Hole sealing agent, preparation method and application thereof, coating film, preparation method of coating film and anti-corrosion product

A technology of sealing agent and coating film, which is applied in the direction of anti-corrosion coating, surface reaction electrolytic coating, coating, etc., can solve the problems of low temperature resistance, restriction, and restriction of the use of inorganic sealing agent, so as to improve high temperature resistance, Improve the effect of high temperature resistance and reduce agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

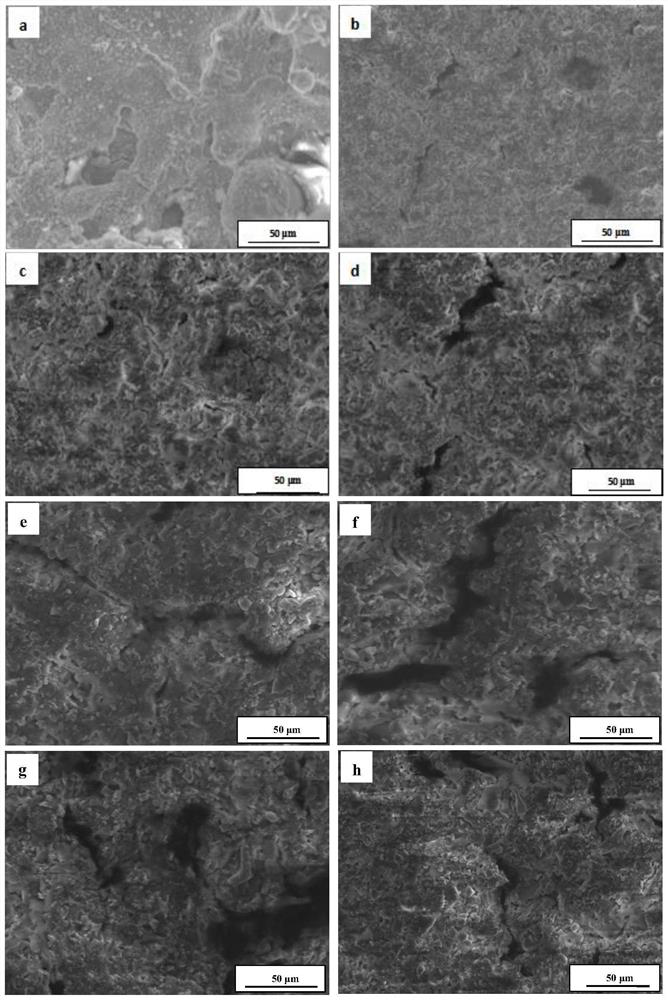

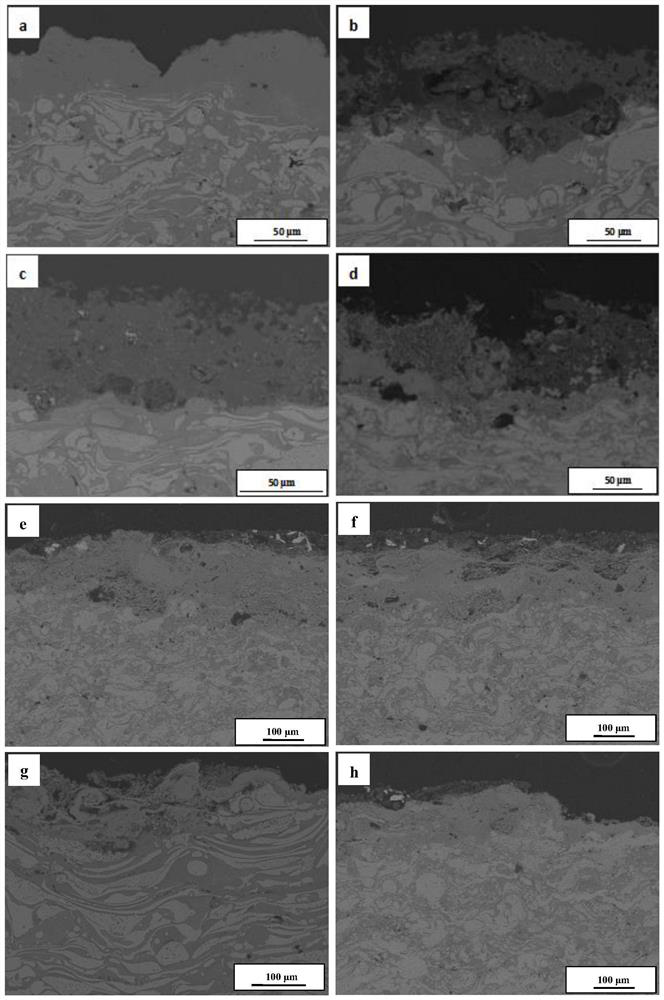

Image

Examples

preparation example Construction

[0054] One embodiment of the present invention also provides a method for preparing a sealing agent, comprising the following steps:

[0055] Mix oxidation-modified nano-aluminum powder, oxidation-modified nano-nickel powder, nano-titanium dioxide and nano-silicon dioxide, add them to the silica sol, and then add a silane coupling agent to prepare the sealing agent.

[0056] On the one hand, the modified oxidation-modified nano-aluminum powder and oxidation-modified nano-nickel powder form protective oxides on the surface, which can resist the erosion of corrosive substances; and have high dispersibility, which can penetrate into the coating effectively On the other hand, due to the nanoparticle effect, during the use of the sealing agent, the oxidation-modified nano-aluminum powder and oxidation-modified nano-nickel powder can be further oxidized at a lower temperature to form dense dioxide Aluminum and nickel oxide, together with nano-titanium dioxide and nano-silicon dioxid...

Embodiment 1

[0099] 1) Heat the nano-aluminum powder to 90°C under the condition of being filled with Ar gas, and then slowly fill it with a mixture of argon, water vapor and oxygen, wherein the volumes occupied by argon, water vapor and oxygen are respectively 65%, 33% and 2%, after reacting for 30-60 minutes, move the nano-aluminum powder to a normal temperature protective gas for cooling to obtain an oxidation-modified nano-aluminum powder.

[0100] 2) Heat the nano-nickel powder to 100°C in a protective gas filled with Ar gas, and then slowly fill it with a mixture of argon, water vapor and oxygen, wherein the volumes occupied by argon, water vapor and oxygen are respectively 65%, 33% and 2%, after reacting for 30-60 minutes, move the nano-nickel powder to normal temperature protective gas for cooling to obtain oxidation-modified nano-nickel powder.

[0101] 3) Mix 6g of ethyl orthosilicate, ethanol with a volume ratio of 4:1 to ethyl orthosilicate, and 0.75g of silane coupling agent, ...

Embodiment 2

[0108] 1) Heat the nano-aluminum powder to 90°C under the condition of being filled with Ar gas, and then slowly fill it with a mixture of argon, water vapor and oxygen, wherein the volumes occupied by argon, water vapor and oxygen are respectively 65%, 33% and 2%, after reacting for 30-60 minutes, move the nano-aluminum powder to a normal temperature protective gas for cooling to obtain an oxidation-modified nano-aluminum powder.

[0109] 2) Heat the nano-nickel powder to 100°C in a protective gas filled with Ar gas, and then slowly fill it with a mixture of argon, water vapor and oxygen, wherein the volumes occupied by argon, water vapor and oxygen are respectively 65%, 33% and 2%, after reacting for 30-60 minutes, move the nano-nickel powder to normal temperature protective gas for cooling to obtain oxidation-modified nano-nickel powder.

[0110] 3) Mix 4.2g tetraethyl orthosilicate, ethanol with a volume ratio of 4:1 to tetraethyl orthosilicate, and 0.525g silane coupling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com