Metal crevice corrosion simulation device and metal crevice corrosion simulation experiment method

A technology for crevice corrosion and simulating devices, which is used in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., and can solve problems such as weak guidance in actual corrosion conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

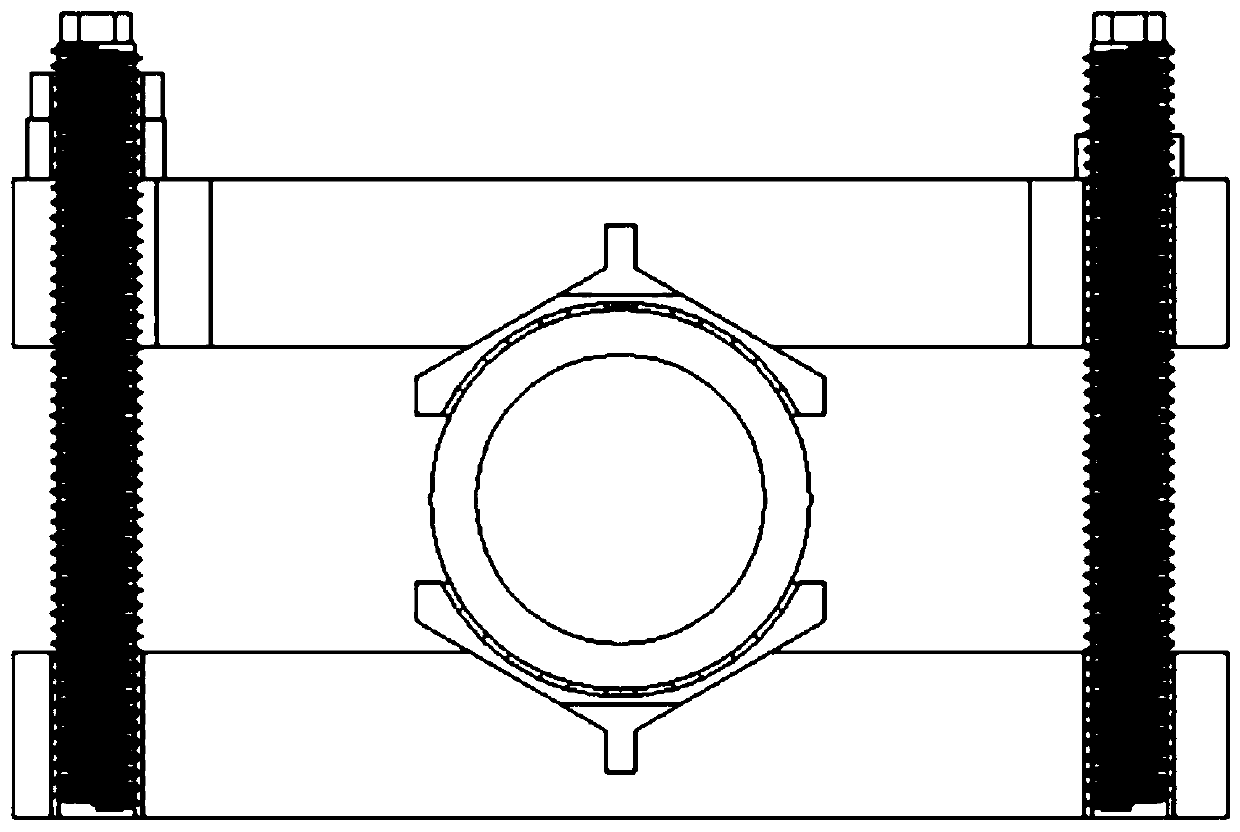

[0066] This embodiment provides a simulation device for metal crevice corrosion, referring to figure 1 and figure 2 As shown, it includes a bottom support plate 1 , a top cover plate 2 , a pressurized backing plate 3 , a support screw 4 and a prefabricated gap gasket 6 . An experimental pipe 7 is sandwiched between a pair of prefabricated gap gaskets 6 arranged up and down. The prefabricated gap gaskets 6 arranged up and down are fixed by the top cover plate 2 above and the bottom support plate 1 below. In this embodiment, the top cover plate 2 is in contact with the pressure pad 3 .

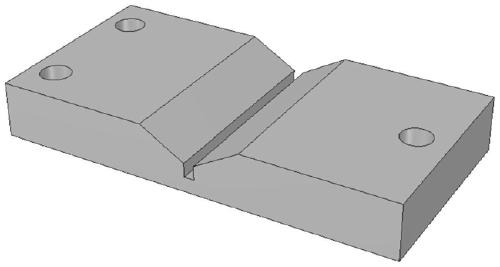

[0067] Refer to the shape of the top cover 2 Figure 4 As shown, the shape of the bottom support plate 1 refers to image 3 shown. In this embodiment, three installation holes are provided on the bottom support plate 1, refer to image 3 As shown, the two mounting holes on the left are used to install the support screw 4, and the support screw 4 supports the bottom support plate 1 and the...

Embodiment 2

[0093] This embodiment provides a simulation device for metal crevice corrosion in a symmetrical arrangement, referring to Figure 7 As shown, the only difference from Embodiment 1 is that in this embodiment, pressure pads 3 and support screws 4 are arranged symmetrically on both sides of the top cover plate 2, and the number of support screws 4 is four (two pairs). , each pair of adjacent supporting screw rods 4 is used to support the pressurized backing plate 3 and the bottom supporting plate 1 . The pressure pads 3 arranged on both sides of the top cover 2 apply downward pressure to compress the top cover 2 and the prefabricated gap gasket 6 to ensure that the experimental pipe 7 does not move sideways.

[0094] All the other structures are the same as in Example 1, and the method of use is also the same as in Example 1.

Embodiment 3

[0096] This embodiment provides a simulation device for asymmetrically arranged metal crevice corrosion, refer to Figure 8 As shown, it includes a bottom support plate 1 , a top cover plate 2 , a pressurized backing plate 3 , a support screw 4 , a first rotating shaft 8 , a second rotating shaft 9 , a T-shaped plate 10 and a prefabricated gap gasket 6 .

[0097] One end of the bottom supporting plate 1 is pierced with a first rotating shaft 8, the first rotating shaft 8 runs through the bottom supporting plate 1 transversely, and both ends of the first rotating shaft 8 are connected in series with rollers, and each roller is provided with a The support hole of the support screw 4 is installed, the top of the support screw 4 is fixedly connected with the pressure backing plate 3, the bottom end of the support screw 4 is fixedly connected with the support hole of the roller, and the support screw 4 can rotate around the first rotation axis 8, and the top One end of the cover pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com