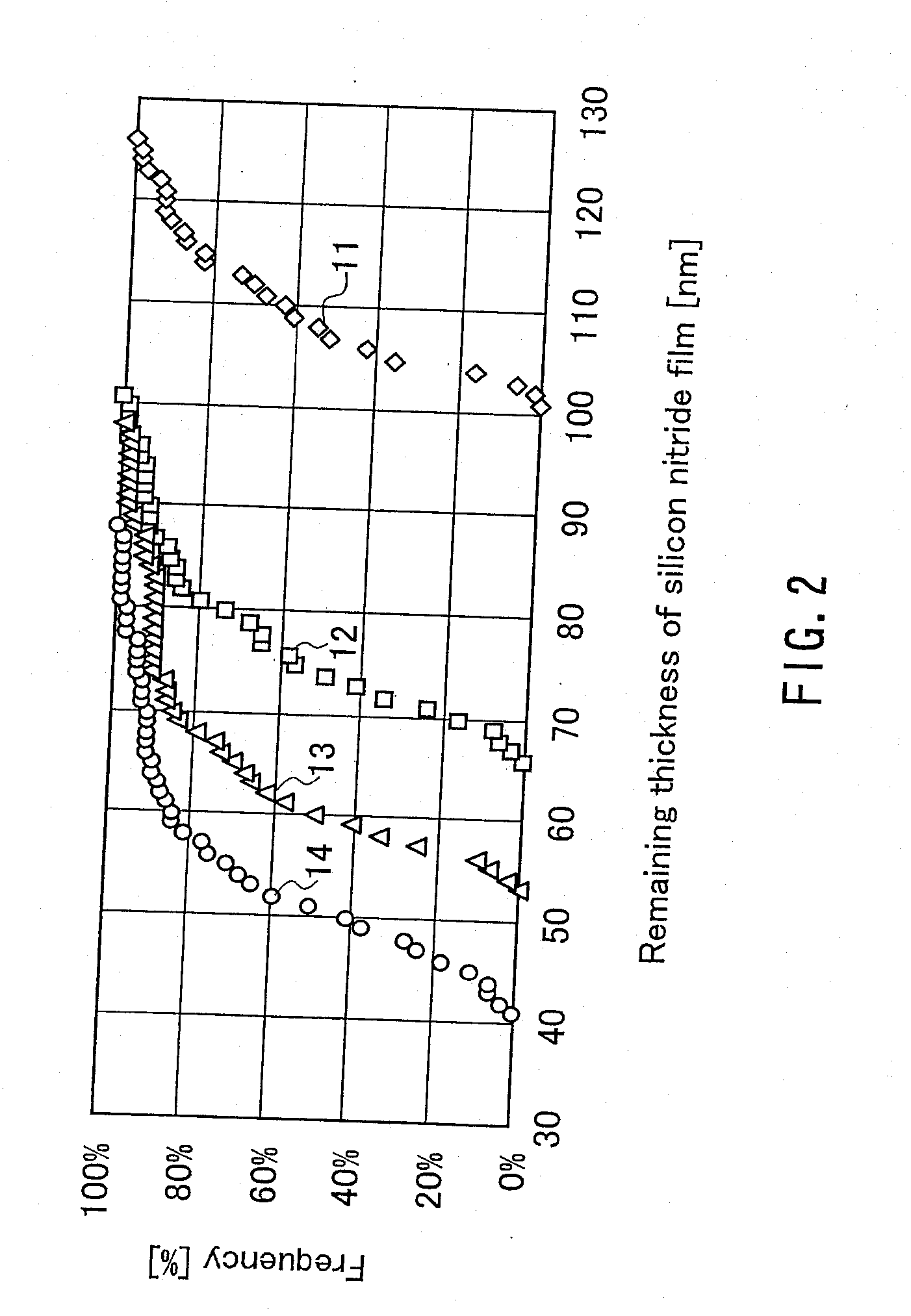

Semiconductor device and method for producing the same

InactiveUS20070087518A1Suppress generationImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingFine structureDevice material

A method for forming STIs in a semiconductor substrate includes forming a protective oxide film on the semiconductor substrate and forming a silicon nitride film on the protective oxide film, performing a photolithography and a dry etching so as to penetrate the silicon nitride film and the protective oxide film and remove part of the semiconductor substrate, thus forming groove portions, forming a buried oxide film in the groove portions and on the silicon nitride film, removing the buried oxide film on the silicon nitride film and a surface portion of the silicon nitride film by a CMP, and removing part of the buried oxide film deposited in the groove portions by a wet etching. It is possible to provide a method for producing STIs capable of forming uniform STI step heights in a semiconductor device with a fine structure.

Owner:PANASONIC CORP

Chloride-free thermal batteries using molten nitrate electrolytes

ActiveUS7629075B2Shorten activation timeReduce weightDeferred-action cellsCell electrodesHigh cellDecomposition

Thermal batteries using molten nitrate electrolytes offer significantly higher cell voltages and marked improvements in energy and power densities over present thermal batteries. However, a major problem is gas-evolution reactions involving the molten nitrate electrolytes. This gassing problem has blocked the advantages offered by thermal batteries using molten nitrates. The solution to this gassing problem is to eliminate the chloride ion contaminates. The most important step in reducing chloride contamination is the avoidance of potassium perchlorate (KClO4) or any other chlorine-containing substances that can decompose to produce chloride ions in any thermal battery component. The Fe+KClO4 pyrotechnic used to activate thermal batteries is a key example. The decomposition of such substances into chloride ions (Cl—) results in passivating-film breakdown and gas-producing reactions with the molten nitrate electrolyte. These reactions largely involve the lithium-component of the anode used in thermal batteries such as Li—Fe (LAN), Li—Si, and Li—Al. The introduction of chloride ions into the nitrate melt via the pyrotechnic materials produces a rapid breakdown of the protective oxide film on lithium-based anodes and leads to gas-producing reactions.

Owner:AXIENT LLC

Oxidation resistant rhenium alloys

InactiveUS20030206823A1Avoid attackBearing componentsSliding contact bearingsRheniumOxidation resistant

An alloy based on a refractory metal such as rhenium resists oxidation by the inclusion of alloying substances with affinity for oxygen or other oxidizing substances. This alloy has excellent high temperature strength and will resist oxidation. The alloy includes oxidation resistant substances, such as soluble metals, that attract oxygen and may form a protective oxide layer over the remaining portion of the rhenium-alloy part or piece. Such soluble alloying constituents may include chromium, cobalt, nickel, titanium, thorium, aluminum, hafnium, vanadium, silicon, aluminum, and yttrium.

Owner:HONEYWELL INT INC

Method of manufacturing semiconductor device

InactiveUS7015107B2Suppress surface roughnessImprove gate reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesSurface roughnessEngineering

When a dummy sidewall and source and drain regions are once formed and then the dummy sidewall is removed to extend the source and drain regions, the removal of the dummy sidewall is performed after formation of a protective oxide film on a gate electrode and on the major surfaces of the source and drain regions. This efficiently prevents conventional surface roughness of the upper surface of the gate electrode and the impurity region due to the removal of the dummy sidewall.

Owner:RENESAS TECH CORP

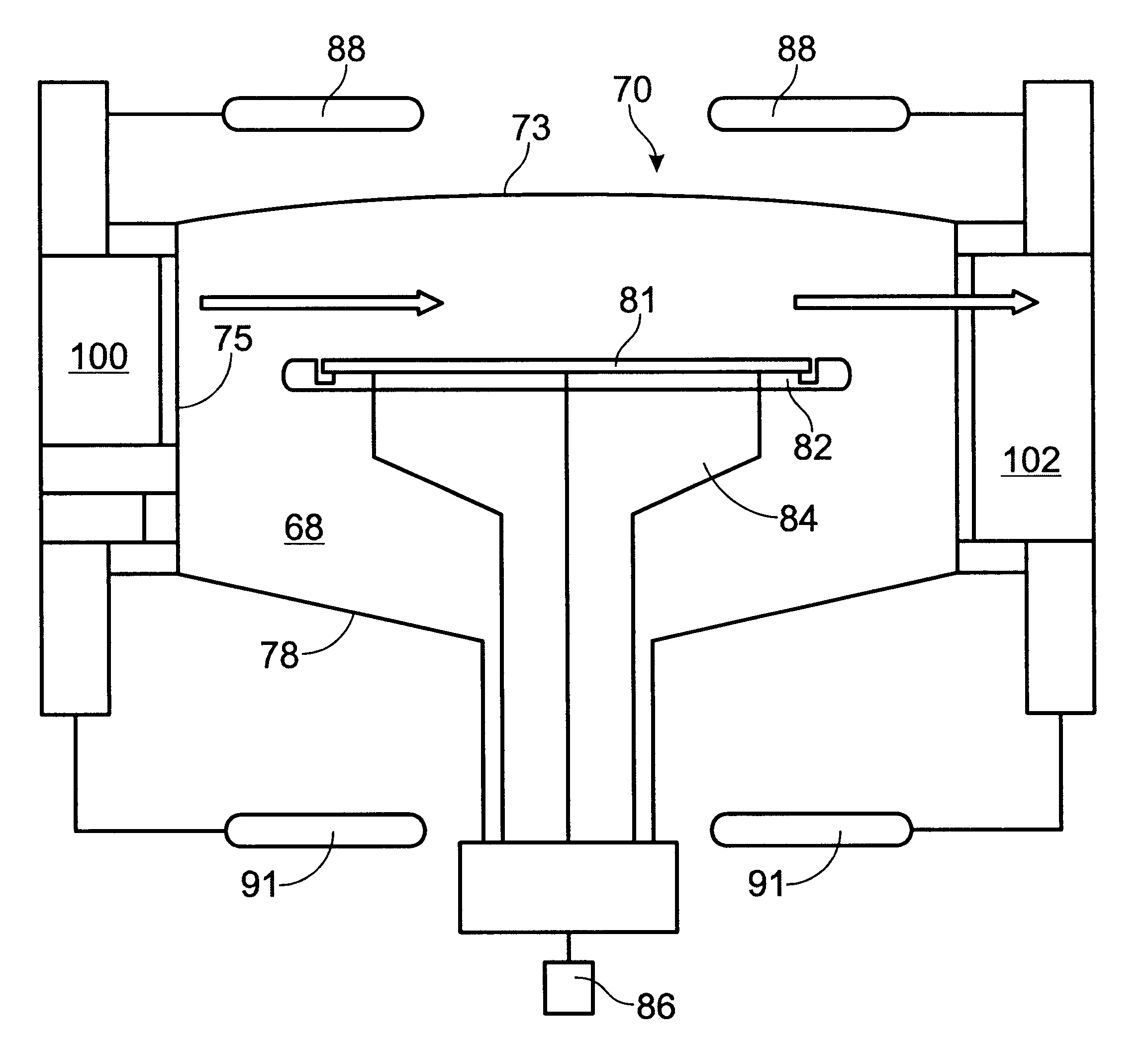

In-situ post epitaxial treatment process

InactiveUS6562128B1Elimination of costly and time-consumingCostly and time-consuming and stepPolycrystalline material growthAfter-treatment detailsProtective oxideSurface response

A process for forming an epitaxial layer on a semiconductor wafer substrate is provided. The process comprises providing a semiconductor wafer substrate and an area for forming an epitaxial layer on said semiconductor wafer substrate. The formation area consists essentially of an epitaxial layer process chamber. The semiconductor wafer substrate is introduced into the epitaxial layer process chamber and an epitaxial layer is formed on at least one surface of the semiconductor wafer substrate. Then, a chemical reagent is introduced into the epitaxial layer process chamber. The chemical reagent reacts with the epitaxial layer surface in situ to form an outer protective oxide layer.

Owner:SEH AMERICA

Hole sealing agent, preparation method and application thereof, coating film, preparation method of coating film and anti-corrosion product

ActiveCN111718606AGood dispersionEvenly dispersedFireproof paintsSurface reaction electrolytic coatingNanoparticles dispersionProtective oxide

The invention relates to a hole sealing agent, a preparation method and application thereof, a coating film, a preparation method of the coating film and an anti-corrosion product. The hole sealing agent comprises oxidation modified nano aluminum powder, oxidation modified nano nickel powder, nano titanium dioxide, nano silicon dioxide, a silane coupling agent and silicon dioxide sol, wherein protective oxides are formed on the surfaces of the modified oxidation-modified nano aluminum powder and oxidation-modified nano nickel powder, can resist corrosion of corrosive substances, have high dispersity and can permeate into defective positions in the coating; meanwhile, the silicon dioxide sol can promote the dispersion of nanoparticles, and the silicon dioxide sol and the silane coupling agent can form an effective hole sealing layer on the surface of the coating; the nano titanium dioxide powder and the nano silicon dioxide powder are uniformly dispersed under the action of the silane coupling agent, so that agglomeration of the nano powder can be reduced, pores of the coating can be effectively filled with nano particles in the hole sealing process, and the high-temperature resistance and the corrosion resistance of the coating are further improved.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com