Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71results about How to "Grain intact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature sintered high-permeability NiCuZn ferrite material

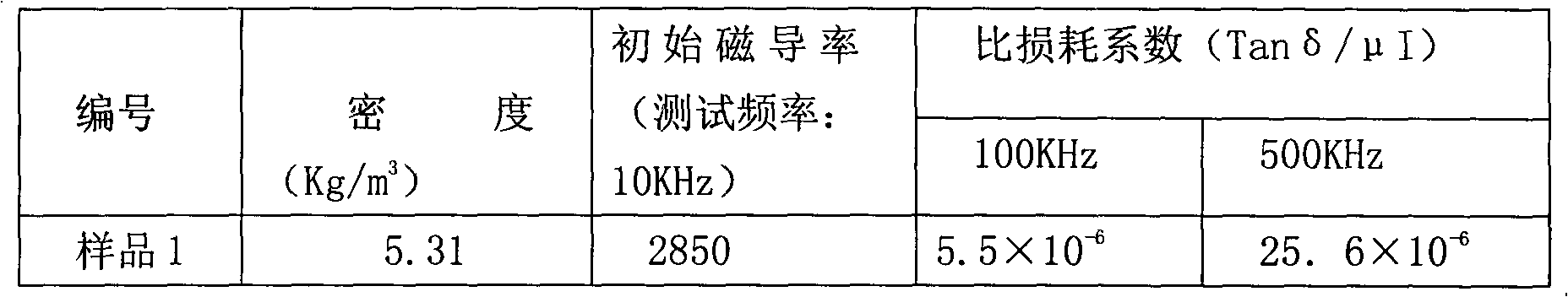

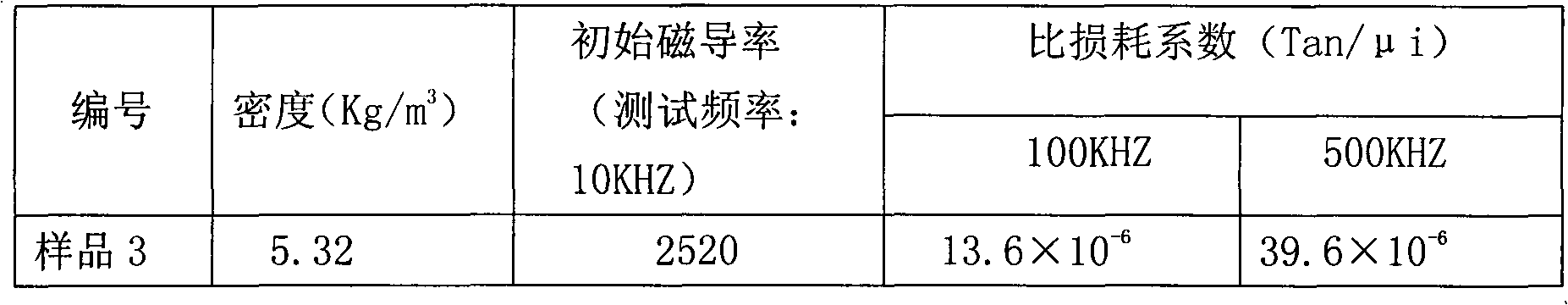

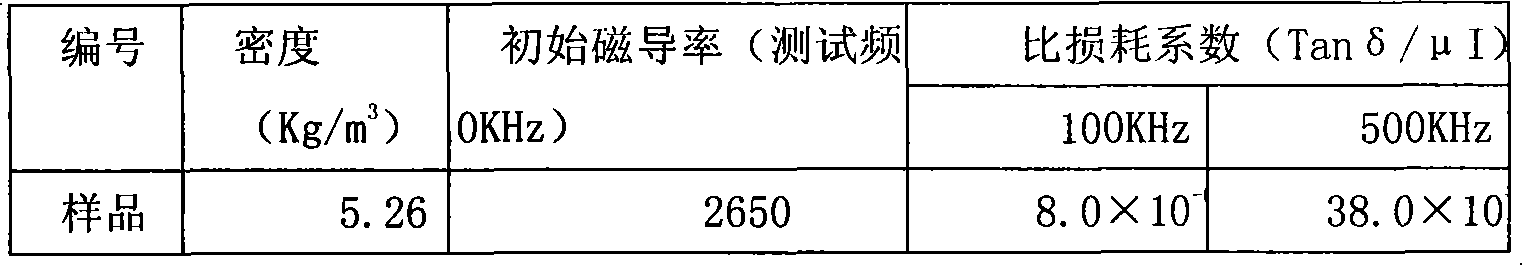

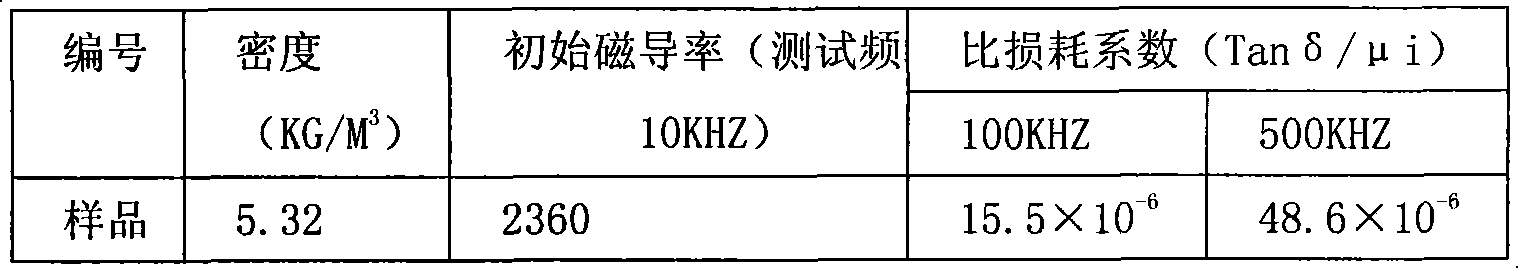

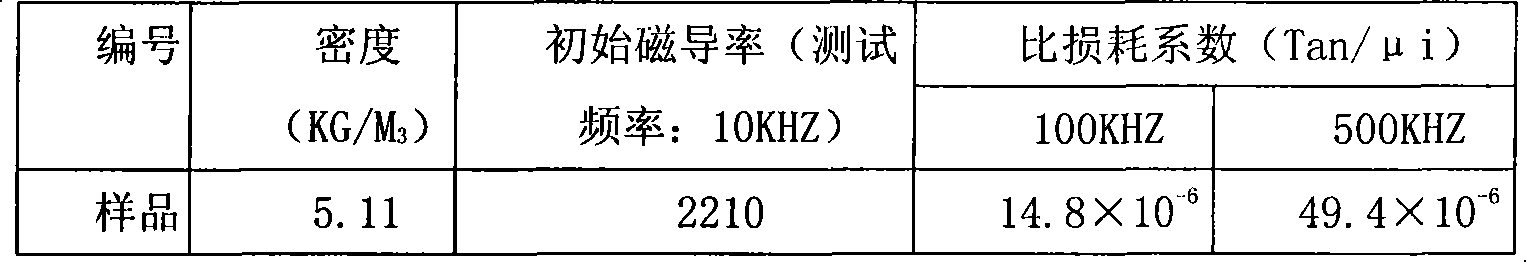

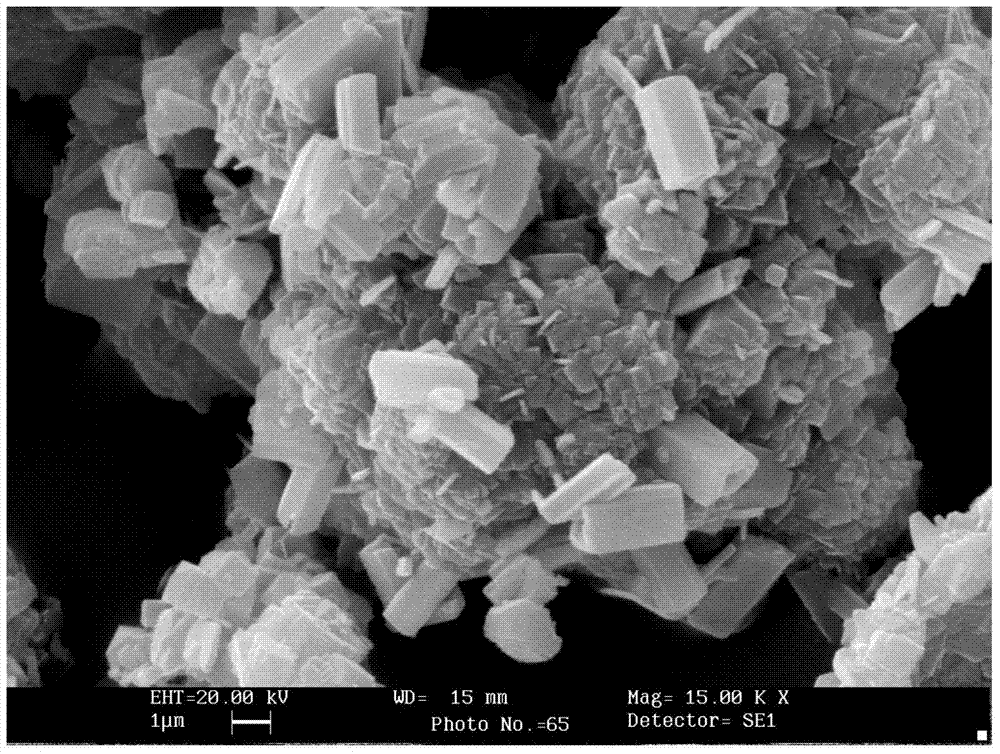

The invention discloses a low-temperature sintered high-permeability NiCuZn ferrite material for a wire wound chip inductor and a preparation method of the ferrite material. The ferrite material comprises the following main components based on oxide content: 40.5 to 49.6 moles percent of Fe2O3, 30 to 47 moles percent of ZnO, 5 to 20 moles percent of CuO and the balance of NiO. The preparation method comprises the following steps of: (1) mixing raw materials, (2) performing primary sanding, (3) performing primary spray drying and granulation, (4) pre-sintering, (5) adding trace elements, (6) performing secondary sanding, (7) performing secondary spray drying and granulation, (8) molding and (9) sintering. By adding auxiliary components such as NaCO3, B2O3, Ta2O5 and the like, the sintering temperature is greatly reduced, the sintering temperature is below 900 DEG C, the high-frequency electromagnetic performance of the material is greatly improved, the sintering density of the material is improved, the mechanical strength of the material is improved, and the manufacturing process requirement of the wire wound chip inductor is met; and on the other hand, energy is saved, and the producing and manufacturing costs are greatly reduced. The initial permeability of the material is 2,850; the specific loss coefficient of the material is less than 5.5*10<-6> under the test conditions of 100 kHz and 0.25mT; and the specific loss coefficient of the material is less than 25.6*10<-6> under the test conditions of 500 kHz and 0.25mT.

Owner:TAIXING ZHONGHENG BUILDING DECORATION ENGCO

Preparation method of lithium titanate cathode material with high tap density

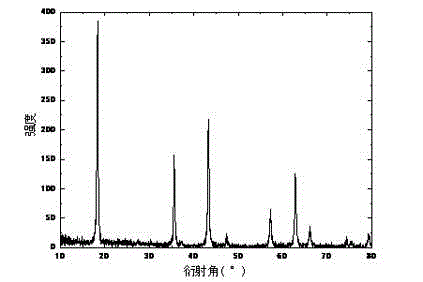

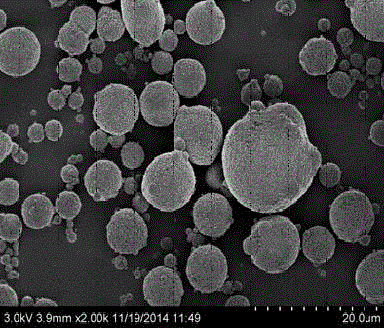

The invention discloses a preparation method of a lithium titanate cathode material with high tap density. The preparation method comprises the following steps: weighing a lithium source and a titanate source according to the mole ratio of Li to Ti being (0.80-0.85): 1, and taking deionized water as a medium; carrying out uniform stirring and spray drying; then, carrying out high-temperature calcination, wet ball-milling, secondary spray drying, secondary high-temperature sintering, and screening to obtain the lithium titanate cathode material. The lithium titanate cathode material obtained according to the preparation method has the advantages that the tap density can be improved to 1.2 g / cm<3> or above; lithium titanate particles obtained during the preparation are spherical, solid in structure and high in dispersity.

Owner:NORTHERN ALTAIR NANOTECH CO LTD

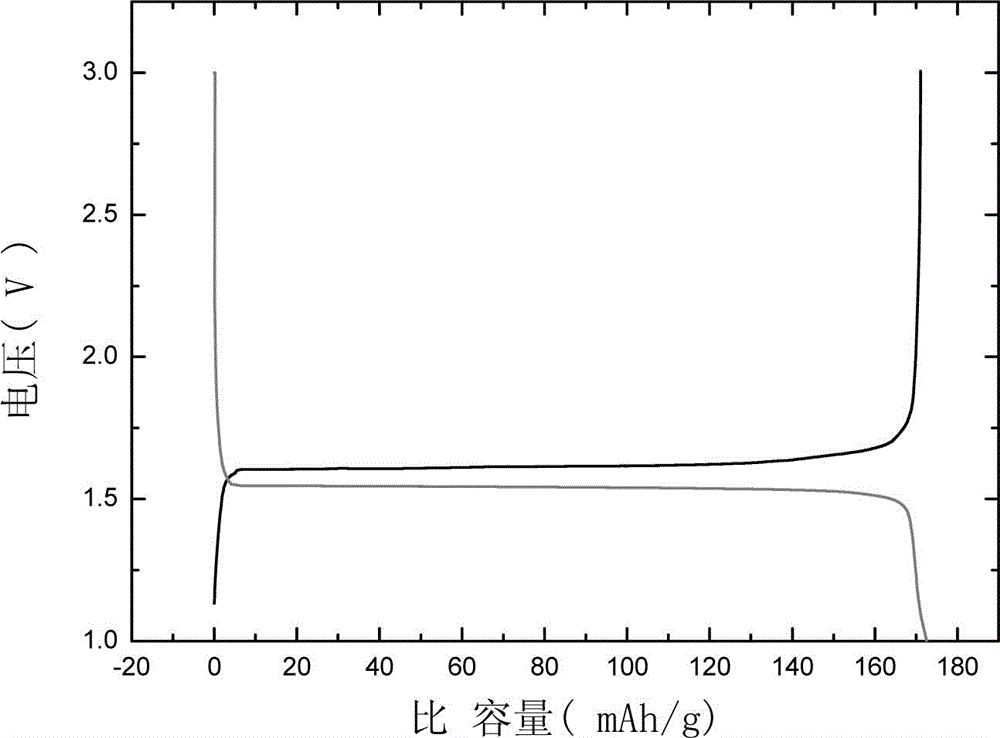

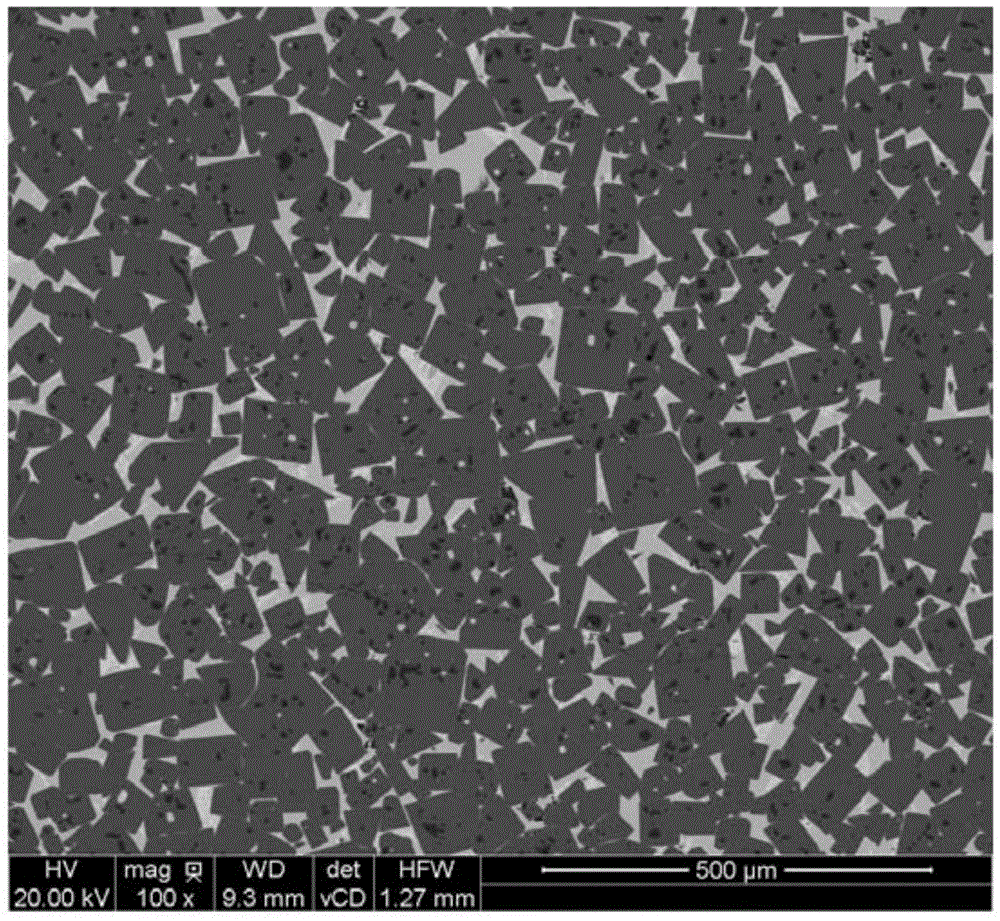

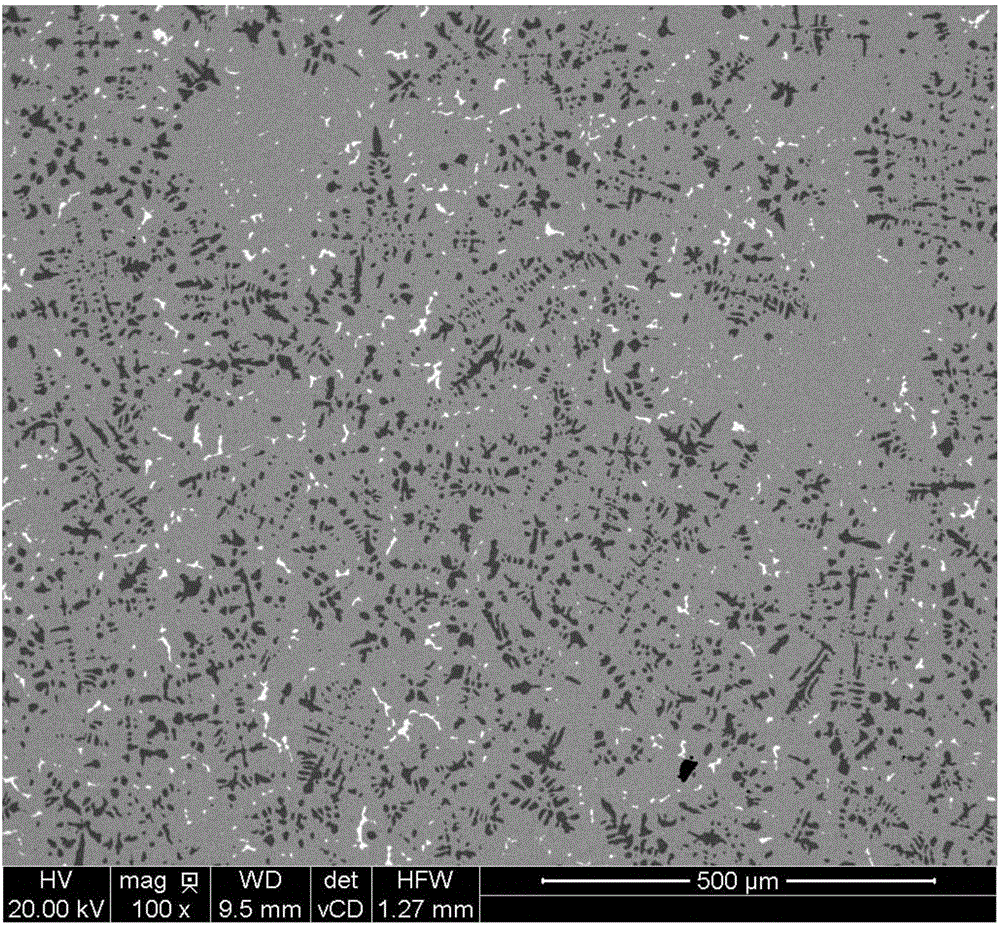

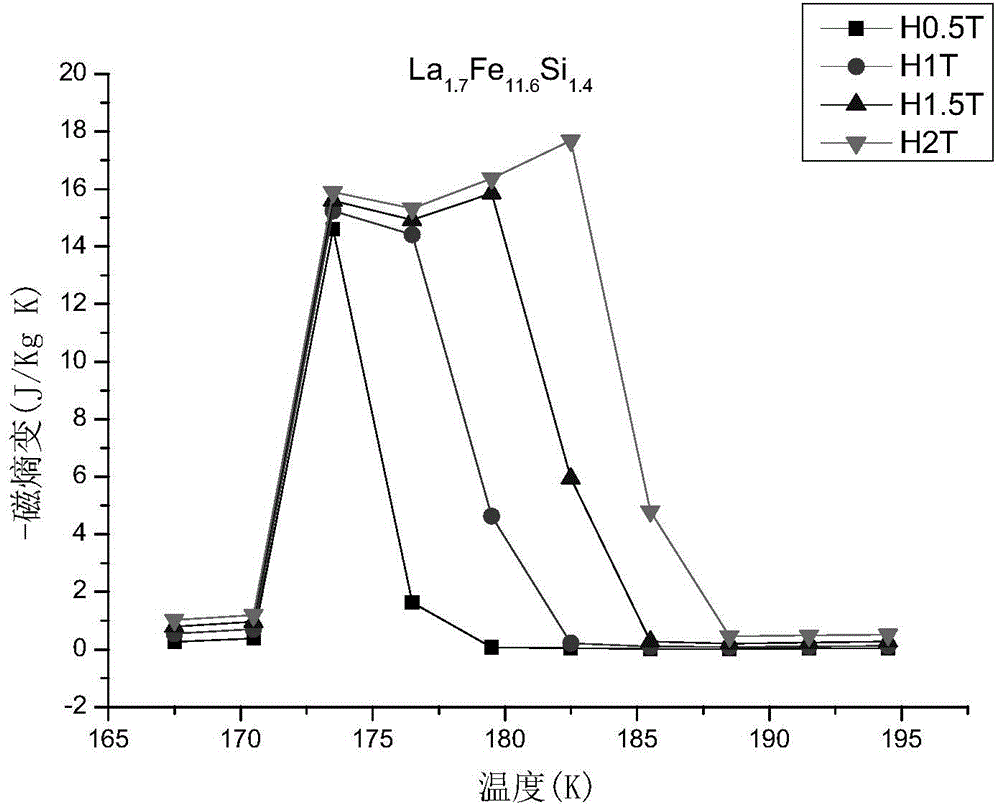

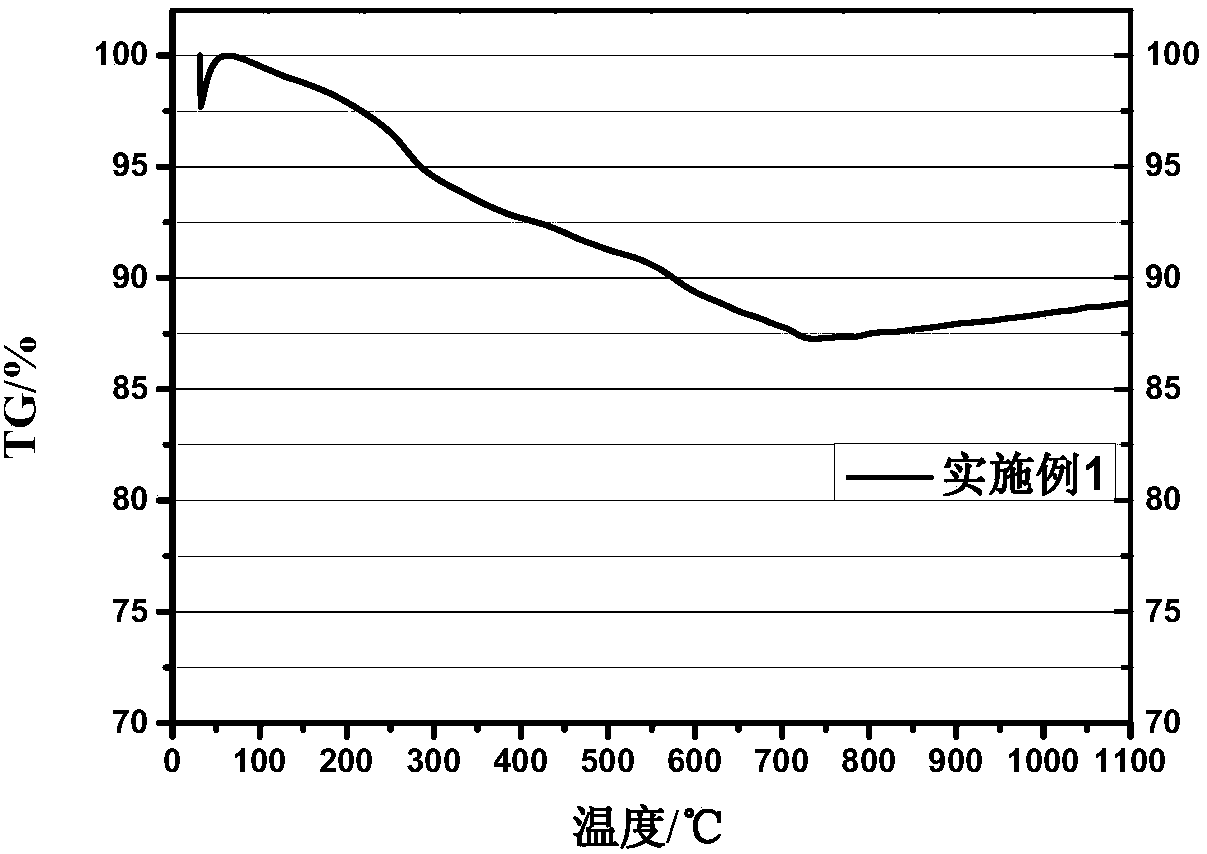

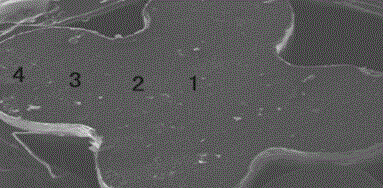

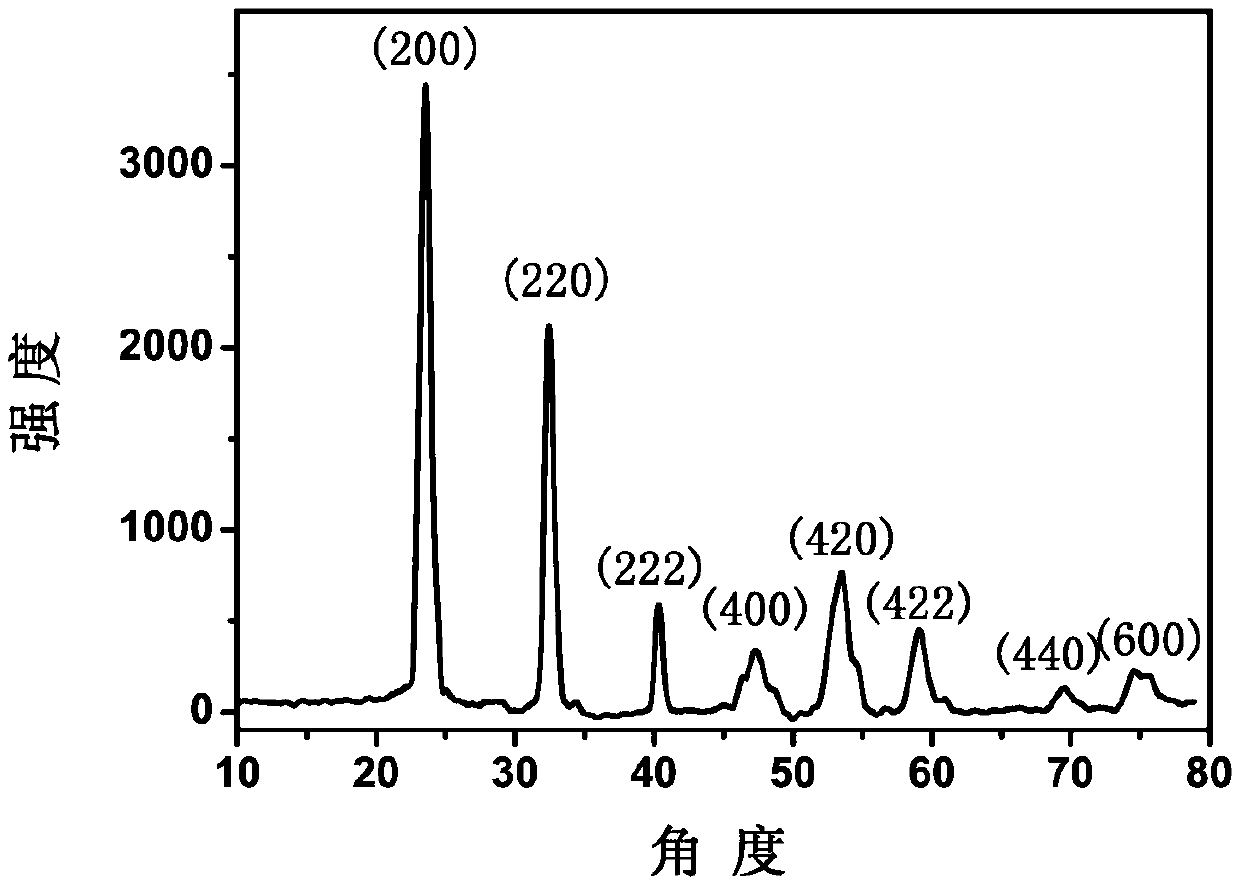

LaFeSi-based magnetic refrigeration material as well as preparation method and application thereof

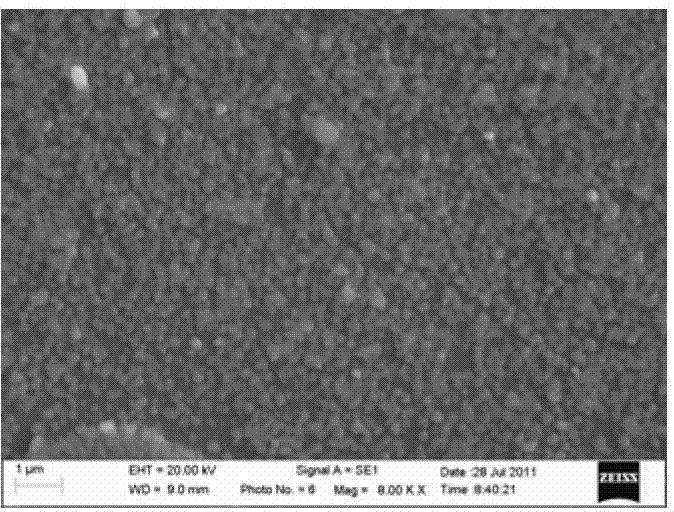

ActiveCN104694813AGrain intactMagnetic entropy change does not decreaseHeat-exchange elementsHysteresisStructural phase

The invention discloses a LaFeSi-based magnetic refrigeration material as well as a preparation method and application thereof. The chemical formula of the refrigeration material is La1+aFe13-b-cCobSicHd and the refrigeration material comprises a NaZn13 structural phase, wherein a is greater than 0 but less than or equal to 1, b is greater than or equal to 0 but less than or equal to 1.2, c is greater than or equal to 1.0 but less than or equal to 1.8 and d is greater than or equal to 0 but less than or equal to 3. The preparation method comprises the following steps: preparing raw materials according to the chemical formula and smelting in the presence of high-purity inert gas to obtain an alloy ingot with uniform components; annealing the alloy ingot in the presence of high-purity inert gas and then quickly quenching to obtain the La(Fe, Co, Si)13-based block magnetic refrigeration material containing the NaZn13 structural phase; and furthermore, introducing hydrogen into the block magnetic refrigeration material. According to the block magnetic refrigeration material, the forming period of a magnetic thermal phase is obviously shortened. The material before hydrogenation needs not to be mechanically crushed to small particles, and the block can be fully hydrogenated to be saturated. The material has a huge magnetocaloric effect and low hysteresis, so that the material is an ideal near room-temperature magnetic refrigeration working material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

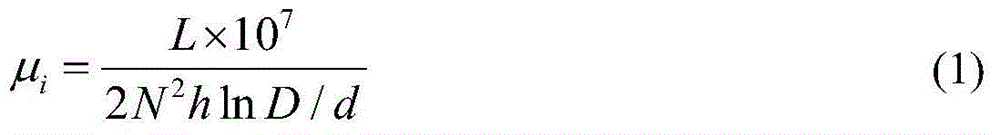

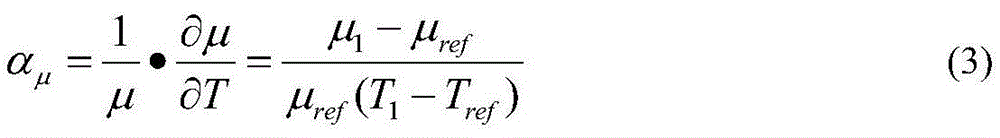

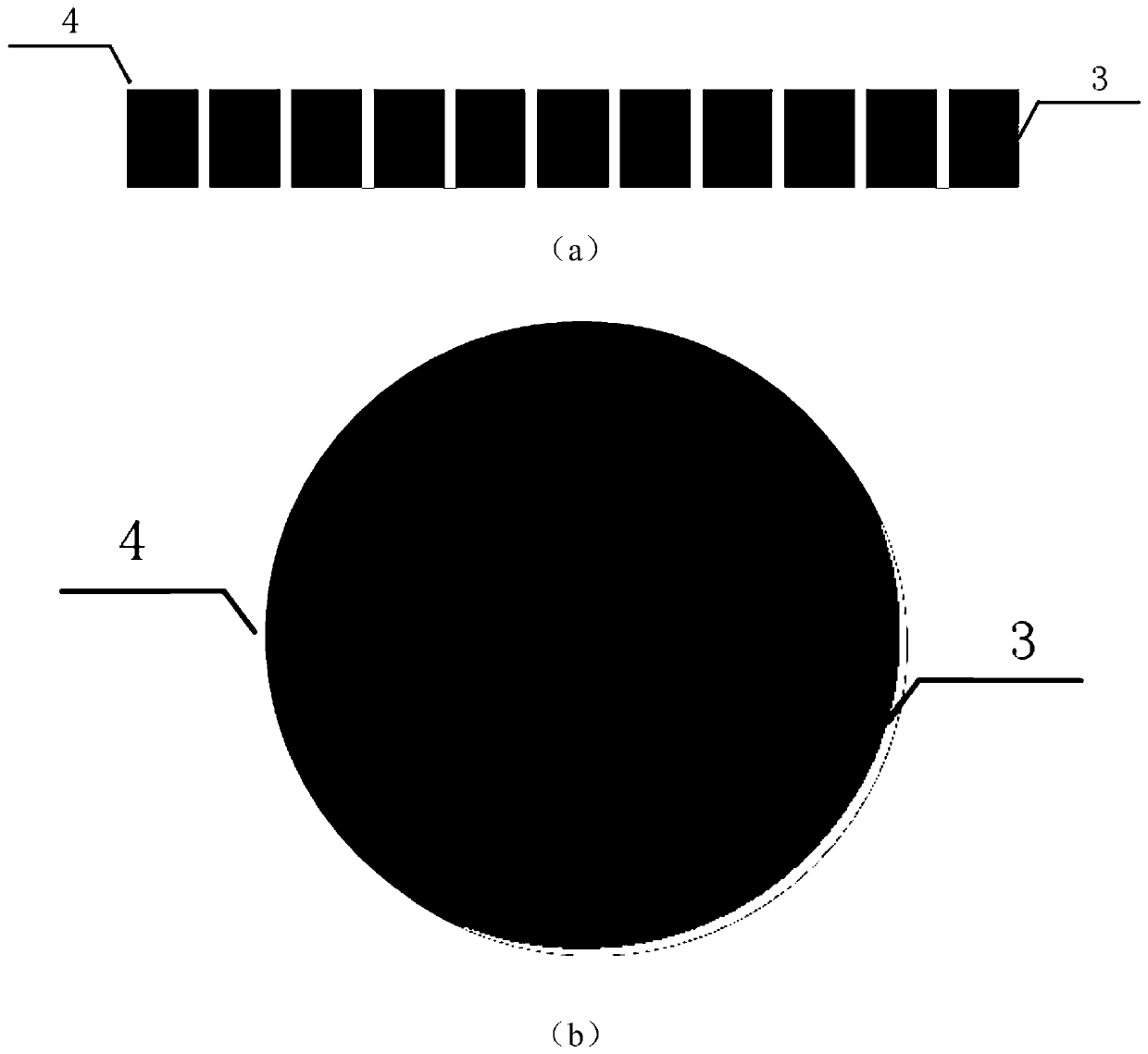

Low-temperature-coefficient high-impedance high-magnetic-permeability manganese zinc ferrite material and preparation method thereof

The invention discloses low-temperature-coefficient high-impedance high-magnetic-permeability manganese zinc ferrite material and a preparation method thereof, and belongs to the technical field of ferrite material preparation. The material comprises the components as follows: main components and at least two additives, wherein the main components comprise the following ingredients: 52.0 to 54.0 mol% of Fe2O3, 19.0 to 24.0 mol% of ZnO, 0.01 to 0.05 mol% of NiO, and the balance of MnO; the additives comprises the following ingredients: 0.01 to 0.08 wt% of CaCO3, 0.01 to 0.10 wt% of MoO3, 0.01 to 0.08 wt% of nano TiO2, 0.01 to 0.04 wt% of Bi2O3, 0.005 to 0.02 wt% of SiO2, 0.01 to 0.12 wt% of V2O5, 0.005 to 0.04 wt% of Nb2O5 and 0.005 to 0.04 wt% of B2O3. According to the invention, the material is uniform in size, obvious in grain boundary, and fewer in gas pores.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

Low-temp sintered aluminium nitride-base composition and its preparing process

A low-temp sintered AIN-base composition is prepared from AIN (50-80 wt%), lead borosilicate glass (15-50), and LiF (rest) through hot pressing and sinter, including heating and pressurizing by threestages, and holding temp at 950 or 1000 deg.C under 18-25 MPa for 2-8 hr. Its advantages include low sinter temp and density, high heat conductivity (11 W / m.k) and low cost.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

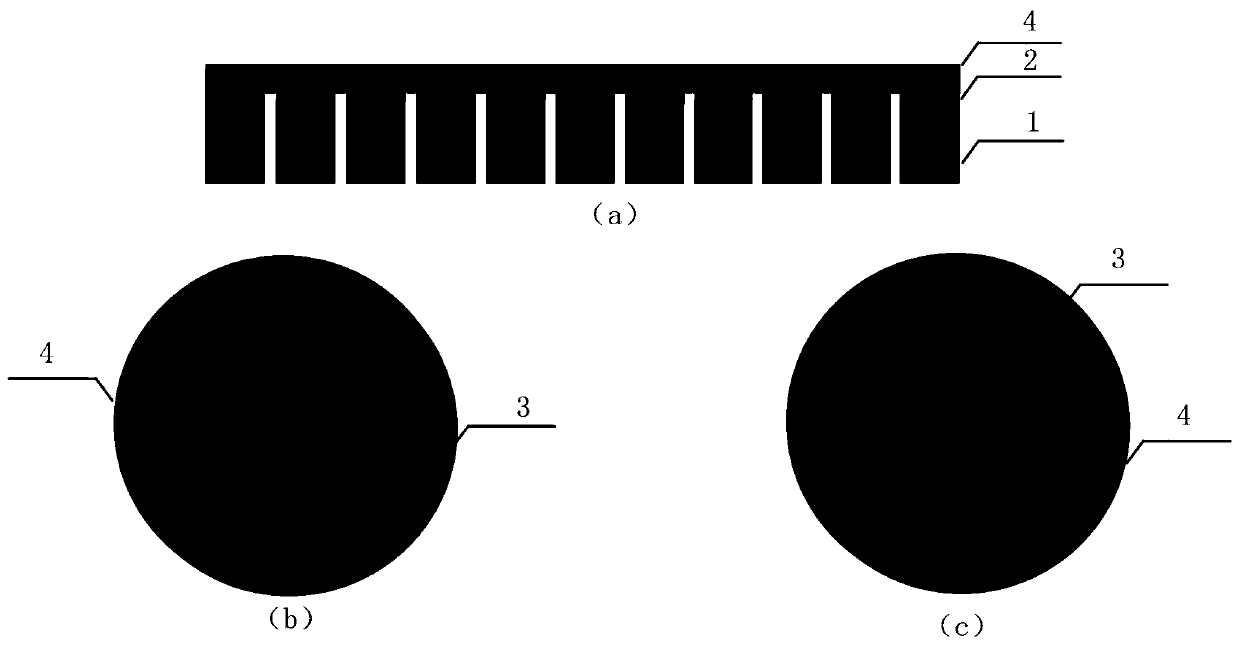

Diamond micro-channel Cu-based CVD diamond heat sink sheet and preparation method thereof

ActiveCN110557936AEasy to peelGood cooling performanceModifications by conduction heat transferHeat sinkNanotechnology

The invention discloses a diamond micro-channel Cu-based CVD diamond heat sink sheet and a preparation method thereof. The diamond micro-channel Cu-based CVD diamond heat sink sheet sequentially comprises a Cu substrate, a micro-through-hole template and a CVD diamond film from bottom to top, wherein the Cu substrate and the micro-through-hole template are provided with nano-diamond particles therebetween, the Cu substrate is embedded with a diamond micro-channel array, the diameter of each diamond micro-channel ranges from 0.3mm to 0.5mm, and the distance between every two micro-channels ranges from 2mm to 3mm. The heat dissipation effect of the heat sink sheet is superior to that of traditional heat sink sheets such as Ag, Cu and Al; the heat dissipation performance of the micro-channelCu-based diamond heat sink sheet is better; the nucleation density and the growth rate of diamond in the micro-through-hole are greatly improved; and the CVD selective growth of the diamond film is realized in the micro-through holes.

Owner:SHAANXI UNIV OF SCI & TECH

Method for producing roll collars by recycling tungsten carbide from waste hard alloy roll collars

InactiveCN102784918ACoarse granularitySave resourcesRecycling and recovery technologiesAlcohol contentAlloy

The invention discloses a method for producing roll collars by recycling tungsten carbide from waste hard alloy roll collars. The method includes the steps: recycling coarse-grain tungsten carbide serving as a raw material from the waste hard alloy roll collars, mixing the coarse-grain tungsten carbide with other raw materials according to a formula of the roll collars, placing the mixture into a rotary mill, adding industrial alcohol which has alcohol content more than 95.5% and account for 13.8%-15.7% of the weight of the raw materials into the mixture, milling the mixture for 22 to 24 hours, screening, drying, blending rubber, pressing, removing rubber, pressurizing 6MPa at the temperature ranging from 1410 DEG C to 1460 DEG C in a vacuum pressurizing sintering furnace for longer than 70min, and uncovering the furnace with the temperature not higher than 100 DEG C to obtain the hard alloy roll collars. The method is physical, pollution-free and low in cost, and the recycled tungsten carbide is complete in shape and unchanged in alloy property.

Owner:蓬莱市超硬复合材料有限公司

Preparation method of pseudo-boehmite with high purity and high crystallization degree

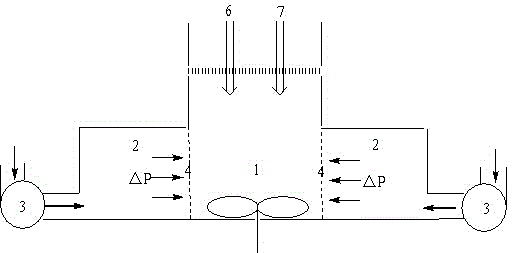

ActiveCN105585036AConstant concentrationReduce aggregation rateAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium oxides/hydroxidesAluminium hydroxideFuel oil

The invention discloses a preparation method of pseudo-boehmite with high purity and high crystallization degree. The method comprises the following steps: (1) bottom water is added into a pressure zone and a reaction zone of a reactor, and a stabilizing agent is added into water in the reaction zone; (2) an aqueous solution of aluminium salts and an alkaline solution are respectively injected into a feed inlet I and a feed inlet II at the upper part of the reaction zone of the reactor, a sol forming reaction is carried out, during the sol forming reaction process, when aluminium hydroxide sol reaches a certain concentration, a pressure pump pumps water in the pressure zone into a reaction zone through a semi-permeable membrane, the sol is kept in a concentration range, and the reaction is continuously carried out for a period of time; (3) after the reaction ends, a stirring paddle at the bottom of the reactor is started, pH value of the reactor is adjusted, temperature is rapidly raised to an aging temperature, after aging, filtering, washing and drying are carried out, the pseudo-boehmite is obtained. The pseudo-boehmite is prepared by a semi-permeable membrane penetration mode, and the obtained pseudo-boehmite has the advantages of high purity, high crystallization degree, and uniform particle size distribution; and the pseudo-boehmite is suitable for preparing carriers and catalysts of hydrotreatment catalysts for wax oil, heavy oil and other inferior raw materials.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

A-site high-entropy perovskite oxide MeTiO3 thermoelectric ceramic and preparation method thereof

The invention discloses A-site high-entropy perovskite oxide MeTiO3 thermoelectric ceramic and a preparation method thereof. The A-site high-entropy perovskite oxide MeTiO3 has a single-phase perovskite structure, the elements in the A-site high-entropy perovskite oxide MeTiO3 are uniformly distributed without agglomeration, and the A-site high-entropy perovskite oxide MeTiO3 has thermoelectric performance and can be used in the field of thermoelectric materials. The chemical composition of the A-bit high-entropy perovskite oxide MeTiO3 is (Ca < 0.2 > Sr < 0.2 > Ba < 0.2 > La < 0.2 > Pb < 0.2 >) TiO3, (Ca < 0.25 > Sr < 0.25 > Ba < 0.25 > La < 0.25 >) TiO3, (Ca < 0.25 > Sr < 0.25 > Ba < 0.25 > Pb < 0.25 >) TiO3, (Ca < 0.25 > Sr < 0.25 > Ba < 0.25 > Nd < 0.25 >) TiO3, (Ca < 0.25 > Sr < 0.25 > Ba < 0.25 > Sm < 0.25 >) TiO3, and (Ca < 0.25 > Sr < 0.25 > Ba < 0.25 > Eu < 0.25 >) TiO3. According to the invention, the high entropy of the perovskite structure is realized, the disorder degree of atom arrangement in the material composition is improved, the phonon scattering is increased, and the thermal conductivity is reduced, so that the thermoelectric performance is improved. In the sintering process, oxygen atoms are migrated and discharged through oxygen vacancies in material crystal lattices, the porosity is reduced, the ceramic density is improved, meanwhile, the oxygen vacancy concentration is improved, and the carrier concentration of the material is improved. By adopting a reduction annealing process of argon and carbon powder, the semiconduction of perovskite oxide is realized, the carrier concentration of the ceramic is improved, the conductivity is improved, and the thermoelectric performance is further improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

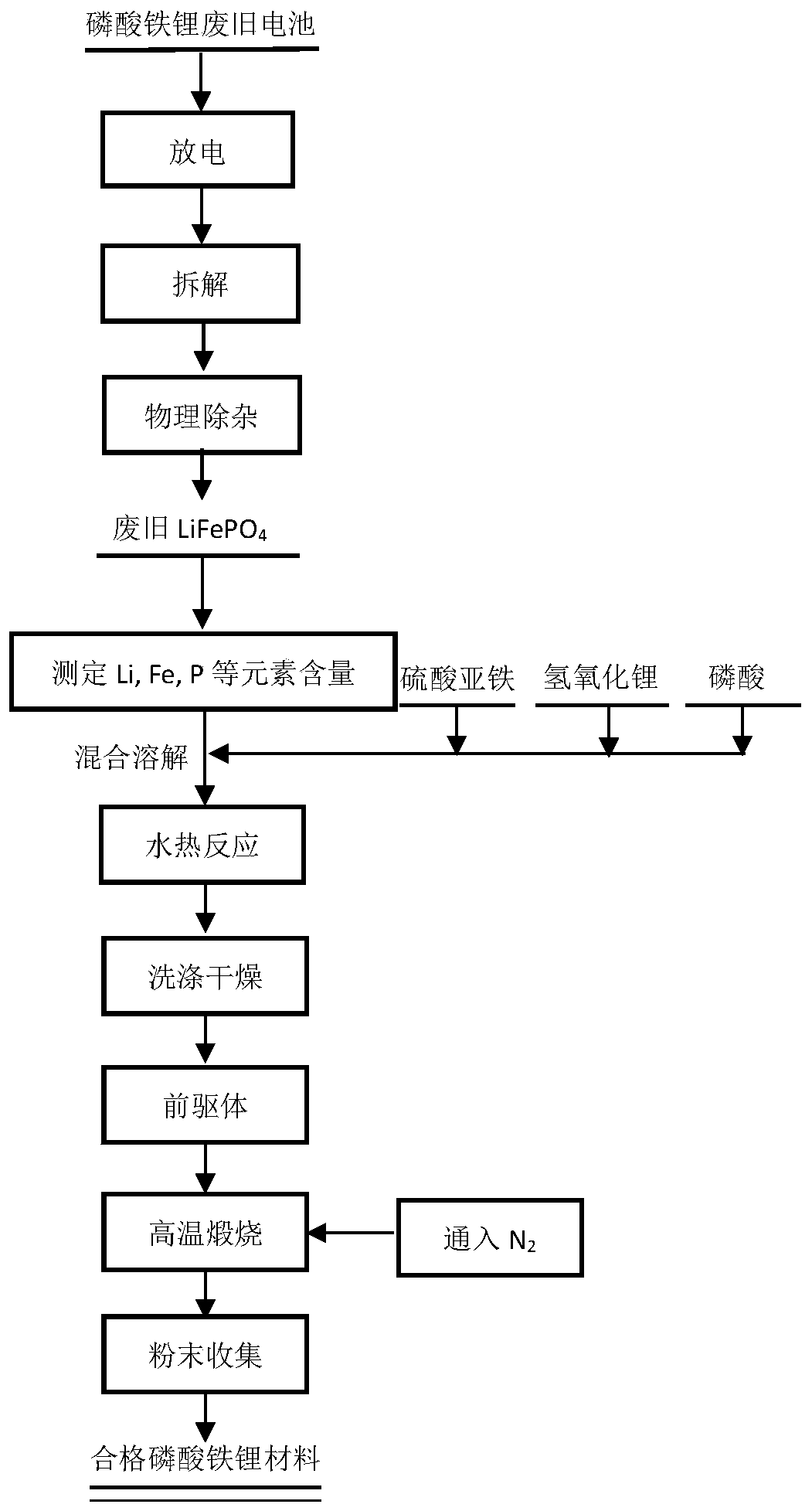

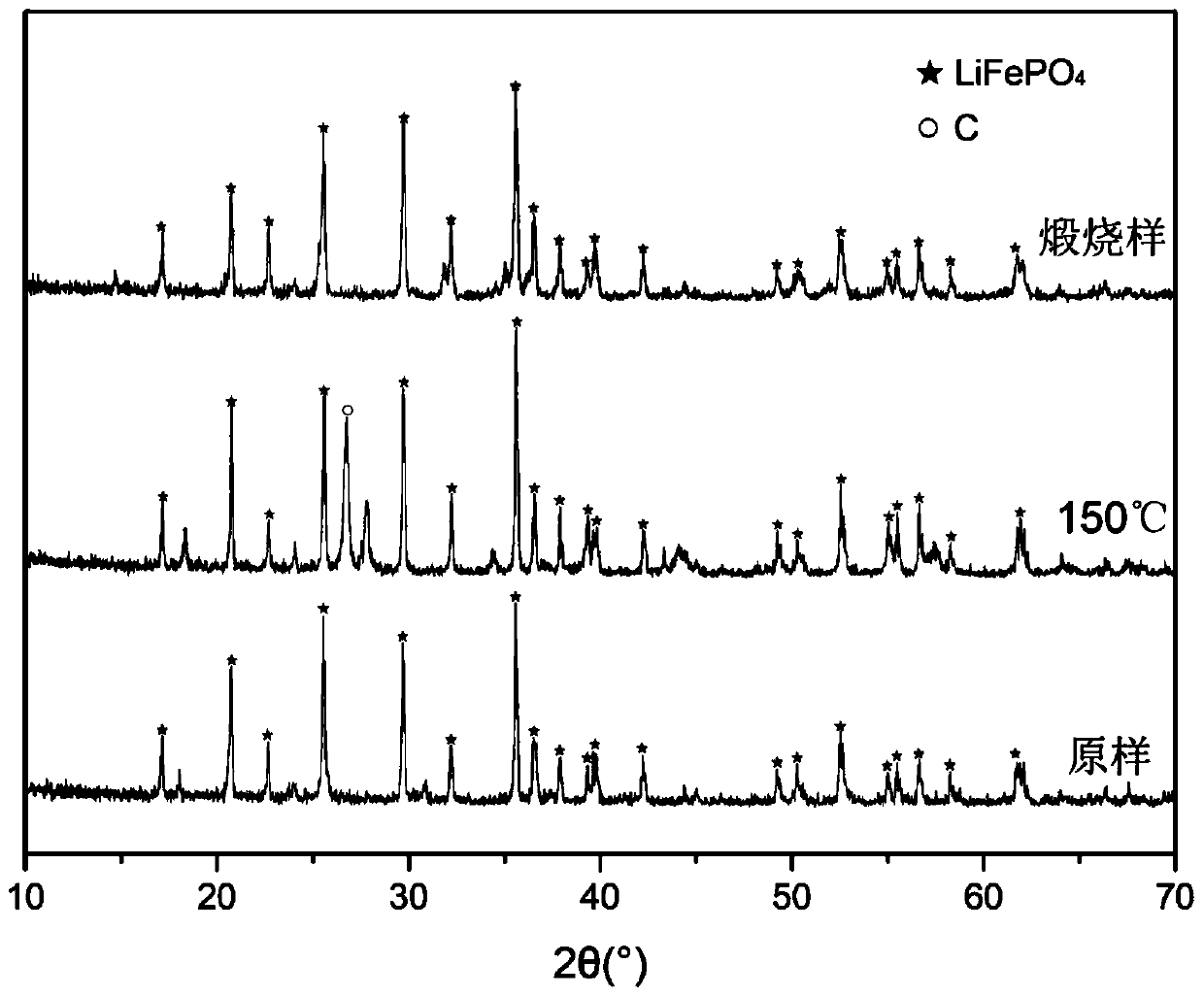

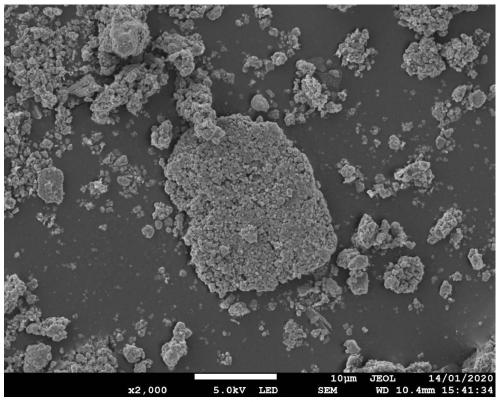

Method for repairing waste lithium iron phosphate material

ActiveCN111547697AReduce the introductionReunion smallCell electrodesWaste accumulators reclaimingCarbon coatingO-Phosphoric Acid

The invention relates to a method for repairing a waste lithium iron phosphate material. The method comprises the following steps: 1) measuring the contents of Li, Fe and P elements in the waste lithium iron phosphate material; 2) preparing a mixed solution containing lithium salt, ferric salt and phosphoric acid, adding the waste lithium iron phosphate material into the mixed solution according to a final stoichiometric ratio of Li:Fe:P of 0.75-1.25:1:1, stirring and mixing the components, and controlling the pH value of the mixed solution to be 5.5-8.5 by using ammonia water in the stirringprocess to obtain a mixture; 3) carrying out hydrothermal reaction on the mixture at 100-200 DEG C to obtain a lithium iron phosphate precursor, and 4) carrying out carbon coating reaction on the lithium iron phosphate precursor at 650-800 DEG C to obtain the repaired lithium iron phosphate battery material. The method realizes direct repair of the waste lithium iron phosphate battery positive electrode material.

Owner:CENT SOUTH UNIV

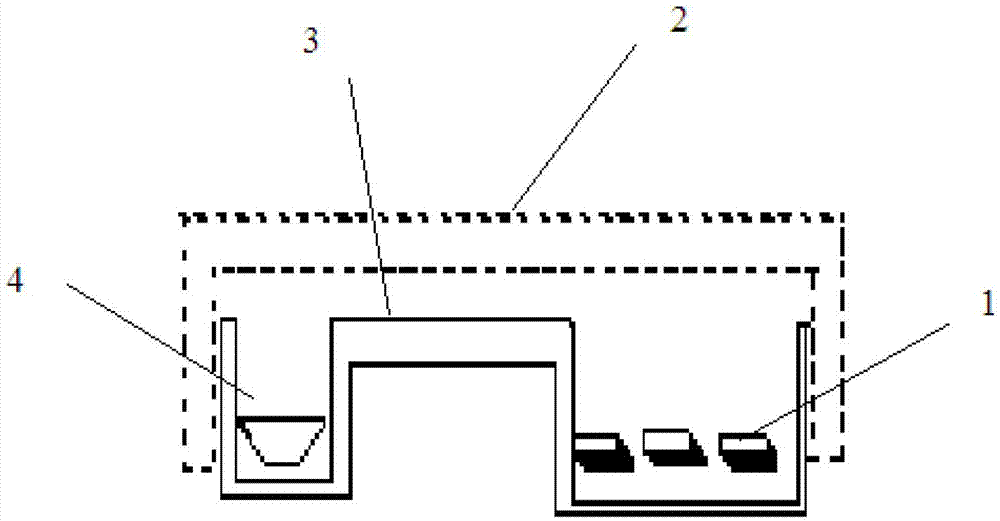

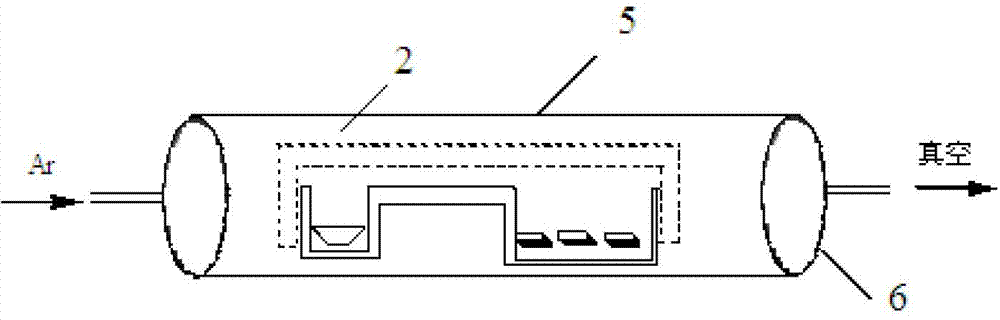

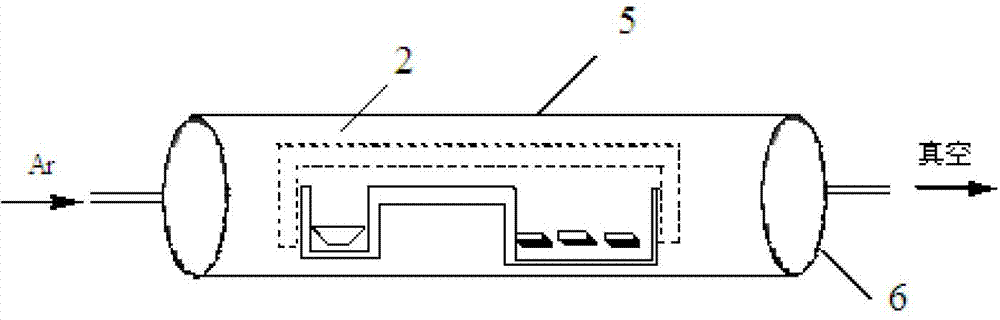

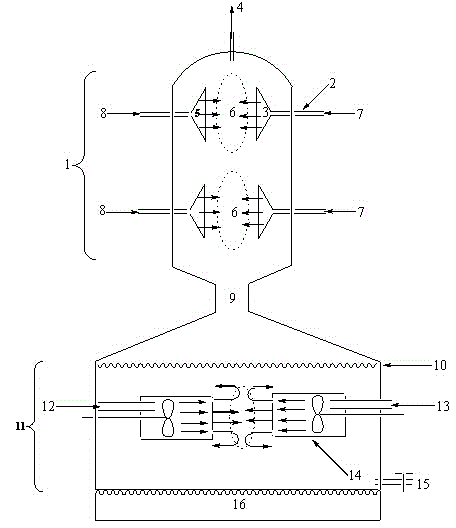

Apparatus and method for carrying out selenylation treatment on CIGS (copper indium gallium selenide) thin films and CIGS thin-film device

InactiveCN103088301AReduce leakageHigh Selenization EfficiencyVacuum evaporation coatingSputtering coatingIndiumThermal insulation

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

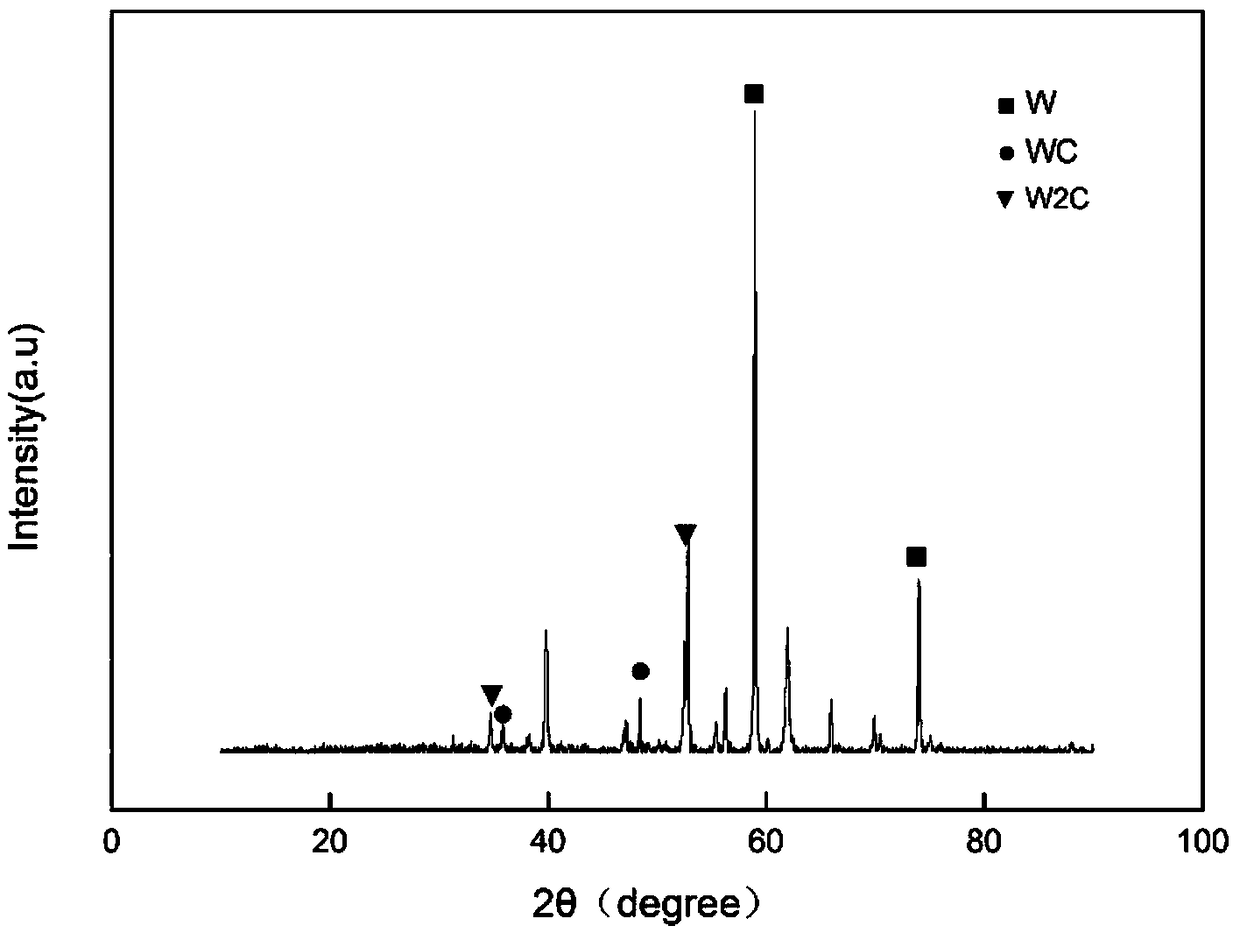

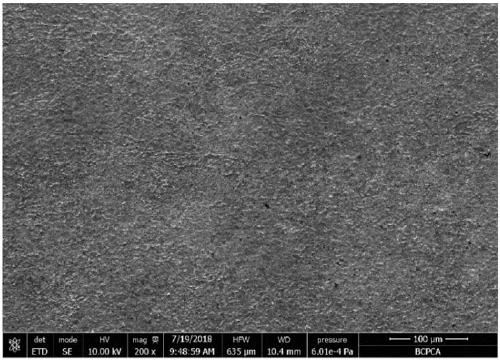

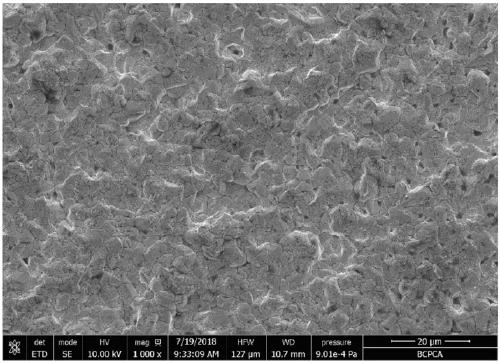

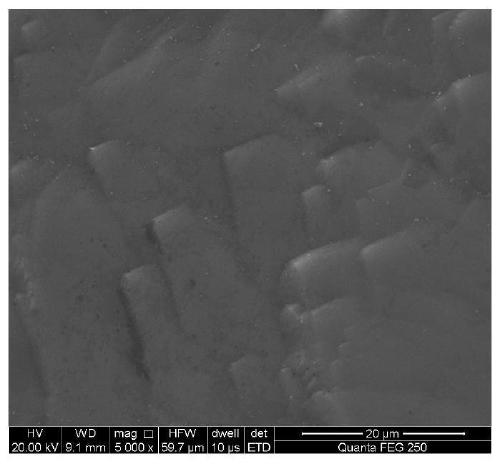

Method for in-situ molten-salt electrodeposition of tungsten carbide/tungsten composite coating

ActiveCN109208046AShort preparation processImprove electrochemical activityCellsElectrodesProcess equipmentTungstate

The invention discloses a method for in-situ molten-salt electrodeposition of a tungsten carbide / tungsten composite coating. According to the method, under the protection of an inert gas, a tungstatesystem is used as a molten salt electrolyte, tungsten carbide or tungsten carbide-cobalt hard alloy is used as an auxiliary electrode, a conductive plated part having undergone grinding and polishingis used as a working electrode, and heat for melting, heat-preserved treatment and in-situ electrodeposition are successively performed to obtain the tungsten carbide / tungsten composite coating. The method for preparing the tungsten carbide / tungsten composite coating through an in-situ molten-salt electrodeposition process in the invention has the characteristics of high efficiency and short preparation process flow; the tungstate system is used as the molten salt electrolyte, and the tungstate system has low volatility, can accelerate the electrochemical dissolving speed of the auxiliary electrode, is beneficial for improving the recycling rate of the auxiliary electrode and can process curved surfaces and workpieces with complex shapes such as inner bores; at the same time, process equipment is simple in structure, easy to operate, and low in cost and pollution; the prepared composite coating has a dense structure, intact crystal grains, high bonding strength, a flat surface, high hardness and good wear resistance; the improvement of the performance of the tungsten coating is realized; and the method is of great theoretical and practical significance.

Owner:BEIJING UNIV OF TECH

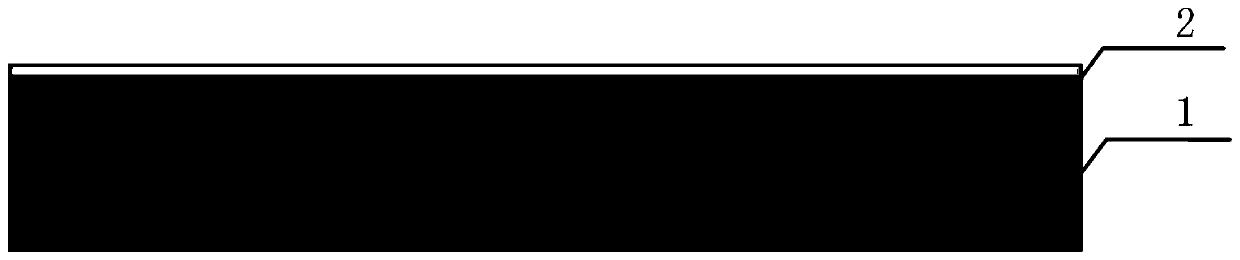

Micro-through-hole Cu-based CVD diamond heat sink sheet and preparation method thereof

ActiveCN110690186AIncrease nucleation densityThermal limitationsDecorative surface effectsSemiconductor/solid-state device detailsNanoparticleHeat sink

The invention discloses a micro-through-hole Cu-based CVD diamond heat sink sheet and a preparation method thereof. The micro-through-hole Cu-based CVD diamond heat sink comprises a Cu substrate, a metal transition layer and a CVD diamond film which are arranged in order from bottom to top, and micro-through-holes with the diameter ranging from 0.3 mm to 0.5 mm and the spacing ranging from 2 mm to3 mm are distributed in the Cu substrate in an array mode; and diamond nanoparticles are electrostatically assembled on the surface of the metal transition layer. The heat dissipation effect of the heat sink sheet is better than that of traditional heat sink sheets such as Ag, Cu and Al, and the adhesion between a diamond film and a Cu metal substrate and the nucleation density of diamond are improved; and the heat dissipation performance of the micro-channel Cu-based diamond heat sink sheet is better.

Owner:SHAANXI UNIV OF SCI & TECH

Method of grain production for heterozygous waxy sugary-2 maize

ActiveUS7678898B2Improve stabilityIncrease temperatureSugar derivativesSugar derivatives preparationFreeze thawingAllele

This patent pertains to a method of producing a waxy maize starch derived from a plant which is heterozygous for the recessive sugary-2 allele by interplanting waxy maize seed which is homozygous for the dominant sugary-2 allele and waxy maize which is homozygous for the recessive sugary-2 allele, one hybrid being male sterile. The maize is harvested and processed together to obtain starch with excellent low temperature and freeze-thaw stability, high pasting temperature, and intact granules.

Owner:CORN PROD DEV INC

Boron-doped diamond electrode with ultrahigh specific surface area as well as preparation method and application of boron-doped diamond electrode

ActiveCN111485223ALarge specific surface areaImprove surface roughnessSpecific water treatment objectivesChemical vapor deposition coatingDiamond electrodesAnisotropic etching

The invention discloses a boron-doped diamond electrode with an ultrahigh specific surface area as well as a preparation method and application of the boron-doped diamond electrode. The boron-doped diamond electrode comprises a substrate and an electrode working layer, wherein the electrode working layer is wrapped on the surface of the substrate, and the substrate is polycrystalline silicon or monocrystalline silicon with a high specific surface area; the electrode working layer is a boron-doped diamond layer; the polycrystalline silicon with the high specific surface area is obtained by performing anisotropic etching or / and isotropic etching on the surface of the polycrystalline silicon; and the monocrystalline silicon with the high specific surface area is obtained by performing anisotropic etching on the surface of the monocrystalline silicon. The boron-doped diamond electrode is characterized in that the boron-doped diamond layer comprises a boron-doped diamond high-conductivity layer, a boron-doped diamond corrosion-resistant layer and a boron-doped diamond strong electrocatalytic activity layer which are different in boron content, and compared with a traditional plate electrode, the silicon-based boron-doped diamond electrode has the advantages of being low in cost and extremely high in specific surface area, and relatively high current intensity is provided by using relatively low current density, so that the a wide application prospect is provided.

Owner:NANJING DAIMONTE TECH CO LTD

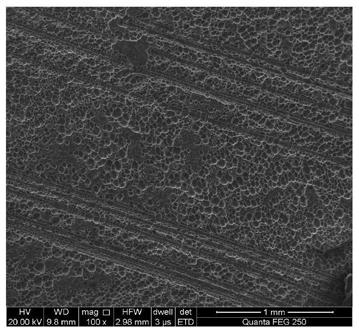

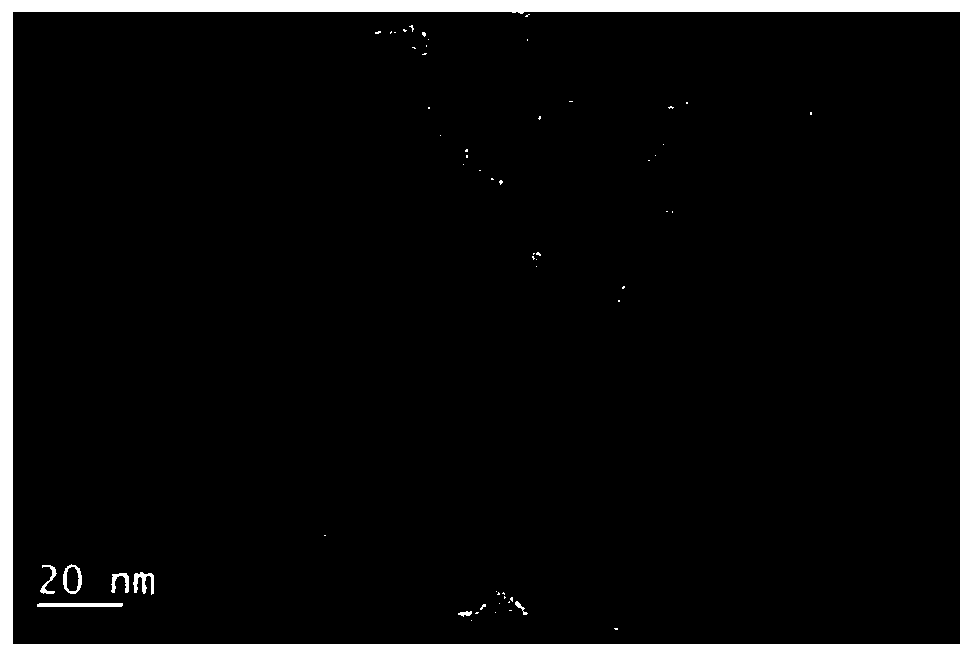

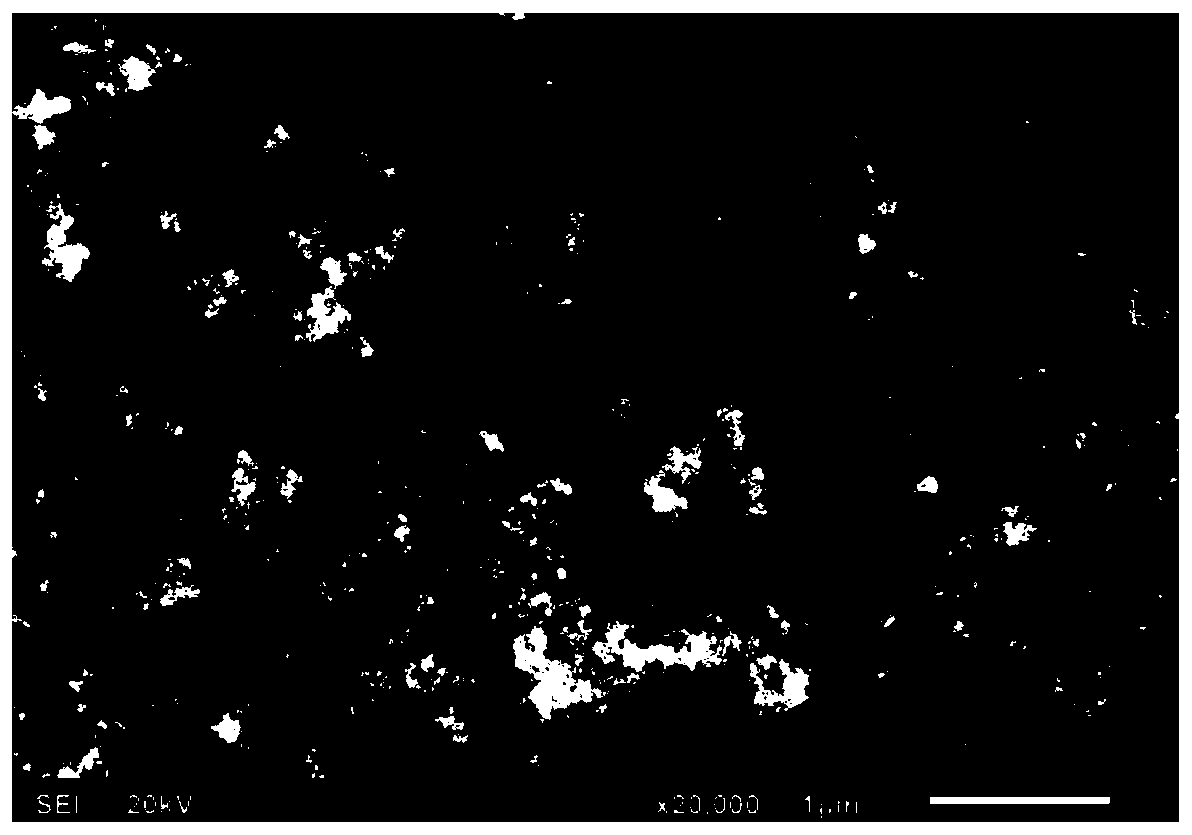

Hydrogenation catalyst composition and preparation method thereof

ActiveCN105618071AAdequate responseQuick buildMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsOxidePrecipitation

The invention discloses a hydrogenation catalyst composition and a preparation method thereof. The hydrogenation catalyst composition comprises an aluminum oxide carrier, an active metal and an auxiliary agent, wherein the active metal is selected from one or more of VIII family and / or VIB family metallic elements, and the auxiliary agent is selected from one or two of silicon or zirconium; the concentration of silicon and / or zirconium in the catalyst, in the form of oxides, are gradually increased from centers to outer surfaces of catalyst particles, wherein the concentration of silicon and / or zirconium at a position of 1 / 3R of particles is 0.1-0.5wt%, the concentration of silicon and / or zirconium at a position of 2 / 3R is 0.5-1.0wt%, the concentration of silicon and / or zirconium at a position of R is 1.0-3.0wt%, and R is the semi-diameter of the catalyst particles by taking the center of the catalyst as an initial point. The catalyst prepared by adopting an impinging stream co-precipitation gel forming mode in the invention is centralized in particle size distribution, and has an ideal pore structure, and the auxiliary agent and the active metal are distributed in the catalyst in a gradient increase mode, so that the deactivation rate of the catalyst can be effectively reduced, and the desulfurization and denitrification capacities of the catalyst are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation of supported O3 catalyst and application thereof in COD removal of high-salt wastewater in coal chemical industry

ActiveCN109939695AUnique methodEasy to operateWater contaminantsCatalyst activation/preparationChemical industryCopper nitrate

The invention relates to a preparation method of a catalyst, in particular to a preparation method of a supported O3 catalyst. The preparation method of the catalyst adopts a hydrothermal method, andthe specific steps are as follows: firstly, a certain mass of gamma-Al2O3 is placed into a container, then potassium permanganate and copper nitrate trihydrate are added, 60-90L deionized water is added to dissolve fully, then the mixture is transferred to a reaction kettle for hydrothermal reaction, after the reaction, the mixture is washed by using deionized water until the water is colorless, the mixture is dried at 90-120 DEG C for 10-15h to obtain heterogeneous double metal oxide catalyst with gamma-Al2O3 supported with MnO2 and CuO, pseudo-boehmite and concentrated nitric acid are added,extruding is carried out, the mixture is dried at 90-120 DEG C for 10-15 h; the invention also provides the application of the catalyst in COD removal of high-salt wastewater in coal chemical industry: the method has the advantages of simple operation, low cost, reusable catalyst, good water treatment effect, large-scale application and no secondary pollution.

Owner:NINGXIA UNIVERSITY

Surface cerium-rich nanometer cerium-zirconium composite oxide as well as preparation and application thereof

ActiveCN109772288AHigh oxygen storage performanceImprove reducibilityMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementCerium

The invention provides surface cerium-rich nanometer cerium-zirconium composite oxide as well as preparation and application thereof. The composite oxide is a composite of cerium-zirconium oxide and rare earth elements, wherein the molar ratio of cerium to zirconium to the rare earth elements is (2-4):3:(0.1-0.5). The cerium-zirconium composite oxide provided by the invention realizes the diversity of formulas in a same material. The cerium-zirconium composite oxide is prepared by a two-step process, and a structure rich in the cerium on the outer layer and rich in the zirconium on the inner layer is formed, so that the composite oxide not only has excellent ageing resistance, oxygen storage performance and reduction performance, but also has good catalytic performance.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

Preparation method of ZSM-5 molecular sieve

ActiveCN105621451ALow water to silicon ratioHigh yield in one potPentasil aluminosilicate zeoliteSilicon dioxideSilicon

A preparation method of a ZSM-5 molecular sieve is characterized in that the method comprises the following steps: allowing a first mixture obtained by uniformly mixing a silicon source, an alkali, crystal seeds and water to stay in a closed reaction kettle at a constant temperature of 150-200DEG C for 10h or below, adding a second mixture obtained by uniformly mixing an aluminum source, the alkali and water, carrying out hydrothermal crystallization on the above obtained third mixture in the closed reaction kettle at 140-180DEG C for 5-20h, and recovering the finally obtained product, wherein a molar ratio of M2O / SiO2 of the first mixture is 0.03-0.07, a molar ratio of H2O / SiO2 of the first mixture is 5-10, the addition amount of the crystal seeds is 1-10% of the weight of the silicon source calculated by silica, a molar ratio of SiO2 / Al2O3 of the first mixture is 20-100, a molar ratio of M2O / SiO2 of the third mixture is 0.03-0.15, and a molar ratio of H2O / SiO2 of the third mixture is 5-15. The method has the advantages of no use of a template, high yield of a single kettle, and high silicon utilization rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

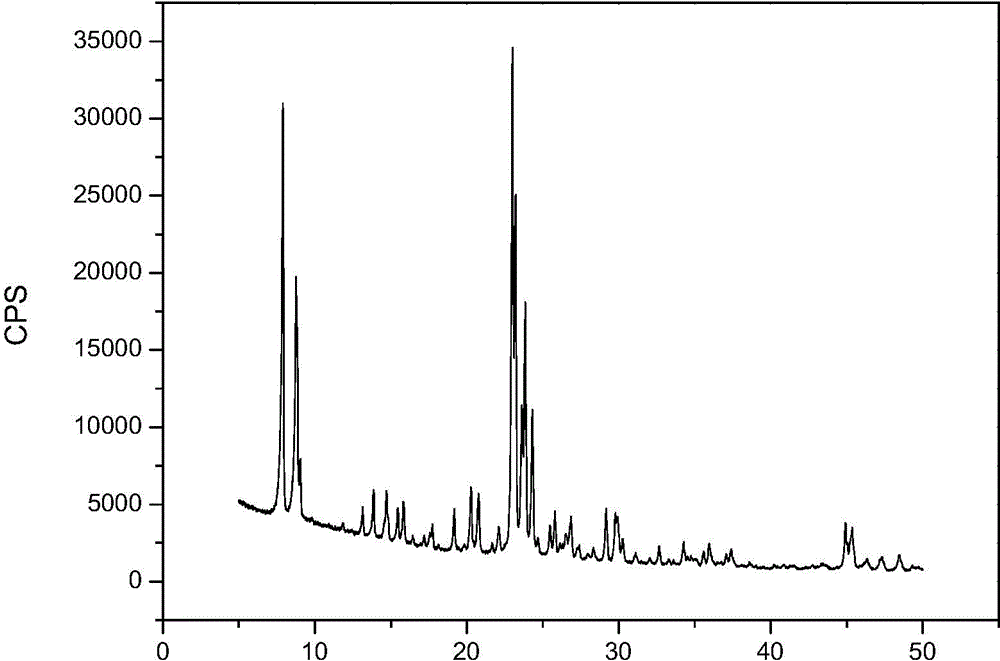

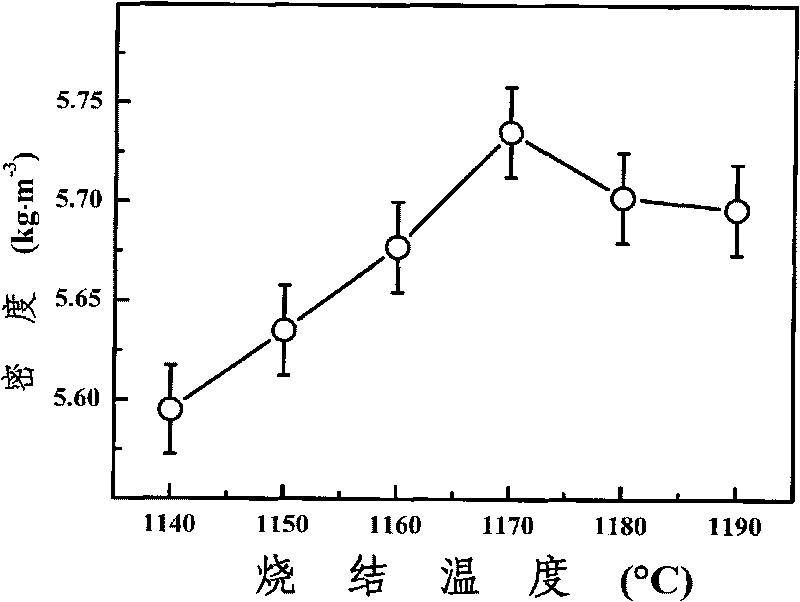

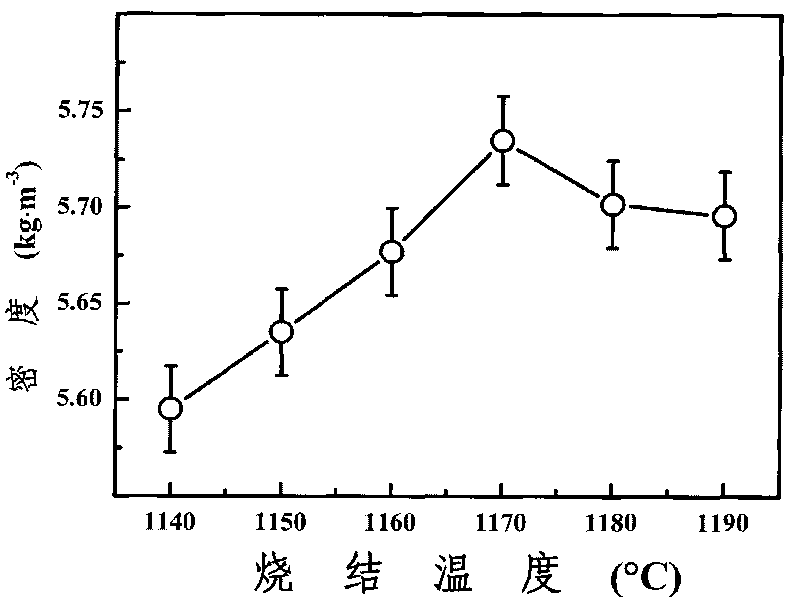

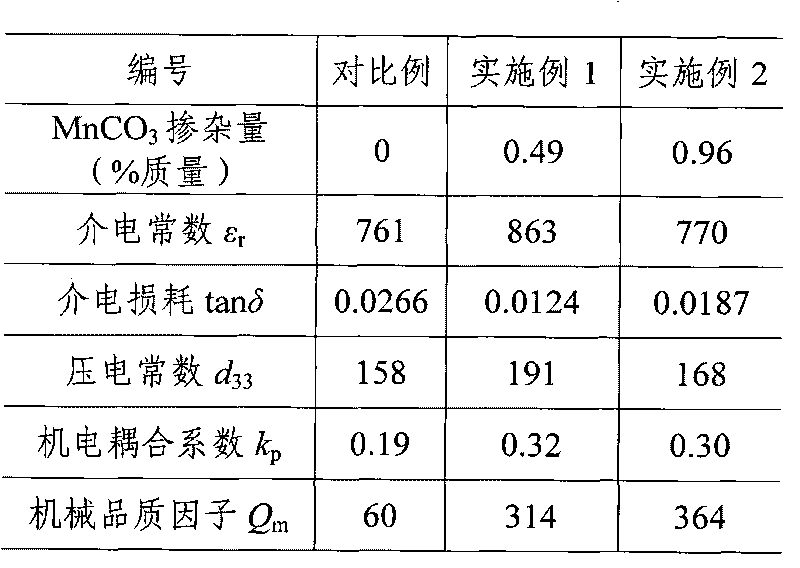

Lead-free piezoceramic material with manganese doping with bismuth titanate sodium group and preparation method thereof

The invention relates to a lead-free piezoceramic material with manganese doping with bismuth titanate sodium group and a preparation method thereof, belonging to the field of functional ceramics. The invention selects 80.15-84.61wt% of Bil / 2Nal / 2TiO3, 10.26-13.19wt% of Bil / 2K1 / 2TiO3, 2.17-5.44wt% of BaTiO3 as the substrate, and takes 0.32-1.28wt% of MnCO3 as the doping material, controls the pre-synthesizing temperature to a range of 800-950 DEG C and preserves the temperature for 1-4 hours; and keeps the sintering temperature to a range of 1130-1190 DEG C and preserves the temperature for 1-4 hours to obtain the novel lead-free piezoceramics. The piezoceramics obtained by utilizing the method provided in the invention have the advantages of high piezoelectric constant (191) and mechanical quality factor (314), good microcosmic structure, complete growth of crystal particles. The lead-free piezoceramics provided in the invention can be used for manufacturing piezoelectric devices such as piezoelectric sensor and actuator and the like.

Owner:XIANGTAN UNIV

Low-hexavalent-chromium precipitated copper and chromium black pigment as well as preparation method and application thereof

ActiveCN108059187AWell-developed grainsImprove securityChromates/bichromatesDispersityInorganic salts

The invention belongs to the technical field of pigment synthesis and discloses a low-hexavalent-chromium precipitated copper and chromium black pigment as well as a preparation method and applicationthereof. The method comprises the following steps: (1) preparing a nitrate solution, preparing raw materials into the nitrate solution containing Cu<2+>, Cr<3+> and Fe<3+>; (2) preparing a combustionsolution, mixing the nitrate solution and auxiliary fuel to obtain the combustion solution; (3) carrying out low-temperature self-propagating combustion: after evaporating and concentrating the combustion solution, heating the solution in a heating device and initiating the self-propagating combustion; collecting a combustion product; (4) mixing and carrying out ball milling: carrying out the ball mixing on the combustion product and inorganic salt and mixing to obtain a mixture; (5) carrying out high-temperature calcining: putting the mixture into the heating device and carrying out the high-temperature calcining; (6) carrying out post-treatment: carrying out water washing on a product obtained by the high-temperature calcining and drying to obtain the copper and chromium black pigment.The copper and chromium black pigment prepared by the preparation method has the advantages of high purity, complete crystalline grains, good dispersity and low hexavalent chromium content; the pigment has a small average grain diameter which can reach 0.5mu m.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

Hydrogenation catalyst composition and preparation method thereof

ActiveCN105817232AEasy to depositHigh metal capacityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsSiliconParticle-size distribution

The invention discloses a hydrogenation catalyst composition and its preparation method. The hydrogenation catalyst composition comprises an alumina carrier, active metal and an auxiliary agent, wherein the active metal is one or more metals selected from VIII group and / or VIB group metallic elements; and the auxiliary agent is one or two elements selected from silicon or zirconium. Concentration of silicon or zirconium in the catalyst is metered according to oxide and gradually decreases from the catalyst granule center to the external surface. Content of silicon and / or zirconium at R of granules is 1.0-3.0 wt%; content of silicon and / or zirconium at 1 / 3 of R is 0.5-1.0 wt%, and content of silicon and / or zirconium at 2 / 3 of R is 0.1-0.5 wt%, wherein R is radius of catalyst granules with the catalyst center as the starting point. The catalyst prepared by an impinging stream co-precipitation gelling mode has the following advantages: particle size distribution is centralized; the catalyst has an ideal pore structure; contents of the auxiliary agent and the active metal in the catalyst are reduced gradiently; inactivation rate of the catalyst can be effectively reduced; and metal-removal and metal-holding capabilities of the catalyst are enhanced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Thermal-shock-resisting soft magnetic ferrite material and preparation method thereof

The invention discloses a thermal-shock-resisting soft magnetic ferrite material and a preparation method thereof. The thermal-shock-resisting soft magnetic ferrite material is characterized by comprising the following raw materials in parts by weight: 50 to 70 parts of iron sesquioxide, 10 to 20 parts of nickel oxide, 5 to 10 parts of zinc oxide, 0.5 to 0.8 part of copper oxide, 0.2 to 0.3 part of vanadium pentoxide, 0.1 to 0.3 part of polyvinylpyrrolidone, 0.4 to 1 part of saw dust, 0.02 to 0.06 part of sodium lignin sulfonate, 2 to 4 parts of organic silicon resin and an appropriate amount of deionized water. By adopting the copper oxide, a crystal grain is more complete, the tissue is compacter, the temperature property can be improved, the thermal shock resistance can be improved, and the magnetic hysteresis loss can be reduced; the vanadium pentoxide is transformed to liquid phase at high temperature and is sintered, and the crystal grain is refined, so that the crystal interface and porosity in the crystal grain can be reduced, the starting magnetic conductivity can be enhanced. The soft magnetic ferrite material has characteristics of high strength, high starting magnetic conductivity and high thermal shock resistance and is capable of meeting the miniaturization requirement of a surface-mounted product.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

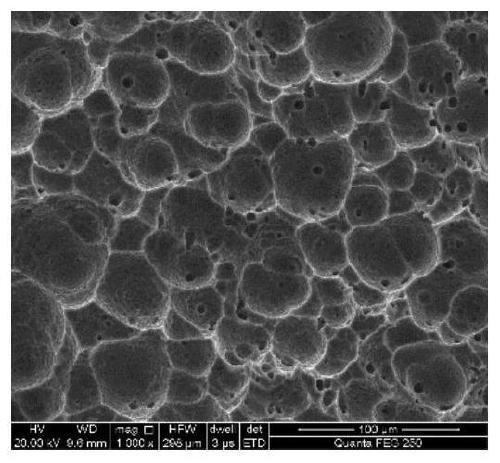

Tungsten trioxide nano hollow sphere semiconductor material and preparation method thereof, gas sensor and preparation method and application thereof

InactiveCN109592713AUniform particle sizeGrain intactTungsten oxides/hydroxidesNanotechnologySemiconductor materialsGas detector

The invention provides a preparation method of a tungsten trioxide nano hollow sphere semiconductor material and belongs to the technical field of semiconductor materials. The preparation method comprises the following steps: mixing soluble hexavalent tungsten salt, an alcohol aqueous solvent and an alkaline precipitator; and carrying out a hydrothermal reaction on the obtained mixed solution to obtain the tungsten trioxide nano hollow sphere semiconductor material. Concentration of the hexavalent tungsten salt is 5-30 mmol / L, concentration of the precipitator is 0.1-0.5 mol / L, the temperatureof hydrothermal reaction is 100-200 DEG C, and the time of hydrothermal reaction is 5-40 hours. By controlling proportion, reaction temperature and reaction time of reaction raw materials, the tungsten trioxide nano hollow sphere semiconductor material which is uniform in particle size, intact in grain size and uniform in wall thickness is obtained. The invention also provides a gas sensor prepared by the tungsten trioxide nano hollow sphere semiconductor material. The gas sensor is applied to detecting organophosphorus pesticides and is high in sensitivity.

Owner:SHANGHAI OCEAN UNIV

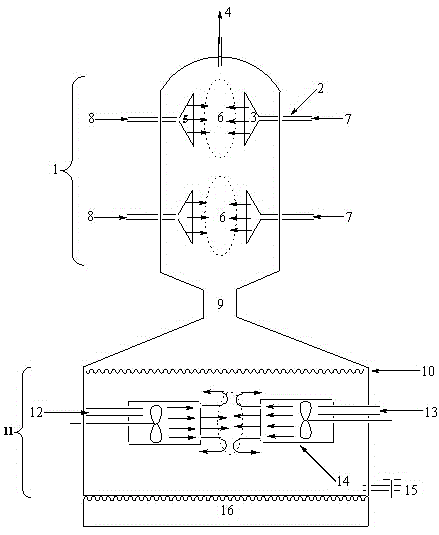

Apparatus and method for carrying out selenylation treatment on CIGS (copper indium gallium selenide) thin films and CIGS thin-film device

InactiveCN103088301BReduce leakageHigh Selenization EfficiencyVacuum evaporation coatingSputtering coatingIndiumThermal insulation

The invention relates to an apparatus and a method for carrying out selenylation treatment on CIGS (copper indium gallium selenide) thin films and a CIGS thin-film device. The apparatus comprises a quartz tube, a selenylation unit is arranged in the quartz tube, the selenylation unit comprises a selenium source groove and a CIGS thin-film groove which are connected through a thermal insulation material, a protective cover is arranged above the two grooves, and a confined space is formed among the protective cover and the two grooves. A solid selenium source and a CIGS thin film are respectively placed in the selenium source groove and the CIGS thin-film groove, and then operations of vacuumizing, heating and selenylation treatment are sequentially performed. The apparatus and the method disclosed by the invention have the advantages of less selenium vapor leakage, high selenylation efficiency, and capability of simultaneously treating multiple samples, and the like, and the stability and the batch preparation of CIGS thin-film solar cell devices are facilitated.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

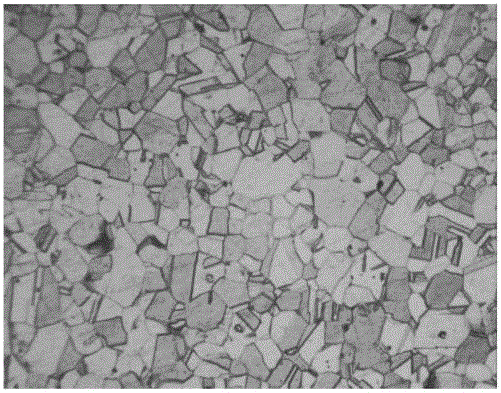

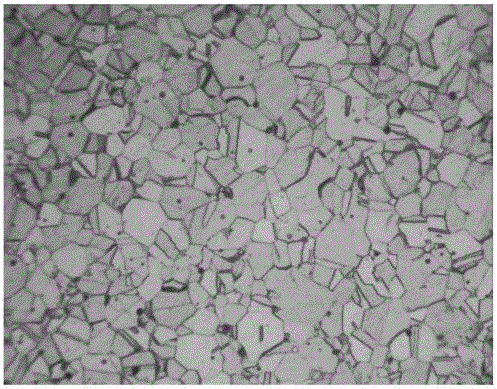

Metallographic-phase corrosive liquid and corrosion method for austenite resisto

InactiveCN106124392ALow costClear grain boundariesWeather/light/corrosion resistanceHydrogen fluorideTest sample

The invention discloses metallographic-phase corrosive liquid for austenite resisto. The metallographic-phase corrosive liquid is prepared from ingredients of hydrogen fluoride solution, saltpeter solution and distilled water, and the volume ratio of the hydrogen fluoride to the saltpeter solution to the distilled water is 1:1:7. The metallographic-phase corrosive liquid can quickly and efficiently corrode a metallographic-phase tissue of a test sample (austenite resisto), the obtained corroded test sample is clear in crystal boundary and complete in crystal particle, and no abnormal corrosion pit or plaque is found in the single crystal particle; meanwhile, the metallographic-phase corrosive liquid is low in cost and easy to operate and has an important improvement effect on metallographic analysis of the austenite resisto.

Owner:ZHANGJIAGANG QINGYAN DETECTION TECH CO LTD

Alumina carrier and preparation method thereof

ActiveCN105817215AHigh metal capacityHigh activityPhysical/chemical process catalystsCrystallinitySilicon

The invention discloses an alumina carrier and its preparation method. With the weight of the carrier as the basis, auxiliaries account for 2-5% when metered on the basis of oxide. The auxiliaries are one or two elements selected from silicon or zirconium; content of silicon or zirconium in alumina decreases progressively from the center of carrier particles to the external surface; content of silicon and / or zirconium at the particle center is 1.5-3.5 wt%; content of silicon and / or zirconium at 1 / 3 of R is 0.5-1.5 wt%; and content of silicon and / or zirconium at 2 / 3 of R is 0.1-0.5 wt%, wherein R is radius of the carrier particle with the alumina center as the starting point. The alumina carrier has high degree of crystallinity, complete crystalline grain and centralized particle size distribution. Distribution of the auxiliaries in alumina decreases gradiently. The alumina carrier is suitable for preparation of a hydrotreating catalyst with high demetalization and good metal-holding capabilities.

Owner:CHINA PETROLEUM & CHEM CORP +1

High magnetic conductive low temperature sintered NiCuZn ferrite material

The invention relates to a NiCuZn ferrite material with high magnetic permeability and low-temperature sintering, whose main phase is a spinel structure, the compositions which are calculated through oxide content are that Fe2O3 is 41-52.8mol%, ZuO is 20-45mol%, and CuO is 1-14mol%, NiO is 2-15mol%. MoO3 and In2O3 are used as additive based on the above materials, MoO3: 0.15wt%-0.25wt% is added, and In2O3: 0.12wt%-0.45wt% is added. Ferrite blanks which are prepared are put in a furnace to be sintered, the sintering temperature is 910-950 DEG C, the sintering time is 6-20 hours, and the temperature is kept for 2-4 hours.

Owner:SHANDONG ZHONGRUI ELECTRONICS

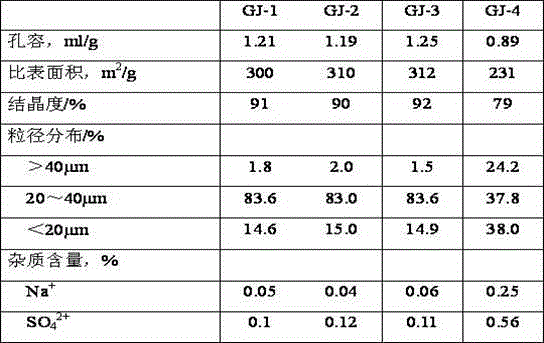

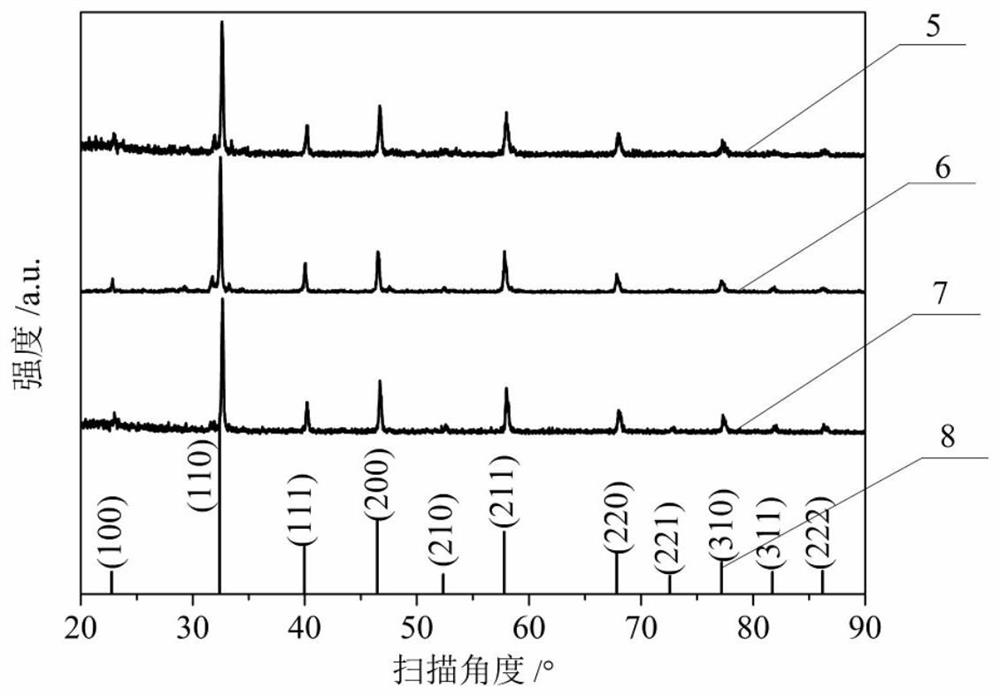

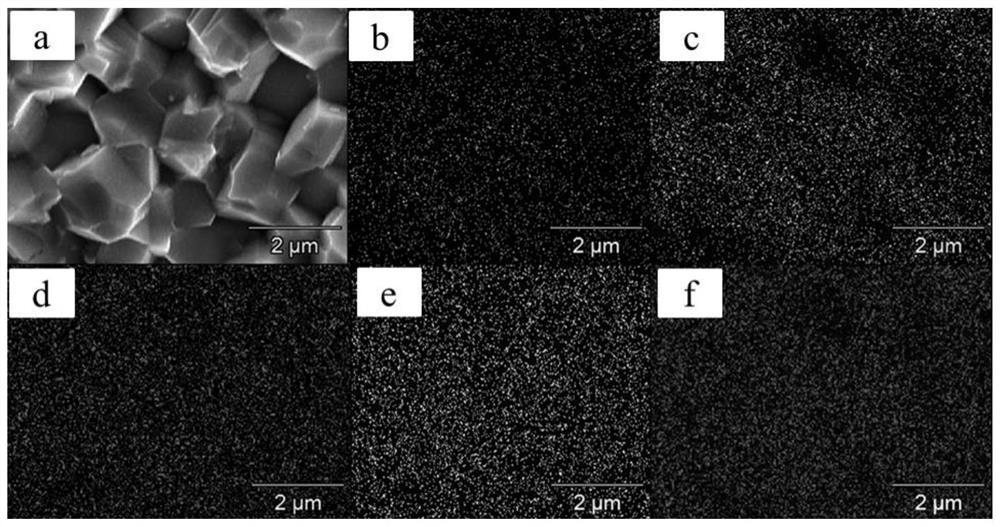

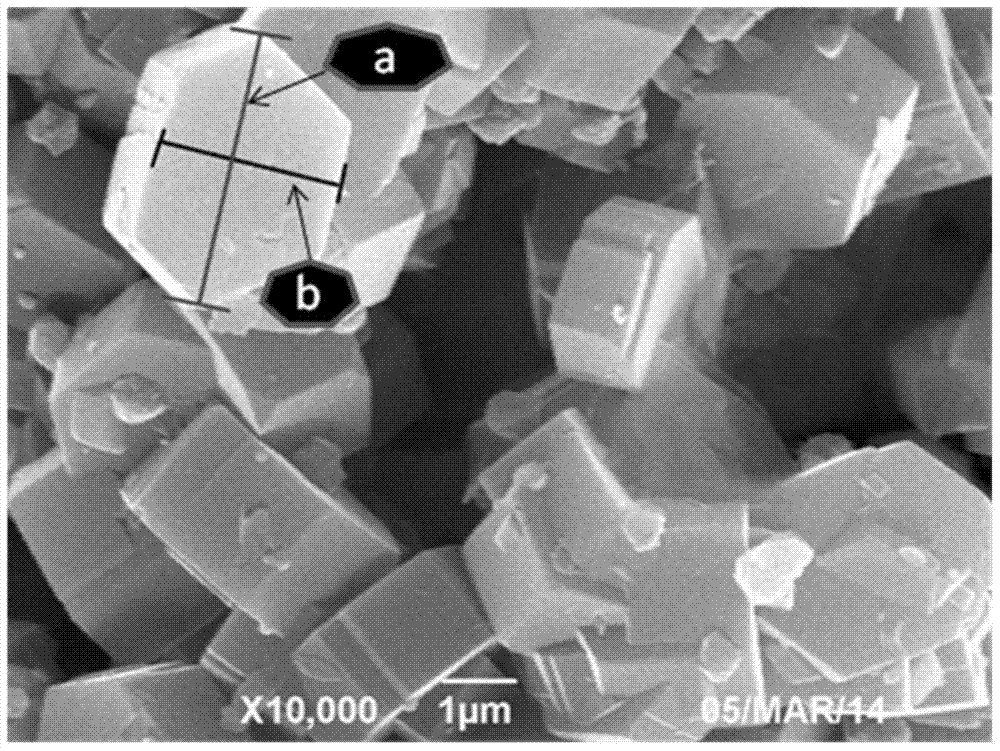

A kind of preparation method of zsm-5 molecular sieve

ActiveCN105692652BGrain intactHigh crystallinityPentasil aluminosilicate zeoliteMolecular sieveSilica gel

A preparation method of ZSM-5 molecular sieve is characterized by comprising the following steps: carrying out hydro-thermal treatment on a first mixture composed of a first silicon source, alkali, seed crystal and water, adding the first mixture which has undergone the hydro-thermal treatment into a second mixture composed of a second silicon source, an aluminium source, alkali and water so as to obtain a third mixture, and carrying out hydrothermal crystallization on the third mixture, wherein the first silicon source is silica gel and the second silicon source is silica sol or water glass. According to the preparation method, the molecular sieve is synthesized without usage of a template and under conditions of low water-to-silicon ratio, controlled heating rate and two-stage crystallization. The preparation method has characteristics of high single-autoclave yield, simple process and high utilization rate of silicon. The prepared ZSM-5 molecular sieve has complete crystal grain, high degree of crystallization and specific hexagon morphology.

Owner:CHINA PETROLEUM & CHEM CORP +1

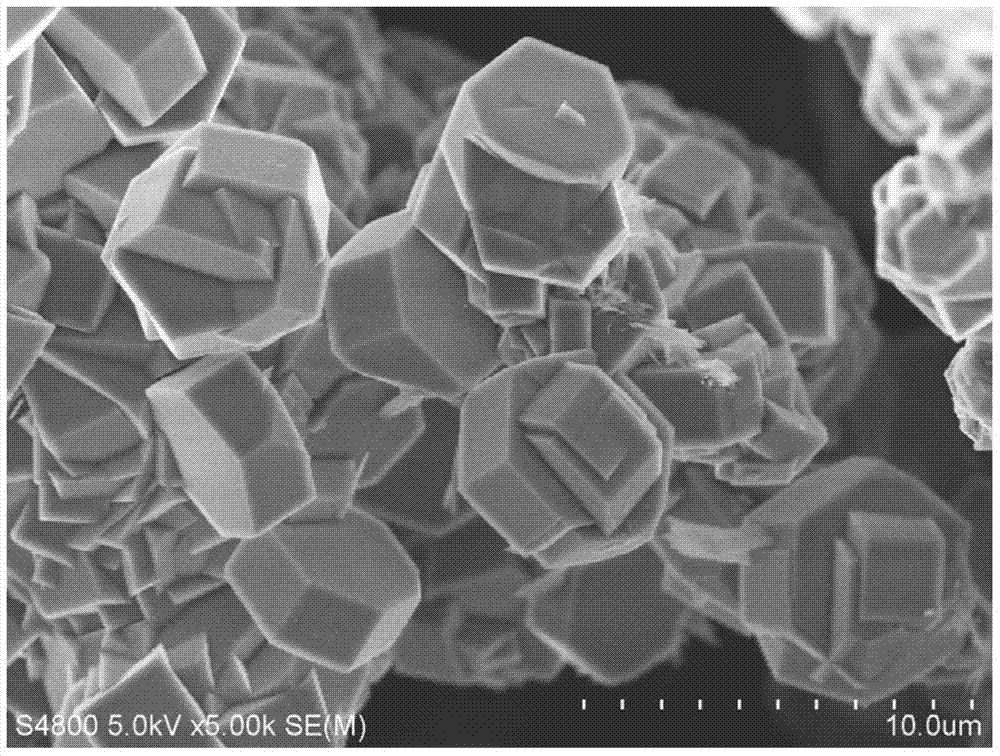

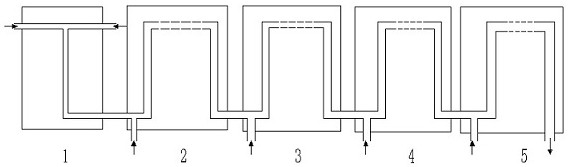

A kind of nay type molecular sieve and preparation method thereof

ActiveCN109721073BSmall grainGrain intactFaujasite aluminosilicate zeoliteMolecular sievePtru catalyst

The invention discloses a NaY type molecular sieve and a preparation method thereof. The preparation method comprises the steps of preparation of a guiding agent, preparation and crystallization of silica-alumina gel, wherein a reaction system adopted by the preparation and crystallization of the silica-alumina gel comprises N microreactors connected in series. The NaY type molecular sieve has theadvantages of high purity, high crystallinity, small particle size, very concentrated crystal particle distribution, large pore size and concentrated pore size distribution, and the preparation method has the advantages of safety, environmental protection, short reaction time, high process continuation efficiency, elimination of the amplification effect, and suitableness for gasoline and diesel hydrocracking catalyst carrier materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com