Tailing sand mortar dry blend and mortar preparation method thereby

A technology of tailings sand and dry mixture, which is applied in the field of building materials, can solve the problems of limited application range, low economic benefits, and inability to solve tailings sand, etc., and achieve the goal of inhibiting volume shrinkage, reducing usage, and economical and practical resource utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

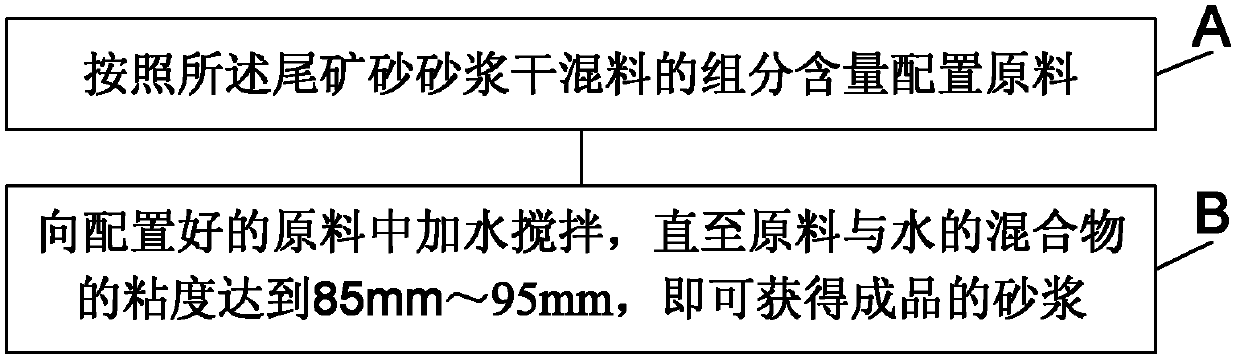

[0043] Such as figure 1 Shown, a kind of preparation method of tailings sand dry-mixed mortar, has applied tailings sand mortar dry-mixed material described in the above-mentioned technical scheme, and it specifically can comprise the following steps:

[0044] Step A, configuring raw materials according to the component content of the tailings sand mortar dry mix;

[0045] Specifically, select natural sand and tailings sand dried to constant weight, and mix them with ordinary Portland cement, cellulose ether, naphthalene-based water reducer and redispersible Latex powder mixed evenly.

[0046] In step B, add water to the prepared raw materials and stir until the consistency of the mixture of raw materials and water reaches 85mm-95mm, and the finished mortar can be obtained.

[0047] It can be seen that the embodiment of the present invention is suitable for preparing ordinary masonry mortar, plastering mortar and bonding mortar. The embodiment of the present invention uses ...

Embodiment 1

[0054] According to the component content ratio provided in Example 1 in Table 1, the natural sand and tailings sand were dried to constant weight, and then 3.26 kg of ordinary Portland cement, 3.26 kg of natural sand, 7.62 kg of tailings sand, cellulose 2.83g of ether, 141.4g of naphthalene-based water reducer, 7.07g of redispersible latex powder, and mix well; add water and stir until the consistency reaches 90mm, and the finished mortar can be obtained. After calculation, the specific performance of the mortar is as follows:

[0055] (1) Wet bulk density: 1916kg / m3;

[0056] (2) Water retention rate: 94%;

[0057] (3) 7d compressive strength: 7.8MPa;

[0058] (4) 28d compressive strength: 11.8MPa;

[0059] (5) 7d flexural strength: 3.1MPa;

[0060] (6) 28d flexural strength: 4.6MPa;

[0061] (7) 14d shrinkage rate: 0.39%;

[0062] (8) 28d shrinkage rate: 0.41%.

[0063] It can be seen that the mortar prepared by using the tailings sand mortar dry mix not only has goo...

Embodiment 2

[0065] According to the component content ratio provided in Example 2 in Table 1, the natural sand and tailings sand were dried to constant weight, and then 3.26 kg of ordinary Portland cement, 3.26 kg of natural sand, 7.62 kg of tailings sand, cellulose 2.83g of ether, 169.68g of naphthalene-based water reducer, 21.21g of redispersible latex powder, and mix evenly; add water and stir until the consistency reaches 92mm, and the finished mortar can be obtained. After calculation, the specific performance of the mortar is as follows:

[0066] (1) Wet bulk density: 1844kg / m3;

[0067] (2) Water retention rate: 97.5%;

[0068] (3) 7d compressive strength: 8.9MPa;

[0069] (4) 28d compressive strength: 13.3MPa;

[0070] (5) 7d flexural strength: 2.4MPa;

[0071] (6) 28d flexural strength: 3.6MPa;

[0072] (7) 14d shrinkage rate: 0.29%;

[0073] (8) 28d shrinkage rate: 0.39%.

[0074] It can be seen that the mortar prepared by using the tailings sand mortar dry mix not only h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com