Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

190 results about "Crevice corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crevice corrosion refers to corrosion occurring in confined spaces to which the access of the working fluid from the environment is limited. These spaces are generally called crevices. Examples of crevices are gaps and contact areas between parts, under gaskets or seals, inside cracks and seams, spaces filled with deposits and under sludge piles.

Austenitic-ferritic stainless steel

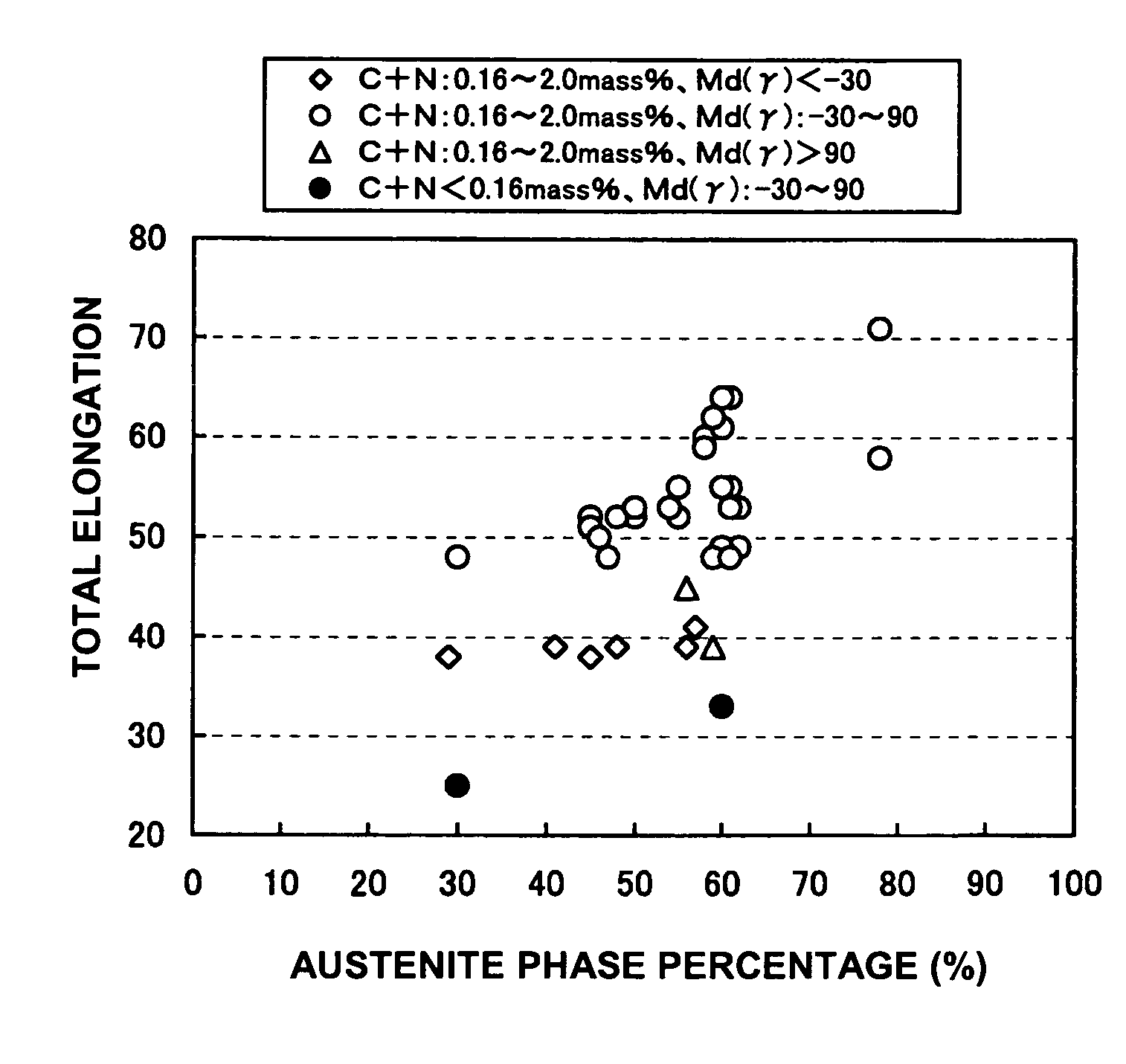

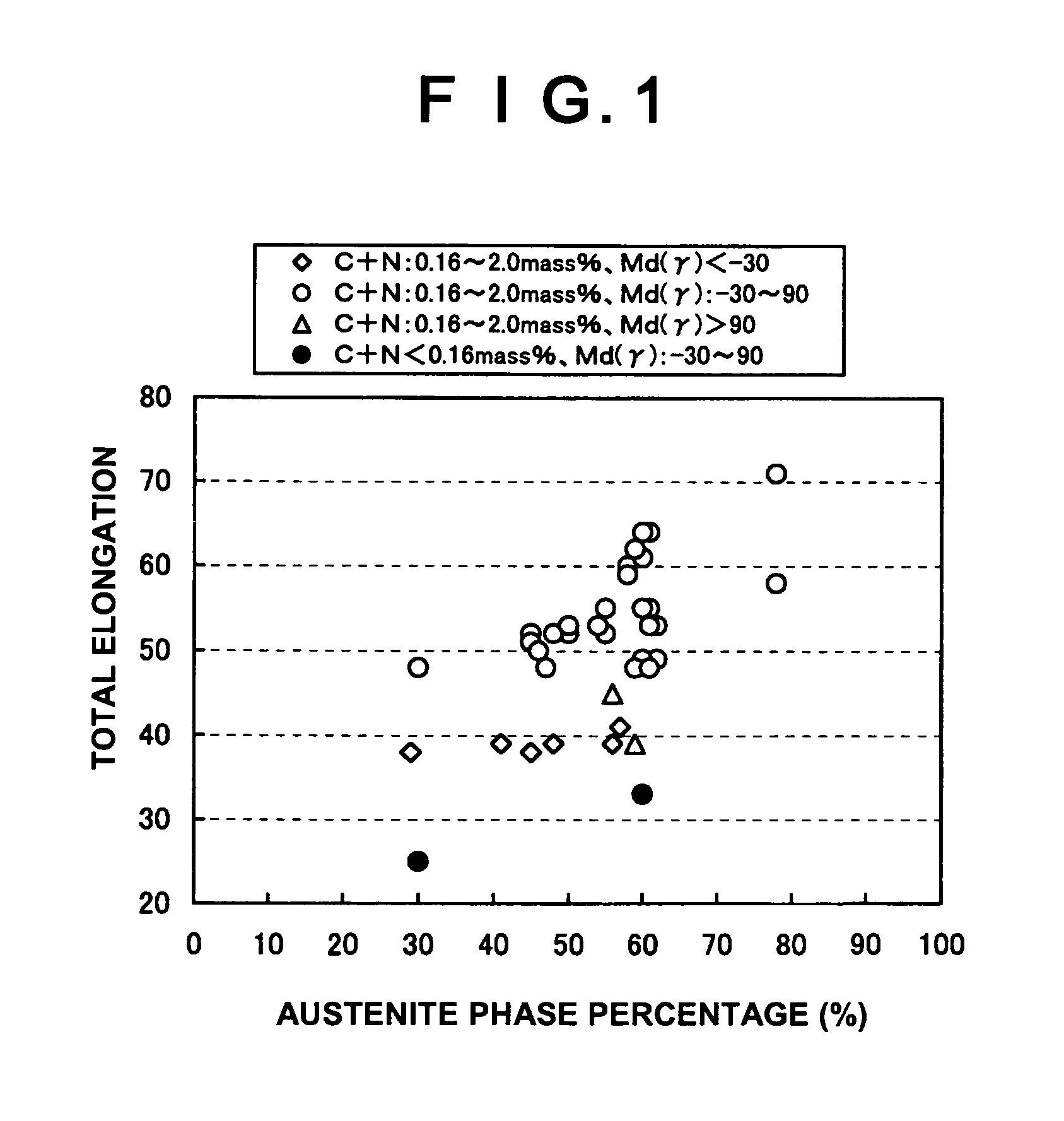

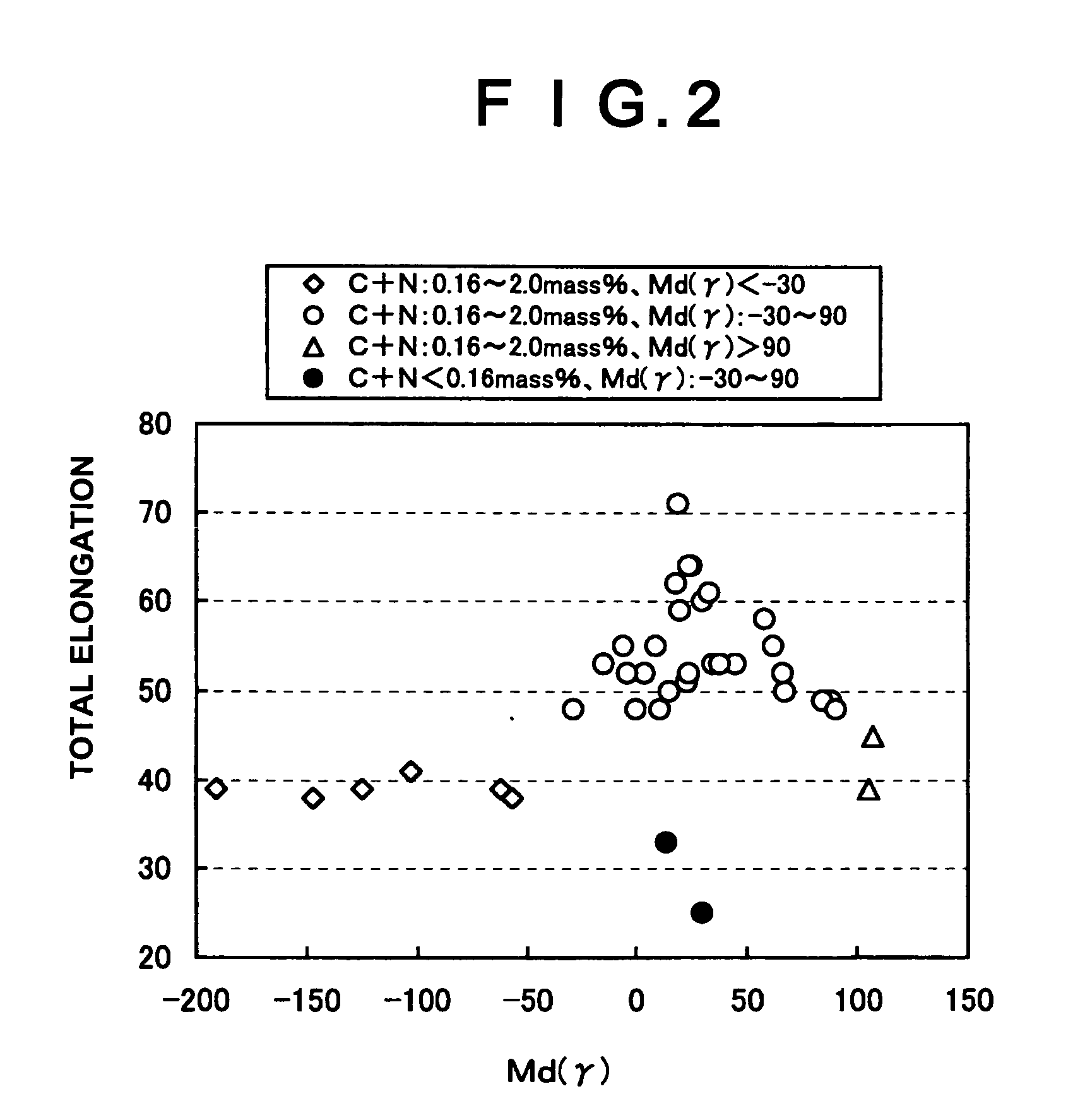

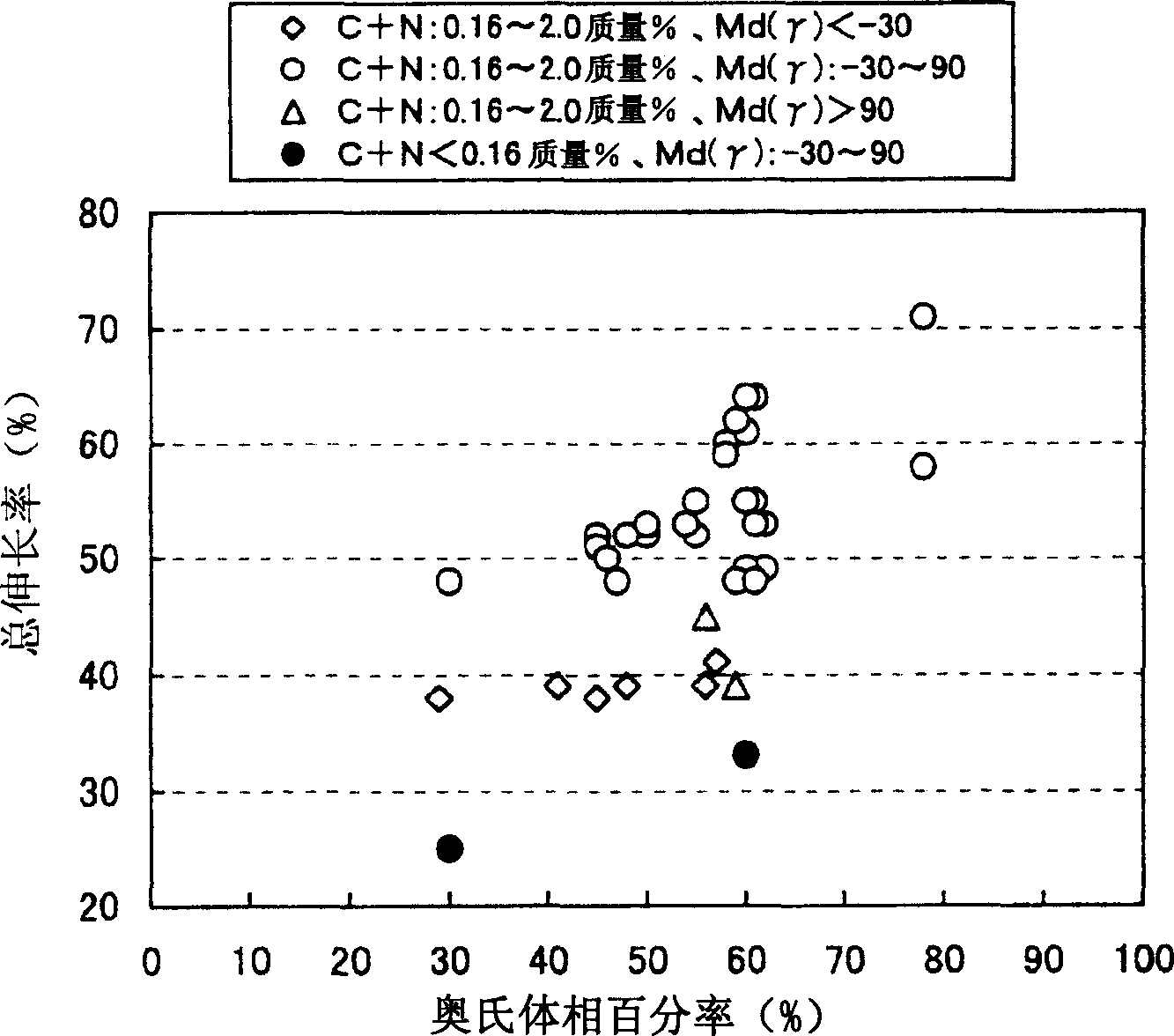

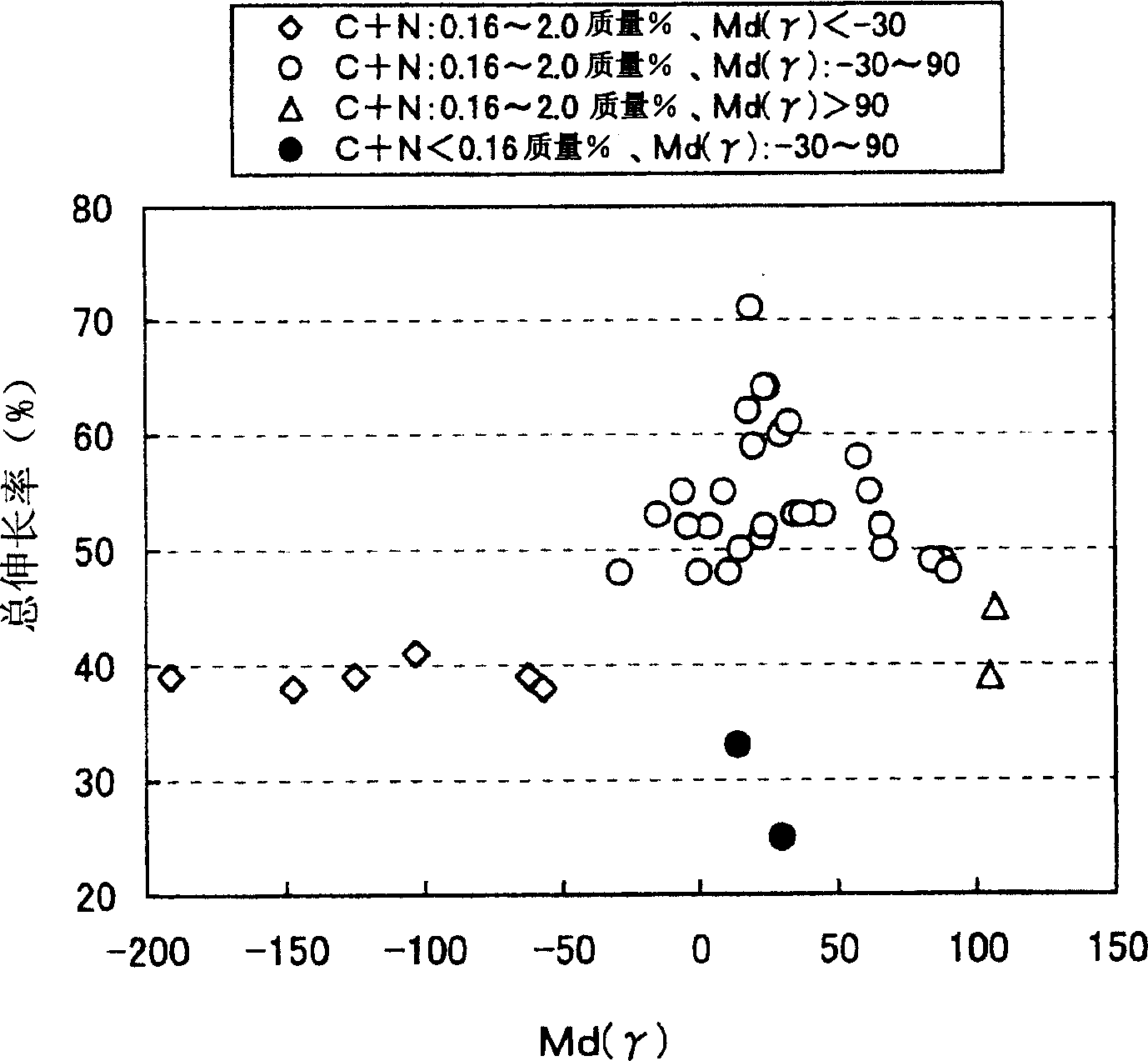

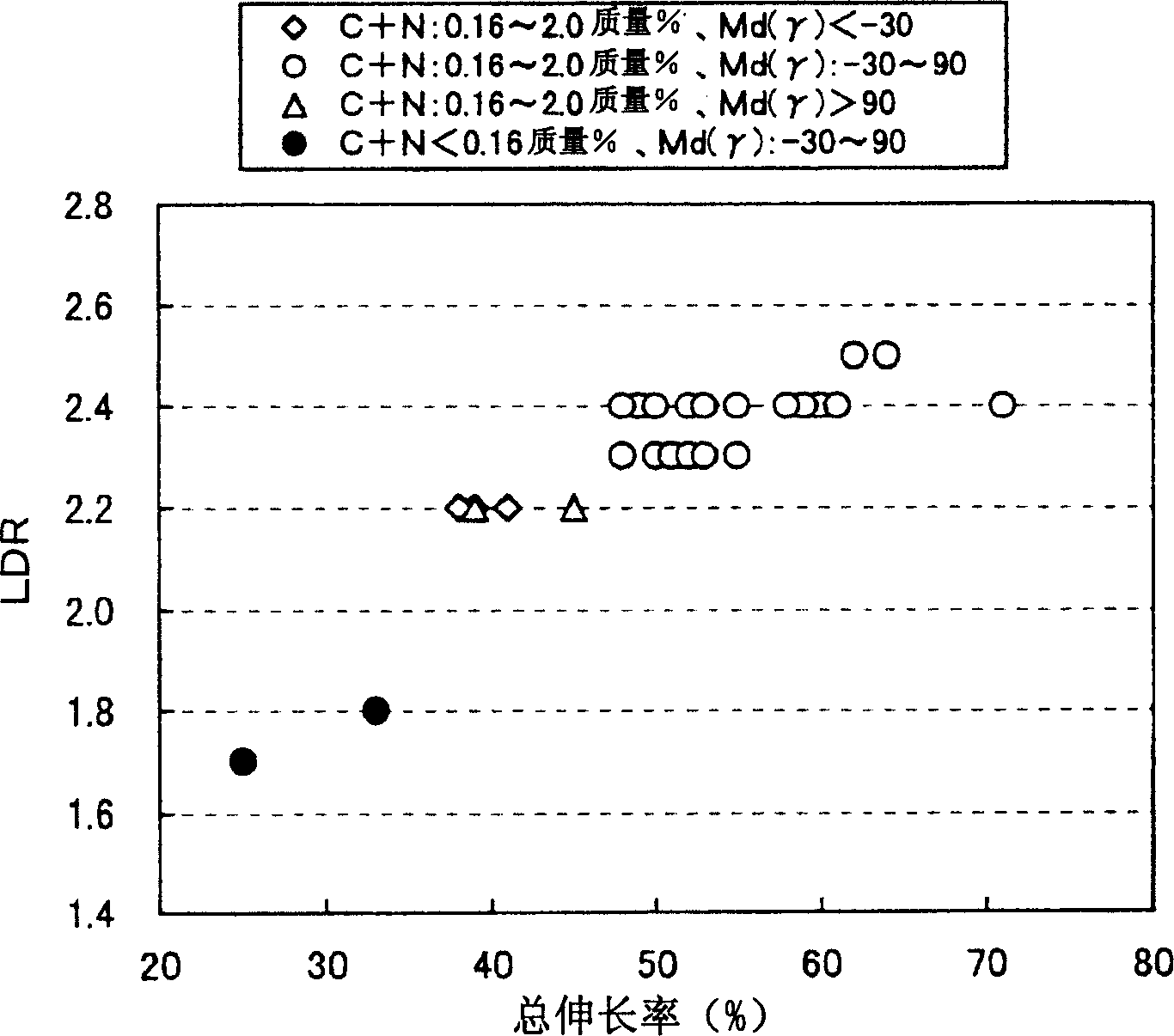

A low Ni and high N austenitic-ferritic stainless steel is disclosed. It includes an austenitic-ferritic stainless steel having high formability and punch stretchability, crevice corrosion resistance, corrosion resistance at welded part, or excellent intergranular corrosion resistance, from a stainless steel structured by mainly austenite phase and ferrite phase, and consisting essentially of 0.2% or less C, 4% or less Si, 12% or less Mn, 0.1% or less P, 0.03% or less S, 15 to 35% Cr, 3% or less Ni, and 0.05 to 0.6% N, by mass, by adjusting the percentage of the austenite phase in a range from 10 to 85%, by volume. Furthermore, it includes an austenitic-ferritic stainless steel having higher formability by adjusting the amount of (C+N) in the austenite phase to a range from 0.16 to 2% by mass.

Owner:JFE STEEL CORP

Austenitic-ferritic stainless steel with excellent formability

An austenitic-ferritic stainless steel having a low Ni content and a high N content is provided. A stainless steel which contains, in mass %, 0.2 % or less of C, 4 % or less of Si, 12 % or less of Mn, 0.1 % or less of P, 0.03 % or less of S, 15 to 35 % of Cr, 3 % or less of Ni, and 0.05 to 0.6 % of N, and is mainly composed of an austenite phase and a ferrite phase, wherein the proportion of said austenite phase is 10 to 85 volume %. The above austenitic-ferritic stainless steel exhibits good formability and high punch stretch formability, and is excellent in the resistance to crevice corrosion, to the corrosion of a welded zone and to intergranular corrosion. The above austenitic-ferritic stainless steel wherein the austenite phase contains C and N in a total amount of 0.16 to 2 mass % exhibits further improved formability.

Owner:JFE STEEL CORP

Process for welding duplex stainless steel

ActiveCN101972878AOvercome adverse defectsGood welding effectArc welding apparatusShielding gasPetrochemical

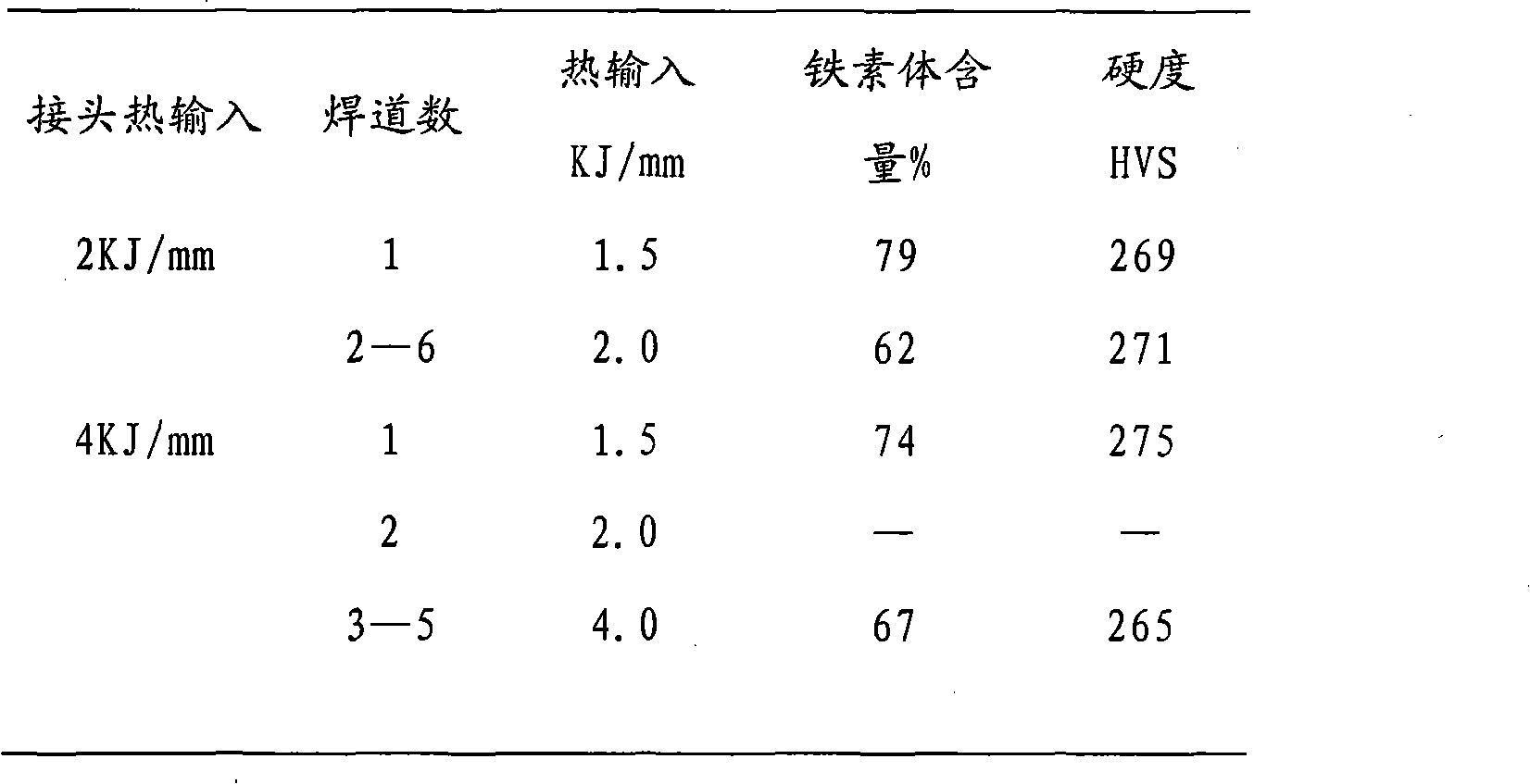

The invention relates to a process for welding duplex stainless steel, in particular to the process for welding the duplex stainless steel used for high-sulfur content refining equipment, highly-corrosive petrochemical equipment and pipelines, high-parameter power devices, and the chloridion-corroded environments of seawater and the like. In the process, a specific protective gas favorable for the welding of the duplex stainless steel is adopted, and simultaneously limited linear energy and inter-layer temperature are regulated in the welding process, so that the unfavorable defects of the conventional welding process can be overcome, and a metallographic structure with the ferrite content of 30 to 70 percent and a ferritic phase in percentage equivalent to that of an austenitic phase is obtained. A welding joint obtained by the welding process has high mechanical properties, high strength and hardness, particularly high yield strength which is about twice that of austenitic stainless steel, high thermal fatigue resistance, pitting corrosion resistance, crevice corrosion resistance, intercrystalline corrosion resistance and high weldability.

Owner:CHINA NAT CHEM ENG NO 7 CONSTR

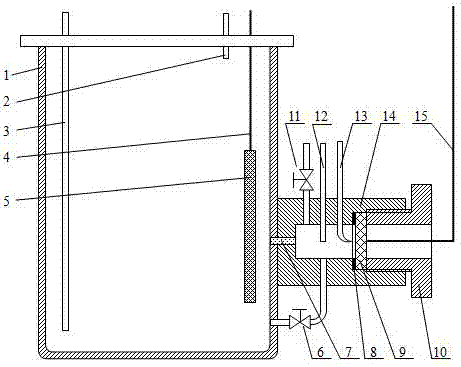

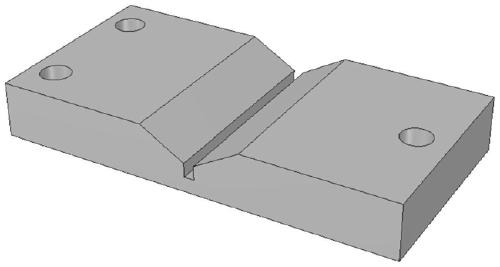

Electrochemical performance testing device for crevice corrosion

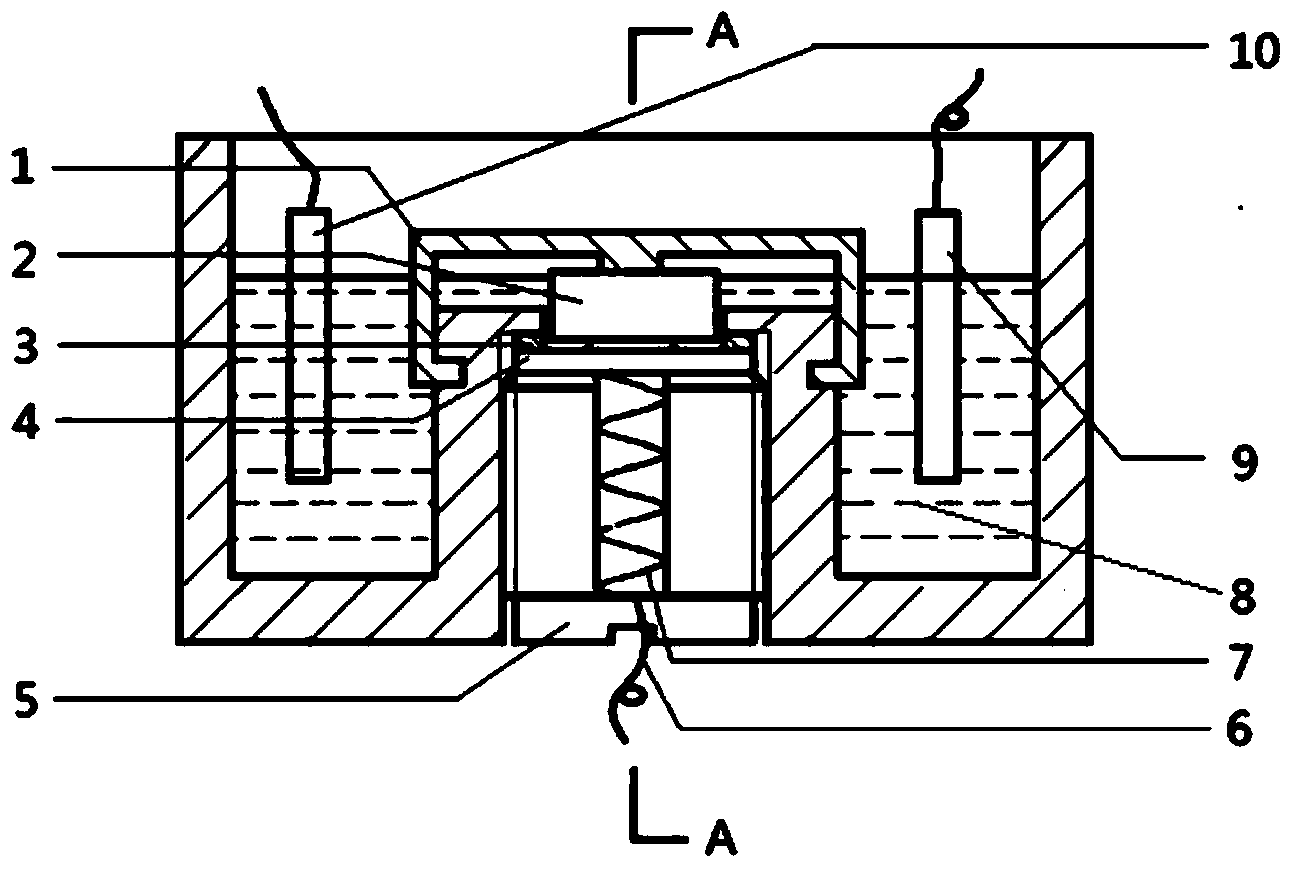

The invention relates to an electrochemical performance testing device for crevice corrosion, belonging to the field of corrosion prevention of metal materials. The testing device comprises a plastic clamp, a polytetrafluoroethylene pressure head, an O-shaped seal gasket, a sample, a plastic bolt, a wire, a spring, a double cylindrical liquor pool and a three-electrode electrochemical testing system, wherein the O-shaped seal gasket is placed on a test face of the sample, and the sample and the seal gasket are compressed at the top of a threaded hole of the liquor pool to seal. The wire connected with the spring is led out from the center of a nut of the plastic screw. The polytetrafluoroethylene pressure head with a bump is placed on the surface of the sample, and crevices in different widths are manufactured by using pressure heads with different heights of bumps. By means of a keyway on the outer wall of the inner cylindrical wall of the liquor pool, the pressure head is compressed on the surface of the sample by the plastic clamp. The three-electrode electrochemical testing system is arranged in the liquor pool and is externally connected with an electrochemical workstation for collecting electrochemical information of the sample in the corrosion process in real time or electrochemically testing the electrochemical information, thereby realizing research on the crevice corrosion of various materials with special crevice width and under liquor environment.

Owner:UNIV OF SCI & TECH BEIJING

Corrosion testing device capable of simulating complex environment and testing method thereof

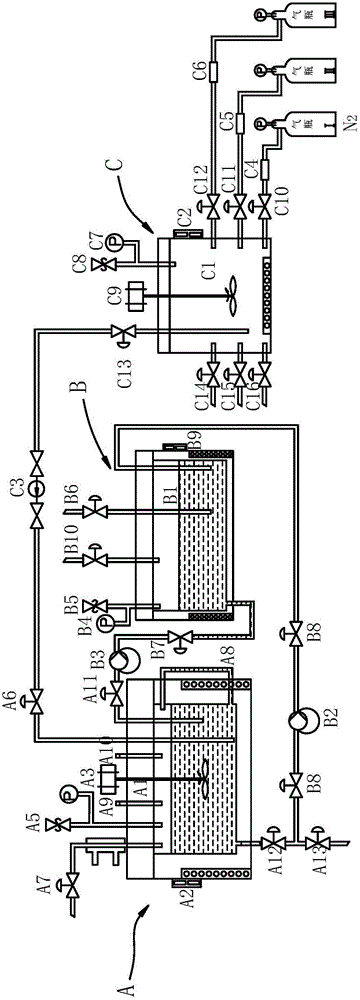

ActiveCN105891094AGuaranteed accuracyEnsure scientificWeather/light/corrosion resistanceTemperature controlGas composition

The invention discloses a corrosion testing device capable of simulating the complex environment and a testing method thereof. The device comprises a dynamic high-temperature autoclave system, a medium circulation system and a gas mixing system which can be used for conducting corrosion tests on a sample; the medium circulation system cooperates with the dynamic high-temperature autoclave system so that the medium in the testing environment can be replaced or circulated, and thus the solution medium or flow velocity under the actual working condition is simulated; the gas mixing system is communicated with and cooperate with the dynamic high-temperature autoclave system to simulate the gas composition and pressure environment required by the tests; the dynamic high-temperature autoclave system is internally provided with a medium temperature controller which is used for simulating the temperature under the actual working condition. According to the testing device, multiple types of testing parameters are considered comprehensively, an expansion interface is provided, multiple types of actual working conditions can be effectively simulated, corrosion performance evaluation and research of multiple types of materials, such as stress corrosion, uniform corrosion, erosion corrosion, pitting corrosion, crevice corrosion, electrochemical corrosion, coating corrosion resistance evaluation and corrosion inhibitor efficiency evaluation, in the complex environment are completed, and correctness and scientificity of the test result are guaranteed.

Owner:HEFEI GENERAL MACHINERY RES INST +1

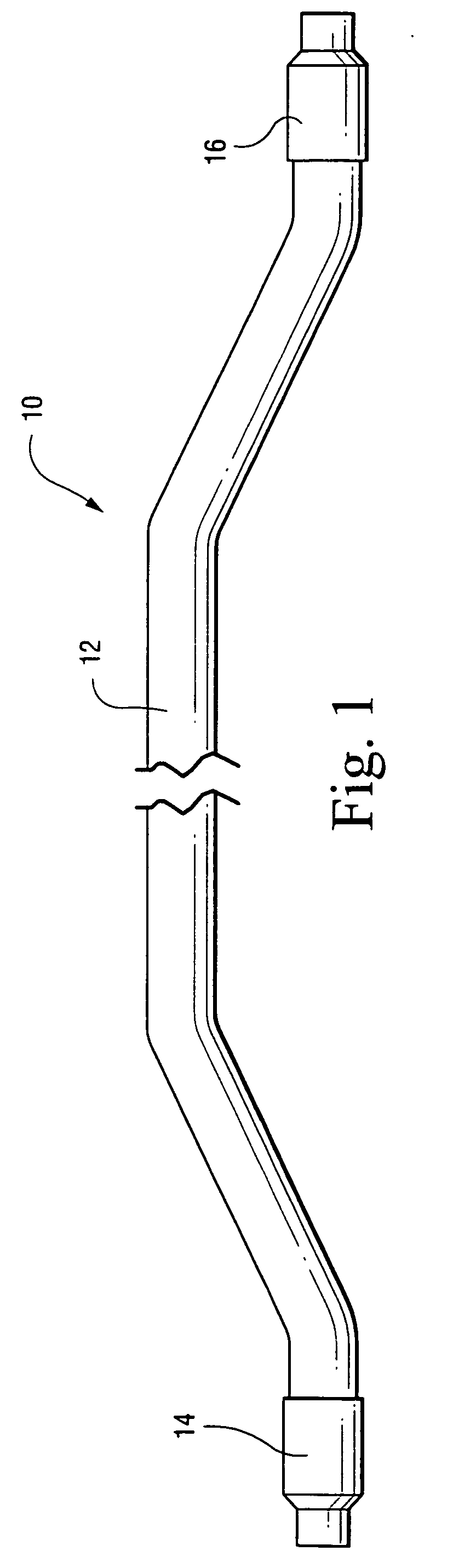

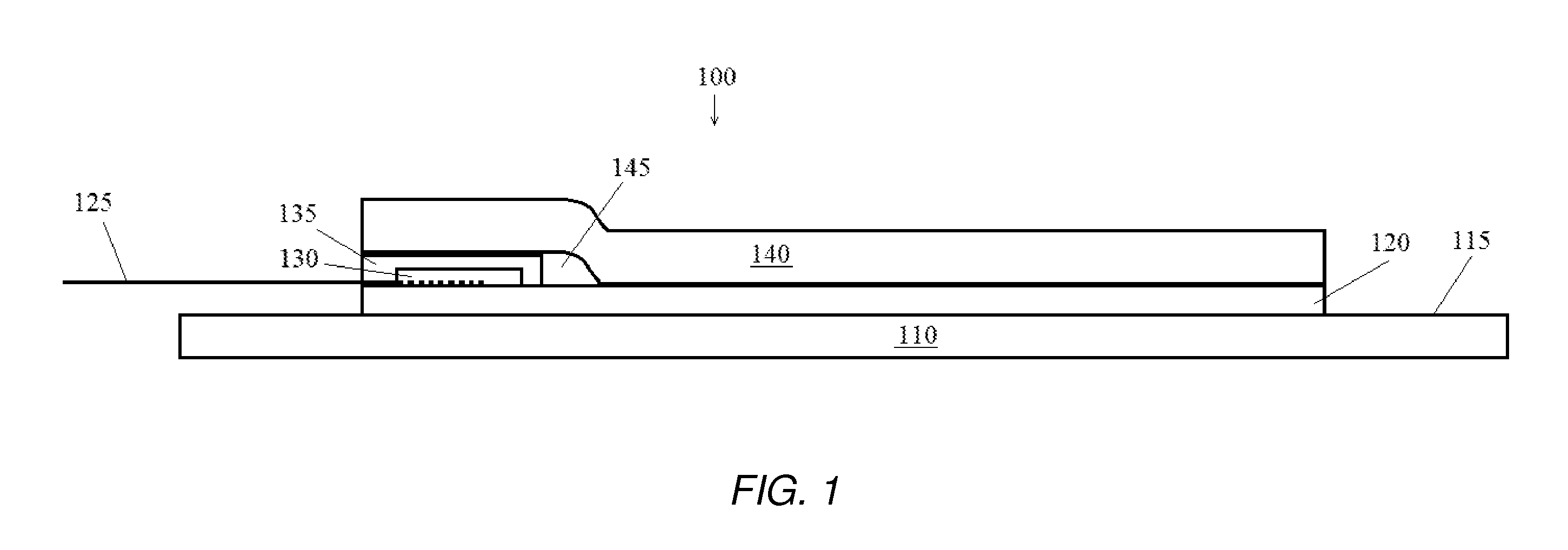

Crevice corrosion-resistant liquid-cooled armature bar clip-to-strand connection and related method

ActiveUS20050247762A1Improved generator availabilityImprove reliabilityTurbinesManufacturing dynamo-electric machinesEngineeringBraze alloy

A brazed joint between an armature bar strand package and an end fitting includes a plurality of strands arranged in a tiered array and forming the strand package; a cavity in the end fitting, free ends of the plurality of strands extending through the opening in the end fitting and received in the cavity; and an essentially phosphorous-free copper-silver braze alloy joining the free ends of the plurality of strands to each other and to interior surfaces of the end fitting.

Owner:GENERAL ELECTRIC CO

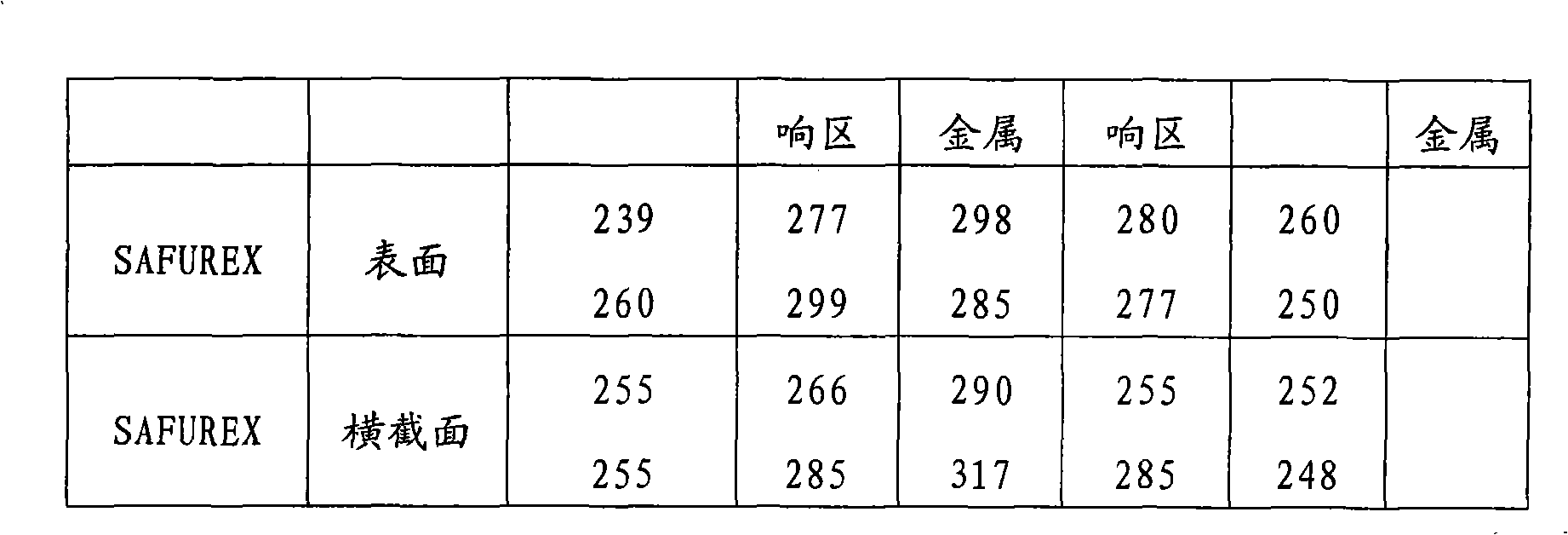

Method of producing stainless steels having improved corrosion resistance

InactiveUS6576068B2Improve the immunityImprove solubilityWelding/cutting media/materialsElectric furnaceNitrogenSS - Stainless steel

A method for producing a stainless steel with improved corrosion resistance includes homogenizing at least a portion of an article of a stainless steel including chromium, nickel, and molybdenum and having a PREN of at least 50, as calculated by the equation:where Cr is weight percent chromium, Mo is weight percent molybdenum, and N is weight percent nitrogen in the steel. In one form of the method, at least a portion of the article is remelted to homogenize the portion. In another form of the method, the article is annealed under conditions sufficient to homogenize at least a surface region of the article. The method of the invention enhances corrosion resistance of the stainless steel as reflected by the steel's critical crevice corrosion temperature.

Owner:ATI PROPERTIES

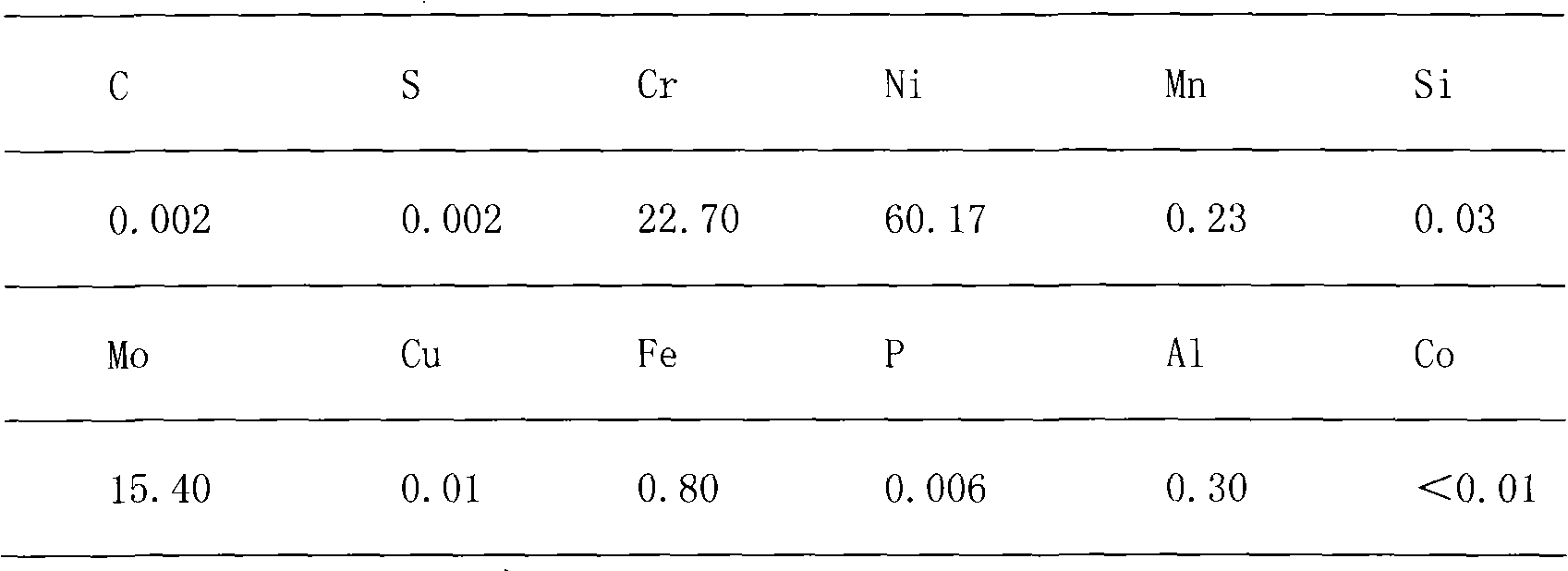

Super diphase stainless steel welding material and production method thereof

ActiveCN101913037AImprove pitting resistanceGood resistance to crevice corrosionWelding/cutting media/materialsSoldering mediaUltimate tensile strengthElectro-slag remelting

The invention relates to a super diphase stainless steel welding material and a production method thereof. The production method sequentially comprises the following procedures of: (1) melting; (2) re-melting electroslag; (3) forging; (4) rolling steel; and (5) drawing. The super diphase stainless steel welding material has favorable pitting resistance, crevice corrosion resistance, vacuole resistance, abrasion corrosion resistance and high fatigue strength in seawater media and good uniform corrosion resistance in various environments, and is the type of steel with strong suitability and wider application range on various media. The mechanical property of the material is shown in as below: sigmab / Mpa>=650, sigma0.2 / Mpa>=450, delta5 / %>=25, Ak / J>=150, HRC-20.

Owner:JIANGSU LIXIN ALLOY IND GENERAL

Corrosion resistance excellent steel for ship

To provide steel for shipbuilding having excellent corrosion resistance which can be put to practical use even without applying coating and electrical protection, particularly steel for shipbuilding in which the improvement of durability to crevice corrosion can be attained, and which exhibits excellent durability even to corrosion owing to the sticking of salt caused by seawater and owing to a wetting environment, and further can exhibit excellent corrosion resistance even when applied to a petroleum based liquid fuel tank. The corrosion resistant steel for shipbuilding has a composition comprising 0.01 to 0.30% C, 0.01 to 2.0% Si, 0.01 to 2.0% Mn and 0.005 to 0.10% Al, and further comprising 0.005 to 0.50% Se, and the balance Fe with inevitable impurities.

Owner:KOBE STEEL LTD

High-Cr ferrite stainless steel and manufacturing method thereof

ActiveCN102392189AReduce manufacturing costGood room temperature toughnessHeat treatment process controlRoom temperatureContinuous annealing

High-Cr ferrite stainless steel and a manufacturing method thereof belong to the technical field of stainless steel. The stainless steel comprises the following components by weight: 26.5<=Cr<=28.0, 3.4<=Mo<=3.9, 1.5<=Ni<=2.0, C<=0.032, N<=0.028, 0.4<=Nb<=0.5, Ti<=0.2, Mn<=0.2, Si<=0.23, S<=0.0039, P<=0.0083, and the balance of Fe, and meets Cr (wt%)+3.3*Mo (wt%)>=38.826. The manufacturing methodcomprises the following steps of: melting, continuous casting or mold casting, thermal grinding, hot rolling and coiling, continuous annealing treatment, oxide scale removal, cold rolling and annealing treatment, pickling and temper rolling, and welding. The advantage is that the high-Cr ferrite stainless steel has good room temperature toughness, pitting resistance, crevice corrosion resistance,stress corrosion resistance, and intergranular corrosion resistance.

Owner:CENT IRON & STEEL RES INST

Threaded joint for steel tubes

ActiveUS20100059986A1Improve the immunityEasy to operateDrilling rodsReflex reflectorsViscous liquidCrevice corrosion

A pin-box type threaded joint for steel tubes having a contact surface (30) including a threaded portion and a nonthreaded metal-to-metal contact portion has improved leak resistance, galling resistance, and corrosion resistance particularly to crevice corrosion. The contact surface of at least one of the pin and the box is coated with a first plating layer (34) made of a Cu—Zn alloy or a Cu—Zn-M1 alloy (wherein M1 is at least one element selected from Sn, Bi, and In). Optionally, an undercoat (32) of one or both of a Ni plating layer (32a) and a Cu plating layer (32b) and an overcoat of a Sn-M2 alloy plating layer (36) (wherein M2 is one or more elements selected from Bi, In, Ni, Zn, and Cu) may be formed below and above the first layer, respectively. A solid lubricating coating (38a) and a viscous liquid or semisolid lubricating coating (38b) may also be formed atop the plating layer as a lubricating coating (38).

Owner:VALLOUREC OIL & GAS FRANCE SAS +1

Marine steel material superior in corrosion resistance

InactiveCN1904118AImprove corrosion resistanceIncreased durabilityWaterborne vesselsAir atmosphereImpurity

Owner:KOBE STEEL LTD

Super duplex stainless steel seamless steel tube and preparation method

ActiveCN103361564AImprove pitting resistanceAccelerated corrosionFurnace typesRigid pipesOrganic acidChemical composition

The invention relates to a super duplex stainless steel seamless steel tube and a preparation method. The super duplex stainless steel seamless steel tube comprises the following chemical components in percentage by weight: 0.015-0.016% of C, 0.65-0.66% of Mn, 0.028-0.029% of P, 0.0004-0.0006% of S, 0.4-0.5% of Si, 6.3-6.4% of Ni, 25.3-25.4% of Cr, 3.3-3.4% of Mo, 0.28-0.29% of N, 0.12-0.13% of Cu and the balance of Fe. The super duplex stainless steel seamless steel tube has the advantages that the pittingresistance, the crevice corrosion resistance and the intercrystalline corrosion resistance are very high, the corrosion rates in organic acid and inorganic acid are low, and intermetallic phases or carbonitride cannot be separated along crystal boundaries or in a transgranular manner when staying at the temperature of 600 to 1000 DEG C.

Owner:JIANGSU YINHUAN PRECISION STEEL TUBE CO LTD

Method for improving biodegradation rate of pure iron or iron alloy and application thereof

InactiveCN102912171AMeet Medical Design RequirementsGood biocompatibilityProsthesisMetallic materialsBiocompatibility Testing

The invention aims to provide a method for improving the biodegradation rate of pure iron or iron alloy, which is characterized in that: pore structures are produced in the pure iron or iron alloy so that the degradation rate of the pure iron or iron alloy in the physiological environment is improved. Due to the adoption of the method, the problem that the degradation rate of the pure iron or iron alloy which develops as the biodegradable metal material is too low is solved. According to the principle of crevice corrosion, various types of pore structures are produced on the iron-based biodegradable material to achieve the purpose of improving the degradation rate of the material. Compared with the materials without the pore structures, the degradation rate of the iron-based biodegradable material is improved markedly, and the original biocompatibility is kept.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

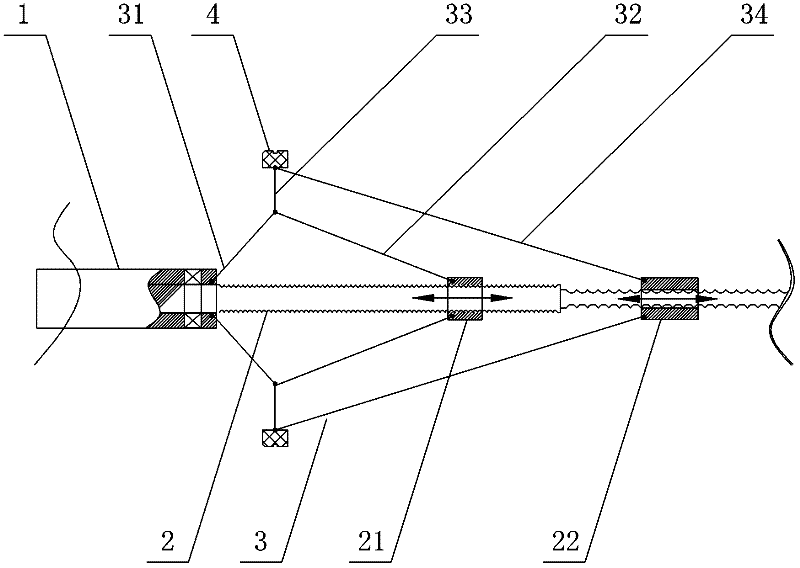

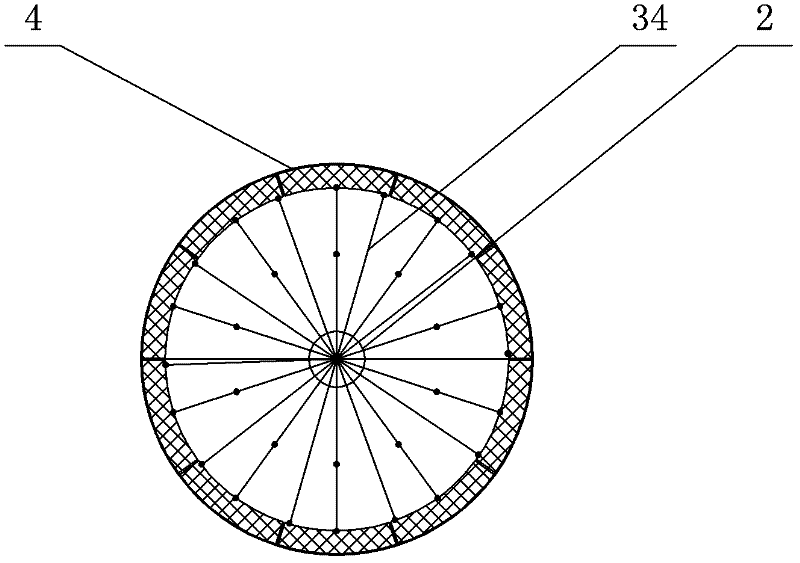

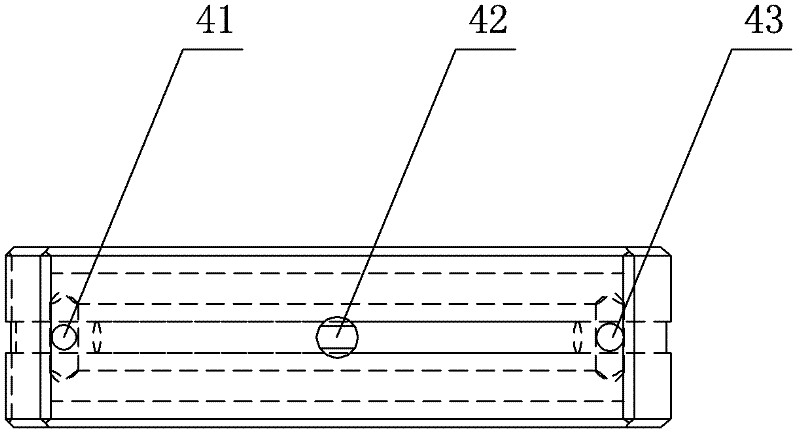

Circumferential seam butt welding protection device

ActiveCN102528343AGuarantee welding qualityAchieve front and back protectionWelding/cutting auxillary devicesAuxillary welding devicesOver oxidationButt welding

A circumferential seam butt welding protection device comprises a fixed sleeve and a rotating shaft. One end of the rotating shaft is inserted into the fixed sleeve, a plurality of link mechanisms are arranged on the fixed sleeve, two thread sections with different thread pitches are arranged on the rotating shaft, an opening-closing slider is arranged on the first thread section, a rotating slider is arranged on the second thread section, and the link mechanisms are respectively connected with the rotating slider and the rotating slider. When the circumferential seam butt welding protection device is in welding preparation, the umbrella-shaped link mechanisms on the rotating shaft play a role, a plurality of back protection cooling blocks form a circumferentially arrayed device by means of synchronous sliding of the opening-closing slider and the rotating slider. During welding, the circumferentially arrayed device can be used for protecting the fronts and the backs of circumferential seams of an end cap and a cylinder body of a closed cylindrical container by means of back cooling and gas protection for a workpiece to be welded. By the aid of the circumferential seam butt welding protection device, the welding quality of the circumferential seams can be ensured, and crevice corrosion and over oxidation of the backs of the circumferential seams in conventional circumferential seam lap welding are avoided.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD

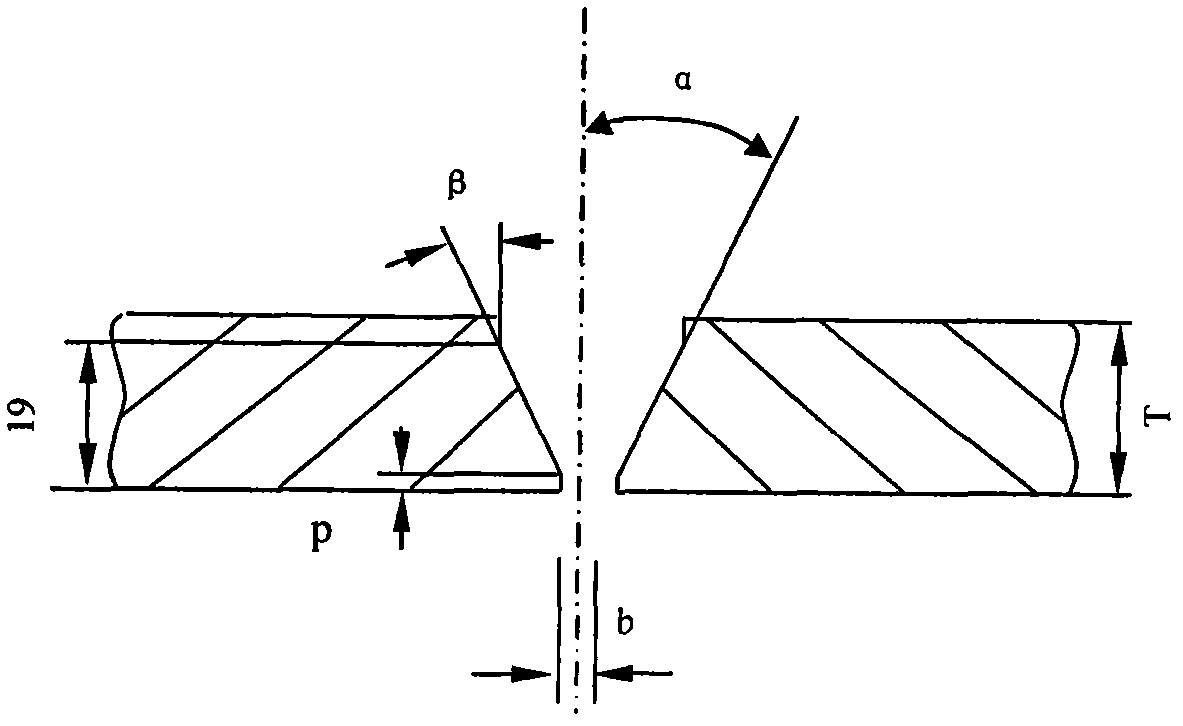

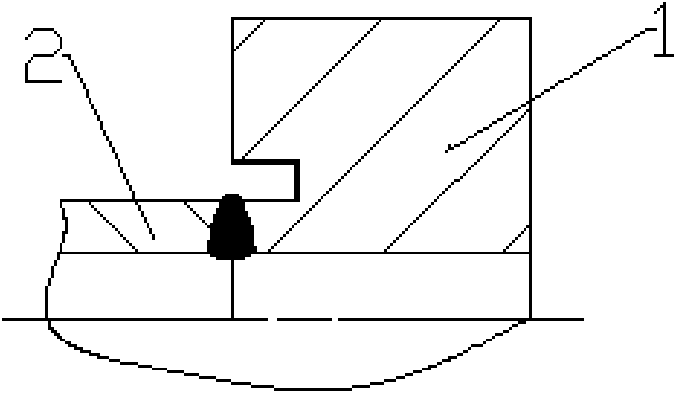

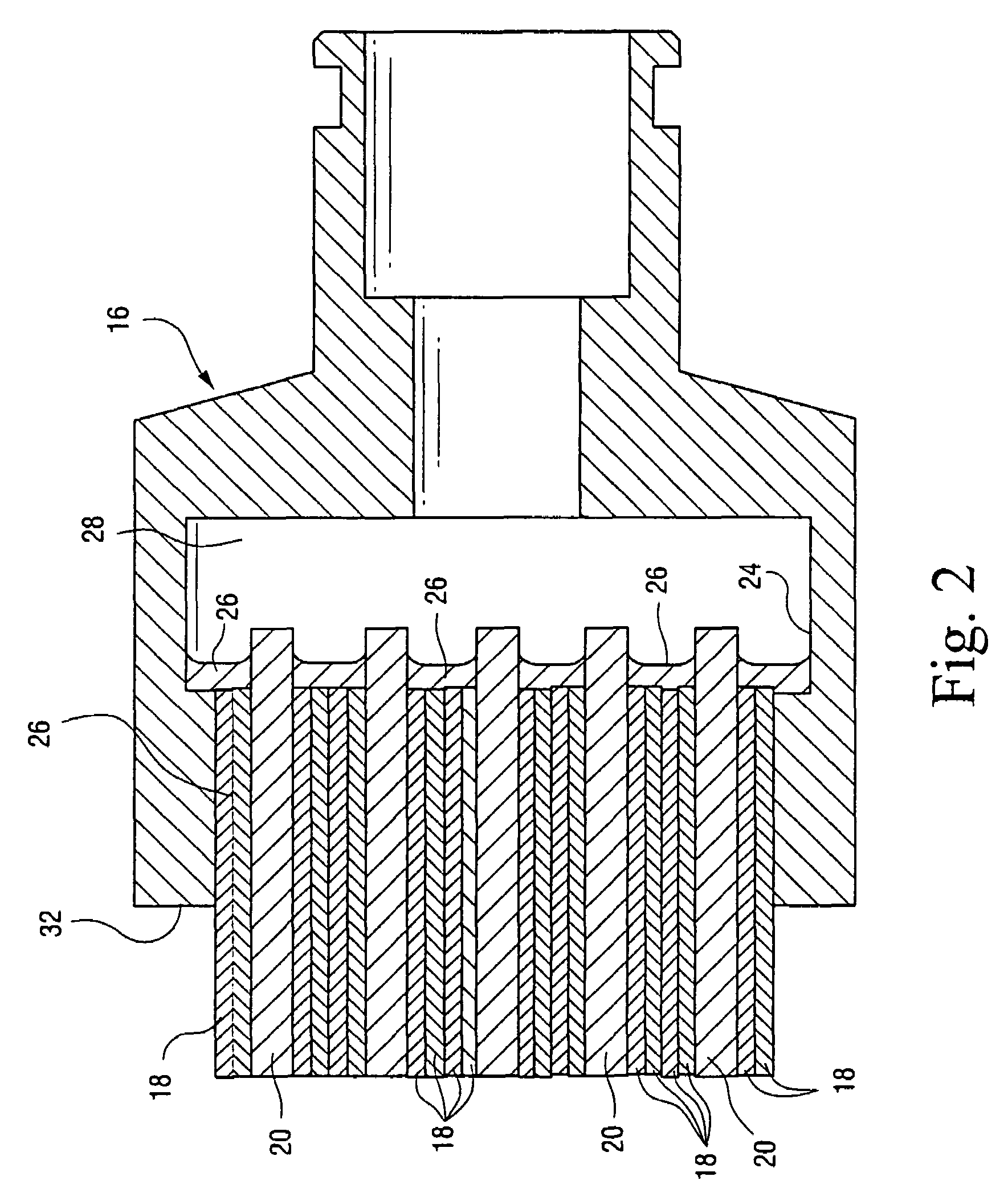

Bore welding method of heat exchange tube and tube plate in heat exchanger

ActiveCN101628354AAvoid crevice corrosion problemsAvoid Effusion CorrosionArc welding apparatusHeat exchange apparatusPlate heat exchangerEngineering

The invention discloses a bore welding method of a heat exchange tube and a tube plate in a heat exchanger, comprising the following steps: processing a circular hole (2) on the tube plate (1), overlapping the welding end of the heat exchange tube (3) on the circular hole (2) of the tube plate (1) during the welding process, performing bore welding at the joint, and inserting the welding end of the heat exchange tube (3) into the circular hole (2) by 0.3-1.8 mm, wherein the diameter of the circular hole (2) on the tube plate (1) is 0.1-0.3 mm larger than the external diameter of the heat exchange tube (3). By welding the heat exchange tube and the tube plate with the method, the invention improves the welding quality and effectively avoids crevice corrosion and deposit fluid corrosion after welding. The bore welding method of a heat exchange tube and a tube plate in a heat exchanger has simple technological operation and excellent welding performance, greatly improves the quality of the heat exchanger and prolongs the service life.

Owner:SICHUAN BLUSR MACHINERY

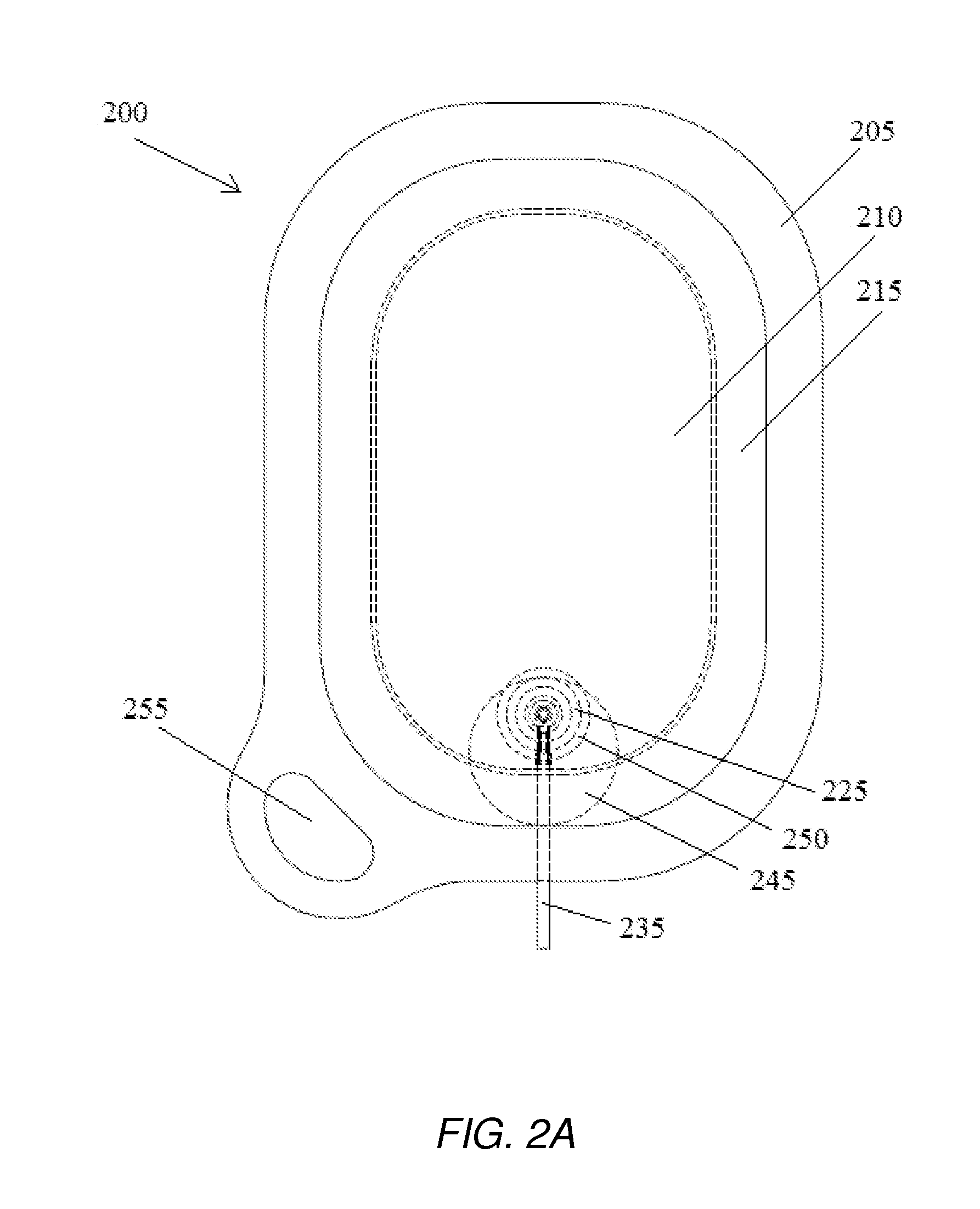

Electrode construction for crevice corrosion protection

An electrode includes an adhesive backing layer including a front surface configured to adhere to skin of a subject and a rear surface, a plate including a rear surface coupled to the front surface of the adhesive backing layer and a front surface comprising a conductive material layer, a conductive hydrogel including a rear surface coupled to a front surface of the conductive material layer, and including a front surface configured to make electrical contact with the skin of the subject, a dielectric film border formed on the front surface of the conductive material layer and defining an area on the front surface of the conductive material layer, and an electrical to lead in electrical contact with the area.

Owner:ZOLL MEDICAL CORPORATION

Crevice corrosion-resistant liquid-cooled armature bar clip-to-strand connection and related method

ActiveUS7216796B2Improve availabilityImprove reliabilityTurbinesManufacturing dynamo-electric machinesEngineeringBraze alloy

Owner:GENERAL ELECTRIC CO

Ultra-low carbon Ni-Cr-Mo5923hMo steel alloy explosion welding high corrosion resistance composite material

ActiveCN101293305AEliminate the detonatorEliminate both sidesNon-electric welding apparatusCrack resistanceStress corrosion cracking

The invention relates to a novel compound material which is formed by an explosion welding technique and a common low alloy steel Q345B as well as by adopting the ultra-low-carbon Ni-Cr-Mo 5923hMo alloy steel as a high anti-corrosion layer. The manufacture method of the invention includes the techniques of surface pre-treatment, explosion welding compounding and annealing for removing a stress. The structure of the invention is that the common low alloy steel is combined with the metallurgy of a 5923hMo anti-corrosion steel multiple layer on the common low alloy steel. The compound material of the invention has the advantages that the multiple layer has excellent anti-corrosion property to most corrosion properties and extremely excellent properties of pit corrosion resistance, crevice corrosion resistance and stress corrosion cracking resistance caused by chlorides; while a basic layer plate has excellent mechanical property to fully play the excellent physical and chemical properties of two metals. The novel compound material can not have the phenomena of cracking or separation on the interface between the basic layer and the composite layer after being processed by the hot and cold techniques such as annealing, leveling and cutting, etc. Analyzed by a physical test and a chemical test, the property index of the novel compound material is completely in accordance with the standard of JB4748-2002 and can meet the property requirements of a device to special materials under execrable working conditions.

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

Alloy material flange and forging technology thereof

ActiveCN104004971AHigh resistivityLower temperature coefficient of resistivityMetal-working apparatusFurnace typesRare-earth elementCerium

The invention discloses an alloy material flange and a forging technology thereof. An alloy blank of the alloy material flange comprises, by weight, 12.7-12.9% of Ni, 25.3-25.5% of Cr, 0.1-0.12% of C, 0.17-0.19% of Si, 0.72-0.79% of Mn, 0.0015-0.0035% of S, 2.25-2.35% of Mo, 3.25-3.45% of Ti, 3-3.25% of Al, 1.25- 1.85% of Cu, 0.015-0.017% of P, 0.9-1.1% of W, 0.018-0.022% of B, 0.9-1.1% of Nb, 0.11-0.13% of rare earth elements and the balance Fe and impurities. The rare earth elements comprise 12-18% of Yb, 6-11% of Er, 19-25% of Dy, 16-26% of Gd, 8-17% of Ce, 13-18% of La and 15-22% of Th. Through raw material chemical analysis, forging temperature and forging ratio control, solid solution treatment after forging, heat treatment and structure hardening treatment after heat treatment, the forge piece can be used under the conditions of high sulphur and phosphorus content and has good mechanical properties. The alloy material has excellent stress corrosion cracking resistance, pitting corrosion resistance and crevice corrosion resistance, has good oxidizing and non-oxidizing hot acid resistance and has stable mechanical properties in a range of a room temperature to a high temperature of 550 DEG C.

Owner:WUXI HUAERTAI MACHINERY MFG

Corrosion resistance excellent steel for ship

InactiveCN1715433AImprove corrosion resistanceIncreased durabilityCrevice corrosionCorrosion resistant

To provide steel for shipbuilding having excellent corrosion resistance which can be put to practical use even without applying coating and electrolytic protection, particularly, steel for shipbuilding in which the improvement of durability to crevice corrosion can be attained, and which exhibits excellent durability even to corrosion owing to the sticking of salt caused by seawater and owing to a wetting environment. The corrosion resistant steel for shipbuilding has a composition comprising 0.01 to 0.30% C, 0.01 to 1.50% Si, 0.01 to 2.0% Mn and 0.005 to 0.10% Al, and further comprising 0.01 to 5.00% Co and 0.0005 to 0.020% Mg, and the balance Fe with inevitable impurities.

Owner:KOBE STEEL LTD

In-situ cast stainless steel

InactiveCN102162074AMagneticExcellent physical and chemical propertiesStress corrosion crackingWear resistance

The invention relates to an in-situ cast stainless steel which comprises the following components in percentage by weight: 0.01-0.12% of C, 15.00-22.00% of Cr, 5.00-10.00% of Ni, 1.00-2.50% of Mo, at most 5.00% of Mn, 0.02-1.00% of Nb, 0.80-2.00% of Si, at most 0.03% of S, at most 0.06% of P, at least 0.02% of Re, 0.05-0.30% of N and the balance of Fe. The heat-treatment-free in-situ cast stainless steel has the advantages of fine structure, higher yield strength and toughness than traditional similar nickel-chromium stainless steel, acid / alkali corrosion resistance, favorable machinability, favorable weldability, environmental protection and energy saving, has favorable stress corrosion cracking resistance, crevice corrosion resistance, corrosion wear resistance and cavitation corrosion resistance especially in a chloridion-containing medium and a sea water corrosion environment, does not need excellent heat treatment equipment, and lowers the cost by about 20% as compared with the traditional stainless steel.

Owner:陈才金

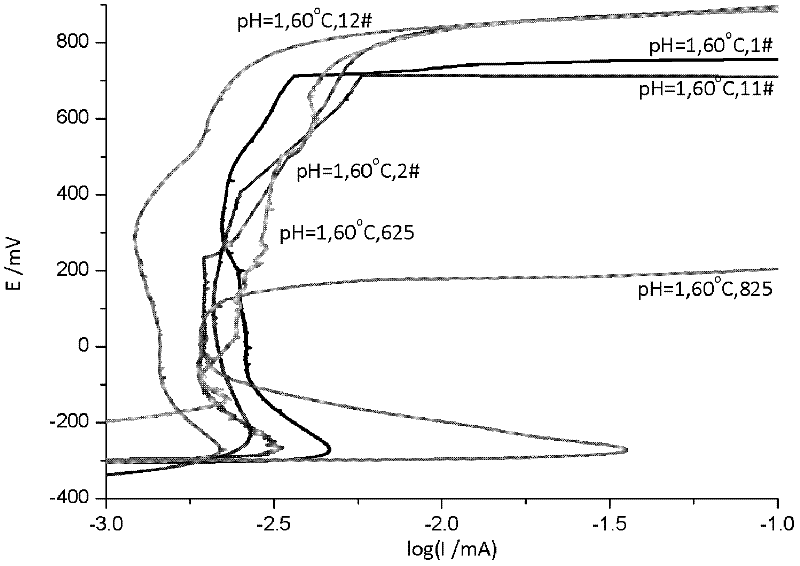

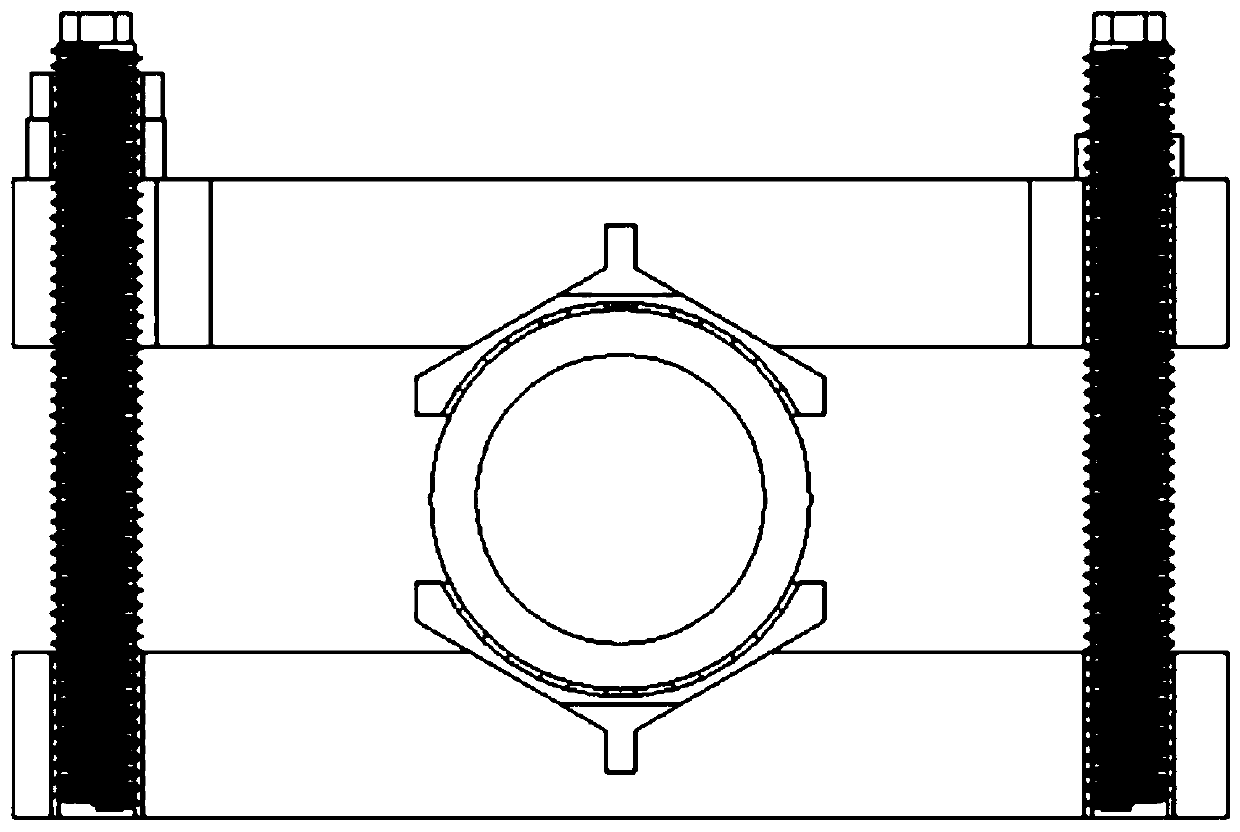

Electrochemical test device for simulating crevice corrosion

ActiveCN107063990AAvoid Test ImpactReflects crevice corrosion resistanceWeather/light/corrosion resistanceNuclear energy generationSalt bridgeTest sample

The invention relates to an electrochemical test device for simulating crevice corrosion. An air inlet pipe and an exhaust pipe are arranged on the top cover of an outer solution tank; an external test sample is hung in the outer solution tank via an auxiliary electrode lead; the bottom of the outer solution tank is connected with the bottom of an internal solution tank via a liquid feed pipe; a suction pipe, a minitype pH electrode and a luggin capillary salt bridge are arranged at the top of the internal solution tank; the internal solution tank is sealed by a test sample indenter; an internal test sample is arranged at the left end of the test sample indenter; the internal test sample is connected with a working electrode; the external solution tank simulates the corrosion environment outside a crevice; the internal solution tank simulates the corrosion environment inside a crevice; the air inlet pipe introduces CO2 and H2S different gases to the external solution tank; the suction pipe vacuumizes the internal solution tank; and a three-electrode system comprising the external test sample, the internal test sample and the luggin capillary salt bridge can collect electrochemical data in real time. The electrochemical test device disclosed by the invention can evaluate the crevice corrosion properties under different solution, atmosphere, temperature and crevice size conditions, and can test the anti-crevice corrosion property of materials at different electrochemical parameters.

Owner:XI'AN PETROLEUM UNIVERSITY

Clamp for securing components

InactiveUS8550411B2Effectively inhibit corrosionPrevent materialPipe supportsElectrical apparatusBiomedical engineeringCrevice corrosion

A clamp for securing components, in particular string-like or linear structural members, like pipelines, hoses, or cables, has at least one clamp part (3). The clamp part outer contour (4) delimits at least partially a receiving space (5) for receiving the component. The one clamp part (3) has a mechanism (6) for minimizing corrosion, in particular, crevice corrosion, at every component that is held. The mechanism has at least one sacrificial element (7) that is visibly consumed with the onset of corrosion and continued duration of use of the clamp fastener. The respective sacrificial element (7) is placed, as an independent component, on the outer contour (4) of the clamp part (3).

Owner:HYDAC ACCESSORIES

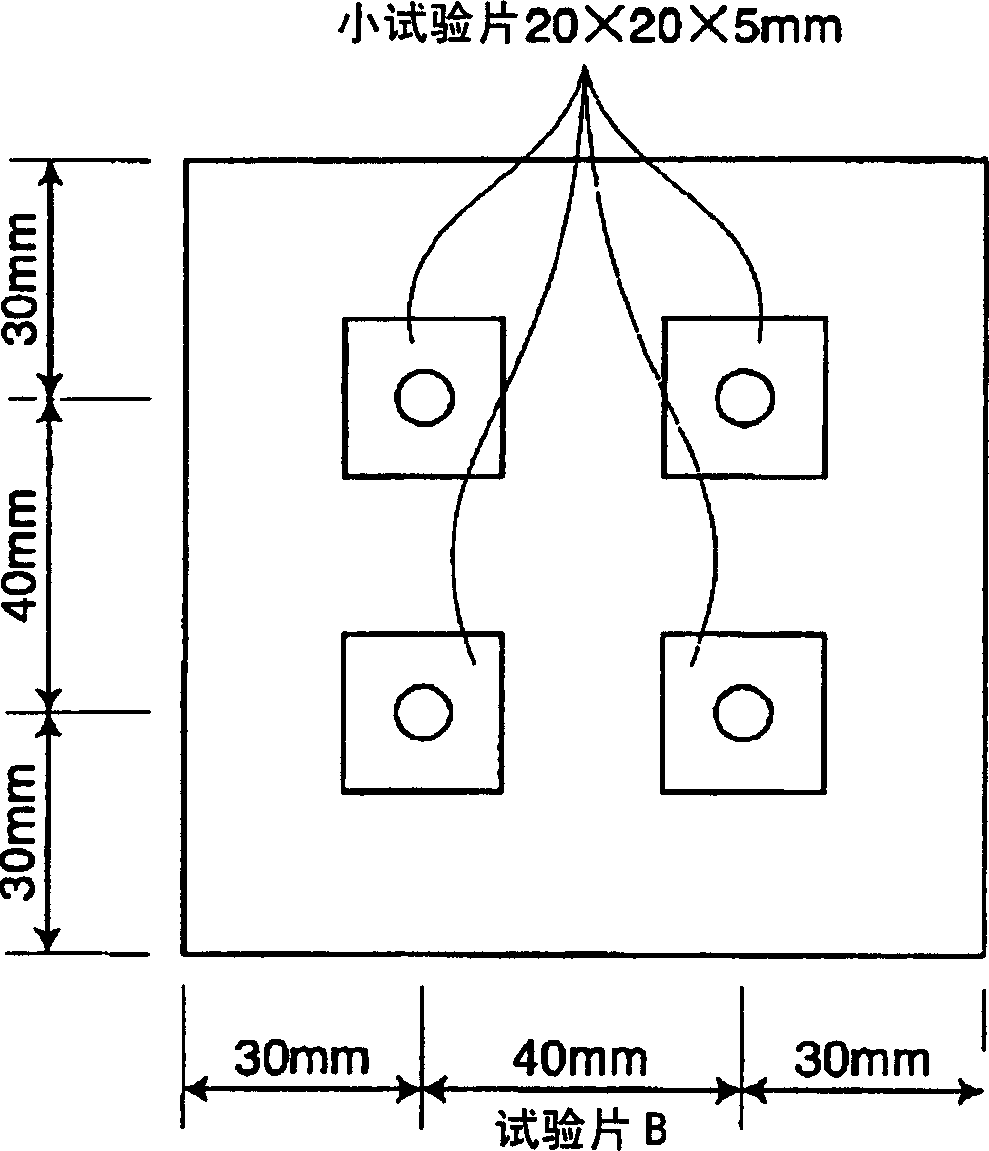

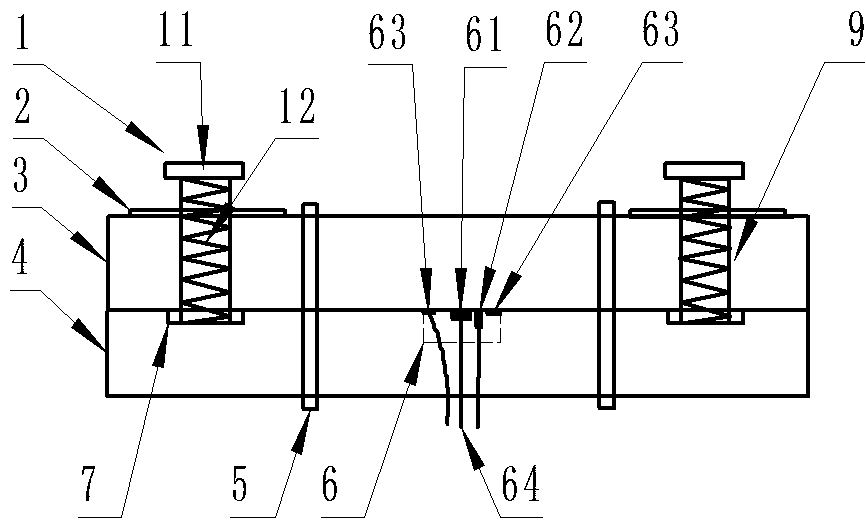

Artificial crevice device for simulating crevice corrosion research in deep-sea environment

ActiveCN110044810AReal-time acquisitionSimple structureWeather/light/corrosion resistancePreparing sample for investigationCircular discEngineering

The invention provides an artificial crevice device for simulating crevice corrosion research in a deep-sea environment. The artificial crevice device for simulating the crevice corrosion research inthe deep-sea environment comprises bolts, angle discs, an upper clamping plate, a lower clamping plate, elastic tightening devices and solid-state three-electrode systems; at least two threaded through holes matched with the bolts are formed in the periphery of the upper clamping plate, and the upper clamping plate is tightly attached to the lower clamping plate by being sleeved and bound with atleast two sets of the elastic tightening devices in a surrounded mode; the bolts are screwed towards the direction of the lower clamping plate through the threaded through holes to form crevices, andscrewing angles can be recorded through the angle discs; and at least one set of the solid-state three-electrode system is installed in the lower clamping plate in a sealing mode, the surfaces of allelectrodes are flush with the attaching surface of the lower clamping plate, and wires connected with the electrodes are guided out through the other side of the lower clamping plate. According to theartificial crevice device for simulating the crevice corrosion research in the deep-sea environment, the structure is simple, the operation is convenient, through the rotation of the bolts on the periphery of the upper clamping plate and the control of the angle discs, the crevices with different spacing and opening angles can be precisely controlled to be formed, and real-time acquisition of electrochemical information at different positions in the crevices in the high-hydrostatic sea water environment can further be realized.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Stainless steel production method

InactiveCN103805870AImprove pitting resistanceGood resistance to crevice corrosionWear corrosionCavitation

The invention relates to a stainless steel production method. The stainless steel comprises the following chemical components (wt.%): 0.01-0.03 of C, 0.05-0.1 of Si, 1-2 of Mi, 0.01-0.001 of S, 0.0015-0.015 of P, 30-35 of Cr, 3-4 of Mo, 0.2-0.8 of Cu, 0.1-0.01 of Le, and the balance Fe. The production method includes: vacuum smelting, electroslag refining, forging cogging, hot rolling molding, cold drawing, and heat treatment. The stainless steel welding material produced by the method has good pitting resistance, crevice corrosion resistance, cavitation and wear corrosion resistance in seawater medium and high fatigue strength.

Owner:丹阳市锦雄机械制造有限公司

Ferritic stainless steel excellent in corrosion resistance and strength of weld zone and tig welded structure

InactiveUS20140023432A1High strengthIncrease resistanceArc welding apparatusFurnace typesWeld strengthUltimate tensile strength

Ferritic stainless steel excellent in corrosion resistance of the weld zone, in particular the corrosion resistance to crevice corrosion, even if eliminating the Ar gas shield at the time of TIG welding and, furthermore, excellent in weld zone strength and a structure of the same are provided. By making the ingredient system one satisfying the following formula (1) in ferritic stainless steel which has predetermined contents of ingredients by mass % under a usual corrosive environment, it is possible to raise the corrosion resistance. Furthermore, under a severely corrosive environment, by making the relationship between the back surface exposed width of the weld bead and the steel sheet thickness satisfy the formula (2) in addition to the relationship of the ingredients prescribed in formula (1), it is possible to obtain a welded structure strong in crevice corrosion. Furthermore, by improving the weld strength by making the contents of Nb and V satisfy formula 3, it is possible to obtain a welded structure with a high weld strength:Si+2.5Al+3Ti≦1.50 (formula (1))0<Wb / 2t≦1.50 (formula (2))(t: sheet thickness of welded metal, Wb: length of bead width exposed at back surface)Nb×V≧0.01 (formula 3)

Owner:NIPPON STEEL & SUMIKIN STAINLESS STEEL CORP

High temperature and high pressure dynamic galvanic corrosion experiment method and device

ActiveCN106501162ALoad accuratelyReliable experimental methodWeather/light/corrosion resistanceMetallic materialsHigh pressure

The invention discloses a high temperature and high pressure dynamic galvanic corrosion experiment method and device. The high temperature and high pressure dynamic galvanic corrosion method is characterized in that evaluation of galvanic corrosion performance of two metal materials coupled in the cyclic dynamic high temperature and high pressure gas- and liquid-phase corrosive media is realized, galvanic corrosion rate is detected, and the connection suitability of the two metal materials, as well as the tightness of the threaded connection, is tested. According to the use and service environment of two metal materials, they are connected by the connecting rod and threaded connection and loaded with a certain torque, and are placed in the cyclic dynamic high temperature and high pressure gas- and liquid-phase corrosive environment. By means of the experiment method and device, the galvanic corrosion rate of the two metal materials coupled can be detected, and the galvanic corrosion damage and the sensitivity factor of the two metal materials coupled can be quantitatively analyzed to test the connection sutability of the two metal materials and the reliability of threaded sealing, the occurrence risk of galvanic corrosion and crevice corrosion can be comprehensively assessed.

Owner:SOUTHWEST PETROLEUM UNIV

Method of producing stainless steels having improved corrosion resistance

InactiveUS20020189399A1Inhibition of developmentPromoting high CCCT valueWelding/cutting media/materialsElectric furnaceNitrogenSS - Stainless steel

A method for producing a stainless steel with improved corrosion resistance includes homogenizing at least a portion of an article of a stainless steel including chromium, nickel, and molybdenum and having a PREN of at least 50, as calculated by the equation: <paragraph lvl="0"><in-line-formula>PREN=CR+(3.3xMo)+(30xN), < / in-line-formula>where Cr is weight percent chromium, Mo is weight percent molybdenum, and N is weight percent nitrogen in the steel. In one form of the method, at least a portion of the article is remelted to homogenize the portion. In another form of the method, the article is annealed under conditions sufficient to homogenize at least a surface region of the article. The method of the invention enhances corrosion resistance of the stainless steel as reflected by the steel's critical crevice corrosion temperature.

Owner:ATI PROPERTIES

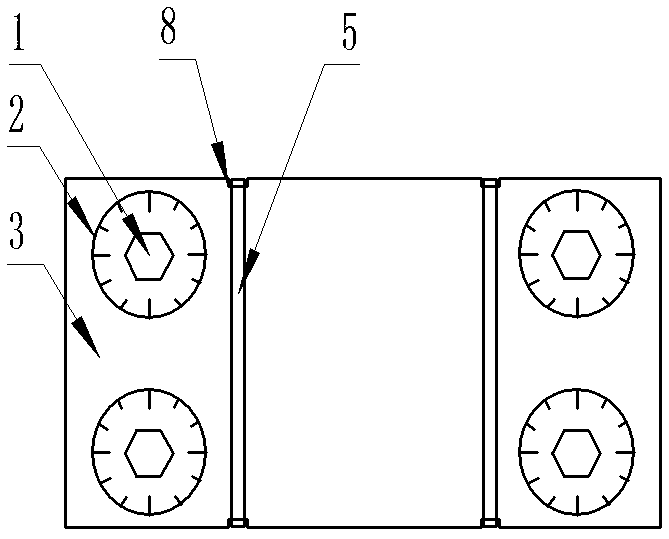

Metal crevice corrosion simulation device and metal crevice corrosion simulation experiment method

PendingCN111380770AWon't breakWill not seriously damageWeather/light/corrosion resistanceInvestigating abrasion/wear resistancePipe fittingCrevice corrosion

The invention provides a metal crevice corrosion simulation device and a metal crevice corrosion simulation experiment method, and relates to the technical field of material corrosion evaluation devices. The metal crevice corrosion simulation device provided by the invention can be used for evaluating the crevice corrosion degree of a to-be-tested metal object in the field environment, and the metal crevice corrosion simulation device provided by the invention is not regarded as an acceleration test method in the service environment, which has important guiding significance for the actual corrosion condition of the actual metal object. According to the metal crevice corrosion simulation device provided by the invention, the to-be-tested metal object cannot be damaged in the crevice corrosion evaluation process, the to-be-tested metal object (pipe fitting) does not need to be processed into an experimental test piece, the surface state of the pipe fitting conforms to the actual workingcondition, a pipeline cannot be seriously damaged, and the processing cost is favorably saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com