Boron-doped diamond electrode with ultrahigh specific surface area as well as preparation method and application of boron-doped diamond electrode

An ultra-high specific surface area, diamond electrode technology, applied in the direction of electrodes, chemical instruments and methods, electrolysis process, etc., can solve the problems of slow mass transfer rate, restricting the electrocatalytic performance of BDD electrodes, and easy to fall off, so as to improve the surface roughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

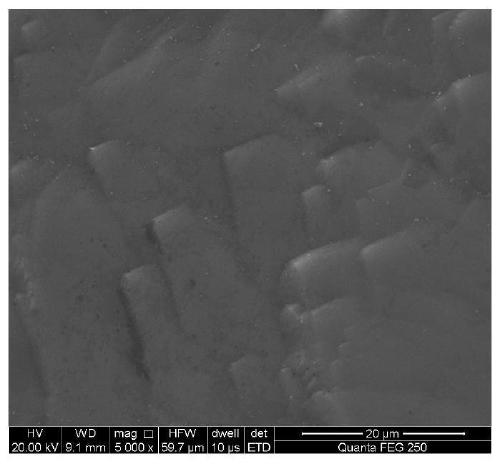

[0064] First perform anisotropic etching on the surface of the polysilicon substrate material, use 10M KOH solution as an anisotropic etching solution, place the polysilicon substrate material in the anisotropic etching solution at 80°C for 60 minutes to complete the etching, Then wash and dry to obtain step-type polysilicon with high specific surface area, whose shape is as follows figure 1 .

[0065] The etched polysilicon was placed in a suspension of nanocrystalline and microcrystalline diamond mixed particles, and ultrasonically oscillated for 30 minutes to obtain a polysilicon substrate with diamond grains attached to the surface.

[0066] Put the substrate into a chemical vapor deposition furnace, keep the distance between the hot wire and the substrate surface at 9 mm, adjust the flow rate of hydrogen gas to maintain 97 sccm during the heating process, and feed methane and borane into the furnace to start deposition. The deposition temperature is 850°C, the deposition...

Embodiment 2

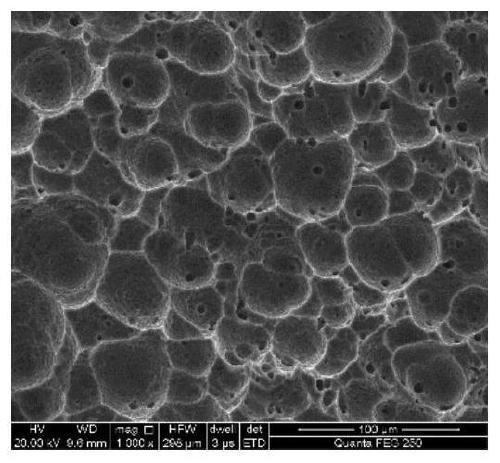

[0073] Embodiment 2 is the same as that in Embodiment 1 except that the polysilicon substrate is etched by an isotropic etching method. The surface of the polysilicon substrate material is isotropically etched first to analyze pure HF and HNO 3 The mixed solution is used as an isotropic etching solution, and the mixed volume ratio is HF:HNO 3 =3:1. The polysilicon substrate material is placed in an isotropic etching solution at room temperature for 2 minutes to complete the etching, then cleaned and dried to obtain pitted microporous composite polysilicon with a high specific surface area, and its shape is as follows: figure 2 .

[0074] The subsequent preparation process is the same as in Example 1, and the electrode properties are shown in Table 2:

[0075] The electrochemical performance of the BDD electrode gained in table 2 embodiment 2

[0076] Oxygen evolution potential / V 2.37 Hydrogen evolution potential / V -0.55 Potential window / V 2.92 B...

Embodiment 3

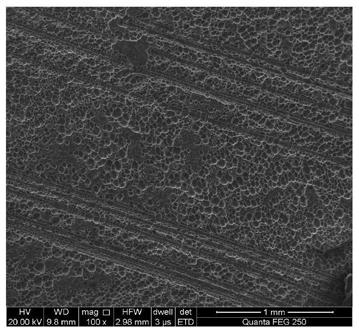

[0085] In Example 3, an anisotropic etching method is used to etch a stepped polysilicon substrate first, and then an isotropic etching method is used, and the etching parameters of the etching solution are the same as those in Embodiments 1 and 2. It looks like image 3 .

[0086] Subsequently, a BDD electrode was prepared, and the preparation method was the same as in Example 1. The electrode properties are shown in Table 4:

[0087] The electrochemical performance of the BDD electrode gained in table 4 embodiment 3

[0088] Oxygen evolution potential / V 2.52 Hydrogen evolution potential / V -0.63 Potential window / V 3.15 Background current / μA / cm 2

12.62

[0089] It can be seen from the above data that the combination of anisotropic etching method and isotropic etching method to etch polysilicon substrate has excellent electrochemical performance and good reversibility of the electrode.

[0090] The BDD electrode prepared in embodiment 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com