LaFeSi-based magnetic refrigeration material as well as preparation method and application thereof

A magnetic refrigeration material, afe13-b-ccobsichd technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of magnetocaloric effect reduction, complex equipment, long production cycle, etc., and achieve magnetic entropy without reducing, High magnetocaloric performance, the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

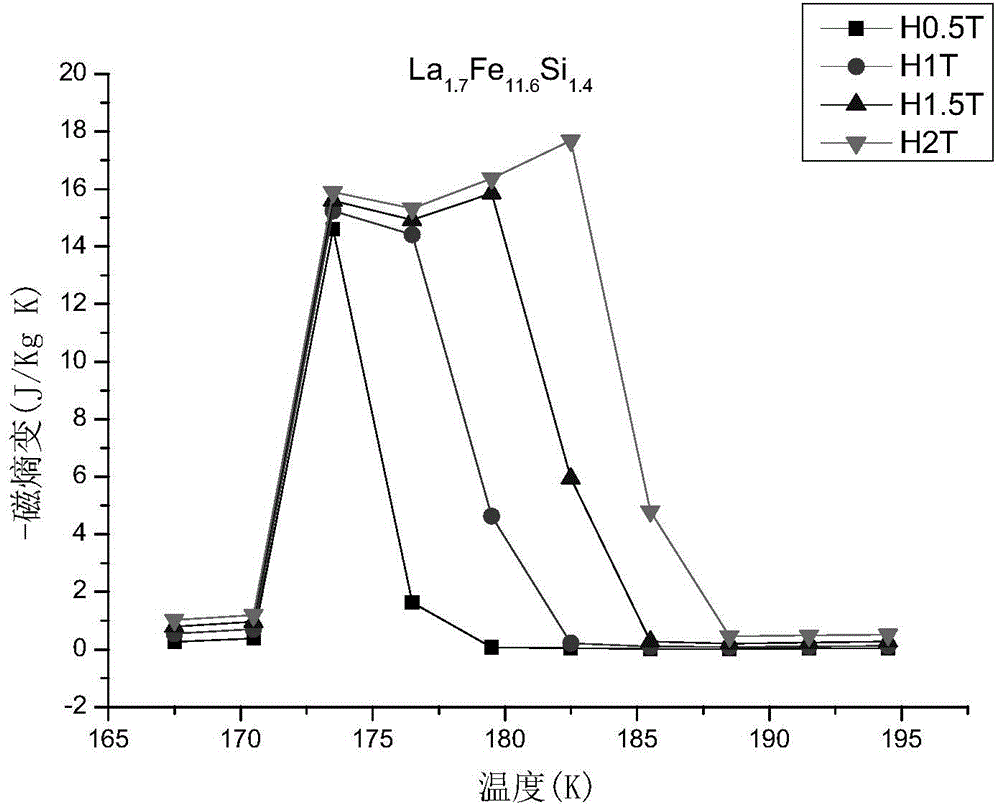

[0049] In this example, the non-stoichiometric ratio La was prepared by adding an appropriate amount of La 1.24 Fe 11.6 Si 1.4 alloy, the specific preparation process is as follows: (1) by chemical formula La 1.24 Fe 11.6 Si 1.4 preparation of raw materials;

[0050] (2) Put the prepared raw materials into the electric arc furnace, vacuumize, clean with high-purity Ar gas, the vacuum degree should be below 5×10-4Pa, and melt under the protection of high-purity inert gas Ar gas to obtain the alloy ingot;

[0051] (3) Put the alloy ingot into the induction melting furnace to evacuate, clean it with high-purity Ar gas, the vacuum degree should be below 1×10-2Pa, and conduct induction melting under the protection of high-purity inert gas Ar gas to obtain columnar alloy ingot;

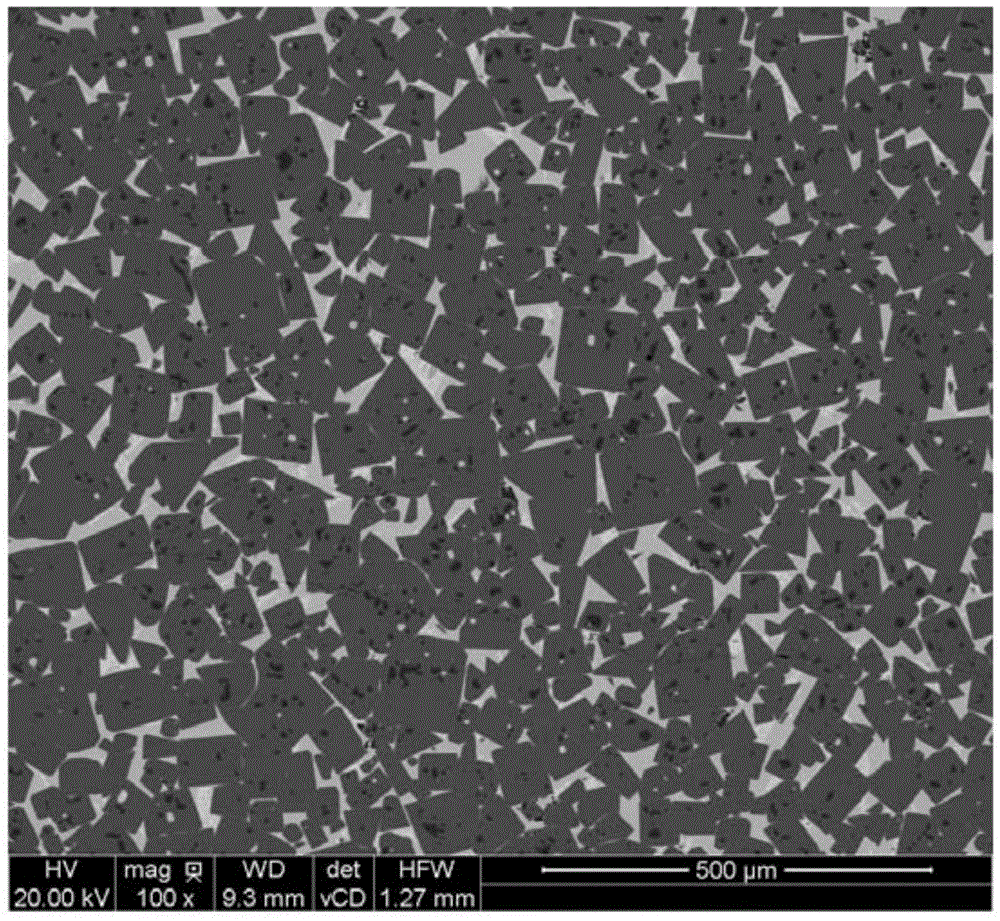

[0052] (4) Anneal the obtained columnar alloy under the protection of high-purity inert gas Ar for 72h, and then quench it in liquid nitrogen or water to prepare a NaZn 13 La(Fe,Si) 13 Magnetic ref...

Embodiment 2-5 and comparative example 1

[0056] A magnetic refrigeration material was prepared in the same manner as in Example 1, except that the composition was changed to that described in Table 1.

[0057] The chemical formula of table 1 embodiment 1-5 and comparative example 1 sample

[0058] Example 1

Embodiment 6-9

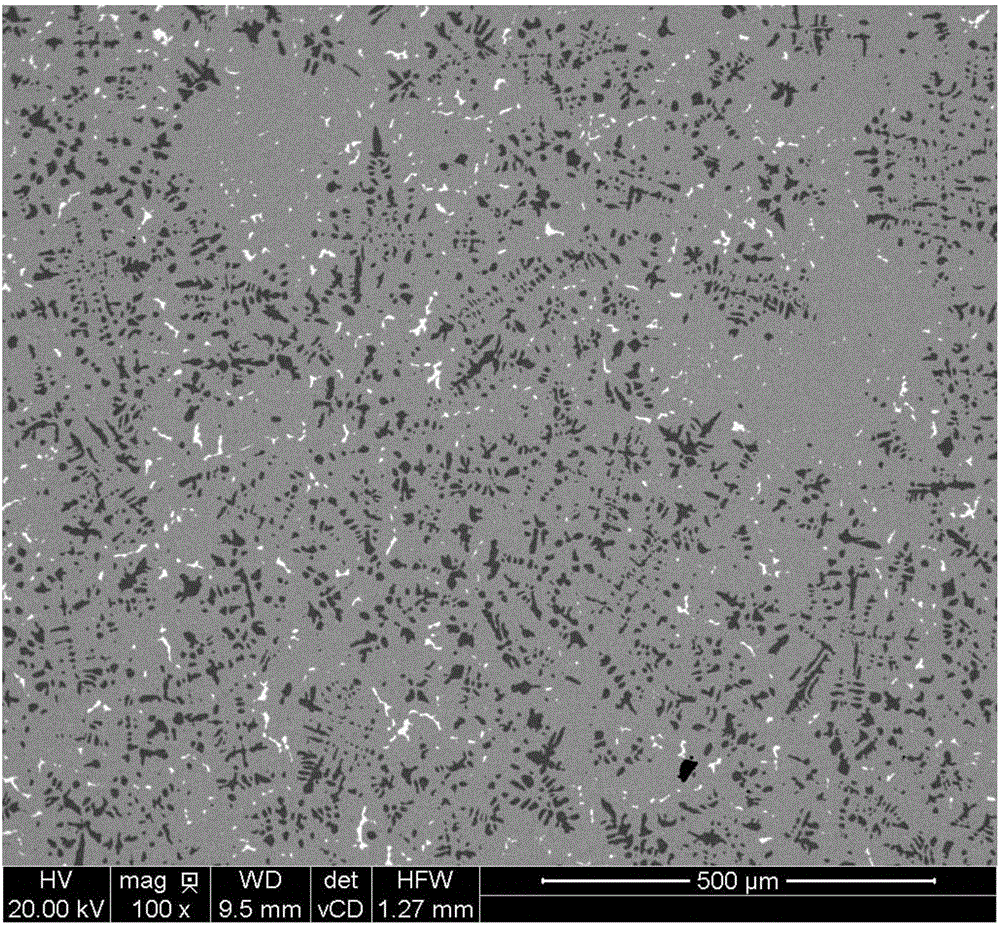

[0060] Prepare magnetic refrigeration material with a kind of method identical with embodiment, its composition is changed into La 1.71 Fe 11.6 Si 1.4 , and its annealing time (step 4, "annealing" in Table 3 is also understood in this way) is changed as described in Table 2.

[0061] The annealing time that adopts in the embodiment 6-9 of table 2

[0062] Example 6

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com