Metallographic-phase corrosive liquid and corrosion method for austenite resisto

A nickel-iron-chromium alloy and austenitic technology, which is applied in the field of metallographic corrosion of nickel-based alloys, can solve the problems of grain rating interference, over-corrosion, and long corrosion time, and achieve improved metallographic analysis, complete grains, and clear border effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] First add 70ml of distilled water into the beaker, then add 10ml of nitric acid solution and 10ml of hydrogen fluoride solution with a disposable plastic dropper, and stir to obtain a metallographic corrosion solution. The mass percent concentration of hydrogen fluoride in the solution is 47%, and the mass percent concentration of nitric acid in the nitric acid solution is 65%.

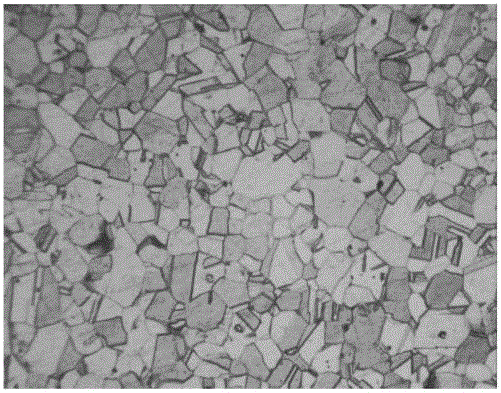

[0028] Then take the No8825 nickel-iron-chromium alloy φ25mm×2mm pipe, use a saw to make a metallographic sample (austenitic nickel-iron-chromium alloy) of φ25mm×2mm×18mm, and use different water abrasive papers to grind from 400 mesh to 1500 mesh For polishing, rinse the sample with tap water before changing the sand paper; then use a silk polishing cloth to first use W1.5 diamond grinding paste for grinding and polishing for 3 minutes, and then choose W0.5 diamond grinding paste for grinding and polishing for 5 minutes. Observe that the surface of the sample is very smooth without any scratch...

Embodiment 2

[0031] First add 70ml of distilled water to the beaker, then add 10ml of nitric acid solution and 10ml of hydrogen fluoride solution with a disposable plastic dropper, and stir to obtain a metallographic corrosion solution. The mass percent concentration of hydrogen fluoride in the solution is 45%, and the mass percent concentration of nitric acid in the nitric acid solution is 68%.

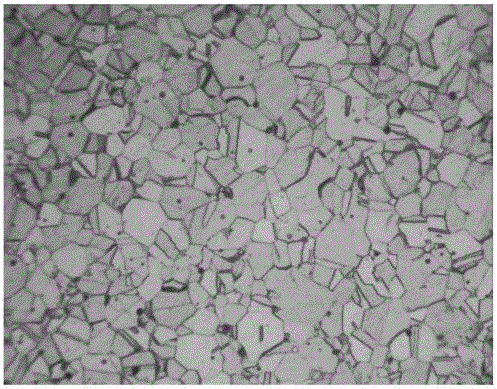

[0032] Corrode with the prepared corrosive solution, take out the absorbent cotton in the corrosive solution with tweezers, and wipe the surface of the No8825 nickel-iron-chromium alloy sample after grinding and polishing in Example 1 for 12 seconds, rinse the surface with clean water, and then clean the surface with distilled water And blow dry, observe with metallographic microscope, get as follows figure 2 As shown in the optical microstructure, the figure 2 It is the optical microstructure under the 200X metallographic microscope, the original size of the picture is 11.37cm×14.65cm, from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com